Page 1

Workshop Service Manual

FENDT 900 Vario - COM III

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

#)%1)OD*,QJCPP)GQTI(GPFV5VT&/CTMVQDGTFQTH

FENDT is a worldwide brand of AGCO

'FKVKQP20

No. X990.005.057.01

3 G - en

FENDT 900 Vario COM III - EAME

English

8QNWOG4

Page 2

All relevant accident prevention regulations and all generally accepted safety, health and

road traffic regulations must be strictly observed. The manufacturer does not accept liability

for damage resulting from unauthorised modifications.

Changes and additions reserved!

Page 3

FENDT 900 Vario - COM III

Table of contents

3

FENDT 900 Vario - COM III

0000 Overall system/tractor

1005 Overall system/transmission

1010 Transmission/differential

1015 Transmission/axle drive

1050 Transmission/housing

1070 Transmission / Brake system

1080 Transmission/drive train

1200 Transmission/front PTO

1220 Transmission / Live PTO

1320 Transmission/front wheel drive

2000 Overall system/engine

2010 Engine/cylinder head

2050 Engine/cooling

2060 Engine/fuel system

2210 Engine/crankcase

2312 Engine/lubrication

2400 Engine/exhaust system

2712 Engine/injectors

3000 Overall system/front axle

3120 Front axle/steering cylinder

3180 Front axle/cardan shaft

4000 Overall system/steering

4090 Steering system / hydraulic steering unit

5030 Vehicle layout/operator's seat

5500 Overall s

ystem/air conditioning system

8100 Overall system/cab

8610 Power lift/EPC electro-hydraulic control

8631 Power lift/hydraulic lift

8800 Overall system/compressed air system

9000 Overall system/electrical system

9015 Electrical system/starter lockout

8QNWOG

8QNWOG

8QNWOG

Page 4

9410 Hydraulic pump installation/LS pump

9430 Hydraulic pump installation/steering pump

9534 Hydraulic piping/"Rüfa"reverse operation

9600 Overall system/hydraulic equipment

9605 Hydraulic equipment/hydraulic connections

8QNWOG

FENDT 900 Vario - COM III

Table of contents

4

9610 Hydraulic equipment/central control block

(ZSB)

9620 Hydraulic equipment/valve fitting

9700

Overall system/electronics

9920 Service/special tools

9975 Service/SERDIA - Deutz engine diagnostics

program

Page 5

A

General

9410

9410

B

Faults Hydraulic pump installation/LS pump

Hydraulic pump installation/LS pump

C

Documents and Diagrams

D

Component location

E

Testing

F

Setting and Calibration

G

Repair

H

Service – Info

Page 6

Page 7

9410 - Hydraulic pump installation/LS pump

Table of contents

3

9410 Hydraulic pump installation/LS pump

G Repair. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Page 8

9410 - Hydraulic pump installation/LS pump

Table of contents

4

Page 9

9410 - Hydraulic pump installation/LS pump

Table of contents

5

G Repair

1 Removing the LS pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2 Installing the LS pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Page 10

9410 - Hydraulic pump installation/LS pump

Table of contents

6

Page 11

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

9410 - Hydraulic pump installation/LS pump

G - Repair

7

T000606

Version 1

22-06-2007

1 Removing the LS pump

Preliminary work:

– Drain fuel

– Remove battery

– Remove fuel tank, right

– Remove fuel hand pump and hydraulic hand pump

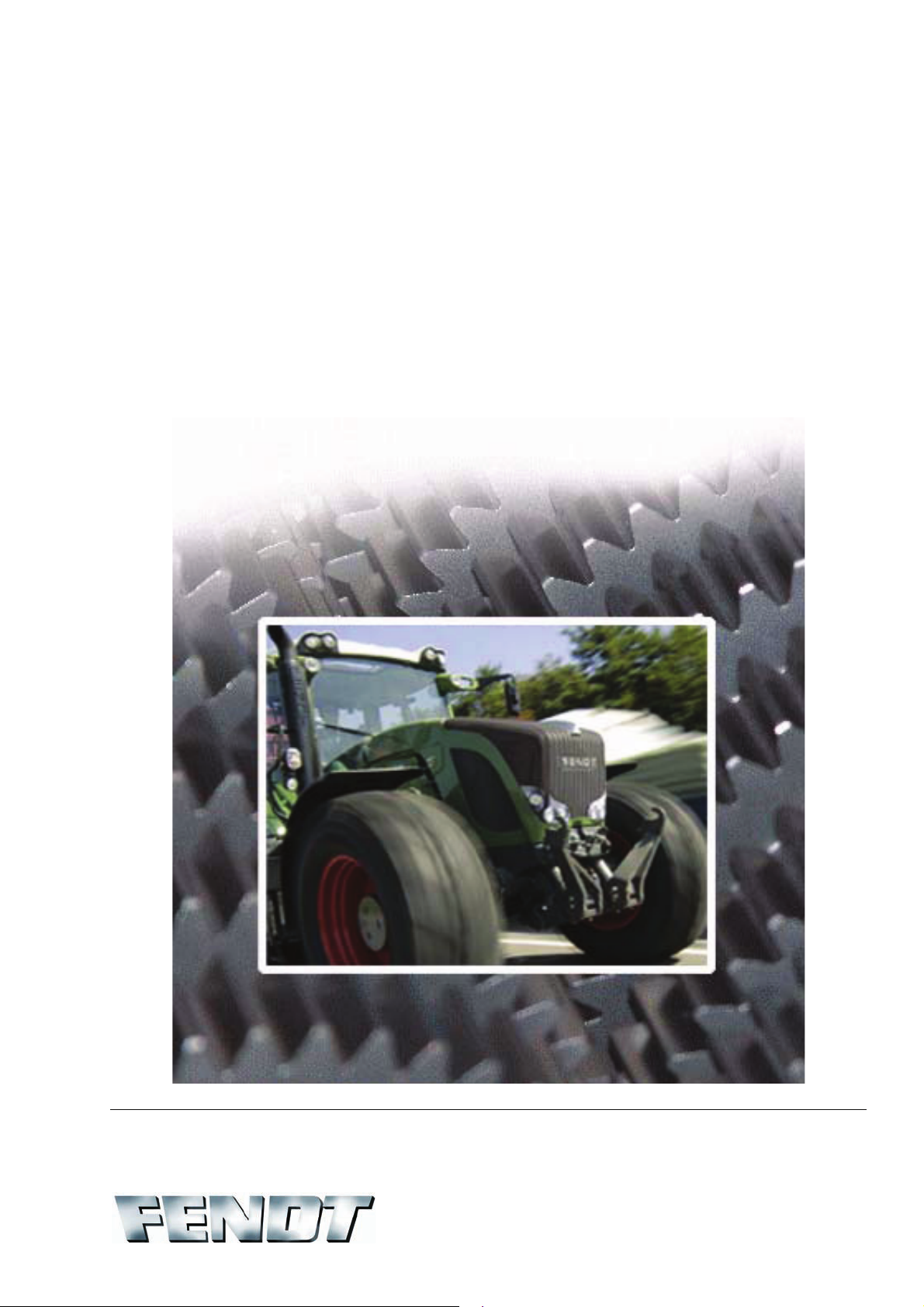

Drain hydraulic oil.

Loosen tank plate bolts and remove right tank plate.

Remove cable clip.

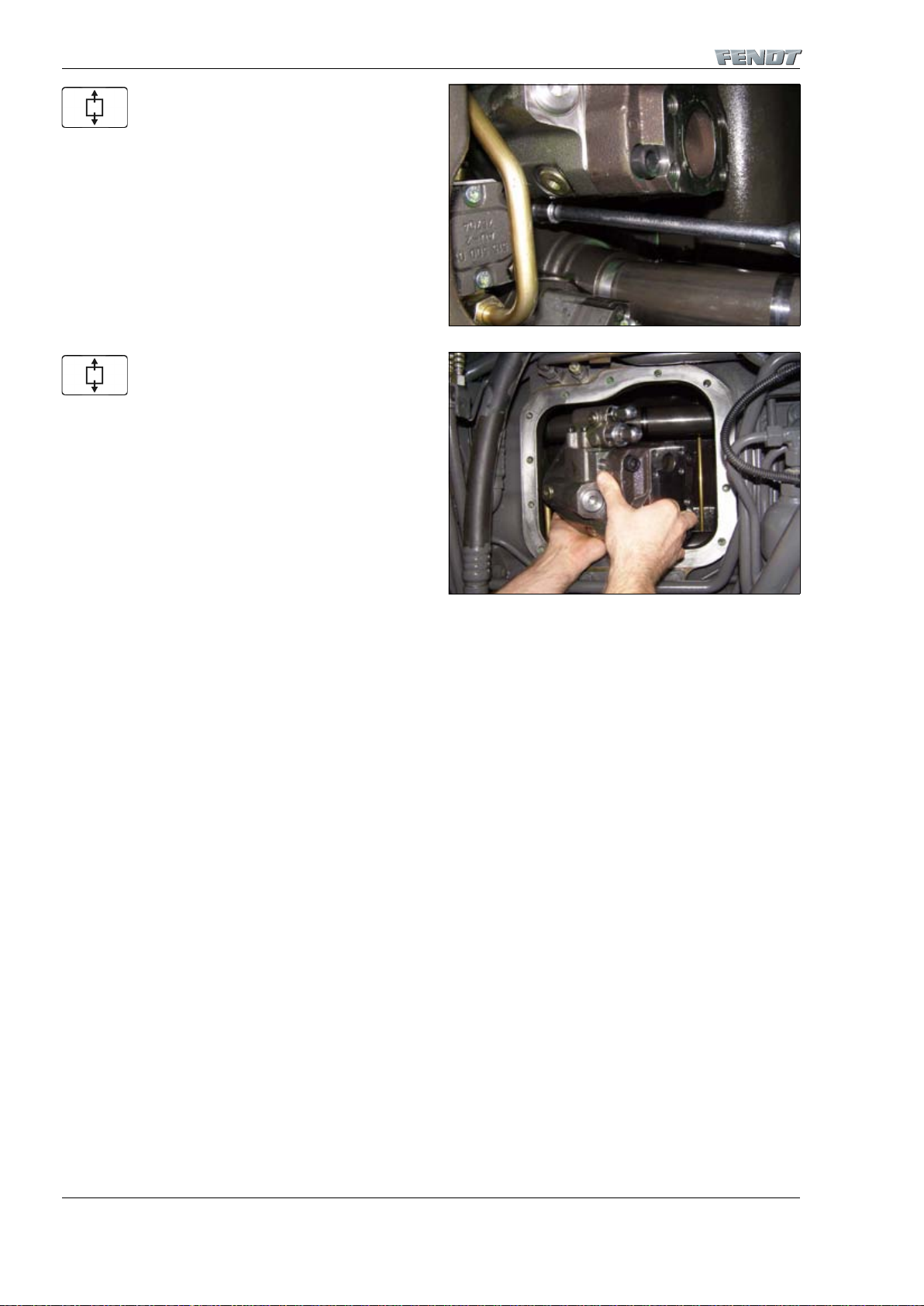

I001690

Fig. 1.

I0 0170 7

Fig. 2.

I001688

Fig. 3.

Page 12

9410 - Hydraulic pump installation/LS pump

G - Repair

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

8

T000606

Version 1

22-06-2007

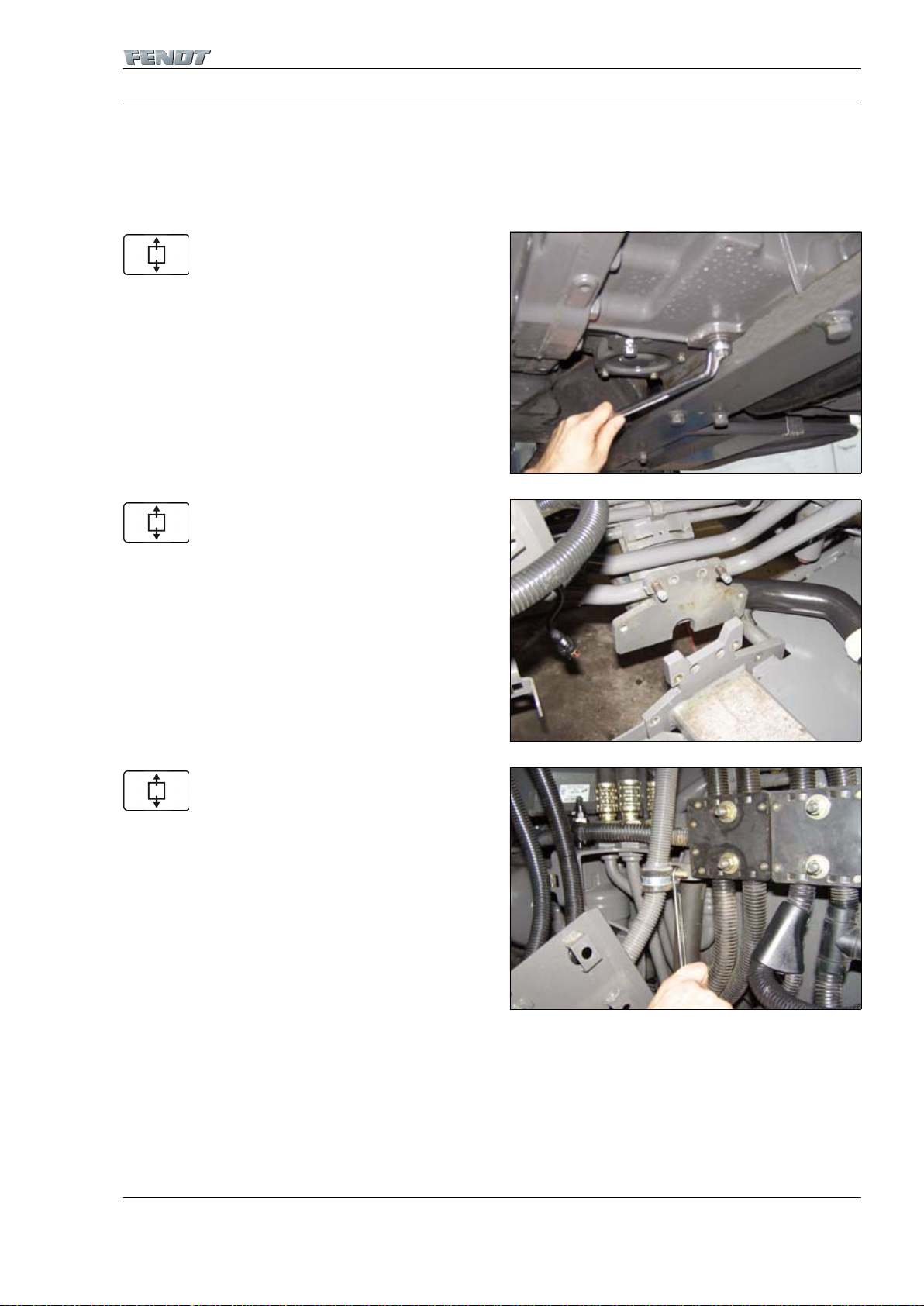

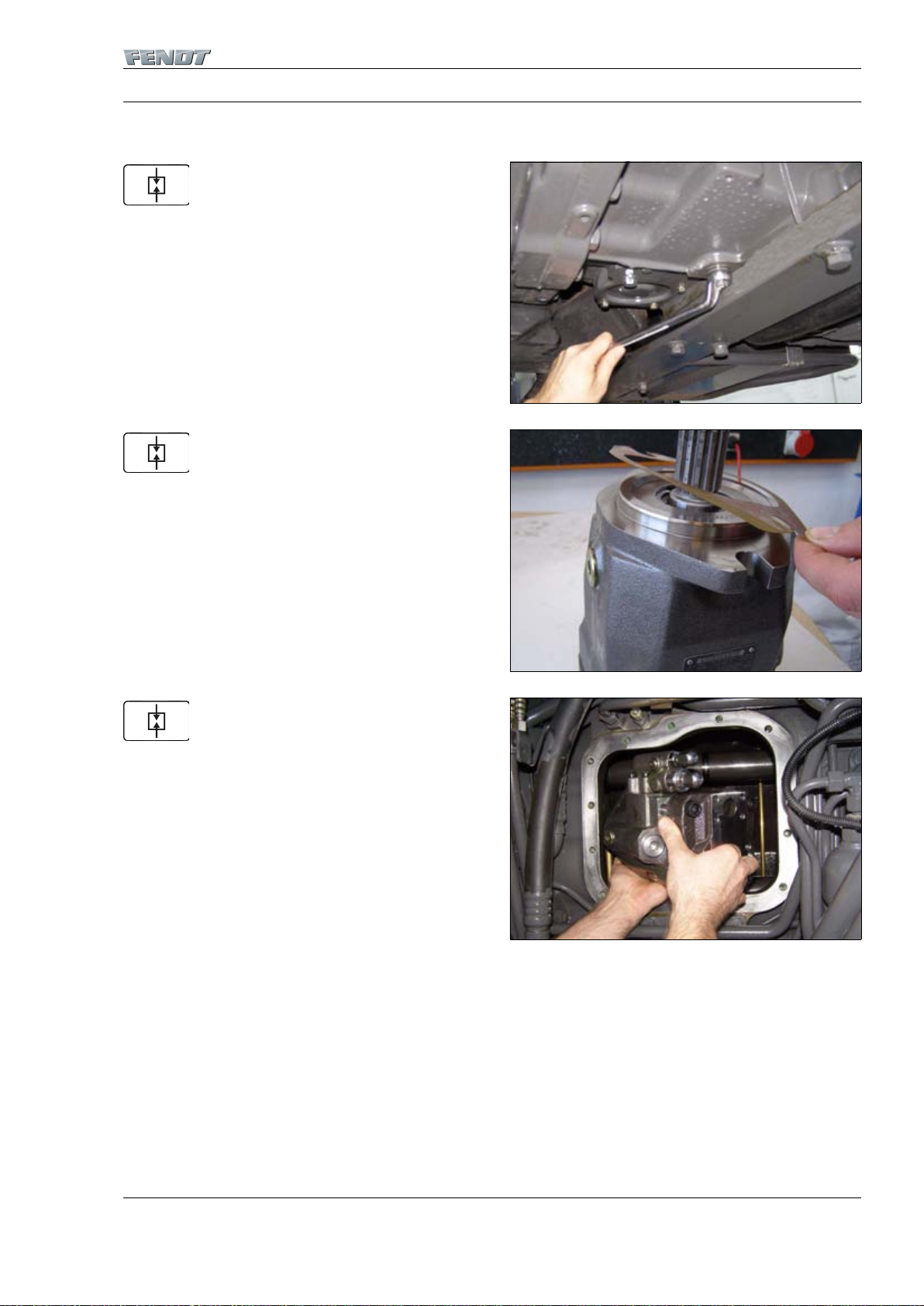

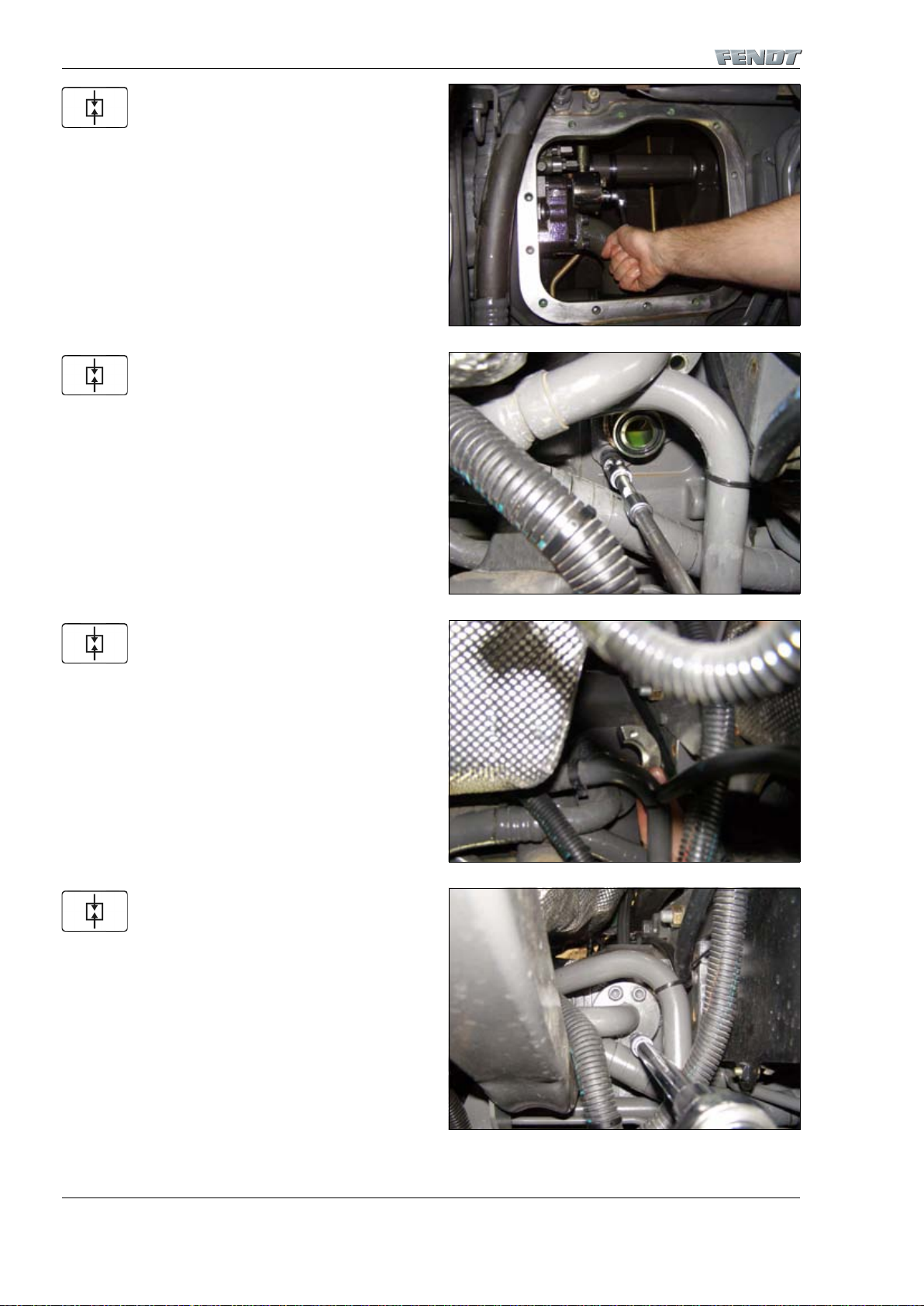

Loosen earth cable on engine.

Pull earth cable through to bracket.

Remove screws of bracket.

Fix cable bracket and cable in place so that cover is easily

accessible.

I001692

Fig. 4.

I001724

Fig. 5.

I001691

Fig. 6.

I001693

Fig. 7.

Page 13

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

9410 - Hydraulic pump installation/LS pump

G - Repair

9

T000606

Version 1

22-06-2007

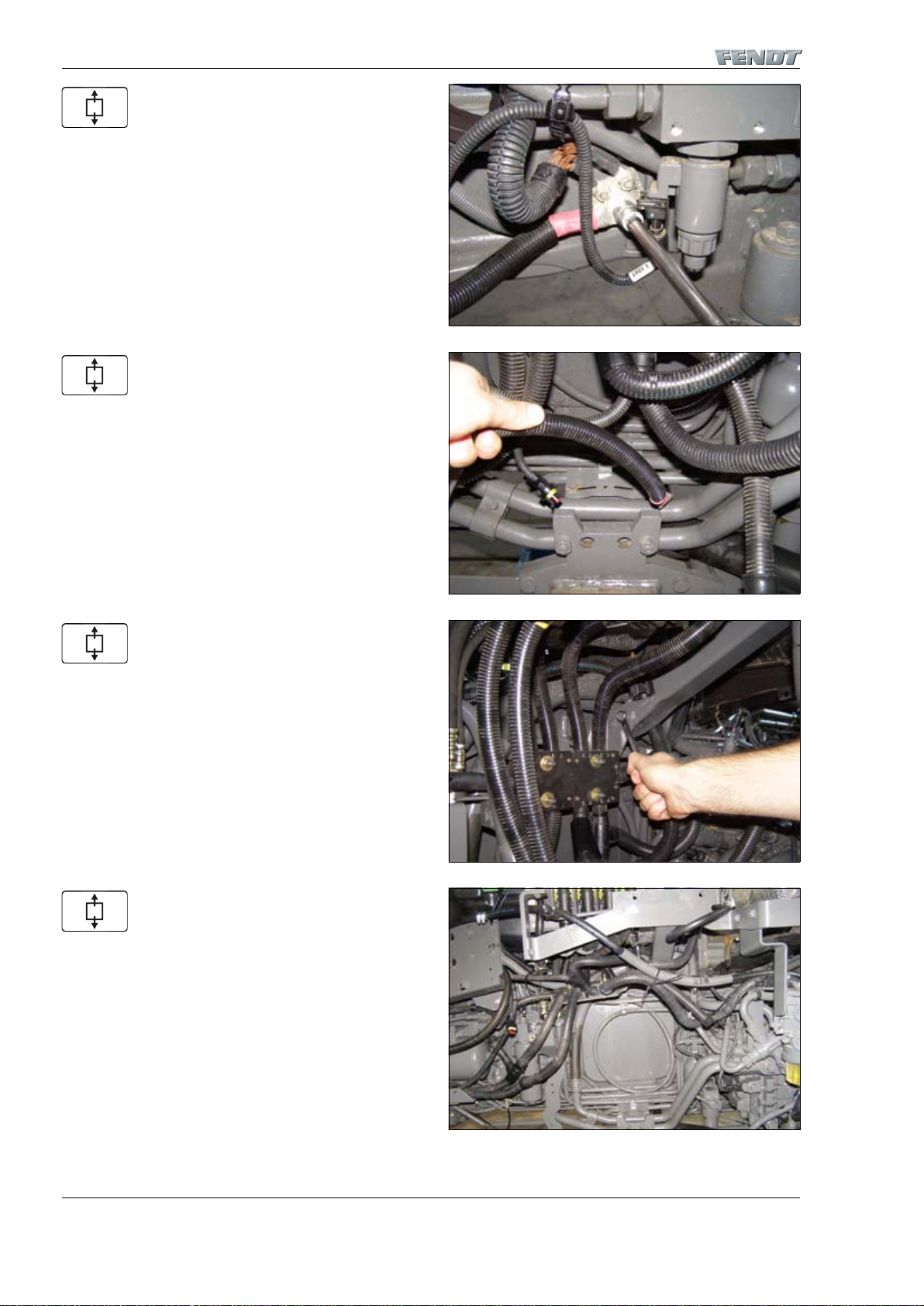

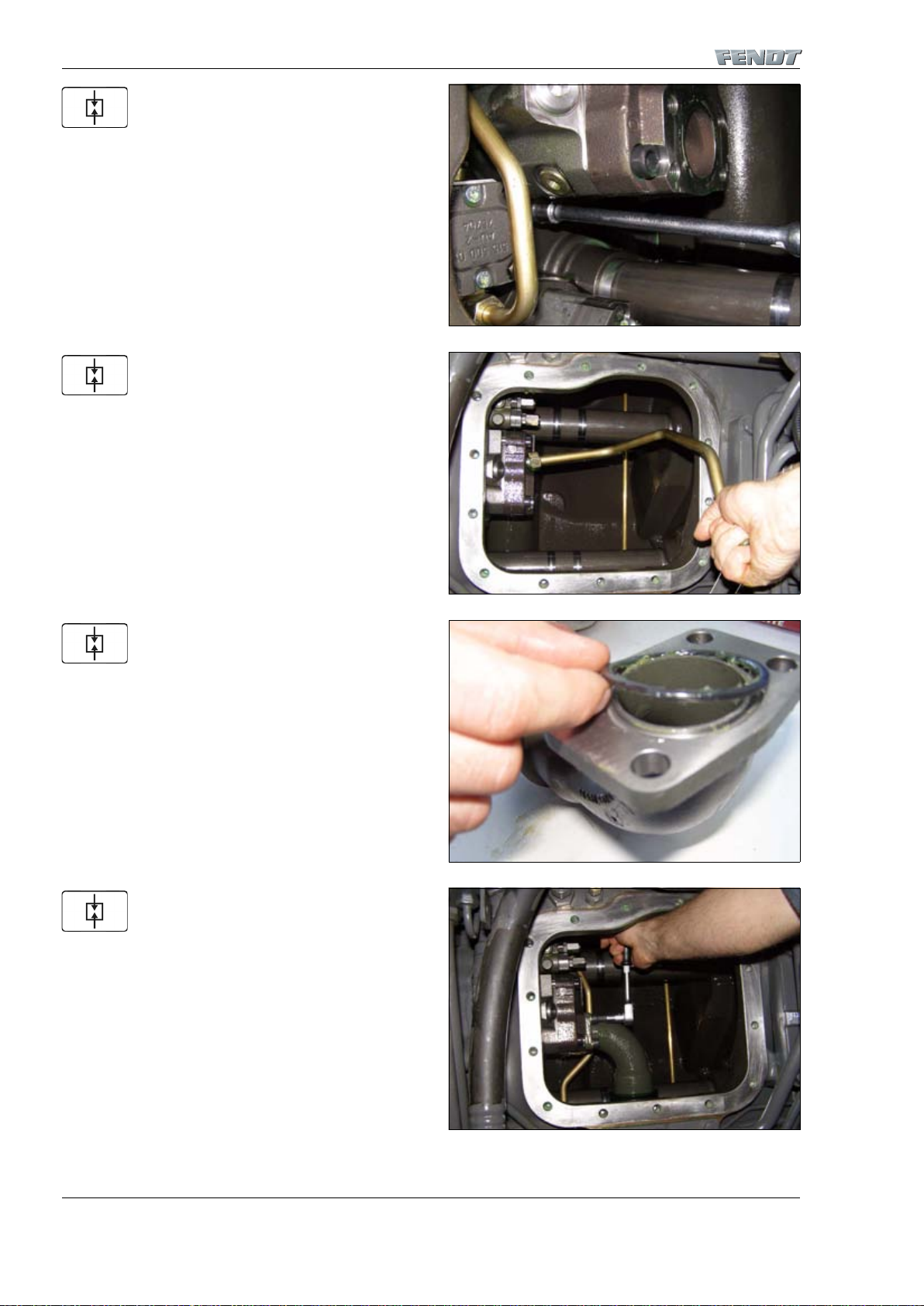

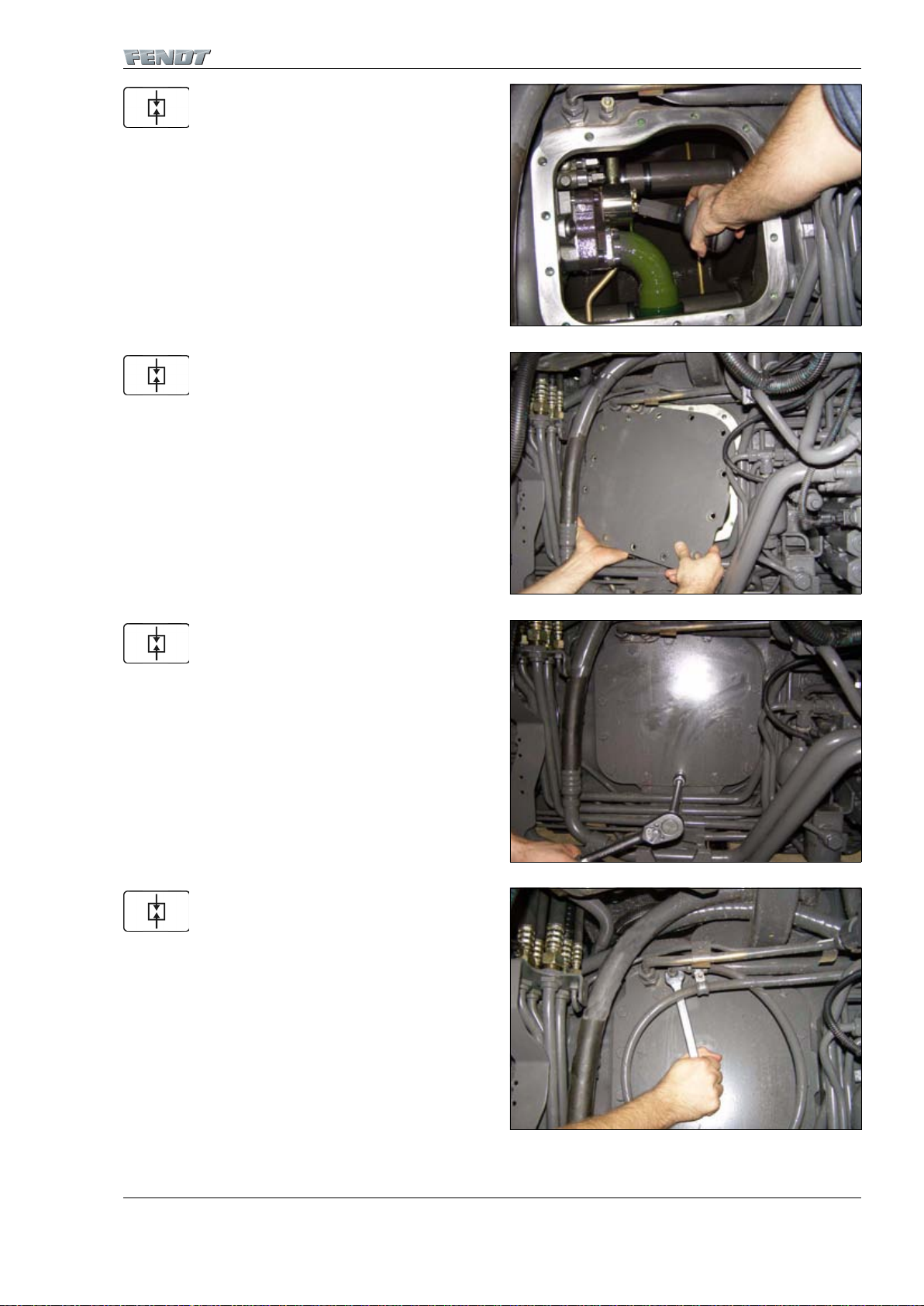

Separate LS line from housing and close lines, preventing

dirt from entering.

Loosen bolts of cover.

Remove cover of hydraulic oil tank.

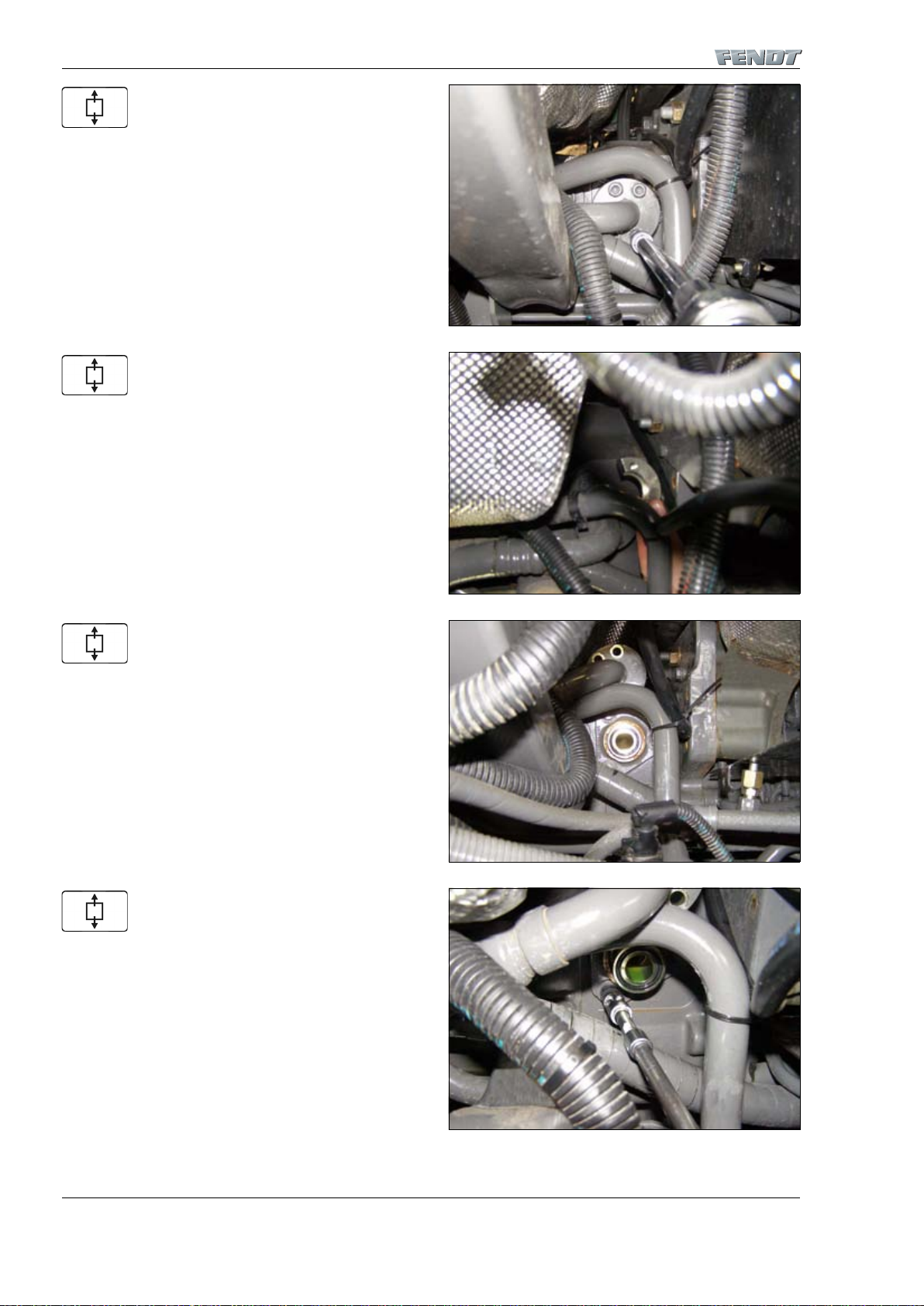

Remove silencer from line flange.

I001689

Fig. 8.

I001694

Fig. 9.

I001695

Fig. 10.

I001696

Fig. 11.

Page 14

9410 - Hydraulic pump installation/LS pump

G - Repair

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

10

T000606

Version 1

22-06-2007

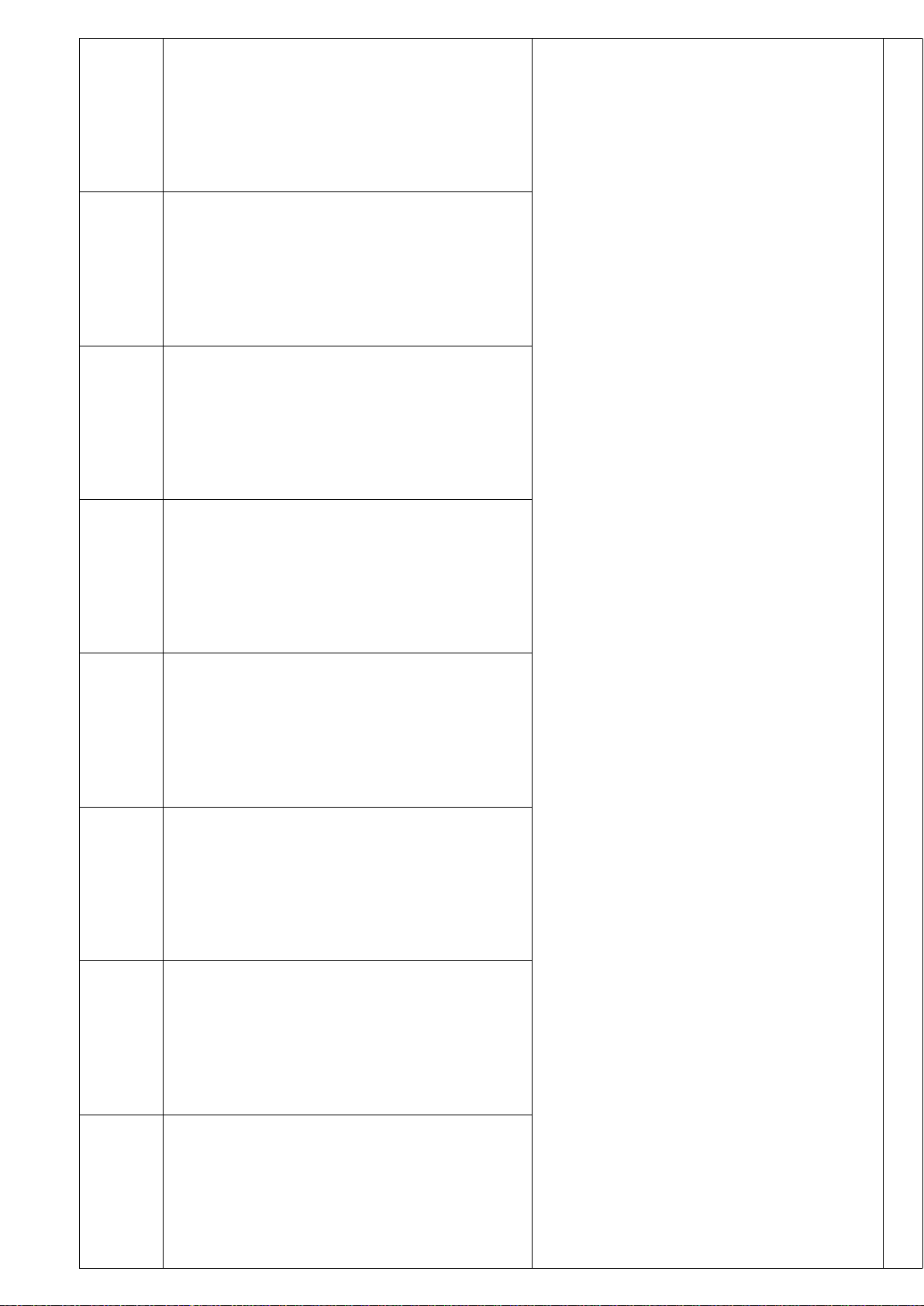

Loosen hexagon socket head screws from flange.

Hold on to crescent-shaped hardware when loosening

flange screws.

Fix pump hose in place on side.

Remove flange of pump line.

I001697

Fig. 12.

I001698

Fig. 13.

I001699

Fig. 14.

I001700

Fig. 15.

Page 15

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

9410 - Hydraulic pump installation/LS pump

G - Repair

11

T000606

Version 1

22-06-2007

Loosen screws of line flange.

Remove pump pressure line.

Remove pump intake line.

Remove hydraulic lines that are in the way when the

pump is removed.

I001701

Fig. 16.

I0 0170 2

Fig. 17.

I0 0170 3

Fig. 18.

I0 0170 4

Fig. 19.

Page 16

9410 - Hydraulic pump installation/LS pump

G - Repair

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

12

T000606

Version 1

22-06-2007

Remove bolts from LS pump.

Remove pump through opening.

NOTE: The pump is relatively heavy, so be careful when

you lift it out. Risk of injury!

I001705

Fig. 20.

I001706

Fig. 21.

Page 17

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

9410 - Hydraulic pump installation/LS pump

G - Repair

13

T000610

Version 1

22-06-2007

2 Installing the LS pump

Preliminary work:

– Clean sealing surfaces of hydraulic oil tank and hydraulic oil tank cover

Mount oil drain plug with new seal ring.

Mount new pump flange seal.

Mount pump through opening.

I001690

Fig. 22.

I0 0170 8

Fig. 23.

I0 0170 6

Fig. 24.

Page 18

9410 - Hydraulic pump installation/LS pump

G - Repair

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

14

T000610

Version 1

22-06-2007

Tighten bolts of pump with a tightening torque of 85 Nm.

Mount removed hydraulic lines.

Insert new O-rings in the suction flange applying a little

grease.

Mount intake line with suction filter on pump.

I001705

Fig. 25.

I001704

Fig. 26.

I001710

Fig. 27.

I001703

Fig. 28.

Page 19

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

9410 - Hydraulic pump installation/LS pump

G - Repair

15

T000610

Version 1

22-06-2007

Insert new O-rings (arrowed) in pump line applying a little

grease.

Thread pump pressure line through opening.

Tighten screws of line flange by hand.

Centre flange on pump line to prevent causing strain and

tighten screws by hand.

I0 0170 9

Fig. 29.

I0 0170 2

Fig. 30.

I001701

Fig. 31.

I0 0170 0

Fig. 32.

Page 20

9410 - Hydraulic pump installation/LS pump

G - Repair

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

16

T000610

Version 1

22-06-2007

Slightly loosen screws of line flange to align it and then

tighten with the prescribed tightening torque.

Slightly loosen screws of flange to align it and then

tighten the screws.

Flange pump hose to pump line and fasten through crescent-shaped hardware.

Tighten hexagon socket head screws.

I0 01701

Fig. 33.

I001700

Fig. 34.

I001698

Fig. 35.

I001697

Fig. 36.

Page 21

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

9410 - Hydraulic pump installation/LS pump

G - Repair

17

T000610

Version 1

22-06-2007

Mount silencer.

Apply X903.050.074 sealant on sealing surfaces and

mount cover.

Tighten screws of tank cover with a tightening torque of

120 Nm

Mount LS line.

I001696

Fig. 37.

I001695

Fig. 38.

I001694

Fig. 39.

I001689

Fig. 40.

Page 22

9410 - Hydraulic pump installation/LS pump

G - Repair

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

18

T000610

Version 1

22-06-2007

Mount cable bracket.

Attach earth cable to engine earth pin.

Mount cable clip.

Mount tank plate with bolts.

Final procedures:

I001691

Fig. 41.

I001692

Fig. 42.

I001688

Fig. 43.

I001707

Fig. 44.

Page 23

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

9410 - Hydraulic pump installation/LS pump

G - Repair

19

T000610

Version 1

22-06-2007

– Mount fuel hand pump and hydraulic oil hand pump

– Fill up hydraulic oil (change hydraulic oil filter and hydraulic oil depending on hours and contamination)

– Mount fuel tank on right

– Mount battery

– Fill up fuel

Page 24

9410 - Hydraulic pump installation/LS pump

G - Repair

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

20

T000610

Version 1

22-06-2007

Page 25

A

General

9430

9430

B

Faults

Hydraulic pump installation/steering

pump

Hydraulic pump installation/steering pump

C

Documents and Diagrams

D

Component location

E

Testing

F

Setting and Calibration

G

Repair

H

Service – Info

Page 26

Page 27

9430 - Hydraulic pump installation/steering pump

Table of contents

3

9430 Hydraulic pump installation/steering pump

G Repair. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Page 28

9430 - Hydraulic pump installation/steering pump

Table of contents

4

Page 29

9430 - Hydraulic pump installation/steering pump

Table of contents

5

G Repair

1 Removing the wheel-driven emergency steering pump . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2 Installing the wheel-driven emergency steering pump . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Page 30

9430 - Hydraulic pump installation/steering pump

Table of contents

6

Page 31

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

9430 - Hydraulic pump installation/steering pump

G - Repair

7

T000613

Version 2

09-11-2007

1 Removing the wheel-driven emergency steering pump

Preliminary work:

– Drain fuel

– Remove fuel tank, right

– Remove battery

– Remove fuel hand pump and hydraulic hand pump

Drain hydraulic oil.

Drain transmission oil.

Loosen tank plate bolts and remove right tank plate.

I001690

Fig. 1.

I001718

Fig. 2.

I0 0170 7

Fig. 3.

Page 32

9430 - Hydraulic pump installation/steering pump

G - Repair

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

8

T000613

Version 2

09-11-2007

Remove cable clip.

Loosen earth cable on engine.

Pull earth cable through to bracket.

Remove cable bracket bolts.

I001688

Fig. 4.

I001692

Fig. 5.

I001724

Fig. 6.

I001691

Fig. 7.

Page 33

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

9430 - Hydraulic pump installation/steering pump

G - Repair

9

T000613

Version 2

09-11-2007

Fix cable bracket and cable in place so that cover is easily

accessible.

Separate LS line from housing and close lines, preventing

dirt from entering.

Loosen bolts of cover.

Remove cover.

I001693

Fig. 8.

I001689

Fig. 9.

I001694

Fig. 10.

I001695

Fig. 11.

Page 34

9430 - Hydraulic pump installation/steering pump

G - Repair

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

10

T000613

Version 2

09-11-2007

Remove intake line with suction filter of LS pump.

Remove pressure line from emergency steering pump.

Loosen emergency steering pump bolts.

Remove emergency steering pump through opening.

I001703

Fig. 12.

I0 01719

Fig. 13.

I001720

Fig. 14.

I001721

Fig. 15.

Page 35

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

9430 - Hydraulic pump installation/steering pump

G - Repair

11

T000614

Version 2

09-11-2007

2 Installing the wheel-driven emergency steering pump

Preliminary work:

– Clean sealing surfaces of housing and cover.

Insert new O-ring on emergency steering pump applying

a little grease.

Mount emergency steering pump.

Tighten bolt with a tightening torque of 70 Nm.

I0 0172 2

Fig. 16.

I0 0172 1

Fig. 17.

I0 0172 0

Fig. 18.

Page 36

9430 - Hydraulic pump installation/steering pump

G - Repair

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

12

T000614

Version 2

09-11-2007

Mount pressure line of emergency steering pump.

Mount intake line with suction filter of LS pump.

Apply X903.050.074 sealant on sealing surfaces and

mount cover.

Tighten screws of tank cover with a tightening torque of

120 Nm

I0 01719

Fig. 19.

I001703

Fig. 20.

I001695

Fig. 21.

I001694

Fig. 22.

Page 37

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

9430 - Hydraulic pump installation/steering pump

G - Repair

13

T000614

Version 2

09-11-2007

Mount LS line.

Mount cable bracket.

Attach earth cable to engine earth pin.

Mount cable clip.

I001689

Fig. 23.

I001691

Fig. 24.

I001692

Fig. 25.

I001688

Fig. 26.

Page 38

9430 - Hydraulic pump installation/steering pump

G - Repair

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

14

T000614

Version 2

09-11-2007

Mount tank plate with bolts.

Mount hydraulic oil drain plug with new seal ring.

Tighten transmission oil drain plug.

Final procedures:

– Mount fuel hand pump and hydraulic oil hand pump

– Fill up hydraulic oil (change hydraulic oil filter and hydraulic oil depending on hours and contamination)

– Fill up transmission oil (change transmission oil filter and transmission oil depending on hours and contamination)

– Mount fuel tank on right

– Reconnect battery

– Fill up fuel

I001707

Fig. 27.

I001690

Fig. 28.

I001718

Fig. 29.

Page 39

A

General

9534

9534

B

Faults Hydraulic piping/"Rüfa"reverse operation

Hydraulic piping/"Rüfa"reverse operation

C

Documents and Diagrams

D

Component location

E

Testing

F

Setting and Calibration

G

Repair

H

Service – Info

Page 40

Page 41

9534 - Hydraulic piping/"Rüfa"reverse operation

Table of contents

3

9534 Hydraulic piping/"Rüfa"reverse operation

C Documents and diagrams . . . . . . . . . . . . . . . . . . . . . .5

G Repair. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Page 42

9534 - Hydraulic piping/"Rüfa"reverse operation

Table of contents

4

Page 43

9534 - Hydraulic piping/"Rüfa"reverse operation

Table of contents

5

C Documents and diagrams

1 Technical drawing of rotary feedthrough (Rüfa) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Page 44

9534 - Hydraulic piping/"Rüfa"reverse operation

Table of contents

6

Page 45

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

9534 - Hydraulic piping/"Rüfa"reverse operation

C - Documents and diagrams

7

T001352

Version 1

21-04-2009

1 Technical drawing of rotary feedthrough (Rüfa)

I003770

Fig. 1.

Item Designation Item Designation

1 Washer 13 Rotor (not available individually)

2 Bearing 15 Ring (not available individually)

3 Hex screw 16 Shim (not available individually)

4 Spring washer 18 Seal set

6 Carrier 21 Thread insert (not available individually)

7 Pressure hose 22 Socket head cap screw

10 Rotary feedthrough (complete) 23 Seal ring

11 Stator (not available individually) 24 Hex screw

12 Stator (not available individually) 25 Spring washer

Page 46

9534 - Hydraulic piping/"Rüfa"reverse operation

C - Documents and diagrams

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

8

T001352

Version 1

21-04-2009

Cross-section of rotary feedthrough

I003767

Fig. 2.

Page 47

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

9534 - Hydraulic piping/"Rüfa"reverse operation

C - Documents and diagrams

9

T001352

Version 1

21-04-2009

Underside view

A.) Ensure the correct positioning of the bores on the carrier ring rotor during installation.

I003768

Fig. 3.

Page 48

9534 - Hydraulic piping/"Rüfa"reverse operation

C - Documents and diagrams

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

10

T001352

Version 1

21-04-2009

Top view

I003769

Fig. 4.

Page 49

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

9534 - Hydraulic piping/"Rüfa"reverse operation

C - Documents and diagrams

11

T001352

Version 1

21-04-2009

Ports on the rotary feedthrough

Piping for the rotary feedthrough (rotor)

Serial

No.

NW Ports Max.

pressure

Max. flow rate Medium Function

Rotor Stator (bar) (l/min)

1 6 M16 x 1.5 M16 x 1.5 8.5 - Compressed air Hand brake

2 6 M16 x 1.5 M16 x 1.5 8.5 - Compressed air Hand brake

3 6 M16 x 1.5 M16 x 1.5 8.5 - Compressed air Hand brake

4 8 M14 x 1.5 M16 x 1.5 8.5 - Compressed air Tank, right

5 8 M14 x 1.5 M16 x 1.5 8.5 - Compressed air Brake, front axle

6 8 M14 x 1.5 M16 x 1.5 8.5 Compressed air Brake, rear axle

7 8 M14 x 1.5 M16 x 1.5 8.5 - Compressed air Tank, l e f t

8 Internal connection channel with 14 - - 9 6 M12 x 1.5 M12 x 1.5 210 1 Hydraulic oil Load sensing (LS)

10 6 M12 x 1.5 M12 x 1.5 30 3 Pentosin

(X902.011.622)

Clutch

11 12 M18 x 1.5 M18 x 1.5 210 50 Hydraulic oil Pump pressure

(p)

12 12 M18 x 1.5 M18 x 1.5 210 50 Hydraulic oil Steering, right

13 12 M18 x 1.5 M18 x 1.5 210 50 Hydraulic oil Steering, left

14 12 M18 x 1.5 M18 x 1.5 3 5 Hydraulic oil Return (R)

15 8 M14 x 1.5 - - - Air Outlet air, hand-

brake

16 8 M16 x 1.5 - - - Air Outlet air, hand-

brake

I003771

Fig. 5.

Page 50

9534 - Hydraulic piping/"Rüfa"reverse operation

C - Documents and diagrams

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

12

T001352

Version 1

21-04-2009

Piping for the rotary feedthrough (stator)

I003772

Fig. 6.

Page 51

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

9534 - Hydraulic piping/"Rüfa"reverse operation

Table of contents

13

G Repair

1 Sealing the rotary feedthrough. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Page 52

9534 - Hydraulic piping/"Rüfa"reverse operation

Table of contents

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

14

Page 53

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

9534 - Hydraulic piping/"Rüfa"reverse operation

G - Repair

15

T002984

Version 1

21-04-2009

1 Sealing the rotary feedthrough

Loosen cap screws (22) by about three turns

I007993

Fig. 1.

Item Designation Item Designation

1 Washer 13 Rotor (not available individually)

2 Bearing 15 Ring (not available individually)

3 Hex screw 16 Shim (not available individually)

4 Spring washer 18 Seal set

6 Carrier 21 Thread insert (not available individually)

7 Pressure hose 22 Socket head cap screw

10 Rotary feedthrough (complete) 23 Seal ring

11 Stator (not available individually) 24 Hex screw

12 Stator (not available individually) 25 Spring washer

I007965

Fig. 2.

Page 54

9534 - Hydraulic piping/"Rüfa"reverse operation

G - Repair

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

16

T002984

Version 1

21-04-2009

Place wood underneath the three lugs, so that there is a

gap between the working surface and the front end of the

rotary feedthrough; using a rubber mallet, tap the screw

head thus moving stator (11) downwards and then remove cap screws (22)

Turn rotary feedthrough and remove hex bolts (24)

Disassemble stator (11) and ring (15) using a mounting lever

Remove stator (11) and ring (15)

I007966

Fig. 3.

I007968

Fig. 4.

I007967

Fig. 5.

I007969

Fig. 6.

Page 55

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

9534 - Hydraulic piping/"Rüfa"reverse operation

G - Repair

17

T002984

Version 1

21-04-2009

Disassemble ring (16)

Push rotor (13) out of stator (12), use the 3 lugs on stator

(12) as a supporting surface

Hold rotor (13) while pushing it out

Take the seal ring and O-ring out of rotor (13)

NOTE: A bent welding wire can be used as an aid here

I007970

Fig. 7.

I007971

Fig. 8.

I007972

Fig. 9.

I007973

Fig. 10.

Page 56

9534 - Hydraulic piping/"Rüfa"reverse operation

G - Repair

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

18

T002984

Version 1

21-04-2009

Take the seal ring and O-ring out of stator (12)

NOTE: A bent welding wire can be used as an aid here

NOTE: Check all surfaces and grooves for damage and wear

Lightly spray all seals with oil

Fit O-rings in stator (12)

Fit seal rings in stator (12), while pressing the seal ring in

a crescent shape

I007974

Fig. 11.

I007977

Fig. 12.

I007976

Fig. 13.

I007980

Fig. 14.

Page 57

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

9534 - Hydraulic piping/"Rüfa"reverse operation

G - Repair

19

T002984

Version 1

21-04-2009

Fit O-rings in rotor (13)

Fit seal rings in rotor (13), while pressing the seal ring in a

crescent shape

Lubricate the sealing washer and place on stator (12)

Insert rotor (13) in stator (12)

I007981

Fig. 15.

I007982

Fig. 16.

I007975

Fig. 17.

I007983

Fig. 18.

Page 58

9534 - Hydraulic piping/"Rüfa"reverse operation

G - Repair

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

20

T002984

Version 1

21-04-2009

Push rotor (13) into stator (12)

Mount ring (15) using hex bolts (24), turn rotor (13) such

that the bore (arrow) of the rotor and of the ring are directly above one another

Lubricate the sealing washer and fit to stator (11)

Press in stator (11)

I007989

Fig. 19.

I007984

Fig. 20.

I007985

Fig. 21.

I007990

Fig. 22.

Page 59

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

9534 - Hydraulic piping/"Rüfa"reverse operation

G - Repair

21

T002984

Version 1

21-04-2009

Lubricate the sealing washer and place on washer (16)

Fit washer (16)

Fit cap screws with seal ring (22, 23)

Tightening torque: 9 Nm

Check for leaks: Charge every port on the rotary

feedthrough in succession with compressed air (own provision), close each outlet and then listen and feel whether

air is escaping from a different outlet

NOTE: see §1

I007986

Fig. 23.

I007988

Fig. 24.

I007965

Fig. 25.

I007987

Fig. 26.

Page 60

9534 - Hydraulic piping/"Rüfa"reverse operation

G - Repair

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

22

T002984

Version 1

21-04-2009

Page 61

A

General

9600

9600

B

Faults Overall system/hydraulic equipment

Overall system/hydraulic equipment

C

Documents and Diagrams

D

Component location

E

Testing

F

Setting and Calibration

G

Repair

H

Service – Info

Page 62

Page 63

9600 - Overall system/hydraulic equipment

Table of contents

3

9600 Overall system/hydraulic equipment

A General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

C Documents and diagrams . . . . . . . . . . . . . . . . . . . . .17

E Measuring and testing . . . . . . . . . . . . . . . . . . . . . . . .25

Page 64

9600 - Overall system/hydraulic equipment

Table of contents

4

Page 65

9600 - Overall system/hydraulic equipment

Table of contents

5

A General

1 Pressure regulation – PR (LS pump). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2 Hydraulic comparison: FENDT 900 COM III to FENDT 900 COM II. . . . . . . . . . . . . . . . . . 10

3 Technical specification: working and steering hydraulics. . . . . . . . . . . . . . . . . . . . . . . . . . 11

4 Overview of pressure measuring points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5 External pressure rise (Power Beyond) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Page 66

9600 - Overall system/hydraulic equipment

Table of contents

6

Page 67

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

9600 - Overall system/hydraulic equipment

A - General

7

T000448

Version 2

07-11-2007

1 Pressure regulation – PR (LS pump)

The LS pump is not driven

The variable displacement piston (1) is brought into contact with the "Q max. stop" by spring force and the pump is stationary in maximum swivel angle position (max. volume flow 163 l/min or 215 l/min).

At the same time, the spring pushes the pressure cut-off valve (2) into the position shown.

The large variable displacement piston chamber is connected to the tank connection via the control line.

The stationary pump is not supplying any oil, so no pressure builds up.

The pump is driven at a constant speed.

The pump generates a volume flow from the suction point to the consumer.

Pressure rises in the high-pressure pipe according to the load resistance of the consumer.

At the same time, this working pressure acts on the measuring surface of the control valve (2).

As long as the working pressure does not reach the set value (Pmax), the force of the spring prevails over the control

piston of the control valve (2).

The control piston remains in its position, and the pump remains in maximum swivel angle position accordingly (Q max).

The consumer is moved at maximum speed.

I001331

Fig. 1.

Page 68

9600 - Overall system/hydraulic equipment

A - General

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

8

T000448

Version 2

07-11-2007

As the working pressure increases, the pressure on the measuring surface of the control valve (2) increases accordingly.

The hydraulic force prevails over the set spring force, and the control valve (2) moves to the right and opens the valve.

The pressure in the large variable displacement chamber of the variable displacement piston (1) increases.

If this pressure increases to exceed the counter pressure built up by the spring force and the pressure in the small chamber, the variable displacement piston moves to the left.

This process denotes the start of control.

A further increase in working pressure creates a larger opening of the control valve (2) and increased pressure in the large

variable displacement chamber (1).

The pump swivels towards zero (Q min) and keeps the working pressure at a constant.

Absolute zero is not reached by this swivel process; "zero" position means that no axial piston movement takes place and

therefore oil is no longer supplied.

However, there may be internal leaking, at the pump itself and at the stationary consumer and the valves.

The pump needs to compensate for this to maintain the pressure.

The pump provides a permanent supply of oil to do this.

The pump remains in a "quasi-zero position".

I001332

Fig. 2.

Page 69

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

9600 - Overall system/hydraulic equipment

A - General

9

T000448

Version 2

07-11-2007

The working pressure at the pressure connection falls (e.g. by actuating a directional control valve).

The pressure on the measuring surface of the control valve (2) falls under the spring pressure and the control piston is

moved to the left by the spring force.

The large variable displacement chamber (1) is relieved by the control line to the tank.

The spring force causes the variable displacement piston to swivel out, thus reaching the axial piston pump.

The maximum volume flow (Q max) of the pump is available for the directional control valve.

I001333

Fig. 3.

Page 70

9600 - Overall system/hydraulic equipment

A - General

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

10

T000446

Version 3

31-10-2008

2 Hydraulic comparison: FENDT 900 COM III to FENDT 900 COM II

Summary and comparison of hydraulic systems

Component FENDT 900 COM III FENDT 900 COM II

LS pump Inclined disc axial-flow piston pump

with pressure and flow rate control

Inclined disc axial-flow piston pump

with pressure and flow rate control

Minimum standby pressure (valves

locked)

22 bar 22 bar

Minimum standby pressure (valves

unlocked)

22 bar 42 to 45 bar

Flow rate 163 l/min (optional 215 l/min) 110 l/min (163 l/min, optional from

10/2 004)

Pump drive 1¼ inch 1 inch from 10/2004 (previously 7/8

inch)

Control pressure differential 20 bar 20 bar

Max. working pressure 200 bar 200 bar

Control pressure 23 bar from the auxiliary pump 23 bar from the LS pump

Auxiliary pump Gear pump Gear pump

Flow rate 22.5 cc/r - 55l/min --->

1-circuit brake system without front

PTO

11 cc/r - 34 l/min

22.5 cc/r + 8 cc/r --->

1-circuit brake system with front PTO

22.5 cc/r + 16 cc/r --->

2-circuit brake system

Connection condition When the pilot pressure is released

or the LS pump is exhausted

LS pump exhausted or steering sluggish

Max. pressure 200 bar 190 bar

Wheel-driven emergency steering

pump

Wheel-driven gear pump ----------

Flow rate 8 cc/r ----------

Control valves SB 23 LS-EHS 2 SB 23 LS-EHS

Max. flow rate 100 l/min (optional 140 l/min - only

Pos. 4 possible)

80 l/min

Measuring and testing - pressure

measuring points

M1 Emergency steering pump pressure

(wheel-driven)

Not present

M2 Auxiliary pump pressure Auxiliary pump pressure

M3 LS pump pressure LS pump pressure

M4 LS pressure LS pressure

M5 Control pressure Control pressure

Page 71

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

9600 - Overall system/hydraulic equipment

A - General

11

T000320

Version 3

05-10-2009

3 Technical specification: working and steering hydraulics

Component Specifications

Working and steering hydraulics Load sensing hydraulics

LS pump PR Inclined disc axial flow piston pump

with pressure and flow rate regulation

Pump (series): flow rate at

rated engine speed = 2200 rpm

163 l/min

Pump (optional): flow rate at

rated engine speed = 2200 rpm

215 l/min

Max. working pressure 200 bar

Control pressure differential 20 bar

Transmission ratio (diesel engine: pump) 0.869

Auxiliary pump PH Gear pump

Flow rate/revolution for

1-circuit braking system without front PTO

22.5 cc/rev. – single pump

Flow rate/revolution for

1-circuit braking system with front PTO

22.5 cc/rev + 8 cc/rev tandem pump

at 25 bar DBV

Flow rate/revolution for

2-circuit braking system with/without front PTO

22.5 cc/rev + 16 cc/rev tandem pump

at 25 bar DBV

Transmission ratio (diesel engine: pump) 0.896

Flow rate at

rated engine speed = 2200 rpm

55 l/min

Max. pressure 190 bar

Drive Flange-mounted to air compressor

Emergency steering pump PNL 8 cc wheel-driven gear pump

Flow rate at 60 km/h 36 l/min

Flow rate at 10 km/h 6 l/min

Drive via 4WD

Auxiliary control valves SB 23 LS-EHS 2

Max. flow rate 100 l/min (optional 140 l/min - only Pos. 4 possible)

Auxiliary control valves (standard) 4 valves, rear:

1.1 "yellow", 1.2 "blue", 1.3 "red", 1.4 "green"

Auxiliary control valves (optional) Max. 6 valves, rear: 1.5 "brown", 1.6 "purple"

+ 2 valves, front: 2.1 "olive", 2.2 "grey"

Actuation system Electro-hydraulic via CAN bus (daisy chain)

Rear power lift (Power) EPC 23 C - SA

Rear power lift (Professional) EPC 23 C - SA/DA

Front power lift (Standard) Hydac valve SA

Front power lift (Enhanced control) EPC 23 C - SA/DA

Hydraulic trailer brake valve Optional

Page 72

9600 - Overall system/hydraulic equipment

A - General

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

12

T000320

Version 3

05-10-2009

1.1 Yellow valve (standard)

1.2 Blue valve (standard)

1.3 Red valve (standard)

1.4 Green valve (standard)

1.5 Brown valve

1.6 Violet valve

CD Overflow oil line (Case Drain)

Hy. ABV Hydraulic trailer brake valve

LS LS control line (load sensing)

P Pump pressure line

RH Return line, rear

2.1 Olive valve

2.2 Grey valve

RF Return line, front

I004435

Fig. 4.

I000956

Fig. 5.

Page 73

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

9600 - Overall system/hydraulic equipment

A - General

13

T000392

Version 3

05-10-2009

4 Overview of pressure measuring points

M1 Measuring point, emergency steering

pump

M2 Measuring point, auxiliary pump

M3 Measuring point, LS pump

M4 Measuring point, LS pressure

M5 Measuring point, control pressure

M6 Rear return flow reference pressure mea-

suring point

I001210

Fig. 6.

M1 pPNL Emergency steering pump pressure

- Since it is flange-mounted to the 4WD, the pump operates only during travel

M2 pPH - Auxiliary pump pressure

- Standby pressure for control pressure

- As needed and at a steering lock of 190 bar

(Need scenario exists only if the LS pump is fully "occupied" with current oil demand, can no

longer meet demand, and pressure requirement from steering system is higher than current

working pressure)

M3 pPR All LS pump pressures

- Min. standby pressure

- Current working pressure

- Max. standby pressure

Other functions (engine speed/cold-start/warm-start) are also active when engine is started.

M4 pLS Control pressure (=command/signal) to the LS pump

M5 pSt Control pressure is required to activate control valves 1…8 and also for the EPC valves

I005866

Fig. 7.

M6 RREF rear Pressure in the rear return flow

- is measured in the rear end plate

Page 74

9600 - Overall system/hydraulic equipment

A - General

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

14

T000392

Version 3

05-10-2009

M7 Front return flow reference pressure mea-

suring point

I005867

Fig. 8.

M7 RREF front Pressure in the front return flow

- is measured in the middle end plate

Page 75

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

9600 - Overall system/hydraulic equipment

A - General

15

T000457

Version 2

31-10-2008

5 External pressure rise (Power Beyond)

Implements with hydraulic consumers that are operated on the tractor often have very long supply lines, which pose the

risk of pressure loss. Hence, the 22 bar of control pressure is not always reached.

The control pressure increase is set and activated via the terminal. This in turn energises the pressure cut-off valve, external LS, reinforcement (DRVE), in dependence of the set value. The wider the pressure cut-off valve opens, the higher

the volume of oil fed by the pressure line (P) to the LS line, which raises the LS pressure.

If additional pressure is present in the external LS line, the control line pressure pushes the pressure cut-off valve further

to the right and the LS pressure is raised.

The flow cut-off valve, external LS relief (SRVE) is required to allow a small volume of oil to flow to the tank (T), thus

relieving the LS line.

The pressure filter, external LS (DFE) protects the system from impurities that penetrate the system via the external LS

line.

I002113

Fig. 9.

Item Designation Item Designation

PR LS pump p Pump pressure

Y084 Control pressure increase solenoid valve

(DRVE)

R Return flow

DFF Pressure filter LS Load sensing pressure

LS ext External load sensing connection M3 Measuring point: pump pressure p

SRVE Flow cut-off valve, external load sensing relief M4 Measuring point: load sensing pressure LS

Page 76

9600 - Overall system/hydraulic equipment

A - General

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

16

T000457

Version 2

31-10-2008

Page 77

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

9600 - Overall system/hydraulic equipment

Table of contents

17

C Documents and diagrams

1 Hydraulic circuit diagram with legend . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Page 78

9600 - Overall system/hydraulic equipment

Table of contents

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

18

Page 79

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

9600 - Overall system/hydraulic equipment

C - Documents and diagrams

19

T000318

Version 2

04-09-2009

1 Hydraulic circuit diagram with legend

Item Designation DIN Item Designation DIN

APE - Entry plate for external pressure supply MVKFS [Y022] - Lowering solenoid valve

(standard front power lift)

Y022

ASP1 - Accumulator, suspension 1 MVKH [Y055] - Rear pressure compensator

lock valve (SA/DA)

ASP2 - Accumulator, suspension 2 MVL [Y012] - Solenoid valve, charge function

(suspension, oil pre-heater)

Y012

AVF 1 - Lock valve, suspension 1 MVP [Y032] - Solenoid valve, pilot pressure Y032

AVF 2 - Lock valve, suspension 2 MVUL [Y082] - Solenoid valve, lower link stabi-

liser lock

Y082

BF - Ventilation filter MVVH [Y060] - Solenoid valve, rear pre-heater Y060

DBV1 - Main pressure-limiting valve MVVM [Y061] - Solenoid valve, central pre-

heater

Y061

DBVF1 - Pressure-limiting valve, suspension 1 OETR - Oil temperature regulator

DBVF2 - Pressure-limiting valve, suspension 2 PH - Auxiliary pump

DBVKF [Y022] - Field pressure valve, DA front

power lift enhanced control

PNL - Emergency steering pump

DBVKH [Y062] - Field pressure valve, DA rear

power lift

PR - LS pump

DBV-L - Pressure-limiting valve, 175 bar steer-

ing

PVL - Priority valve, steering

DFE - Pressure filter, external LS RLF - Return line filter

DFP - Pressure filter, pilot pressure RVF1 - Non-return valve, suspension 1

DFWH - Flow monitor, auxiliary pump RVFH - Non-return valve, raise suspension

DRVE [Y084] - Pressure cut-off valve, Power

Beyond

RVFS - Non-return valve, lower suspension

DRVF [Y013] - Suspension load pressure/lower RVL1-3 - Non-return valve, steering 1-3

DRVP - Pressure cut-off valve, pilot pressure RVN - Non-return valve, emergency steering

pump

DS1 - Pressure switch, LS pump monitor SFH - Auxiliary pump suction filter

DSF [B063] - Pressure switch, filter monitor B063 SFN1+2 - Suction filter, emergency steering

pump 1+2

DWKF - Pressure compensator, front power

lift, SA

SFR - Suction filter, LS pump

DWL - Pressure compensator, steering SRVE - Flow cut-off valve, external LS relief

DWP - Pressure compensator, pilot pressure SVUL [Y083] - Solenoid valve, lower link stabi-

liser release

Y083

EPH - End plate, rear valve block TG [B013] - Temperature sensor B013

EPM - End plate, centre VBF - Valve block, suspension

FKH - Front power lift VBL - Valve block, steering

FSP - Front power lift accumulator VBP - Valve block, pilot pressure supply

FSS [B084] - Level switch B084 WV1 - LS shuttle valve 1

GDR - Silencer, LS pump WVP - Shuttle valve, pilot pressure

HKH - Rear power lift ZF1 - Federungszylinder 1

HP - Hand pump, pilot pressure – emergency

supply

ZL - Steering cylinder

Hy.ABV - Hydraulic trailer brake ZSB - Central control block

Page 80

9600 - Overall system/hydraulic equipment

C - Documents and diagrams

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

20

T000318

Version 2

04-09-2009

K - Hydraulic oil cooler ZSP - Auxiliary accumulator, suspension

LE - Steering unit Autoguide

M1 - Measuring point, emergency pumps APLE - Connection plate for el.-hyd. steering

system

M2 - Measuring point, auxiliary pumps DRVLE - Pilot pressure cut-off valve, el.-hyd.

steering system

M3 - Measuring point, LS pump MVLE1 [Y085] - Solenoid valve, pilot pres-

sure/switch-off (Auto-Guide)

M4 - Measuring point, LS pressure MVLE2 [Y086] - Solenoid valve, steering dis-

connect (Auto-Guide)

M5 - Measuring point, control pressure PVLE - Proportional valve, el.-hyd. steering sys-

tem

MVFF [Y067] - Solenoid valve, lock suspension Y067 VBLE1 - Valve block, el.-hyd. steering system 1

MVFH [Y065] - Solenoid valve, raise suspen-

sion

Y065 VBLE2 - Valve block, el.-hyd. steering system 2

MVFW [Y063] - Solenoid valve, wobble stabiliser

Y063 VLE1 - LE priority valve (oversteering valve)

MVKF [Y021] - Front pressure compensator

lock valve (SA/DA)

Y021 VLE2+3 - LE switch off 1 + 2 valves

MVKFH [Y021] - Lifting solenoid valve (standard front power lift)

Y021 WVLE - LS shuttle valve, el.-hyd. steering sys-

tem

Item Designation DIN Item Designation DIN

Page 81

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001-

922 .. 0101-1000 928 .. 1001-

922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

9600 - Overall system/hydraulic equipment

C - Documents and diagrams

21

T000318

Version 2

04-09-2009

I000962

Fig. 1. Pumps

Page 82

9600 - Overall system/hydraulic equipment

C - Documents and diagrams

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

22

T000318

Version 2

04-09-2009

I000937

Fig. 2. Central control block and steering

Page 83

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

9600 - Overall system/hydraulic equipment

C - Documents and diagrams

23

T000318

Version 2

04-09-2009

I000968

Fig. 3. Rear valve block

Page 84

9600 - Overall system/hydraulic equipment

C - Documents and diagrams

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

24

T000318

Version 2

04-09-2009

I000969

Fig. 4. Central valve block

Page 85

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

9600 - Overall system/hydraulic equipment

Table of contents

25

E Measuring and testing

1 Test report, fax template . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Page 86

9600 - Overall system/hydraulic equipment

Table of contents

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

26

Page 87

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

9600 - Overall system/hydraulic equipment

E - Measuring and testing

27

T000371

Version 4

05-10-2009

1 Test report, fax template

Pressure testing

NOTE: Initial condition of tractor for all measurements:

– Engine in idle (800 rpm)

– Valves and EPC are locked

– No steering

– In tractors with hydraulic trailer brakes, release the pressure with the trailer brake button while the handbrake is ap-

plied

– Oil temperature 40-50°C

FENDT Measurement no.

Chassis no.: Op. hrs. reading: Keyword: Name: Date:

LS pump test

[PR]

M2

(bar)

M3

(bar)

M4

(bar)

M5

(bar)

Oil tem-

perature

A SETPOINT

ACTUAL

SETPOINT

ACTUAL

SETPOINT

ACTUAL

SETPOINT

ACTUAL

A1 Minimum standby pressure

(Valves locked)

12-18 20-24 0 0

A2 Minimum standby pressure

(Valves unlocked)

34-40 20-24 0 22-25

A3 Free steering when stationary

To left/right

(Valves unlocked)

34-40

/

Depending

on resis-

tance

/

Depending

on resis-

tance

/

22-25

A4 Turn steering to stop

To left/right

(Valves unlocked)

34-40

/

195-200

/

170-180

/

22-25

A5 Yellow control valve

Raise/lower

34-40

/

198-210

/

198-210

/

22-25

A6 Blue control valve

Raise/lower

34-40

/

198-210

/

198-210

/

22-25

A7 Red control valve

Raise/lower

34-40

/

198-210

/

198-210

/

22-25

A8 Green control valve

Raise/lower

34-40

/

198-210

/

198-210

/

22-25

A9 Brown control valve

Raise/lower

34-40

/

198-210

/

198-210

/

22-25

A10 Violet control valve

Raise/lower

34-40

/

198-210

/

198-210

/

22-25

A11 Olive control valve

Raise/lower

34-40

/

198-210

/

198-210

/

22-25

A12 Grey control valve

Raise/lower

34-40

/

198-210

/

198-210

/

22-25

A13 Rear EPC with external

pushbutton to stop

34-40 198-210 198-210 22-25

A14 Front power lift with external

pushbutton to stop

34-40 198-210 198-210 22-25

A15 Suspension ON or during

raising

(Valves unlocked)

34-40 198-210 198-210 22-25

Page 88

9600 - Overall system/hydraulic equipment

E - Measuring and testing

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

28

T000371

Version 4

05-10-2009

Auxiliary pump test

[PH]

M2

(bar)

M3

(bar)

M4

(bar)

M5

(bar)

Oil tem-

perature

B Connect the short circuit hose to a con-

trol valve and

use the terminal to set the valve to

max. flow rate and

deflect or

– Short circuit hose from pressure con-

nection, external to return line, rear

SETPOINT

ACTUAL

SETPOINT

ACTUAL

SETPOINT

ACTUAL

SETPOINT

ACTUAL

B1 Free steering when stationary

(Valves unlocked)

Depending

on resis-

tance

Depending

on resis-

tance

Depending

on resis-

tance

22-25

B2 Steering at stop to

left/right

(Valves unlocked)

190 - 200 Depending

on resis-

tance

175 - 185 22-25

B3

Wheel-driven steering pump test M1

(bar)

M1

(bar)

Oil temperature

C [PNL]

- only when driving forwards

SETPOINT ACTUAL

C1 10 k m/h 0.4

C2 40 km/h 1. 5

C3

Further measurements M1

(bar)

M2

(bar)

M3

(bar)

M4

(bar)

M5

(bar)

Oil tem-

perature

D special conditions/combina-

tions/sequences/settings/imple-

ments

SET-

POINT

ACTUAL

SET-

POINT

ACTUAL

SET-

POINT

ACTUAL

SET-

POINT

ACTUAL

SET-

POINT

ACTUAL

D1

D2

D3

D4

Page 89

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

9600 - Overall system/hydraulic equipment

E - Measuring and testing

29

T000371

Version 4

05-10-2009

Measuring leak oil volume at LS pump

NOTE: Do not perform measurement, unless:

– There are genuine doubts about the pump volume

– The overall hydraulic function has already been checked

Preparation:

Direct the leak oil line of the LS pump into a receptacle with a litre scale.

Starting condition of tractor

– Oil temperature 50°C

– With a maximum standby pressure of 200 bar and zero delivery

– Engine speed 1500 rpm

Pump status Leak oil

New Approx. 5 l/min

Permissible, normal state Up to 12 l/min

Worn From 12 l/min

Page 90

9600 - Overall system/hydraulic equipment

E - Measuring and testing

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

30

T000371

Version 4

05-10-2009

Page 91

A

General

9605

9605

B

Faults

Hydraulic equipment/hydraulic connec-

tions

Hydraulic equipment/hydraulic connections

C

Documents and Diagrams

D

Component location

E

Testing

F

Setting and Calibration

G

Repair

H

Service – Info

Page 92

Page 93

9605 - Hydraulic equipment/hydraulic connections

Table of contents

3

9605 Hydraulic equipment/hydraulic connections

G Repair. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Page 94

9605 - Hydraulic equipment/hydraulic connections

Table of contents

4

Page 95

9605 - Hydraulic equipment/hydraulic connections

Table of contents

5

G Repair

1 Removing rear hydraulic quick-release coupler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2 Installing rear hydraulic quick-release coupler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Page 96

9605 - Hydraulic equipment/hydraulic connections

Table of contents

6

Page 97

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

9605 - Hydraulic equipment/hydraulic connections

G - Repair

7

T000621

Version 1

22-06-2007

1 Removing rear hydraulic quick-release coupler

NOTE: The coupler housing does not have to be removed if only the quick-release coupling inserts are removed.

For greater clarity, the work was performed with the control valve removed.

Loosen coupler housing bolts and remove housing (when

the control valve is installed, a long Allen key is required).

Remove protective cap of coupler.

Remove circlip from coupler insert.

I001740

Fig. 1.

I001741

Fig. 2.

I001742

Fig. 3.

Page 98

9605 - Hydraulic equipment/hydraulic connections

G - Repair

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

8

T000621

Version 1

22-06-2007

Operate release lever to push out and remove coupler.

Remove pressure sleeve with circlip pliers.

Remove circlip from release lever.

Remove release lever.

I0 01743

Fig. 4.

I0 01744

Fig. 5.

I0 01745

Fig. 6.

I0 01746

Fig. 7.

Page 99

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

9605 - Hydraulic equipment/hydraulic connections

G - Repair

9

T000621

Version 1

22-06-2007

Remove plastic cover and pressure lever.

I001747

Fig. 8.

Page 100

9605 - Hydraulic equipment/hydraulic connections

G - Repair

919 .. 0101-1000 925 .. 1001- 934 .. 0101-1000

919 .. 1001- 928 .. 0101-1000 934 .. 1001922 .. 0101-1000 928 .. 1001922 .. 1001- 931 .. 0101-1000

925 .. 0101-1000 931 .. 1001-

10

T000622

Version 1

22-06-2007

2 Installing rear hydraulic quick-release coupler

Prepare cleaned parts of hydraulic coupler for assembly.

Insert new support rings and O-rings.

Insert release rocker in coupler housing, ensure that the

marking points to the release lever.

Insert release lever in bore.

I0 01748

Fig. 9.

I0 01749

Fig. 10.

I0 01747

Fig. 11.

I0 01746

Fig. 12.

Loading...

Loading...