Page 1

OPERATING MANUAL

FENDT

916 Vario

920 Vario

924 Vario

926 Vario

930 Vario

930.000.000.014 Englisch

Page 2

Vehicle type .............................

Chassis No. ............................. After-Sales Service

Vehicle delivery

Vehicle pre-delivery inspection by the Service Workshop

For information, technical date etc. refer to Service Schedule.

Check oil level, top up if necessary.

Engine, transmission, axle drives, front axle differential, hub drives, front PTO, lift shaft

lubrication. Fill the hydraulic system with additional oil for external consumers as per

customer order.

Check fluid level, and top up if necessary.

Cooling system, clutch operation, brake actuation, air conditioning if installed.

Grease vehicle as per Lubrication Chart, lubricate all joints.

Check steering and toe-in. Check tyre pressures. Check that wheel nuts are firmly

attached.

Test electrical system. Check fault memory. Check battery charge status. Check the

function and settings of the lighting and signalling system.

Fill up with diesel, use pre-filter if necessary.

Check that brakes are working effectively.

Information to be given on vehicle delivery

Draw attention to safety instructions within the Operating Manual and on the vehicle

itself.

Information on keeping to countryu-specific regulations regarding vehicle speed and

trailer braking systems.

Explain the following features in detail - see index - and show how they are operated.

See also separate vehicle delivery test log.

Operating controls, transmission, multiple display, initial start-up, starting, and switching off,

fault display, code table, clearing the warning and fault messages.

Explain "Important Information on Service and Maintenance". See inside back cover.

Hand over tool box accessories.

Fill in warranty and delivery card and forward immediately to the factory.

For 50 km/h version, draw attention to the required regular vehicle inspections

(country-specific).

Vehicle delivered on . . . . . . . . . . . . . . .

Signature of mechanic . . . . . . . . . . . . . . . . .

Page 3

OPERATING MANUAL

FENDT 916 Vario

From chassis number 916 .. 7001

FENDT 920 Vario

From chassis number 920 .. 7001

ETManufacturer

ETAuthor

AGCO GmbH

FENDT 924 Vario

From chassis number 924 .. 7001

FENDT 926 Vario

From chassis number 926 .. 7001

FENDT 930 Vario

From chassis number 930 .. 2001

Maschinen und Schlepperfabrik D-87616 Marktoberdorf / Bavaria / Germany

Telephone +49 8342 77-0 Facsimile +49 8342 77-222

© PSD / Ko - SG 10.04

2941 F - en

Page 4

Customer-notes

Text-module

Dear Customer,

Please note the following:

● Before using the tractor, carefully read

through this Manual to familiarize yourself

with all operating controls and their functions

before you begin work. This also applies to

the operating instructions of the implement

manufacturer.

● Follow all the operating and maintenance instructions. If you do so, your tractor will give

you many years of economic and trouble-free

operation. You will find an overview of all

maintenance operations in the Service Schedule in this Manual.

● Maintenance and repair work should be carried only at your service workshop. see also

the "Important service and maintenance information".

Text-module

Authorised use

This tractor is designed only for normal agricultural operations or similar purposes, for example in

municipal applications.

Any other type of use is considered unauthorised. The manufacturer will not be liable for any

damage resulting from such uses, which will be

entirely at the owner's risk.

Authorised use also means fulfilling the operating, service and maintenance conditions set out

by the manufacturer.

Operation, maintenance and repair of the tractor

is restricted to persons who are familiar with this

kind of work and aware of the inherent dangers.

All relevant accident prevention regulations and

all generally accepted health & safety standards

and road traffic regulations must be observed

The manufacturer does not accept liability for damage resulting from unauthorised modifications.

Text-module

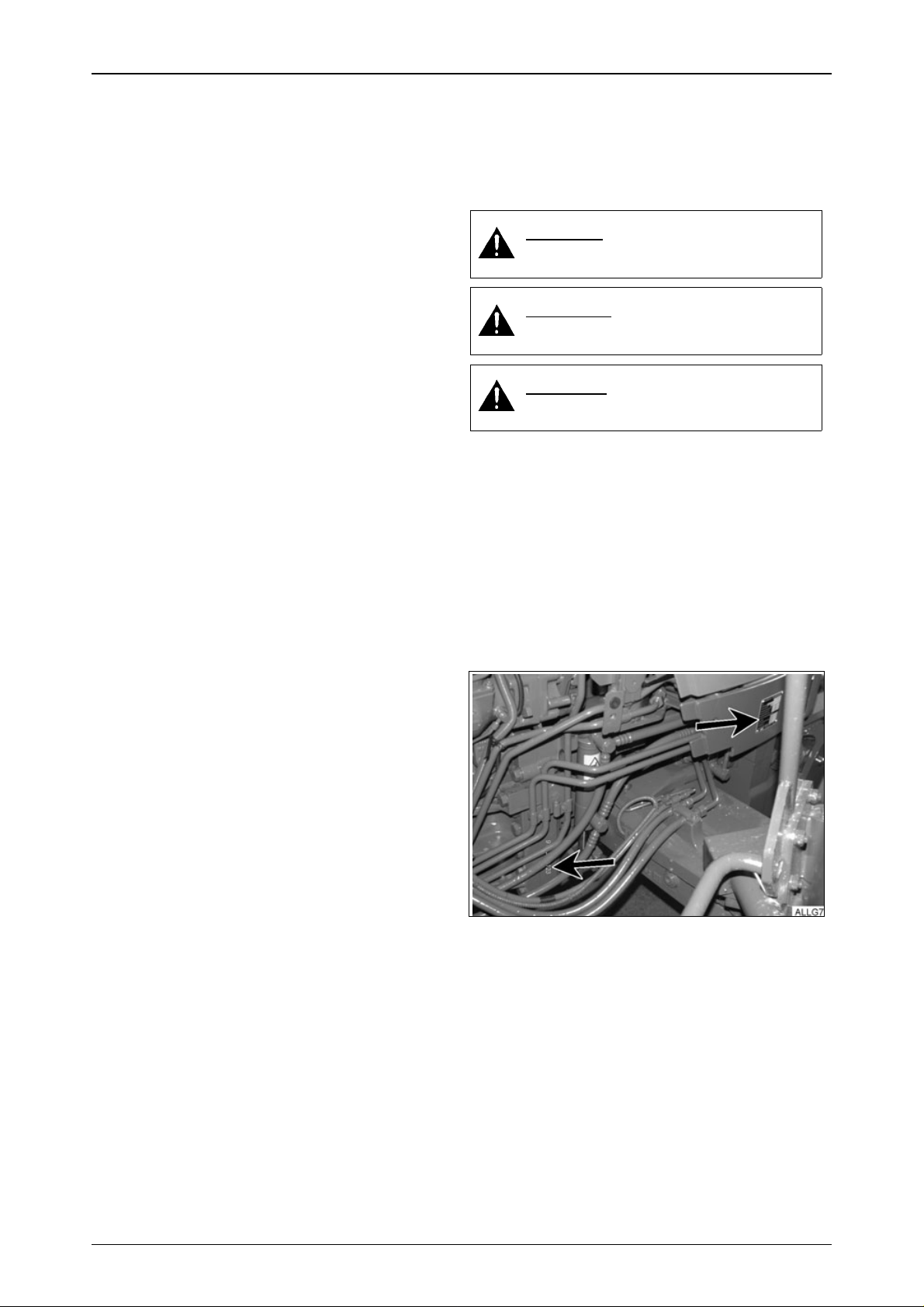

Marking of places that affect your

safety

Make sure that any other users have read all the

safety instructions as well.

The various levels of safety instructions can be

distinguished as follows:

DANGER:

Risk of serious accident.

WARNING:

Risk of injury.

CAUTION:

Possible risk of injury.

Text-module

The Operating Manual is an integral part of the

vehicle package and must be passed on to any

subsequent owner in the event of resale. The attention of the new owner should be drawn to this

information.

If this Manual is lost or damaged and you need a

new one, please contact your Fendt dealer,

There you will be able to purchase a replacement.

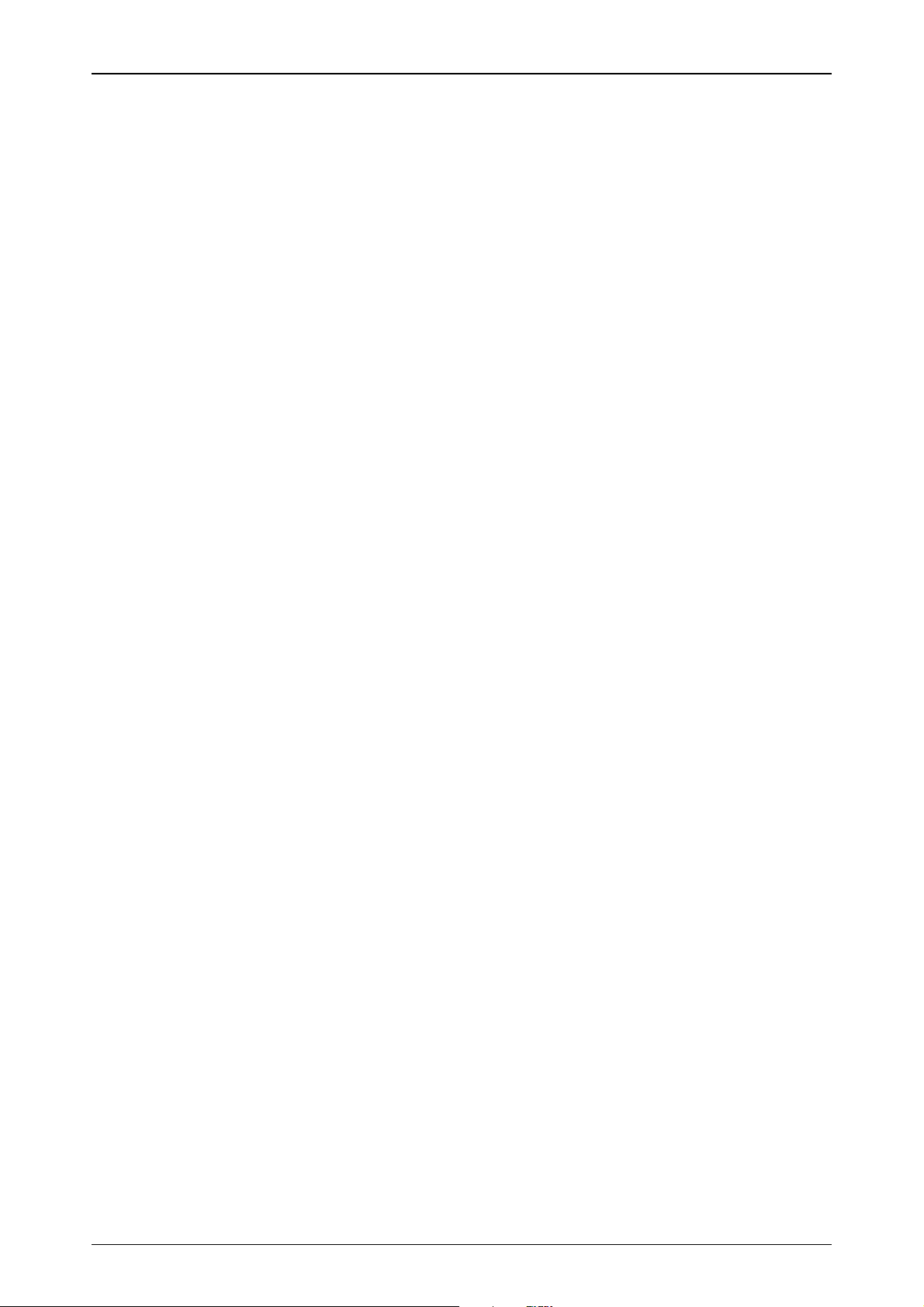

Vehicle Identification Number

Operation_Pic_number:ETpicture-module

Text-module

The Vehicle Identification Number is on the right

frame and also stamped on the rating plate.

Text-module

All specifications in the Manual are subject to the

usual tolerances. We reserve the right to make

design changes as part of technical further development, without making alterations to this Manual. The drawings and illustrations in the manual are used for function description, some of

the items shown are not necessarily included in

the vehicle delivery contents.

4

Page 5

SAFETY INSTRUCTIONS...............9

NUMERICAL INDEX

OPERATION....................................14

1. Driver seat ................................................14

1.1 Super deluxe seat......................................14

2. Display instruments and operating

controls.....................................................15

2.1 Front controls.............................................15

2.2 Glow and starter switch..............................16

2.3 Combination switch....................................16

2.4 Steering wheel adjustment.........................16

2.5 Quick reverse.............................................16

2.6 Dashboard .................................................17

2.7 Indication of fluid levels..............................18

2.8 Operating status display ............................18

2.9 Multiple display ..........................................19

2.10 Operating controls, right.............................19

2.11 Multi-function armrest ................................20

2.12 Operating console, right side.....................21

2.13 Vario terminal.............................................22

2.14 Camera function.........................................26

2.15 Quick Jump................................................26

2.16 Cab top section, front.................................28

2.17 Cab top right side.......................................28

2.18 Power outlets.............................................29

2.19 Reset function............................................31

3. Heating and ventilation ...........................31

3.1 Heater with 3-speed blower.......................31

3.2 Auxiliary ventilation in cab roof ..................32

3.3 Air conditioning ..........................................32

4. Rearwiew mirror.......................................33

5. Start-up.....................................................33

5.1 Daily check.................................................33

5.2 Cold weather operation..............................34

5.3 Tool box.....................................................34

6. Starting and stopping the engine...........34

6.1 Memory function ........................................34

6.2 Starting the engine.....................................35

6.3 Jump starting .............................................36

6.4 Tow-starting...............................................37

6.5 Stopping the engine...................................37

6.6 Stopping and immobilising the tractor........37

7. Vario transmission...................................37

7.1 Joystick......................................................37

7.2 Neutral position..........................................37

7.3 Selecting acceleration rates.......................38

7.4 Driving mode selector................................39

7.5 Driving the tractor.......................................40

7.6 Changing direction of travel.......................42

7.7 Programmed changes of travel direction...43

7.8 Cruise control.............................................44

7.9 Load limit control........................................46

7.10 Storing engine speeds...............................47

7.11 Towing instructions....................................48

8. Fuel consumption measurement............48

8.1 Activating fuel consumption

measurement.............................................48

9. Tractor Management System (TMS).......49

9.1 Engine management system .....................50

9.2 Accelerator mode.......................................50

9.3 Setting engine speed range.......................51

10. PTO............................................................53

10.1 Rear PTO...................................................53

10.2 Engaging and disengaging rear PTO.........54

10.3 Front PTO..................................................55

10.4 Engaging and disengaging front PTO........56

10.5 Calibrating rear and front PTO coupling ....56

11. Four wheel drive (4-WD)..........................58

12. Differential lock........................................58

13. Front axle suspension.............................59

14. Power lift and PTO automatic mode ......60

14.1 Power lift automatic mode..........................60

14.2 PTO automatic mode.................................61

14.3 PTO automatic mode with power lift..........62

15. Brakes.......................................................63

15.1 Foot brake..................................................63

15.2 Hand brake ................................................63

15.3 Trailer brake...............................................64

15.4 Engine brake..............................................64

16. Steering.....................................................65

16.1 Steering wheel adjustment.........................65

17. Hydraulics.................................................65

17.1 General notes on hydraulic operations......65

17.2 Valve locking..............................................66

17.3 Valve equipment........................................67

17.4 Operating the valves..................................67

17.5 Priority function..........................................69

17.6 Setting the valves.......................................70

17.7 External valve actuation.............................73

17.8 Hydraulic connectors .................................74

18. Electronic lifting gear control, rear........75

18.1 Controls......................................................75

18.2 EPC safety lock..........................................76

18.3 Control panel functions..............................77

18.4 Working with the EPC................................79

18.5 Electronic slip control.................................81

18.6 Electro-hydraulic external control...............83

5

Page 6

NUMERICAL INDEX

18.7 Electronic power lift control / double action

operation (EPC/DA)...................................84

18.8 Implement socket.......................................85

19. Three-point link........................................85

19.1 Lower links.................................................85

19.2 Extendable lifting struts..............................86

19.3 Mechanical side locks................................87

19.4 Top link ......................................................87

20. Front power lift.........................................88

20.1 Lower links.................................................88

20.2 Standard version........................................89

20.3 Comfort version..........................................90

21. Trailing devices........................................96

21.1 Calculation of trailer weights......................96

21.2 Trailer bracket............................................97

21.3 Hitching a trailer manually..........................97

21.4 Automatic trailer coupling...........................98

21.5 Ball coupling, drawbar, piton fix.................99

21.6 Hydraulic trailer hitch ...............................102

22. Compressed air system ........................104

22.1 Operating.................................................104

22.2 Maintenance ............................................105

29. Implement control..................................120

29.1 Assigning control terminal........................120

29.2 Loading the implement software for

implement control ....................................122

29.3 Setting up the control terminal for

implement control ....................................123

29.4 Operating the implement with the

joystick.....................................................124

29.5 Implement diagnosis function ..................125

30. Variotronic Ti..........................................126

30.1 Functions .................................................126

30.2 Triggers....................................................126

30.3 Menu functions.........................................127

30.4 Operating.................................................129

30.5 Storing data..............................................133

30.6 Retrieving stored data..............................134

30.7 Changing operational sequences

manually ..................................................134

30.8 Changing relative factors.........................135

30.9 Modifying configuration lists.....................136

30.10 Function indicator on the main menu.......138

30.11 Menu colours ...........................................138

30.12 Messages for information.........................138

23. Additional ballasting..............................106

23.1 Front ballast.............................................106

23.2 Front/rear load weights............................106

23.3 Wheel weights..........................................107

23.4 Water ballasting of tyres ..........................107

24. Track adjustment...................................108

24.1 Lighting wide vehicle................................108

24.2 Rear axle stub..........................................108

25. Twin tyres...............................................110

25.1 Conditions for use....................................110

25.2 Twin tyres.................................................110

26. On-board computer ...............................111

26.1 Setting the clock.......................................111

26.2 Adjusting speed indicator.........................111

26.3 Fault display.............................................112

26.4 Selecting tyre size....................................112

26.5 Backup indicators.....................................113

27. Computer................................................114

27.1 Computer functions..................................114

27.2 Select main menu....................................114

27.3 Setting measurement and counting

direction...................................................115

27.4 Manually triggered measuring and

counting...................................................115

27.5 Operating automatic measurement and

counting...................................................116

28. Storing the settings...............................117

28.1 Setting that can be saved ........................117

28.2 Saving names and settings......................118

28.3 Calling up settings....................................119

CARE AND MAINTENANCE......139

1. General....................................................139

2. Opening the bonnet...............................139

3. Engine oil change..................................140

3.1 Draining engine oil...................................140

3.2 Replacing the engine oil filter...................140

3.3 Filling with engine oil................................141

3.4 Checking engine oil level.........................141

4. Fuel system............................................142

4.1 Replacing the fuel filter ............................142

4.2 Bleeding the fuel system..........................143

4.3 Fuel prefilter.............................................143

5. Dry air filter.............................................144

5.1 Vacuum check .........................................144

5.2 Removing/installing the main cartridge....144

5.3 Cleaning the main cartridge.....................145

5.4 Replacing safety cartridge .......................145

6. Cooling system......................................145

6.1 Cleaning the cooling system....................145

6.2 Checking the coolant level.......................146

6.3 Replacing coolant ....................................146

6.4 Cleaning the cooling/heating system.......146

7. V belt.......................................................147

7.1 Right hand V belt .....................................147

7.2 Left V-belt.................................................147

8. Brake and clutch system.......................148

6

Page 7

NUMERICAL INDEX

9. Front PTO ...............................................149

10. Transmission and axle drives...............149

10.1 Changing the transmission oil..................149

10.2 Checking the transmission oil level..........150

10.3 Changing the oil in the axle drives...........151

11. Four-wheel drive axle............................151

11.1 Changing the oil in the front axle

differential gear........................................151

11.2 Replacing the oil in front axle hub drives.152

11.3 Front axle suspension..............................152

12. Power lift.................................................153

13. Hydraulic system...................................153

13.1 Checking oil level in hyrdraulic system....153

13.2 Changing the hydraulic oil........................154

13.3 Hydraulic oil filter......................................154

14. Steering...................................................156

15. Front wheels...........................................156

15.1 Checking toe-in........................................156

16. Heating and ventilation .........................157

16.1 Removing the heater fan filter..................157

16.2 Replacing the roof fan filter......................157

16.3 Replacing the recirculating air filter..........158

17. Air conditioning .....................................158

17.1 Condenser ...............................................158

17.2 Compressor V-belt...................................159

18. Windshield washer system...................159

19. Cleaning the tractor...............................159

19.1 Clean the cab's air spring bellows............159

20. Electrical and electronic systems........160

20.1 Battery......................................................160

20.2 Alternator .................................................160

20.3 Electrowelding..........................................160

20.4 Adjusting the headlights...........................160

20.5 Adjusting the auxiliary headlampss..........161

20.6 Auxiliary lights, Xenon headlights............161

20.7 Additional installation of electrical and

electronic equipment................................162

IMPLEMENTS...............................204

1. Reversing device ...................................204

FAULTS AND REMEDIAL

ACTIONS........................................205

1. Warning and fault messages................205

1.1 Warning messages..................................205

1.2 Fault messages........................................211

1.3 Clearing a warning or fault message .......215

1.4 General faults...........................................216

2. Variotronic Ti fault messages...............223

3. Warning and information messages

for implement settings..........................227

4. Flame starting system faults ................228

5. Fault code tables....................................229

6. Emergency operation............................245

TECHNICAL DATA.......................247

1. Technical data........................................247

2. Tyre pressures.......................................251

3. Tyre combinations.................................252

4. Fuel and lubricants Vario 916 - 930......253

4.1 Bio-diesel.................................................254

4.2 Bio hydraulic oil........................................254

5. Lubrication chart....................................255

5.1 Filling points.............................................255

5.2 Lubrication points.....................................256

21. Fuses.......................................................163

21.1 Fuse holder X050.....................................164

21.2 Fuse holder X051.....................................165

21.3 Fuse holder F060 - F067 .........................166

21.4 Fuse holder (A013)..................................167

22. Wiring diagrams.....................................168

22.1 Legend for circuit diagrams......................168

22.2 Colour coding for electric wires................171

22.3 Wiring diagrams.......................................171

7

Page 8

NUMERICAL INDEX

8

Page 9

SAFETY INSTRUCTIONS

Safety and accident prevention regulations

WARNING:

Before every operation, check the tractor for road worthiness and operational safety.

Carefully read the Manual and observe all safety instructions.

Safety signs on the machine must be replaced if damaged or lost.

General safety and accident

prevention regulations

Text-module

1.Follow the general safety and accident

prevention regulations, as well as the safety

information in this manual.

2.When driving on public roads, follow the usual

traffic regulations!

3.Before starting work, familiarise yourself with

all operating controls and their functions. Don't

wait until after you have started working!

4.Start the engine from the driver seat only. Do

not attempt to start by shorting across the

starter terminals, as this can cause the tractor

to move immediately!

5.Before starting up, check the area is clear (e.g.

children). Ensure that nothing obstructs vision.

6.Never leave the engine running in a confined

space!

7.The driver should wear close-fitting clothing.

Avoid wearing loose-fitting garments!

8.Take extra care when handling fuel - serious

fire hazard. Never re-fuel in the presence of

sparks or naked flames. Do not smoke when

re-fuelling.

9.Before re-fuelling, turn off the engine and

remove the ignition key. Do not re-fuel in

confined spaces. Clean up spillages

immediately!

10.To avoid fire hazard, keep the tractor clean.

11.Beware of leaking brake fluid and battery

acid (these are toxic and corrosive).

ETNum-list

Carrying passengers

Text-module

1.Passenger should be carried only if the tractor

is fitted with an appropriate passenger seat.

2.Do not carry passengers in any other other

circumstances.

ETNum-list

Driving the tractor

Text-module

1.Driving speed must always be adapted to the

current situation. Avoid sudden cornering

when driving uphill or downhill, or across

gradients. Disengage the differential lock

when cornering. Never disengage the clutch to

shift gears when travelling downhill!

2.Make sure all trailers and implements are

properly hitched. Driving characteristics,

steering and braking are affected by mounted

implements, trailers and ballast weight.

Therefore, always ensure that there is

adequate steering and braking capacity.

3.Observe the maximum permissible gross

vehicle weight, axle loads and tyre load

capacity, especially if heavy implements are

attached.

4.When negotiating bends with implements

connected or hitched up, always allow for the

overhang and oscillating weight of the

implement.

ETNum-list

Front loader operation

Text-module

1.Never allow anyone to stand in the hazard

area, or within the working range of the front

loader. Keep the area clear of bystanders at all

times. Do not operate the front loader unless

there is a clear view of the entire working area

- illuminate the area if necessary.

2.It is not permitted to use the standard loader

(as supplied) as a working platform. If using

the loader with a special working platform,

additional safety measures are required.

3.Do not handle round bales, pallets etc. unless

the loader is suitably equipped for this

purpose. If loading objects that cannot be

secured and may fall off, do not use the front

loader unless the driving seat is protected by a

robust canopy.

9

Page 10

SAFETY INSTRUCTIONS

4.When the front loader is raised, the risk of the

tractor tipping over is greater, and the braking

effect at the rear axle may also be reduced.

Adapt your driving style and ensure adequate

ballasting at the rear. For additional loading,

we recommend attaching the Fendt 870 kg

additional weight at the three-point link - fit

wheel weights and fill the tyres if necessary.

5.Keep a safe distance from high-voltage

cables.

6.When on public roads, bring the front loader

into the transport position and secure it. Keep

a maximum distance of 3.5 m between the

implement and the centre of the steering

wheel. If the forward projection exceeds 3.5 m,

appropriate measures must be taken to

guarantee safe traffic conditions (e.g. use

people on foot acting as guides or mirrors at

road junctions). Transporting equipment or

materials with a front loader working

implement, e.g. a scoop, is not permitted when

travelling on public roads.

7.Danger from unintended lowering of the front

loader. Always secure hydraulic lever at the

end of operation. Before leaving the tractor,

completely lower the front loader to the

ground.

8.For safety reasons the front loader should be

mounted and removed by one person only , the

driver himself.

9.Always keep hands away from the crushing

and cutting areas while parts may still be

moving.

10.Detach the front loader with the attached

implement (bucket, fork) only on firm and

level ground. Always use the supports

provided.

1 1.The front loader must be parked and secured

in such a way as to prevent unauthorised

persons or children from causing it to tip over .

12.When mounting the front loader, connect all

hydraulic connections including the auxiliary

return, if equipped in this way. Always

connect hydraulic hose for cylinder load

pressure to +. Take great care not to confuse

connections since this may cause accidents

through reversed functions, e.g. lifting

instead of lowering. Before fitting the multiple

coupler, remove the load from hydraulic

hoses and unplug rear hydraulic

connections, lower the power lift and operate

only via EPC. Hydraulic fluid interflow can

create danger from unintentional equipment

motion.

ETNum-list

Leaving the tractor

Text-module

1.Make sure the tractor is properly secured

against running off (parking brake, wheel

chocks). Switch off the engine and apply the

hand brake!

2.Remove the ignition key and lock the cab if

necessary.

3.Never leave the tractor unattended while the

engine is running.

4.Never leave the cab while the tractor is in

motion.

5.Completely lower the mounted implement

before leaving the tractor.

ETNum-list

Mounted and trailing equipment

Text-module

1.Only attach implements and trailers using the

prescribed devices.

2.Use only trailers which comply with the

country-specific regulations. Do not exceed

maximum vertical bearing load. Ensure that

the tractor-trailer brake system is functioning

correctly.

3.Take special care when hitching trailers or

implements!

4.Secure trailers and implements to prevent

them rolling. Make sure that detached

implements and components are safely

parked.

5.Be sure all protection devices are correctly

attached and in the safety position before

operating the tractor.

6.When using the power lift, always remain well

outside the travel range of the three-point link

attachment!

ETNum-list

PTO operation

Text-module

1.Always switch off the engine, before fitting or

removing the drive shaft. The PTO shaft must

be in 0-position.

2.During PTO operations, allow no-one in the

vicinity of the rotating PTO or drive shaft.

3.Make sure drive shaft and PTO are equipped

with protective guards and sleeves.

4.After switching off the PTO, the attached

implement may continue running due to the

flywheel mass. In this case, do not go near the

implement. Approach it only when it has come

to a complete standstill.

5.When the drive shaft is removed, cover the

PTO shaft with its protective cap.

10

ETNum-list

Page 11

Maintenance

Text-module

1.Before maintenance and repair work, switch

off the engine and remove the ignition key.

Relieve pressure from implement lines, e.g. to

the front loader.

2.Any person should keep clear of a lifted,

unsecured load (e.g. tilted cab and similar).

3.Never open or remove any protection devices

while the engine is running.

4.Never grasp leaking pressure lines.

Pressurised fluids (diesel or hydr . oil) escaping

under high pressure can penetrate the skin

and cause severe injuries. If this has occurred,

seek medical advice at once to avoid the risk

of serious infection.

5.Keep at a safe distance from hot areas.

6.Hydraulic accumulator and connected pipes

are highly pressurised. Only remove and

repair in accordance with instructions provided

in Technical Manual.

7.To avoid eye injury, do not look directly at the

surface of the activated radar sensor.

8.Dispose of oil, fuels and filters properly!

9.For fitting tires, specialist knowledge and

special mounting tools are required.

10.Run the tractor for a short time, then

retighten all wheel nuts and bolts; check

them regularly. For correct torque values

refer to TECHNICAL DATA.

11.Before working on the electrical system,

always remove the ground strap from the

battery . Observe the following, when carrying

out electric welding. When carrying out

electric welding on tractor or mounted

implements, make sure that both battery

terminals are disconnected. Attach the

ground terminal as close as possible to the

welding point.

12.Spare parts must at least meet the technical

requirements stated by the manufacturer.

You can ensure that this is the case by using

genuine spare parts!

SAFETY INSTRUCTIONS

Text-module

Advice for front loader maintenance:

1.Before undertaking maintenance work, lower

the front loader to the ground, switch off the

engine and remove the ignition key.

2.If the pipe fracture protection has engaged,

support the load before starting repairs, and

slowly retract the cylinder.

3.Hydraulic hoses deteriorate with age. Check

the condition of hydraulic hoses at regular

intervals, and replace them in good time.

4.After attachment and repair operations, drive

the tractor for a short time then retighten all

mounting screws and nuts and check them

regularly.

5.Retighten eccentric bolt for front loader

attachment, if necessary.

ETNum-list

ETNum-list

11

Page 12

SAFETY INSTRUCTIONS

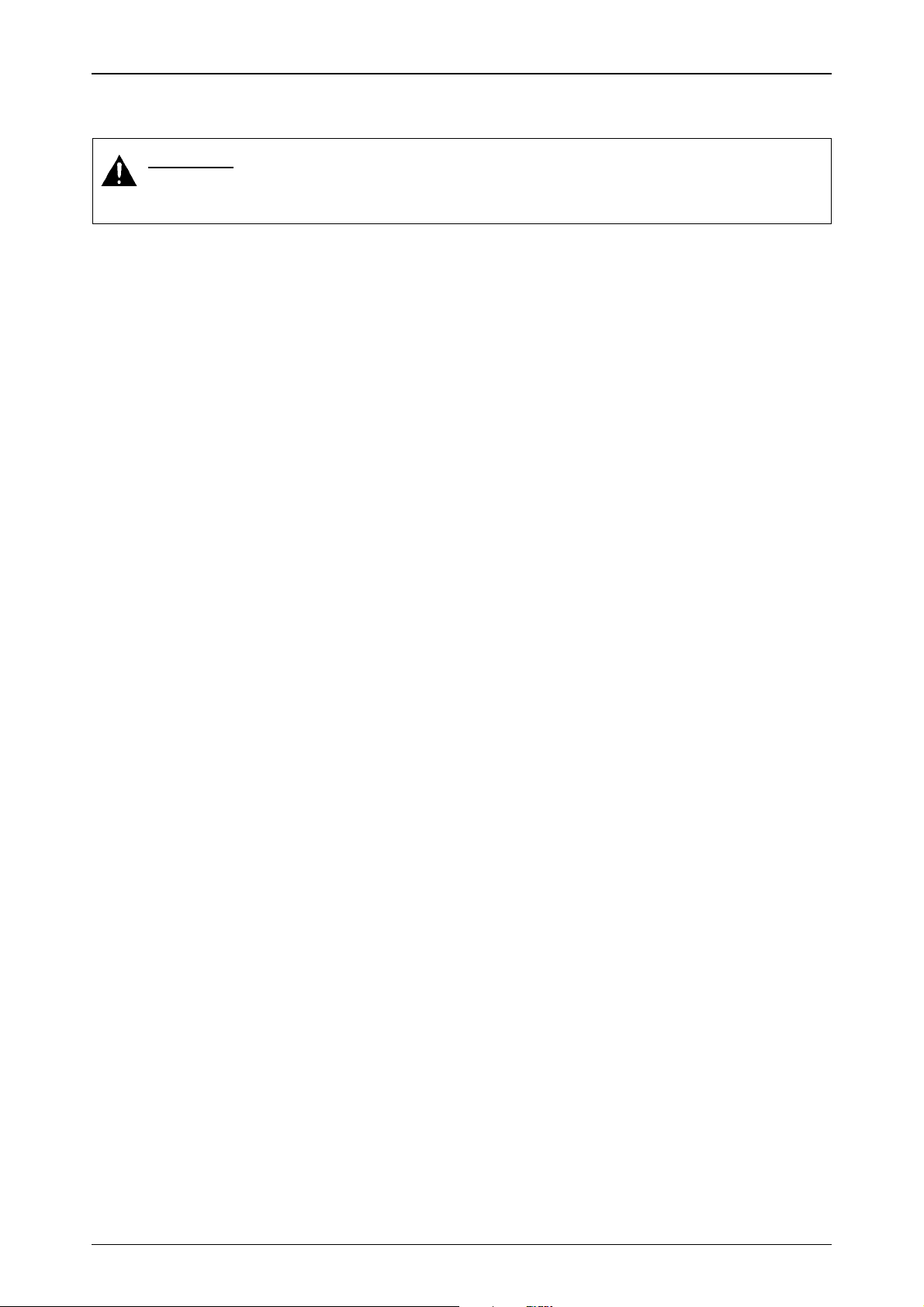

Location of safety signs

Operation_Pic_number:1

Fig.1

Inside the cab on the right.

Operation_Pic_number:1

Operation_Pic_number:1

Fig.4

On the left and right rear mudguards beside the

lifting gear control.

Operation_Pic_number:1

Fig.2

Inside the cab on the right.

Operation_Pic_number:1

Fig.3

On the right rear mudguard.

Fig.5

At left front of hydraulic cylinder of front axle

suspension.

Operation_Pic_number:1

Fig.6

On pressure reservoir of front axle suspension.

12

Page 13

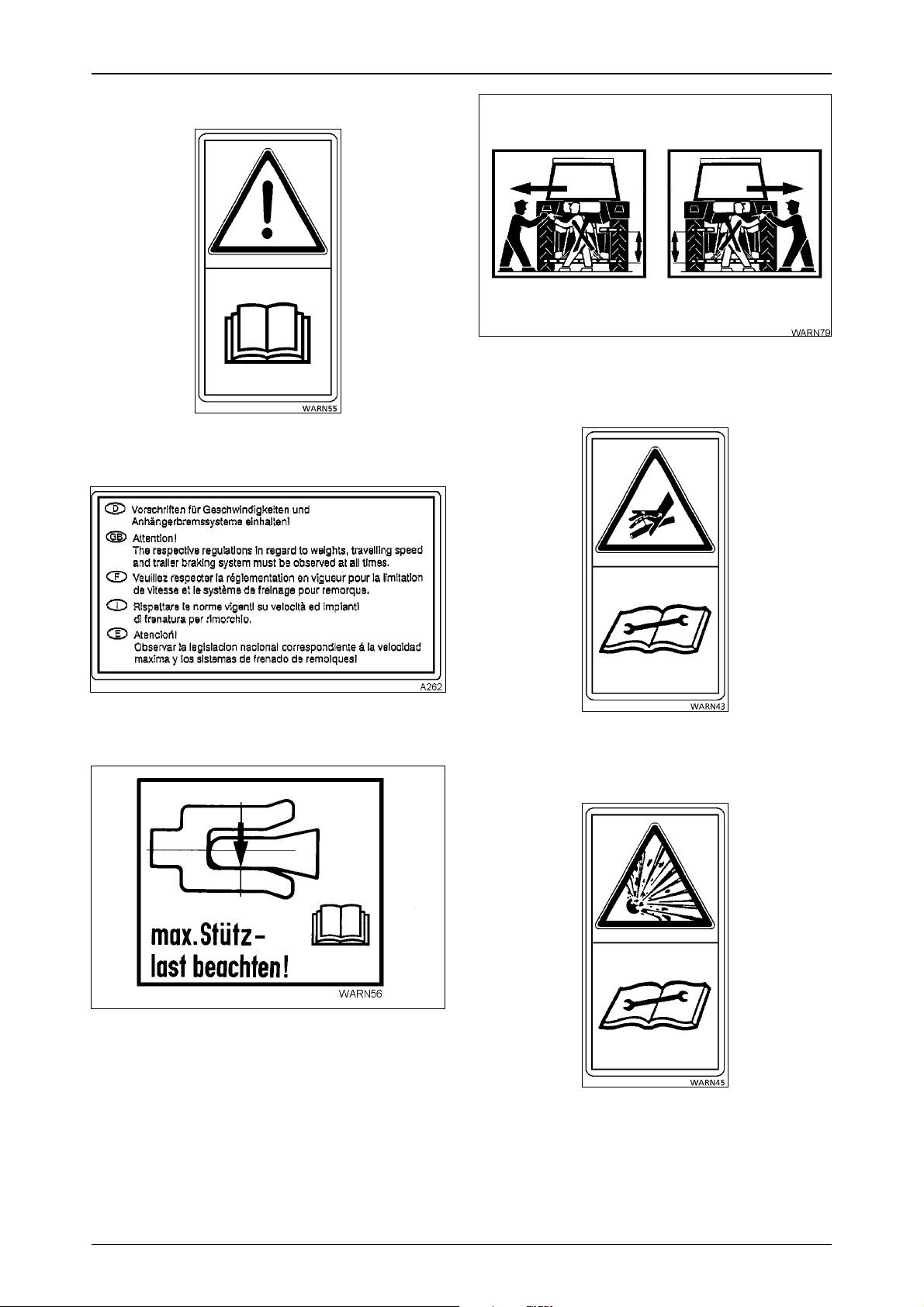

Operation_Pic_number:1

Inside the cab on left.

Operation_Pic_number:1

SAFETY INSTRUCTIONS

Fig.7

Fig.8

Inside the cab, on the cover of the emergency

operation controls.

Operation_Pic_number:1

Fig.9

On the front loader forks, left and right.

Operation_Pic_number:1

Fig.10

Inside the cab, on the left, on the transverse

beam of the front windscreen.

13

Page 14

OPERATION

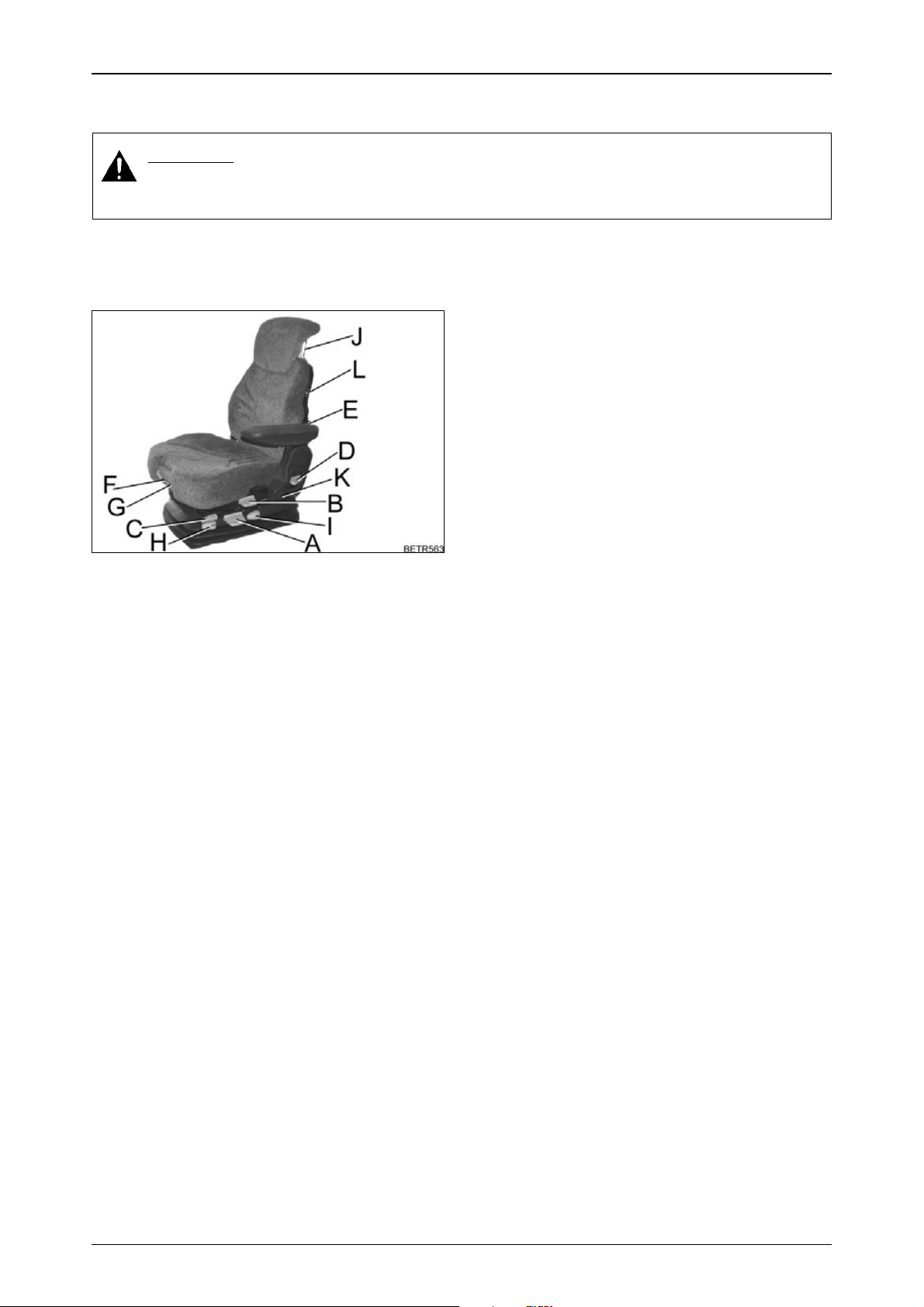

1. Driver seat

WARNING:

Never adjust the seat while the tractor is moving (risk of accident).

If a seat belt is available, always attach it.

1.1 Super deluxe seat

Operation_Pic_number:1

Fig.1

Text-module

A = Automatic weight and height adjust-

ment.

B = Swivel mechanism.

C = Longitudinal adjustment.

D = Backrest adjustment.

E = Lumbar support (curvature), pneumatic

operation.

F = Seat bolster (depth adjustment).

G = Seat bolster (tilt adjustment).

H = Horizontal springing (on/off).

I = Vertical springing (adjustable from soft to

hard in four levels).

J = Backrest extension.

K = Behind the moulding:

Seat belt fixing point.

L = Seat heating.

14

Page 15

OPERATION

2. Display instruments and operating controls

2.1 Front controls

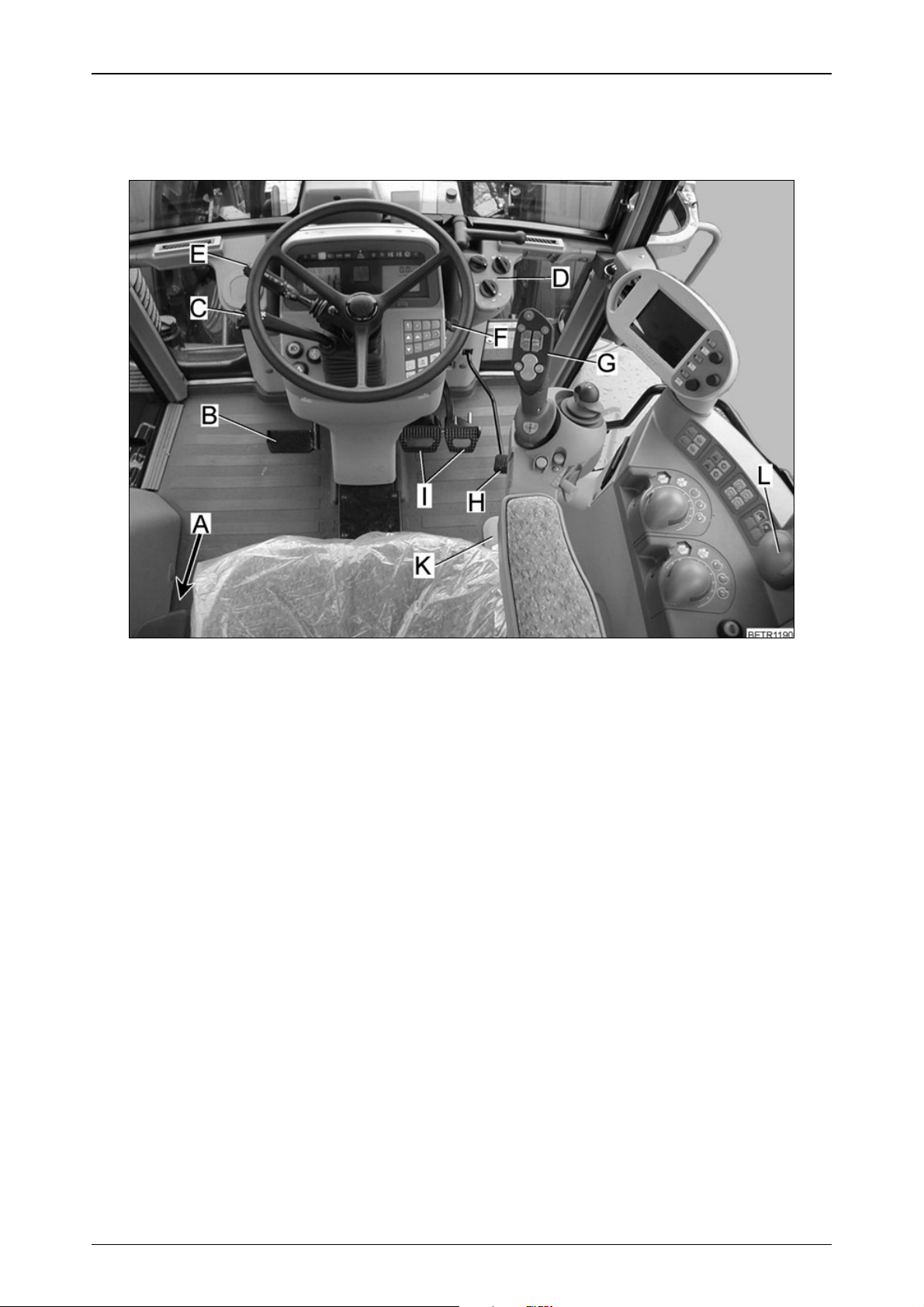

Operation_Pic_number:1

Fig.2

Text-module

A = Hand brake

B = Clutch pedal

C = Steering wheel adjustment and quick reverse.

D = Heater and fan controls (see also OPERATION Section 3).

E = Combination switch

F = Heater starter switch

G = Multi-function armrest

H = Accelerator pedal

I = Brake pedals

K = Emergency operation controls (under the cover).

L = Hand throttle

15

Page 16

OPERATION

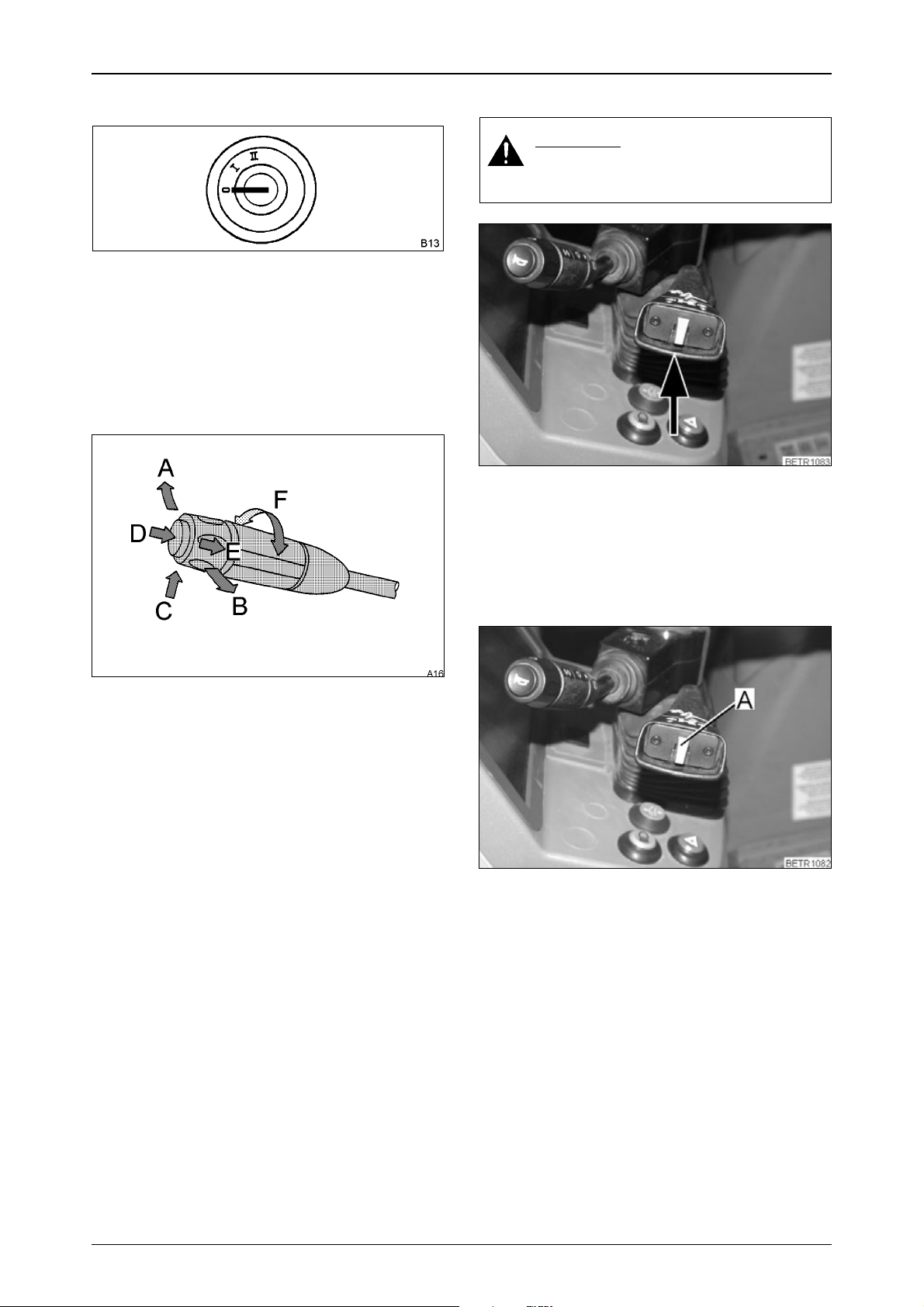

2.2 Glow and starter switch

Operation_Pic_number:1

Fig.3

Text-module

0 = Ignition off, key can be removed.

I = General ignition, key cannot be removed

+ preheating (automatic).

II = Starting + ignition.

2.3 Combination switch

Operation_Pic_number:1

2.4 Steering wheel adjustment

WARNING:

Never adjust the steering wheel

while the tractor is moving!

Operation_Pic_number:1

Fig.5

Text-module

● Pull up lever and adjust steering wheel to the

desired position (see also OPERATION Section 16).

Fig.4

Text-module

A = Right indicator.

B = Left indicator.

C = 1. With lights switched on: toggle low

beam, high beam.

2. With lights switched off headlight flas-

her.

D = Horn

E = Windshield washer system (wipers run

automatically).

F = Windshield wipers with intermittent and

continuous operation.

2.5 Quick reverse

Operation_Pic_number:1

Fig.6

● Press button (A).

The tractor slows to a standstill, then accelerates

in the opposite direction up to previous transmission ratio (see also OPERATION Section 7.6).

16

Page 17

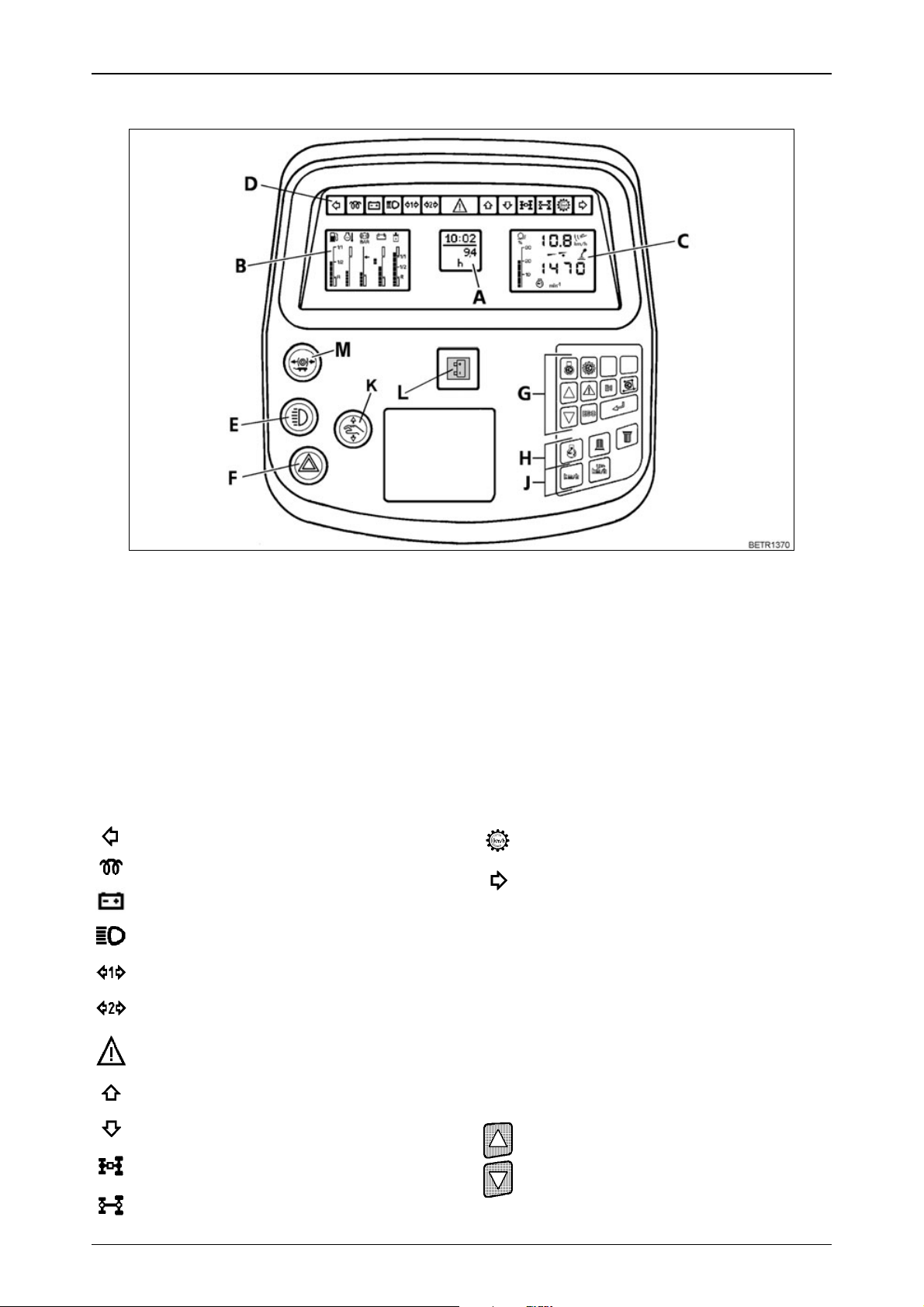

2.6 Dashboard

Operation_Pic_number:1

OPERATION

Text-module

A = Multiple display

B = Indication of fluid levels

C = Operating status display

D = Indicator lamps

E = Lights including side lights

F = Hazard warning flasher switch

G = Key pad for on-board computer (also

see OPERATION Section 26).

Text-module

Left turn signal indicator, green.

Preheater indicator lamp, red.

Alternator 2 not charging, red.

High beam, blue.

1st trailer light indicator, green.

2nd trailer light indicator, green.

Hazard light, red.

Forward direction of travel, green.

Reverse direction of travel, green.

4-WD engaged, green.

Fig.7

H = Key pad for rpm indicators (also see

OPERATION Section 2.8).

J = Key pad for speed display (also see

OPERATION Section 2.8).

K = Emergency mode (also see FAULTS

AND REMEDIAL ACTIONS Section 6).

L = Alternator 1 not charging, red.

M = Hydraulic trailer brake (optional), (see

also OPERATION Section 15.3).

Cruise control on.

Right turn signal indicator, green.

If one of the indicator lamps for forward/reverse

fails, back-up indicators can be activated on the

multiple display (A) activation (see see

OPERATION Section 26.5).

Text-module

Automatic dimmer

for forward/reverse indicator lamps, 4-WD, differential lock and related buttons.

At dusk or in the dark, the dimmer can be adjusted manually.

Brightness is increased or decreased by

pressing one of the two buttons.

Differential lock engaged, red.

17

Page 18

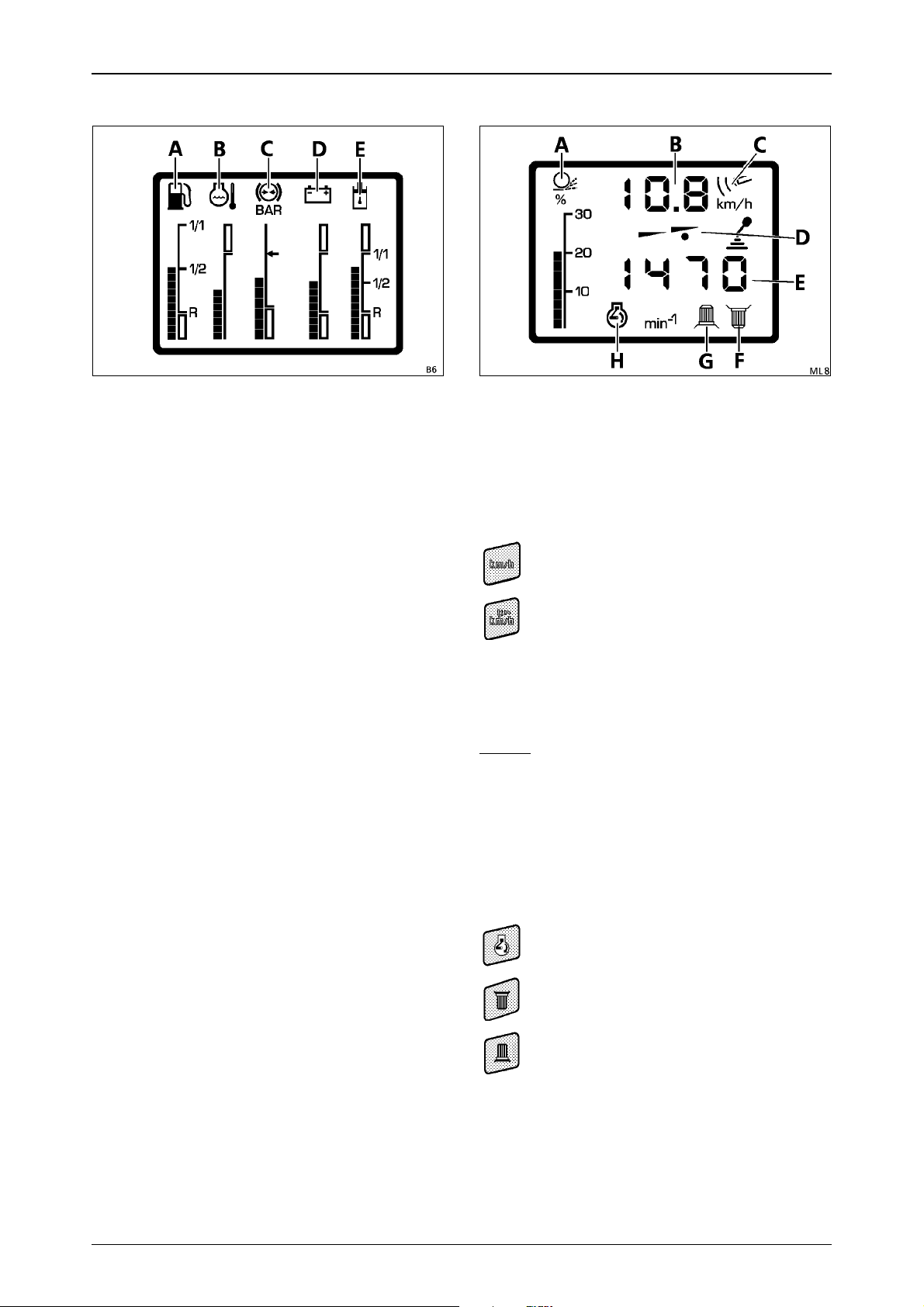

OPERATION

2.7 Indication of fluid levels

Operation_Pic_number:1

Fig.8

Text-module

A = Fuel supply

B = Engine temperature

When the bar indicators reach the red

zone, relieve the engine of load immediately and allow to cool down for about

2 minutes at 1000 rpm, then turn the en-

gine off.

C = Compressed air supply

D = On-board electrical system voltage

E = Hydraulic oil supply

2.8 Operating status display

Operation_Pic_number:1

Fig.9

Text-module

A=Wheel slip in %;

(only if optional radar sensor is equipped).

B=Tractor speed in km/h.

Text-module

On tractors with the optional radar sensor, use

these keys to change to:

theoretical speed measurement

calculated from transmission speed.

actual speed based on signal from radar

sensor, symbol (C) is lit.

Theoretical speed calculation is activated automatically when tractor speed is over

15 km/h, the wheel slip indicator (A) and symbol

(C) then go out.

NOTE:

For a precise reading, adjust the speed indicator under operating conditions (see also

OPERATION Section 26.2).

Text-module

D=Driving mode indicator

the selected driving mode is indicated by

a spot (D).

E=Rpm indicator

Text-module

can be changed with the buttons to:

engine speed symbol (H) is displayed.

rear PTO speed symbol (F) is displayed.

front PTO speed symbol (G) is displayed.

18

Page 19

OPERATION

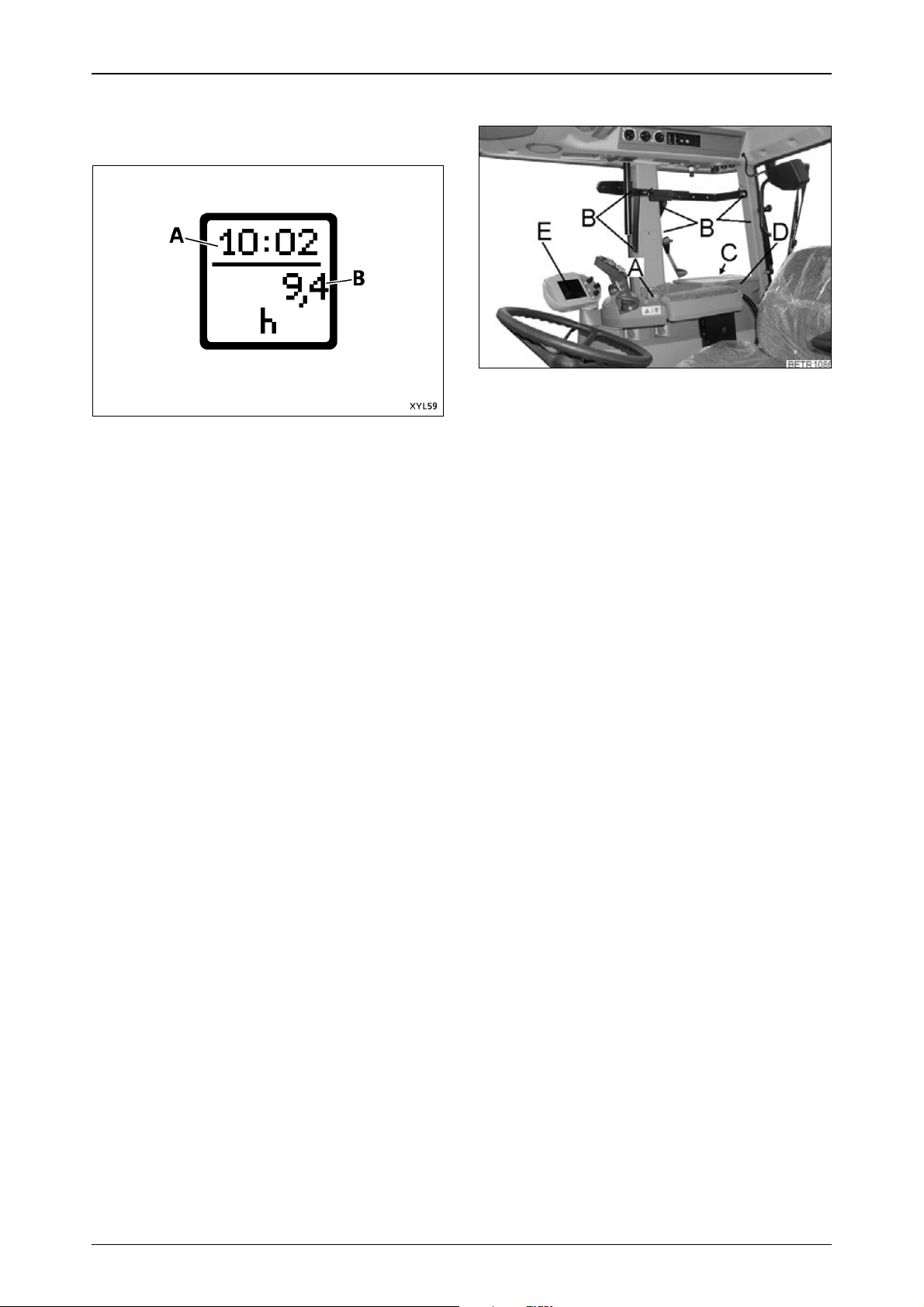

2.9 Multiple display

For warnings, fault messages and on-board

computer functions.

Operation_Pic_number:1

Fig.10

In the basic display, the clock (A) and operating

hours (B) are indicated. This is interrupted for

warnings, fault messages and on-board

computer functions.

2.10 Operating controls, right

Operation_Pic_number:1

Fig.11

Text-module

A = Hand throttle

B = Behind the moulding, M10 threaded ho-

les for fixing additional equipment, e.g.

radio or telephone, (see also CARE AND

MAINTENANCE Section 20.7).

C = Fuses

D = Document box

E = Control terminal

19

Page 20

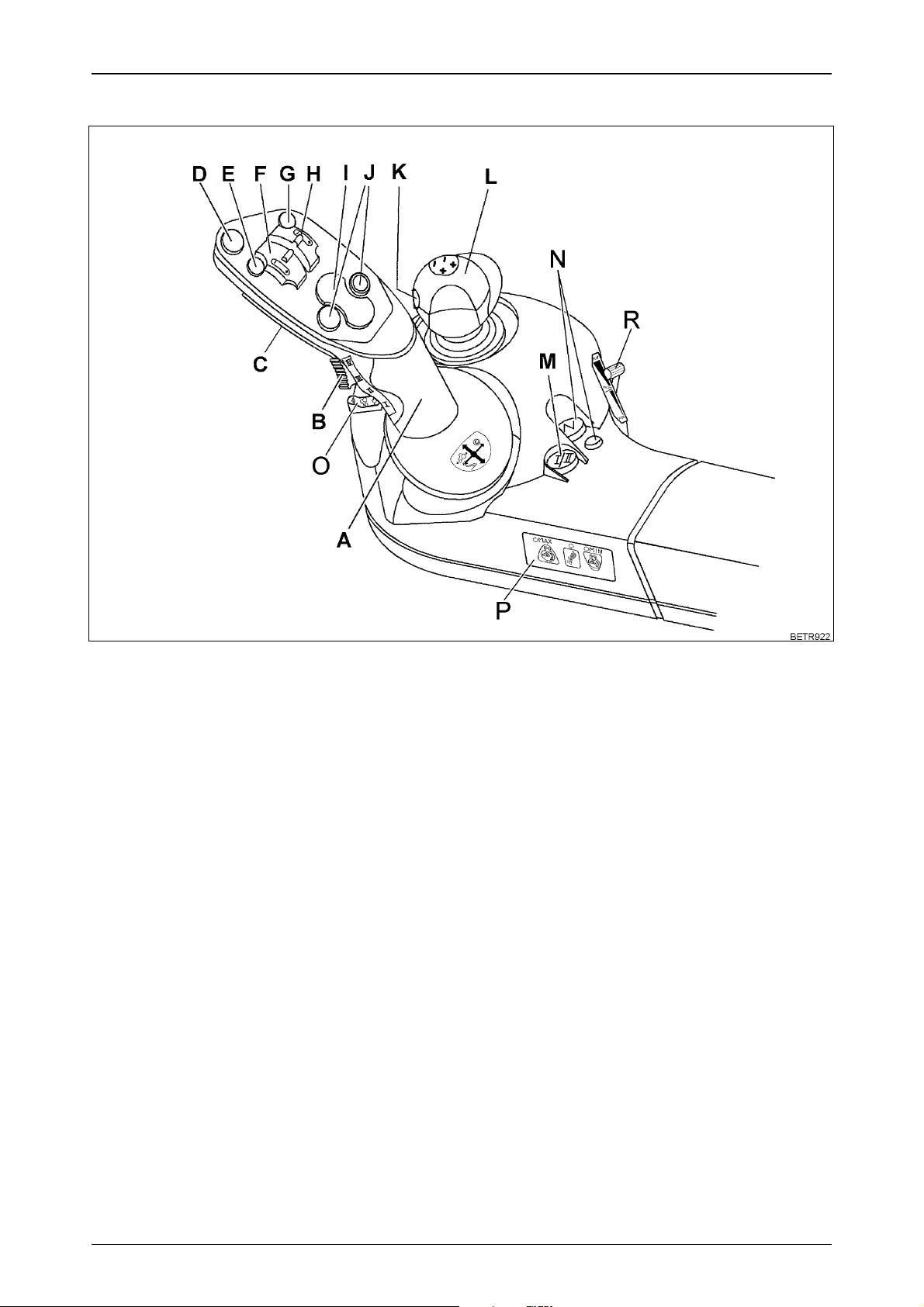

OPERATION

2.11 Multi-function armrest

Operation_Pic_number:1

Fig.12

Text-module

A = Joystick (see also OPERATION Section 7.1).

B = Acceleration rate selection (see also OPERATION Section 7.3).

C = Activating button on the back of the joystick.

D = EPC PTO automatic mode stop button (see also OPERATION Section 14.2).

E = Floating position of hydraulic valve, green or blue (see also OPERATION Section 17.3).

F = Lifting/lowering hydraulic valve, green or blue (see also OPERATION Section 17.3).

G = Floating position of hydraulic valve red or yellow (see also OPERATION Section 17.3).

H = Lifting/lowering of hydraulic valve red or yellow (see also OPERATION Section 17.3).

I = Rear power lift/ PTO automatic mode (see also OPERATION Section 14.2).

J = Front power lift/ PTO automatic mode (see also OPERATION Section 14.2).

K = 3rd hydraulic circuit on front loader.

L = Crossgate lever, lifting/lowering and floating position of hydraulic valves, yellow/blue or red/

green (see also OPERATION Section 17.3).

M = Driving mode selector (see also OPERATION Section 7.4).

N = Neutral button with neutral selected LED (see also OPERATION Section 7.2).

O = Accelerator pedal function (see also OPERATION Section 9.2).

P = Electronic engine control (also refer to OPERATION Section 9).

R = Accelerator pedal release (see also OPERATION Section 9.2).

20

Page 21

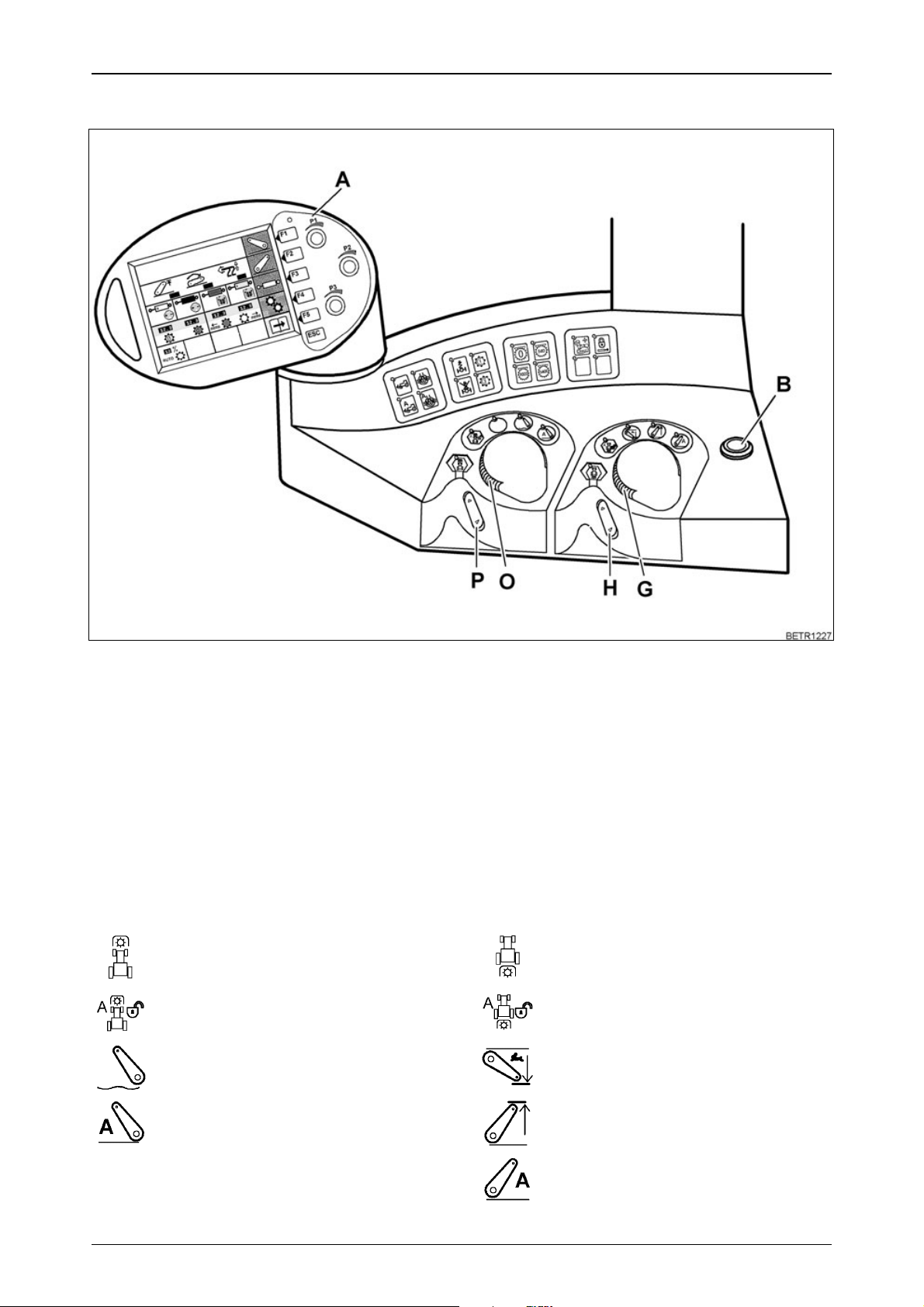

2.12 Operating console, right side

Operation_Pic_number:1

OPERATION

Fig.13

Text-module

A = Vario terminal (see also OPERATION Section 2.13).

B = Additional headlamps (on front of roof; can be switched on only when the headlamps are on -

these then go off).

G = Depth regulation rear power lift.

H = Quick lift rear power lift.

O = Comfort front power lift depth control.

P = Quick Lift, comfort front power lift.

Text-module

Front PTO and front power lift operation (see

also OPERATION Section 10.3, OPERATION

Section 20.3).

PTO ON/OFF

PTO automatic mode

Floating position

Text-module

Rear PTO and rear power lift controls (see

also OPERATION Section 10.1, OPERATION

Section 18).

PTO ON/OFF

PTO automatic mode

Quick insert

EPC automatic mode

Hitch-lift

EPC automatic mode

21

Page 22

OPERATION

Text-module

4-WD (see also OPERATION Section 11).

4-WD 100%; ON/OFF

4-WD automatic mode ON/OFF

Text-module

Differential lock (see also OPERATION

Section 12).

Differential lock 100 % ON/OFF

Differential lock automatic mode ON/

OFF

Text-module

Front axle suspension (also see OPERATION

Section 13).

Suspension locked

Suspension ON

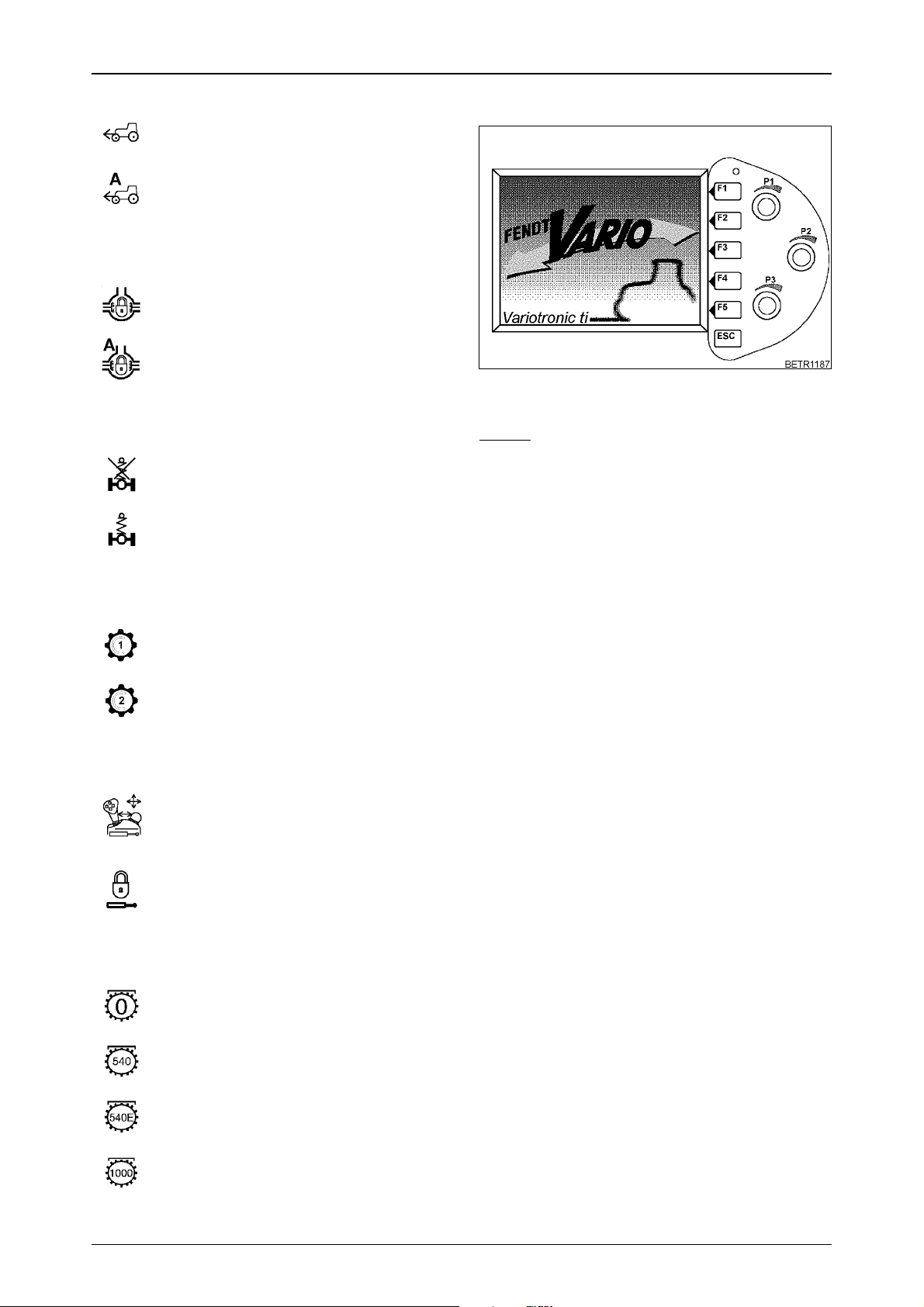

2.13 Vario terminal

Operation_Pic_number:1

Fig.14

Text-module

NOTE:

At low temperatures, a red-orange discolouration along with a decrease in contrast and

delayed display may occur for up to 20 minutes.

At high temperatures there may be a loss of

contrast.

Text-module

Tempomat cruise control (see also OPERATION Section 7.8).

Memory 1

Memorised speed 2

Text-module

Hydraulic valves (see also OPERATION

Section 17.3).

Hydraulic valve control

The operating functions of the crossgate

lever and the controls on the joystick are

interchanged.

Locking the hydraulic valves

Text-module

Speed preselection for rear PTO (see also

OPERATION Section 10.1).

PTO neutral

Text-module

After the start-up display , the following first main

menu is displayed.

PTO 540

Economy PTO (750)

PTO 1000

22

Page 23

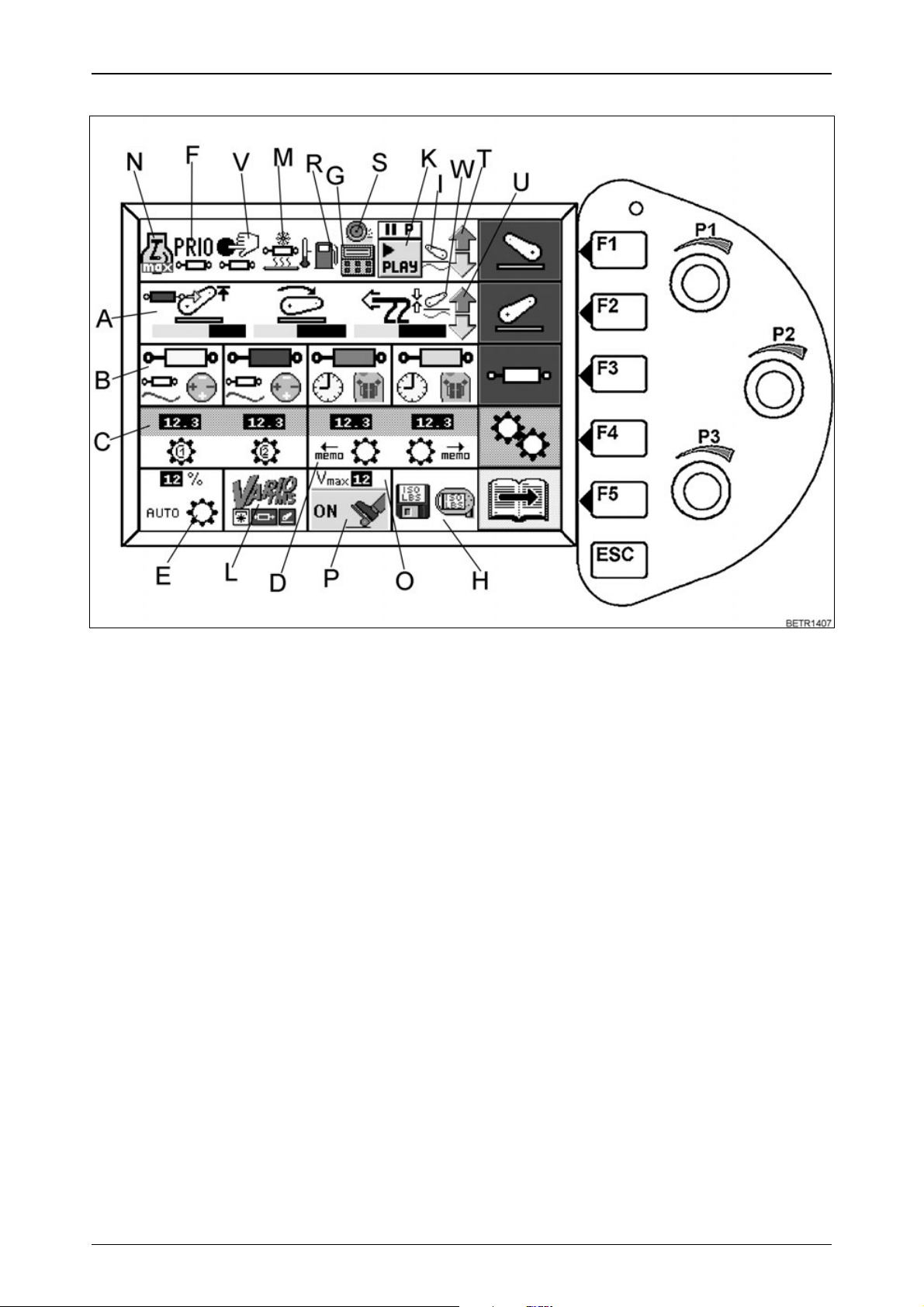

First main menu

Operation_Pic_number:1

OPERATION

Text-module

Pressing keys (F1 - F5) gives access to the following functions.

F1 = Comfort front power lift

F2 = Rear EPC

F3 = Electric valves

F4 = Transmission settings

F5 = Switch to 2nd main menu level

Display of prevailing operating status of:

A = Rear EPC

B = Electric valves

C = Cruise control

D = Programmed changes in direction of travel

E = Load limit control

F = Prioritised valve

G = Active on-board computer

H = LBS-ISO function (optional)

I = Front power lift - floating position

K = Variotronic Ti - function display

L = Tractor Management System

M = Hydraulic valve heating

N = Stored engine speed activated

O = Accelerator range

P = Accelerator pedal drive active

R = Measuring fuel consumption

S = Slip control active (optional)

T = Front EPC active

U = Rear EPC active

V = External valve actuation

W = Rear power lift - floating position

Fig.15

23

Page 24

OPERATION

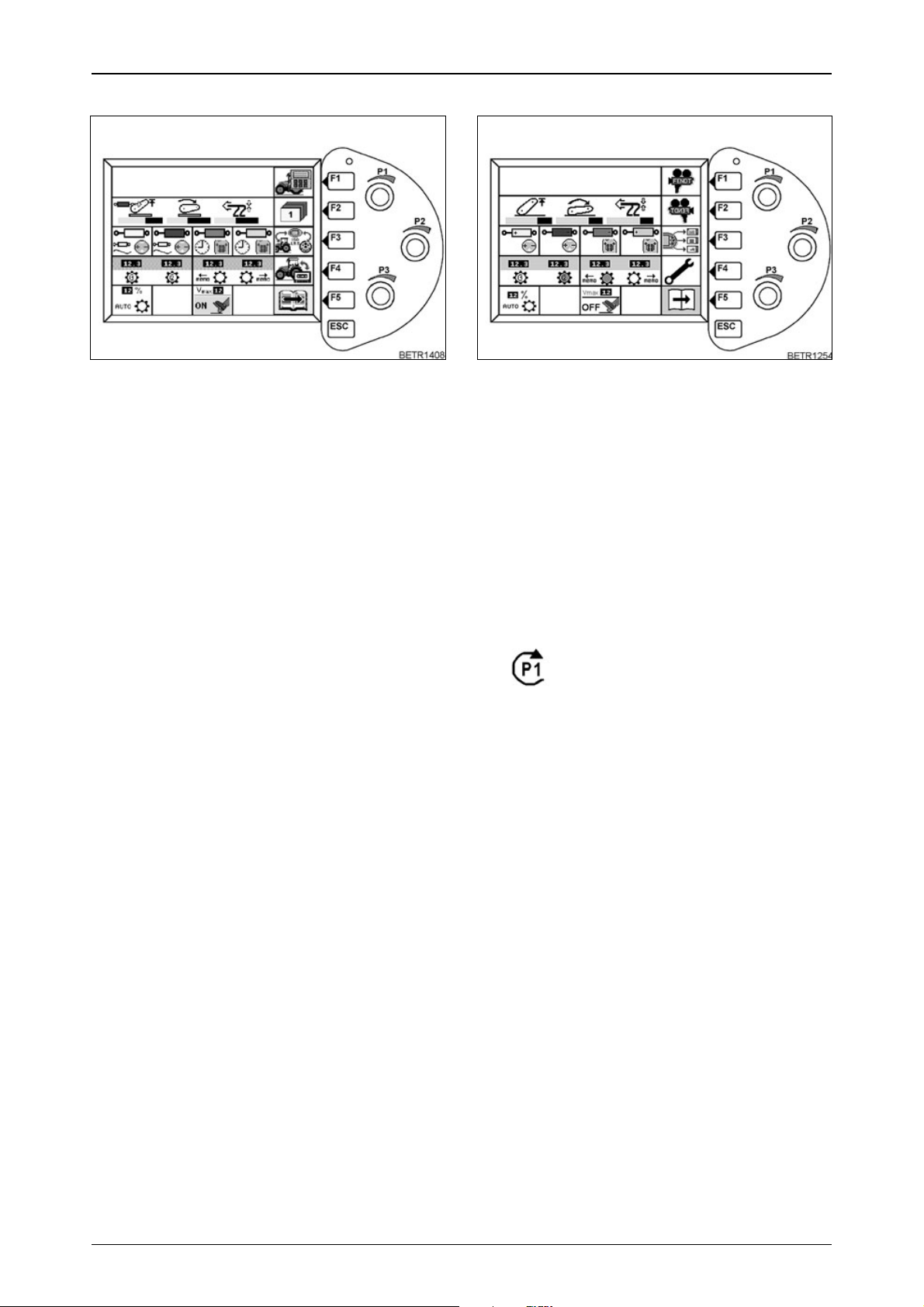

Second main menu

Operation_Pic_number:1

Fig.16

Text-module

Pressing keys (F1 - F5) gives access to the following functions.

F1 = On-board computer

F2 = Store terminal settings

F3 = Implement control

F4 = Variotronic Ti

F5 = Switch to third menu

Press the ESC key

● Display returns to first main menu.

Third main menu

Operation_Pic_number:1

Fig.17

Text-module

Pressing keys (F1 - F5) gives access to the following functions.

F1 = Camera image (optional).

F2 = Camera image mirrored (optional).

F3 = Quick Jump

F4 = Terminal settings

F5 = Switch to first main menu

Text-module

Settings can be made with the 3 rotary controls

(P1, P2, P3) or

a preset menu page (Quick Jump) can be selected.

Text-module

The right rotary control for the

settings is displayed in the Vario

terminal.

Press the ESC key

● Display returns to first main menu.

24

Page 25

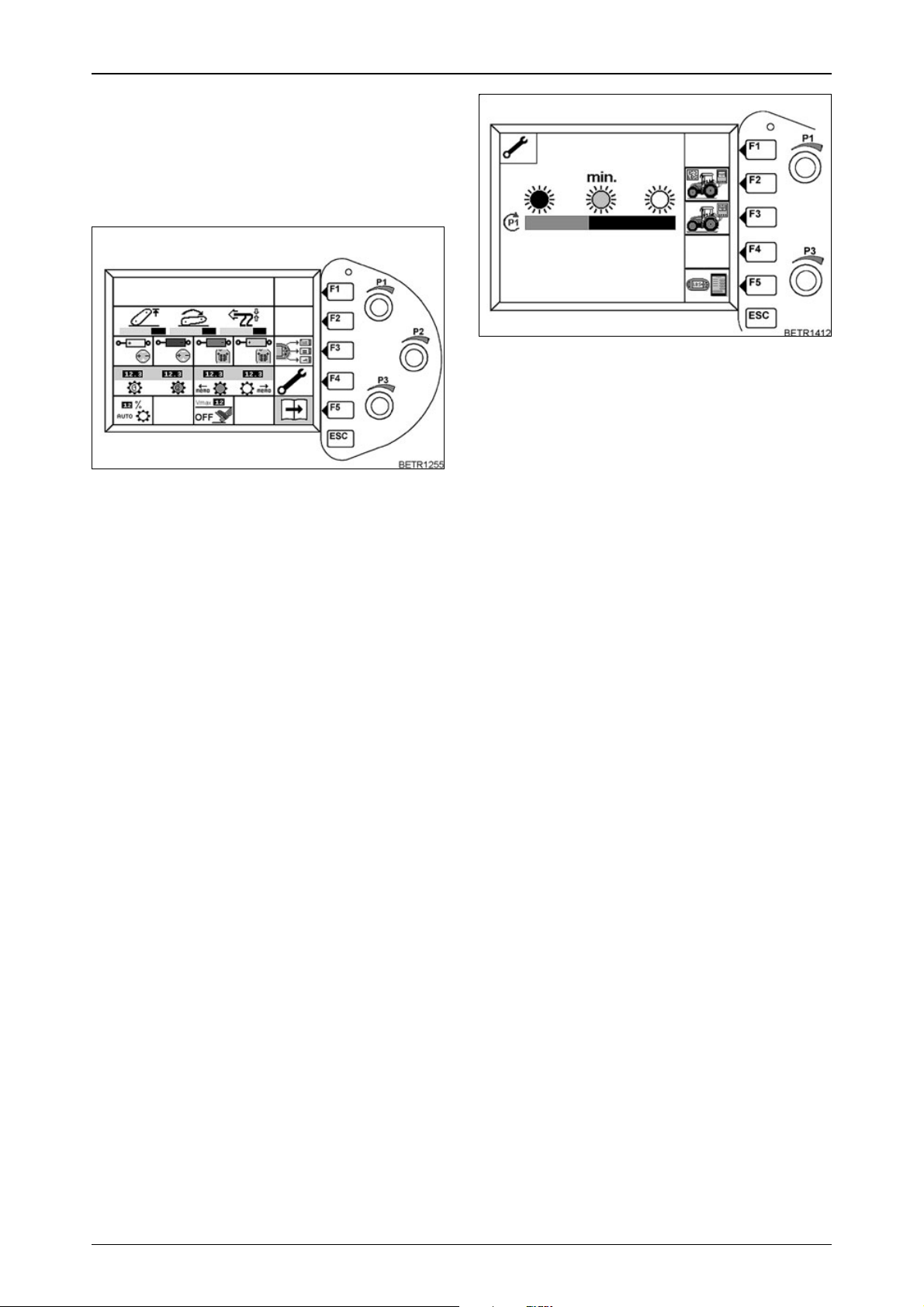

OPERATION

Adjusting screen brightness and

contrast

The brightness of the Vario terminal is

automatically adjusted.

Dimming can be adjusted steplesssly if

necessary.

Operation_Pic_number:1

Fig.18

Text-module

It is set in the third main menu

● Press key F4.

Following sub-menu for terminal settings appe-

ars.

Operation_Pic_number:1

Fig.19

● Rotary control (P1) for setting degree of dimming.

Bar indicators:

right = no dimming.

left = max. dimming.

Any setting between the two positions is possible.

Text-module

Pressing keys (F1 - F5) gives access to the following functions.

F1 = No function.

F2 = Service function (LBS-ISO) for the work-

shop.

F3 = Service function for the workshop.

F4 = No function.

F5 = LBS-ISO (optional).

Press ESC key

● Display returns to first main menu.

25

Page 26

OPERATION

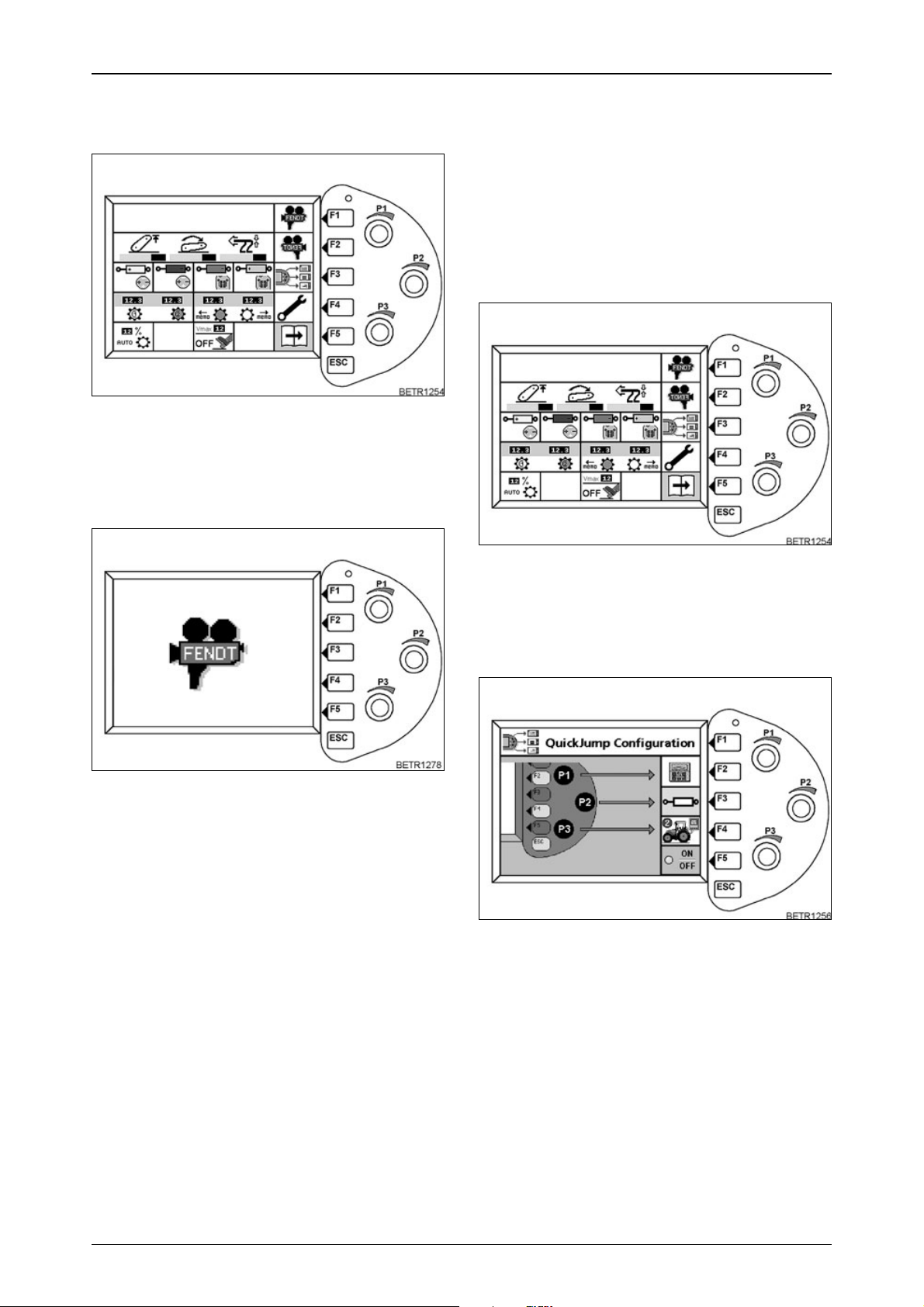

2.14 Camera function

Text-module

(optional).

Operation_Pic_number:1

Fig.20

● Press the F1 or F2 key.

Following sub-menu for terminal settings appe-

ars.

Operation_Pic_number:1

2.15 Quick Jump

Text-module

This function allows a preset menu page to be

selected directly from the first menu level.

Turning the rotary control (P1 - P3) slightly, selects the preset menu page.

Press ESC key

● Display returns to first main menu.

Selecting menu pages

Operation_Pic_number:1

Fig.21

Text-module

Press the ESC key twice.

● Toggles between main, implement and camera menus.

Setting brightness and contrast.

● Brightness can be set with the rotary control

(P1).

● Contrast can be set with the rotary control

(P2).

Fig.22

● Press F3 key.

Following sub-menu for terminal settings appe-

ars.

Operation_Pic_number:1

Fig.23

● Choose the desired menu page with the F2 F4 keys.

Press key repeatedly until the desired menu

page appears.

● Switch function on and off with the F5 key.

● LED lights up green - function is on.

Text-module

26

Page 27

OPERATION

Selection of the jump menu items

The jump menu items that can be selected, depend on the tractor equipment, e.g. if no front

power lift is fitted, this jump menu item is not

shown in the selection list.

Front power lift

Rear power lift

Rear power lift settings

Rear power lift settings, slip control

Overview of electrical valves

On-board computer 1- 4

Load implement settings

Only possible if Teach In and the

automatic modes for the power lift and

PTO are not active.

Save implement settings

Only possible if Teach In and the

automatic modes for the power lift and

PTO are not active.

Implement control

Only possible if implement being

installed.

Teach-in

Camera

Electrical valves 1-4

Cruise control, load limit control

Quick reverse

Engine speed min. - max.

Fuel consumption indicator

Camera image mirrored

Terminal settings

Implement control diagnostics

Tractor diagnostics 1

Tractor diagnostics 2

On-board computer overview

TMS settings

Page with speeds

27

Page 28

OPERATION

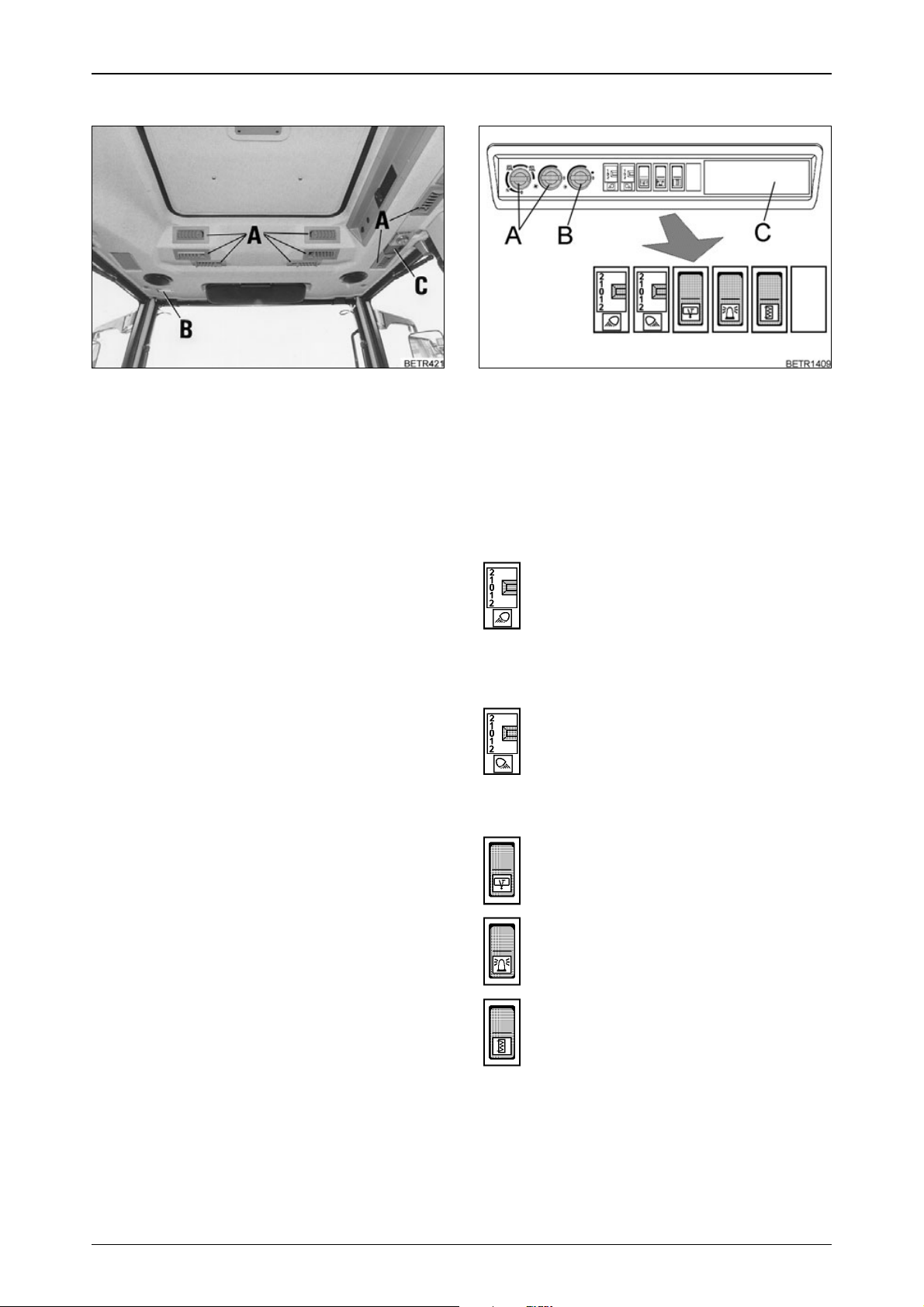

2.16 Cab top section, front

Operation_Pic_number:1

Fig.24

Text-module

A = Adjustable air nozzles

B = Cab lighting

C = Right-hand console lights

2.17 Cab top right side

Operation_Pic_number:1

Fig.25

Text-module

A = Auxiliary ventilation (see also OPERA-

TION Section 3.2).

B = Air conditioning ON/OFF and tempera-

ture control switch (see also OPERATION Section 3.3).

C = Space for radio installation, blanking pa-

nel. Connectors behind the panel are fitted as standard.

Work lamps at the front and at mirror

brackets:

2 = front and at mirror bracket.

1 = front.

0 = off.

1 = on rear view mirror bracket.

2 = front and at mirror bracket.

Working lights at the rear and on

mudguard:

2 = at rear and on mudguard.

1 = rear.

0 = off.

1 = on mudguard.

2 = at rear and on mudguard.

Rear window wiper and washing system.

Warning beacon.

Heated rear windshield.

28

Page 29

OPERATION

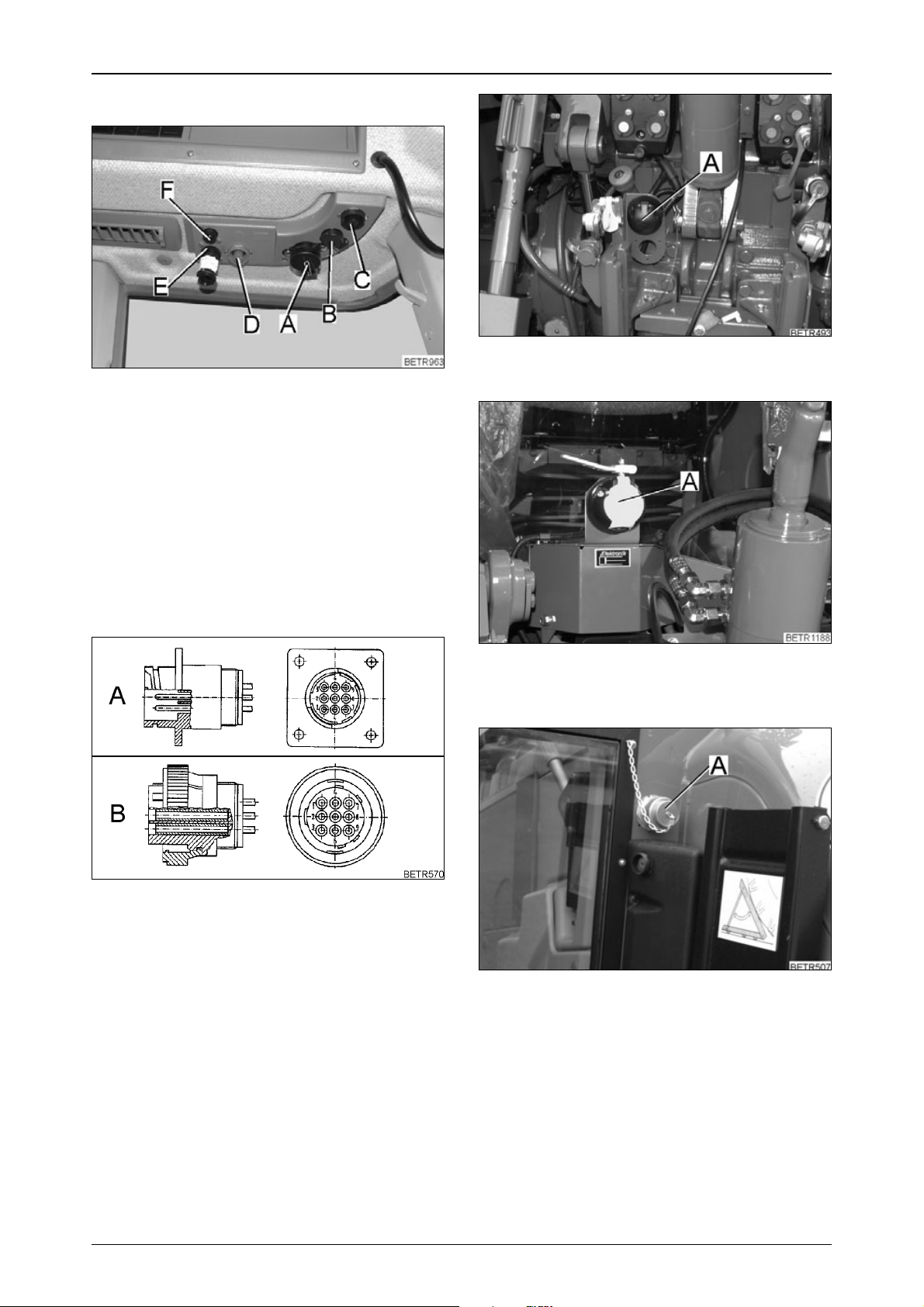

2.18 Power outlets

Operation_Pic_number:1

Fig.26

Text-module

A = 25 A constant current socket.

B = 10 A socket.

C = Implement socket.

D = Socket (blue) for external pulse counter .

E = LBS-ISO socket (optional) short circuit

plug must remain in place due to feedback.

F = Camera socket (optional).

Operation_Pic_number:1

A = Trailer socket.

Operation_Pic_number:1

Fig.28

Pin - attribution LBS-ISO implement

socket cabin

Operation_Pic_number:1

Fig.27

A = Connector within cabin.

B = Connector for LBS-ISO Terminal.

Pin 1 = not used.

Pin 2 = CAN Low input.

Pin 3 = CAN Low output.

Pin 4 = CAN High input.

Pin 5 = CAN High output.

Pin 6 = CAN-EN.

Pin 7 = Power supply for connected implement

(maximum load 5A).

Pin 8 = CAN GND.

Pin 9 = Ground connection for connected imple-

ment.

Fig.29

A = Electro-hydraulic external control:

Operation_Pic_number:1

Socket for external sensor.

Fig.30

LBS-ISO socket (A) rear (optional).

29

Page 30

OPERATION

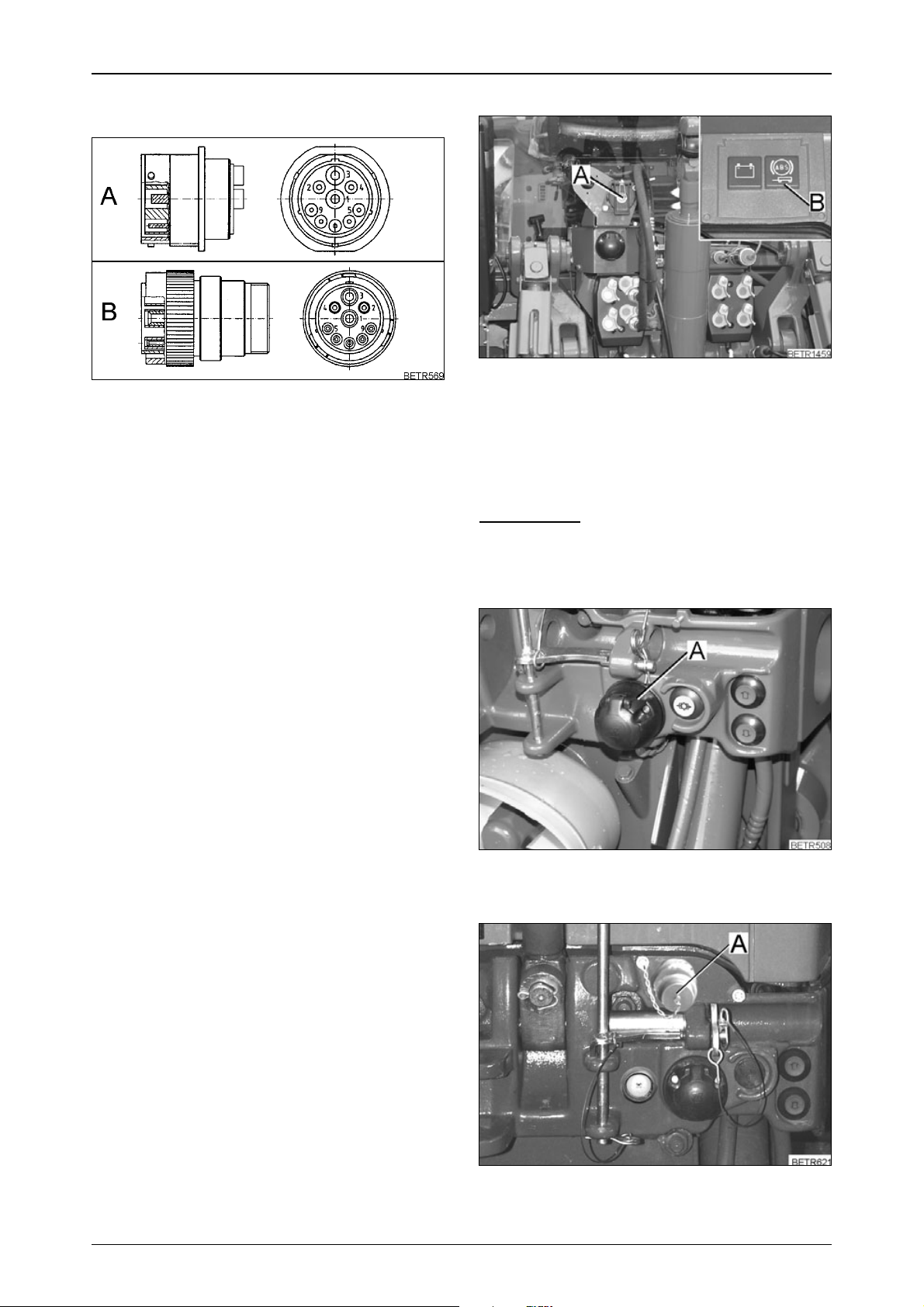

Pin - attribution LBS-ISO implement

socket rear and front

Operation_Pic_number:1

Fig.31

A = LBS-ISO socket for the mounted implement.

B = LBS-ISO connector for the mounted

implement.

Pin 1 = Earth 60A.

Pin 2 = Earth 25A.

Pin 3 = 60A power supply.

Pin 4 = 25A power supply for implement electro-

nics.

Pin 5 = Control signal for switching the end sy-

stem, bridged with pin 4 in the connector .

Pin 6 = CAN-EN.

Pin 7 = CAN GND.

Pin 8 = CAN High.

Pin 9 = CAN Low.

ABS socket (A)

Operation_Pic_number:1

Fig.32

1 = + UB 30

2 = + UB 15

3 = Earth electronics

4 = Earth tractor body

5 = Indicator lamp

IMPORTANT:

When turning the ignition ON or OFF, the indicator lamp (B) in the instrument panel must

light up briefly for monitoring purposes.

Operation_Pic_number:1

Fig.33

Socket (A) at front (with front power lift only).

Operation_Pic_number:1

Fig.34

LBS-ISO socket (A) front (optional).

30

Page 31

OPERATION

2.19 Reset function

Operation_Pic_number:1

Fig.35

Reset - initiate function.

● Press clutch pedal.

● Press push button (A).

To end Reset function.

● Stop the tractor.

● Switch ignition OFF/ON.

Text-module

When a reset is made, the following are restored to their basic settings.

● Cruise control (Memory 1 - final speed, Me-

mory 2 - 10 km/h).

● Load limit control (14% reduction to rated

speed).

● Valves (valid for all valves - lift 30 l, lower

30 l, time 10 seconds, floating position active).

● Rear lifting gear (upper limit 100% up, Trac-

tion/Position control 100% Position, lowering

speed 50%).

● Comfort front power lift (upper limit of tra-

vel 100% up, lifting speed 30 l, lowering

speed 5 l).

3. Heating and ventilation

3.1 Heater with 3-speed blower

Operation_Pic_number:1

Fig.36

The heating depends on the water temperature.

Switch on fan (control knob A).

Fan off.

Fan speed 1.

Blower speed 2.

Blower speed 3.

Directing the air stream (control knob C).

Air outlet nozzles closed.

through air vents in the footwell.

through air vents in the footwell and in

front of the windscreen.

through air outlet nozzles in front of

windshield, recirculated air mode on at the

same time.

Text-module

Switching on the heater (control knob B).

The control knob is ued to switch the cab heating

on/off, and for stepless adjustment to the desired

temperature.

NOTE:

If operating the air conditioning, set all control knobs to '0'.

31

Page 32

OPERATION

3.2 Auxiliary ventilation in cab

roof

Text-module

CAUTION:

When using the tractor for spraying

operations (e.g. weed or pest

control), fit filter cartridge

(aerosols). Use only fan speed 1.

After each spraying operation,

replace the filter cartridge with a

normal cartridge. Follow the

instructions given with the filter . Cab

and filter do not guarantee 100%

protection against harmful

chemicals. Follow the

manufacturer's instructions!

Operation_Pic_number:1

3.3 Air conditioning

WARNING:

All repair and maintenance work

must be carried out by qualified

personnel only.

Avoid all contact with liquid coolant.

If accidentally splashed in the eyes,

seek medical advice immediately.

No welding should be carried out on

or near any parts of the air

conditioning systems! Risk of

poisoning!

Maximum ambient temperature for

coolant 80 °C.

Check the V-belt only while the

engine is stopped. Attach the

protective grille again.

Operation_Pic_number:1

Fig.37

Text-module

Recirculated air/fresh air (A)

MIN = 100% recirculated air - 0% fresh air.

MAX = 0% recirculated air - 100% fresh air.

N = Normal setting approx. 80% recircu-

lated air - 20% fresh air.

0 = No fresh air.

The control knob position determines the mix

between recirculated and fresh air.

Text-module

Blower (B)

MIN = Minimum blower output.

MAX = Maximum blower output.

0 = Fan off.

Depending on the selector position, the blower

output can be increased steplessly.

Fig.38

● Start engine tractor (air conditioning only

works with the engine running).

● Switch on blower with selector (A).

● Switch on air conditioning with selector (B).

Indicator lamp (C) shows that the system is

working.

Text-module

The air flow is controlled by and directed through

nozzles (in cab roof cladding).

MIN = Minimum blower output, cooling

power.

MAX = Maximum blower output, cooling

power.

0 = Blower / air conditioning OFF.

Depending on the selector position, the blower

output and cooling power can be increased steplessly.

NOTE:

For health reasons it is advisable not to allow

the air inside the cab to drop by more than approx. 5 - 8 °C below the outside temperature.

Do not expose yourself directly to cold

draughts - danger of catching cold! For

energy economy and greater efficiency, we

recommend using the recriculated air mode.

32

Page 33

OPERATION

4. Rearwiew mirror

CAUTION:

Before driving the tractor and

starting work, adjust the mirror to

guarantee a clear view of the road

and of the working area to the rear.

Pull-out rearview mirror

Operation_Pic_number:1

Fig.39

● Adjust to tractor and/or trailer width using

screw (arrowed).

5. Start-up

5.1 Daily check

Text-module

Tractor must be in proper working condition.

Operation_Pic_number:1

Fig.40

● Check fuel level. If necessary , top up through

filler neck (A).

T op up with fuel after the day's operation to avoid

build-up of condensation. If it has run dry, bleed

the system.

● Check engine oil level (see also CARE AND

MAINTENANCE Section 3.4).

● Check transmission oil level (see also CARE

AND MAINTENANCE Section 10.2).

● Drain the water from compressed air bottle

(see also OPERATION Section 22.1).

33

Page 34

OPERATION

5.2 Cold weather operation

Text-module

Keep battery well charged; fill with winter fuel. At

temperatures below -12°C, add flow improver or

up to 30% petroleum.

Top up engine oil with HD-SAE 10W;

Antifreeze in coolant 35 - 50 vol.-%.

Engine warmer

(optional).

Operation_Pic_number:1

6. Starting and stopping

the engine

DANGER:

Start the engine from the driver seat

only. Never short circuit the battery.

Never leave the engine running in a

confined space!

Do not use priming fuel (e.g.

Startpilot)!

6.1 Memory function

● Start tractor.

● The following image appears.

Tractor in neutral position

(stationary)

Operation_Pic_number:1

Fig.41

● Connect engine warmer to mains supply

(220 V) using the cable supplied.

Warming time at least 3 hours, depending on

outside temperature. Preheating is only necessary in extreme cases.

Text-module

Compressed air system

● Open the antifreeze pump (see also OPERATION Section 22.1).

5.3 Tool box

Operation_Pic_number:1

Fig.43

Key F4 = Activate selected settings (see OPE-

RATION Section 28.1).

Key F5 = Activate the base settings.

If no key is activated, after about 10 seconds the

tractor's base settings are activated.

Fig.42

Removable tool box (A).

34

Page 35

OPERATION

Tractor in driving mode

If the tractor moves off immediately after it is

started, the following picture appears.

Operation_Pic_number:1

Fig.44

The selected settings (see OPERATION

Section 28.1) can not be activated.

Key F5 = Main menu appears.

The main menu appears automatically after

about 10 seconds.

6.2 Starting the engine

IMPORTANT:

Do not start or operate the tractor without a

battery. This could destroy the alternator.

Pay attention to warnings and fault messages. If necessary, switch off the engine immediately.

● Apply the hand brake.

● Depress clutch pedal (starting inhibit is deac-

tivated).

● Switch off PTOs and other drives.

● Electrical operating Switch off all consumers

if possible.

Operation_Pic_number:1

Text-module

or

The selected settings (see OPERATION

Section 28.1) should be activated.

Bring tractor to a standstill and press the neutral

button, further operation (see OPERATION

Fig. 43).

Fig.45

● Turn ignition key to position I, following symbols are illuminated:

● The LED neutral switch on the multi-function

joystick.

Charge indicator lamps.

Driving direction indicators.

Wait until preheat indicator flashes.

Steady light indicates preheating time.

● Turn ignition key to II and once the engine

has started, move it back to I.

● Battery charge indicator lamps must go out.

NOTE:

If at very low temperatures the engine does

not start within about 20 seconds, abort the

starting procedure, allow the starter to cool

down and wait for about 1 minute before trying again.

Switch off ignition before attempting to start

again.

Allow starter to cool down. Do not operate the

starter while the engine is still turning. In the

event of repeatedly unsuccessful starting attempts, refer to 'F AUL TS AND REMEDIAL ACTION'.

To avoid unnecessary white smoke, operate

the tractor at 1,000 rpm maximum for up to

5 minutes (depending on temperature). (Can

be driven with no load).

35

Page 36

OPERATION

NOTE:

The flame start control unit detects faults in

the flame starting system; these faults are indicated through various flash codes displayed on the preheating indicator (see

FAULTS AND REMEDIAL ACTIONS

Section 4.1).

6.3 Jump starting

WARNING:

A 24 V olt current destroys electronic

components.

Do not allow contact between the

non-insulated parts of the battery

clamps. The jump lead connected to

the positive terminal should not

come into contact with any

electrically conductive parts of the

vehicle - danger of shorting!

To avoid sparks, always attach the

jump lead clamps in the correct

order.

Use jump leads to connect positive terminal to

positive terminal and negative terminal to

negative terminal of the assisting battery.

Operation_Pic_number:1

Jump starting a partially discharged battery

with another battery.

● Connect jump leads to the assisting battery in

sequence (1-4).

● Start engine immediately.

● Once the engine is running, disconnect the

cables in reverse order.

If the attempt is unsuccessful.

● Connect jump leads to two assisting batteries

in sequence (1-8).

● Start engine immediately.

● Once the engine is running, disconnect the

cables in reverse order.

Text-module

NOTE:

Assisting batteries must have a voltage of

12 volts and around the same capacity (Ah)

as the discharged batteries.

When jump starting, the engine must be

started immediately after connecting, otherwise the assisting battery will become discharged as well.

Do not reverse the terminal polarity.

Use only jump leads with sufficient crosssection, and with insulated clamps.

Do not disconnect a discharged battery from

the on-board electrical system.

If the tractor is left unused for an extended

period, the battery can be recharged with a

battery charger (12V).

Fig.46

When battery partially discharged, jump starting from another tractor.

● Connect jump leads to the discharging tractor's battery in sequence (1-4).

● Start the engine of the second tractor.

● Start engine after ca. 15 minutes.

● Once the engine is running, disconnect the

cables in reverse order.

36

Page 37

OPERATION

6.4 Tow-starting

WARNING:

Tow-starting is not possible!

6.5 Stopping the engine

● Turn ignition key to position 0.

Text-module

NOTE:

After operating at full load, do not stop the engine immediately but allow it to cool down for

about 2 minutes at about 1000 rpm.

6.6 Stopping and immobilising

the tractor

WARNING:

Before leaving the tractor, apply the

hand brake, stop the engine, lower

hydraulic implements to the ground

and remove the ignition key. Make

sure the tractor is secured to

prevent it rolling. On slopes, chock

the wheels. If the tractor is left on a

public road, switch on the hazard

warning lights and place the hazard

warning triangle.

Hazard warning triangle

Operation_Pic_number:1

7. Vario transmission

7.1 Joystick

Operation_Pic_number:1

Fig.48

Text-module

A = Setting forward transmission ratio.

B = Setting reverse transmission ratio.

C = Change of direction of travel (forward/re-

verse using the joystick).

D = Tempomat cruise control ON.

7.2 Neutral position

WARNING:

Before leaving the tractor , make sure

the transmission is set in neutral

and engage parking brake.

If the engine is started or hand brake is applied,

the transmission shifts to Neutral position.

Operation_Pic_number:1

Fig.47

The hazard warning triangle (A) is attached

behind the driver seat (hazard warning triangle

not included as standard).

We would recommend ordering the warning

triangle from:

GEKA GmbH Germany 73054 Eislingen / Fils

Schloßstraße 97

Tel. 0049 7161/99903-0

Fax 0049 7161/99903-99

Fig.49

Text-module

● The transmission is neutralised or activated

with the neutral button (N).

Indicators with Neutral position selected.

1.LED (N1) lights up.

2.Travel direction indicator lamps (C) flash.

3.Clock and operating hours (D) indicators on

the multiple display.

37

Page 38

OPERATION

ETNum-list

Indicators when Neutral position is

disengaged.

1.LED (N1) is not lit.

2.Direction of travel indicator (C) are lit.

3.ACTIVE symbol indicator (E) on the multiple

display.

4.Warning light (F) flashes.

ETNum-list

7.3 Selecting acceleration rates

Operation_Pic_number:1

Setting acceleration rate I

Operation_Pic_number:1

Fig.51

Text-module

Procedure:

Press key, graphic (K) is displayed.

Press one of the keys repeatedly until

symbol (X) flashes.

Press key, graphic (W) is displayed, speed

is indicated in km/h.

Press one of keys repeatedly until the

desired value is displayed.

The indicated value is immediately

effective, press ESC to store the value.

Fig.50

Text-module

● Using the switch (arrowed), four different ac-

celeration rates can be selected, even while

moving.

With steady actuating of the joystick in one direction and at steady engine speed, driving speed

increases slowest in Rate I and fastest in Rate

IV.

In Rate I, the rate of change of speed can be set

at between 0.02 km/h and 0.5 km/h using the

keypad on the dashboard (at rated engine

speed).

The following table shows the change of speed if

the joystick is pressed once, and the time to reach maximum speed if the joystick is pressed

steadily, for the 4 acceleration rates.

Rate One push 0 to 50 km/h

I 0.02 - 0.5 km/h 250-45.5 secs

II 0.5 km/h 45.5 secs

III 1 km/h 23.8 secs

IV 2 km/h 10 secs

Values at engine rated speed.

Text-module

Press key repeatedly until clock and

operating hours are shown on the multiple

display.

Text-module

NOTE:

The acceleration rate cannot be set when

neutral position is switched off.

Text-module

Recommended use

Rate I = Use for specialist operations, e.g. ro-

ad-milling machine.

Rate II = Use in field work, heavy traction

work.

Rate III = Use in field work, heavy traction

work.

Rate IV = Use for transport operations.

NOTE:

When the cruise control is on, the time to reach the stored speed depends on the acceleration rate selected. Position I is not programmable.

38

Page 39

OPERATION

7.4 Driving mode selector

WARNING:

When selecting driving mode,

tractive power is interrupted. Do not

use on slopes (uphill or downhill).

Operation_Pic_number:1

Fig.52

The currently selected mode is indicated by a

spot (A). The selected mode is indicated by a

flashing spot.

Text-module

● The driver can use button (M) to switch from

range I to range II.

NOTE:

The last range selected is always set, even after turning the ignition on or off.

Text-module

Switching when tractor stationary

● Select Neutral position or

● operate clutch pedal.

● Select the desired mode.

Text-module

Selecting driving mode I or II while

travelling

Driving mode selection is not possible if:

● Neutral position is engaged.

● Transmission oil temperature below 10°C.

● Engine brake actuated.

Text-module

Switching from operating range II to I

when travelling

Driving mode selection is not possible if:

● Ground speed over 20 km/h.

● Neutral position is engaged.

● Engine speed over 2300 rpm.

● Transmission oil temperature below 10°C.

● Engine brake actuated.

NOTE:

In unfavourable conditions, e.g. cold weather ,

selecting a driving mode may simply cause

the neutral position to be selected. Interruption of tractive power, repeat driving mode

selection with button (M/ OPERATION

Fig. 52).

Cruise control and Quick Reverse function

deactivated.

RANGE I (field)

For heavy field use at a speed of:

0.02 - 32 km/h forward.

0.02 - 20 km/h in reverse.

Text-module

RANGE II (road)

For fast transport at speeds of:

0.02 - 50 km/h forward.

0.02 - 38 km/h in reverse.

Text-module

39

Page 40

OPERATION

7.5 Driving the tractor

WARNING:

Always engage the gears when

travelling downhill. Do not select

neutral.

At engine speeds over 2600 rpm, the

transmission ratio is no longer

reduced; to reduce speed, apply the

brake.

Operation_Pic_number:1

Turboclutch

The transmission control includes a turboclutch

function. This allows the tractor to be stopped

with the accelerator pedal.

This means:

1.No engine stalling under difficult conditions.

2.No wheel spinning.

3.Full power transmission from approx.

1,250 rpm engine speed.

ETNum-list

Deactivating turboclutch function

Operation_Pic_number:1

Fig.53

Text-module

Starting off forward from a standstill:

● Press and hold the activating button (C, on

back of joystick).

● If the joystick is moved forward, the tractor

moves off and accelerates forward.

● If the joystick is released, it automatically returns to center position and speed remains

constant.

● If the joystick is pulled back, the tractor slows

down and braking is applied until it comes to

an actuated standstill.

Text-module

Reversing from a standstill:

● Press and hold the activating button (C, on

back of joystick).

● If the joystick is pulled back, the tractor will

move off in reverse and accelerate.

● If the joystick is released, it automatically returns to center position and speed remains

constant.

● If the joystick is moved forward while reversing, the tractor slows down and is positively

braked until it comes to a standstill.

Text-module

NOTE:

It is also possible to operate the joystick first,

then press the activating button afterwards.

NOTE:

Optionally, a warning beep sounds when driving in reverse.

Text-module

Fig.54

● Press key (F4). The following sub-menu appears.

Operation_Pic_number:1

Fig.55

Required conditions:

1.Engine is running.

2.No current fault messages.

3.Transmission in neutral.

4.System not in emergency operation.

ETNum-list

● Pressing key (F2) switches turboclutch

function on and off.

When the function is on, symbol (A) appears as

shown, when the function is off, the symbol is

shown with a red cross superimposed.

After every cold start, the turboclutch function is

automatically activated again.

Text-module

40

Page 41

OPERATION

Driving off using the turboclutch

function

● Setting the engine idle speed.

● Apply the brake.

● Press activating button and use the joystick to

select the desired direction of travel.

● Release the brake and start off by accelerating slightly.

● Use the joystick to obtain the desired ground

speed.

NOTE:

Avoid stopping for long periods (>1 min.) with

the turboclutch on.

When operating with sustained load, do not

allow the engine speed to drop below

1,250 rpm.

Do not operate the clutch pedal for long periods.

Text-module

Stopping and starting on slopes

● Move joystick against the actual travel direction.

The tractor slows down until it comes to a standstill. 'Active' symbol flashes.

NOTE:

Below an engine speed of 1,250 rpm, depending on load, turbo clutch function will allow

transmission slip.

Text-module

Clutch pedal

For connecting implements, the tractor can be

controlled for gradual movements with the clutch

pedal.

In sudden emergencies, the tractor can be stopped by pressing the clutch and brake pedals.

Text-module

Final speed control

Final speed is a cruise control function which

compensates for variations in engine speed.

TEA

about 33 km/h 32.5 km/h 31 km/h

about 44 km/h 43.5 km/h 42 km/h

about 51 km/h 50.5 km/h 49 km/h

T = Theoretical final speed

E = Switch-on speed

A = Cut-out speed

The speed control is terminated by operating

any of the following:

1.Joystick

2.Brake pedals (including independent wheel

brake)

3.Engine brake pedal

4.Clutch pedal

ETNum-list

41

Page 42

OPERATION

7.6 Changing direction of travel

The tractor slows to a standstill, then accelerates

in the desired direction until the previous transmission ratio is reached.

The change of direction may be activated by:

- with the button on the steering wheel adjustment.

- with the joystick.

Text-module

Direction changing is cancelled when the

following are operated:

1.Joystick.

2.Neutral button.

ETNum-list

The following factors will block the function,

but not terminate it:

1.Load limit control.

2.Final speed limit.

3.Engine speed above 2,600 rpm.

4.Turboclutch function.

ETNum-list

IMPORTANT: