Page 1

FAULTS AND REMEDIAL ACTIONS

1. Warning and fault messages

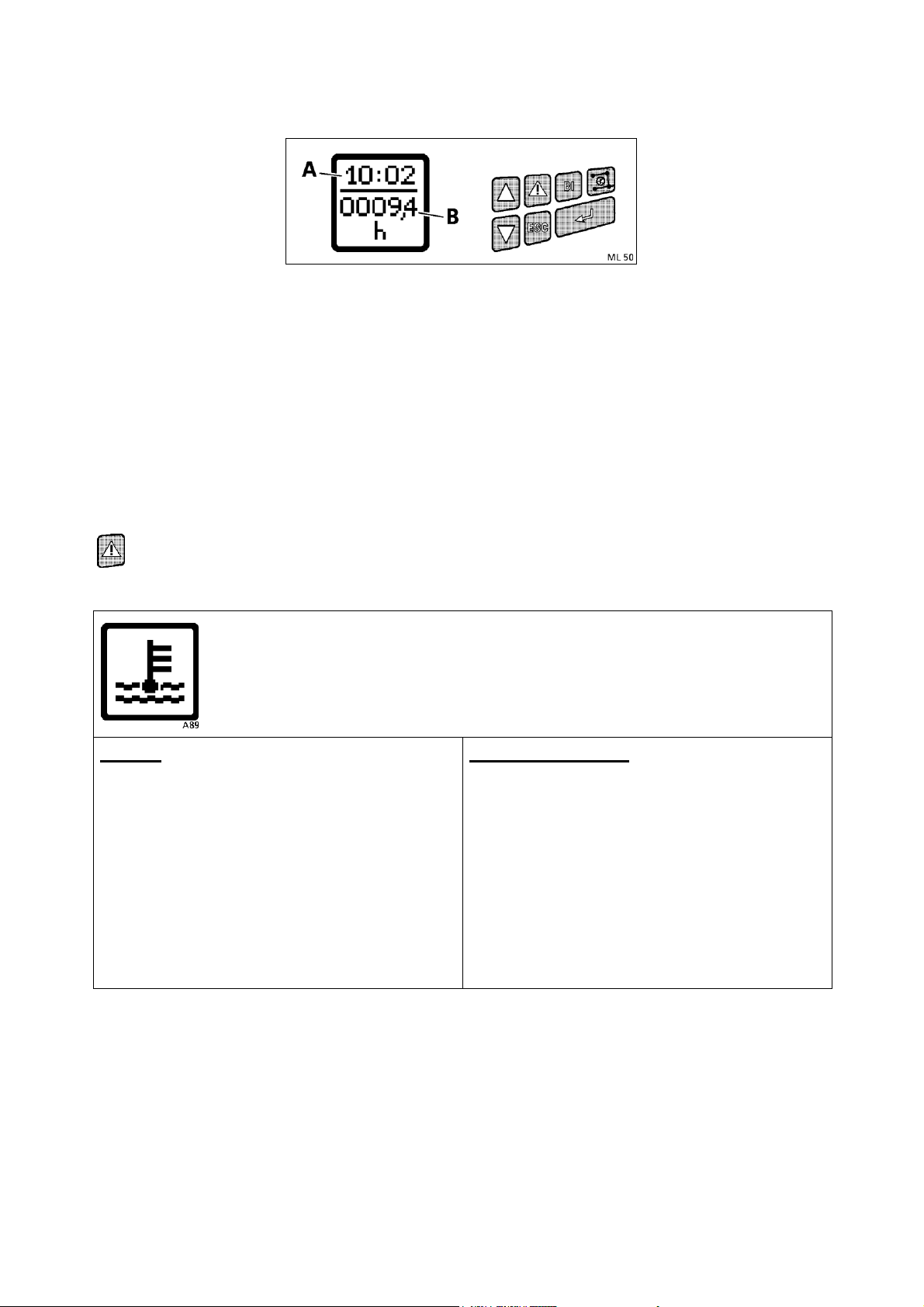

Fig.1

Warning and fault messages are indicated on the multiple display. The warning lamp also flashes and

a warning tone is sounded.

Fault codes are stored and can be called up for more accurate definition of the fault. These codes are

memorised to be called up in the workshop for rapid fault location.

In normal status, display shows the clock (A) and the number of operating hours (B).

1.1

Warning messages

No fault code, no storage.

Calling up several concurrently existing warnings

Press the button to show the symbols for existing warning messages one after the other. If the

button is not pressed for 3 seconds, the symbol for the warning message indicated first

reappears.

1. Engine temperature

Display accompanied by a continuous beep and warning light.

Unload the engine immediately, then switch off.

Cause

Remedial Action

Clogged radiator fins.

Blow or spray fin from inside to outside.

Not enough cooling water.

Top up with warm water while the engine is

running.

V-belt is loose or torn.

Re-tension or change the belt.

Thermostat does not open.

Replace thermostat (workshop task).

Coolant circuit dirty.

Clean out the inside of the system with hot

flushing liquid, e.g. P3 (at workshop).

Viscous fan faulty.

Replace viscous fan (at workshop).

Page 2

FAULTS AND REMEDIAL ACTIONS

2. Engine oil pressure

Display accompanied by a continuous beep and warning light.

Switch off engine immediately.

Check the oil level.

Cause

Engine oil pressure too low as a result of

insufficient or excessively thin oil.

Oil control valve in filter head dirty.

Remedial Action

Top up engine oil or fill with correct oil.

Clean oil control valve (workshop task).

3. Charge air temperature

Display accompanied by a continuous beep and warning light.

Unload the engine immediately, then switch off.

Cause

Remedial Action

Charge air dirty.

Check charge air cooler, and clean if necessary.

Cracked V-belt.

Replace V-belt.

Viscous fan faulty.

Replace viscous fan (at workshop).

4. Hydraulic oil temperature

Display accompanied by a continuous beep and warning light.

Relieve the hydraulic system of load and switch off the engine.

Cause

When carrying out hydraulic operations, the control valve does not engage in 'Neutral'.

Three-point implement is non-standard / lateral

support set too narrow.

Three-point implement too heavy / overpressure

valve continuously activated in upper limit

position of power lift.

Insufficient oil suply for the operation concerned.

Final shutoff incorrectly adjusted.

Remedial Action

Set control valve to "Neutral" and lock / have fault

corrected at workshop.

Adapt three-point implement to standard /

change side support. If necessary make lifting

struts longer, if lifting height is sufficient.

Connect upper link to a different point on the

implement; measure pressure during the lifting

process (at workshop).

Check and top up oil level.

Re-adjust final shutoff (at workshop).

Display accompanied by a continuous beep and warning light.

Hydraulic tank could be empty.

Flow rate is limited to 10 l/min for all valves.

Page 3

FAULTS AND REMEDIAL ACTIONS

6. Contaminated transmission oil filter

Display accompanied by warning light.

Note: Change the cartridge as soon as the display appears. The display may go out

again, still change the cartridge.

Cause

Contaminated hydraulic oil filter element.

Remedial Action

Replace filter unit.

7. Excessive transmission oil temperature (95 - only in range II)

Cause

Heavy traction work over extended period in

range II.

Cooler soiled.

Turboclutch function active for too long.

Clutch pedal depressed for too long.

Remedial Action

Switch to driving mode I.

Clean the transmission oil cooler.

Increase engine speed (above 1400 rpm).

Release clutch pedal.

8. Transmission oil temperature too high (105)

Cause

Transmission oil too hot.

Cooler soiled.

Remedial Action

Allow transmission oil to cool down.

Clean the transmission oil cooler.

9. Oil level too low in brake and clutch system

Indication accompanied by intermittent audible signal and warning lamp.

Cause

Oil leakage.

Remedial Action

Check brake system for leaks. If necessary, fill up

with hydraulic oil (Pentosin CHF 11 S).

Page 4

FAULTS AND REMEDIAL ACTIONS

10. Contaminated air filter

Indication accompanied by intermittent audible signal and warning lamp.

Cause

Air filter main cartridge dirty.

Remedial Action

Check air filter main cartridge. If necessary, clean

or replace the air filter main cartridge.

11. Instrument cluster memory

Display accompanied by a continuous beep and warning light.

Cause

Invalid programming of combination instrument.

Remedial Action

Re-programme (at workshop).

12. Hand brake on

Indication accompanied by intermittent audible signal and warning lamp.

Note: only when tractor moving.

Cause

Hand brake applied.

Remedial Action

Release parking brake.

13. Engine speed too high

Indication accompanied by intermittent audible signal and warning lamp.

Cause

Engine speed too high.

Remedial Action

Reduce engine speed.

14. Rear PTO on neutral

Display accompanied by warning light.

Cause

PTO speed not preselected.

Remedial Action

Pre-select PTO speed.

Page 5

FAULTS AND REMEDIAL ACTIONS

15. Engine speed below 500 rpm and turboclutch function

switched off

Indication accompanied by intermittent audible signal and warning lamp.

Cause

Engine speed too low.

Remedial Action

Increase engine speed.

16. Front /rear PTO overspeed

Display accompanied by warning light.

Cause

Remedial Action

In PTO stage 1000, from 1170 rpm.

Reduce PTO speed.

In PTO stage 540E as of 630 rpm.

Reduce PTO speed.

In rear PTO 540 setting, from 630 rpm.

Reduce PTO speed.

17. Valve prioritisation

Display accompanied by warning light.

Cause

Remedial Action

Prioritised valve is requiring more oil than the

pump can provide.

Valve priority is deactivated temporarily until the

pump is able to provide the required quantity

again.

18. Driving mode selector

Indicator goes off after about 3 seconds.

Cause

Range control oil too cold.

Remedial Action

Repeat operating range selection at oil temperatures above 10C or shift while at a standstill.

19. Variotronic Ti

Cause

Engine speed below 400 rpm when playback is

started.

Remedial Action

Increase engine speed. Start playback again.

Page 6

210

FAULTS AND REMEDIAL ACTIONS

21. Variotronic Ti

Cause

Ground speed too low when playback started.

Remedial Action

Increase the ground speed. Start playback again.

22. Variotronic Ti

Cause

Speed greater than 25 km/h when a playback

process starts.

Remedial Action

Reduce speed of travel. Start playback process

again.

23. Seat switch

Cause

Remedial Action

Driver seat empty for more than 3 seconds.

Sit on the driver seat.

If the Tractor Management System (TMS) is

active, engine speed is reduced.

In accelerator pedal mode, the direction of travel

must be actuated again while the tractor is

actively stopped.

Playback of Variotronic Ti functions must be

started again.

Repeat driving mode selection.

Page 7

211

1.2

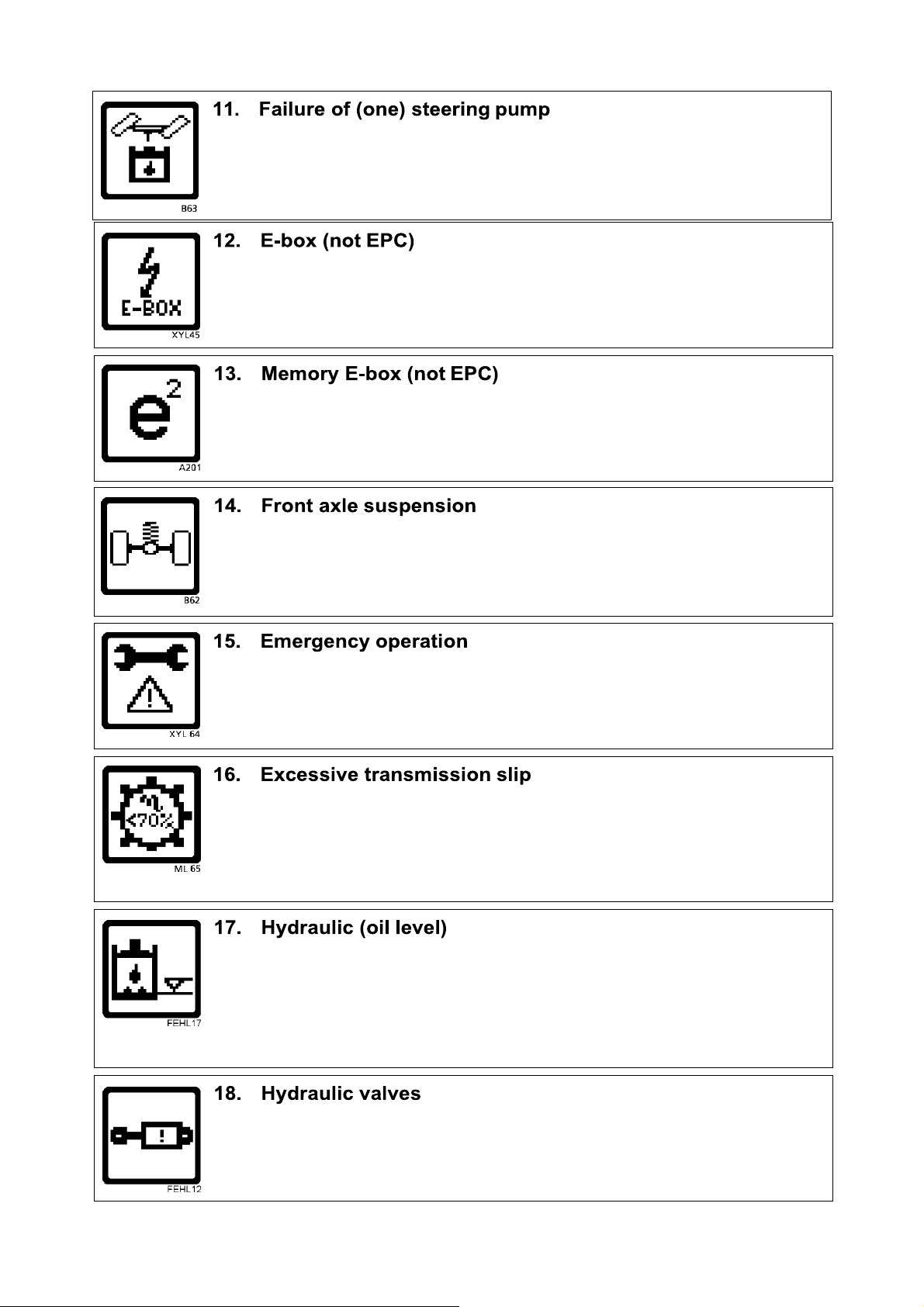

Fault messages

FAULTS AND REMEDIAL ACTIONS

Indication accompanied by intermittent audible signal and warning lamp.

Fault codes are stored and can be called up for more accurate definition of the fault. These codes are

memorised to be called up in the workshop for rapid fault location.

In the event of a fault message, proceed as follows:

● Make the system operative by turning ignition off-on (reset).

● If it was a temporary fault, the system is operative again.

If the fault is displayed again:

● Call up fault code and refer to the code table for what measures to take.

Reading out a fault code

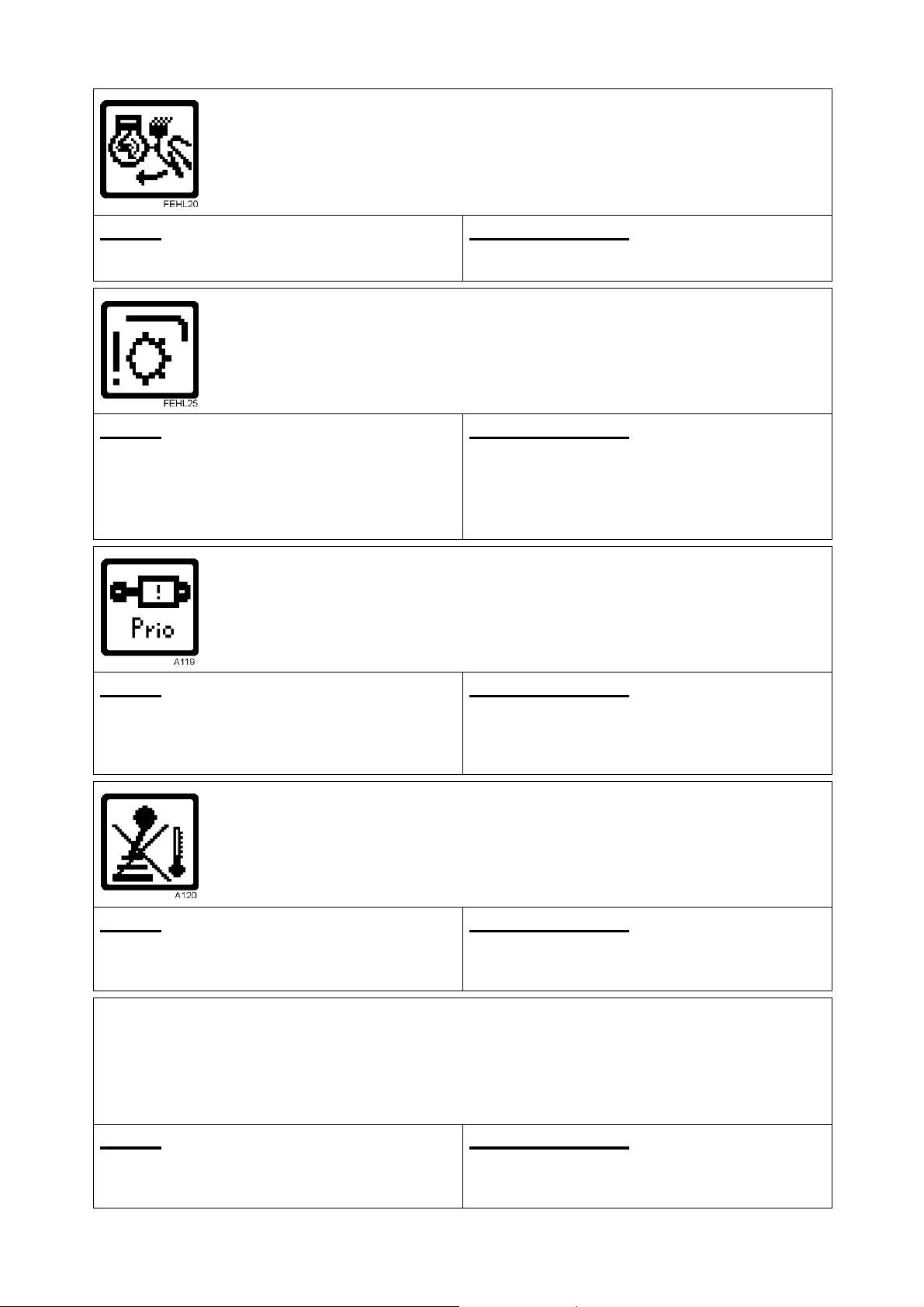

Fig.2

Press button, fault code (B) is shown on the multiple display.

Showing more than one fault message at the same time

If the button is pressed repeatedly, the symbols for all existing faults are displayed one after the

other, then symbol (A), code (B), next symbol, next code, and so on. If the button is not pressed

for 3 sec., the symbol for the first fault displayed appears again.

Try activating with alternate key.

Switching on may no longer be possible.

Try activating with alternate key.

Switching off may no longer be possible.

Page 8

212

FAULTS AND REMEDIAL ACTIONS

Move Quick Lift switch fully or turn ignition off and on again.

Move Quick Lift switch fully or turn ignition off and on again.

Rear/front automatic mode on/off switch faulty.

Automatic mode stop button faulty.

Call up fault code and refer to the code table for what measures to take.

No pressure, speed or volume monitoring.

It is essential to determine the cause of the fault immediately using the code table

(see FAULTS AND REMEDIAL ACTIONS Section 5).

Display accompanied by a continuous beep and warning light.

Electronic connections between components are faulty or cut. Other fault codes may

occur.

In the event of failure of the forward/reverse indicator lamps, the backup indicators

can be activated (see also OPERATION Section 26.5).

Try engaging with another button (5 seconds).

Page 9

213

FAULTS AND REMEDIAL ACTIONS

E-box hardware fault.

Replace corresponding E-box (at workshop).

E-box basic programming invalid

(reprogramming, workshop task).

No longer functioning.

Suspension remains in the last position selected.

Partial failure of the electronic monitoring system.

Use the emergency mode only to move the tractor out of potential danger or to drive

to the workshop.

Specified/actual transmission slip limit exceeded. This fault may occasionally occur

under extreme conditions (e.g. at very low gear oil temperature) even if transmission

is mechanically sound. If the problem persists in normal operating conditions, contact

the workshop immediately.

Hydraulic tank empty.

Valves, front power lift and rear EPC are locked.

Refill hydraulic oil or switch the valve to floating position manually, so that oil can flow

back out of the external cylinder (see also OPERATION Section 17.4).

Switch ignition OFF and ON (Reset).

Valve remains incorrectly positioned or goes into neutral.

Display accompanied by a continuous beep and warning light.

Steering pump or control pump failed. Reduce vehicle speed. Contact the workshop

immediately and have the fault corrected.

Page 10

214

FAULTS AND REMEDIAL ACTIONS

Hydraulic oil temperature too low.

Operate until the oil has warmed up and unlock the valve again.

After manual operation, the valves cannot only be operated again with the crossgate

lever or toggle switches after a Reset (engine OFF then ON).

Level of coolant too low.

Top up with coolant.

CAN bus communication restricted.

Impossible to control the mounted implement via Vario Terminal.

Check operating manual of the implement manufacturer or contact their service.

Relieve right or left draft sensing pin of load.

In accelerator pedal mode, the driving direction must be re-entered if the tractor is in

active stationary mode.

Variotronic Ti functions cannot be played back.

Valves cannot be actuated.

Page 11

215

FAULTS AND REMEDIAL ACTIONS

1.3

Clearing a warning or fault message

Press key and hold.

Then press button.

Each stored fault messages must be cleared individually. Clearing a fault message does not remove

the fault, it is simply no longer displayed.

If the fault is still present, it is indicated again the next time the tractor is started.

One or more functions faulty when activating the memory function.

Start tractor again, if the fault message is still there. Call workshop.

Restricted operation. Call workshop.

Call workshop.

Release activating key.

Accelerator mode is no longer possible.

Calibrate the driving mode selector.

One or more functions defective.

Variotronic Ti functions cannot be played back.

Page 12

216

FAULTS AND REMEDIAL ACTIONS

1.4

General faults

1. Engine does not start

Cause

Air in the fuel system.

Fuel system clogged with dirt.

In very cold conditions: failing cold-start system.

In winter, at temperatures under -5 C: fuel feed

blocked by ice or paraffin.

No starter contact / faulty starter unit.

No power supply to electric shut-off.

Remedial Action

Bleed air from the fuel system.

Clean the filter inlet. If necessary, change filter

box; vent system.

Flame heater system needs repair (in workshop).

Unblock filter duct and fuel filter. Use to winter-

grade fuel. Bleed air from system.

Main shift lever in neutral (starter lockout!).

Check power connection of battery starter.

Check fuses and connectors.

2. Engine cuts out

Cause

Remedial Action

Air in the fuel system.

Bleed air from the fuel system.

Fuel system clogged with dirt.

Clean the filter inlet. If necessary, replace filter

element.

Bleed air from system.

In winter, at temperatures under -5 C: fuel feed

blocked by ice or paraffin.

Unblock filter duct and fuel filter. Use to winter-

grade fuel. Bleed air from system.

3. Poor engine performance

Cause

Fuel filter soiled.

Fuel delivery pump dirty.

Engine brake is not fully open.

Turbocharger: leaky intake system / charger

damaged.

Remedial Action

Replace filter box. Bleed air from the fuel system.

Clean supply pump and bleed air from the

system (workshop task).

Check engine brake (setting and ease of opera-

tion).

Check intake and exhaust ducts / check

turbocharger (workshop task).

4. Engine produces a lot of smoke

Cause

Remedial Action

Injection nozzles not working properly.

Check pressure and spray pattern of nozzles (at

workshop).

Injection volume / start of delivery incorrectly set.

Adjust settings (at workshop).

5. Engine causes a lot of noise

Cause

Imbalance on fan shroud due to soiling.

Remedial Action

Clean the fan shroud.

Page 13

217

FAULTS AND REMEDIAL ACTIONS

6. Tractor does not start off

Cause

Actuator not functioning.

No operating range selected.

Adjustment not functioning.

Inlet circuit does not work.

Leak in the main circuit.

Internal leak in the main circuit.

High-pressure limiting valve does not shut.

Flush valve stuck open.

Transmission characteristic not programmed.

Rpm adjustment not set.

Remedial Action

Mechanical Auxiliary mode.

Select operating range I or II. Use auxiliary lever,

if necessary.

Measure servo pressure (too low).

Measure feed and outlet pressure.

Measure feed and outlet pressure.

Check transmission characteristic (at workshop).

Measure control pressure.

Start off in the other directon of travel

Record the transmission characteristic (at

workshop).

Set the rpm adjustment.

7. Transmission oil temperature too high

Cause

Cooler soiled.

Heavy traction in operating range II.

Clutch operated over extended period.

Turboclutch function active for long period.

Leak in the main circuit.

Leakage in feed circuit.

Leakage in outlet line.

High-pressure limiting valve does not shut.

Internal leak in the main circuit.

Remedial Action

Clean the radiator.

Switch to driving mode I.

Fully engage the clutch.

Increase engine speed.

Measure feed and outlet pressure.

Measure feed and outlet pressure.

Measure outlet pressure.

Measure control pressure.

Check transmission characteristic (at workshop).

8. Interruption of tractive power while reversing or during

acceleration-deceleration changes

Cause

Flush valve stuck open.

High-pressure limiting valve does not shut.

Remedial Action

Replace purge valve.

Replace high-pressure limiting valve.

9. Tractor no longer reaches maximum speed

Cause

Incorrect transmission calibration.

Adjustment does not function properly.

Leak in the main circuit.

Remedial Action

Record the transmission characteristic (at

workshop).

Measure servo pressure (too low).

Measure feed and outlet pressure.

Page 14

218

FAULTS AND REMEDIAL ACTIONS

9. Tractor no longer reaches maximum speed

Valve for mechanical speed limitation either

faulty or incorrectly set.

Fuel filter soiled.

Intercooler pressure too low.

Replace valve.

Replace filter box. Bleed air from the fuel system.

Check the charge air pressure.

10. Tractor does not pull

Cause

Feed quantity too flow.

Leak in the main circuit.

High-pressure limiting valve does not shut.

Flush valve stuck open.

Remedial Action

Measure feed and outlet pressure.

Measure feed and outlet pressure.

Measure control pressure.

Drive in opposite direction of travel.

11. System pressure too low

Cause

No feed for servo pump.

Servo pump does not deliver.

Leakage in pressure or suction line.

40 bar pressure limiting valve does not close.

18 bar pressure control valve does not close.

Leak in comfort circuit.

Remedial Action

Check lubricating pressure.

Check servo pump pressure.

Check oil level in clutch housing (too high).

Measure servo pump pressure (= lubrication

pressure).

Measure feed pressure (= system pressure).

Measure feed pressure, visual check.

12. Inlet pressure too low

Cause

No feed for servo pump.

Servo pressure less than 18 bar.

Leak in comfort circuit.

Leak in feed line.

Leak in outlet line.

Hydrostatic drive leaks or lifts off.

High-pressure valve is loose.

Output pressure control valve does not shut.

Input pressure control valve does not shut.

Remedial Action

Check lubricating pressure (= 0)

Measure servo pressure.

Measure servo pressure, visual check.

Measure output pressure (too low).

Measure output pressure (too low).

Measure output pressure (too low).

Measure output pressure (too low).

Measure output pressure (too low).

Measure output pressure (= input pressure).

13. Output pressure too low

Cause

Remedial Action

Input pressure too low.

Measure input pressure (too low).

Leak in outlet line.

Measure input pressure (under load too low,

without load OK).

Page 15

219

FAULTS AND REMEDIAL ACTIONS

13. Output pressure too low

Hydrostatic unit leaks.

High-pressure valve is loose.

Outlet pressure limiting valve does not close.

Measure input pressure (too low).

Measure feed pressure (too low), tighten.

Output pressure = pre-cooler flow pressure.

14. Battery charge indicator lamp lit

Cause

Contact problem on alternator connector.

Cable from alternator to charging indicator lamp

has interrupted ground connection or wire.

Fault in alternator.

Remedial Action

Check connectors (in workshop).

Eliminate the short circuit (in workshop).

Check the alternator. Repair, or replace if

necessary (at workshop).

15. No reading on the digital display

Cause

Interrupted power supply.

Remedial Action

Replace fuse and check connectors.

Check fuses and connectors.

16. General faults in the electrical system

Cause

No contact between terminals and battery cables.

Remedial Action

Remove any oxidation from terminals and

clamps, tighten the clamp screws; coat terminals

with anticorrosion grease.

17. Turn signal / hazard warning system not functioning

Cause

Power supply interrupted; hazard warning flasher

inoperative.

Remedial Action

Check fuse / power supply and replace signal

pulse generator if necessary.

18. Turn signal indicator lamps do not come on

Cause

Bulbs faulty in corresponding turn signal lamps

on tractor or trailer.

Remedial Action

Replace bulbs; establish current / ground

contact; check trailer cable connectors.

19. Brakes do not function properly (to be dealt with at the

service workshop)

Cause

Brake pedals have too much free travel / uneven

braking effect.

Brake pedal movement is spongy and too long.

Oil loss in brake and clutch system.

Remedial Action

Adjust foot brake, repair if necessary.

Bleed air from the foot brake circuit. Eliminate

cause of leak, as necessary.

Remedy the cause of oil loss.

Page 16

220

FAULTS AND REMEDIAL ACTIONS

20. Electronic control hydraulics (EPC) rear, position control at

front not functioning.

Cause

Safety lock active.

Rear EPC: lifting gear switched to operation with

dual-action additional control unit / lever cannot

be changed over.

Lifting height limitation is set to min. lift.

Fuses blown.

Remedial Action

Press quick lift switch beyond Stop position until

indicator lamps light up.

Relieve the lifting gear of load, switch off engine,

switch the lever fully and release the safety lock.

If necessary, increase lift.

Change fuses.

21. Fault in the lifting gear control

Cause

Remedial Action

For example, loose electrical connections, failure

of an electronic component, etc.

Call up fault code on the multiple display, if

necessary contact the after-sales service

workshop.

22. Slip control operating inaccurately

Cause

Speed signals in the EPC E-box are inaccurate.

Remedial Action

Adjust the radar sensor.

23. Hydraulic traction control unsatisfactory (insufficient

number of governor pulses)

Cause

Remedial Action

Position / traction setting is set too far towards

Position.

If necessary, set more towards 'Traction.

Plough blade is blunt (no cutting action).

Sharpen plough blade.

Working implement unsuitable for control

hydraulics.

Use an implement suitable for the control

hydraulics.

24. Lifting gear does not lower

Cause

Lowering speed setting too far towards. No lowering.

Remedial Action

If necessary, set more towards "Max. lowering

speed".

25. Excessive noise in hydraulic system

Cause

Hydraulic oil still cold.

Insufficient oil in the hydraulic oil reservoir.

Air drawn in through suction line connections or

pump shaft seal.

Suction filter soiled.

Remedial Action

Let engine run for a few minutes at average

speed before any hydraulic work.

Top up oil level in accordance with specifications.

Seal the connections and/or replace the

hydraulic pump (at workshop).

Replace suction filter.

Page 17

221

FAULTS AND REMEDIAL ACTIONS

26. Hydraulic system does not lift

Cause

Hydraulic oil still cold.

Insufficient oil in the hydraulic oil reservoir.

Air drawn in through suction line connections.

Suction filter soiled.

Remedial Action

Let engine run for a few minutes at average

speed before any hydraulic work.

Top up oil level in accordance with specifications.

Seal the connections (at workshop).

Replace suction filter.

27. Heater ineffective

Cause

Heating water valve is partially closed / air filter

dirty.

Remedial Action

Open the heating water valve / replace air filter.

28. Heater fan not working

Cause

Power supply to blower interrupted or blower

failed / blocked.

Remedial Action

Check fuse / power supply, remove foreign

bodies (in workshop).

29. Air-sprung seat fails to adjust

Cause

Compressed air compressor not functioning.

Remedial Action

Check fuse / power supply.

30. Air conditioning does not work

Cause

Remedial Action

Fresh air fan not switched on / not functioning /

temperature selector set at '0'.

Switch on fan / set temperature selector to

desired outlet air temperature / check fuse and

power supply.

AC compressor not functioning - magnetic clutch

not engaging / V-belt is too slack or cracked.

Check fuse / power supply for magnetic clutch or

V-belt.

Insufficient refrigerant in the system (system on,

engine speed 2,000 rpm; ball must be floating in

sight glass on fluid reservoir).

Top up refrigerant (at workshop).

31. Cooling effect of air conditioning inadequate

Cause

Condenser dirty (upstream of engine radiator).

Fresh air/ recirculating air filter dirty.

Evaporator iced up.

Insufficient refrigerant in the system (system on,

engine speed 2,000 rpm; ball in sightglass of fluid

tank must be floating).

Remedial Action

Blow out or spray condenser from inside out.

Blow out recirculated air filter, tap out the fresh air

filter; replace if necessary.

Reset temperature selector; have the cause

rectified (at workshop).

Top up refrigerant (at workshop).

Page 18

222

FAULTS AND REMEDIAL ACTIONS

32. Blue ball in fluid tank turned pink

Cause

Dryer in fluid reservoir is saturated.

Remedial Action

Replace fluid reservoir (workshop job - refer to

workshop manual, air conditioning section).

33. Water drips from fan casing (air conditioning)

Cause

Condensation outlet blocked (line ends at left and

right cab access ladders).

Remedial Action

Clear the water outlet (blow through if

necessary).

Page 19

223

FAULTS AND REMEDIAL ACTIONS

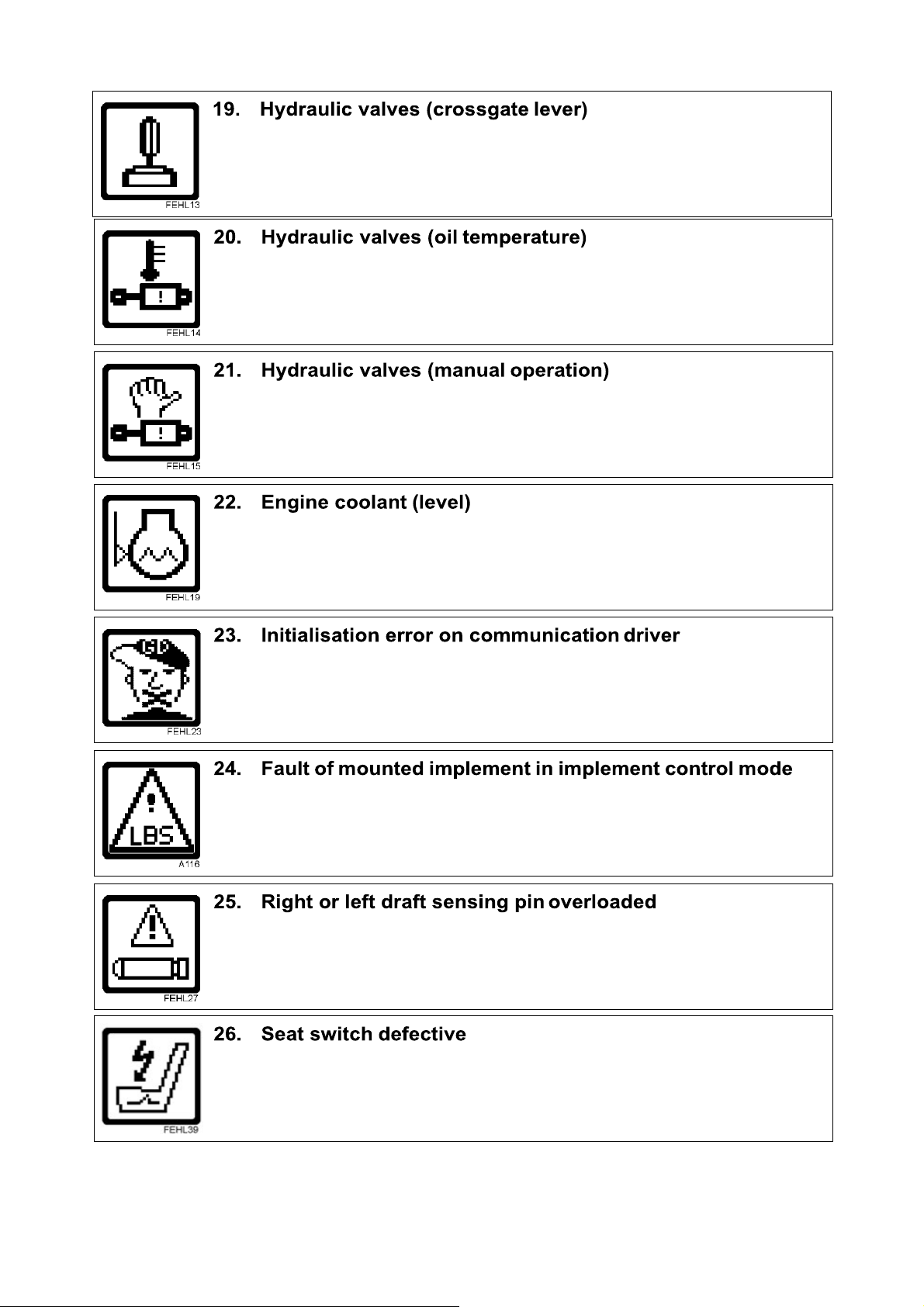

2. Variotronic Ti fault messages

Fault messages are displayed as symbols on the Vario terminal.

Each stored fault messages must be cleared individually. Clearing a fault message does not remove

the fault, it is simply no longer displayed.

Fig.3

● Press key (F3). Confirm fault message.

● Press key (F4). Cancel process.

If this occurs several times, consult workshop.

If this occurs several times, consult workshop.

Process is cancelled.

Read error code from the multi-display. Consult workshop.

Page 20

224

FAULTS AND REMEDIAL ACTIONS

Process is cancelled.

Create configuration. Start recording again.

Call workshop.

Call workshop.

Call workshop.

Read error code from the multi-display. Consult workshop.

Process is cancelled.

Page 21

225

FAULTS AND REMEDIAL ACTIONS

Call workshop.

Setting different in recording/playback. Change the setting pre-selection.

Press F4 key. Latest settings are activated.

Press F5 key. Base settings are activated.

Change the direction of travel (drive forward). Start playback again.

Change direction of travel (to reverse). Start playback again.

Call workshop.

Call workshop.

Page 22

226

FAULTS AND REMEDIAL ACTIONS

Confirm fault messages.

Recording is stopped.

Page 23

227

FAULTS AND REMEDIAL ACTIONS

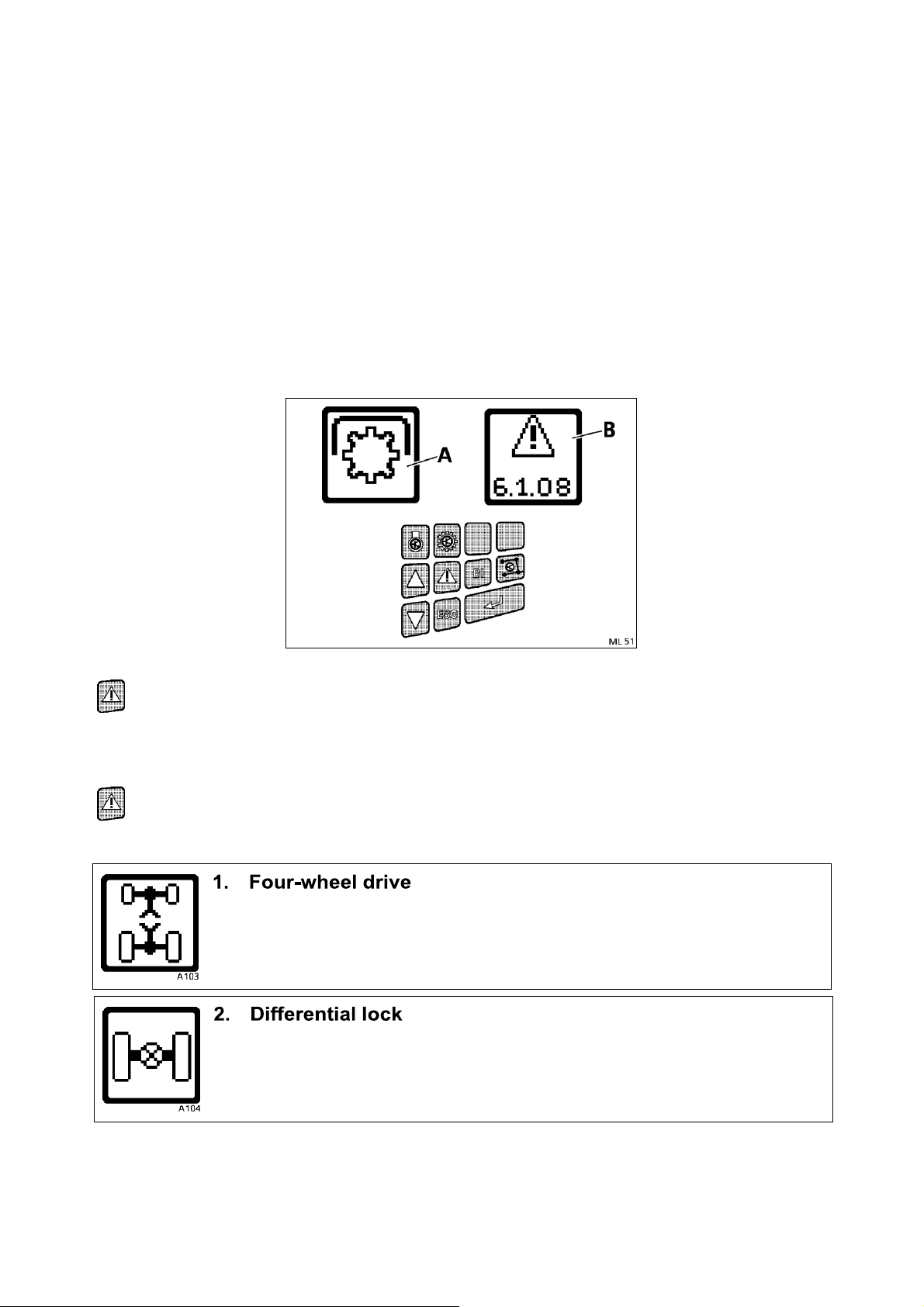

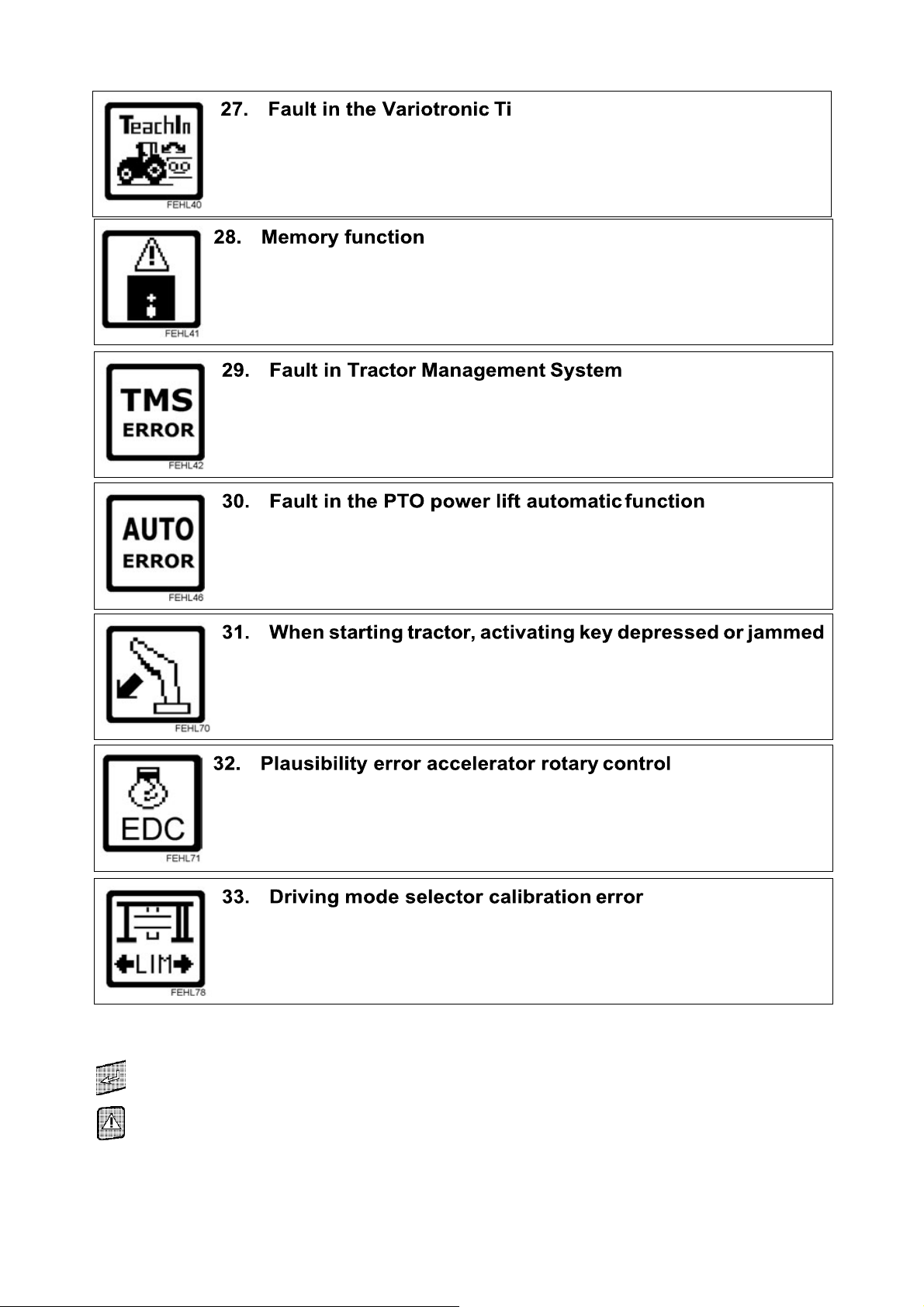

3. Warning and information messages for implement settings

Fig.4

Warning and information messages (A) are shown on the Vario terminal.

Process is not started.

Put transmission into neutral.

Process is not started.

End FRONT power lift/PTO automatic function on the control console.

Process is not started.

Switch off REAR power lift/PTO automatic mode on the operating console.

Process is not started.

Switch off FRONT and REAR power lift/PTO automatic mode on the operating

console.

Process is not started.

Increase engine speed.

Page 24

228

FAULTS AND REMEDIAL ACTIONS

4. Flame starting system faults

The flame starting system control unit detects faults in the flame starting system, and indicates these

with flash codes on the preheating indicator lamp.

The flashing duration is about 60 secs.

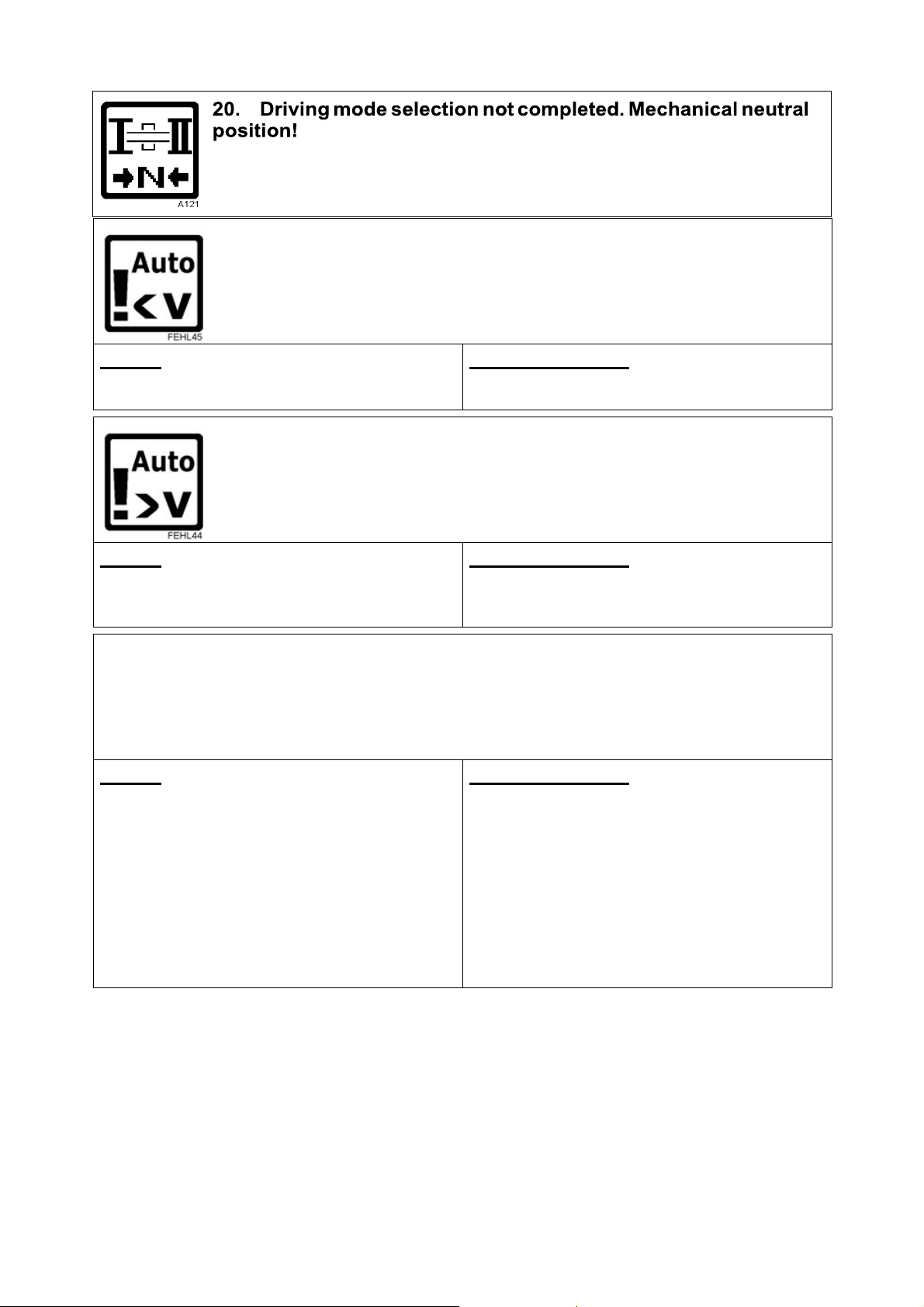

Fig.5

The following faults are detected:

Fault code A:

● Break in the flame glow plug element loop or its supply line.

Fault code B:

● Faulty fuse for the flame start control unit or no supply voltage (B+).

Fault code C:

● Break in the solenoid valve line or coil.

In all cases, only the indicator lamp flashes. Solenoid valve and flame heater plug remain switched off.

Page 25

229

FAULTS AND REMEDIAL ACTIONS

5. Fault code tables

General

Fault code

Cause

Effect and remedy

0.0.11

Data transfer from

No forward/reverse indicator,

0.0.12

Tractor electronic system for

4-WD, diff. lock and

0.0.13

instrument cluster inoperative.

Front/rear PTO speed.

0.0.14

0.0.15

0.0.16

0.0.17

0.0.18

0.0.1A

0.0.20

0.0.1B

Variotronic Ti data transfer

faulty.

Auxiliary operation.

0.0.1F

Joystick data transfer faulty.

Valves, electronic accelerator, transmission functions not functioning.

0.1.50

Combination instrument not

programmed.

Programme combination instrument.

0.1.51

Engine oil pressure sensor

faulty.

No more monitoring of engine oil pressure.

0.1.54

Sensor for compressed air supply is faulty.

Display no longer valid.

0.1.55

Hydraulic oil supply sensor

faulty.

No monitoring of hydraulic oil level.

0.1.56

Engine temperature sensor

faulty.

Engine temperature is not monitored.

0.1.57

Charge air temperature sensor.

No monitoring of intercooler temperature.

0.1.59

Sensor for fuel supply faulty.

No monitoring of fuel supply indicator.

Electronic engine control

Fault code

Cause

Effect and remedy

1.1.01

EDC control unit line discontinuity.

Normal operation - fault indication.

1.1.03

Foot throttle potentiometer

plausibility error.

Accelerator pedal mode not functioning.

1.1.04

Tractor Management System

(TMS) checksum error.

Tractor Management System (TMS) not

functioning, EOL programming.

1.1.05

Engine configuration could not

be read by the electrical engine

control module.

Tractor Management System (TMS) not

operational.

1.1.7 E

FENDT control unit, line discontinuity.

Loss of enhanced features, only foot

throttle available.

1.1.7F

Hand throttle memory buttons

faulty.

Loss of enhanced features, only foot

throttle available.

1.1.9 E

Operating console, line discontinuity.

Loss of enhanced features, only foot

throttle available.

1.1.9F

Operating console, line discontinuity.

Loss of enhanced features, only foot

throttle available.

1.1.A0

Connection to EDC control unit,

EDC control unit faulty.

Normal operation - fault indication.

1.1.A1

FENDT control module to EDC

control module connection

faulty.

Reduced engine power.

Page 26

230

FAULTS AND REMEDIAL ACTIONS

Fault code

Cause

Effect and remedy

1.1.BO

Communication driver initialisation error; limited CAN bus

communication.

EOL programming.

1.1.EO

Calibrated values from manual

throttle rotary control incorrect.

Manual throttle rotary control calibration.

Electronic engine control

Fault code

Cause

Effect and remedy

1.2.13

Battery voltage too low.

Reduced engine operation.

1.2.17

Engine overspeed.

After the overspeed is left, normal operation.

1.2.18

Start of injection incorrectly set.

Reduced end speed, reduced engine

power. Check fuel system.

1.2.1A

Needle movement sensor incorrect values.

Engine control changed.

1.2.9B

Solenoid valve has incorrect

values.

Reduced end speed, reduced engine

power.

1.2.1E

Injection pump.

Reduced speed, reduced engine power.

1.2.1F

Engine control unit or connection interrupted.

Auxiliary operation.

1.2.21

FENDT control module to

transmission bus connection in terrupted.

Optimum engine control not possible.

1.2.23

FENDT control module to EDC

control module connection interrupted.

Loss of enhanced features, only foot

throttle available.

1.2.25

Main relay does not open.

Battery is discharged.

1.2.2A

FENDT control module to EDC

control module connection interrupted.

Normal operation - fault indication.

1.2.2B

FENDT control module to EDC

control module connection interrupted.

No control of engine brake.

1.2.2C

FENDT control unit connection

to engine brake interrupted.

No control of engine brake.

1.2.2D

FENDT control module to EDC

control module connection interrupted.

Loss of enhanced features, only foot

throttle available.

1.2.2 E

FENDT control module to EDC

control module connection interrupted.

Optimum engine control not possible.

1.2.38

Control unit.

Reduced speed, reduced engine power.

1.2.42

Injection pump.

Reduction in power.

1.2.46

Control unit.

Loss of enhanced features, only foot

throttle available.

1.2.81

Pedal position sensor signal

wrong.

Normal operation - fault indication.

1.2.82

Injection pump, supply of flow.

Engine cuts out, engine does not start.

1.2.84

Engine speed sensor, control

module.

Reduced speed, reduced engine power.

1.2.85

Boost pressure sensing device.

Reduced engine power.

1.2.87

Temperature sensor (coolant),

control module.

Reduced engine power.

1.2.89

Injection pump.

Engine does not start.

1.2.91

rpm sensor.

Reduced speed, reduced engine power.

1.2.92

Injection pump, engine control

module.

Reduced end speed, reduced engine

power.

Page 27

231

FAULTS AND REMEDIAL ACTIONS

Fault code

Cause

Effect and remedy

1.2.96

Control unit.

Engine cuts out.

1.2.99

Control unit to injection pump

connection is interrupted.

Reduced speed, reduced engine power.

1.2.A2

Engine control unit or injection

pump.

Reduced speed, reduced engine power.

1.2A6

Engine control unit or injection

pump.

Reduced speed, reduced engine power.

1.2.A8

Engine control unit has wrong

value.

Normal operation - fault indication.

1.2.A9

Injection pump.

Reduced end speed, reduced engine

power.

1.2.B1

Control unit to injection pump

connection is interrupted.

Reduced speed, reduced engine power.

1.2.B2

Control unit, injection pump.

Reduced speed, reduced engine power.

1.2.B3

Interrupted power supply.

Engine stops, engine does not start.

1.2.B4

Control unit to injection pump

connection is interrupted.

Loss of enhanced features, only foot

throttle available.

1.2.B5

Control unit, injection pump.

Reduced speed, reduced engine power.

1.2.B6

Control unit, injection pump.

Reduced speed, reduced engine power.

1.2.B7

Engine speed sensor.

Reduced speed, reduced engine power.

1.2.B9

Control unit, injection pump.

Engine stops.

1.2.C1

Pump control unit faulty.

Engine goes into idle.

1.2.C3

EDC control module - pump

controller connection interrupted.

Engine goes into idle.

1.2.C4

Injection pump.

Engine goes into idle.

1.2.C5

Stop solenoid valve.

Reduced speed, reduced engine power.

1.2.C7

Injection pump, fuel lines faulty.

Engine stops. Check fuel system.

1.2.C8

Control unit, needle movement

sensor, boost pressure sensor.

Engine stops.

1.2.C9

Injection pump.

Normal operation - fault indication.

1.2.CA

Injection timing mechanism values not within tolerance.

Reduced rpm, reduced engine power.

Check fuel system.

1.2CB

Control unit to injection pump

connection is interrupted.

Loss of enhanced features, only foot

throttle available.

1.2.CD

Injection pump.

Reduced speed, reduced engine power.

1.2.DE

Control unit.

Loss of enhanced features, only foot

throttle available.

1.2.EO

EDC control unit not connected.

Normal operation - fault indication.

1.2.E1

PTO rpm or speed signal incorrect.

Normal operation - fault indication.

Implement control

Fault code

Cause

Effect and remedy

2.1.EO

CAN communication E-Box CAN joystick defective.

Implements can no longer be controlled

using the joystick.

2.1.EE

LBS job computer inoperative.

Check CAN bus system for implement

control.

2.1.EF

Error message from mounted

implement.

Refer to implement manufacturer's manual.

Page 28

232

FAULTS AND REMEDIAL ACTIONS

Operating console

Fault code

Cause

Effect and remedy

3.1.01

3.1.02

3.1.03

3.1.04

Programming error.

Call workshop.

3.1.05

3.1.06

Transmission

Fault code

Cause

Effect and remedy

4.1.01

Joystick acceleration switch

I-IV faulty.

Auxiliary operation.

4.1.04

Clutch pedal potentiometer

faulty.

No monitoring of transmission ratios.

4.1.05

Pressure sensor II defective.

Reduced comfort.

4.1.06

Accelerator rotary control faulty.

Load limit control not functioning.

4.1.07

High-pressure sensor faulty.

Peak loads in the transmission are no

longer monitored.

4.1.08

Operating range I/II analogue

device (function angle device)

faulty.

Operating range switching I/II not operational.

4.1.20

Accelerator cancellation rotary

control incorrectly calibrated or

not calibrated.

Accelerator mode not working.

4.1.21

Reverse mode switch is defective.

Reverse mode operation and accelerator

mode no longer possible.

4.1.22

Accelerator cancellation rotary

control faulty.

Restriction in operation of accelerator

mode.

4.1.23

Joystick signal Tempomat on

faulty.

Auxiliary operation.

4.1.24

Hand brake switch faulty.

Hand brake automatic mode not working.

4.1.25

Joystick F-R quick reverse signal faulty.

Auxiliary operation.

4.1.26

Joystick signal accelerator

mode faulty.

Accelerator mode not working.

4.1.27

Armrest signal rapid reversal

(F/R rocker) faulty.

Rapid reverse not working.

4.1.28

Track width adjustment faulty.

Auxiliary operation.

4.1.29

Joystick park position signal

faulty.

Auxiliary operation.

4.1.2A

Bevel pinion rpm sensor direction signal faulty.

Auxiliary operation.

4.1.2B

Driving mode I/II selection button faulty.

Tractor remains in current dricing mode.

No further selection until ignition ON/

OFF.

4.1.2C

'Neutral selection' button faulty.

Auxiliary operation.

4.1.2D

Quick Reverse button (steering

column) faulty.

Quick Reverse only available with the

joystick.

4.1.2E

Joystick key 'v+' faulty.

Auxiliary operation.

4.1.2F

Joystick v- faulty.

Auxiliary operation.

4.1.31

Direction signal speed sensor

for hydrostatic unit faulty.

Auxiliary operation.

4.1.32

Joystick activating button faulty.

Auxiliary operation.

4.1.42

Speed sensor hydrostatic unit

faulty.

Auxiliary operation.

233

Page 29

FAULTS AND REMEDIAL ACTIONS

Fault code

Cause

Effect and remedy

4.1.44

Speed sensor engine 1 faulty.

Auxiliary operation.

4.1.45

Bevel pinion speed sensor

faulty.

Auxiliary operation.

4.1.50

Transmission oil filter dirty.

Auxiliary operation.

4.1.53

Transmission oil temperature

over 110.

Damage to traction drive.

4.1.58

Slip values of transmission ratios beyond acceptable limits.

Occasional occurrences in extreme conditions have no effect. If the problem persists in normal conditions, contact the

workshop immediately.

4.1.59

Emergency operation manually

induced or by electrical activation; emergency operation defective when operated non-manually.

Fault code not in the memory.

4.1.61

Faulty activation of operating

range I valve.

Auxiliary operation.

4.1.62

Faulty activation of operating

range II valve.

Auxiliary operation.

4.1.63

Faulty activation of valve for

mechanical speed limitation.

Max. speed 30 km/h only.

4.1.64

Faulty actuation of turboclutch

valve.

Auxiliary operation.

4.1.65

Faulty activation of cardan

brake.

Call workshop.

4.1.66

Faulty activation of cardan

brake.

Call workshop.

4.1.67

Faulty activation of cardan

brake.

Call workshop.

4.1.70

Tempomat cruise control 1 key

faulty.

No Tempomat cruise control.

4.1.71

Tempomat cruise control 2 key

faulty.

No Tempomat cruise control.

4.1.72

Filter contamination switch defective.

No monitoring of filter contamination.

4.1.73

Temperature output sensor

faulty.

No temperature output monitoring.

4.1.74

Parking brake position recognition switch faulty.

Hand brake position not detected, no

hand brake automatic mode.

4.1.76

Engine brake switch faulty.

No engine brake function.

4.1.77

Joystick acceleration rate I-IV

faulty.

Operation only possible in acceleration

rate III.

4.1.78

Starting cut-out seat switch for

accelerator mode faulty.

Selection of direction of travel is always

deactivated in accelerator mode when

vehicle stationary for 3 seconds.

4.1.82

Plausibility error (engine

speed) between hydrostatic

unit speed sensor and bevel pinion speed sensor.

Auxiliary operation.

4.1.83

Plausibility error (direction) between hydrostatic unit speed

sensor and bevel pinion speed

sensor.

Auxiliary operation.

4.1.84

Plausibility error between the

joystick controls (F/R, Tempomat cruise control).

Auxiliary operation.

4.1.85

Engine speed sensor I plausibility error.

Auxiliary operation.

234

Page 30

FAULTS AND REMEDIAL ACTIONS

Fault code

Cause

Effect and remedy

4.1.86

Plausibility error between pres-

sure sensor I and pressure sen-

sor II.

Reduced comfort.

4.1.87

Plausibility error on F/R button

on steering column.

No F/R function on steering column.

4.1.88

Plausibility error on ON/OFF

button for accelerator pedal

drive.

No function.

4.1.94

CAN communication E-Box

and joystick faulty.

Joystick functions restricted. Call workshop.

Transmission

Fault code

Cause

Effect and remedy

4.1.A0

Adjuster actuation faulty.

Auxiliary operation.

4.1.A1

Control unit mechanical stop

defective.

Auxiliary operation.

4.1.A2

Faulty CAN bus connection to

control unit.

Auxiliary operation.

4.1.A3

Control unit incremental sensor

faulty / not plausible.

Auxiliary operation.

4.1.A4

Adjuster EST track signal faulty/missing.

Auxiliary operation.

4.1.A5

Adjuster reference not found.

Auxiliary operation.

4.1.A6

Incorrect control unit reference

point during operation.

Auxiliary operation.

4.1.B0

Initialisation error on communi-

cation driver. CAN bus commu-

nication restricted.

Restricted operation.

4.1.B1

Fatal error range control with

subsequent emergency operation (e.g. valve fault).

Auxiliary operation.

4.1.B2

Transmission ratio limiting

faulty.

EOL programming.

4.1.B3

Quick Reverse acceleration

rate parameters out of tolerance.

EOL programming.

4.1.B4

Engine speed sensor I plausibility error.

EOL programming.

4.1.B5

Rapid reversing ramp parameter for Tractor Management System (TMS) checksum error.

Rapid reversing not operational in the

Tractor Management System (TMS).

4.1.EO

Turboclutch characteristic faulty/incorrectly memorised.

EOL programming.

4.1.E1

Traction control pressure regulator parameter fault/read error.

EOL programming.

4.1.E2

Pressure regulator parameters

in traction control are not plausible or read in incorrectly.

No traction control function.

4.1.E3

Accelerator checksum error.

EOL programming.

4.1.E4

Brake control checksum error.

EOL programming.

4.1.E9

Values of operating range shift

II-I not within tolerance.

Only shift while at a standstill.

4.1.EA

Incorrect EOL programming.

Auxiliary operation.

4.1.EB

Range-change values out of tolerance or range-change not

calibrated.

Auxiliary operation.

235

Page 31

FAULTS AND REMEDIAL ACTIONS

Fault code

Cause

Effect and remedy

4.1.EC

Accelerator rotary control values not within tolerances or no

calibration of accelerator rotary

control.

Auxiliary operation.

4.1.ED

Clutch pedal potentiometer values out of tolerance or clutch

not calibrated.

Auxiliary operation.

4.1.EE

Transmission characteristic values out of tolerance or no calibration of transmission.

Auxiliary operation.

4.1.EF

Turboclutch values out of tolerance or no calibration.

Auxiliary operation.

4.1.FF

Error in transmission EST control unit.

Auxiliary operation.

Four-wheel drive and differential lock

Fault code

Cause

Effect and remedy

5.1.31

100% 4-WD button faulty.

'4-WD automatic mode' available only.

5.1.32

Key for automatic 4WD faulty.

'100% 4-WD' available only.

5.1.33

Faulty 4-WD clutch solenoid

valve.

Function terminated, 4-WD engages.

5.1.34

Steering angle sensor 1 faulty.

4-WD / differential lock automatic mode

Stop not functioning.

5.1.35

Steering angle sensor 2 faulty.

4-WD / differential lock automatic mode

Stop not functioning.

5.1.51

100% differential lock button

faulty.

Only 'Differential lock automatic mode'

function available.

5.1.52

Key for automatic differential

lock faulty.

'100% differential lock' is only function

still available.

5.1.53

Differential lock solenoid actuation faulty.

End of function, differential lock not disengaging.

5.1.54

Left brake pedal switch faulty.

'100% differential lock' is only function

still available.

5.1.55

Right brake pedal switch faulty.

'100% differential lock' is only function

still available.

Suspension

Fault code

Cause

Effect and remedy

5.1.61

Front axle suspension position

sensor faulty.

Front axle suspension does not function.

Possible to continue without suspension.

5.1.62

Front axle suspension "Raise"

solenoid actuation faulty.

Front axle suspension does not function.

Possible to continue without suspension.

5.1.63

Incorrect activation of solenoid

valve 'lower'for front axle suspension.

Front axle suspension does not function.

Possible to continue without suspension.

5.1.64

Front axle suspension on/off

key defective.

Front axle suspension does not function.

Possible to continue without suspension.

5.1.65

Lock front axle suspension key

faulty.

Locking of front axle suspension no longer possible.

5.1.6 E

No calibration of position sensor.

Front axle suspension does not function.

Readjust position sensor.

Page 32

236

FAULTS AND REMEDIAL ACTIONS

Power lift and PTO automatic mode

Fault code

Cause

Effect and remedy

5.1.91

Joystick rear automatic mode

on/off button faulty.

Rear automatic mode not working.

5.1.93

Joystick front automatic mode

on/off button faulty.

Front automatic mode not functioning.

5.1.95

Joystick automatic mode stop

button faulty.

Automatic mode cannot be switched on

and off.

Hydraulic system (push button / flow controller)

Fault code

Cause

Effect and remedy

5.1.98

Control pump oil pressure monitoring faulty.

Possible failure of work hydraulics.

5.1.99

Signal of flow control sensor

disturbed or no oil pressure on

the auxiliary pump.

Possible failure of auxiliary pump (constant displacement pump).

Other fault codes

Fault code

Cause

Effect and remedy

5.1.00

Control unit fault.

E-Box faulty.

5.1.8D

Checksum error. Old automatic

mode configuration data.

Reduced comfort.

5.1.8F

Checksum error. Old automatic

function sequential data.

Reduced comfort.

5.1.9A

Plausibility check error on flow

controller with ignition ON and

engine OFF.

No pressure monitoring.

5.1.9B

8 bar pressure switch faulty.

No pressure monitoring.

5.1.B0

Initialisation error on communi-

cation driver. CAN bus commu-

nication restricted.

EOL programming.

5.1.9E

Engine coolant level too low or

empty.

Risk of engine damage. Once the warning has been confirmed, the error message is output every 120 sec. if the coolant has not be topped up.

5.1.9F

Engine coolant level sensor defective.

No coolant level monitoring.

5.1.FF

Comfort E-box no longer receiving CAN data for engine

speed and PTO speed.

Various indicators no longer available or

comfort E-box fails completely.

Rear PTO

Fault code

Cause

Effect and remedy

6.1.01

Button in cab faulty.

Does not function, PTO disengages.

6.1.02

Key on right mudguard faulty.

PTO can only be switched on/off with the

cab button. Button must be pressed for at

least 5 secs.

6.1.03

Button on left mudguard faulty.

PTO can only be switched on/off with the

cab button. Button must be pressed for at

least 5 secs.

6.1.04

PTO shaft clutch solenoid valve

faulty.

Does not function, PTO disengages.

237

Page 33

FAULTS AND REMEDIAL ACTIONS

Fault code

Cause

Effect and remedy

6.1.05

PTO shaft rpm sensor faulty.

PTO can only be switched on/off with the

cab button. Button must be pressed for at

least 5 secs.

6.1.10

Speed sensor shaft faulty.

6.1.11

Automatic mode on operating

console faulty.

Automatic mode is ended and PTO disengages.

6.1.15

Neutral speed selection key

faulty.

Does not function, PTO disengages.

6.1.16

Selection range key 540 faulty.

No function of range selection key 540.

6.1.17

Setting 540E selection button

faulty.

Setting 540E selection button does not

function.

6.1.18

Speed selection key 1000

faulty.

No function of speed selection key 1000.

6.1.1A

Setting 540 valve faulty.

Does not function, PTO disengages.

6.1.1B

Control valve 540E faulty.

Does not function, PTO disengages.

6.1.1C

Control valve 1000 faulty.

Does not function, PTO disengages.

6.1.41

Cab button plausibility error.

Does not function, PTO disengages.

6.1.42

Right mudguard button plausibility error.

Does not function, PTO disengages.

6.1.43

Left mudguard button plausibility error.

Does not function, PTO disengages.

6.1.45

PTO clutch rpm sensor plausibility error.

PTO can only be operated via keys inside

the cab, key must be kept pressed for at

least 5 secs.

6.1.50

Speed sensor PTO shaft plausibility error.

When engaging, the button must be pressed for at least 5 secs.

6.1.55

Plausibility error in speed selection key neutral.

Does not function, PTO disengages.

6.1.56

Plausibility error in speed selector key 540.

No function of 540 selection.

6.1.57

540E setting pre-selection button plausibility error.

No function of 540E selection.

6.1.58

Plausibility error in speed selection key 1000.

No function of 1000 selection.

6.1.60

Plausibility error between PTO

clutch rpm and PTO stub shaft

speed.

Does not function, PTO disengages.

6.1.BO

Initialisation error on communi-

cation driver. CAN bus commu-

nication restricted.

EOL programming.

6.1.C1

Switch-on speed not reached

for PTO/power lift automatic

mode.

Increase ground speed to more than

1 km/h.

6.1.EO

Checksum parameter current

control for range shifting faulty.

EOL programming.

6.1.E1

Checksum PTO parameter

faulty.

EOL programming.

238

Page 34

FAULTS AND REMEDIAL ACTIONS

Front PTO

Fault code

Cause

Effect and remedy

7.1.01

PTO key inside the cab faulty.

Does not function, PTO disengages.

7.1.04

Clutch operation solenoid

faulty.

7.1.05

PTO shaft rpm sensor faulty.

To engage, the button must be pressed

for at least 5 sec.

7.1.09

Automatic front PTO key on

operating console defective.

Automatic mode is ended and PTO disengages.

7.1.41

Cab button plausibility error.

Does not function, PTO disengages.

7.1.C1

Switch-on speed not reached

for PTO/power lift automatic

mode.

Increase ground speed to more than

1 km/h.

EPC-C rear power lift

Fault code

Cause

Effect and remedy

8.3.11

Lift final stage defective.

Control is terminated and locked.

8.3.12

Lower final stage defective.

Control is terminated and locked.

8.3.14

Rear left 'Lift'key is defective.

Control is terminated and locked.

8.3.15

Left rear "Lower" button faulty.

Control is terminated and locked.

8.3.16

V regulator less than 1 Volt.

Control is terminated and locked.

8.3.17

Battery voltage over 18 V.

Control is terminated and locked.

8.3.18

Rear right 'Lift' key is defective.

Control is terminated and locked.

8.3.19

Rear right 'Lower' key is defective.

Control is terminated and locked.

8.3.22

Position sensor defective.

Control is terminated and locked.

8.3.23

Setpoint rotary control defective.

Control is terminated and locked.

8.3.26

Faulty external sensor.

Control is terminated and locked.

8.3.31

Right draught sensing pin defective.

Control is continued

8.3.32

Left load sensor pin faulty.

Control is continued

8.3.33

Battery voltage less than

10.5 V.

Control is continued

8.3.40

Quick Lift switch faulty.

Raise and Lower only possible with the

rear controls.

8.3.41

Fast feed-in button faulty.

Fast feed-in does not function.

8.3.42

Hitch button faulty.

Hitch key not functioning.

8.3.43

Automatic rear lifting gear key

(control console) defective.

Automatic rear lifting gear key not operational.

8.3.50

Warning, right load sensor pin

overloaded.

Warning is not stored. Relieve drafting

sensing pin of load.

8.3.51

Warning, left load sensor pin

overloaded.

Warning is not stored. Relieve drafting

sensing pin of load.

Front power lift

Fault code

Cause

Effect and remedy

9.1.50

Valve not registered on CANbus.

Valve actuation not possible.

9.1.5F

Incorrect messages sent on

CAN bus. Electronics in valve

faulty.

Valve goes into neutral position.

9.1.51

Electronics in valve faulty.

Valve goes into neutral position. Replace

valve.

Page 35

239

FAULTS AND REMEDIAL ACTIONS

Fault code

Cause

Effect and remedy

9.1.52

Voltage in the valve less than

8 V.

Valve goes into neutral position.

9.1.53

Voltage in excess of 18 V.

Valve goes into neutral position.

9.1.54

Valve actuator falls short. Drops

in control pressure or oil too vis-

cous at low temperatures.

Valve goes into neutral position.

9.1.5A

Valve actuator goes too far.

Valve goes into neutral position.

9.1.5B

Floating position not reached.

Valve goes into neutral position.

9.1.5C

Manual actuation.

None.

9.1.55

High overvoltage over 45 V.

Valve goes into neutral position.

9.1.56

Final stage error (pilot control

solenoid valve).

Valve goes into neutral position.

9.1.57

Position pickup sensor error.

Valve goes into neutral position.

9.1.58

Valve actuator does not return.

Valve slide jams.

9.1.59

Slide valve jams because of

dirt.

Valve slide jams.

9.1.A0

No memorised values after engine re-start.

Reduced driving comfort.

9.1.A1

9.1.B0

Position sensor is not calibrated.

No position control possible.

9.1.B1

Position sensor transmits no

values or wrong values.

No position control possible.

9.1.B2

Set point rotary control not calibrated.

Setpoint values cannot be set.

9.1.B3

Setpoint potentiometer sends

no values or incorrect values.

Setpoint values cannot be set.

9.1.C0

Operating console not available.

No automatic mode, no general locking.

9.1.C1

Automatic mode button faulty.

No automatic mode.

9.1.C2

Overall locking key faulty.

No overall locking of valves.

9.1.C3

Floating position button faulty.

No floating position.

9.1.C4

Front power lift Raise button

faulty.

Front power lift cannot be raised properly.

9.1.C5

Front power lift 'Lower' faulty.

Front power lift cannot be lowered properly.

9.1.C6

Possible fault on CAN bus to

operating console.

Status changes cannot be detected. Engagement/disengagement possibly being

overridden.

9.1.C7

9.1.C8

9.1.C9

9.1.CA

9.1.D0

External Lift key faulty.

Front power lift cannot be lowered properly.

9.1.D1

External Lower key faulty.

Front power lift cannot be lowered properly.

9.1.D2

External key actuates twice or

key sticks.

Front power lift cannot be lowered properly.

Page 36

240

FAULTS AND REMEDIAL ACTIONS

Electric valves (oeprating console)

Fault code

Cause

Effect and remedy

A.1.C0

Control console not available,

e.g. CAN-bus not connected.

No automatic mode. No general locking

of valves.

A.1.C1

Automatic mode button faulty.

No automatic mode.

A.1.C2

Overall locking key faulty.

No overall locking of valves.

A.1.C3

Floating position button faulty.

No floating position.

A.1.C4

Timer function button faulty.

No timer function.

A.1.C5

Crossgate lever/joystick switchover button faulty.

Not possible to switch between crossgate

lever operation and joystick operation.

A.1.C6

Operating console CAN bus

faulty.

Change of status not detected. Switching

on/off is ignored. Valve locked.

A 1.C7

A.1.C8

A.1.C9

A.1.CA

A.1.CB

CAN joystick not available.

Not possible to operate valves.

A.1.CC

E-Box and CAN joystick CAN

connection faulty.

Limited operation of valves.

Electric valves (crossgate lever)

Fault code

Cause

Effect and remedy

A.1.B0

Crossgate lever not adjusted.

Valves cannot be actuated. Carry out adjustment.

A.1.B1

Signal fault.

Valve position cannot be controlled properly.

A.1.B2

A.1.B3

A.1.B4

A.1.B5

Crossgate lever recognition of

centre position faulty.

Valve position cannot be operated accurately. Calibrate.

Electric valves (buttons / switches)

Fault code

Cause

Effect and remedy

A.1.FA

External valve actuation. Spool

valve external pushbutton for

rear LIFT faulty.

Rear external controls not working.

A.1.FB

External valve actuation. Spool

valve external pushbutton for

rear LOWER faulty.

Rear external controls not working.

A.1.FC

External valve actuation. Spool

valve external pushbutton rear

actuates twice or pushbutton is

faulty.

Change controls or exchange keys.

A.1.D1

Valve 3, signal disturbed or

faulty valve.

'Lift' and/or 'Lower' valve 3 faulty.

A.1.D3

Valve 4, signal disturbed or

faulty valve.

'Lift' and/or 'Lower' valve 4 faulty.

A.1.D4

Faulty solenoid switch for release of external controls of

standard front power lift.

Position of shutoff cock for front power lift

cannot be detected.

A.1.D5

External front power lift 'Lower'

button faulty.

Front power lift cannot be lowered properly.

Page 37

[НАЗВАНИЕ ДОКУМЕНТА]

МИХАИЛ ДОБРЫДЕНЬ

FAULTS AND REMEDIAL ACTIONS

Fault code

Cause

Effect and remedy

A.1.D6

External front power lift 'Raise'

button faulty.

Front power lift cannot be raised properly.

A.1.D7

Hydraulic oil level sensor faulty.

Hydraulic oil level no longer monitored.

A.1.D9

Hydraulic tank is empty.

Possible damage to pump or undesired

valve responses.

A.1.DA

Kickout push button faulty.

No Kickout function.

A.1.DB

Hydraulic oil characteristic not

plausible.

Incorrect display of hydraulic oil supply.

Reprogramme EOL.

A.1.DC

Priority volume of hydraulic oil

greater than pump volume.

Reduce priority hydraulic oil quantity.

A.1.DD

Front external key actuates

twice or key sticks.

Front power lift cannot be lowered properly.

Electrical valves (valve 1)

Fault code

Cause

Effect and remedy

A.1.10

Valve not registered on CAN

bus.

Valve actuation not possible.

A.1.1F

CAN-BUS error, valves.

Valves locked.

A.1.11

Electronics in valve faulty.

Valve goes into neutral position.

A.1.12

Voltage in the valve less than

8 Volt.

Valve goes into neutral position.

A.1.13

Voltage in excess of 18 V.

Valve goes into neutral position.

A.1.14

Valve actuator falls short.

Valve goes into neutral position.

A.1.1A

Valve actuator goes too far.

Valve goes into neutral position.

A.1.1B

Floating position not reached.

Valve goes into neutral position.

A.1.1C

Manual actuation.

A.1.15

High overvoltage over 45 V.

Valve goes into neutral position.

A.1.16

End stage error (end stage for

pilot control solenoid).

Valve goes into neutral position.

A.1.17

Position pickup sensor error.

Valve goes into neutral position.

A.1.18

Valve actuator does not return

to neutral position.

Valve remains set.

A.1.19

Valve actuator not in neutral position when switched on.

Valve remains set.

Page 38

[НАЗВАНИЕ ДОКУМЕНТА]

МИХАИЛ ДОБРЫДЕНЬ

FAULTS AND REMEDIAL ACTIONS

Spool valves (valve 2)

Fault code

Cause

Effect and remedy

A.1.20

Valve not registered on CAN

bus.

Valve actuation not possible.

A.1.2F

CAN-BUS error, valves.

Valves locked.

A.1.21

Electronics in valve faulty.

Valve goes into neutral position.

A.1.22

Voltage in the valve less than

8 Volt.

Valve goes into neutral position.

A.1.23

Voltage in excess of 18 V.

Valve goes into neutral position.

A.1.24

Valve actuator falls short.

Valve goes into neutral position.

A.1.2A

Valve actuator goes too far.

Valve goes into neutral position.

A.1.2B

Floating position not reached.

Valve goes into neutral position.

A.1.2C

Manual actuation.

A.1.25

High overvoltage over 45 V.

Valve goes into neutral position.

A.1.26

End stage error (end stage for

pilot control solenoid).

Valve goes into neutral position.

A.1.27

Position pickup sensor error.

Valve goes into neutral position.

A.1.28

Valve actuator does not return

to neutral position.

Valve remains set.

A.1.29

Valve actuator not in neutral position when switched on.

Valve remains set.

Spool valves (valve 3)

Fault code

Cause

Effect and remedy

A.1.30

Valve not registered on CAN

bus.

Valve actuation not possible.

A.1.3F

Valve CAN BUS error.

Valves locked.

A.1.31

Electronics in valve faulty.

Valve goes into neutral position.

A.1.32

Voltage in the valve less than

8 Volt.

Valve goes into neutral position.

A.1.33

Voltage in excess of 18 V.

Valve goes into neutral position.

A.1.34

Valve actuator falls short.

Valve goes into neutral position.

A.1.3A

Valve actuator goes too far.

Valve goes into neutral position.

A.1.3B

Floating position not reached.

Valve goes into neutral position.

A.1.3C

Manual actuation.

A.1.35

High overvoltage over 45 V.

Valve goes into neutral position.

A.1.36

End stage error (end stage for

pilot control solenoid).

Valve goes into neutral position.

A.1.37

Position pickup sensor error.

Valve goes into neutral position.

A.1.38

Valve actuator does not return

to neutral position.

Valve remains set.

A.1.39

Valve actuator not in neutral position when switched on.

Valve remains set.

Page 39

[НАЗВАНИЕ ДОКУМЕНТА]

МИХАИЛ ДОБРЫДЕНЬ

FAULTS AND REMEDIAL ACTIONS

Spool valves (valve 4)

Fault code

Cause

Effect and remedy

A.1.40

Valve not registered on the

CAN bus.

Valve actuation not possible.

A.1.4F

CAN-BUS error, valves.

Valves locked.

A.1.41

Electronics in valve faulty.

Valve goes into neutral position.

A.1.42

Voltage in the valve less than

8 Volt.

Valve goes into neutral position.

A.1.43

Voltage in excess of 18 V.

Valve goes into neutral position.

A.1.44

Valve actuator falls short.

Valve goes into neutral position.

A.1.4A

Valve actuator goes too far.

Valve goes into neutral position.

A.1.4B

Floating position not reached.

Valve goes into neutral position.

A.1.4C

Manual actuation.

A.1.45

High overvoltage over 45 V.

Valve goes into neutral position.

A.1.46

End stage error (end stage for

pilot control solenoid).

Valve goes into neutral position.

A.1.47

Position pickup sensor error.

Valve goes into neutral position.

A.1.48

Valve actuator does not return

to neutral position.

Valve remains set.

A.1.49

Valve actuator not in neutral position when switched on.

Valve remains set.

Electric valves (E-box)

Fault code

Cause

Effect and remedy

A.1.A0

EEPROM error.

Loss of enhanced features when operating valves.

A.1.A1

A.1.A2

More valves connected than

are registered through end-ofline programming. Undertake

programming.

Not all valves can be operated.

A.1.FO

Valve control for the switching

of the pilot control of all electrical valves with front power lift

faulty.

All valves go into neutral position.

A.1.F1

Valve control for the heating of

all electrical valves with front

power lift faulty.

Reduced operation in cold conditions.

A.1.F2

Valve control for switching the

pilot control of all spool valves

with front power lift faulty.

Call workshop.

A.1.F3

Valve control for switching the

pilot control of all spool valves

with front power lift has interrupted supply line.

Call workshop.

Page 40

Download from: https://truckmanualshub.com/

FAULTS AND REMEDIAL ACTIONS

Variotronic Ti

Fault code

Cause

Effect and remedy

B.1.11

Electrical fault, automatic

mode.

Call workshop.

B.1.12

Electrical fault, terminal.

Call workshop.

B.1.21

Communications error, internal

communication.

Call workshop.

B.1.22

Communications error between

terminal and Variotronic Ti.

Call workshop.

B.1.23

Communications error between

control console and Variotronic

Ti.

Call workshop.

B.1.24

Communications error between

joystick and Variotronic Ti.

Call workshop.

B.1.41

Communications error, internal

communication.

Call workshop.

B.1.42

Communications error between

terminal and Variotronic Ti.

Call workshop.

B.1.43

Communications error between

control console and Variotronic

Ti.

Call workshop.

B.1.44

Error counter between joystick

and Variotronic Ti.

Call workshop.

B.1.BO

Error reader Variotronic Ti.

Call workshop.

B.1.B4

Error in the memory function.

Restart tractor. If error is still there, consult workshop.

Loading...

Loading...