Page 1

Werkstatthandbuch

Workshopmanual

Manuel de réparation

Manuel d´atelier

Manuale per I´officina

Motor

Engine

Moteur

Motore

MAN D 0836 LE (Mechanical part)

X990.005.039.010

Page 2

MAN D 0836 LE

Favorit 916 916/../3001Favorit 920 920/../3001Favorit 924 924/../3001Favorit 926 926/../3001-

Herausgegeben von der Abt. Kundendienst der Fa. ACGO GmbH & Co., Marktoberdorf

Alle Rechte vorbehalten – Printed in Germany. Diese Druckschrift darf ohne unsere schriftliche Genehmigung

Weder ganz noch auszugsweise vervielfältigt werden.

Published by the Service Division of ACGO GmbH & Co., Marktoberdorf

Copyright –All rights reserved – Printed in Germany. Rproduction of this publication, in whole or parts,

without our prior authorisation, is prohibited.

Peblié par le Service Aprés-vente de ACGO GmbH & Co., Marktoberdorf

Tous droits réservés – Printed in Germany Cette brochure ne peut être reproduite, ni totalement,

ni par extraits sans notre autorisation écrite.

Pubblicato dal reparto tecnico della ACGO GmbH & Co., Marktoberdorf

Tutti i dirette riservati – Printed in Germany La riproduzione die questo libro, sia completa che in parte

É vietata senza la nostra autorzzazione.

Redatto dal reparto assistenza della ditta ACGO GmbH & Co., Marktoberdorf

Tutti i diritti riservati - printed in Germany. Laa riproduzione di questo opuscolo, parziale o integrale,

non è ammessa senza autorizzazione scritta.

Page 3

WERKSTATTHANDBUCH

WORKSHOPMANUAL

MANUEL D´ATELIER

MANUAL DE TALLER

MANUALE PER L‘OFFICINA

MOTOR / ENGINE / MOTEUR / MOTORE

MAN D 0836 LE

(Mechanical part)

Ausgabe 05/2001

Xaver FENDT GmbH & CO.

Ein Unternehmen der AGCO-Corp.

Maschinen- und Schlepperfabrik, Marktoberdorf / Bayern Germany

Postfachadresse: D-87609 Marktoberdorf, Postfach 1155

Telefon (0 83 42) 77-0 Telefax (0 83 42) 77-2 22 (Kundendienst)

Bestell-Nr.

X 990.005.039.010

2672 C - en EKI 09/01 © Printed in Germany – All rights reserved

Page 4

VORWORT

Das vorliegende Werkstatthandbuch wurde für die

Reparaturwerkstätten unserer Vertretungen zusammengestellt und enthält alle Demontage- und Montagevorgänge, die im Zusammenhang mit Einstellarbeiten und der Auswechselung von Teilen

erforderlich ist.

Sind Teile auszuwechseln, so dürfen nur OriginalErsatzteile verwendet werden. Teile-Bestellungen

bitten wir unter Angabe der Fahrgestell-Nummer nach

den jeweils gültigen Ersatzteilunterlagen auf zugeben.

Es wird vorausgesetzt, daß diese Arbeiten von

Fachleuten ausgeführt werden; daher wurde auf die

Beschreibung allgemein bekannter Reparaturen

verzichtet.

Handelsübliche Werkzeuge und allgemeines Gerät,

das zur Ausrüstung einer Werkstatt gehört, wird

hierbei vorausgesetzt.

Spezialwerkzeuge sind auf das notwendige Maß

beschränkt und am Schluß des Buches in einer

Zusammenfassung gezeigt. Hinsichtlich der Pflegeund Wartungsarbeiten verweisen wir auf die Betriebsanleitungen.

Von den Werkstätten sind ie Technischen Daten zu

beachten.

Die einschlägigen Unfallverhütungsvorschriften sowie

die sonstigen allgemeinen anerkannten sicherheitstechnischen und arbeitsmedizinischen

Regeln sind einzuhalten.

Dieses Werkstatthandbuch unterliegt keinem Änderungsdienst, wir weisen aus diesem Grunde auf die

zusätzlich herauskommenden technischen Rundschreiben besonders hin. Bei Neuauflage eines

Werkstatthandbuches werden alle Änderungen

berücksichtigt und mit eingearbeitet.

Gegenüber Darstellungen und Angaben dieses

Werkstatthandbuches sind technische Änderungen,

die zur Verbesserung des Produktes notwendig

werden, vorbehalten. Nachdruck und Vervielfälti gung

jeglicher Art, auch auszugsweise, bedarf unserer

schriftlichen Genehmigung.

FOREWORD

This workshop manual was compiled for our agent´s

repair workshops and contains all the dismantling and

assembly procedures necessary in connection with

adjustments and replacement of parts.

If parts have to be renewed, only original replacement

parts may be used. Orders für parts must state the

chassis number and be in line with the latest parts

decomentation.

It is assumed that these repairs will be carried out by

skilled mechanics; descriptions of routine repair work

have, theerfore, been omitted.

It is furher assumed that the workshop concerned is

equipped with standard tools and has the normal

workshop facilities. The special tools are restricted to

the essential minimum and are shown in a summery

at the back of this manual.

Please refer to the Operating Instructions for details of

general maintenance and care operations.

Workshops must observe the technical data.

The accident prevention regulations and all other

generally recognized regulations on safety and

occupational medicine are to be observed.

This workshop manual is not subject to an updating

service. For this reason we draw your attention to the

supplementary technical circulars which are published

separately. New issues of a workshop manual

incorporate all the latest changes.

In view of continuous desing improvements or

changes, the technical specifications and the

illustrations shown in this Workshop Manual are

subject to alteration. Reprinting and reproduction, in

part or in whole, are subject to our written approval.

de/en

Page 5

AVANT PROPOS

Le présent Manuel de Réparation a été concupour

les Ateliers de Réparation de nos dépositaires et il

contient toutes les instructions de démontage et de

montage nécessitées par les travauc de réglade et

de remplacement des piéces.

Dés qu´il s´agit de remplacer des piéces, il faut

utiliser uniquement des piéces de rechange

originales. Pour commander les piéces de

rechange, nous prions de nous indiquer le numéro

du chassis et le numéro de référence de la piéce

concernée.

On considére que ces travaux sont effectués par

des spécialistes et c´est pourquoi les réparations

courantes ne sont pas décrites.

On considére également que l´on dispose des outils

classiques et de l´appareillage équipant

normalement un atelier.

Les outils spéciaux ont été réduits au strct

nécessaire et ils sont énumérés la fin du manuel.

En ce qui cincerne les travaux d´entretien, priére de

consulter les Instructions de Service.

Les ateliers de réparation devront tenir compte des

caractéristiques techniques.

Il convient de respecter les consignes générales de

sécurité et de prévention des accidents en vigueur.

Le présent Manuel de Réparation n´est soumit á

aucune midification, et c´est pourquoi il convient de

consulter les Circulaires Techniques publiées par la

suite. L´édition d´un nouveau Manuel de Réparation

tient compte de toutes les modification nécessaires.

Sous féserve de modifications techniques

nécessaires á lámélioration des produits présentés

par des illustrations et des indications référencées

dans ce Manuel d´Atelier.

Réimpression et reproduction meme partielle, quelle

qu´en soit la nature, interdtes sans l´autorisation

écrite de nos service.

PROLOGO

El presente Manual de Rparaciones ha sido

elaborado para los talleres de nuestros servicios

oficiales y comprende todos los trabjos de montaje

y desmontaje qu son necesarios para la sustitución

de piezas o trabajos de ajuste.

Cuando se sustituyan piezas deberán utilizarse

unicamente piezas de repuesto originales. Los

pedidos de las piezas de repuesto, sirvanse

hacerlos indicando el número de chasis y siguiende

el catálogo de repuestons que tenga validenz.

Es una condición previa que los trabajos sean

ilevados a cabo por personal especializado. Por

este motivo, hemos desistido de describir

reparaciones comúnmente conocidas.

Naturalmente, damos por sobreentendido que los

talleres deberán estar equipados con herramientas

y utillaje adecuado. La cantidad de herramientas

especiales a utilizar ha sido reducida a la medida

necesaria y van relacionadas al final de este libro.

Los puntos referentes a trabajos de mantenimiento

y de conservación sirvanse consultar el Manual de

Instrucciones. Los talleres están obligados a tener

en cuenta los datos técnicos.

Se cumplirán las normas aplicables para la

prevención de accidentes asi como todas las demás

normas de seguridad y medicina laboral

generalmente aceptas.

Este Manual de Reparaciones no está sometido a

modificaciones y, por lo tanto, les rogamos tengan

especialmente en cuenta las circularse técnicas

que, adicionalmente, se irán publicando. Cuando un

Manual de Reparaciones sea editado de nuevo se

tendrán en cuenta y serán introducidas todas las

modificaciones.

Nos reservamos el derecho de introducir

modificaciones técnicas necesarias para el

mejoramiento de las productas, aunque difieran de

las ilustraciones y datos contenidos en este Manual

de Taller. La reimpresión del presente libro o

cualquiera forma de reproducción, aunque sea

parcial, requiere nuestra autorización por escrito.

fr/es

Page 6

PREMESSA

Il presente manuale è stato redatto per le

officine dei nostri concessionari e contiene

tutte le indicazioni relative allo smontaggio ed

al montaggio che si rendono necessari per la

registrazione e la sostituzione di ricambi.

Se ci sono parti da sostituire devono essere

utilizzati assolutamente ricambi originali. I

ricambi devono venire ordinati indicando il

numero di telaio, secondo la documentazione

ricambistica in vigore.

E‘ necessario che questi lavori vengano

effettuati da personale specializzato, perciò le

riparazioni generalmente note non sono

descritte in questo manuale.

Si presuppone la presenza degli attrezzi

necessari e di dispositivi in generale che fanno

parte della dotazione di un‘officina.

Attrezzi speciali sono limitati al minimo

indispensabile e vengono elencati alla fine di

questo manuale. Per quanto riguarda la

manutenzione si prega di consultare le

istruzioni per l‘uso.

Le officine devono osservare i dati tecnici.

Rispettare le norme antinfortunistiche nonché

le generali norme tecniche sulla sicurezza e di

medicina sul lavoro.

Questo manuale non è soggetto a nessun

servizio di aggiornamento, per questo motivo

rimandiamo ad ulteriori comunicazioni

tecniche. In caso di aggiornamento di un

manuale si tiene conto delle variazioni, che

vengono poi incluse nella nuova versione.

Ci riserviamo il diritto di apportare modifiche

rispetto ad illustrazioni ed indicazioni di questo

manuale, che si rendono necessarie per il

miglioramento del prodotto. Stampa e

riproduzione di ogni genere, anche parziale, di

questo manuale solo previa nostra

autorizzazione scritta.

it

Page 7

Table of contents Page

Specifications ............................................................................................................................... 9

Service data.................................................................................................................................10

Tightening torque values...............................................................................................................24

Turbocharger, troubleshooting......................................................................................................28

View of engine D 0836 LE 501......................................................................................................30

Checking compression .................................................................................................................31

Checking valve timing...................................................................................................................32

Setting valve clearance.................................................................................................................33

Reassembling and refitting intake pipe...........................................................................................35

Removing and refitting turbocharger..............................................................................................36

Removing and refitting manifold ....................................................................................................38

Removing and refitting cylinder head.............................................................................................39

Dismantling and reassembling the rocker arm assembly.................................................................43

Removing and refitting valves .......................................................................................................45

Removing and refitting valve guides ..............................................................................................48

Replacing valve seat insert ...........................................................................................................49

Re-machining the valve seat.........................................................................................................51

Reseating valves..........................................................................................................................54

Replacing engine coolant..............................................................................................................55

Removing and refitting the thermostatic valve ................................................................................57

Removing and refitting water pump...............................................................................................58

Removing and refitting coolant pipe ...............................................................................................62

Layout of fuel system ...................................................................................................................63

Fuel pre filter / Cartridge ...............................................................................................................64

Purging Air from Fuel Supply System............................................................................................66

Removing and refitting heater plug................................................................................................67

Power - belts ...............................................................................................................................68

Removing and refitting the starter engine .......................................................................................71

Removing and refitting generator...................................................................................................72

Removing and refitting air compressor ...........................................................................................74

Replacing crankshaft front seal .....................................................................................................79

Removing and refitting flywheel.....................................................................................................80

Removing and refitting crankshaft seal (flywheel) ...........................................................................82

Removing and refitting flywheel.....................................................................................................83

Removing and refitting the timing case..........................................................................................85

Removing and refitting camshaft ...................................................................................................89

Removing and refitting intermediate flange....................................................................................91

Removing and refitting the con-rod bearing shells ..........................................................................92

Removing and refitting the crankshaft............................................................................................93

Removing and refitting con-rod......................................................................................................96

Removing and refitting the piston rings ........................................................................................ 101

Page 8

Table of contents Page

Replacing cylinder liners............................................................................................................. 103

Layout of engine lubrication ........................................................................................................ 104

Replacing oil filter.......................................................................................................................105

Removing and refitting oil cooler................................................................................................. 106

Removing and refitting oil pan..................................................................................................... 108

Removing and refitting oil pump ..................................................................................................111

Removing and refitting splash nozzle........................................................................................... 114

Checking Start of Delivery VP44 ................................................................................................. 115

Fuel Injection Pump VP 44 - Mounting - Dismounting ...................................................................122

Checking injection nozzles ..........................................................................................................132

Replacing Injection valve with needle Motion sensor..................................................................... 135

Special tools.............................................................................................................................. 138

Page 9

Fav 900

Engine / Generalities

Specifications

A

Généralités

Fav 900 from chassis number 23/3001and up

12/03/2001

2000 000005

A

a

1/1

Chapitre Docu-No.

Reg.

Date Édition

Page

Specifications

Text-module

Engine

Design In-line vertical

Principle of operation

4- Stroke Diesel with turbocharger and inter-

cooler

Method Direct injection

Number of cylinders 6

Compresssion ratio 18 : 1

Bore

108 mm (4.25")

125 mm (4.92")

Stroke

Swept volume 6871 cm³ (419.29 in³)

Firing sequence 1-5-3-6-2-4

Emission category MVEG 1

Max. output to ISO 1585 88/195 EWG

D 0836 LE 501 210 kW (285 PS) at 2250 rpm (281HP)

D 0836 LE 502 186 kW (255 PS) at 2250 rpm (249HP)

D 0836 LE 503 162 kW (220 PS) at 2150 rpm (217 HP)

D 0836 LE 504 146 kW (200 PS) at 2150 rpm (196 HP)

Max. torque to ISO 1585 88/195 EWG

D 0836 LE 501 1 175 Nm at 1400 rpm

D 0836 LE 502 1070 Nm at 1400 rpm

D 0836 LE 503 970 Nm at 1400 rpm

D 0836 LE 504 880 Nm at 1400 rpm

Rotation in rpm Idling speed - Final speed

D 0836 LE 501 / 502 800±30 ; 2250; 2420-2480

D 0836 LE 503 / 504 800±30 ; 2150; 2320-2380

Start of delivery Crankshaft angle before TDP

D 0836 LE 501 / 502 / 503 / 504 0°±0,5°

Engine number D 0836 LE 50. 164 9790 ... and up 5°±0,5°

Lubrication Forced feed lubrication

method gear oil pump

Quantities

Quantities in oil pan min. 18 ltr . (19 qt.)

max. 23 ltr. (24.3 qt.)

Oil change with filter 25,5 ltr. (27 qt.)

Cooling Liquid cooling

Method Impeller pump

Coolant temperature

D 0836 LE 501 / 502

normal 102°C (215°F)

momentary max. 108°C (226°F)

D 0836 LE 503 / 504

normal 105°C (221°F)

momentary max. 1 13°C (235°F)

Page 10

Fav 900

Engine / Generalities

Service Data

A

General

Fav 900 chassis number 23/3001and up

13/03/2001

2000 000006

A

b

1/14

Capitel Docu-No.

Index

Date Version

Page

Service Data

Text-module

Crankcase

PM-Picturemodule

Text-module

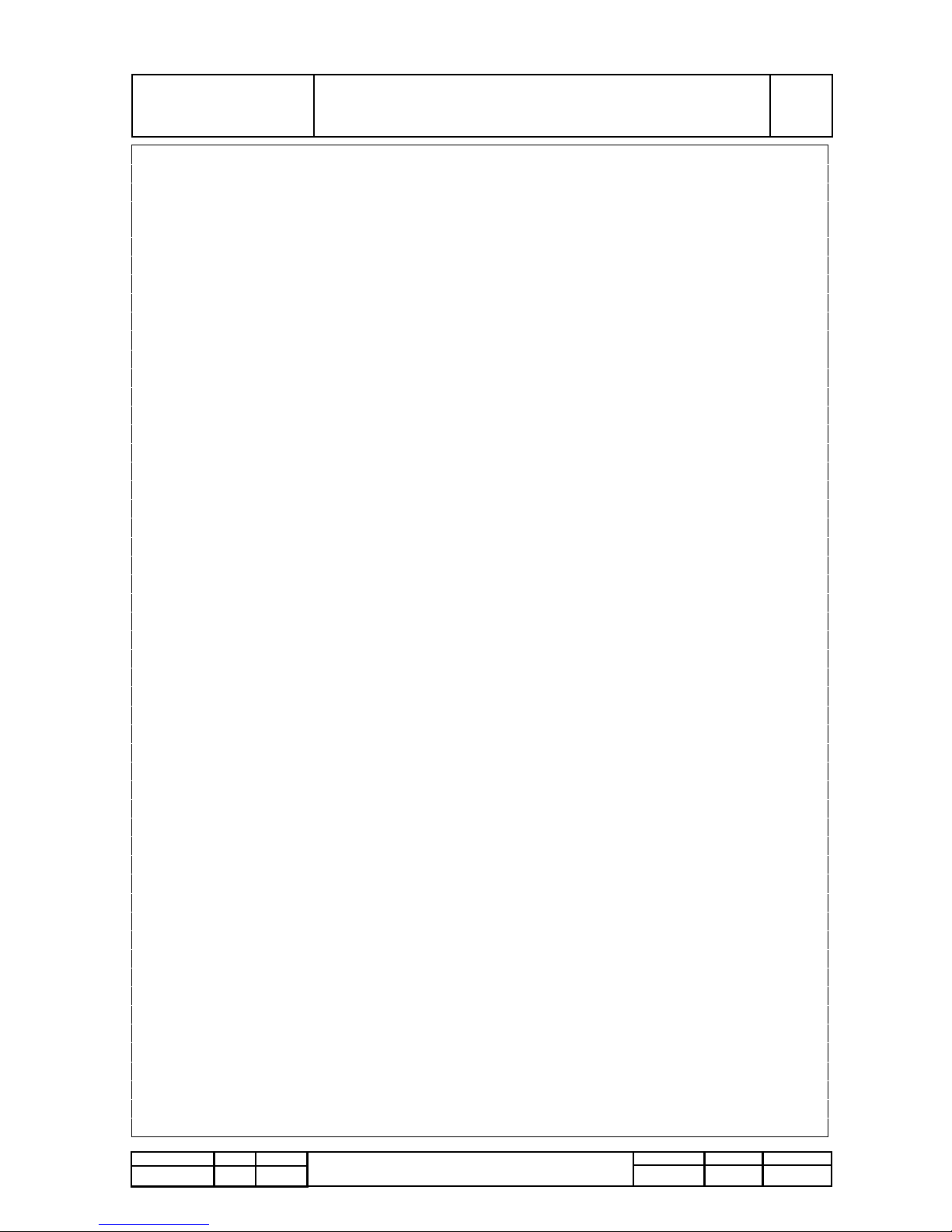

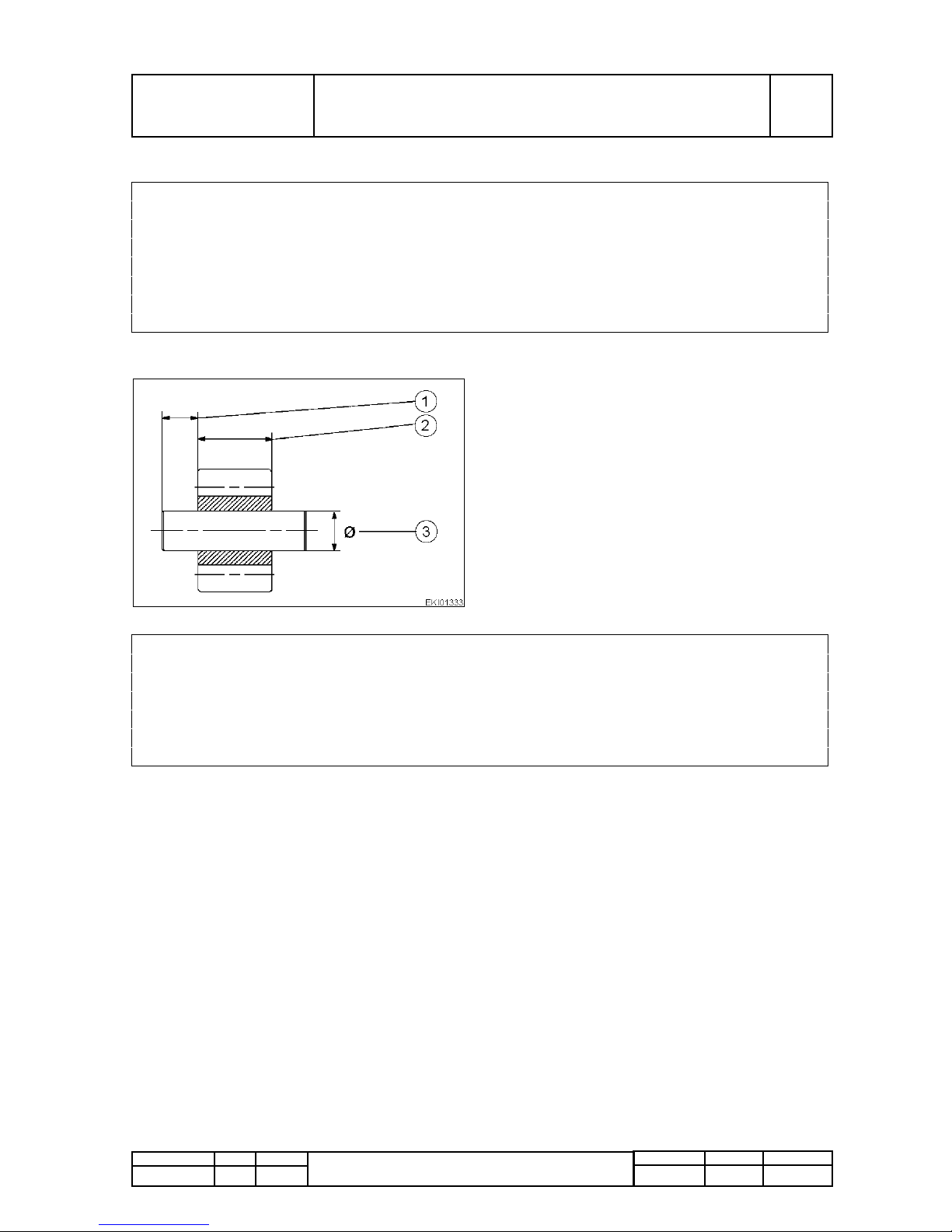

Cylinder liner

PM-Picturemodule

Text-module

PMTAB_Picture

1. 116,0-116,1 mm (4.4567 - 4.4570 ")

2. Standard size: 4,00-4,03 mm (.157 - .159")

Oversize: 4,20-4,23 mm (.165 - .167")

3. Standard size: 111,50-111,52 mm

(4.389 - 4.390")

Oversize 0,5 mm: 112,00-112,02 mm

(4.409 - 4.410")

4. Max. permissible taper over length of cylinder

PMTAB_Picture

1. 115,74-115,88 mm (4.556 - 4.562")

2. Standard size 4,04-4,06 mm (.159 - .160")

Oversize: 4,24-4,26 mm (.167 - .168")

3. 108,00-108,22 mm (4.252 - 4.260")

max. wear limit: 0,1 (.039") above basic size

4. Max. permissible taper over length of cylinder

5.Standard size: 111,475-111,490 mm

(4.388 - 4.389")

Oversize: 0,5 mm (.020"): 111,975-111,990 mm

(4.408 - 4.409")

Page 11

Fav 900

Engine / Generalities

Service Data

A

General

Fav 900 chassis number 23/3001and up

13/03/2001

2000 000006

A

b

2/14

Capitel Docu-No.

Index

Date Version

Page

Service Data

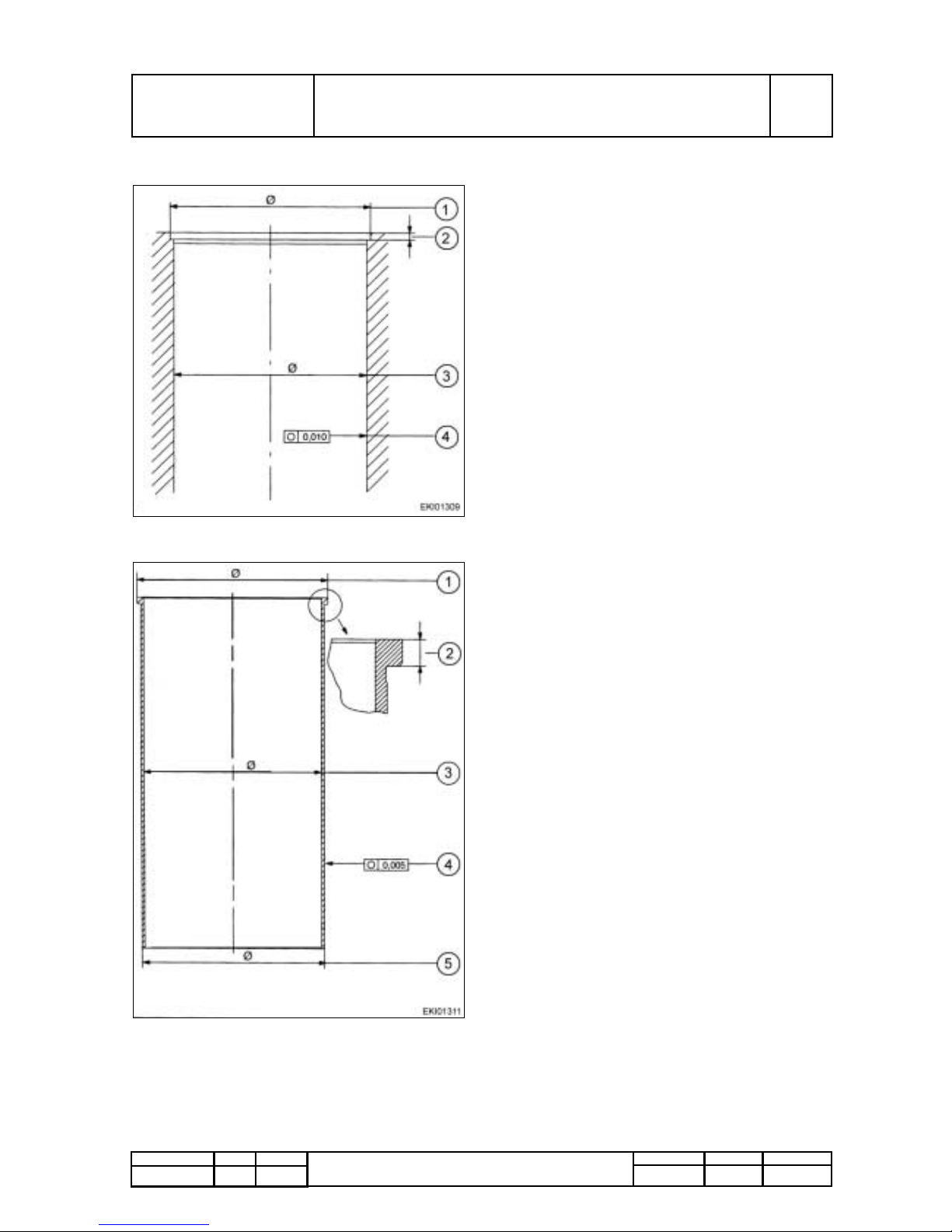

Crankshaft

PM-Picturemodule

PM-Picturemodule

Text-module

PMTAB_Picture

1. Dimensions:

Standard: 76,981-77,000 mm (3.031 - 3.032“)

Under size: 0,10 mm (.004"): 76,881-76,900 mm

(3.027 - 3.028")

2. Con-rod bearing journal diameter:

Standard : 69,981-70,000 mm (2.755 - 2.756")

Under size: 0,10 mm (.004"): 69,881-69,900 mm

(2.751 - 2.752")

PMTAB_Picture

1. For all crankshaft journals:

maximal permissible runout

maximal deviation from conical form

2. Thrust bearing journal width:

Standard size: 34,000-34,062 mm

(1.339 - 1.341")

Repair sizes: 34,500-34,562 mm (1.358 - 1.361")

Page 12

Fav 900

Engine / Generalities

Service Data

A

General

Fav 900 chassis number 23/3001and up

13/03/2001

2000 000006

A

b

3/14

Capitel Docu-No.

Index

Date Version

Page

Service Data

Main bearing

PM-Picturemodule

PM-Picturemodule

Text-module

Flywheel

PM-Picturemodule

PMTAB_Picture

1. Standard size: 2,468-2,480 mm (.097 - .098")

Oversize 0,10 mm (.004"): 2,518-2,530 mm

(.099 - .100")

2. Fitted bearing inner Ø for main bearing :

Standard size : 77,040-77,086 mm

(3.033 - 3.035")

Undersize 0,10mm (.004"): 76,940-76,986 mm

(3.029 - 3.031")

Housing bore for main bearing: 82,000-82,022

mm (3.228 - 3.229")

Axial play: 0,040-0,105 mm (.002 - .004")

Spread of main spearing shells: 0,5-1,5 mm

(.020 - .059")

PMTAB_Picture

max permissible crankshaft axials play:

0,200-0,395 mm (.008 - .016")

1. Thrust bearing journal width thrust washer:

Standard size: 2,850-2,900 mm (.112 - .114")

Repair size: 3,100-3,150 mm (.122 - .124")

2. 27,967-28,000 mm (1.101 - 1.102")

PMTAB_Picture

1. Watch position of chamfer!

Fitting temperature (Shrink-on temperature):

220-240°C (428-464°F)

2. Flywheel: 352,390-352,447 mm

(13.874 - 13.876")

Ring gear (Internal): 351,671-351,760 mm

(13.845 - 13.849")

m total. = 50,3 kg (110.89 lbs.)

J total = 1,65 kgm²

3.Number of teeth : Z=125, Module 3

Mating gear (Z=11)

Backlash : 0,4-0,7 mm (.016 - .020")

Page 13

Fav 900

Engine / Generalities

Service Data

A

General

Fav 900 chassis number 23/3001and up

13/03/2001

2000 000006

A

b

4/14

Capitel Docu-No.

Index

Date Version

Page

Service Data

Text-module

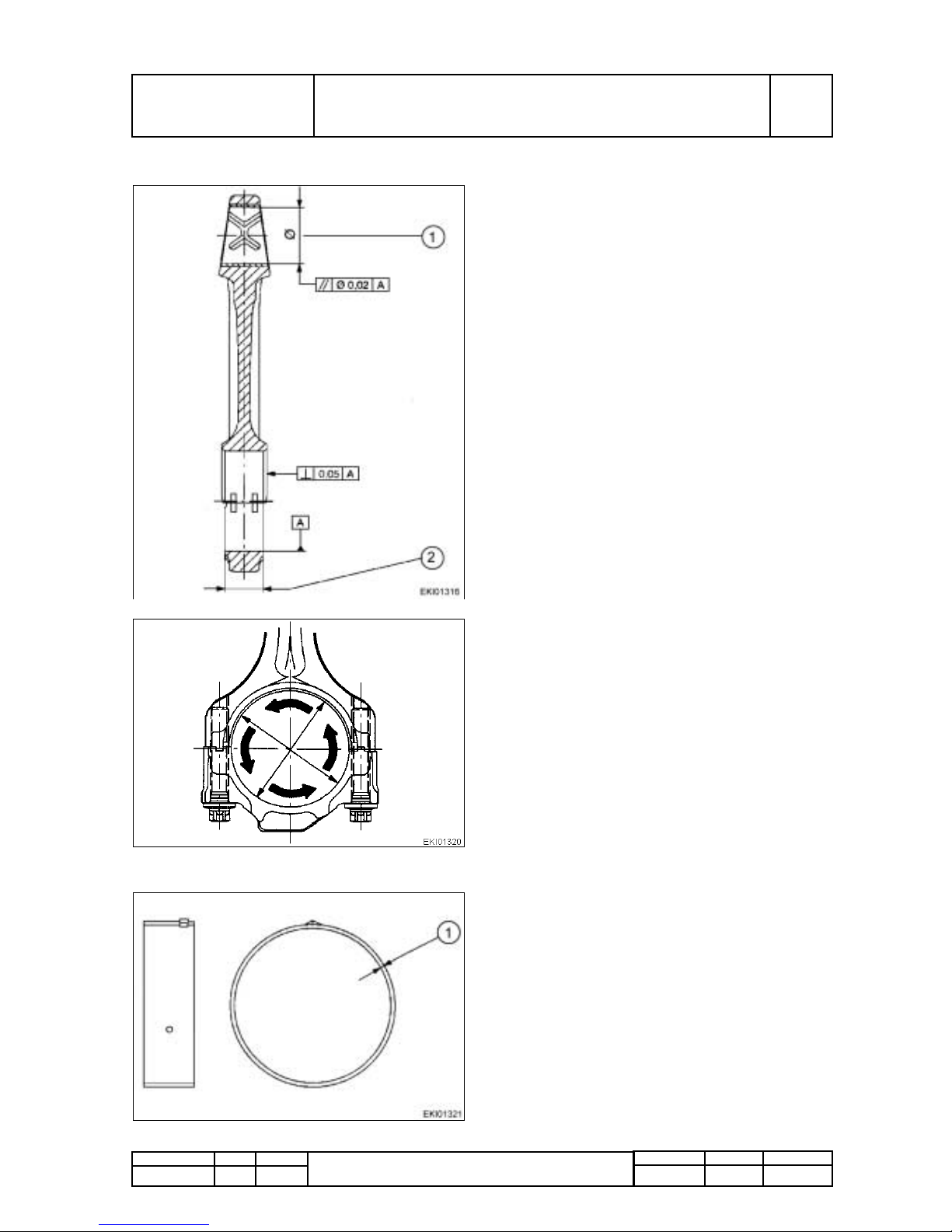

Connecting rod

PM-Picturemodule

PM-Picturemodule

Text-module

Con-rod bearing

PM-Picturemodule

Text-module

PMTAB_Picture

1. 42,050-42,066 mm (1.655 - 1.656")

2. 32,78-32,88 mm (1.290 - 1.294")

Con-rod journal width: 33,0-33,1mm

(1.299 - 1.303")

PMTAB_Picture

Fit con-rod bearing caps (without shells). Measure

basic bore with an internal micrometer.

74,000-74,019 mm (2.913 - 2.914")

PMTAB_Picture

1. Standard size: 1,975-1,987 mm (.077 - .078")

Oversize 0,10 mm (.004"): 2,025-2,037 mm

(.079 - .080")

Spread of new bearing shells : 0,5-2,0 mm

(.020 - .079")

Page 14

Fav 900

Engine / Generalities

Service Data

A

General

Fav 900 chassis number 23/3001and up

13/03/2001

2000 000006

A

b

5/14

Capitel Docu-No.

Index

Date Version

Page

Service Data

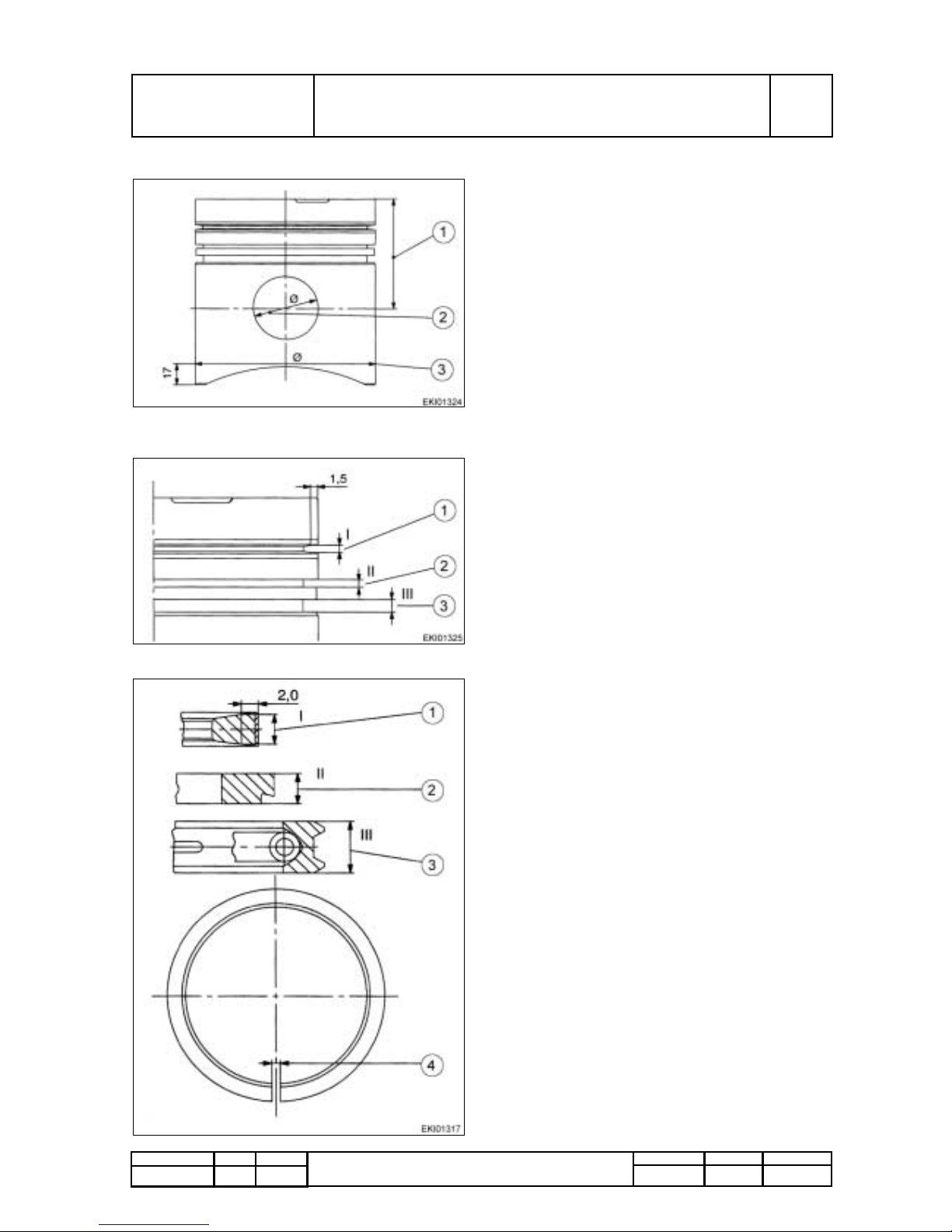

Piston

PM-Picturemodule

Text-module

Piston ring grooves

PM-Picturemodule

Text-modulePiston rings

PM-Picturemodule

PMTAB_Picture

1. Compresion height: 63,90-64,00 mm

(2.516 - 2.519")

with undersizes 0,2 mm (.008"): 63,70-63,80 mm

(2.508 - 2.511")

with undersizes 0,4 mm (.016"): 63,50-63,60 mm

(2.500 - 2.503")

Piston projection above crankcase: 0,0093-0,391

mm (.004 - .015")

2. 42,003-42,009 mm (1.6537 - 1.6539")

Piston pin diameter: 41,994-42,000 mm

(1.6533 - 1.6535")

3. 107,891-107,900 mm (4.2477 - 4.2480")

PMTAB_Picture

1. 2,685 mm (.106")

2. 2,54-2,56 mm (.100 - .101")

3. 4,02-4,04 mm (.158 - .159")

Piston rings

PMTAB_Picture

1. Ring - keystone ring:

Height: 2,429-2,463 mm (.096 - .097")

2. Ring - chamfered ring:

Height: 2,478-2,490 mm (.097 - .098")

Axial play: 0,050-0,082 mm (.002 - .003")

3. Ring - D-ring with spring:

Height: 3,975-3,990 mm (.156 - .157")

Axial play: 0,030-0,065 mm (.001 - .002")

4. End gap clearance:

1. Ring: 0,35-0,55 mm (.001 - .002")

2. Ring: 0,3-0,5 mm (.001 - .002")

3. Ring: 0,3-0,6 mm (.001 - .002")

Page 15

Fav 900

Engine / Generalities

Service Data

A

General

Fav 900 chassis number 23/3001and up

13/03/2001

2000 000006

A

b

6/14

Capitel Docu-No.

Index

Date Version

Page

Service Data

Text-module

Cylinder head

PM-Picturemodule

PM-Picturemodule

Text-module

PMTAB_Picture

1. 10,000-10,015 mm (.3937 - .3942") at intake

and exhaust valves

2. 14,1-14,15 mm (.555 - .557")

3. 97,8-98,0 mm (3.850 - 3.860")

Minimum: 96,8 mm (3.811")

alpha = 60° Intake valve

beta = 45° Exhaust valve

PMTAB_Picture

1. Valve guide bore in cylinder head:

Standard size: 16,000-16,018 mm (.630 - .631")

Oversize: 16,250-16,268 mm (.640 - .641")

2. Valve guide outer diameter:

Standard size: 16,028-16,046 mm (.631 - .632")

Oversize: 16,278-16,296 mm (.641 - .642")

3. Standard size:

Intake valve: 10,8-10,9 mm (.425 - .429")

Exhaust valve: 11,0-11,1 mm (.433 - .437")

Oversize:

Intake valve: 11,0-11,1 mm (.433 - .437")

Exhaust valve: 11,2-11,3 mm (.441 - .445")

4. Cylinder head basic bore:

Standard size: 51,00-51,03 mm (2.008 - 2.009")

Oversize: 51,20-51,23 mm (2.016 - 2.017")

Valve seat insert outer diameter:

Standard size: 51,10-51,11 mm (2.011 - 2.012")

Oversize: 51,30-51,31 mm (2.019 - 2.020")

5.Cylinder head basic bore:

Standard size: 44,000-44,025 mm

(1.732 - 1.733")

Oversize: 44,200-44,225 mm (1.740 - 1.741")

Valve seat insert outer diameter:

Standard size: 44,10-44,11 mm (1.736 - 1.737")

Oversize: 44,30-44,31 mm (1.744 - 1.745")

Page 16

Fav 900

Engine / Generalities

Service Data

A

General

Fav 900 chassis number 23/3001and up

13/03/2001

2000 000006

A

b

7/14

Capitel Docu-No.

Index

Date Version

Page

Service Data

Valves

PM-Picturemodule

PM-Picturemodule

Text-module

PMTAB_Picture

1. Intake valve: 9,965-9,980 mm (.3923 - .3929")

Exhaust valve: 9,950-9,965 mm (.3917 - .3923")

Wear limit: max. 0,1 mm (.0039")

2. Valve recess:

Intake valve : 0,25-0,71 mm (.010 - .028")

Exhaust valve: 0,45-1,05 mm (.018 - .041")

PMTAB_Picture

Valve springs:

Untensioned approx.: 59,5-61,0 mm

(2.343 - 2.401")

Spring resistance L = 45 mm: 410-471 N

(92 - 106 lbs.)

Spring resistance L = 33,5 mm: 744-825 N

(167 - 185 lbs.)

Page 17

Fav 900

Engine / Generalities

Service Data

A

General

Fav 900 chassis number 23/3001and up

13/03/2001

2000 000006

A

b

8/14

Capitel Docu-No.

Index

Date Version

Page

Service Data

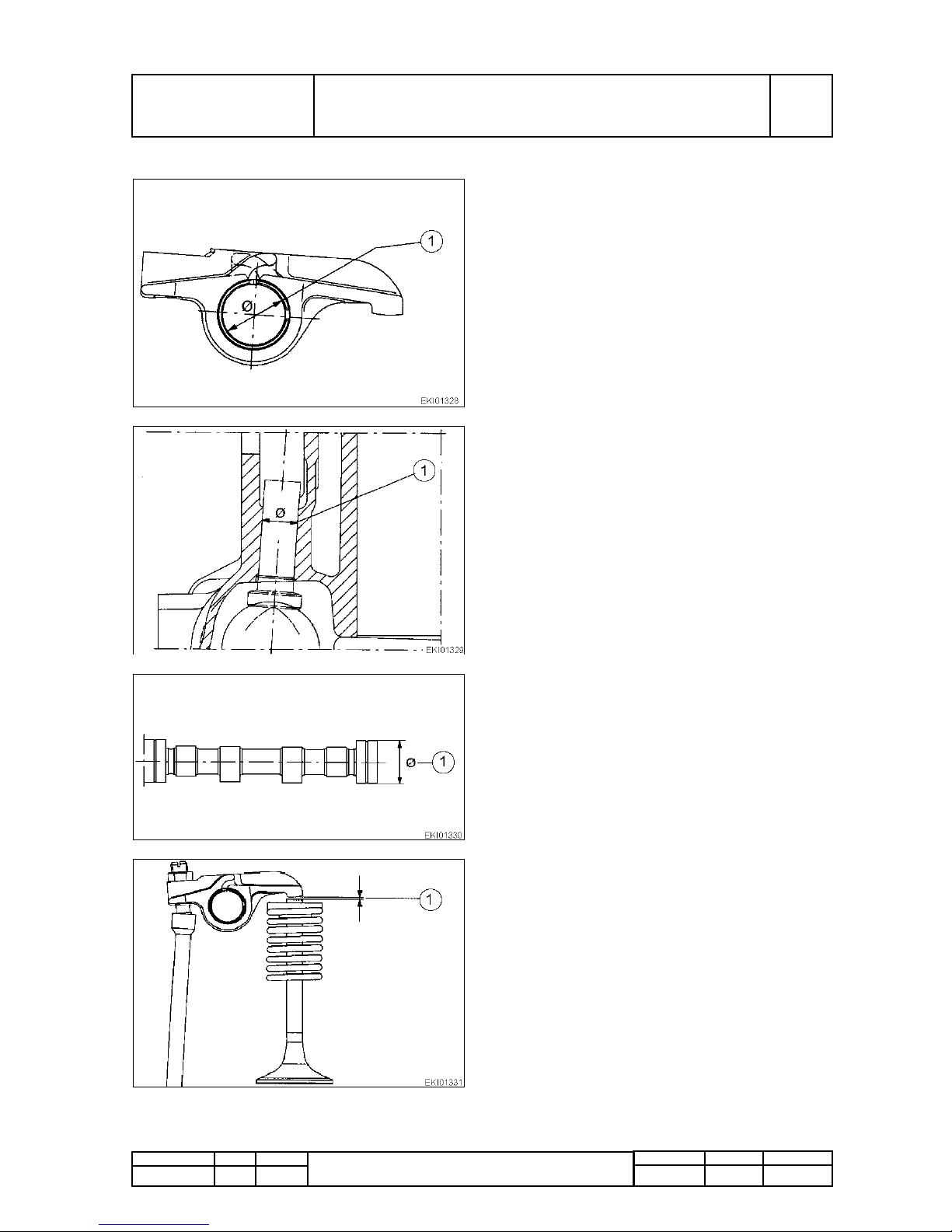

Valve operation

PM-Picturemodule

PM-Picturemodule

PM-Picturemodule

PM-Picturemodule

PMTAB_Picture

Rocker arm

1. 20,000-20,001 mm (.78740 - .78744")

Diameter of rocker arm bearing: 19,957-19,970

mm (.7857 - 7862")

Wear limit: 0,08 mm (.003")

PMTAB_Picture

Valve tappets

1. Tappet housing bore:

Standard size: 20,000-20,021 mm (.787 - .788")

Oversize: 20,250-20,271 mm (.797 - .798")

Tappet outer diameter:

Standard size: 19,944-19,965 mm (.785 - .786")

Oversize: 20,194-20,215 mm (.795 - .796")

PMTAB_Picture

Camshaft

Camshaft bush inner diameter: 55,07-55,14 mm

(2.168 - 2.170")

1. 1. 54,91-54,94 mm (2.162 - 2.163")

Camshaft axial diameter: 0,14-0,27 mm

(.0055 - .0106")

Wear limit: 1,5 mm (.059")

PMTAB_Picture

Valve clearance

1. Adjust when engine is cold.

Intake valve: 0,5 mm (.020")

Exhaust valve: 0,5 mm (.020")

Page 18

Fav 900

Engine / Generalities

Service Data

A

General

Fav 900 chassis number 23/3001and up

13/03/2001

2000 000006

A

b

9/14

Capitel Docu-No.

Index

Date Version

Page

Service Data

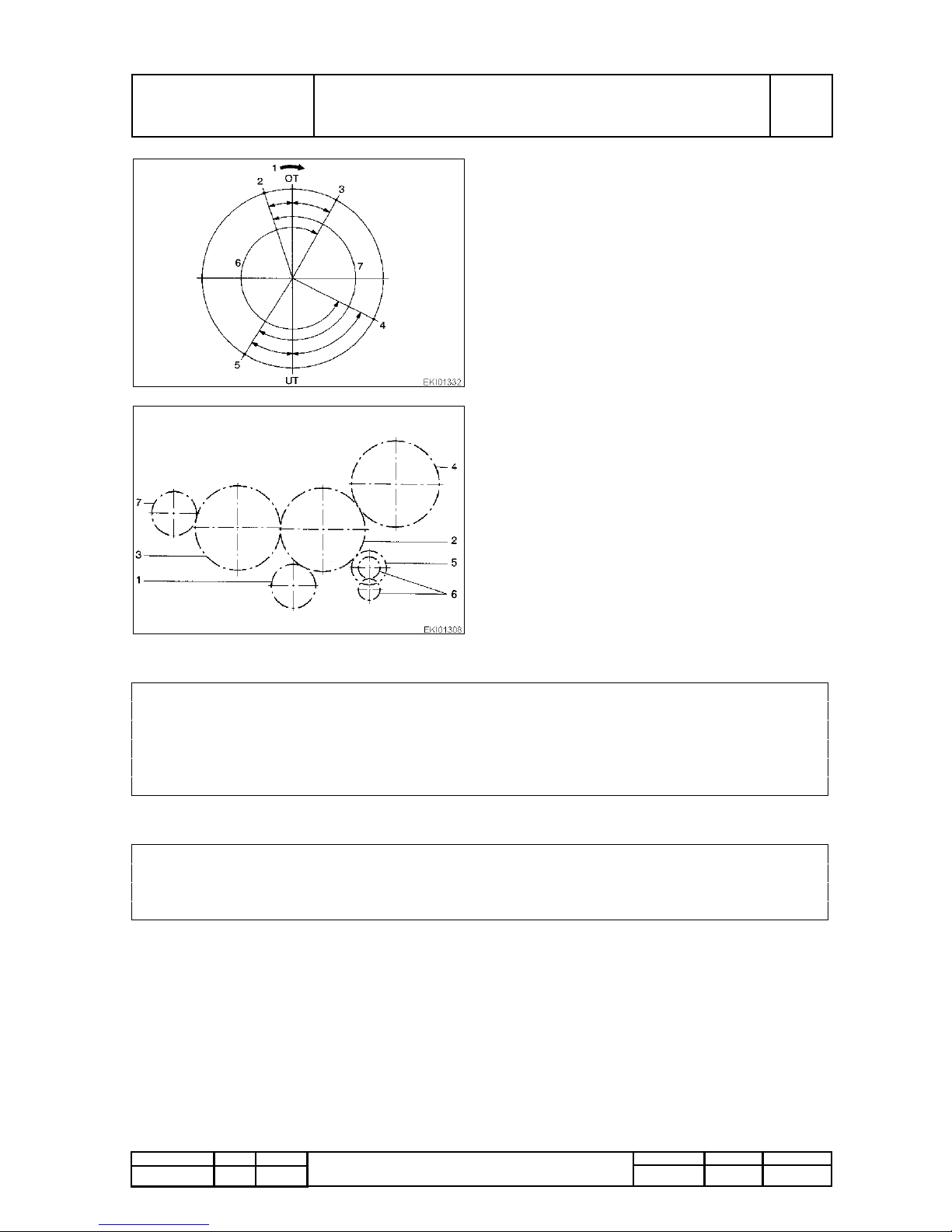

PM-Picturemodule

PM-Picturemodule

Text-module

Backlash between

Text-module

Compression pressures

Text-module

PMTAB_Picture

Valve timing

1. Engine direction of rotation

2. Intake valve opens 18° before TDC.

3. Exhaust valve closes 29° after TDC.

4. Exhaust valve opens 63° before TDC.

5. Intake valve closes 32° after bottom dead

point.

6. Exhaust valve opening point 272°.

7. Intake valve opening point 230°.

Figures in degrees relate to the crankshaft angle.

PMTAB_Picture

Layout of engine timing

1. Crankshaft gear

2. Intermediate timing gear

3. Camshaft gear

4. Injection pump drive gear

5. Oil pump drive gear

6. Oil pump delivery gear

7. Power take off / air compression take off

Crankshaft gear and intermediate gear 0,000-0,465 mm (0 - .018")

Intermediate gear and crankshaft gear 0,062-0,324 mm (.002 - .013")

Intermediate gear and injection pump drive 0,10-0,27 mm (.004 - .010")

Intermediate gear and oil pump drive 0,100-0,266 mm (.004 - .010")

Oil pump delivery gears 0,10-0,22 mm (.004 - .009")

Camshaft gear and hydraulic pump gear 0,10-0,15 mm (.004 - .006")

good above 30 bar (435 PSI)

permissible 27 - 30 bar (391 - 435 PSI)

needs repairing under 26 bar (377 PSI)

pressure difference max. 4 bar (58 PSI)

Page 19

Fav 900

Engine / Generalities

Service Data

A

General

Fav 900 chassis number 23/3001and up

13/03/2001

2000 000006

A

b

10/14

Capitel Docu-No.

Index

Date Version

Page

Service Data

Engine lubrication

Text-module

Oil pump

PM-Picturemodule

Text-module

Text-module

V alve opening pressures

Bypass valve for full flow oil filter 2-3 bar (29 - 44 PSI)

Oil pump pressure relief valve 5-6 bar (73 - 87 PSI)

Pressure valve of oil nozzles

Opening pressure 1,9-2,1 bar (27.5 - 30.5 PSI)

Closing pressure 1,4-1,6 bar (20.3 - 23.2 PSI)

Oil splash nozzle orifice 1,75-1,85 mm (.069 - .073")

PMTAB_Picture

Oil pump drive gear

1. 16 mm (.630")

2. D 0836 LE 501/502: 31,925-31,950 mm

(1.257 - 1.258")

D 0836 LE 503/504: 31,920-31,950 mm

(1.257 - 1.258")

Housing depth: 32,000-32,039 mm

(1.260 - 1.261")

Housing bore: 10000 N

3. Shaft: 15,94-15,95 mm (.627 - .628")

Housing bore: 16,000-16,018 mm (.630 - .631")

Oil pump delivery at pump speed (with SAE 20W/20 Oil, at 90°C (194°F) and p=6bar (87 PSI))

Gear spread 32 mm (1.260")

at n = 1008 1/min (rpm 800 1/min) 17 ltr./min (4.5 GPM)

at n = 2709 1/min (rpm 2150 1/min) 53,5 ltr./min (14 GPM)

at n = 2835 1/min (rpm 2250 1/min) 56,5 ltr./min (15 GPM)

ati n = 2961 1/min (rpm 2350 1/min) 59 ltr./min (15.5 GPM)

at n = 3087 1/min (rpm2450 1/min) 62,5ltr./min (16.5 GPM)

Page 20

Fav 900

Engine / Generalities

Service Data

A

General

Fav 900 chassis number 23/3001and up

13/03/2001

2000 000006

A

b

11/14

Capitel Docu-No.

Index

Date Version

Page

Service Data

Cooling system

PM-Picturemodule

PM-Picturemodule

Text-module

PMTAB_Picture

Water pump (engine)

1. Gap between impeller and housing:

0,5-0,9 mm (.020 - .035")

2. Impeller diameter: 136 mm (5.354")

3. Bearing location in housing:

54,940-54,970 mm (2.163 - 2.164").

Bearing diameter:

54,981-54,994 mm (2.1646 - 2.1651")

4. Bore in hub: 25,000-25,013 mm (.984 - .985").

Bearing shaft diameter: 25,048-25,061 mm

(.986 - .987").

5. Impeller bearing shaft bore: 16,000-16,018

mm (.630 - .631"). Bearing shaft diameter :

16,045-16,056 mm (.6316 - .6321).

PMTAB_Picture

Thermostat

Opening at 83°C (±2°) (181°F ±3.6°F).

Fully open: 95°C (203°F).

1. Stroke: min 8 mm at 95°C (.315" at 203°F).

Page 21

Fav 900

Engine / Generalities

Service Data

A

General

Fav 900 chassis number 23/3001and up

13/03/2001

2000 000006

A

b

12/14

Capitel Docu-No.

Index

Date Version

Page

Service Data

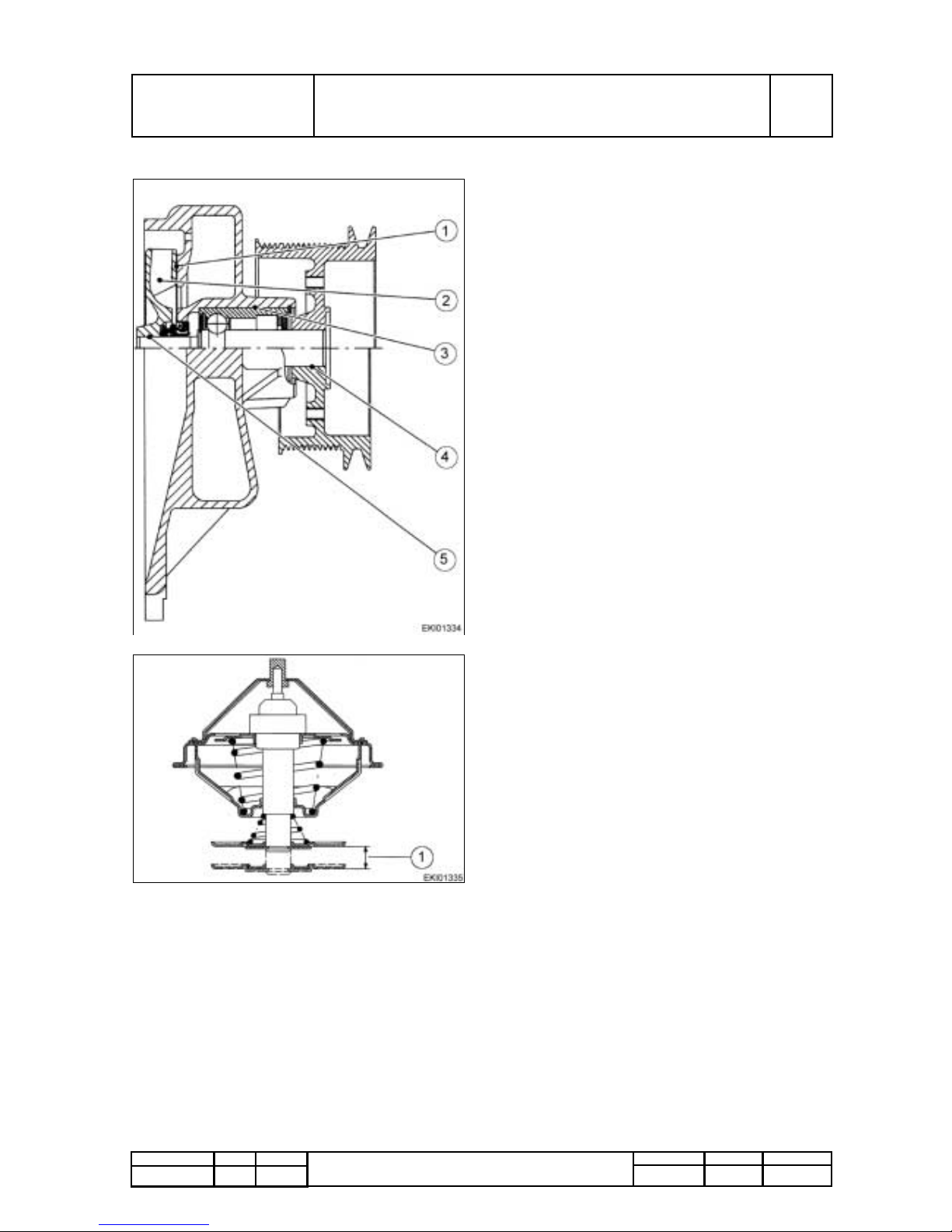

Turbocharger

PM-Picturemodule

PM-Picturemodule

Text-module

Manufacturer KKK

D 0836 LE 501/502/503/504 HX40-8274AW/H18W A8

PMTAB_Picture

Axial play

1. 0,038-0,093 mm (.0015 - .0037")

PMTAB_Picture

Radial play

1. 0,329-0,501 mm (.0130 - .0197")

Page 22

Fav 900

Engine / Generalities

Service Data

A

General

Fav 900 chassis number 23/3001and up

13/03/2001

2000 000006

A

b

13/14

Capitel Docu-No.

Index

Date Version

Page

Service Data

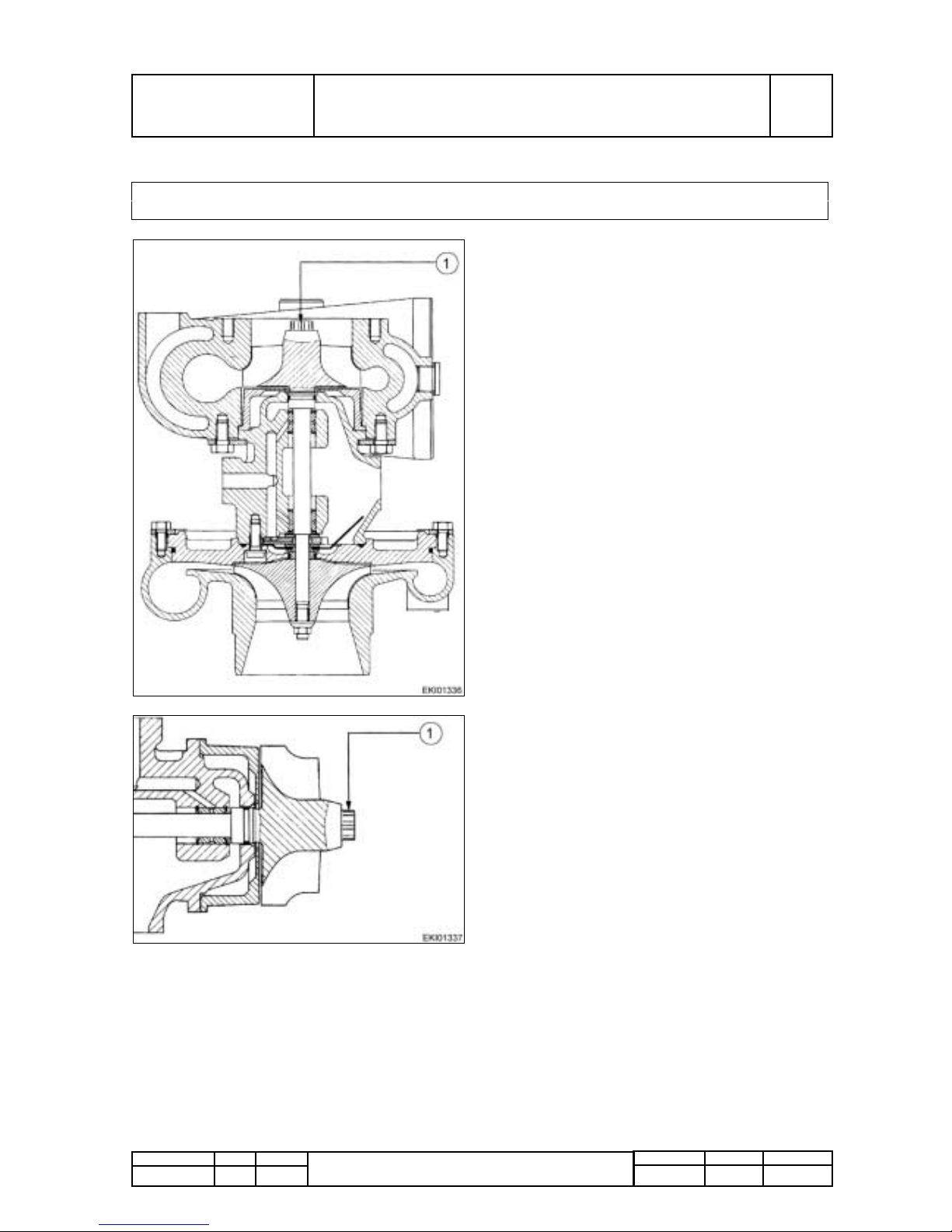

Fuel system

Injection nozzles

PM-Picturemodule

Manufacturer Bosch

Type : DSLA 154 P 625

N° of orifices 6

Nozzle opening pressure :

Nozzle holder new : 320 + 8 bar (4641 +1 16 PSI)

Nozzle holder used : 300 + 8 bar (4351 +1 16 PSI)

Nozzle injection pump with vane-cell feed pump

and automatic pressure controlled injection timer

2,68-3,47 mm (.106 - .137")

Nozzle holder KDEL 82 P 55

PMTAB_Picture

Injection pump

Nozzle injection pump with vane pump and

automatic pressure controlled injection timer

Manufacturer : Bosch.

Type: VP 44.

Page 23

Fav 900

Engine / Generalities

Service Data

A

General

Fav 900 chassis number 23/3001and up

13/03/2001

2000 000006

A

b

14/14

Capitel Docu-No.

Index

Date Version

Page

Service Data

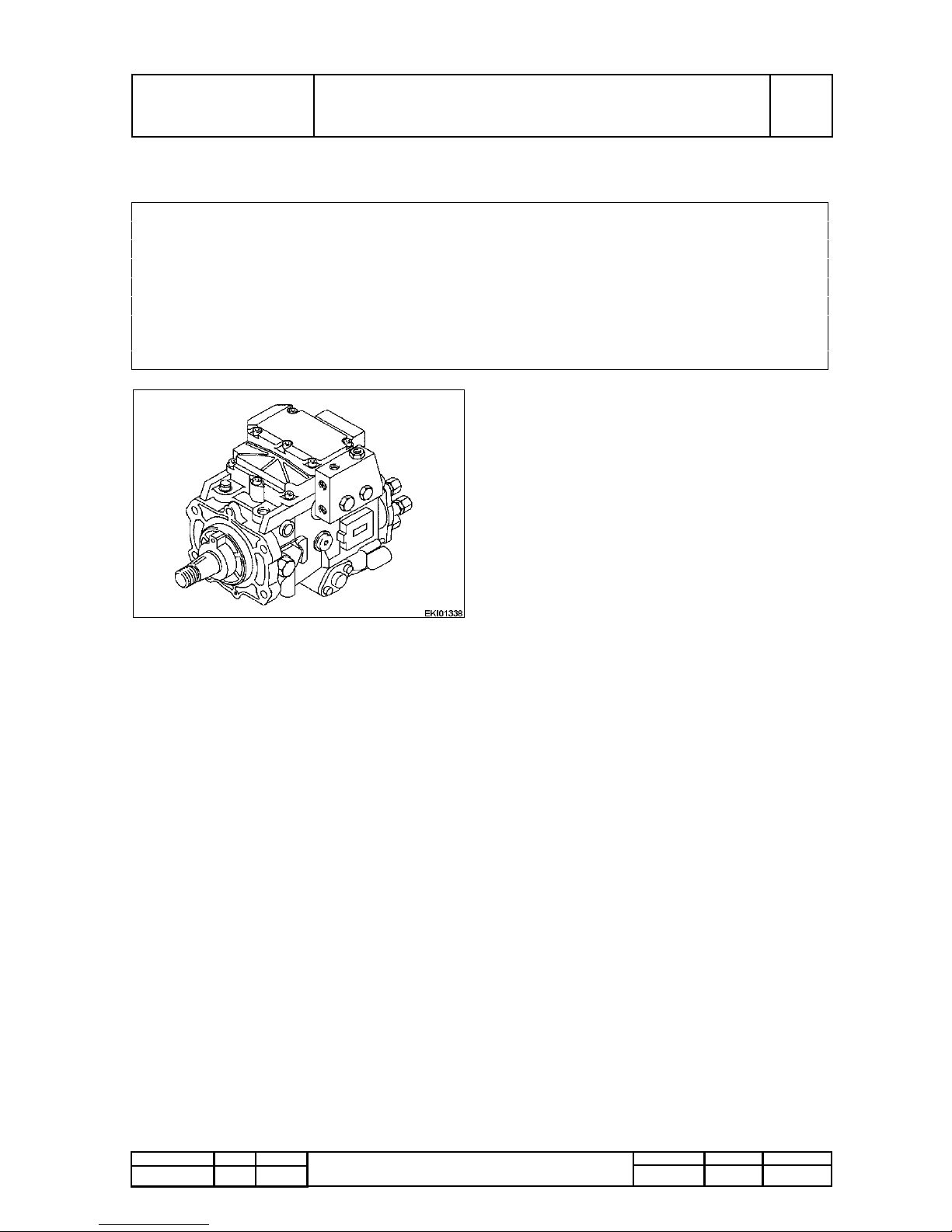

PM-Picturemodule

PM-Picturemodule

Text-module

Power take-off for hydraulic pump / Air compressor

PM-Picturemodule

PMTAB_Picture

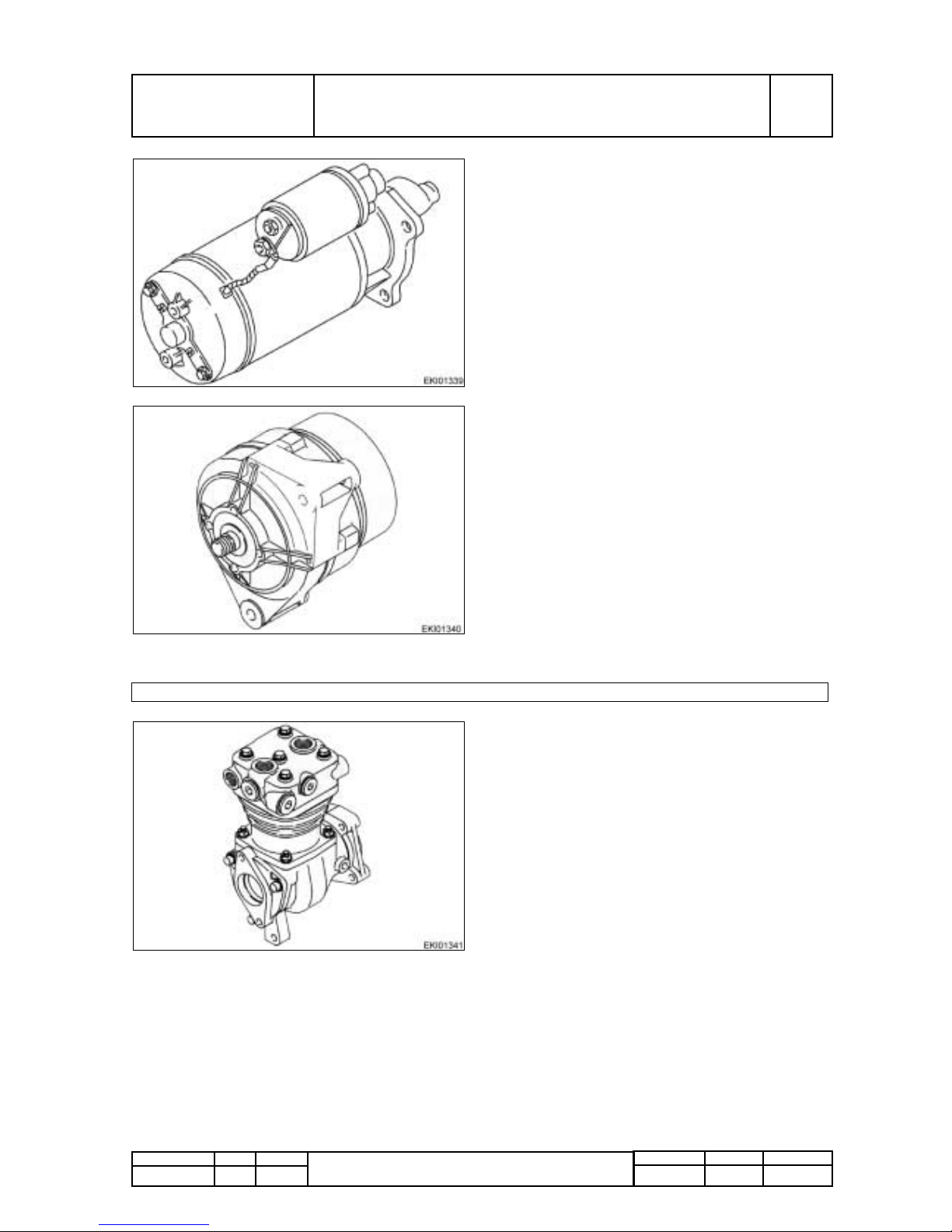

Starter

Manufacturer : Bosch

Type : EV

operationg method : pre-engaged drive

Starter pinion gear

Number of teeth: 11

Module: 3

Nominal voltage: 24 Volt

Nominal output : 4 kW (5.36 HP)

PMTAB_Picture

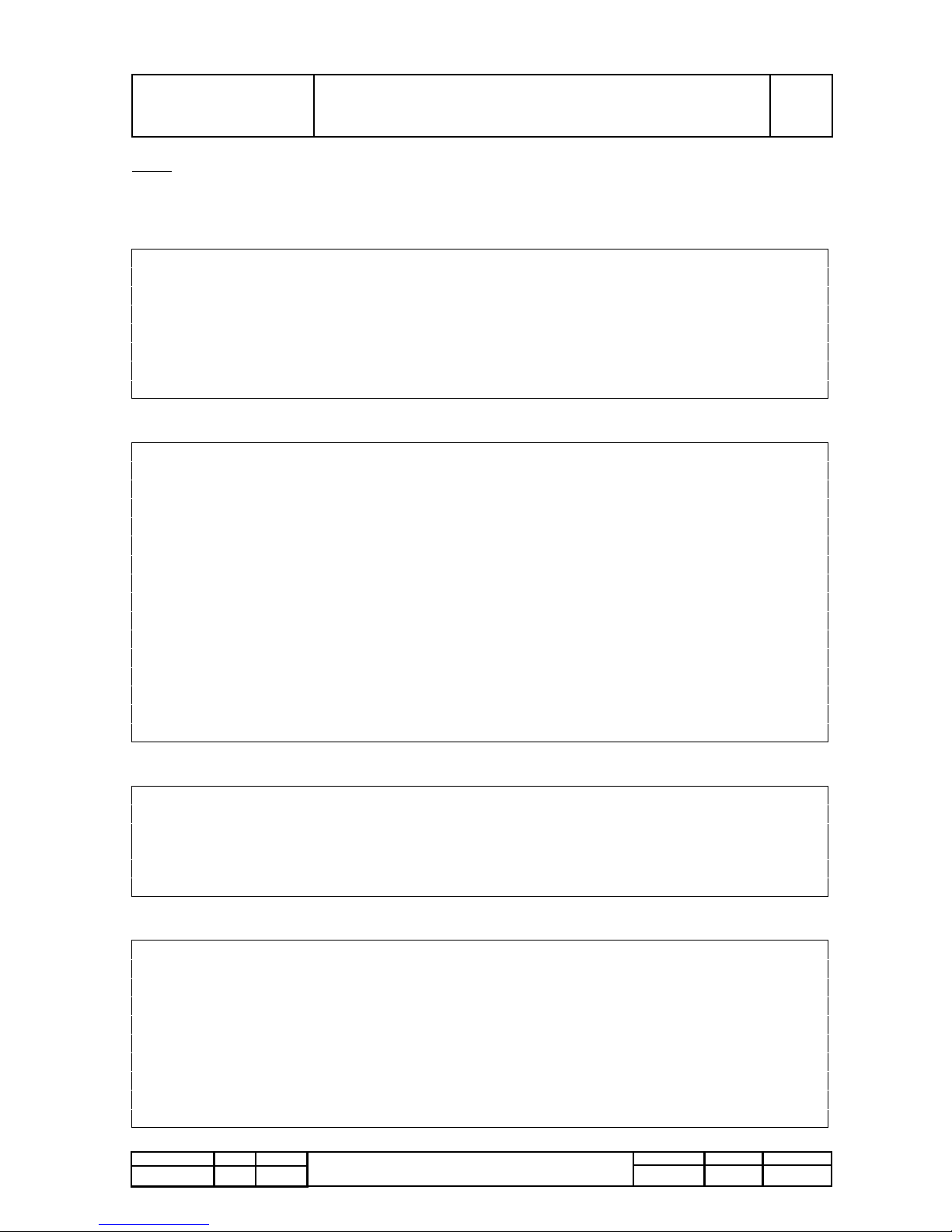

Generator

Manufactured : Bosch

Type : KC

Operating method : 3_PHASE

Nominal voltage : 14 Volt

Max. current : 45-90 Ampere

Speed 0,97 * engine speed

PMTAB_Picture

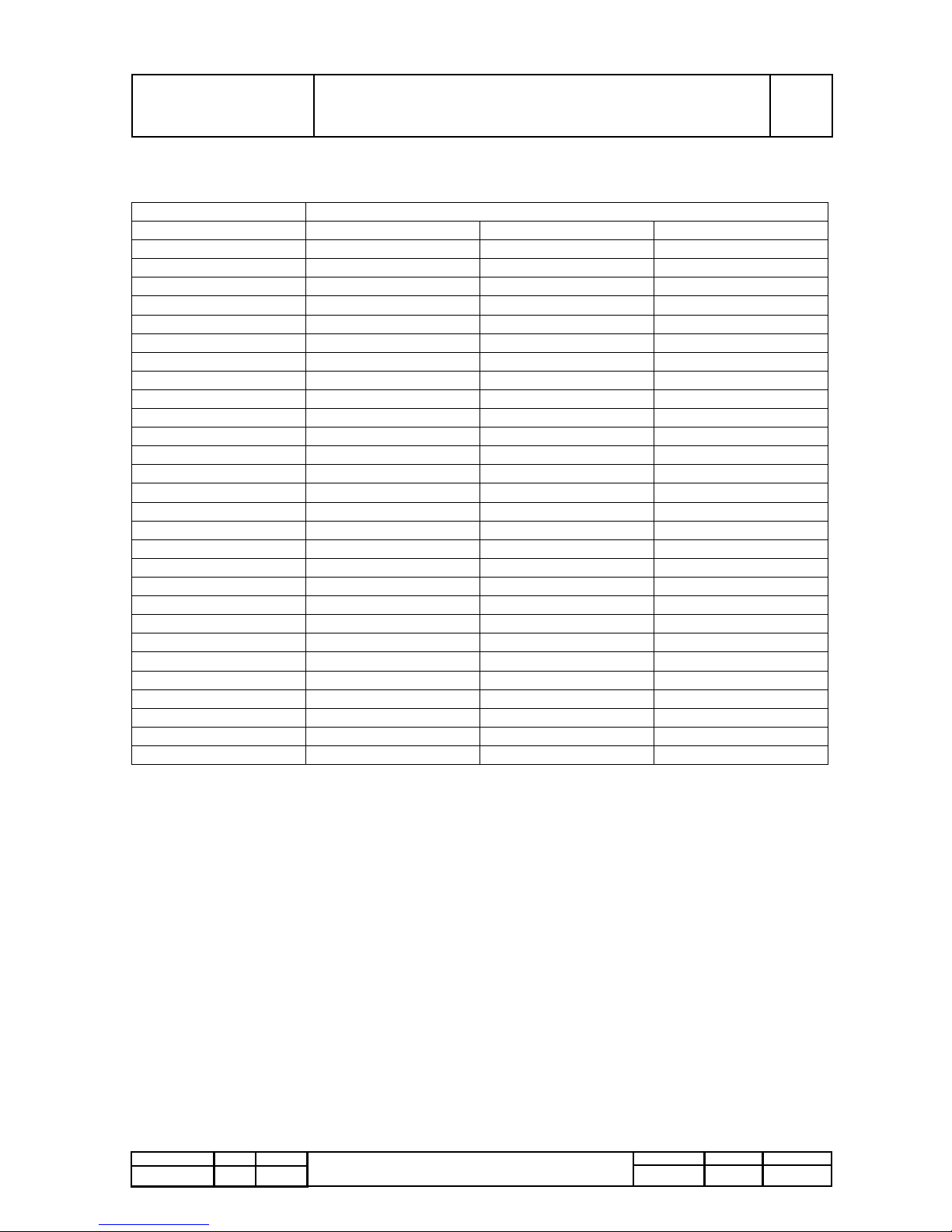

Air compressor

Single cylinder air compressor

Manufacturer: Knorr

Lubrication: Circulatory system with pressure

compression

Cooling: air-cooled

Displacement: 213 cm³ (129 in³)

Op speed: max. 3000 1/min

Op presure: max 12,5 bar (181 PSI)

Page 24

Fav 900

Engine / Generalities

Tightening Torque values

A

General

Fav 900 from chassis number 23/3001and up

13/03/2001

2000 000007

A

a

1/4

Capitel Docu-No.

Index

Date Version

Page

Tightening Torque values

Text-module

Note:

All threaded unions not specified in this table must be tightened according to our works

standard M 3059. Bolts and screws must be lightly oiled before tightening !

Plugs

Crankcase, crank gear

Cylinder head

Lubrication

DIN 908

M 14*1,5; M16*1,5 80 Nm (59,00 lbf-ft)

M 18*1,5; M22*1,5 100 Nm (73,76 lbf-ft)

M 24*1,5; M26*1,5 120 Nm (88,51 lbf-ft)

M 30*1,5 150 Nm (1 10,63 lbf-ft)

DIN 7604

AM 10*1; M12*1,5 50 Nm (36,88 lbf-ft)

AM 14*1,5 80 Nm (59,00 lbf-ft)

Crankshaft bearing cap on and crankcase

Initial torque 1 15 Nm (84,82 lbf-ft)

Angular torque 90-100°

Damper on crankshaft M14*1,5 10,9

Initial torque 150 Nm (1 10,63 lbf-ft)

Angular torque 90-100°

Damper on crankshaft M14*1,5 12,9

Initial torque 150 Nm (1 10,63 lbf-ft)

Angular torque 90-100°

Angular torque 90-100°

Flywheel on crankshaft

Initial torque 100 Nm (73,76 lbf-ft)

Angular torque 90-100°

Con-rod bearing caps

Initial torque 50-60 Nm (36,88-44,25 lbf-ft)

Angular torque 90-100°

For tightening and retightening of cylinder head bolts see following page

Lock nut for valve adjusting screw 40 Nm (29,50 lbf-ft)

Cheese-head screws with hexagonal socket for bolts of interme-

diate gear

1 15 Nm (84,82 lbf-ft)

Collar screw for crankshaft 65 Nm (47,94 lbf-ft)

Rocker socket (T orx E12) 65 Nm (47,94lbf-ft)

Oil pressure valve for piston spray nozzle 38-42 Nm (28,03-30,98 lbf-ft)

Oil pump drive gear on shaft 30 Nm (22,13 lbf-ft)

Screw plug for pressure relief valve in crankcase 60Nm (44,25 lbf-ft)

Oil pan drain plug 60Nm (44,25 lbf-ft)

Screw plug for oil filter head (M 10*1) 20 Nm (14,75 lbf-ft)

Threaded coupling for oil filter 40 Nm (29,50 lbf-ft)

Screw plug in oil filter (M 18*1,5) 30 Nm (22,13 lbf-ft)

Screw plug in oil filter (M 24*1,5) 30 Nm (22,13 lbf-ft)

Screw plug in oil filter (M 30*1,5) 40 Nm (29,50 lbf-ft)

OIl change filter 25 Nm (18,44 lbf-ft)

Page 25

Fav 900

Engine / Generalities

Tightening Torque values

A

General

Fav 900 from chassis number 23/3001and up

13/03/2001

2000 000007

A

a

2/4

Capitel Docu-No.

Index

Date Version

Page

Tightening Torque values

Cooling system

Exhaust / Intake manifolds

Fuel system

Starter / Alternator /Compressor

Sensors

Screw plug in coolant pipe (M14*1,5) 20 Nm (14,75 lbf-ft)

Hose clips :

Clamping range 12 to 31 mm, 9 mm wide 3,6 Nm (2,66 lbf-ft)

over 32 mm, 13 mm wide 5 Nm (3,69 lbf-ft)

Exhaust manifold on cylinder head

Initial torque 50-55 Nm (36,88-40,75 lbf-ft)

Angular torque 90-100°

Banjo bolt of solenoid valve 10-15 Nm (7,38-1 1,06 lbf-ft)

Knuckle pin clap of turbocharger 12 Nm (8,85 lbf-ft)

Nozzle holder in cylinder head 70 Nm (51,63 lbf-ft)

Nozzle adjusting nut 45 Nm (33,19 lbf-ft)

Banjo bolt for leak oil 10-12 Nm (7,38-8,86 lbf-ft)

Pressure line at nozzle

Initial torque 10 Nm (7,38 lbf-ft)

Angular torque 60°

Banjo bolt on oil filter 20-30 Nm (14,75-22,13 lbf-ft)

Fuel filter 10-15 Nm (7,38-1 1,06 lbf-ft)

Purge plug on fuel filter 8-10 Nm (5,90-7,38 lbf-ft)

Alternator pulley 75-85 Nm (55,32-62,69 lbf-ft)

Compressor drive gear 200-250 Nm (147,51-184,39 lbf-ft)

Oil pressure sensor 80 Nm (59,00 lbf-ft)

T emperature sensor switch 15 Nm (11,06 lbf-ft)

Coolant T emperature sensor (EDC) 35 Nm (25,82 lbf-ft)

Page 26

Fav 900

Engine / Generalities

Tightening Torque values

A

General

Fav 900 from chassis number 23/3001and up

13/03/2001

2000 000007

A

a

3/4

Capitel Docu-No.

Index

Date Version

Page

Tightening Torque values

Assembly tightening torques to works standard M 3059

External or internal hexagon nuts and bolts, heads without collar or flange.

Tread size * Pitch Property class / Tightening torque in Nm (lbf-ft)

at 8,8/8 at 10,9/10 at 12,9/12

M4 2,5 (1,84) 4,0 (2,95) 4,5 (3,32)

M5 5,0 (3,69) 7,5 (5,53) 9,0 (6,64)

M6 9,0 (6,64) 13,0 (9,59) 15,0 (1 1,06)

M7 14,0 (10,33) 20,0 (14,75) 25,0 (18,44)

M8 22,0 (16,23) 30,0 (22,13) 35,0 (25,81)

M8*1 23,0 (16,96) 35,0 (25,81) 40,0 (29,50)

M10 45,0 (33,19) 65,0 (47,94) 75,0 (55,32)

M10*1,25 45,0 (33,19) 65,0 (47,94) 75,0 (55,32)

M10*1 50,0 (36,88) 70,0 (51,63) 85,0 (62,62)

M12 75,0 (55,32) 105,0 (77,44) 125,0 (92,20)

M12*1,5 75,0 (55,32) 1 10,0 (81,13) 130,0 (95,88)

M12*1,25 80,0 (59,00) 1 15,0 (84,20) 135,0 (99,57)

M14 1 15,0 (84,20) 170,0 (125,39) 200,0 (147,51)

M14*1,5 125,0 (92,20) 185,0 (136,45) 215,0 (158,58)

M16 180,0 (132,76) 260,0 (191,77) 310,0 (228,64)

M16*1,5 190,0 (140,14) 280,0 (206,52) 330,0 (243,40)

M18 260,0 (191,77) 370,0 (272,90) 430,0 (317,15)

M18*2 270,0 (199,14) 290,0 (213,89) 450,0 (331,90)

M18*1,5 290,0 (213,89) 410,0 (302,40) 480,0 (354,03)

M20 360,0 (265,52) 520,0 (383,53) 600,0 (442,54)

M20*2 380,0 (280,27) 540,0 (398,28) 630,0 (464,66)

M20*1,5 400,0 (295,02) 570,0 (420,41) 670,0 (494,17)

M22 490,0 (361,40) 700,0 (516,29) 820,0 (604,80)

M22*2 510,0 (376,16) 730,0 (538,42) 860,0 (634,30)

M22*1,5 540,0 (398,28) 770,0 (567,92) 900,0 (663,80)

M24 620,0 (457,29) 890,0 (656,43) 1040,0 (767,06)

M24*2 680,0 (501,54) 960,0 (708,06) 1130,0 (833,44)

M24*1,5 740,0 (545,8) 1030,0 (759,69) 1220,0 (899,82)

Page 27

Fav 900

Engine / Generalities

Tightening Torque values

A

General

Fav 900 from chassis number 23/3001and up

13/03/2001

2000 000007

A

a

4/4

Capitel Docu-No.

Index

Date Version

Page

Tightening Torque values

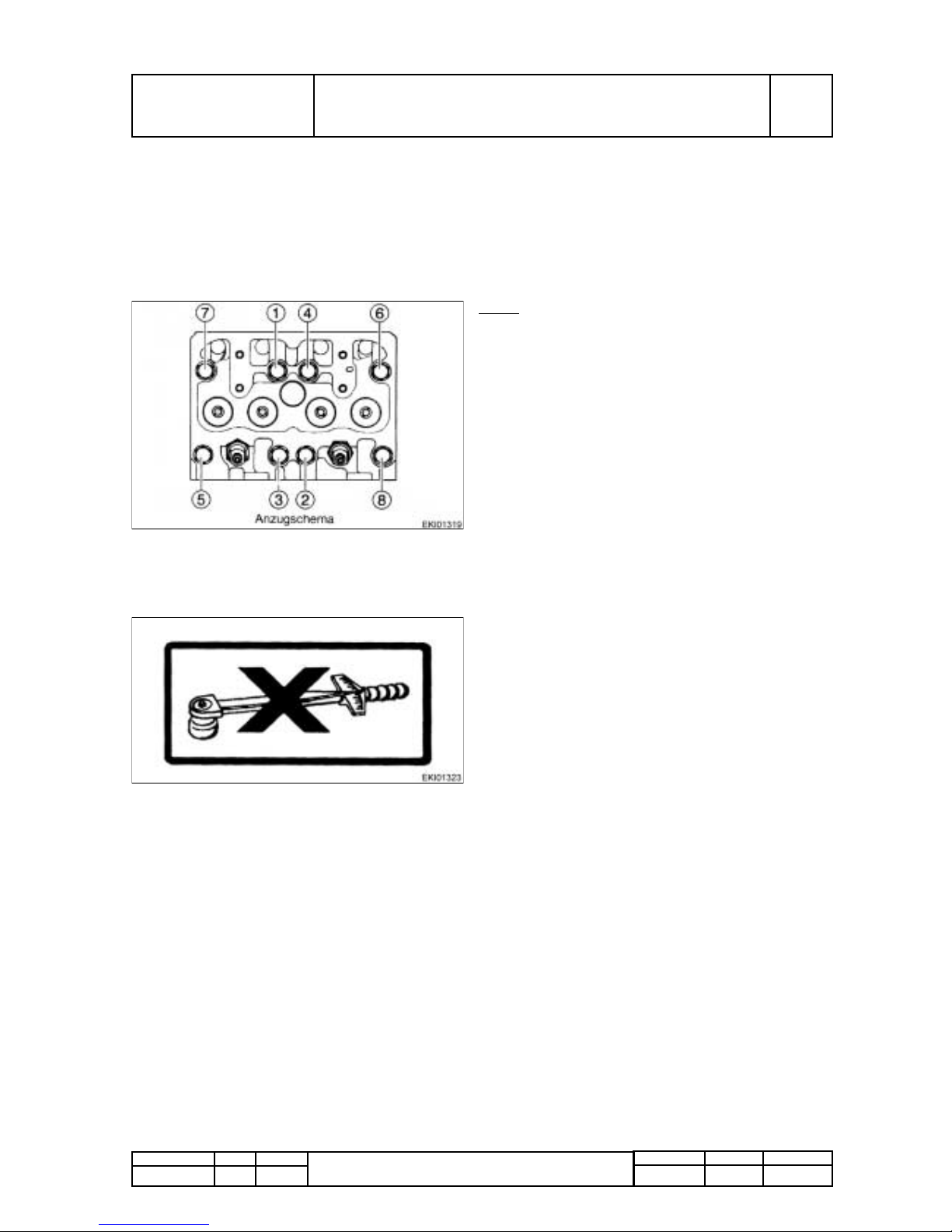

Cylinder head bolts

Tightening cylinder head bolts following repair work (new engine)

Only for Torx-head screws.

No tightening for Torx-head screws.

Tightening cylinder head bolts following repair work

(cold engine)

Only for Torx-head screws.

PM-Picturemodule

PM-Picturemodule

Text-module

Tightening cylinder head bolts following repair work

Only for Torx-heads.

No tightening for Torx-head screws.

PMTAB_Picture

Note:

Only use new cylinder head bolts. do not re use.

before inserting bolts, lubricate threads (not the

tapped bores) and the bolt heads with "Optimoly

White T" paste. Do not use oils or additives

containing MoS

2

-h. Tighten bolts by the torque

angle method following the diagram :

● 1.st initial stage = 10 Nm (7,38 lbf-ft).

● 2.nd initial stage = 80 Nm (59,00 lbf-ft).

● 3.rd initial stage = 150 Nm (110,63 lbf-ft).

● 4.tth initial stage = 90°.

● 5.th initial stage = 90°.

● Final stage = 90°.

Adjust valve play

PMTAB_Picture

Put on sticker number 51.97801-0150.

Page 28

Fav 900

Engine / General system

Turbocharger, troubleshooting

B

Faults

Fav 900 chassis number 23/3001 and up

15.2.2001

2000 000003

B

a

1/2

Capitel Docu-No.

Index

Date Version

Page

Turbocharger, troubleshooting

Text-module

Before replacing the turbocharger, check the following:

Excessive engine oil consumption, lack of power and abnormal intake or exhaust noises are a frequent

cause of unnecessary turbocharger replacement.

Examination of the allegedly defective parts by the manufacturer often shows the turbocharger to be in

perfectly good working order.

To avoid this situation, the following checks must be performed :

Text-module

Excessive oil consumption

Bullet-List

● Check air filter contamination

● Check intake pipe for restricted cross section (e.g. damage, dirt)

Either are possible causes for increased oil consumption due to the higher pressure.

Bullet-ist

● Check turbocharger for external traces of oil

Excessive oil consumption of the turbocharger is due to bearing wear, quickly resulting in mechanical

damage.

Text-module

Lack of power

For satisfactory power, observe correct settings for:

Bullet-

● start of fuel delivery

● valves clearance

● engine control (at full load)

● exhaust brake (must open fully).

Bullet-List

Also check:

● Cylinder compression

● air filter contamination

● intake system for restricted cross sections and leaks

● exhaust system for damage and leaks.

If none of these checks reveal the cause of poor performance, the turbocharger has to be also checked

for:

Bullet-List

● Coking of turbine impedes easy rotation. (Axial movement may realese coking.)

● Dirt within compressor

● Damage by foreign objects

● Turbine wheel in contact with housing

Remove visible contamination of compresssor side and check bearing clearance.

Text-module

Note:

Do not damage the compressor fan wheel.

Bullet-List

Abnormal intake and exhaust noises

● Check intake and exhaust system adjacent to the turbocharger assembly. Damaged gaskets must

be replaced (can mislead to failure diagnostic of turbocharger).

● If this does not eliminate the abnormal noises, the turbocharger is to be replaced. (A turbocharger in

good condition does not generate noise!)

Text-module

Page 29

Fav 900

Engine / General system

Turbocharger, troubleshooting

B

Faults

Fav 900 chassis number 23/3001 and up

15.2.2001

2000 000003

B

a

2/2

Capitel Docu-No.

Index

Date Version

Page

Turbocharger, troubleshooting

Oil in intake pipes and intercooler

Oilspray within the intake system is necessary. It lubricates inlet valve seats.

If too much oil is encountered to such an extent that puddles can be found within the air box of the

intercooler, there is a serious risk of engine "runaway", an uncontrolled increase of engine speed .

Leaks must immediately be removed.

Possible origins:

Bullet-List

● Engine oil level too high - Check whether proper dipstick is used -

● Inadequate engine oil, check "Lubricants " schedule.

● Operation on not allowed high slanting angles

● High pressure within crankcase, e. g. Oil release valve failure (Crank case venting) or worn piston

rings

Text-module

Turbocharger compressor coking

Can occur by excessive intake air temperature, e.g. during constant full load opreation.

Coking may result in reduced intake air pressure, there will not be a noticeable power reduction or a

diminished acceleration behavior. Coking may result in exhaust turbitidy.

If Turbocharger compressor coking occurs:

Bullet-List

● Disassemble compressor housing. Avoid compressor fan wheel damage which could result in

balancing problems and strong vibrations until complete destruction of the turbocharger.

● Use a solvent to remove coking from the compressor housing

Bullet-List

● In severe cases, use special oil with low coking risk.

Warning:

Never inject solvent spray while the engine is running - Accident Hazard !!! -

Page 30

Fav 900

Engine / Generalities

View of engine D 0836 LE 501

D

Component Location

Fav 900 chassis number 23/3001and up

09/03/2001

2000 000003

D

a

1/1

Capitel Docu-No.

Index

Date Version

Page

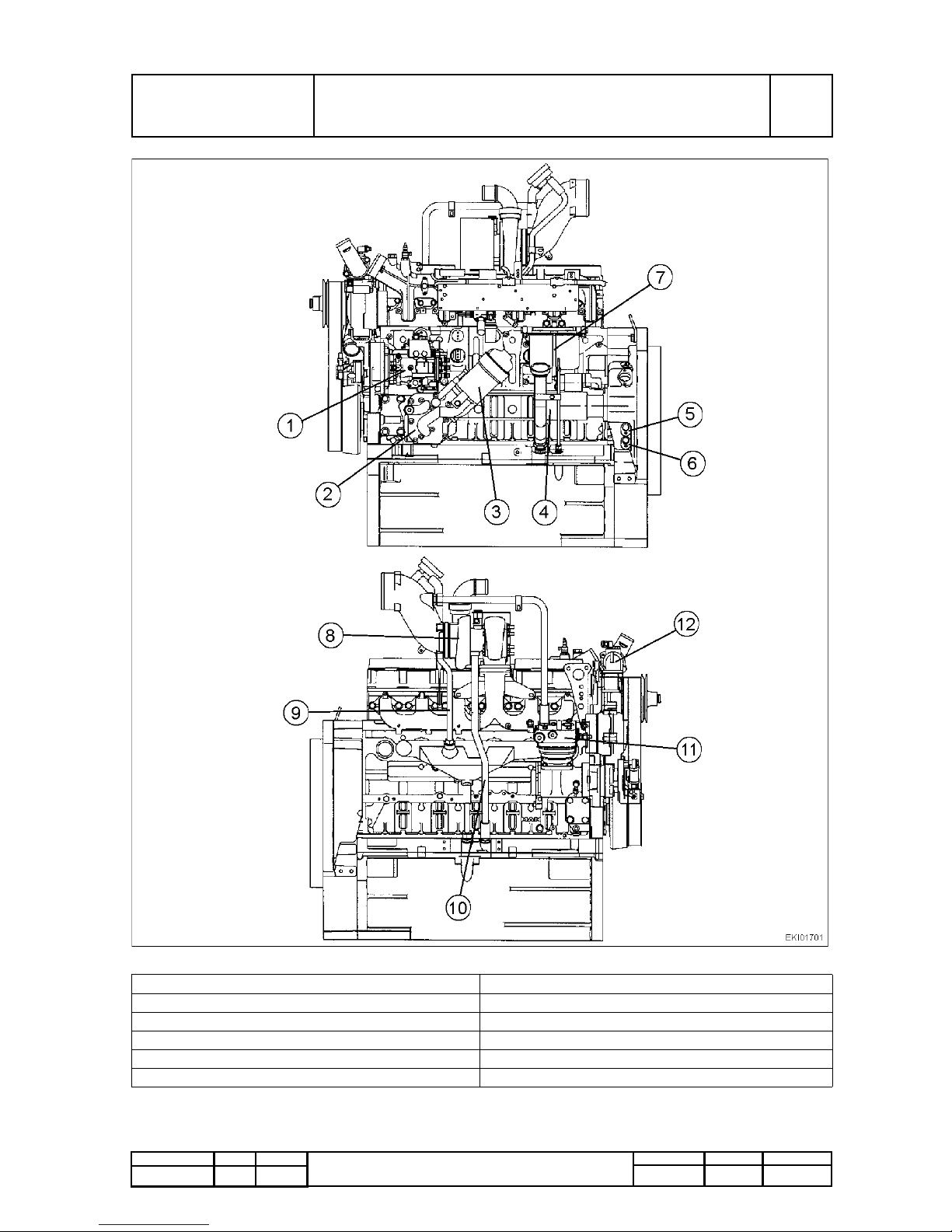

View of engine D 0836 LE 501

PM-Picturemodule

Text-module

PMTAB_Picture

1 Fuel injection pump (VP44) 7 Fuel filters

2 Lubricant cooler 8 Turbocharger

3 Lubricant filter 9 Lubrication oil turbocharger (pressure)

4 Oil filling socket, Oil level indicator 10 Lubrication oil return from turbocharger

5 B10 - Sensor , Engine 1 11 Air compressor

6 B1 1 - Sensor , Engine 2 12 Thermostat

Page 31

Fav 900

Engine / Cylinder head

Checking compression

E

Testing

Fav 900 chassis number 23/3001and up

20.2.2001

2010 000001

E

a

1/1

Capitel Docu-No.

Index

Date Version

Page

Checking compression

PM-Picturemodule

PM-Picturemodule

PM-Picturemodule

PM-Picturemodule

PMTAB_Picture

● Warm up engine until coolant temperature

reaches 60 to 80°C (140 - 176°F).

● Check valves clearance and adjust.

● Remove all injectors and injector holders.

● See values of compression in chapter "Service

Data".

Starting with the 1st cylinder, fit new seal and

tighten. Install test adaptor of compression

recorder with threaded union and tighten.

PMTAB_Picture

Screw compression recorder onto test adaptor

and insert test sheet.

Using the starter motor, turn engine until the

indicator no longer deflects.

Connect compression recorder with test adapter

to the other cylinders and proceed as above.

PMTAB_Picture

Depending on the design of the compression

recorder, the engine can also be cranked directly

from the compression recorder.

To do this, the starter has to be connected to the

appropriate electrical leads.

PMTAB_Picture

Compare data and remove compression recorder

and test adapter. Apply "Never Seeze" to contact

faces of injector holders.

Fit injector holder and injectors using a new seal.

Screw on union nut and tighten to specified

torque.

Re-connect injection and leak-oil lines.

Note:

The union nut can be tightened with an open

end wrench without removing the injection

pipe.

Page 32

Fav 900

Engine / Cylinder head

Checking valve timing

F

Setting and Calibration

Fav 900 chassis number 23/3001and up

20.2.2001

2010 000002

F

a

1/1

Capitel Docu-No.

Index

Date Version

Page

Checking valve timing

Text-module

Checking valve timing

Shifting of the camshaft drive gear can result in severe engine damage.

It is therefore necessary to ensure a correct fit by checking the valve timing after repair.

The above takes into consideration that tappet push rods are not distorted!

Proceed as follows:

Bullet-List

● Fit engine actuation device to flywheel housing.

● Remove crankcase venting pipe.

● Accurately set valve play of 1st cylinder.

● Actuate engine against rotating direction to approx. 40°C before TDP.

● Set dial gauge onto intake valve spring retainer of 1st cylinder and set at "0".

● Slowly turn crankshaft in rotating direction and watch the pointer:

● Immediatey when the pointer moves, the intake valve opens.

● Take reading from graded scale on flywheel and compare with valve timing.

Note:

By fitting a dial gauge to both intake and exhaust valve spring retainers of the 1st cylinder, it is

possible to check all valve timings and the valve stroke by continued turning of the engine. V alve

stroke desired value: 5,0 to 5,7 mm (.197 - .224").

Page 33

Fav 900

Engine / Cylinder head

Setting valve clearance

F

Setting and Calibration

Fav 900 chassis number 23/3001 and up

15.2.2001

2010 000003

F

a

1/2

Capitel Docu-No.

Index

Date Version

Page

Setting valve clearance

PM-Picturemodule

PM-Picturemodule

Text-module

Setting valves clearance:

Valves overlap on cylinder:

PM-Picturemodule

PMTAB_Picture

Engine must be cold for adjusting valve clearance.

(max. coolant temperature 50° C (122°F))

Setting valve clearance.

PMTAB_Picture

Rotate crankshaft using turning device until the

piston of the cylinder to be set is at top dead

centre ( TDC ) and the rocker arms are not loaded.

The valves of the synchronous cylinder are now

overlapping.

153624

624153

PMTAB_Picture

Layout of cylinder sequence and position of valves

I Fan end

II Flywheel end

A Exhaust valve

E Intake valve

Page 34

Fav 900

Engine / Cylinder head

Setting valve clearance

F

Setting and Calibration

Fav 900 chassis number 23/3001 and up

15.2.2001

2010 000003

F

a

2/2

Capitel Docu-No.

Index

Date Version

Page

Setting valve clearance

PM-Picturemodule

PMTAB_Picture

● Insert gauge between valve shaft and rocker .

● With valve setting tool loosen lock nut and turn

setting screw until gauge can be moved with a

slight resistance.

● Tighten lock nut.

● Check clerance again.

● Refit cylinder head covers.

● Tighten screws and bolts to adequate torque.

Page 35

Fav 900

Engine / Cylinder head

Reassembling and refitting intake pipe

G

Repair

Fav 900 chassis number 23/3001 and up

15.2.2001

2010 000002

G

a

1/1

Capitel Docu-No.

Index

Date Version

Page

Reassembling and refitting intake pipe

PM-Picturemodule

PM-Picturemodule

PM-Picturemodule

PMTAB_Picture

Removing intake pipe

Note:

T o avoid engine damage, always ensure clean

conditions when working on intake system.

● Disconnect pressure sensor for intercooler

● Disconnect wiring to flame booster plug, to

solenoid switch ant to the temperature sensors.

● Remove fuel lines to flame booster plug and to

solenoid valve.

● Remove wiring harness.

● Remove fuel filter.

● Remove fuel pre filter with manual lifting pump

● Remove collars of the injection lines and of the

fuel lines wich are fitted onto the intake

manifold.

PMTAB_Picture

Loose and remove intake pipe fixing bolts on the

cylinder head.

Detach intake pipe, remove traces of gasket

residue from sealing faces of intake pipe and

cylinder head.

Note:

Do not allow dirt particles to enter the inlet

ports.

PMTAB_Picture

Refitting intake pipe

Position intake pipe using new gaskets.

Insert fixing bolts.

Watch proper positionning of the gasket.

Tighten to specified torque.

replace all parts wich have been removed before

Purge fuel system.

Page 36

Fav 900

Engine / Cylinder head

Removing and refitting turbocharger

G

Repair

Fav 900 chassis number 23/3001 and up

15.02.2001

2010 000004

G

a

1/2

Capitel Docu-No.

Index

Date Version

Page

Removing and refitting turbocharger

PM-Picturemodule

PM-Picturemodule

PM-Picturemodule

PM-Picturemodule

PMTAB_Picture

Removing turbocharger

Remove crankcase venting (pressure control

valve).

Remove air intake pipe from compressor to intake

manifold.

Remove air intake manifold.

PMTAB_Picture

Remove oil return line and feed line.

PMTAB_Picture

Remove heat protection panel

PMTAB_Picture

Unscrew the turbocharger.

Remove turbocharger.

Note:

Shut all inlet and outlet ports in order to

prevent particle contamination.

Page 37

Fav 900

Engine / Cylinder head

Removing and refitting turbocharger

G

Repair

Fav 900 chassis number 23/3001 and up

15.02.2001

2010 000004

G

a

2/2

Capitel Docu-No.

Index

Date Version

Page

Removing and refitting turbocharger

PM-Picturemodule

PM-Picturemodule

PMTAB_Picture

Refitting the turbocharger

Check intake pipe and exhaust manifold for

eventual foreign objects.

Examine oil feed and return lines for eventual

damage, jamming and leaks.

Replace all gaskets.

Refitting the turbocharger occurs in the inversed

sequence as the removing

For refitting use new gaskets and new locking

nuts.

Before connecting oil feed line, fill bearing case

with clean engine oil.

Check all connection fot tightness and absence of

mecanical stress.

PMTAB_Picture

Note:

The clamped section of the hose must always

be behind the collar of the hose.

1. Pipe

2. Gap

3. Hose

4. Collar

5. Hose clip

Note:

Use only clean water as a lubricant.

Page 38

Fav 900

Engine / Cylinder head

Removing and refitting exhaust manifold

G

Repair

Fav 900 Chassis number 23/3001 and up

15.02.2001

2010 000003

G

a

1/1

Capitel Docu-No.

Index

Date Version

Page

Removing and refitting exhaust manifold

PM-Picturemodule

PM-Picturemodule

PM-Picturemodule

PM-Picturemodule

PMTAB_Picture

Removing the exhaust manifold

Remove turbocharger.

Note:

Protect exhaust port on turbocharger from

contamination.

Unscrew and remove nuts from exhaust manifold.

PMTAB_Picture

Guidance pins (visible on photograph) may be

used.

Remove manifold.

PMTAB_Picture

Refitting the exhaust manifold

Clean sealing faces of both, cylinder head and

manifold.

Bumped side (1) of gasket facing the cylinderhead

(2), depression facing the manifold (3).

PMTAB_Picture

Insert screws and tighten to adequate torque.

Refit the turbocharger.

Page 39

Fav 900

Engine / Cylinder head

Removing and refitting cylinder head

G

Repair

Fav 900 chassis number 23/3001 and up

16.02.2001

2010 000006

G

a

1/4

Capitel Docu-No.

Index

Date Version

Page

Removing and refitting cylinder head

PM-Picturemodule

PM-Picturemodule

PM-Picturemodule

PM-Picturemodule

PMTAB_Picture

Removing the rocker

Remove cylinder head cover.

PMTAB_Picture

Loosen clamping bolts and remove rocker arm.

Dismantling, overhauling and reassembling rocker

assembly.

Removing the cylinder head

● Drain coolant,

● remove lines from injection nozzles,

● Remove intake pipe,

● Remove exhaust manifold,

● Remove coolant pipe.

PMTAB_Picture

Remove push rods.

PMTAB_Picture

Loosen cylinder head bolts in reverse sequence of

tightening (for tightening torque values refer to

chap 2000 Reg A).

Note:

Cylinder head bolts must not be re-used.

Remove cylinder head and lay down in such way

to prevent damage.

Remove cylinder head gasket.

Page 40

Fav 900

Engine / Cylinder head

Removing and refitting cylinder head

G

Repair

Fav 900 chassis number 23/3001 and up

16.02.2001

2010 000006

G

a

2/4

Capitel Docu-No.

Index

Date Version

Page

Removing and refitting cylinder head

PM-Picturemodule

PM-Picturemodule

PM-Picturemodule

PMTAB_Picture

Before refitting the cylinder head :

● Clean all the parts which have been removed.

● Clean sealing faces of cylinder head and

crankcase, and blow out tapped holes in

crankcase.

● In the event of repeated leaking, use the

straight edge to chek the sealing faces of

cranskcase and cylinder head for distortion.

● Uneven cylinder heads can be surface ground

by up to 1 mm.

● Remachined sealing surfaces are measured in

relation to the bore centre of the cranskshaft

bearing.

Note:

Sealing surface of the cylinder head and

crankcase may only be cleaned manually by

scraper and slight sandpaper on a polishing

block.

PMTAB_Picture

Insert two 6h 8x10 DIN 7 straight pins per head

into the leading surface of the crankshaft housing

to locate the cylinder heads

PMTAB_Picture

If these straight pins need replacing, observe the

max. projection of 4,5mm.

Page 41

Fav 900

Engine / Cylinder head

Removing and refitting cylinder head

G

Repair

Fav 900 chassis number 23/3001 and up

16.02.2001

2010 000006

G

a

3/4

Capitel Docu-No.

Index

Date Version

Page

Removing and refitting cylinder head

PM-Picturemodule

PM-Picturemodule

PM-Picturemodule

PM-Picturemodule

PMTAB_Picture

Refitting the cylinder head

Note:

Cylinder head gasket must always be replaced.

Install a dry new gasket carefully positioned

according to the hole pattern . Fit cylinder head.

PMTAB_Picture

Note:

To prevent distortion between cylinder heads

and manifolds, we recommend the following

steps :

● Refit cylinder heads using guidance bolts.

● Oil the new cylinder head bolts and their rest

surface with "Optimoly Withe T" paste.

● Hand tighten new cylinder head bolts.

● Mount rectified ruler (Special tool) onto the

exhaust side. Tighten screws at 20 Nm. If no

ruler is available, fit exhaust pipe and tighten at

20 Nm.

PMTAB_Picture

● Tighten progressively cylinder head bolts in the

indicated sequence at the prescribed torque.

● Remove the rectified ruler.

PMTAB_Picture

Refitting the rocker assembly

Check push rods for distortion and wear in the ball

sockets.

When inserting the push rods ensure correct fit in

the socket of the valve tappets.

Fit rocker arm bracket.

Page 42

Fav 900

Engine / Cylinder head

Removing and refitting cylinder head

G

Repair

Fav 900 chassis number 23/3001 and up

16.02.2001

2010 000006

G

a

4/4

Capitel Docu-No.

Index

Date Version

Page

Removing and refitting cylinder head

PM-Picturemodule

PM-Picturemodule

PM-Picturemodule

PMTAB_Picture

Tighten bolts slightly and align rocker arms with

valves.

Subsequently tighten bolts to specified torque.

PMTAB_Picture

● Set valve clearance, chap 2010 Reg F

● Refit coolant pipe,

● Refit exhaust manifold,

● Refit intake pipe,

● Refit the injectors lines.

PMTAB_Picture

Refit cylinder head cover with a dry new gasket.

Insert screws and tighten.

Fill up with coolant.

Tighten cylinder head bolts once more.

Page 43

Fav 900

Engine / Cylinder head

Dismantling and reassembling the rocker arm assembly

G

Repair

Fav 900 chassis number 23/3001 and up

19.02.2001

2010 000007

G

a

1/2

Capitel Docu-No.

Index

Date Version

Page

Dismantling and reassembling the rocker arm assembly

PM-Picturemodule

PM-Picturemodule

PM-Picturemodule

PM-Picturemodule

PMTAB_Picture

Dismantling the rocker arm assembly

Remove rocker arm assembly

Clamp rocker bearing bracket in a vise (use

non-metallic jaws).

PMTAB_Picture

Remove circlip.

PMTAB_Picture

Remove parts separately from the rocker shaft.

1 Central spring

2 Stop washer

3 Rocker arm

4 Rocker bearing bracket

5 Circlip

6 Outside spring

7 Rocker shaft

PMTAB_Picture

Note:

If the rocker bearing bushes need replacing,

use new or reconditioned ready-to-install

rocker arms.

Page 44

Fav 900

Engine / Cylinder head

Dismantling and reassembling the rocker arm assembly

G

Repair

Fav 900 chassis number 23/3001 and up

19.02.2001

2010 000007

G

a

2/2

Capitel Docu-No.

Index

Date Version

Page

Dismantling and reassembling the rocker arm assembly

PM-Picturemodule

PM-Picturemodule

PMTAB_Picture

Reassembling the rocker arm assembly

Coat rocker bushes with "Optimol White T"paste.

Refit circlip on the rocker shaft.

Coat rockershaft and bearing bracket bore with

"Optimol White T" paste.

Slide stop washer, outer spring, stop washer,

rocker arm (end flush with bushing facing the

bearing bracket) and bearing bracket into the

rocker shaft.

When clamping the assembled rocker shaft into

the bearing bracket, ensure that the shaft end is

supported. (Use non-metallic jaws).

PMTAB_Picture

Fit parts in the sequence shown, compressing

springs, and insert circlip.

Refit rocker arm assembly , see chapter 2010 Reg

G - Cylinder head removing and refitting.

Page 45

Fav 900

Engine / Cylinder head

Removing and refitting valves

G

Repair

Fav 900 chassis number 23/3001 and up

19.02.2001

2010 000008

G

a

1/3

Capitel Docu-No.

Index

Date Version

Page

Removing and refitting valves

PM-Picturemodule

PM-Picturemodule

PM-Picturemodule

PMTAB_Picture

Removing valves

Remove rocker arm assembly and cylinder head

(Chapter 2010 Reg G).

Note:

Valve springs and spring plates can be

replaced without removing the cylinder head.

This requires the appropriate piston to be at

TDC.

The use of a valve fitting tool is necessary.

● Place fitting lever to cylinder head.

● Turn screw (1) until the lever (2) is slightly

raised.

PMTAB_Picture

Note:

If a valve bench is available, this can be used

for the above operations.

● Push valve fitting lever down and remove valve

collets.

● Lift lever and swing to one side Caution:

Beware of spring tension. Danger of injury !

● Remove upper spring plate (2), valve spring (3)

and washer (4).

● Turn cylinder head over and extract intake (5)

exhaust (6) valve.

● Check valves for damage and replace weak

springs.

● Measure valve spring and replace weak

springs.

● Check valve stem and guides for scoring and

wear; if necessary , measure guides with a plug

gauge.

● Check valve seats for severe wear and signs of

burning, if necessary reseat valves or replace

the insert.

● Remachine valve seat (following grinding

machine manufaturer's instructions), or

replace.

PMTAB_Picture

Refitting valves

Lubricate valve stems and insert into valve guides.

Note:

Minor valve seating damage can be removed

by reseating using a valve grinding paste.

When fitting new valves these must be

reseated so that uniform seating is attained, if

necessary machine the valve seat insert.

Page 46

Fav 900

Engine / Cylinder head

Removing and refitting valves

G

Repair

Fav 900 chassis number 23/3001 and up

19.02.2001

2010 000008

G

a

2/3

Capitel Docu-No.

Index

Date Version

Page

Removing and refitting valves

PM-Picturemodule

PM-Picturemodule

PM-Picturemodule

PM-Picturemodule

PMTAB_Picture

Turn cylinder head over.

Place valve fitting lever.

Fit washer, valve spring and upper spring plate.

PMTAB_Picture

Compress spring with fitting lever and insert

collets.

Note:

Make sure collets fit properly: they can cause

severe damage by springing out.

PMTAB_Picture

Measuring valve recess

● Position gauge holder with dial gauge at the

cylinder head.

● Press tip of gauge onto cylinder head.

● Set dial gauge at "0".

● Swing gauge towards valve head and read

recess.

PMTAB_Picture

If after skimming the cylinder head faces, valve

recess is inadequte or valve projection is

excessive, the valve seat insert must be

re-ground.

1 Valve recess

Note:

- When skimming the cylinder head sealing

face, the max. dimension must not exceed 1

mm (0.039“).

- After skimming, observe injection nozzle

projection. Replace standard - copper sealing

ring with a thicker one.

Page 47

Fav 900

Engine / Cylinder head

Removing and refitting valves

G

Repair

Fav 900 chassis number 23/3001 and up

19.02.2001

2010 000008

G

a

3/3

Capitel Docu-No.

Index

Date Version

Page

Removing and refitting valves

PM-Picturemodule

PMTAB_Picture

1= Copper - Sealing ring

2 = Injection nozzle projection (2,68 - 3,47mm).

Available sealing ring thicknesses : 0,5 / 1,0 / 1,5 /

2,0 / 2,5 / 3,0 mm (.020 / .039 / .059 / .079 / .098 /

.118")

Page 48

Fav 900

Engine / Cylinder head

Removing and refitting valve guides.

G

Repair

Fav 900 chassis number 23/3001 and up

19.02.2001

2010 000009

G

a

1/1

Capitel Docu-No.

Index

Date Version

Page

Removing and refitting valve guides.

PM-Picturemodule

PM-Picturemodule

PM-Picturemodule

PMTAB_Picture

Removing the valve guide

Removing and refitting the cylinder head.

Removing and refitting the valves.

Position cylinder head on a press with the

combustion chamber side facing upwards. Use a

mandrel to press out the valve guide.

PMTAB_Picture

Refitting the valve guide

Lubricate new valve guides and using a mandrel

and spacer sleeve, press in form the rocker arm

side.

PMTAB_Picture

Valve guides differ in length only.

1 Exhaust = shorter guide

2 Intake = longer guide

3 Press-in depth (see Servicing Data)

Press-in depth is governed by the spacer sleeve.

Note:

After replacing the valve guides it is necessary

to re-grind the valve seats ( see Servicing Data

and instructions by the manufacturer of the

valve lathe used in your workshop).

Page 49

Fav 900

Engine / Cylinder head

Replacing valve seat insert

G

Repair

Fav 900 chassis number 23/3001and up

19.02.2001

2010 000010

G

a

1/2

Capitel Docu-No.

Index

Date Version

Page

Replacing valve seat insert

Text-module

Remove valve seat insert

Note:

When replacing valve seat inserts, it is advisable to replace valve guides, since this is the only

way to guarantee precise reseating of the new inserts.

A tool was therefore designed with which valve guidance and valve seat inserts can only be

replaced together, or alternately the valve guides alone.

PM-Picturemodule

PM-Picturemodule

PM-Picturemodule

PMTAB_Picture

Using a valve lathe machine a 3 - 4 mm

(.118-.157") wide groove in the valve valve seat

inserts.

Insert internal extractor claw in the machined

groove and tighten.

PMTAB_Picture

Note:

To prevent damage to the cylinder head face,

insert a washer (1) or other suitable object

underneath the feet (4) of the support legs.

Screw spindle (2) into extractor (5), align support

legs (4) and extract valve seat insert by turning the

nut (3).

Clean contact surface of insert in the cylinder

head.

PMTAB_Picture

If a valve lathe is not available, proceed as follows:

● Using an arc-welder, apply two welding beads

to the valve seat (arrowed).

● Extract valve seat insert.

● Clean insert contact surface in the cylinder

head.

Page 50

Fav 900

Engine / Cylinder head

Replacing valve seat insert

G

Repair

Fav 900 chassis number 23/3001and up

19.02.2001

2010 000010

G

a

2/2

Capitel Docu-No.

Index

Date Version

Page

Replacing valve seat insert

PM-Picturemodule

Text-module

Note:

After cooling down: re-machine valve seats.

After re-machining: clean cylinder head and check for leaks with a cylinder detector.

Overheating of the cylinder head (above +200°C / 392°F ) causes the core plugs to become loose,

and they must be replaced.

To do this, clean core holes, blow out ducts and press in new core plugs using a mandrel and

"LOCTITE 270".

PMTAB_Picture

Replacing valve seat insert

Immerse cylinder head in a hot water bath and

heat up to approx. 80°C (176°F).

Supercool new insert to approx -200°C (-328°F)

and insert into the cylinder head.

When the temperature has equalized, check by

pressing in a mandrel to the end position.

Refit valve guides.

Note:

When replacing the valve seat inserts, it is

necessary to re-machine valve seats.

Page 51

Fav 900

Engine / Cylinder head

Re-machining the valve seats

G

Repair

Fav 900 chassis number 23/3001and up

19.02.2001

2010 000011

G

a

1/3

Capitel Docu-No.

Index

Date Version

Page

Re-machining the valve seats

PM-Picturemodule

PM-Picturemodule

PM-Picturemodule

PMTAB_Picture

Re-machining the valve seat

(with Mira-Precision tvalve seat re-machining tool)

1. Crank

2. Rocker switch

3. Hand grip

4. Lubricating nipple

5. Mains supply

6. Solenoid valve with coil

7. Guide tube

8. Swivel arm

9. Guide mandrel

10.Cutter

11.Allen screw

12.Chuck

13.Lubricating nipple

14.Clamping lever

15.Guide ball

16.Thrust nut with mm-dial

PMTAB_Picture

Select suitable guide mandrel, insert with

open-end wrench (SW 12) and tighten.

Note:

For maximum precision, the guide mandrel

must have a perfect fit.

Select cutting with appropriate valve face with a

seat angle and insert.

PMTAB_Picture

Adjust cutter with setting gauge and secure with

Allen screw.

Using a guide mandrel insert tool into valve guide.

Page 52

Fav 900

Engine / Cylinder head

Re-machining the valve seats

G

Repair

Fav 900 chassis number 23/3001and up

19.02.2001

2010 000011

G

a

2/3

Capitel Docu-No.

Index

Date Version

Page