Fenix Imvico EPC1100 Operation Manual

EPC1100 THERMAL PRINTER

Operation Manual - Version 1.0

July-2000

FENIX IMVICO

EPC1100 OPERATION MANUAL

2/37

Revision list for the EPC1100 thermal printer operation manual.

Date: 11-07-2000

Page Type of revision Before change After change

FENIX IMVICO

EPC1100 OPERATION MANUAL

3/37

I N D E X

FIGURES AND TABLES 4

IMPORTANT NOTES ON EPC1100 HANDLING 5

1- INTRODUCTION 6

2- INSTALLATION 7

2.1- INSTALLING THE EPC1100 PRINTER 7

2.2- EPC1100 CONNECTORS 8

2.2.1- POWER SUPPLY CONNECTOR 8

2.2.2- COMMUNICATIONS CONNECTOR 10

2.2.2.1- SERIAL PORT CONNECTION (RS-232 / TTL) 10

2.2.2.2- PARALLEL PORT CONNECTION (CENTRONICS) 11

2.3- INTERFACING WITH A PERSONAL COMPUTER 12

2.3.1- Parallel input/output 12

2.3.2- Serial input/output 14

3- BASIC OPERATIONS 17

3.1- LOADING PAPER 17

3.2- TEST PRINT PROCEDURE 18

3.2.1- Programming the baud rate 18

3.2.2- Hexadecimal mode 19

4- ERROR PROCESSING 21

5- PRINTER COMMANDS 22

APPENDIX A- SOFTWARE EXAMPLES 33

APPENDIX B- SPECIFICATIONS 34

APPENDIX C- HOW TO ORDER 35

APPENDIX D- FAQ (Frequently Asked Questions) 36

APPENDIX E- PHYSICAL DIMENSIONS 37

FENIX IMVICO

EPC1100 OPERATION MANUAL

4/37

FIGURES AND TABLES

Fig. 2.1-

EPC1100 installation 7

Fig. 2.2-

EPC1100 connectors location 8

Fig. 2.3-

Power supply connector – CON1 9

Fig. 2.4-

Communications connector – CON4 10

Fig. 2.5-

Centronics cable pin-out 12

Fig. 2.6-

Timing for receiving parallel data 13

Fig. 2.7(A)-

RS-232 cable pin-out 14

Fig. 2.7(B)-

RS-232 cable pin-out 15

Fig. 2.8-

Serial input/output signal timing chart 15

Fig. 3.1-

Loading paper 17

Fig. 3.2-

Accessing the self-test button 18

Fig. 3.3-

Sample ticket 20

Fig. 5.1-

PC437 Standard Europe character table 22

Fig. 5.2-

Example of bitmap graphic 26

Fig. 5.3-

Bitmap image layout 27

Fig. 5.4-

Head logical blocks for dynamic division 30

Fig. 5.5-

Head logical blocks for fixed division 31

Table 2.1-

Serial connector pin-out 10

Table 2.2-

Parallel connector pin-out 11

Table 5.1-

Character/line in relation to character spacing 24

Table 5.2-

Printer command summary 32

FENIX IMVICO

EPC1100 OPERATION MANUAL

5/37

IMPORTANT NOTES ON EPC1100 HANDLING

In order to guarantee a long life of the printer, it is necessary to keep some

precautions on the EPC1100 handling. Please read carefully next lines to make a

good use of the printer.

SAFETY PRECAUTIONS

•

BEWARE not to invert power supply polarity. This may irremediably

damage the printer.

•

Use power supply voltage within specified range. Overvoltage may

irremediably damage the printer. Voltage under the specified range may

cause incorrect operations. FENIX advises to use, at least, a 30W power

supply (for VCC=VP= 5v dc and fixed division mode) .

•

When switching the power supply ON, turn on Vcc and Vp simultaneously,

or turn on Vcc f irst, an d then Vp.

•

When switching the power supply OFF, turn off Vcc and Vp simultaneously,

or turn off Vp first , and then Vcc.

•

When using two power supply lines (a Vcc=5v line and a Vp=4,2~8,5v

line), both GND should be common.

•

Keep EPC1100 away from water or any other liquid.

•

DO NOT put any objects into the printer. It could cause severe damage like

shortcircuits, broken thermal head or general printer failure.

•

DO NOT blow the EPC1100.

•

NEVER modify the EPC1100.

•

DO NOT try to repair the EPC1100 by yourself. If some failure is detected

contact with your usual dealer technical service.

RECOMMENDATIONS

•

Before connecting any input interface, verify the correct operation of the

EPC1100 printer with self test feature.

•

Avoid using EPC1100 in environments where there are excessive

temper atures or moistu re.

•

Place the EPC1100 in such a way that connection wires are not crushed or

twisted.

FENIX IMVICO

EPC1100 OPERATION MANUAL

6/37

____________________________________________________________________

1 – INTRODUCTION

The EPC1100 is a low cost, high performance thermal printer which covers any

application where small place is available, and low noise and low power supply are

needed. It has graphics capabilities and bar code representation.

The structure of the EPC1100 allows setting it into a panel as well as into other

appropriate chassis where a printer is needed. It can be used in industrial,

professional o r l aboratory environments.

Its easy manipulation makes it suitable for applications where the handling of the

printer does not need specific technical knowledge, such as receipts, security

systems, medical instrumentation, process control systems, etc.

Main features of the EPC1100 printer are:

•

Easy maintenance structure.

•

Easy installation procedure.

•

Compact and lightweight.

•

Single 5V dc power supply.

•

High resolution printing (8 dots/mm).

•

Both parallel CENTRONICS and serial (RS-232 and TTL) data input interface.

•

Allows normal, double width, double height and double width-height attributes.

•

Scalable font (independent scale in X / Y axis).

•

Programmable character and line space.

•

Graphic bitmap printing capabilities.

•

CODE39 Bar Code.

•

Hexadecimal mode for easy software debugging.

•

Easy paper loading with paper roll drop – in.

•

Self test feature.

•

PC 437 Standard Europe character table used.

This manual is a guide of the printer operations and is addressed to the application’s

designer. In following chapters ther e is a detailed description of hardware and

software configuration to take advantage of the features of the EPC1100 printer.

FENIX IMVICO

EPC1100 OPERATION MANUAL

7/37

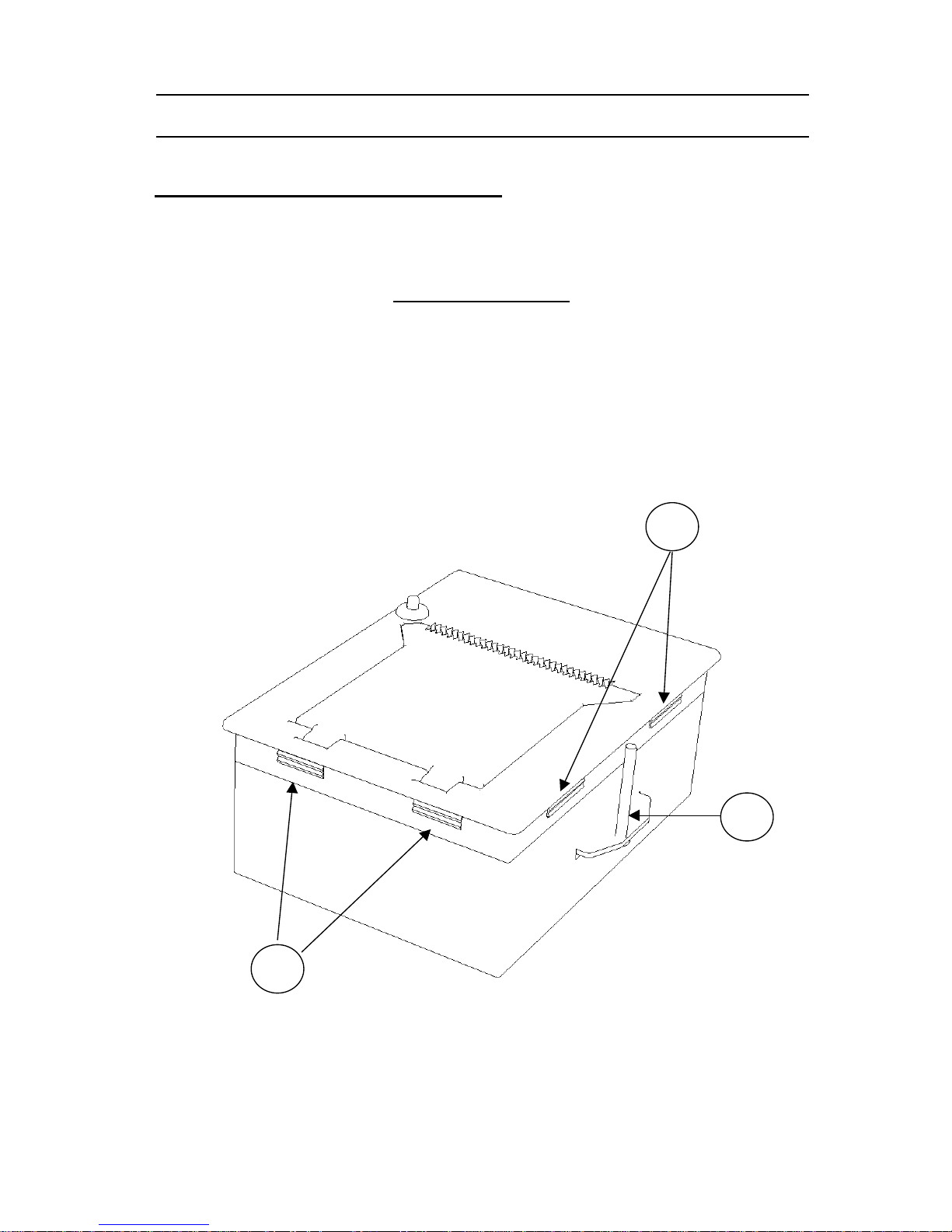

2 - INSTALLATION

2.1.- INSTALLING THE EPC1100 PRINTER

The EPC1100 is a panel printer thought to be easily set into a wall, a case or another

kind of appropriate receptacle. To install the EPC1100 printer follow next steps:

•

Make a rectangular hole of

91x124 mm (approx.)

on the surface where the printer

will be set.

•

Place the EPC1100 printer into the hole and push until the pieces marked with an

A

in

Fig. 2.1

make pressure enough to secure the EPC1100 to the surface.

•

Optionally, two metric screws DIN965 M3 / L35 (Part B in

Fig. 2.1

) can provide

better holding of the EPC1100 to the surface.

•

Connect the power supply and the communications port to the back side of the

printer (see

Fig.2.2

EPC1100 connectors location

or refer to chapters

2.2.1.-

Power

supply connector

and

2.2.2.-

Communications Connector

).

Fig. 2.1-

EPC1100 installation.

A

A

B

FENIX IMVICO

EPC1100 OPERATION MANUAL

8/37

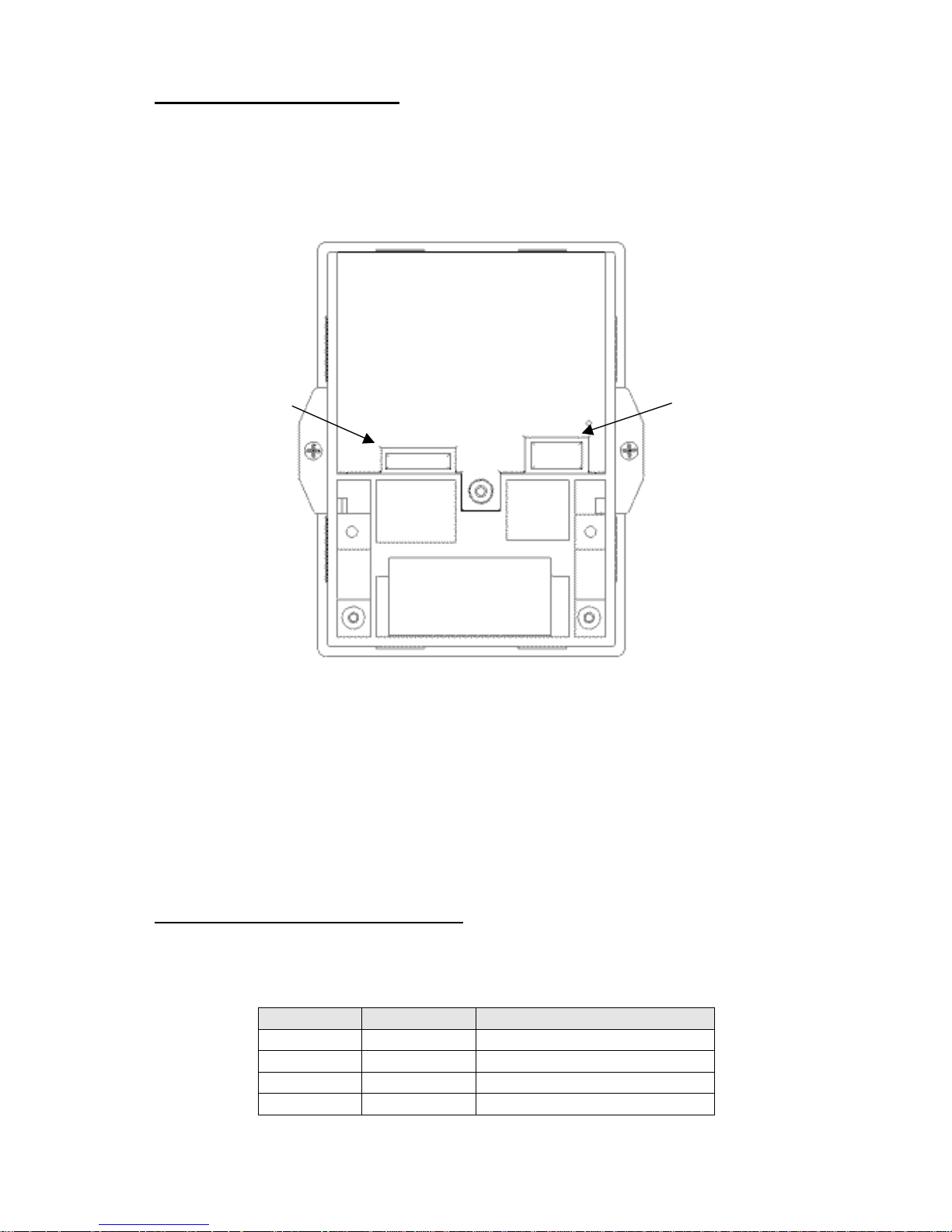

2.2.- EPC1100 CONNECTORS

On the back side of the EPC1100 user can find the two necessary connectors:

•

CON1: Power supply connector.

•

CON4: Communications connector.

Fig. 2.2-

EPC1100 connectors location.

2.2.1- POWER SUPPLY CONNECTOR

Attach power supply cable to connector

CON1

. Verify power supply voltage before

making the connection.

Terminal nº Signal Name Function

1 GND GND

2 VP Printer power (4,2v~8,5v dc)

3 VCC Logic power (5v dc)

4 GND GND

CON1:

Power supply

CON4:

Communications

FENIX IMVICO

EPC1100 OPERATION MANUAL

9/37

Fig.2.3-

Power supply connector CON1.

Use a connector JST Ref. VHR-4N (housing)

SVH-21T-P1.1 (contacts)

The EPC1100 requires two power sources: VP (4,2v~8,5v dc) for driving the thermal

head and motor, and VCC (5v dc) for logic electronics. The power supplies must

satisfy the following conditions:

VCC (for logic electronics) :

5v dc +/- 0,25v , 0,2 A

VP (for thermal head and motor):

4,2v ~ 8,5v dc

The maximum current consumption (Ipmax) for thermal head and motor change

according to the following equation :

Ip = N*Vp/(Rh) +0,4 (A)

Ip: Peak current (A)

N: Number of dots that are driven at the same time (

See 5- PRINTER COMMANDS

)

N = 64 (dynamic division)

N = 192 (fixed division)

Vp: Head driven voltage (V)

Rh: Head resistance (Ohms)

0,4 : maximum current for driving the motor

•

For example, if VP = VCC = 5v dc, N =64 and Rh = Rank A (~ 187 ohms)

Ipmax = 64*5/(178)+0,4 = 2,19 A

•

If VP=VCC = 5v dc, N=192 and Rh = Rank A (~ 187 ohms)

Ip

max = 192*5/(178)+0,4 = 5,79 A

See HOW TO ORDER if using a different VP=5v dc.

WARNING : Beware not to invert the polarity of power supply. This may

irremediably damage the printer. Power must be turned on in proper

order. Turn on both Vcc and Vp simultaneously, or turn on Vcc first and then Vp.

Otherwise, the EPC1100 thermal printer may be damaged. To turn the power off,

first turn off Vp and then Vcc or turn off both Vcc and Vp simultaneously.

FENIX advises to use, at least, a 30w power supply (for VCC=VP=5V dc) when

fixed division print mode is used.

4 3 2 1

FENIX IMVICO

EPC1100 OPERATION MANUAL

10/37

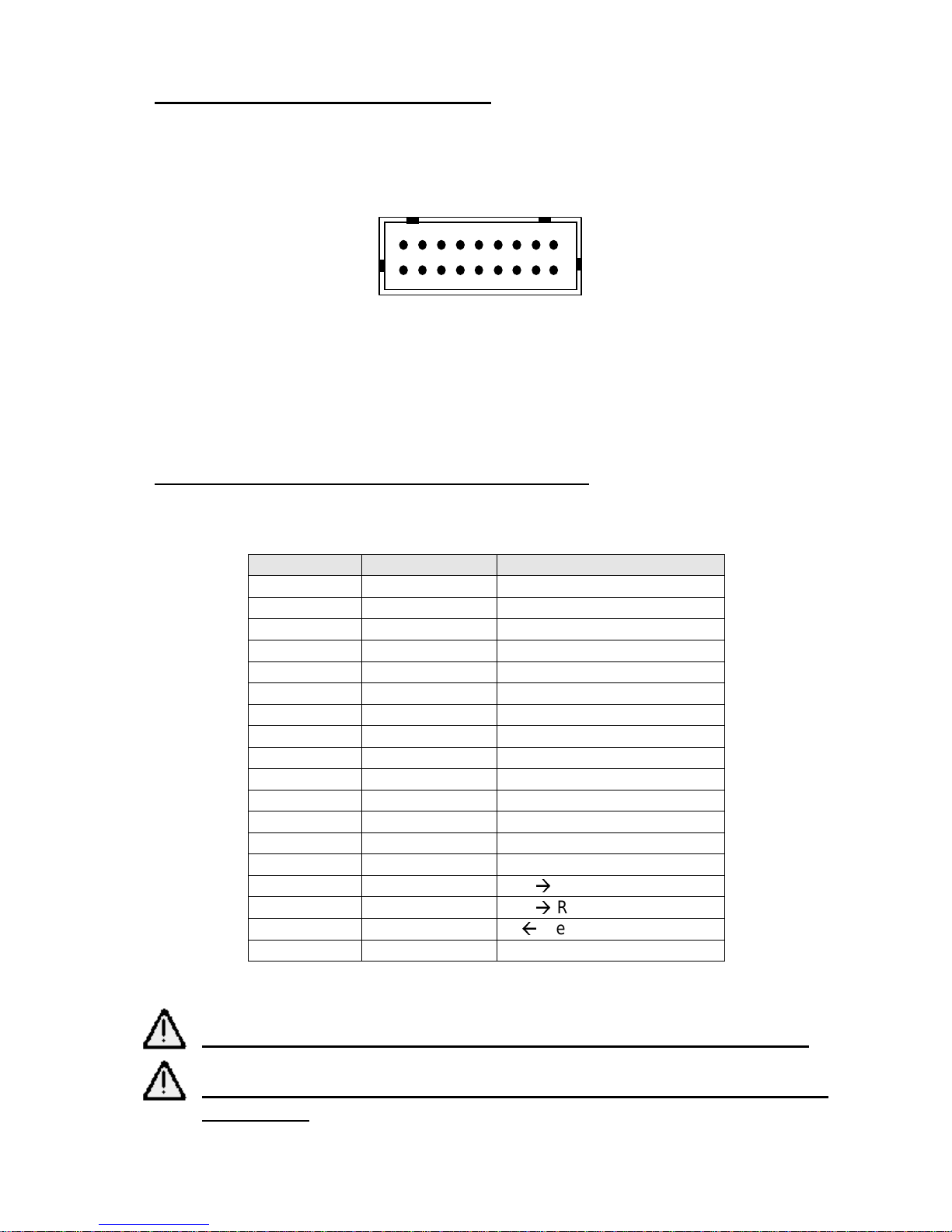

2.2.2.- COMMUNICATIONS CONNECTOR

Both SERIAL RS-232/TTL and PARALLEL CENTRONICS ports use the same

connector –

CON4

.

Fig. 2.4

- Communications connector CON4.

Use a connector JST Ref.- PHDR-18VS (housing)

SPHD-001T-P0.5 (contacts)

2.2.2.1.- SERIAL PORT CONNECTION (RS-232 / TTL)

If you use the serial interface, attach serial port cable to connector

CON4

.

Terminal nº Signal Name

Function

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

TXD

Out Transmit Data

16

/RTS

Out Rquest to Send

17

RXD

In Receive Data

18

GND

Table 2.1-

Serial connector pin-out.

See HOW TO ORDER to select the RS232 or TTL voltage level.

See chapter “3.2.1.- Programming the baud rate” to configure

Serial Po rt.

1

18

FENIX IMVICO

EPC1100 OPERATION MANUAL

11/37

2.2.2.2- PARALLEL PORT CONNECTION (CENTRONICS)

If you use the parallel interface, attach CENTRONICS cable to connector

CON4

.

Terminal nº Signal Name Function

1/STBIn

Strobe

2 DATA0

3 DATA1

4 DATA2

5 DATA3

6 DATA4

7 DATA5

8 DATA6

9 DATA7

In Data Bus

10 /ACK OutAcknowledge

11 BUSY OutBusy

12 PE OutPaper Error

13 /ERROR OutError

14 GND GND

15

16

17

18

Table 2.2-

Parallel connector pin-out.

FENIX IMVICO

EPC1100 OPERATION MANUAL

12/37

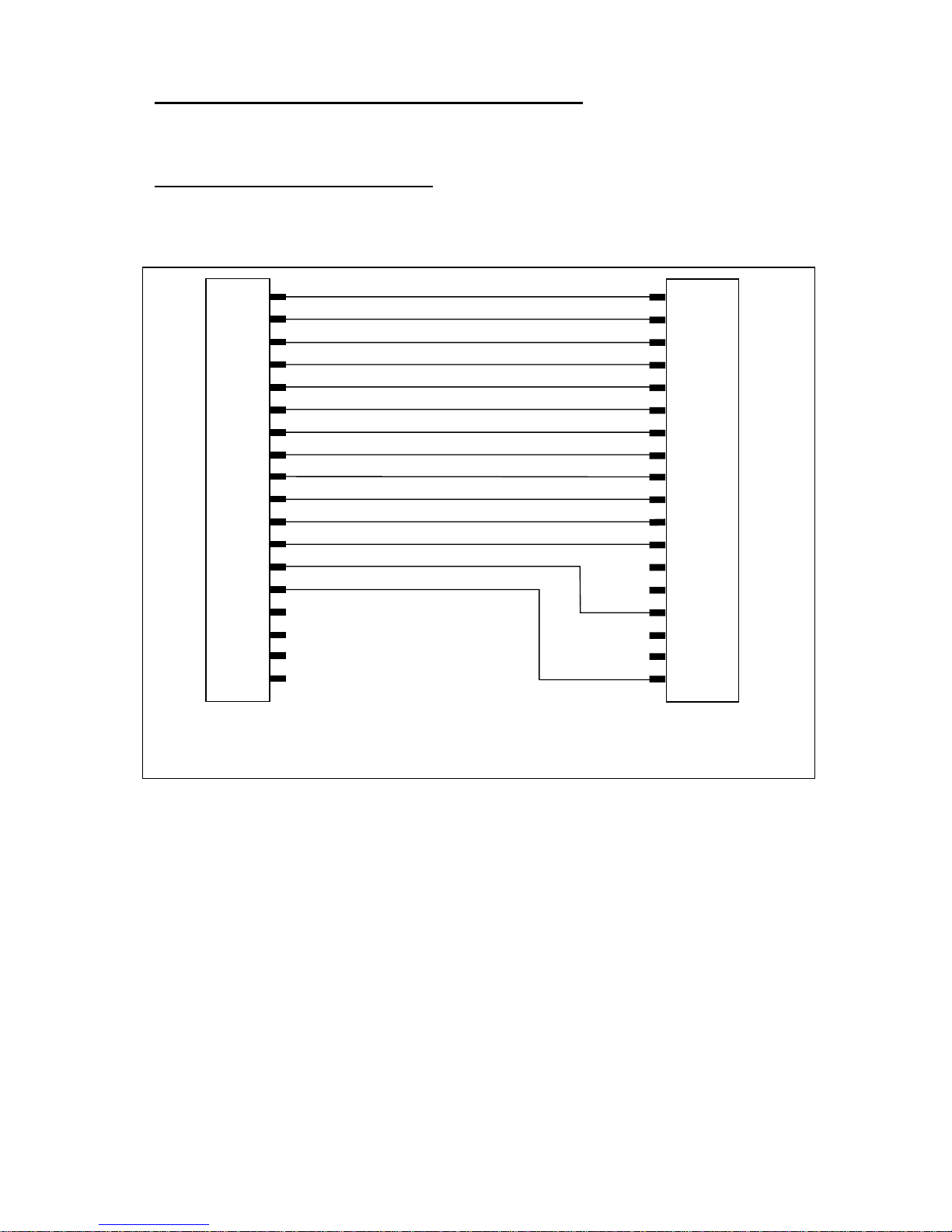

2.3- INTERFACING WITH A PERSONAL COMPUTER

Before connecting any cable to EPC1100 check the correct pinout.

2.3.1- PARALLEL INPUT/OUTPU

Following drawings show how to make the interface cables with a compatible PC.

Fig. 2.5

- Centronics cable pinout.

The busy and acknowledge signals are output every byte. If 128 bytes have been

stored in the EPC1100 input buffer, the busy status continues until the amount of data

stored in the input buffer becomes 127 bytes or less.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18 to 25

/Strobe

Data 0

Data 1

Data 2

Data 3

Data 4

Data 5

Data 6

Data 7

/Acknowledge

Busy

Paper end

/Error

GND

EPC1100 CENTRONICS

CONNECTOR

PC CENTRONICS DB-25M

CONNECTOR

Loading...

Loading...