Page 1

Operator's Manual

VarioGuide

VarioGuide Novatel

VarioGuide Trimble

Marktoberdorf

AGCO GmbH - Johann-Georg-Fendt-Str. 4 - D-87616

Marktoberdorf

FENDT is a worldwide brand of AGCO

© AGCO 2015

Original Operator's Manual

November 2015

438.020.070.012

4832

EAME

English

Page 2

Page 3

Dear Customer

Please note the following:

• Before using the tractor, carefully read through this operator’s manual and familiarize yourself with all

operating controls and their functions before you begin work. This also applies to the operator's manual

for implements.

•

Observe all the operating and maintenance instructions. If you do so, your tractor will give you many

years of economic and trouble-free operation. You will find an overview of all maintenance operations in

the maintenance schedule in this maintenance manual.

• Maintenance and repair work should only be carried out at your service workshop.

Disregarding the symbols and the associated safety instructions—which are divided into three hazard

levels—can lead to considerable damage to the tractor, the mounted implements or other property.

Adhering to the safety instructions is also required in order to prevent such damage from occurring.

.

VarioGuide

438.020.070.012

Page 4

.

VarioGuide

438.020.070.012

Page 5

Proper use of VarioGuide

This tractor is designed exclusively for normal agricultural operations or suchlike, e.g. municipal

applications. Any other type of use is considered unauthorized. The manufacturer will not be liable for any

damage resulting from such use, which will be entirely at the owner's risk.

Authorized use also includes observing the operating, maintenance and repair conditions set out by the

manufacturer in order to protect your claims under warranty if necessary.

Special attention must be paid to safety instructions marked with this symbol, as well as the words

DANGER, WARNING and CAUTION.

Operation, maintenance and repair of the tractor are restricted to persons who are familiar with this

equipment and aware of the inherent dangers.

The relevant accident prevention regulations must be observed, as must as any generally acknowledged

safety, industrial medicine and traffic regulations. The manufacturer does not accept liability for damage

resulting from unauthorized modifications to the machine.

Since it is working equipment, the tractor is not suitable for taking on board or transporting children and

young persons. If children or young persons are nonetheless present in the tractor, the operator must be

aware that they require strict supervision. It must be impossible for any children and young persons on

board to operate the technical controls on the tractor or any equipment mounted on it. Under no

circumstances may children or young persons remain alone in the cab when the operator leaves the

tractor.

.

Disclaimer

AGCO-Fendt accepts no responsibility or liability for damage to property, injury to persons or death caused

by improper or negligent use of its products, including the VarioGuide system and its components. AGCO

moreover accepts no responsibility for the use of AGCO implements or of the GNSS signal for purposes

other than those intended.

AGCO is also unable to guarantee the accuracy, integrity, continuity or availability of the GNSS signal.

When operating the VarioGuide system, it is the operator's responsibility to exercise general caution and

navigation-related judgment.

The following pages contain specific safety precautions that must be read before using VarioGuide

products and observed during their use.

NOTE:

When third-party way line guidance systems are used with Fendt equipment, AGCO Fendt shall exclude

any warranty or liability for damage to property, injury to persons or death.

Copyright law

The information contained herein is protected by copyright by AGCO. In the case of the names of

companies and products specified here, these may be registered brand names or trademarks of the

relevant owner.

The duplication of this document, or parts thereof, in any form and in any way is forbidden without express

written agreement from AGCO. No part of this document may be quoted by persons who are not

employed by AGCO without written approval from AGCO. AGCO reserves the right to make changes to

the information contained in this document without prior notice.

Although this document has been prepared with the utmost care, AGCO shall not be held liable for any

mistakes or omissions. No liability shall be accepted for damages in connection with the use of this

information.

VarioGuide

438.020.070.012

Page 6

.

Up-to-date at the time of going to press

The high safety and quality level of the FENDT machines is ensured by constant development work on

designs, equipment and accessories. We would therefore ask you to bear in mind that changes in form,

equipment or technology may be required at any time. The details of delivery, appearance, technical data

and functions of the machine is only correct at the time of going to press It may not be possible to deliver

some of the equipment until later, or it may only be offered in certain markets. No claims may be derived

from the information, illustrations or descriptions contained in this instruction sheet.

VarioGuide

438.020.070.012

Page 7

Table of contents

VarioGuide

1 Introduction ..............................................................11

1.1 Delivery of VarioGuide system ......................................13

1.2 OPERATOR'S MANUAL FENDT VarioGuide ...........................14

2 Safety instructions ........................................................15

2.1 Safety and accident prevention regulations ..........................17

2.1.1 Marking of places that affect your safety ................................17

2.1.2 Advice for the operator .............................................17

2.1.3 Safe operating environment .........................................18

2.1.4 Switching off in an emergency situation ................................18

3 VarioGuide definitions and specifications ...................................19

3.1 Definitions .........................................................21

3.1.1 GNSS and correction signal ..........................................21

3.1.2 Satellite reception ................................................21

3.1.3 Signal interruption ................................................23

3.1.4 Static and dynamic accuracy (satellite drift) ..............................23

3.1.5 Convergence time ................................................23

3.1.6 Conditions of use and application possibilities ............................23

3.1.7 Restrictions .....................................................23

3.1.8 Switch-off limits .................................................24

3.2 Specification .......................................................25

3.2.1 Topcon accuracy specifications .......................................25

3.2.2 Trimble accuracy specifications .......................................25

4 Quick Start ...............................................................27

4.1 VarioGuide menu tree ..............................................29

4.2 VarioGuide info ....................................................31

4.3 Vario-Guide Main Menu .............................................32

4.4 Implement selection ................................................34

4.5 Field Settings ......................................................36

4.6 Steering behavior ..................................................38

4.7 Signal settings .....................................................39

4.8 System info .......................................................40

5 Map view .................................................................41

5.1 Overview ..........................................................43

5.1.1 Map view menu tree ..............................................43

5.1.2 Map view ......................................................43

5.2 Display ............................................................45

5.2.1 Full screen .....................................................45

5.2.2 Zoom .........................................................46

5.2.3 Info bar ........................................................46

5.2.4 Steering status ..................................................47

5.2.5 Novatel bar indicator, Trimble ........................................47

5.3 Functions ..........................................................49

5.3.1 Set markers .....................................................49

5.3.2 Marker settings ..................................................50

5.3.3 Worked area settings ..............................................50

VarioGuide

438.020.070.012

Page 8

Table of contents

6 VarioGuide components and calibrations ...................................53

6.1 Calibrations ........................................................55

6.1.1 Calibrate steering angle sensor and steering valve .........................55

7 Start-up ..................................................................63

7.1 Load implement ....................................................65

7.1.1 Caution ........................................................65

7.1.2 Load implement settings (7" terminal) ..................................65

7.1.3 Load implement settings (10.4" terminal) ................................66

7.2 Create implement ..................................................67

7.2.1 Call up implement settings on 7" .....................................67

7.2.2 Call up implement settings on 10.4" ...................................68

7.2.3 Front-mounted implement ..........................................69

7.2.3.1 Install front-mounted implement ...............................69

7.2.3.2 Determine the working width, navigation point distance and coupling

length ........................................................70

7.2.3.3 Set the working width of the front-mounted implement ..............71

7.2.3.4 Set the navigation point of the front-mounted implement .............72

7.2.3.5 Set the coupling length for the front-mounted implement ............73

7.2.3.6 Set the center of the front-mounted implement ....................74

7.2.3.7 Set the trigger for the front-mounted implement ...................75

7.2.4 Rear-mounted implement ...........................................76

7.2.4.1 Install rear-mounted implement ................................76

7.2.4.2 Determine the working width, navigation point distance and coupling

length ........................................................77

7.2.4.3 Set the navigation point of the rear-mounted implement ..............78

7.2.4.4 Set the coupling length for the rear-mounted implement .............79

7.2.4.5 Set the center of the rear-mounted implement ....................80

7.2.4.6 Set the trigger for the rear-mounted implement ....................81

7.3 Save mounted implement data ......................................82

7.3.1 Save implement on stopping ........................................82

7.4 Exchange implement data and field data .............................84

7.4.1 Plug in the USB stick and call up data exchange ...........................84

7.4.1.1 Insert USB stick ...........................................84

7.4.1.2 Call up data exchange on 10.4" ................................84

7.4.2 Transfer implement data and field data to the USB stick .....................85

7.4.2.1 Select and transfer all data ....................................86

7.4.3 Transfer implement and field data from the USB stick to the terminal ...........87

7.4.3.1 Select and transfer all data ....................................89

7.5 Correction signals ..................................................90

7.5.1 Overview of correction signals depending on the receiver ...................90

7.6 Submeter range with NovAtel receiver ...............................91

7.6.1 Autonomous ....................................................91

7.6.2 EGNOS / WAAS .................................................92

7.7 Centimeter range with NovAtel receiver .............................93

7.7.1 FENDT base station ...............................................93

7.7.1.1 Configure the FENDT base station correction signal .................93

7.7.1.2 Fallback: FENDT base station ..................................94

7.7.2 External station ..................................................95

7.7.2.1 Configure the external station correction signal .....................95

7.7.2.2 External fallback station ......................................96

7.7.3 RTK network (internal mobile radio modem) ..............................96

7.7.3.1 Configure the internal mobile modem correction signal ...............96

7.7.3.2 Activate/deactivate internal mobile modem fallback ..................98

7.7.4 RTK network (external mobile radio modem) .............................98

VarioGuide

438.020.070.012

Page 9

Table of contents

7.7.4.1 Configure the external mobile modem correction signal ...............98

7.8 Submeter range with Trimble receiver .............................. 100

7.8.1 Autonomous ................................................... 100

7.8.2 EGNOS / WAAS .................................................101

7.8.3 RangePoint RTX .................................................102

7.9 Decimeter range with Trimble receiver ..............................103

7.9.1 CenterPoint RTX Satellite .......................................... 103

7.9.1.1 Set correction signal for Centerpoint RTX Satellite ..................103

7.9.1.2 Fallback for Centerpoint RTX Satellite ...........................104

7.10 Centimeter range with Trimble receiver ............................105

7.10.1 FENDT base station ............................................. 105

7.10.1.1 Configure the FENDT base station correction signal — Trimble AG-715

450 MHz radio modem ........................................... 105

7.10.1.2 Configure the FENDT base station correction signal (Trimble 900 MHz) .

7.10.2 RTK network (internal GSM/GPRS modem) ............................ 107

7.10.2.1 Configure the internal mobile modem correction signal (GSM/GPRS) ... 107

7.10.3 RTK network (external mobile radio modem) ........................... 108

7.10.3.1 Configure the external mobile modem correction signal .............108

7.10.4 Trimble receiver settings ..........................................109

7.10.4.1 xFill settings ............................................ 109

106

7.11 Field Settings .................................................... 111

7.11.1 Add field ..................................................... 111

7.11.2 Record field boundary ............................................112

7.11.3 Record/manage obstacles .........................................115

7.12 Way-line .........................................................119

7.12.1 Create and save way line .........................................119

7.12.2 Path to path distance ............................................ 124

7.13 Check system .................................................... 125

7.13.1 Check system info/system status ...................................125

7.14 Activate VarioGuide system .......................................127

7.14.1 Switch on automatic way line guidance ...............................127

7.15 Adjust way line ...................................................128

7.15.1 Way line offset ................................................ 128

7.16 Headland settings ................................................ 129

7.16.1 Headland settings .............................................. 129

7.16.2 Headland management TI/AutoTI ................................... 131

7.17 Operation with the base station ................................... 133

7.17.1 Brief description ............................................... 133

7.17.2 Scope of delivery and accessories ...................................133

7.17.3 LED and keys on the base station ................................... 136

7.17.4 Initial start-up ..................................................137

7.17.5 Operating modes ............................................... 138

7.17.6 Start-up ...................................................... 138

7.17.7 Set the base station channel on the tractor ............................ 139

7.17.8 Operate base station with external battery .............................141

8 Faults and remedy ........................................................143

8.1 Fault diagnostics .................................................. 145

8.1.1 Problems and possible remedial action ................................ 145

9 Appendix ................................................................ 149

9.1 Glossary .......................................................... 151

9.1.1 Glossary ...................................................... 151

VarioGuide

438.020.070.012

Page 10

Table of contents

VarioGuide

438.020.070.012

Page 11

Table of contents

1. Introduction

1.1 Delivery of VarioGuide system ...........................................13

1.2 OPERATOR'S MANUAL FENDT VarioGuide ................................14

VarioGuide 11

438.020.070.012

Page 12

Table of contents

12 VarioGuide

438.020.070.012

Page 13

1.1 Delivery of VarioGuide system

Vehicle type

1. Introduction

Chassis no.

OmniSTAR

Serial number

Information to be provided at vehicle delivery

Draw attention to safety instructions in the vehicle operator's manual, on the vehicle itself and in the

VarioGuide operator's manual.

Draw attention to country-specific compliance with regulations for the registration and use of radio

signals.

System delivery and instructions on the VarioGuide track guidance system.

For further information and notes, refer to the appropriate sections in the operator's manual.

Read safety precautions

Select correction signal

Implement settings in VarioGuide

Configure trigger settings in VarioDoc

Check system status

Create way-line

. . . / . . / . . . . .

OSN

Service workshop

Switch on automatic way line guidance

Delivered on . . . . . . . . . . . . . . . .

Signature of mechanic . . . . . . . . . . . . . . . . .

Customer's signature. . . . . . . . . . . . . . . . .

VarioGuide 13

438.020.070.012

Page 14

1. Introduction

1.2 OPERATOR'S MANUAL FENDT VarioGuide

Fendt VarioGuide

This operator's manual is only valid in conjunction with the operator's manual for the tractor

AGCO GmbH

Maschinen und Schlepperfabrik 87616 Marktoberdorf / Bavaria / Germany

www.fendt.com

© PSD / AP 2015-11

4832

14 VarioGuide

438.020.070.012

Page 15

Table of contents

2. Safety instructions

2.1 Safety and accident prevention regulations ...............................17

2.1.1 Marking of places that affect your safety .....................................17

2.1.2 Advice for the operator ..................................................17

2.1.3 Safe operating environment ..............................................18

2.1.4 Switching off in an emergency situation .....................................18

VarioGuide 15

438.020.070.012

Page 16

Table of contents

16 VarioGuide

438.020.070.012

Page 17

2. Safety instructions

2.1 Safety and accident prevention regulations

2.1.1 Marking of places that affect your safety

Make sure that any other users have read all the safety instructions as well.

The various levels of safety instructions can be distinguished as follows:

DANGER:

This symbol, together with the word DANGER, means there is an immediate risk of

danger that must be prevented to avoid the risk of DEATH OR SEVERE INJURY.

WARNING:

This symbol, together with the word WARNING, means a potential risk of danger that

must be prevented to avoid the risk of DEATH OR SEVERE INJURY.

CAUTION:

This symbol, together with the word CAUTION, means there is a potential danger that

must be prevented to avoid the risk of MINOR INJURY.

The operator's manual is an integral part of the vehicle package and must be passed on to any subsequent

owner in the event of resale. The attention of the new owner should be drawn to this information.

If this manual is lost or damaged and you need a new one, please contact your Fendt dealer, from whom

you will be able to purchase a replacement.

2.1.2 Advice for the operator

The purpose of VarioGuide is to assist the operator in steering the tractor. The operator must remain

attentive at all times and have full control over the machine.

VarioGuide cannot detect obstacles such as persons or objects that are not defined and saved in the

system. While automatic steering is in operation, the operator must ensure that a suitable distance is kept

from such obstacles.

VarioGuide may be deactivated briefly if the GNSS or correction signal is lost. It is therefore essential that

the operator is constantly aware of the position of the tractor and the conditions in the field.

WARNING:

Hazard due to vehicle movements Risk of injury and death! Material damage is possible.

When driving on public roads or in areas where there is a risk of injury to others, the

electrohydraulic steering system must not be pre-activated; automatic way-line guidance

must not be activated.

WARNING:

Hazard due to vehicle movements Risk of injury and death! Material damage is possible.

While the system is switched on, the operator must remain on the operator platform

within the vehicle at all times. The operator must attentively follow all the operating

conditions and be ready to intervene at any time, should this be necessary.

WARNING:

Hazard due to vehicle movements Risk of injury and death! Material damage is possible.

Before the operator leaves the tractor, the automatic steering system must be switched

off and the tractor must be parked properly.

VarioGuide 17

438.020.070.012

Page 18

2. Safety instructions

2.1.3 Safe operating environment

WARNING:

Hazard due to vehicle movements Risk of injury and death! Material damage is possible.

The automatic way line guidance system may only be used if the tractor is located in an

open area away from persons, buildings and other machinery: At a safe distance from

persons. At a safe distance from obstacles.

lines. On private property without public access.

WARNING:

Hazard from operating the system outside of approved national signal areas Risk of injury

and death! Material damage is possible. Do not operate VarioGuide and its base station

outside the authorised national frequency ranges, to avoid interference with other

systems (remote-controlled cranes, forestry cranes, etc.).

At a safe distance from high-voltage power

2.1.4 Switching off in an emergency situation

The operator can switch off the way line guidance system in an emergency situation by moving the

steering wheel, giving him manual control over the vehicle. To switch the way line guidance system back

on, the switch-on conditions must be fulfilled and the activation button must be pressed.

WARNING:

Hazard due to vehicle movements Risk of injury and death! Material damage is possible.

While the system is switched on, the operator must remain on the operator platform

within the vehicle at all times. The operator must observe all operating conditions

attentively and be ready to intervene immediately whenever necessary.

18 VarioGuide

438.020.070.012

Page 19

Table of contents

3. VarioGuide definitions and specifications

3.1 Definitions ..............................................................21

3.1.1 GNSS and correction signal ...............................................21

3.1.2 Satellite reception .....................................................21

3.1.3 Signal interruption .....................................................23

3.1.4 Static and dynamic accuracy (satellite drift) ...................................23

3.1.5 Convergence time .....................................................23

3.1.6 Conditions of use and application possibilities .................................23

3.1.7 Restrictions ..........................................................23

3.1.8 Switch-off limits ......................................................24

3.2 Specification ............................................................25

3.2.1 Topcon accuracy specifications ............................................25

3.2.2 Trimble accuracy specifications ............................................25

VarioGuide 19

438.020.070.012

Page 20

Table of contents

20 VarioGuide

438.020.070.012

Page 21

3. VarioGuide definitions and specifications

3.1 Definitions

3.1.1 GNSS and correction signal

GNSS (Global Navigation Satellite System) is a global navigation satellite system designed for position

determination and navigation using satellite signals and signals received from pseudolites (terrestrial

transmitters which emit signals like those of a satellite).

Data for position determination is currently supplied by North America's NAVSTAR GPS and Russia's

GLONASS system. Galileo, the European satellite navigation system, is currently under development.

VarioGuide processes both GPS and GLONASS signals and is designed to operate with future systems.

GNSS satellites communicate their exact position and time via radio. For position determination a receiver

has to be supplied with signals from at least four satellites simultaneously. The four signal propagation

times (from the satellites to the receiving aerial) are then calculated in the receiving device. This is used to

determine the current position.

Stationary receiving stations improve positional accuracy by transmitting correction signals (DGPS) to

users:

• with geostationary satellites such as Europe's EGNOS, North America's WAAS and OmniSTAR

(VarioGuide functions with VBS and HP).

• terrestrially with a base station or RTK network.

3.1.2 Satellite reception

• The GNSS signal and the correction signal may

be obstructed by dense trees, copses,

buildings, high-voltage power lines etc.

• VarioGuide loses the correction signal when the

correction signal satellite is less than 5 to 8

degrees above the aerial level.

NOTE:

The correction signal satellite is geostationary

above the equator.

Fig. 1

Fig. 2

VarioGuide 21

438.020.070.012

Page 22

3. VarioGuide definitions and specifications

• The GNSS signal can be obstructed by dense

trees, copses, buildings, high-voltage power

lines etc.

• VarioGuide may lose the connection to certain

satellites, including the correction signal

satellite, if the vehicle is operated on slopes,

causing the satellite to be out of the aerial's

reception range.

Fig. 3

• VarioGuide steers the tractor, NOT the

implement.

• If the implement does not run concentrically to

the tractor because it is being pulled downhill,

for example, deviations in accuracy may occur.

• The wave angle and thus reception of the

correction signal decreases as the vehicle

moves further north.

• Hilly terrain causes reception of satellite signals

to deteriorate.

•

The GNSS system does not offer uniform

availability around the clock and for every

location.

Fig. 4

Fig. 5

Fig. 6

22 VarioGuide

438.020.070.012

Page 23

3. VarioGuide definitions and specifications

3.1.3 Signal interruption

Position determination takes a certain amount of time after activation before reaching the specified level of

accuracy. Temporary obstruction may cause the system to lose its connection to the satellite signal. This

may result in reduced levels of accuracy, the need to redetermine position, or failures depending on the

system.

3.1.4 Static and dynamic accuracy (satellite drift)

Satellite drift

A certain amount of drift occurs on satellite-based navigation systems. The accuracy is therefore defined

statistically and specified as a percentage of the operational period.

•

Static accuracy: Measured position of the stationary tractor over 1–3 days. The average value

determined states how close the measured value comes to the actual position.

•

Dynamic accuracy: Pass-to-pass accuracy from way line to way line, which must be achieved when

crossing the field within 15 minutes. If a longer period of time passes between two passes, a certain

amount of drift will be noticeable.

3.1.5 Convergence time

The convergence time is the time required by the system after activation to determine the position of the

tractor. Satellite-supported correction signals require a certain amount of time after activation before they

reach the specified level of accuracy. Signal interruptions, e.g. due to obstacles such as buildings or trees,

delay this process. After an extended interruption in the correction signal, the system loses the level of

accuracy already achieved and starts the signal setup again from the beginning.

3.1.6 Conditions of use and application possibilities

Operating conditions

Ideal for satellite signal reception:

• The tractor is located on level ground or the base station is perfectly horizontal.

•

Signal reception is not obstructed.

Possible applications for the system

• Guidance along parallel waylines in straight lines, bends and circular paths

• Road speed 0.1 km/h to 25 km/h forwards and reverse

• Parallel moving of the waylines (wayline offset) to the left and right to balance drift out, set

automatically or manually.

• Offset of the center line of the processed area to the center of the tractor, manually adjustable, required

for asymmetrical implements, e.g. mower combinations

• Saving of fields with waylines, obstacles and mapped areas

• Saving of the implement settings

• Display unit showing current wayline number

• Mapping the processed area

• Supply of multiple tractors via one base station

3.1.7 Restrictions

• Potential loss of GNSS signal due to obstructions near copses, trees and buildings.

• Potential loss of correction signal due to obstructions near copses, trees and buildings.

•

Electromagnetic interference, e.g. from overhead lines.

VarioGuide 23

438.020.070.012

Page 24

3. VarioGuide definitions and specifications

• Number of receivable satellites restricted by the inclined position of the tractor on the terrain.

• The system will not be able to work in regions where the OmniSTAR satellite is too close to the

horizon. This also applies for heavily undulating terrain, particularly in the case of (Northern) slopes,

possibly combined with other obstacles.

•

Use at higher latitudes (here it is better to set the waypoints on a North/South rather than on an East/

West axis).

• Reduced accuracy is also possible on slopes and on implements with a strong side pull.

• Reduced accuracy is possible where the load on the tractor's front axle is too high or too low.

• Reduced accuracy is possible with greasy, sandy or very uneven ground conditions.

• The range of the base station depends on the nature of the terrain and on the weather. Accuracy

decreases as the distance increases.

• The tractor is too far away from the base station.

• After an interruption in the power supply to the base station, there may be shifts in track after

restarting. It is possible to make a manual correction on the terminal.

3.1.8 Switch-off limits

The automatic steering system automatically switches off for the following functions or limits:

• The steering wheel is operated.

•

The accuracy indicator (bar indicator) shows fewer than three bars.

• Road speed is below 0.1 km/h or over 25 km/h.

• The angle between the driving line and the wayline exceeds 75°.

• The machine deviates from the wayline to the side:

- Lateral deviation more than 0.6 m on the HP or RTK version.

- Lateral deviation more than 1.2 m on the VBS version.

24 VarioGuide

438.020.070.012

Page 25

3.2 Specification

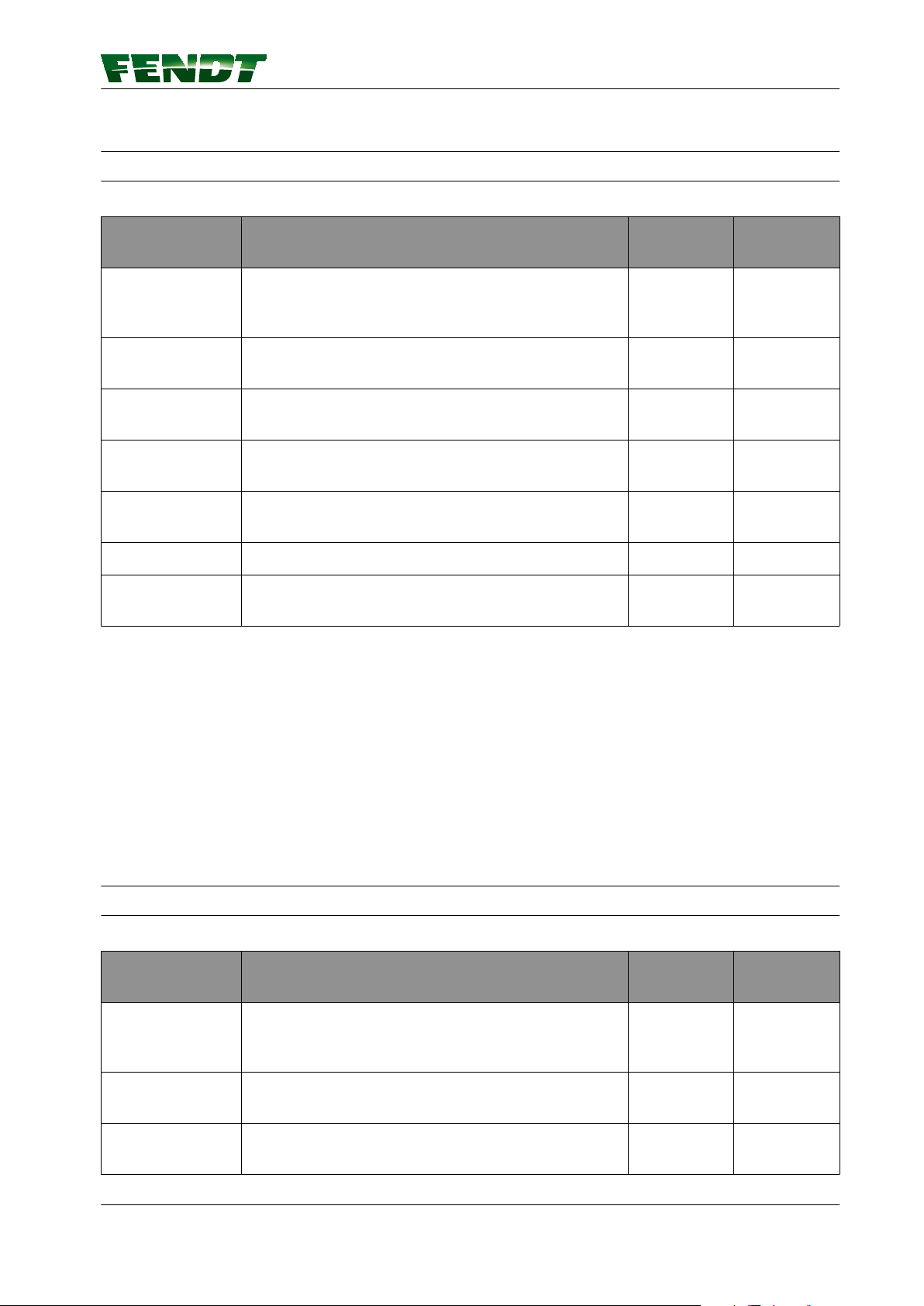

3.2.1 Topcon accuracy specifications

VarioGuide supports the following GNSS accuracy options:

3. VarioGuide definitions and specifications

Correction

Correction source

services

AUTONOMOUS The position is determined without correction signals,

[1]

Static

accuracy

n/a n/a

using only GPS and GLONASS satellites. Sub-meter

(SM) accuracy class

EGNOS European Geostationary Navigation Overlay System,

+/- 150 cm +/- 20 cm

free satellite service for Europe

WAAS Wide Area Augmentation System, free satellite

+/- 150 cm +/- 20 cm

service for North America

OmniSTAR VBS OmniSTAR Virtual Reference Station, subscription

+/- 80 cm +/- 20 cm

satellite service

OmniSTAR HP OmniSTAR High Performance, subscription satellite

+/- 10 cm +/- 5 cm

service

Base station RTK corrections with a dedicated reference station

RTK network RTK corrections via mobile communications network

+/- 2 cm +/- 2 cm

+/- 2 cm +/- 2 cm

(GSM/GPRS) or radio

[1]

The specifications for the VarioGuide system are subject to GNSS system features, US Department of Defense

deteriorations in operation, ionospheric and tropospheric conditions, satellite geometries, length of the base line

and multipath effects. OmniSTAR VBS, OmniSTAR HP, WAAS and EGNOS are independent GNSS upgrade

services. AGCO accepts no responsibility for the performance of these services.

Dynamic

accuracy

Accuracy of the system in the field

The achievable level of accuracy depends on various factors:

• Reception conditions of GNSS and correction signal

Tractor conditions, e.g. implement conditions and settings

•

• Conditions in the field

• Ground conditions

3.2.2 Trimble accuracy specifications

VarioGuide supports the following GNSS accuracy options:

Correction

Correction source

services

AUTONOMOUS The position is determined without correction signals,

using only GPS and GLONASS satellites. Sub-meter

(SM) accuracy class

EGNOS European Geostationary Navigation Overlay System,

free satellite service for Europe

WAAS Wide Area Augmentation System, free satellite

service for North America

[1]

Static

accuracy

Dynamic

accuracy

n/a n/a

+/- 150 cm +/- 20 cm

+/- 150 cm +/- 20 cm

VarioGuide 25

438.020.070.012

Page 26

3. VarioGuide definitions and specifications

Correction

Correction source

services

RangePoint RTX Trimble Correction Service

CenterPoint RTX

Trimble Correction Service

[1]

Static

accuracy

+/- 50 cm +/- 15 cm

+/- 4 cm +/- 4 cm

Standard

CenterPoint RTX

Trimble Correction Service

+/- 4 cm +/- 4 cm

Fast

Base station RTK corrections with a dedicated reference station

RTK network RTK corrections via mobile communications network

+/- 2 cm +/- 2 cm

+/- 2 cm +/- 2 cm

(GSM/GPRS) or radio

[1]

The specifications for the VarioGuide system are subject to GNSS system features, US Department of Defense

deteriorations in operation, ionospheric and tropospheric conditions, satellite geometries, length of the base line

and multipath effects. RangePoint RTX, CenterPoint RTX, WAAS and EGNOS are independent GNSS expansion

services. AGCO accepts no responsibility for the performance of these services.

Accuracy of the system in the field

The achievable level of accuracy depends on various factors:

• Reception conditions of GNSS and correction signal

Tractor conditions, e.g. implement conditions and settings

•

• Conditions in the field

• Ground conditions

Dynamic

accuracy

26 VarioGuide

438.020.070.012

Page 27

Table of contents

4. Quick Start

4.1 VarioGuide menu tree ...................................................29

4.2 VarioGuide info .........................................................31

4.3 Vario-Guide Main Menu ..................................................32

4.4 Implement selection .....................................................34

4.5 Field Settings ...........................................................36

4.6 Steering behavior .......................................................38

4.7 Signal settings ..........................................................39

4.8 System info ............................................................40

VarioGuide 27

438.020.070.012

Page 28

Table of contents

28 VarioGuide

438.020.070.012

Page 29

4.1 VarioGuide menu tree

4. Quick Start

Fig. 1

VarioGuide 29

438.020.070.012

Page 30

4. Quick Start

Fig. 2

30 VarioGuide

438.020.070.012

Page 31

4.2 VarioGuide info

(A) Display and input of wayline distance

(B) Number of GNSS satellites used

(C) Steering behavior for joining wayline

(D) Current steering status

(E) Steering behavior on wayline

(F) Correction signal and accuracy

(G) Field Settings

(H)

AutoTI status

Press each icon to move directly ("Quick Jump") to

the following pages:

(A) Implement Settings

(B) Signal settings

(C) Steering behavior for joining wayline

(D) System info

(E) Steering behavior on wayline

(F) Correction signal

(G) Create wayline

(H) Headland settings

4. Quick Start

Fig. 3

VarioGuide 31

438.020.070.012

Page 32

4. Quick Start

4.3 Vario-Guide Main Menu

Softkeys

(A) Open "Field settings" page

(B) Open "Implement selection/settings" page

(C) Open "Steering settings" page

(D) Open "Signal settings" page

(E) Open "Headland settings" page

(F) A

(H) Jump back one menu level

(I) Wayline adjustment

(J) Manual offset to the left or right in the

(K) Reset values

utoTI activation

direction of travel

Fig. 4

32 VarioGuide

438.020.070.012

Page 33

Display

(A) Current offset display

(B) Display offset value for manual wayline

offset

(C) Overall offset display

4. Quick Start

Fig. 5

VarioGuide 33

438.020.070.012

Page 34

4. Quick Start

4.4 Implement selection

Softkeys

(A) Create new implement

(D) Change front-mounted implement settings

(F) Change rear-mounted implement settings

(G) Change implement settings on second rear-

mounted implement

(H) Jump back one menu level

Fig. 6

34 VarioGuide

438.020.070.012

Page 35

Display

(A) Working width display: actual determined/

measured working width

(B) Overlap display: required overlap (affects the

map display and the wayline distance)

(C) Calculated wayline distance display

(D) Symbol: Implement determines wayline

guidance

(E) Front-mounted implement selection field

(F) Symbol: Implement is used for processed

area

(G) Rear-mounted implement selection field

(H) Second rear-mounted implement selection

field

(I) Implement offset (calculated)

4. Quick Start

Fig. 7

VarioGuide 35

438.020.070.012

Page 36

4. Quick Start

4.5 Field Settings

Softkeys

(A) Add field

(C) Add boundary

(E) Create way-line

(G) Add obstacle

(H) Jump back one menu level

(I) Popup wayline information

Fig. 8

36 VarioGuide

438.020.070.012

Page 37

Display

(A) Manage fields pull-down menu

(B) Field boundary available yes/no

(C) Way-line pull-down menu

(D) Obstacles pull-down menu

4. Quick Start

Fig. 9

VarioGuide 37

438.020.070.012

Page 38

4. Quick Start

4.6 Steering behavior

(H) Back

Fig. 10

38 VarioGuide

438.020.070.012

Page 39

4.7 Signal settings

(A) Correction signal

(B) System info

(C) Gyro compass

(D) NMEA data interface

NOTE:

Press the respective softkey to access the

required page.

4. Quick Start

Fig. 11

VarioGuide 39

438.020.070.012

Page 40

4. Quick Start

4.8 System info

(A)

GNSS position: The green tick will appear

whenever a valid GNSS position has been

successfully determined from the GNSS data

and the correction signal data. The number

of GNSS satellites is also displayed.

(B)

Correction signal: The green tick will appear

whenever a correction signal can be

received. In addition, you will see the time in

s taken to receive the correction signal

update. If 999 is shown here, the correction

signal cannot be currently updated or

received.

(C)

Gyro compass initialisation: The green tick

will appear once initialisation has been

successful. Whenever the receiver has been

switched on, a short distance exceeding 1.5

km/h must be driven to initialise the gyro

compass (see Note below).

(D)

Steering system: The green tick will appear

whenever the self-test was successful. The

EHL is ready for operation and can be preactivated.

(E)

Distance to wayline: The distance to the

wayline must be less than 10 m.

(F)

Joining angle to wayline: The wayline

joining angle must be less than 75°.

(G)

Speed: The speed must be between 0.1 km/

h and 25 km/h.

(H)

Gyro compass calibration: The green tick

will appear whenever the self-test of the

gyro compass was successful.

(I)

GNSS receiver: The green tick will appear

whenever the self-test was successful.

Fig. 12

40 VarioGuide

438.020.070.012

Page 41

Table of contents

5. Map view

5.1 Overview ...............................................................43

5.1.1 Map view menu tree ...................................................43

5.1.2 Map view ...........................................................43

5.2 Display .................................................................45

5.2.1 Full screen ..........................................................45

5.2.2 Zoom ..............................................................46

5.2.3 Info bar .............................................................46

5.2.4 Steering status .......................................................47

5.2.5 Novatel bar indicator, Trimble .............................................47

5.3 Functions ...............................................................49

5.3.1 Set markers ..........................................................49

5.3.2 Marker settings .......................................................50

5.3.3 Worked area settings ...................................................50

VarioGuide 41

438.020.070.012

Page 42

Table of contents

42 VarioGuide

438.020.070.012

Page 43

5.1 Overview

5.1.1 Map view menu tree

Map view menu tree

5. Map view

Fig. 1

NOTE:

Depending on the equipment version, the description and images in the Operator's Manual may differ from

the system installed in the tractor.

NOTE:

To navigate to the main page, press the softkey

in the map view.

5.1.2 Map view

The map view shows the display functions from VarioDoc and VarioGuide.

VarioDoc:

• Mapping the processed area

•

Markers

NOTE: May only be set in map view

• Obstacles

NOTE: Values from VarioGuide

VarioGuide 43

438.020.070.012

Page 44

5. Map view

• Boundaries

NOTE: Values from VarioGuide

• Background

NOTE:

Only with VariableRateControl

VarioGuide:

• Mapping the processed area

• Position of the machine

• Target way-line

• Way-line distance

• Correction signal info

• Steering status

NOTE:

Set trigger functions and implement width for area marker in VarioDoc.

NOTE:

See also the VarioDoc operator’s manual.

44 VarioGuide

438.020.070.012

Page 45

5.2 Display

5.2.1 Full screen

5. Map view

Fig. 2

(C) Marker settings

(D) Worked area settings

(F) Road/field mode

NOTE:

In road mode, the implement is not shown.

(G) Set markers

(H) Change display size

(I) Switch between 2D and 3D

(K) Zoom

VarioGuide 45

438.020.070.012

Page 46

0,00

5. Map view

5.2.2 Zoom

Configure zoom

Press soft key (K), zoom will change

gradually.

NOTE: In 2D mode, 4 levels of magnification

are possible. In 3D mode, 3 levels of

magnification are possible.

5.2.3 Info bar

Fig. 3

The Info bar shows all information which is

permanently visible to the operator for safety

reasons and to keep him informed.

Fig. 4

Fig. 4

Way line number

Way line numbers are displayed at fixed positions in the status bar, depending on the track width. The

current way line number is always shown on an extended line in front of the representation of the tractor.

Way line deviation

There are two modes for displaying the current way line deviation.

Mode 1 shows two direction arrows above the current way line (orange

arrow = minor deviation; orange and red arrow = major deviation.

Mode 2 is activated by selecting the tractor icon between the arrows. The

tractor icon will also be replaced by a number box showing the current deviation in meters. Press again to

show the tractor icon.

Arrows are positioned to the right of the tractor icon and point to the left:

•

As the tractor is to the right of the target way line, the activated way line guidance system will steer the

tractor to the left.

Arrows are positioned to the left of the tractor icon and point to the right:

As the tractor is to the left of the target way line, the activated way line guidance system will steer the

•

tractor to the right.

46 VarioGuide

438.020.070.012

Page 47

5. Map view

5.2.4 Steering status

Steering status information

Steering status is shown in map view and on the VarioGuide information page as a steering wheel icon

which varies in appearance.

Steering icon struck through on a white background: Not ready for operation. The activation

conditions have not been satisfied, and the automatic steering system cannot be enabled.

Steering icon on a white background: Ready for operation. The automatic steering system can be

activated.

Steering icon on an orange background: The automatic steering system has been activated but not

all activation conditions are satisfied (distance to way line too great, etc.).

Steering icon on a green background: Automatic steering is active.

Steering icon with a warning triangle on a white background: A system fault has occurred.

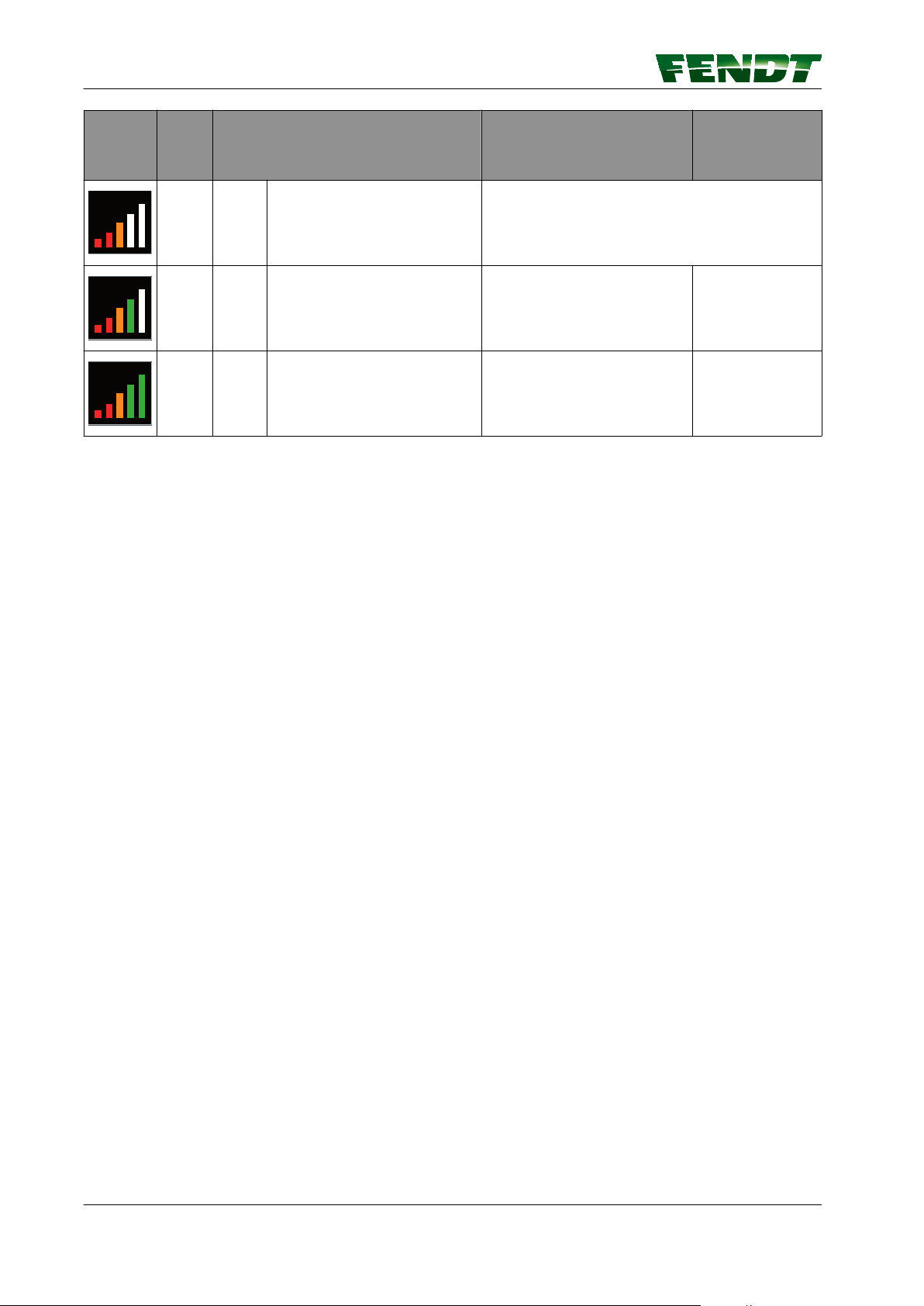

5.2.5 Novatel bar indicator, Trimble

NOTE:

Automatic wayline guidance can only be activated when at least three bars are displayed.

The accuracy of positioning is dependent upon the positions of the satellites relative to each other and the

position of the receiver, as well as the accuracy of time measurement and the runtime.

At favourable angles (~ 90°), the accuracy of measurement will be greater than at acute angles or angles of

approx. 180°.

HDOP (Horizontal Dilution of Precision)

The HDOP value is a measure of measured value scatter; the lower the value, the lower the degree of

measurement error.

SV

SV indicates the number of satellites used.

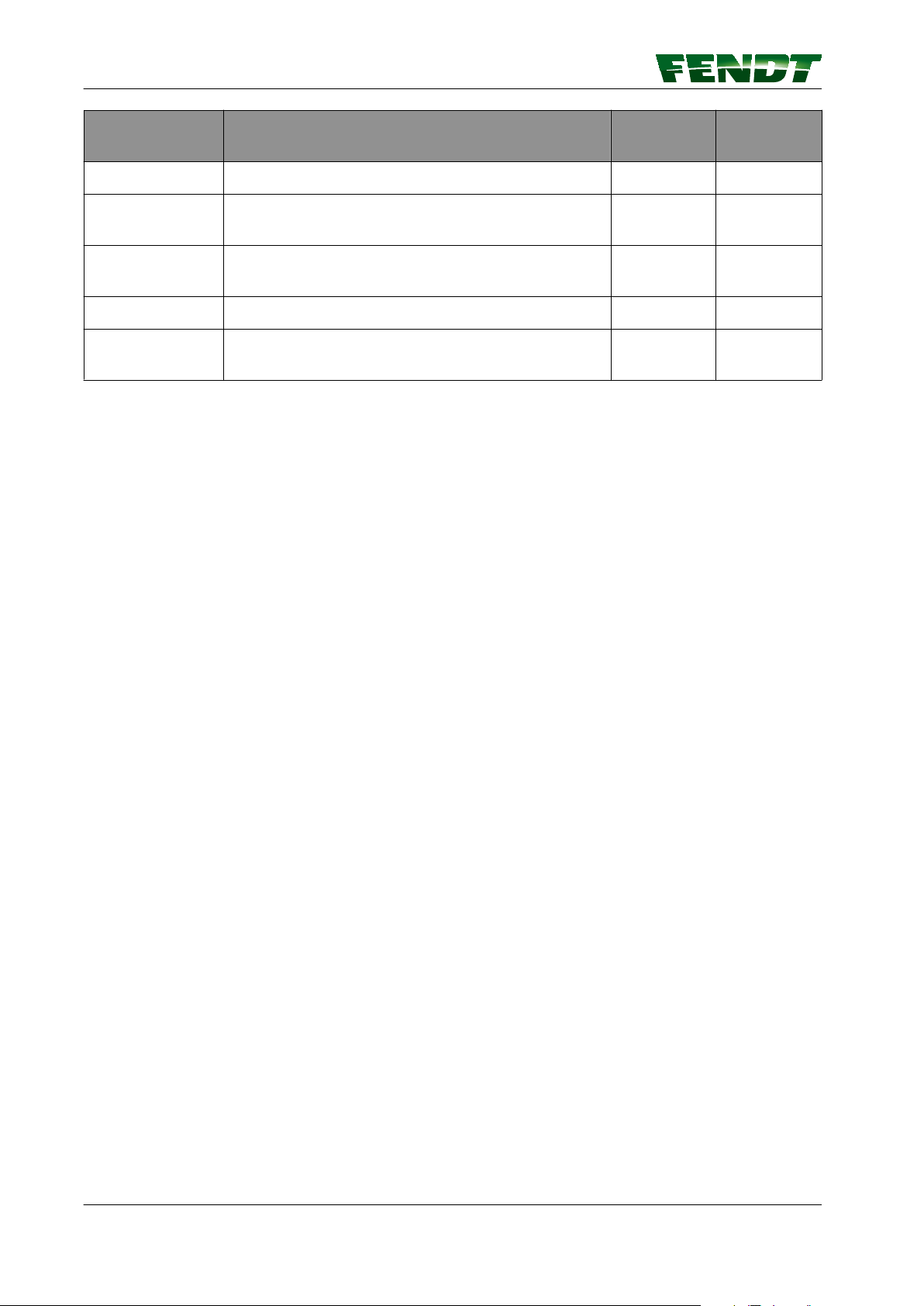

Bar

indicato

r

GNSS Correction signal HDOP

NOK NOK - - -

SV

OK NOK only if fallback is deactivated

OK OK

VarioGuide 47

438.020.070.012

Page 48

5. Map view

Bar

indicato

r

GNSS Correction signal HDOP

SV

OK OK every over 3 bars

OK OK every =< 1.5 >= 6

OK OK every =< 1.3 >= 7

48 VarioGuide

438.020.070.012

Page 49

5.3 Functions

5.3.1 Set markers

Procedure

1.

Press soft key , current position will be

saved and the pop-up shown below will

appear.

Select marker color

2.

5. Map view

Fig. 5

NOTE: A number ID starting at 1 is also

assigned for each individual marker color.

The name of the marker can be changed in

the marker settings menu.

3.

Confirm with . The pop-up will close

Fig. 6

VarioGuide 49

438.020.070.012

Page 50

5. Map view

5.3.2 Marker settings

Marker selection

Press the softkey (C) in full-screen mode to open a

selection list featuring the markers set for the

field. You can change the names of existing

markers and delete existing markers in this list.

5.3.3 Worked area settings

Fig. 7

Fig. 8

(A) Worked areas

Activate/Deactivate

The area colored green on the map shows the processed area. This processed area is linked to the Trigger

Settings page in VarioDoc/VarioGuide. The processed area is displayed on the map depending on the way

in which the settings have been set and if they have been set at all.

50 VarioGuide

438.020.070.012

Page 51

Procedure

Press soft key (D) and a pop-up appears.

1.

Color settings for processed area.

Press soft key (A) or (B) to activate manual or

2.

automatic color selection.

(A) MAN/AUTO softkey

(B) Manual color selection softkey

(C) Delete the area marker in the current

field

5. Map view

Fig. 9

Delete the area marker in the current field

Press soft key (C) and a pop-up appears.

3.

Fig. 10

Fig. 11

VarioGuide 51

438.020.070.012

Page 52

5. Map view

4.

Press the soft key , the area marker in the

current field is deleted and the pop-up

closes.

Manual color selection

Press soft key (B) and a pop-up appears.

5.

Fig. 12

Select the setting option:

6.

° Soft key (A) to change between manual

and automatic color display

°

(I) is the setting for the number of normalcolored waylines between two

contrasting waylines

° Soft key (J) for contrast color selection

° (K) is the setting for the wayline number;

starts from color change

NOTE: Using these setting options, you

can highlight the area that contains

tramlines in a different color.

Fig. 13

Fig. 14

52 VarioGuide

438.020.070.012

Page 53

Table of contents

6. VarioGuide components and calibrations

6.1 Calibrations .............................................................55

6.1.1 Calibrate steering angle sensor and steering valve ..............................55

VarioGuide 53

438.020.070.012

Page 54

Table of contents

54 VarioGuide

438.020.070.012

Page 55

6. VarioGuide components and calibrations

6.1 Calibrations

6.1.1 Calibrate steering angle sensor and steering valve

WARNING:

Hazard from automatic deflection of the front wheels Risk of injury and death! Material

damage is possible. During calibration check that there are no people or objects within

the steering area!

NOTE:

The steering angle sensor and steering valve must be calibrated before being used for the first time and

whenever the E-box is replaced.

NOTE:

It is recommended that the steering angle sensor and steering valve are calibrated when:

• The tractor does not drive straight along the way-lines

•

Other steering problems (e.g. tractor begins to sway) occur

NOTE:

If required, calibrate the front axle suspension (please speak to your Fendt dealer).

Calibrating the steering angle sensor (2401)

NOTE:

To operate the automatic track guidance, it is essential that the steering angle sensor is calibrated.

Proceed as follows:

• Operate the hand brake.

• Start engine.

Confirm the warning and fault messages

displayed on the instrument panel with ESC.

Fig. 1

Press RETURN; the first main menu level

appears on the multiple display.

Press one of the buttons repeatedly until

symbol (A) flashes.

Press RETURN; the second main menu level

appears on the multiple display.

Fig. 2

VarioGuide 55

438.020.070.012

Page 56

6. VarioGuide components and calibrations

Press one of the buttons repeatedly until the

symbol (A) flashes.

Confirm with RETURN.

Press one of the buttons repeatedly until the

symbol (A) flashes.

Confirm with RETURN.

Fig. 3

Input code 2401.

Press one of the buttons until the desired

number is displayed.

Confirm with RETURN.

Turn steering wheel against the left steering lock

and hold.

Confirm with RETURN.

Fig. 4

Fig. 5

Fig. 6

56 VarioGuide

438.020.070.012

Page 57

Turn steering wheel against the right steering lock

and hold.

Confirm with RETURN.

Release hand brake and drive the tractor forwards

slowly, keeping the wheels straight.

NOTE:

This calibration is an important requirement for

ensuring correct way-line guidance.

Confirm with RETURN.

6. VarioGuide components and calibrations

Fig. 7

If calibration is completed without errors, O.K.

appears and the new sensor settings are saved.

NOTE:

Settings are only stored when ignition key has

been turned to "0" position.

Wait for at least 30 seconds before switching on

ignition again!

If incorrect values are detected or the conditions

are not met, the message ERROR appears.

2401 = calibration code

FXX = fault code

Fig. 8

Fig. 9

Fig. 10

VarioGuide 57

438.020.070.012

Page 58

6. VarioGuide components and calibrations

Fault code Cause

F01

F08

F09

F10

F11

F12

F13

Preliminary conditions not satisfied

Calibration taking too long (more than 30 seconds)

User terminated calibration with ESC

Plausibility: "Center position" signal

Plausibility: "Left stop" signal

Plausibility: "Right stop" signal

Plausibility: Calibrated values match

NOTE:

If incorrect values are found, contact your Fendt dealer.

Calibrating VarioGuide steering valve (2403)

WARNING:

Hazard from automatic deflection of the front wheels Risk of injury and death! Material

damage is possible. During calibration check that there are no people or objects within

the steering area!

NOTE:

During calibration, the valve slider free travel is determined.

NOTE:

To operate the automatic track guidance, it is essential to calibrate the steering valve.

Please note:

• Do not leave operator's seat (seat contact

switch).

•

Start engine.

• Tractor stationary.

• Point wheels straight ahead.

• Do not move the steering wheel.

Confirm the warning and fault messages

displayed on the instrument panel with ESC.

Fig. 11

58 VarioGuide

438.020.070.012

Page 59

Press RETURN; the first main menu level

appears on the multiple display.

Press one of the buttons repeatedly until

symbol (A) flashes.

Press RETURN; the second main menu level

appears on the multiple display.

Press one of the buttons repeatedly until the

symbol (A) flashes.

Confirm with RETURN.

6. VarioGuide components and calibrations

Fig. 12

Press one of the buttons repeatedly until the

symbol (A) flashes.

Confirm with RETURN.

Input code 2403.

Press one of the buttons until the desired

number is displayed.

Confirm with RETURN.

Fig. 13

Fig. 14

Fig. 15

VarioGuide 59

438.020.070.012

Page 60

6. VarioGuide components and calibrations

The image shown opposite is displayed.

NOTE:

• The calibration runs automatically (approx. 5

minutes max.)

•

Do not actuate steering.

• Do not leave operator's seat (seat contact

switch).

The image shown opposite is displayed.

Fig. 16

If calibration is completed without errors, O.K.

appears and the new sensor settings are saved.

NOTE:

Settings are only stored when ignition key has

been turned to "0" position.

Wait for at least 30 seconds before switching on

ignition again!

If incorrect values are detected or the conditions

are not met, the message ERROR appears.

2403 = calibration code

FXX = fault code

Fig. 17

Fig. 18

Fig. 19

60 VarioGuide

438.020.070.012

Page 61

Fault code Cause

6. VarioGuide components and calibrations

F01

F02

F03

F06

F07

F08

F09

F11

F12

Preliminary conditions not satisfied

Front wheels are not straight

Manual steering wheel actuation during calibration

No movement in direction "steering to left"

No movement in direction "steering to right"

Calibration taking too long

User terminated calibration with ESC

Plausibility: Signal in direction "steering to left"

Plausibility: Signal in direction "steering to right"

NOTE:

If incorrect values are found, contact your FENDT dealer.

VarioGuide 61

438.020.070.012

Page 62

6. VarioGuide components and calibrations

62 VarioGuide

438.020.070.012

Page 63

Table of contents

7. Start-up

7.1 Load implement .........................................................65

7.1.1 Caution .............................................................65

7.1.2 Load implement settings (7" terminal) .......................................65

7.1.3 Load implement settings (10.4" terminal) .....................................66

7.2 Create implement .......................................................67

7.2.1 Call up implement settings on 7" ..........................................67

7.2.2 Call up implement settings on 10.4" ........................................68

7.2.3 Front-mounted implement ...............................................69

7.2.3.1 Install front-mounted implement ....................................69

7.2.3.2 Determine the working width, navigation point distance and coupling length ....70

7.2.3.3 Set the working width of the front-mounted implement ...................71

7.2.3.4 Set the navigation point of the front-mounted implement ..................72

7.2.3.5 Set the coupling length for the front-mounted implement .................73

7.2.3.6 Set the center of the front-mounted implement .........................74

7.2.3.7 Set the trigger for the front-mounted implement ........................75

7.2.4 Rear-mounted implement ................................................76

7.2.4.1 Install rear-mounted implement .....................................76

7.2.4.2 Determine the working width, navigation point distance and coupling length ....77

7.2.4.3 Set the navigation point of the rear-mounted implement ...................78

7.2.4.4 Set the coupling length for the rear-mounted implement ..................79

7.2.4.5 Set the center of the rear-mounted implement .........................80

7.2.4.6 Set the trigger for the rear-mounted implement .........................81

7.3 Save mounted implement data ...........................................82

7.3.1 Save implement on stopping .............................................82

7.4 Exchange implement data and field data ..................................84

7.4.1 Plug in the USB stick and call up data exchange ................................84

7.4.1.1 Insert USB stick ................................................84

7.4.1.2 Call up data exchange on 10.4" .....................................84

7.4.2 Transfer implement data and field data to the USB stick ..........................85

7.4.2.1 Select and transfer all data .........................................86

7.4.3 Transfer implement and field data from the USB stick to the terminal ................87

7.4.3.1 Select and transfer all data .........................................89

7.5 Correction signals .......................................................90

7.5.1 Overview of correction signals depending on the receiver ........................90

7.6 Submeter range with NovAtel receiver ....................................91

7.6.1 Autonomous .........................................................91

7.6.2 EGNOS / WAAS ......................................................92

7.7 Centimeter range with NovAtel receiver ..................................93

7.7.1 FENDT base station ....................................................93

7.7.1.1 Configure the FENDT base station correction signal ......................93

7.7.1.2 Fallback: FENDT base station .......................................94

7.7.2 External station .......................................................95

7.7.2.1 Configure the external station correction signal ..........................95

7.7.2.2 External fallback station ...........................................96

7.7.3 RTK network (internal mobile radio modem) ...................................96

7.7.3.1 Configure the internal mobile modem correction signal ....................96

7.7.3.2 Activate/deactivate internal mobile modem fallback .......................98

7.7.4 RTK network (external mobile radio modem) ..................................98

7.7.4.1 Configure the external mobile modem correction signal ....................98

VarioGuide 63

438.020.070.012

Page 64

Table of contents

7.8 Submeter range with Trimble receiver ................................... 100

7.8.1 Autonomous ........................................................ 100

7.8.2 EGNOS / WAAS ......................................................101

7.8.3 RangePoint RTX ......................................................102

7.9 Decimeter range with Trimble receiver ...................................103

7.9.1 CenterPoint RTX Satellite ............................................... 103

7.9.1.1 Set correction signal for Centerpoint RTX Satellite .......................103

7.9.1.2 Fallback for Centerpoint RTX Satellite ................................104

7.10 Centimeter range with Trimble receiver .................................105

7.10.1 FENDT base station .................................................. 105

7.10.1.1 Configure the FENDT base station correction signal — Trimble AG-715 450

MHz radio modem ....................................................105

7.10.1.2 Configure the FENDT base station correction signal (Trimble 900 MHz) ...... 106

7.10.2 RTK network (internal GSM/GPRS modem) ................................. 107

7.10.2.1 Configure the internal mobile modem correction signal (GSM/GPRS) ........ 107

7.10.3 RTK network (external mobile radio modem) ................................ 108

7.10.3.1 Configure the external mobile modem correction signal ..................108

7.10.4 Trimble receiver settings ...............................................109

7.10.4.1 xFill settings ................................................. 109

7.11 Field Settings ......................................................... 111

7.11.1 Add field .......................................................... 111

7.11.2 Record field boundary .................................................112

7.11.3 Record/manage obstacles ..............................................115

7.12 Way-line ..............................................................119

7.12.1 Create and save way line ..............................................119

7.12.2 Path to path distance ................................................. 124

7.13 Check system ......................................................... 125

7.13.1 Check system info/system status ........................................125

7.14 Activate VarioGuide system ............................................127

7.14.1 Switch on automatic way line guidance ....................................127

7.15 Adjust way line ........................................................128

7.15.1 Way line offset ..................................................... 128

7.16 Headland settings ..................................................... 129

7.16.1 Headland settings ................................................... 129

7.16.2 Headland management TI/AutoTI ........................................ 131

7.17 Operation with the base station ........................................ 133

7.17.1 Brief description .................................................... 133

7.17.2 Scope of delivery and accessories ........................................133

7.17.3 LED and keys on the base station ........................................ 136

7.17.4 Initial start-up .......................................................137

7.17.5 Operating modes .................................................... 138

7.17.6 Start-up ........................................................... 138

7.17.7 Set the base station channel on the tractor ................................. 139

7.17.8 Operate base station with external battery ..................................141

64 VarioGuide

438.020.070.012

Page 65

7. Start-up

7.1 Load implement

7.1.1 Caution

WARNING:

The tractor should only be operated with the automatic steering system when it is used in

an area well away from buildings, other machinery and people.

NOTE:

A quick turn of the steering wheel de-activates automatic steering.

7.1.2 Load implement settings (7" terminal)

NOTE:

This function can be used to load settings for an implement that has already been created, and to add the

settings in the VarioGuide (implement settings and way-line distance). A new implement can also be

created.

Call up the management main menu (7")

Applications main menu

The view shown opposite appears once button (D)

has been pressed on the external control panel.

Select management (softkey G).

(D) Application selection control panel

(G) Management softkey

Load implement settings

• When softkey (A, see #unique_42/

unique_42_Connect_42_T021795-FIE910) is

pressed, the pop-up shown opposite appears.

Select implement and confirm.

Fig. 1

Fig. 3

VarioGuide 65

438.020.070.012

Page 66

2011

35101011

1024

Verwaltung Info

D

7. Start-up

7.1.3 Load implement settings (10.4" terminal)

NOTE:

This function can be used to load settings for an implement that has already been created, and to add the

settings in the VarioGuide (implement settings and way-line distance). A new implement can also be

created.

Call up the management main menu (10.4"

terminal)

Information management

(D) Management

Load implement settings

• When softkey (A, see #unique_42/

unique_42_Connect_42_T021795-FIE910) is

pressed, the pop-up shown opposite appears.

Select implement and confirm.

Fig. 4

Fig. 6

66 VarioGuide

438.020.070.012

Page 67

7.2 Create implement

7.2.1 Call up implement settings on 7"

Procedure

7. Start-up

Fig. 7

Press the positioning button on the external control panel.

1.

Under "Management info", press the soft key for the on-board computer; "On-board computer" page

2.

is displayed.

On the "On-board computer" page, press the soft key for the trigger settings; "Trigger settings" page

3.

is displayed.

On the "Trigger settings" page, press the "Front-mounted implement" soft key; the "Implement

4.

settings" page is displayed.

VarioGuide 67

438.020.070.012

Page 68

7. Start-up

7.2.2 Call up implement settings on 10.4"

Procedure

Fig. 8

On the "Tractor Info" page, press the softkey for VarioDoc, and "VarioDoc Info" is displayed In

1.

"VarioDoc Info", press the VarioDoc softkey, and the "VarioDoc Main Page" appears.

In "VarioDoc Main Page", press the soft key for the on-board computer; the "On-board computer" page

2.

is displayed

On the "On-board computer" page, press the trigger settings; the "Trigger settings" page is displayed

3.

On the "Trigger settings" page, press the "Front-mounted implement" soft key; the "Implement

4.

settings" page is displayed.

68 VarioGuide

438.020.070.012

Page 69

7.2.3 Front-mounted implement

Geräteanbauposition auswählen

Heck

7.2.3.1 Install front-mounted implement

Procedure

Press softkey (A). A pop-up appears.

1.

7. Start-up

Select front-mounted implement.

2.

Fig. 9

Fig. 10

VarioGuide 69

438.020.070.012

Page 70

7. Start-up

3.

Assign a name and press to confirm.

Fig. 11

7.2.3.2 Determine the working width, navigation point distance and coupling length

Working width Center Navigation point Coupling length

Actual working width of

the implement

Movement of the

implement from the

center (e.g. for mowers)

Distance of the

horizontal rotational axis

of the implement from

the lower link hooks

Distance of the

processing area of the

implement from the

lower link hooks

Procedure

Start work and drive approx. 10 m.

1.

Measure the processed width (working width).

2.

Measure the length between the navigation point of the implement and the attachment hook

3.

NOTE:

The navigation point is the point on the implement that follows the wayline.

Measure the length between the start of the processed area and the attachment hook of the front

4.

power lift

NOTE: If the mark is to be created at the end of the implement, measure from this point to the end

of the implement.

70 VarioGuide

438.020.070.012

Page 71

7.2.3.3 Set the working width of the front-mounted implement

Procedure

Select the working width field (A) by touch or

1.

via the external control panel.

Set the processed width value via the

2.

external control panel.

7. Start-up

Fig. 12

VarioGuide 71

438.020.070.012

Page 72

7. Start-up

7.2.3.4 Set the navigation point of the front-mounted implement

Procedure

Select the navigation point field (A) by touch

1.

or via the external control panel.

Set the navigation point distance via the

2.

external control panel.

Fig. 13

72 VarioGuide

438.020.070.012

Page 73

7.2.3.5 Set the coupling length for the front-mounted implement

Procedure

Select the coupling length field (A) by touch

1.

or with the external control panel.

Set the coupling length distance via the

2.

external control panel.

7. Start-up

Fig. 14

VarioGuide 73

438.020.070.012

Page 74

7. Start-up

7.2.3.6 Set the center of the front-mounted implement

Procedure

Select the center field (A) by touch or via the

1.

external control panel.

Set the center via the external control panel.

2.

NOTE:

Only set the center if the mounted

implement deviates from the center.

Fig. 15

74 VarioGuide

438.020.070.012

Page 75

7.2.3.7 Set the trigger for the front-mounted implement

Procedure

Select and activate the trigger by touch or via

the external control panel.

NOTE:

Measurement takes place once all activated

trigger conditions are fulfilled simultaneously.

(A) Toggle switch Auto/I (ON)

NOTE:

If toggle switch (A) is set to I, the

distance and area are always

measured, except when the on-board

computer is paused. The other buttons

are grayed out.

If toggle switch (A) is set to AUTO, the

distance and area measurement

depends on triggers (B) to (F).

(B) Front power lift trigger OFF/ON

(C) Front PTO trigger OFF/ON

(D) EHS valve trigger OFF/ON

(E) External counter trigger OFF/ON

(F) VarioGuide trigger OFF/ON

(H) Jump back one menu level

7. Start-up

Fig. 16

VarioGuide 75

438.020.070.012

Page 76

Geräteanbauposition auswählen

Heck

7. Start-up

7.2.4 Rear-mounted implement

7.2.4.1 Install rear-mounted implement

Procedure

Press softkey (A). A pop-up appears.

1.

Select the rear-mounted implement.

2.

Fig. 17

Fig. 18

76 VarioGuide

438.020.070.012

Page 77

Select the trailer type.

Gezogenes Gerät

Heckkraftheber

Heckgeräteanbauposition auswählen

3.

Assign a name and press to confirm.

4.

7. Start-up

Fig. 19

Fig. 20

7.2.4.2 Determine the working width, navigation point distance and coupling length

Working width Center Navigation point Coupling length

Actual working width of

the implement

Movement of the

implement from the

center (e.g. for mowers)

Distance of the

horizontal rotational axis

of the implement from

the lower link hooks

Distance of the

processing area of the

implement from the

lower link hooks

VarioGuide 77

438.020.070.012

Page 78

7. Start-up

Procedure

Start work and drive approx. 10 m.

1.

Measure the processed width (working width).

2.

Measure the length between the navigation point of the implement and the attachment hook

3.

NOTE:

The navigation point is the point on the implement that follows the wayline.

Measure the length between the start of the processed area and the attachment hook of the front

4.

power lift

NOTE: If the mark is to be created at the end of the implement, measure from this point to the end

of the implement.

7.2.4.3 Set the navigation point of the rear-mounted implement

Procedure