Page 1

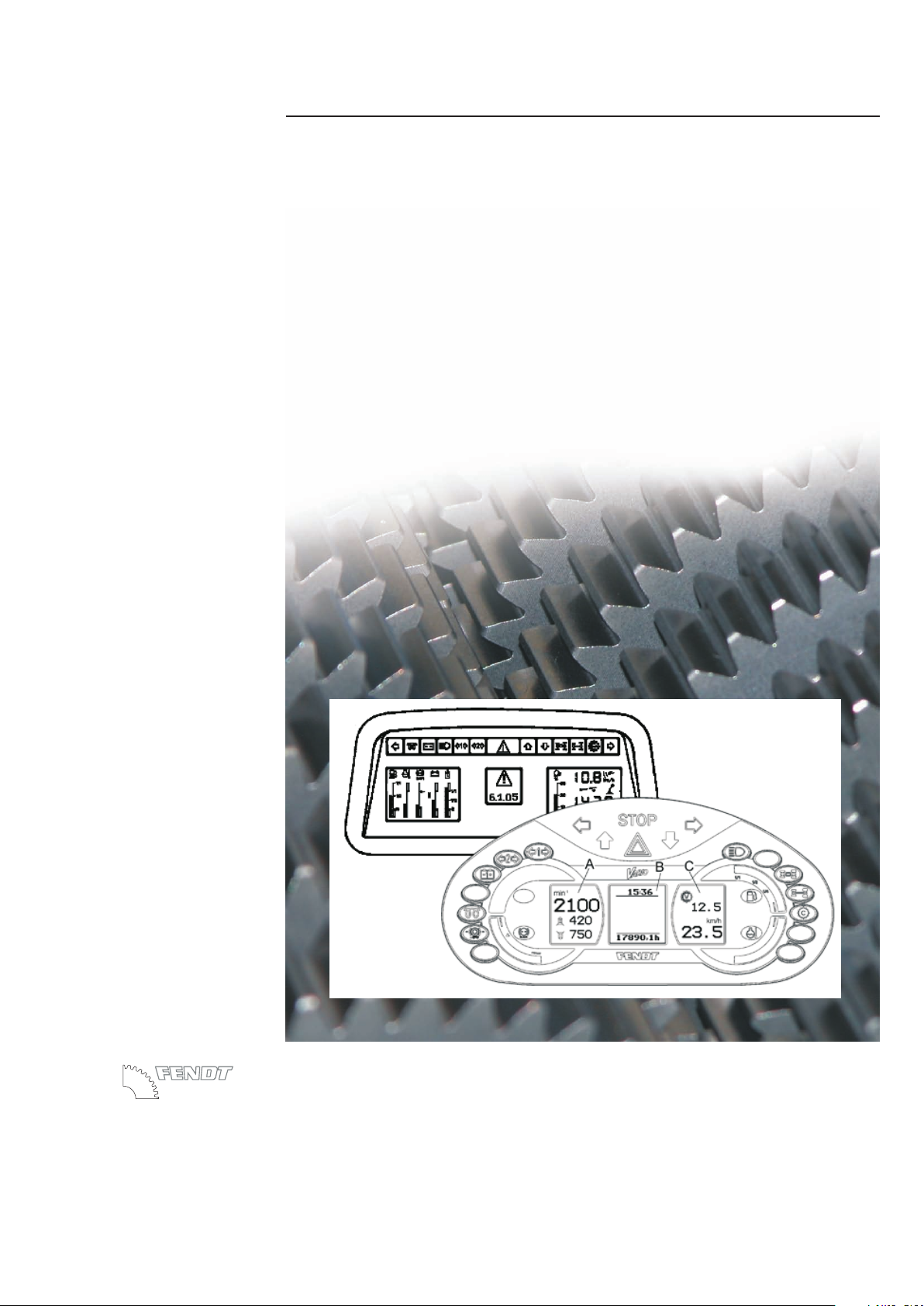

Service Training

Vario tractors - fault code tables

Edition

09/2007

Service-Training

Dokumentation

X990.005.448.012 - Englisch

PSD - 3289 G - en

AGCO GmbH

Johann-Georg-Fendt-Str. 4 D-87616 Marktoberdorf

Farmer 400

Favorit 700

Favorit 900

FENDT 700 Vario

FENDT 800 Vario

FENDT 900 Vario

FENDT 300 Vario (COM III)

FENDT 400 Vario (COM III)

FENDT 700 Vario (COM III)

FENDT 800 Vario (COM III)

FENDT 900 Vario (COM III)

Page 2

All relevant accident prevention regulations and all generally accepted safety, health and

road traffic regulations must be strictly observed. The manufacturer does not accept liability

for damage resulting from unauthorised modifications.

AGCO GmbH

87616 Marktoberdorf

Tel.: (08342) 77 - 0 Fax: (08342) 77 -222

Page 3

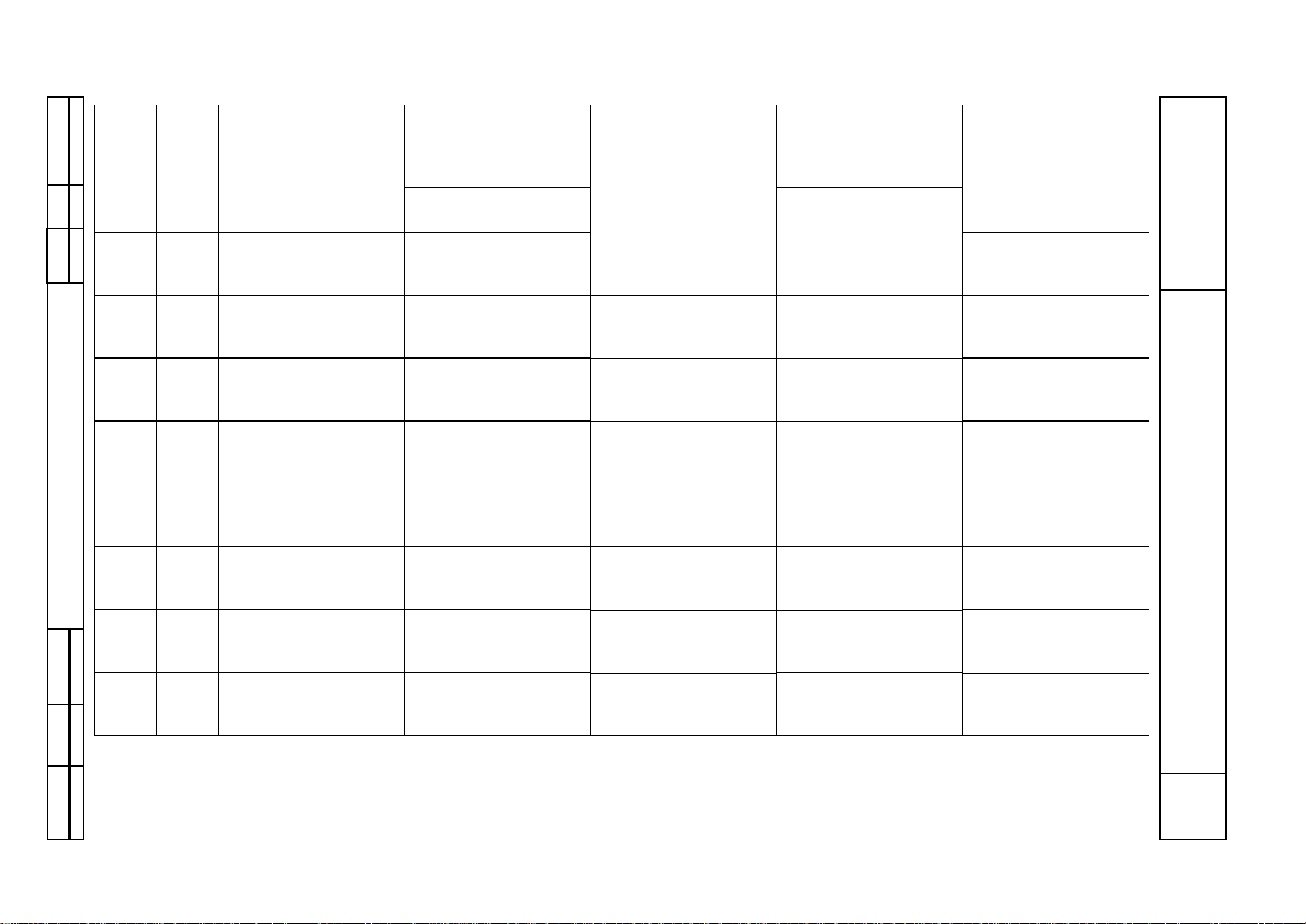

FENDT 409

Vario 409 .. / 1001-

FENDT 410

FENDT 411

FENDT 412

FENDT 711

FENDT 712

FENDT 714

FENDT 716

FENDT 815

FENDT 817

FENDT 818

FENDT 916

Vario 410 .. / 1001-

Vario 411 .. / 1001-

Vario 412 .. / 1001-

Vario 711 .. / 1001-

Vario 712 .. / 1001-

Vario 714 .. / 1001-

Vario 716 .. / 1001-

Vario 715 .. / 1001-

Vario 717 .. / 1001-

Vario 718 .. / 1001-

Vario 916 .. / 1001-

FENDT Vario (COM I / COM II)

FENDT 920

FENDT 924

FENDT 926

FENDT 930

Vario 920 .. / 1001-

Vario 924 .. / 1001-

Vario 926 .. / 1001-

Vario 930 .. / 1001-

Fault code table

Fault code table

Tableau de codes défauts

Tableau de codes défauts

Tabella codici disturbi

Tabella codici disturbi

Tabla códiga averías

Tabla códiga averías

Storingscodetabel

StörcodetabelleStörcodetabelle

Storingscodetabel

410 .. 1001- / 411 .. 1001- / 412 .. 1001- * 711 .. 1001- / 712 .. 1001- / 714 .. 1001- / 716 .. 1001-

.. 1001- / 717 .. 1001- / 718 .. 1001- * 916 .. 1001- / 920 .. 1001- / 924 .. 1001- / 926 .. 1001- / 930 .. 1001-

409 .. 1001- /

715

Page 4

Page 5

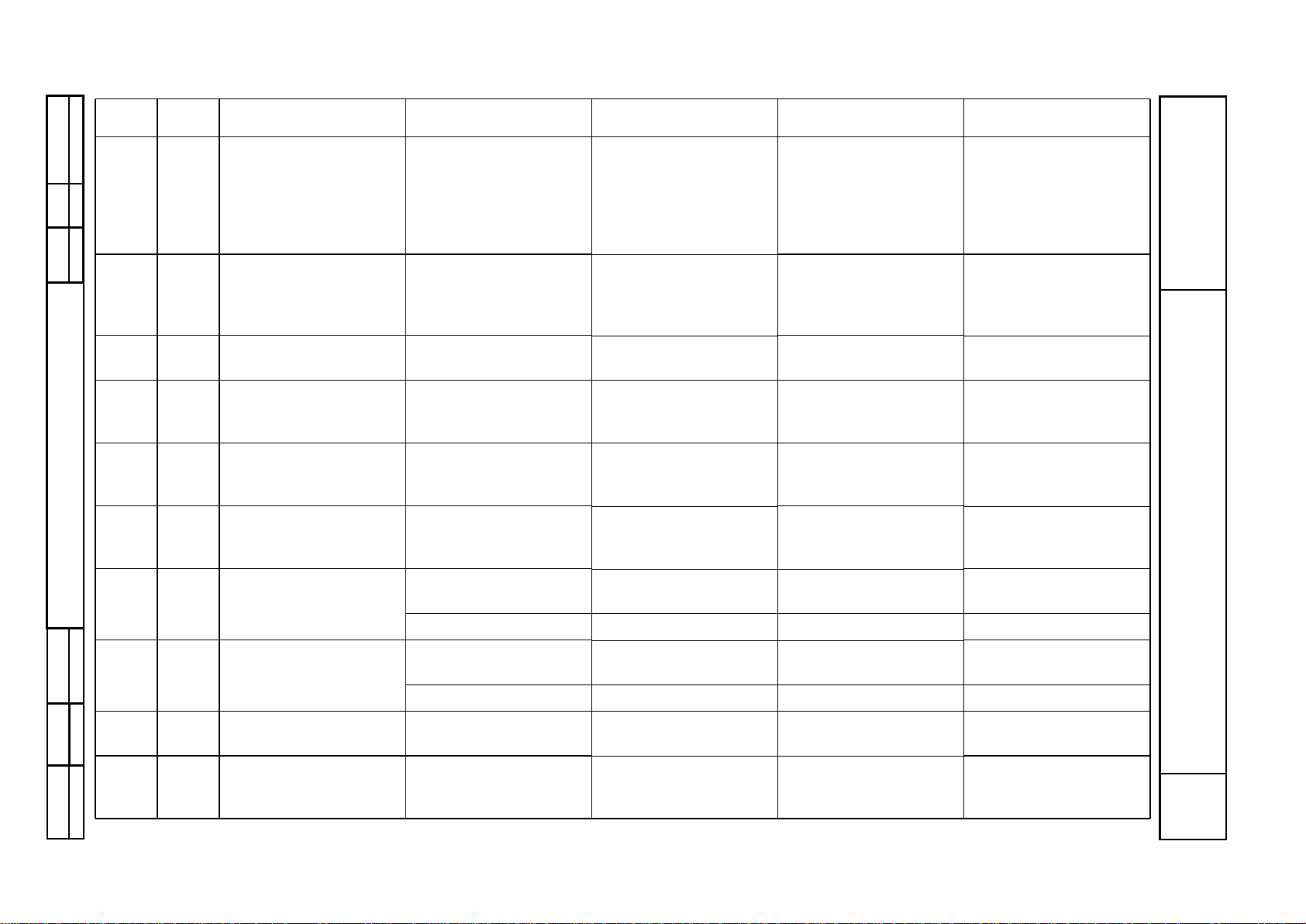

all Vario tractors

Tractor / General system

Vario Tractors - Fault Codes

B

Faults

12/1999

0000 000001

B

f

1/58

Capitel Docu-No.

Index

Date Version

Page

Vario Tractors - Fault Codes

FCT_InitPage

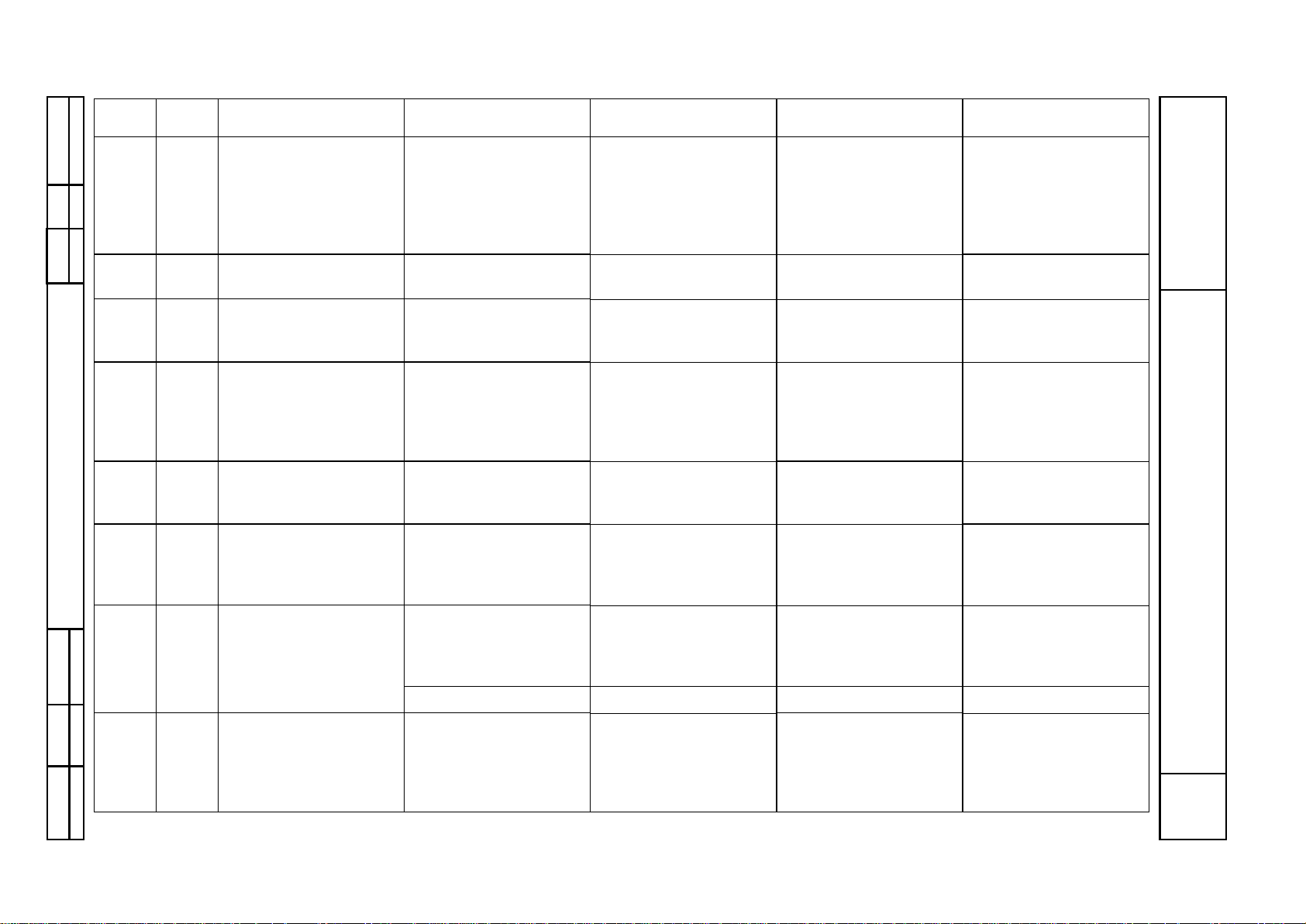

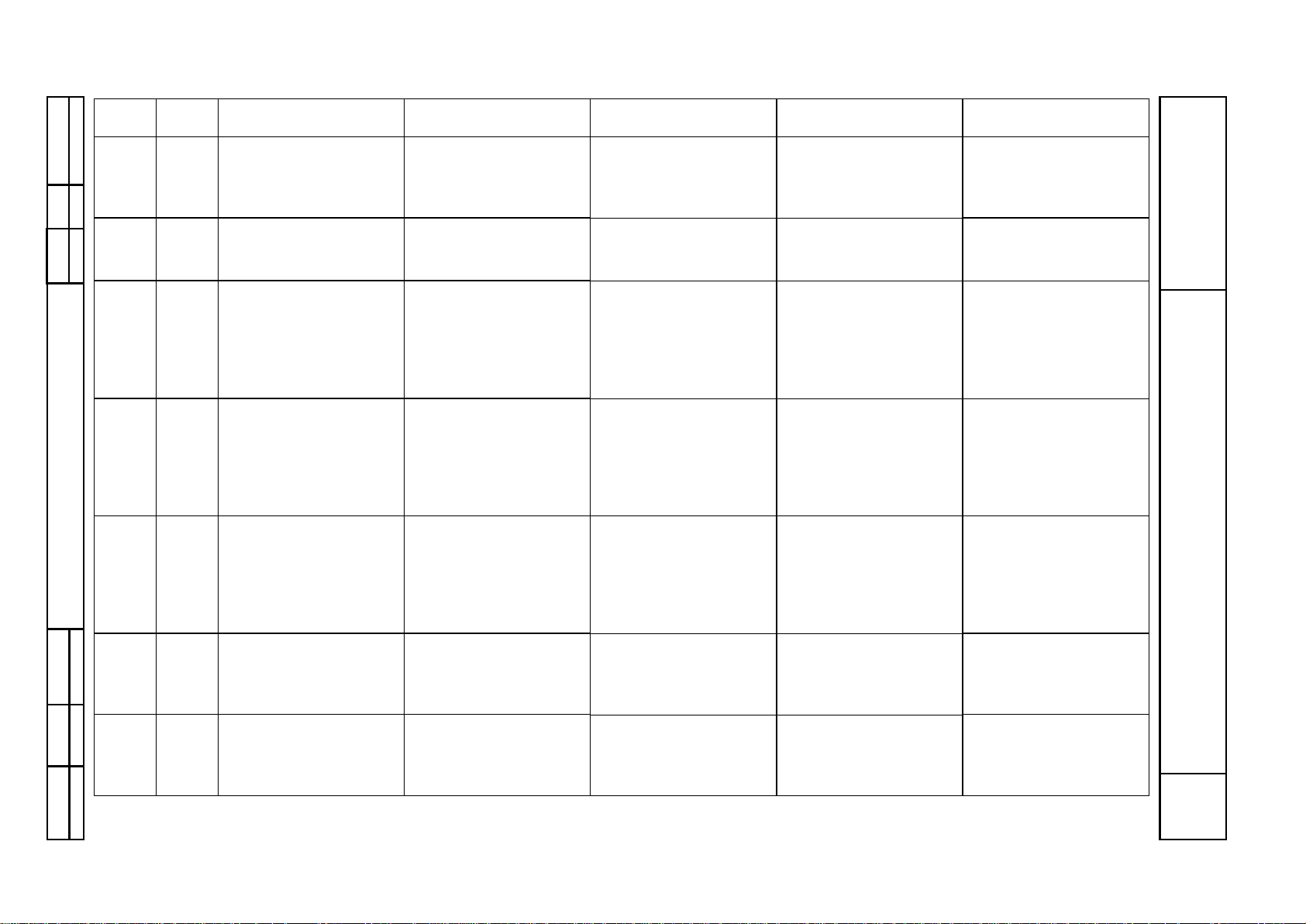

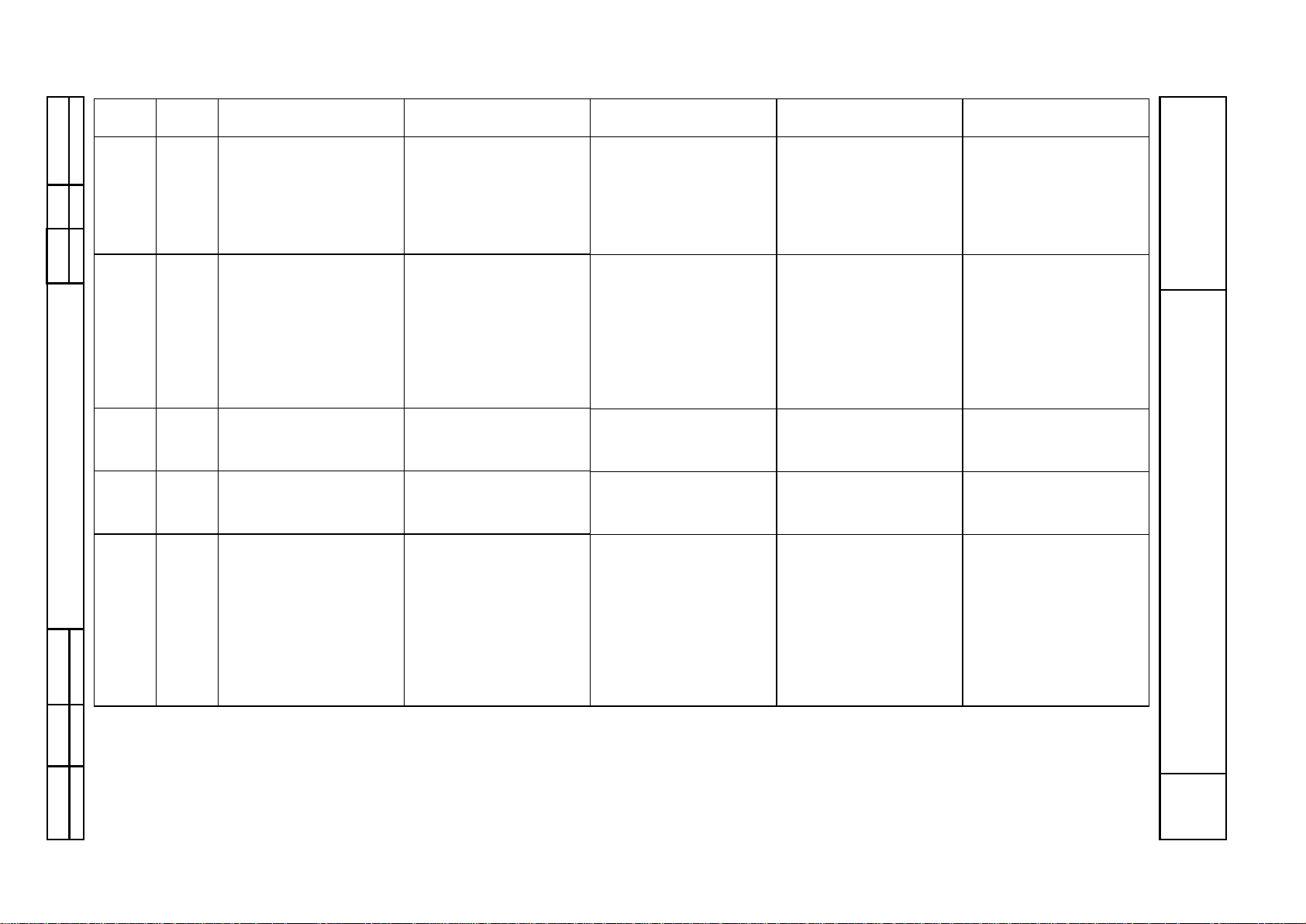

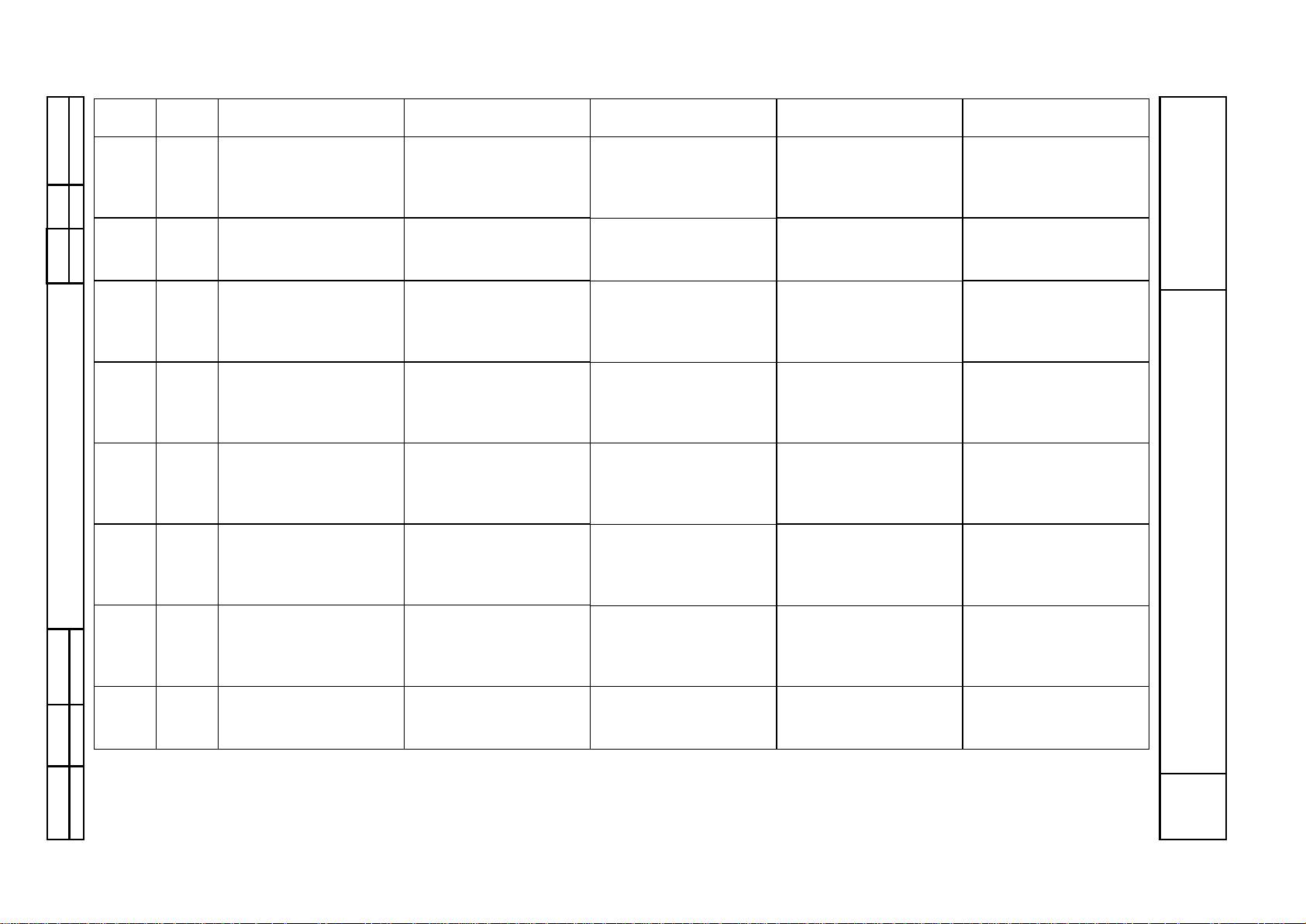

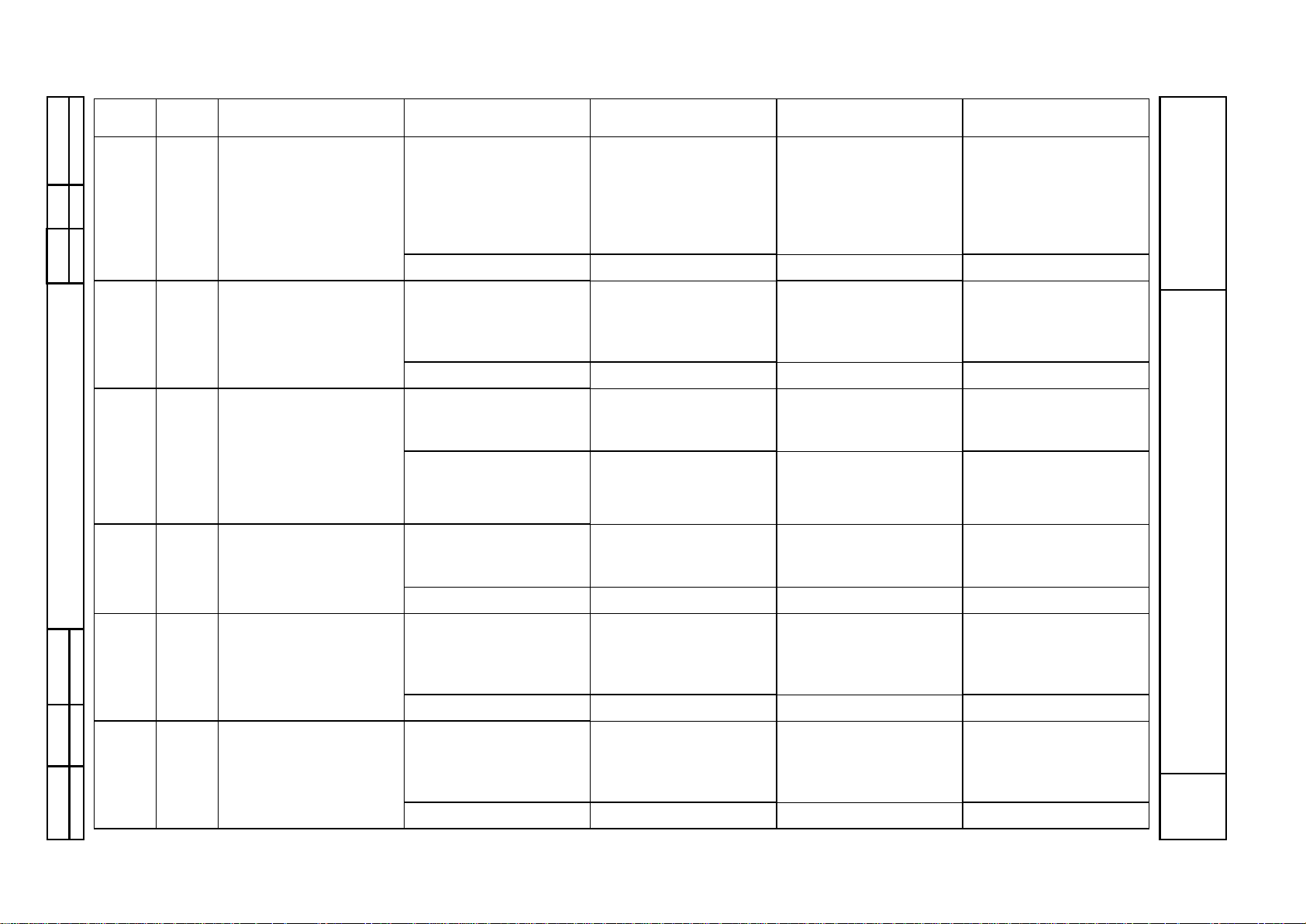

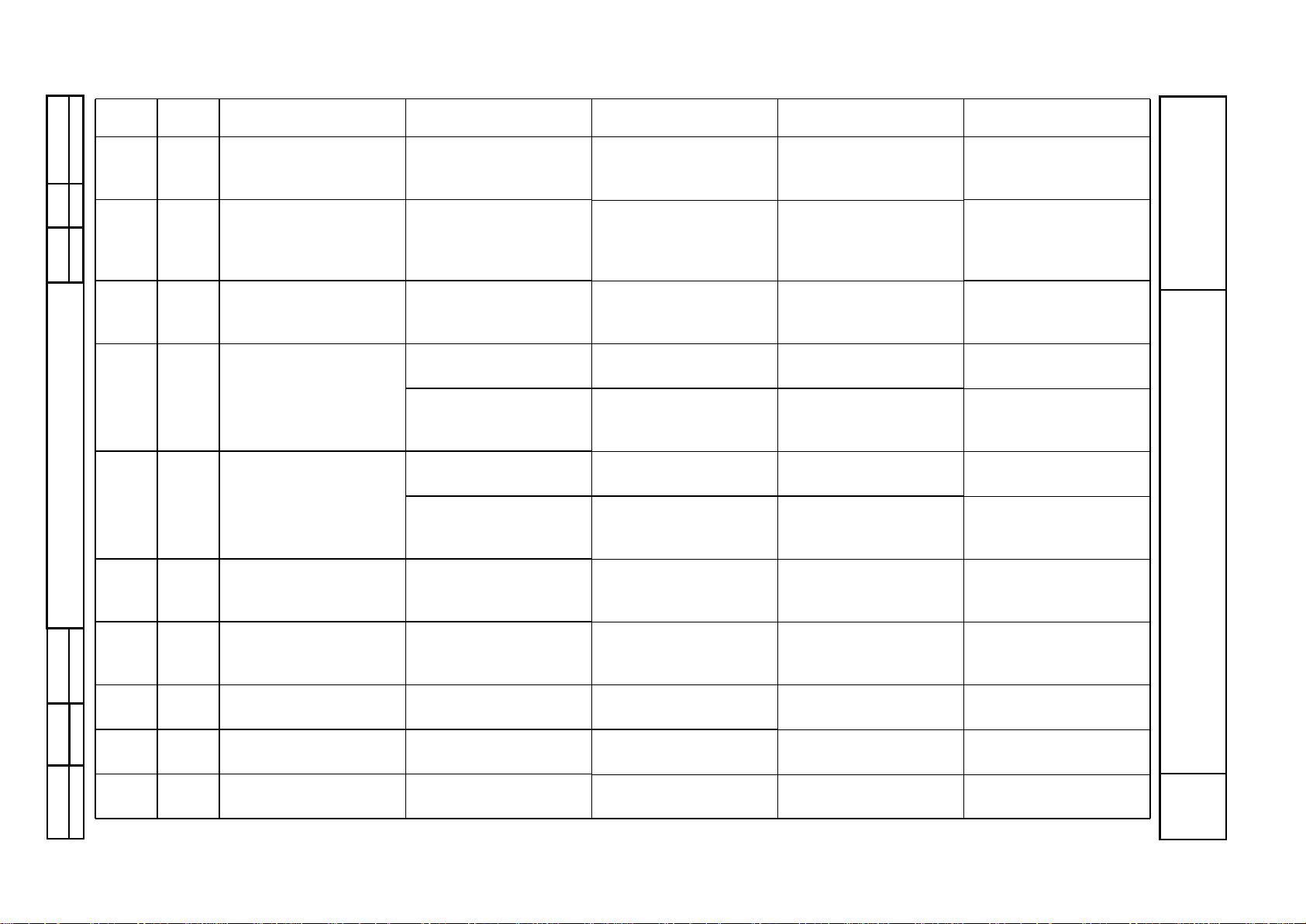

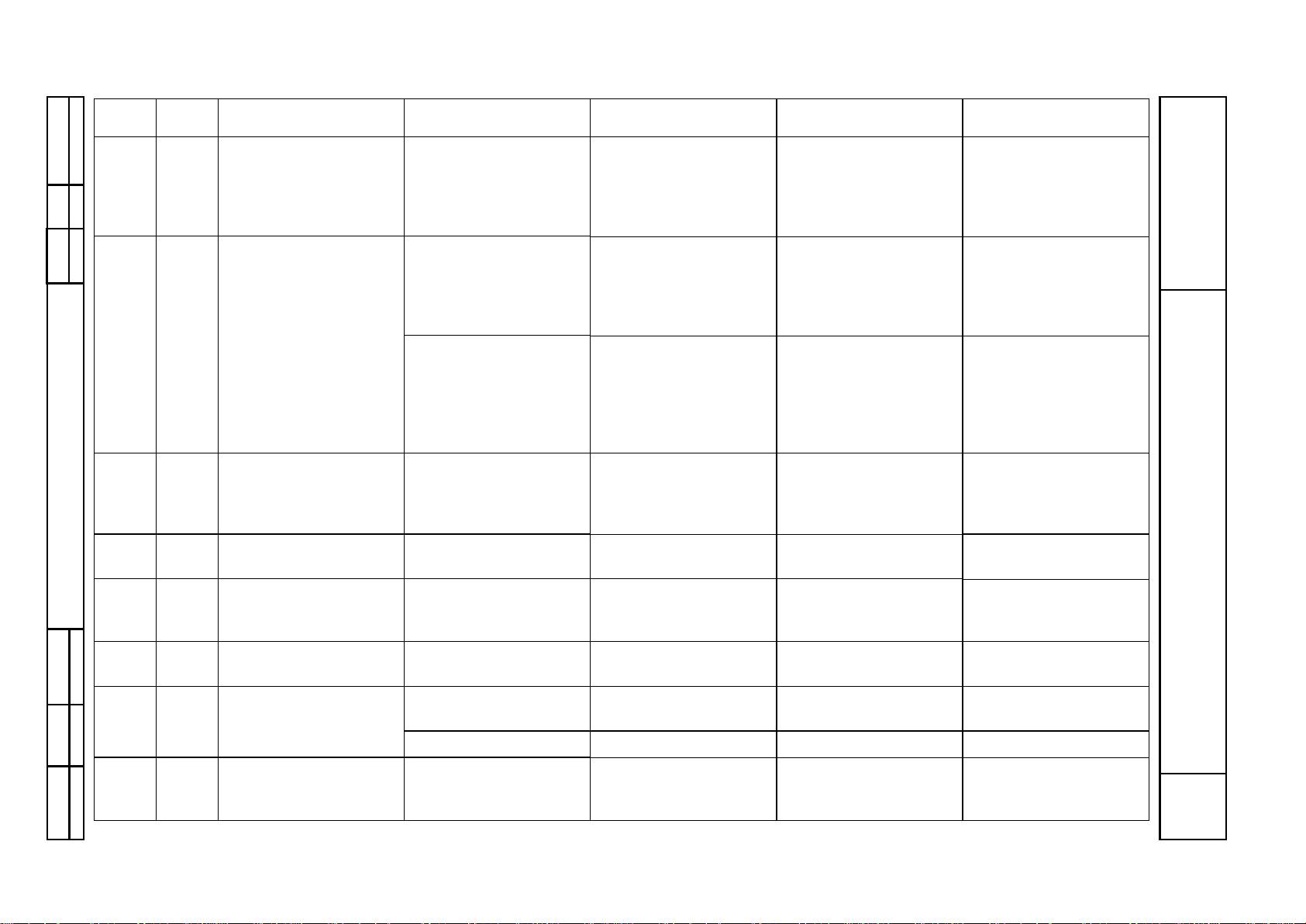

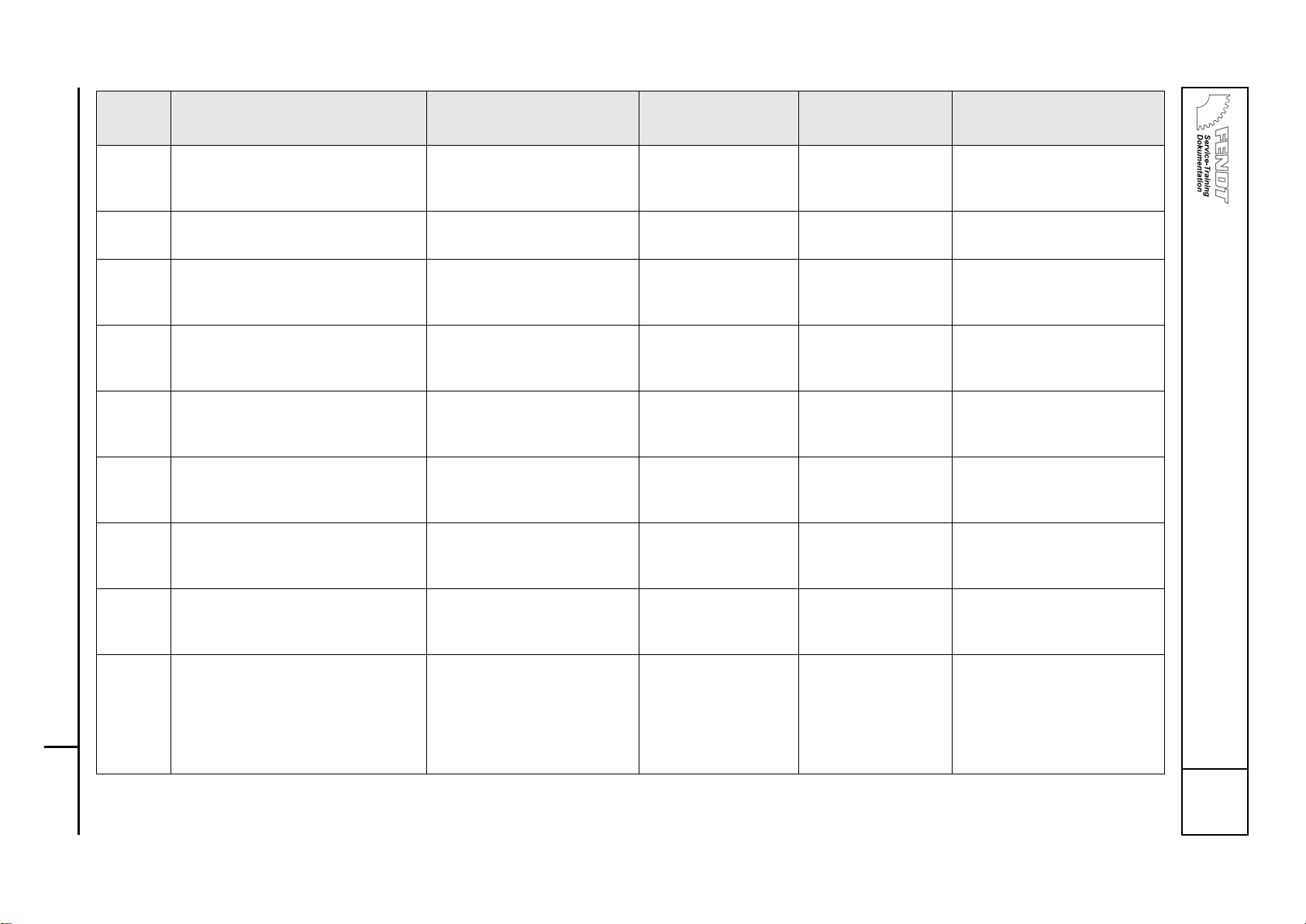

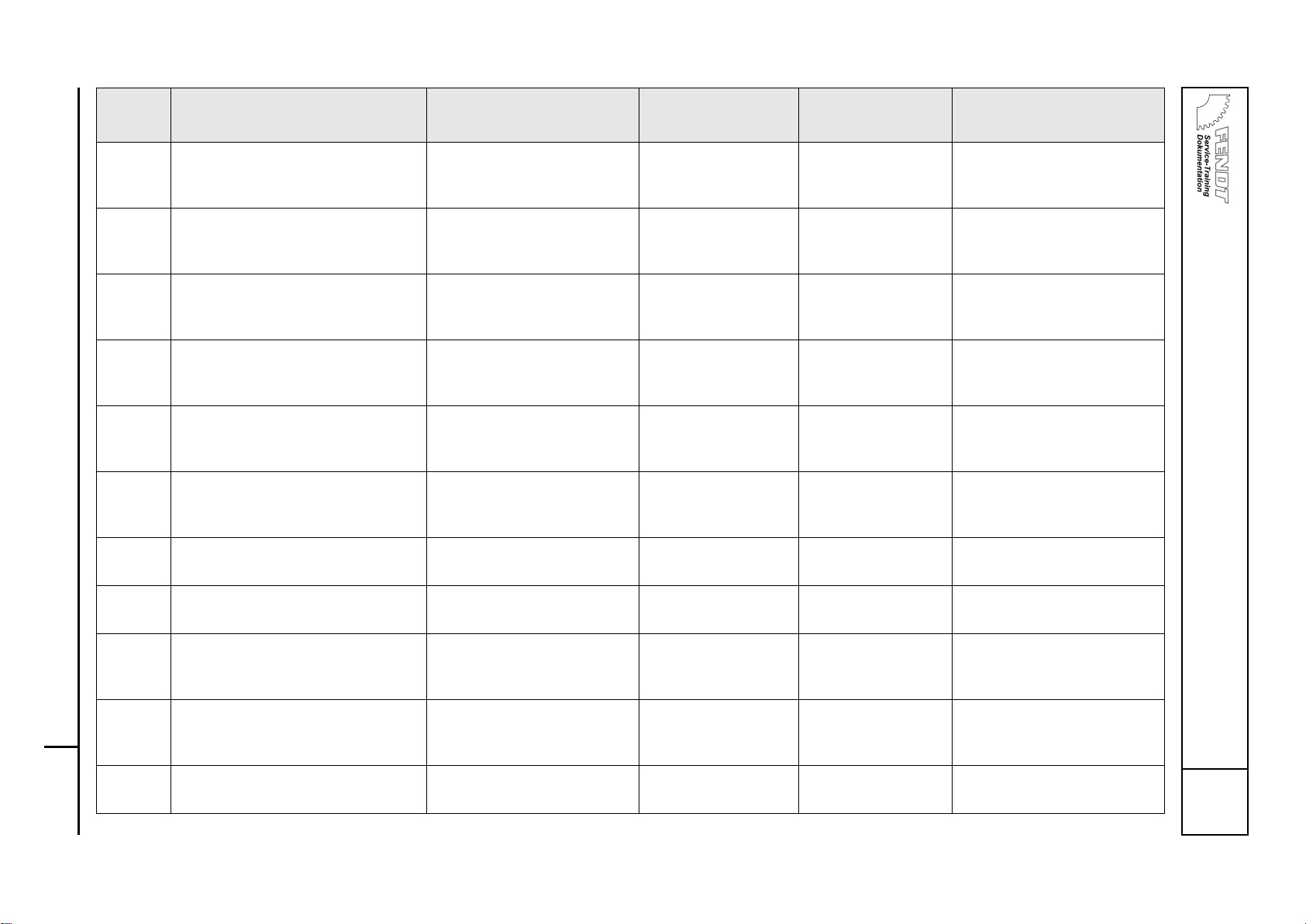

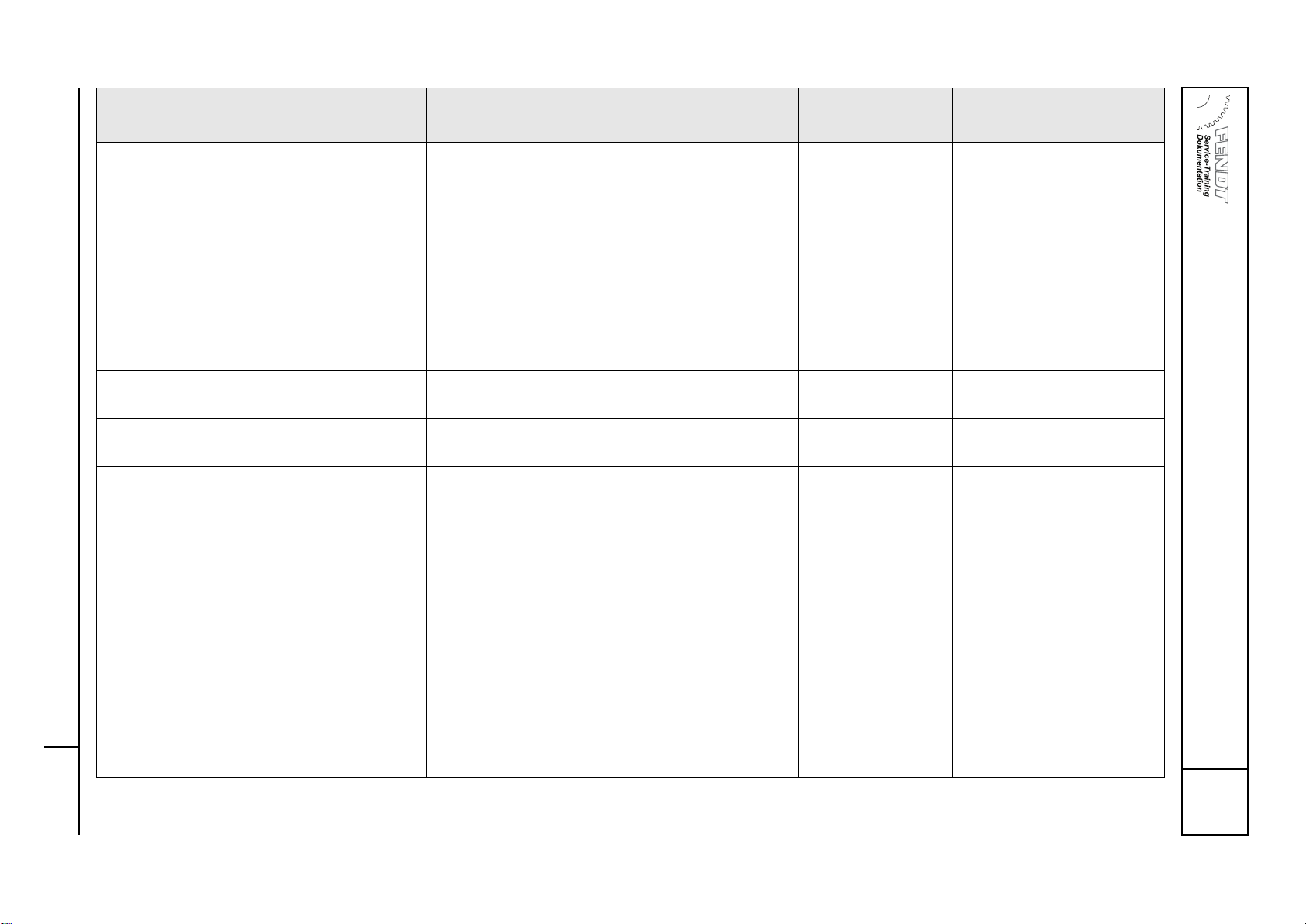

Fault

code

Id code Brief description Description Consequences Link FENDIAS / Note

0.0.11 A021;

A022

ECU, EDC;

ECU, EMR

EDC / EMR bus fault.

Fault in ECU

Tractor can be driven

using accelerator.

Programming errors in

ECU.

Fault message, no

restrictions.

EOL reprogramming

necessary.

0.0.12 A008 Vario terminal Bus fault No functions available,

no display

Power supply for CAN

bus is in circuit board

A013; fuse F039, F046

0.0.13 A004 Control console Bus fault No functions available,

no display

Power supply for CAN

bus is in circuit board

A013; fuse F040, F041

0.0.14 A009 Transmission control

unit

Bus fault No functions available,

no display

Power supply for CAN

bus is in circuit board

A013; fuse F040, F041

0.0.15 A001,

A002

4WD engagement;

Diff. lock engagement

Bus fault No functions available,

no display

Power supply for CAN

bus is in circuit board

A013; fuses F040, F041

0.0.16 A001,

A002

Rear PTO Bus fault No functions available,

no display

Power supply for CAN

bus is in circuit board

A013; fuses F040, F041

0.0.17 A001,

A002

Front PTO Bus fault No functions available,

no display

Power supply for CAN

bus is in circuit board

A013; fuses F040, F041

0.0.18 A005,

A014

Rear EPC Bus fault No functions available,

no display

Power supply for CAN

bus is in circuit board

A013; fuses F040, F041

0.0.19 A002 Front power lift Bus fault No functions available,

no display

See Service Training

EPC C

(X990.005.023.026en)

Page 6

all Vario tractors

Tractor / General system

Vario Tractors - Fault Codes

B

Faults

12/1999

0000 000001

B

f

2/58

Capitel Docu-No.Index

Date Version

Page

Vario Tractors - Fault Codes

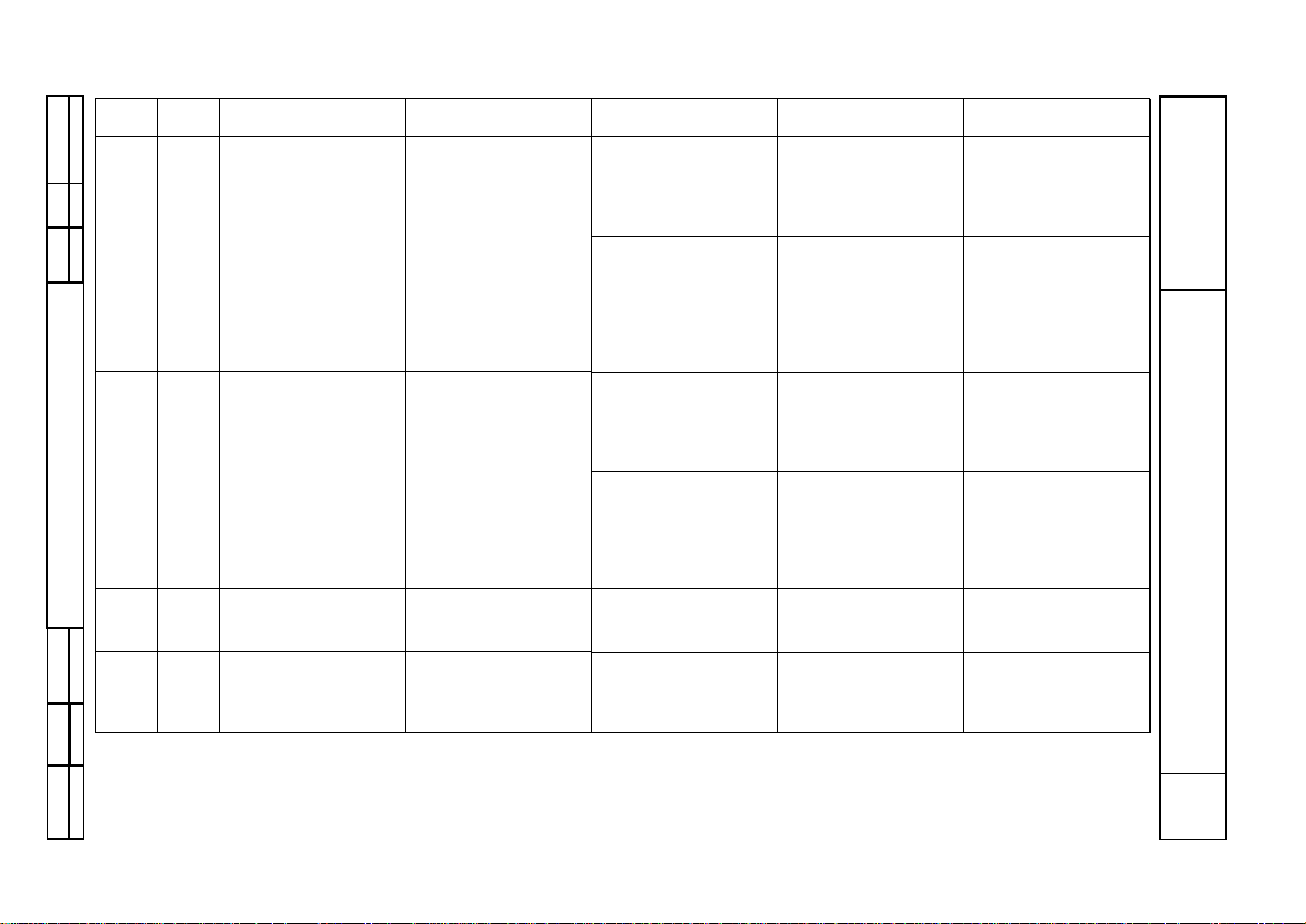

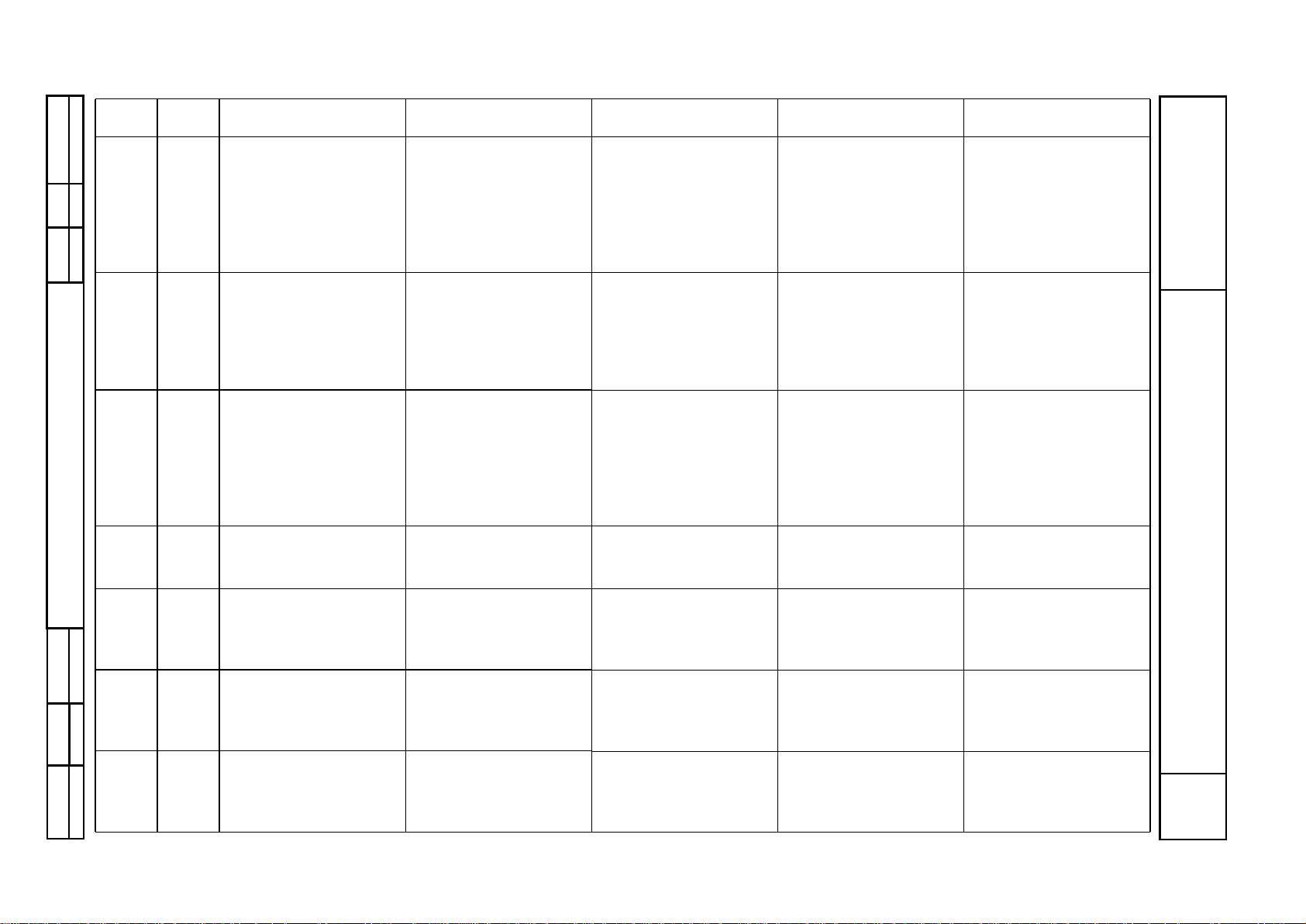

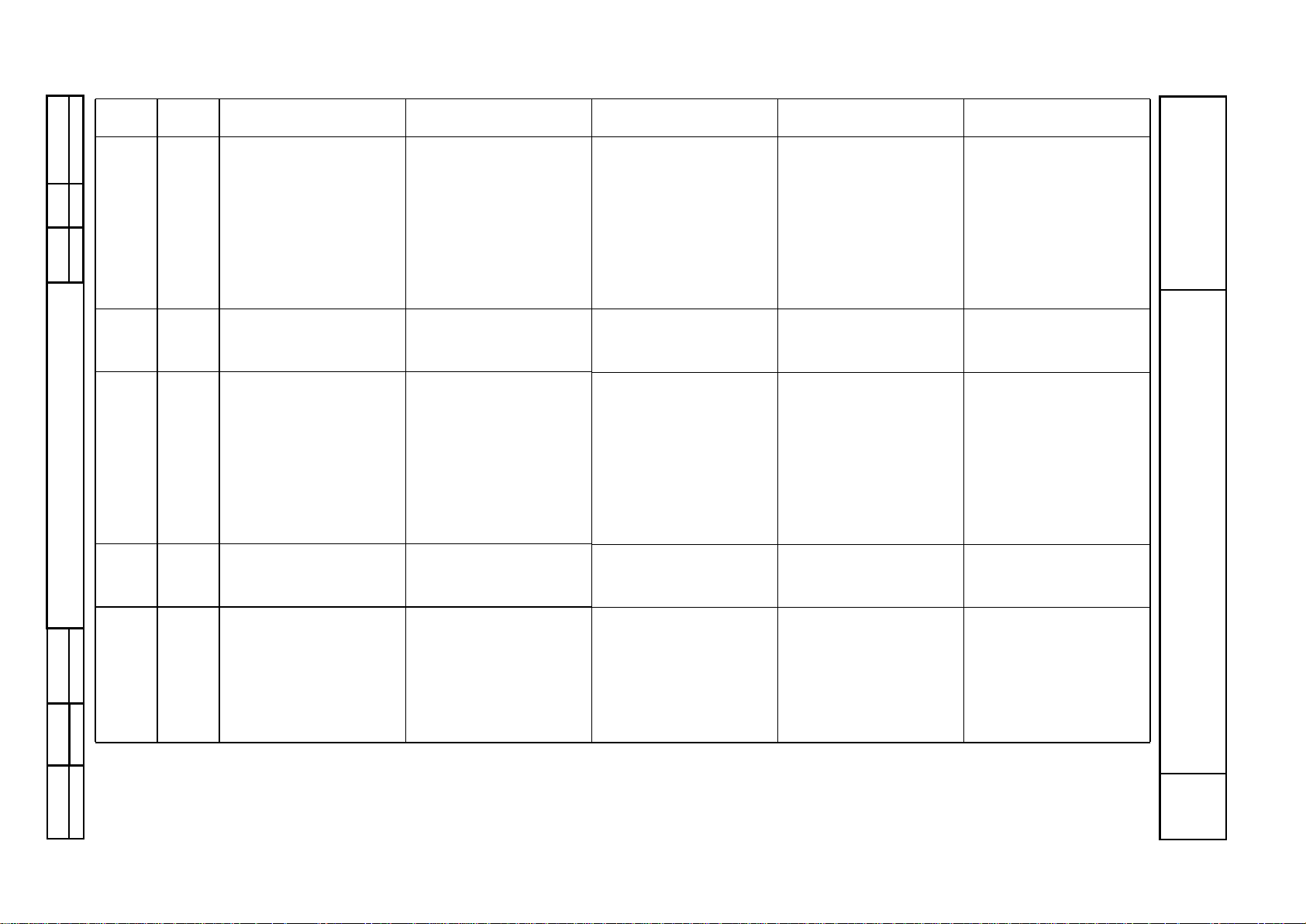

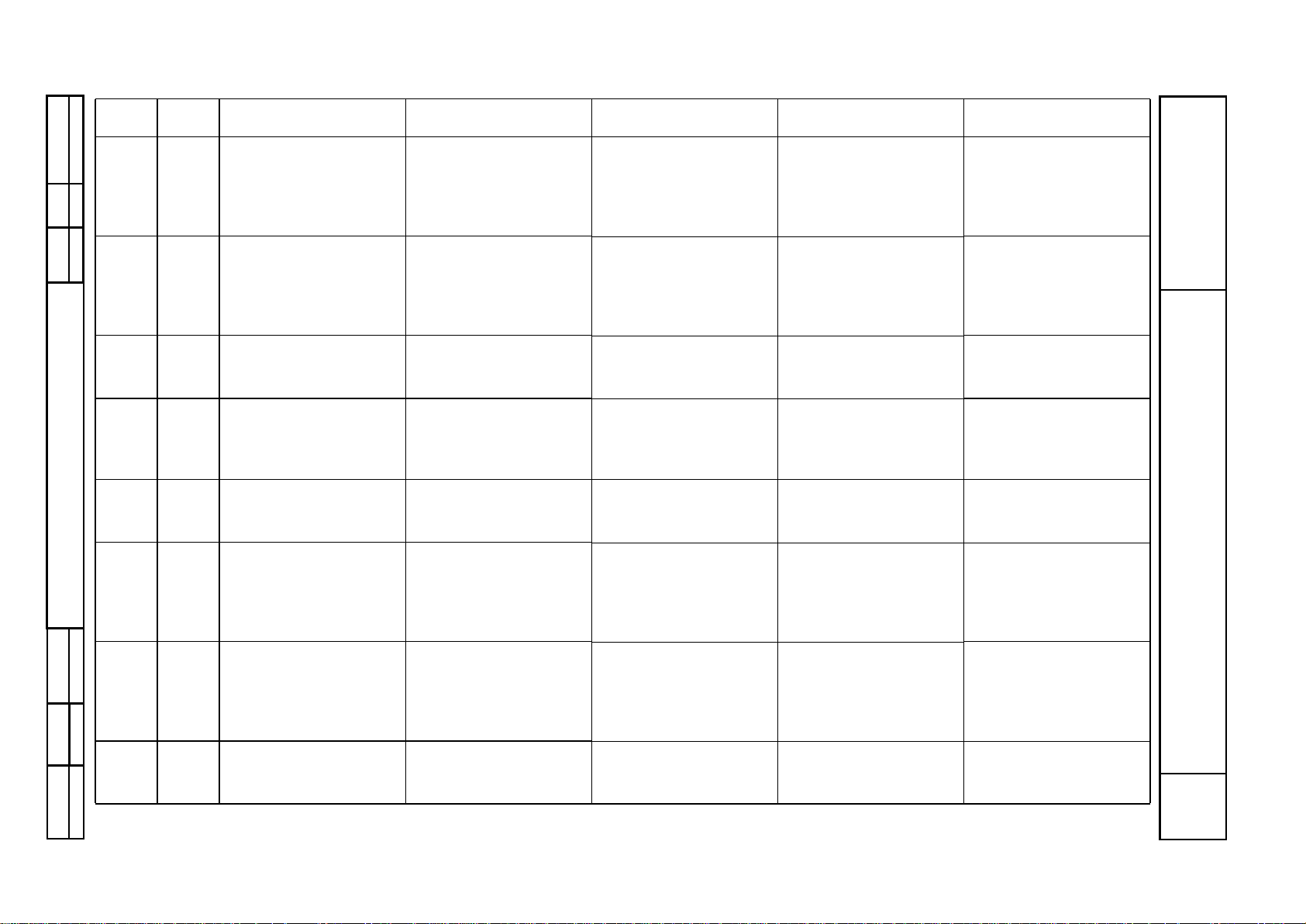

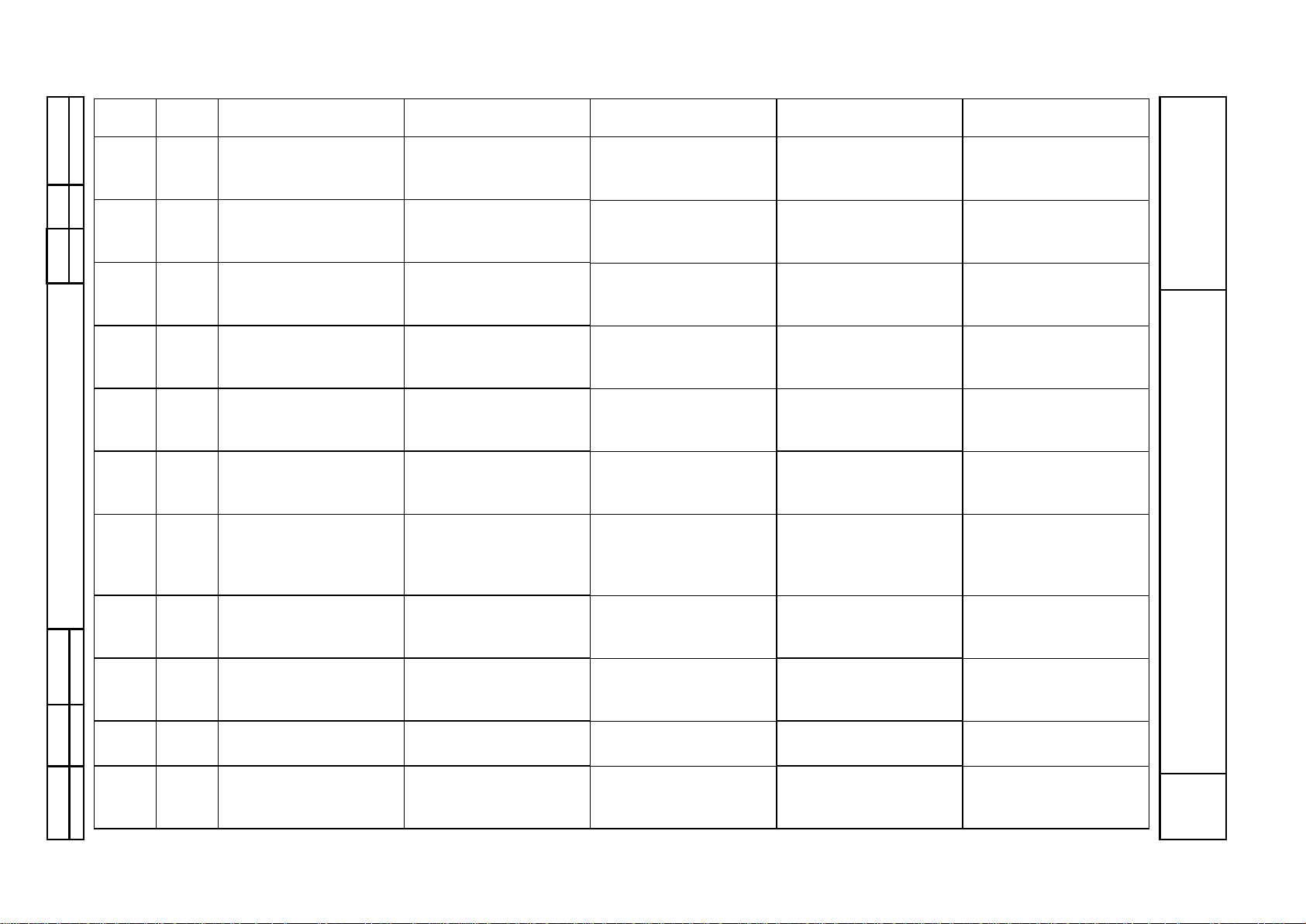

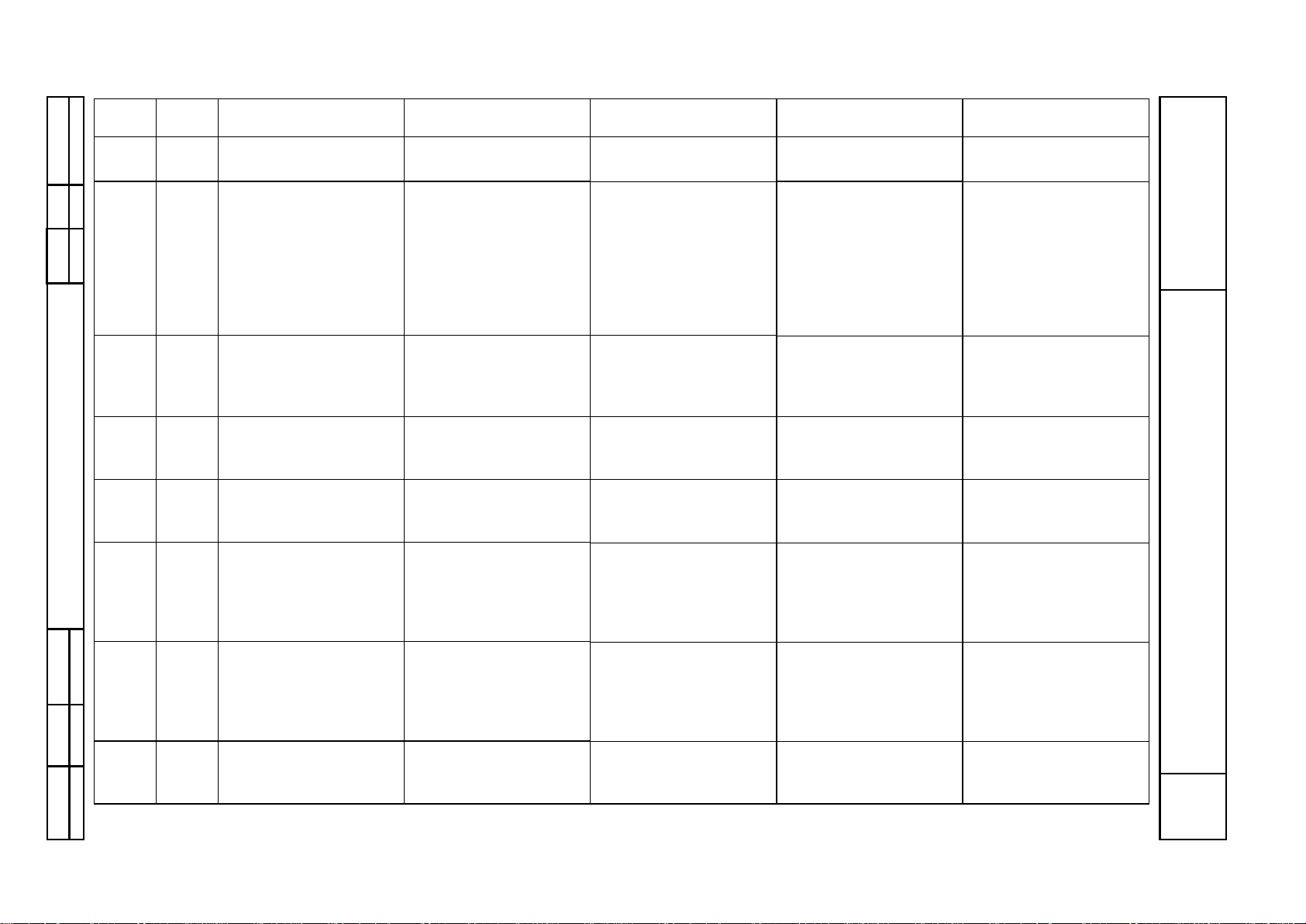

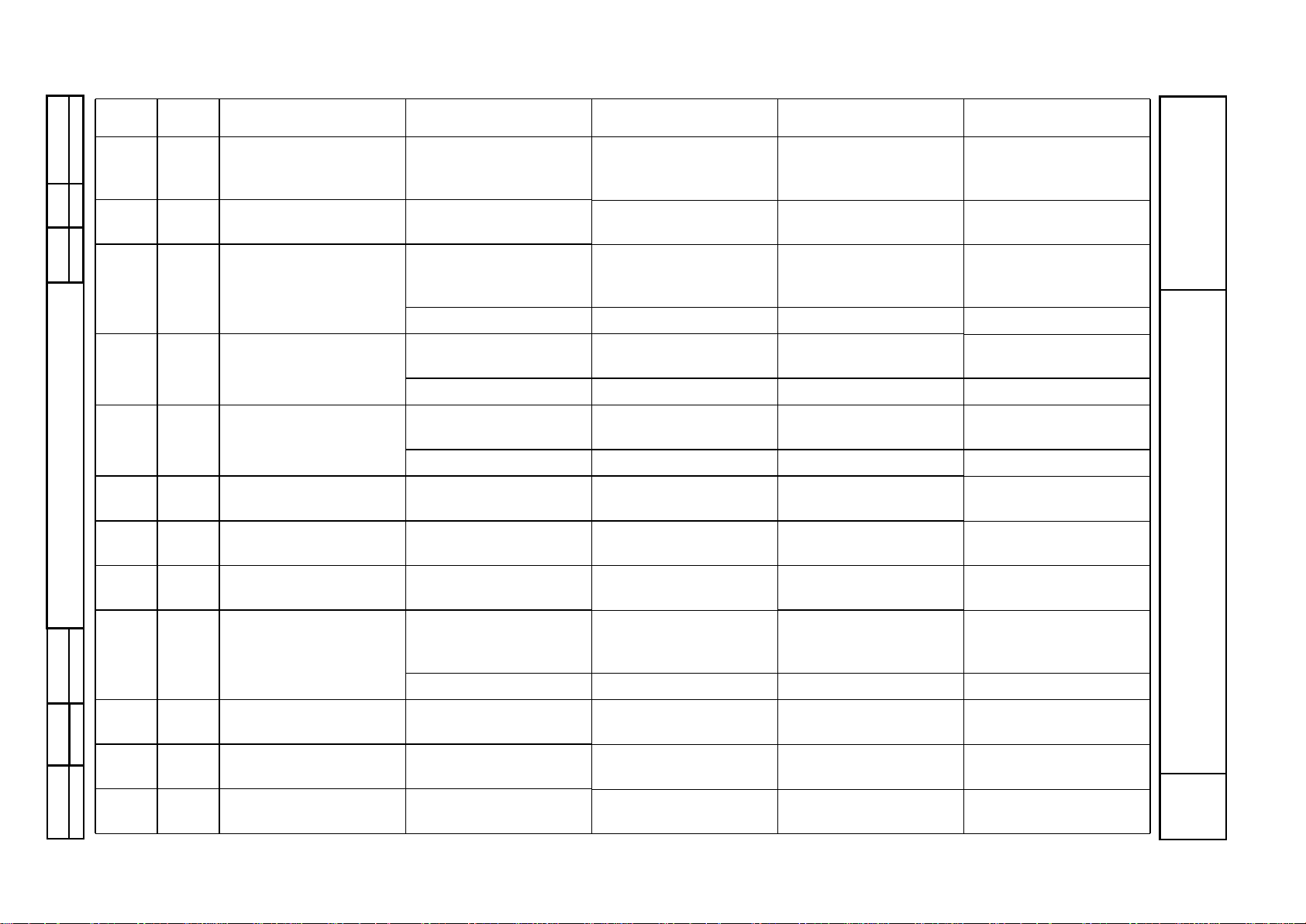

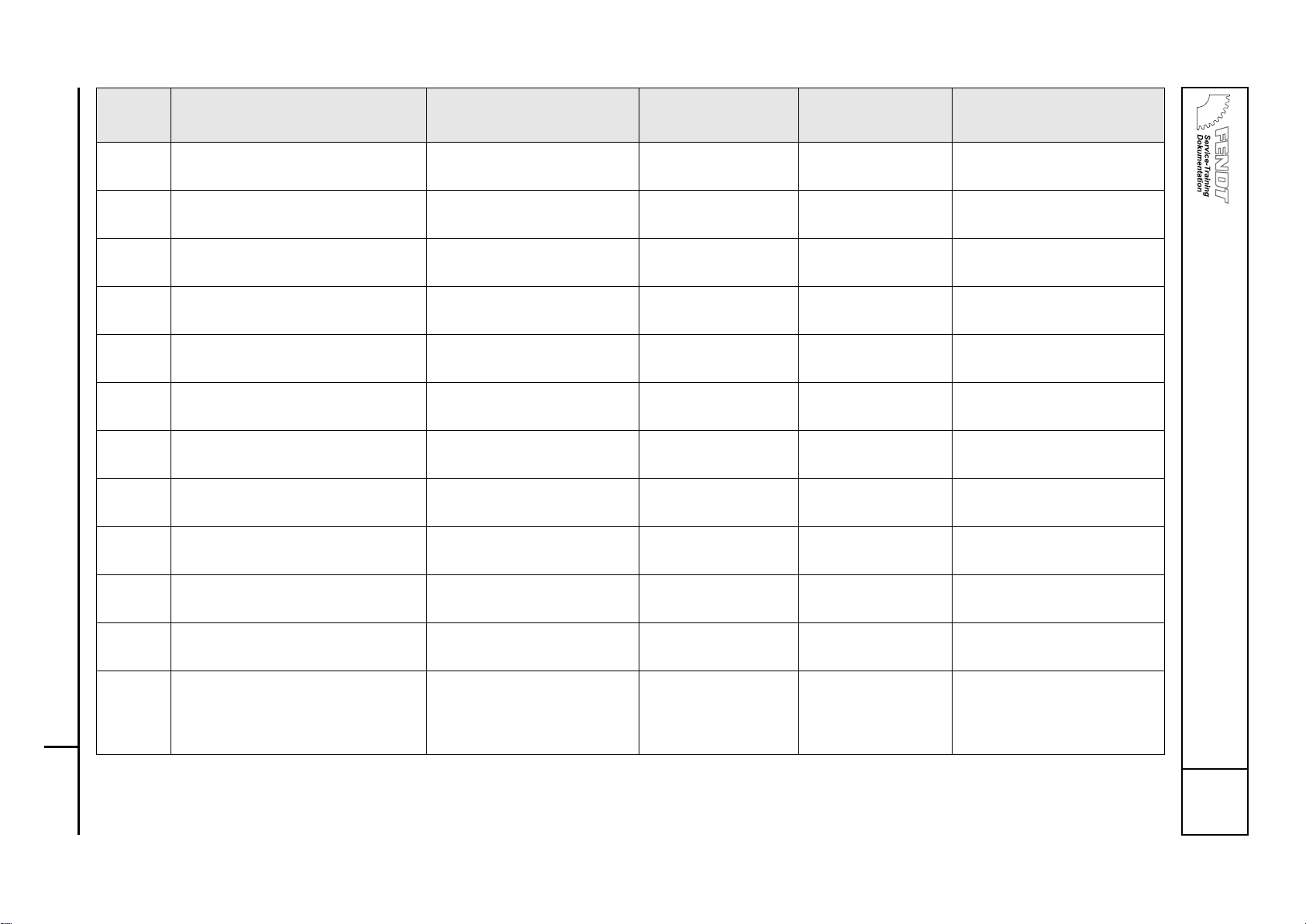

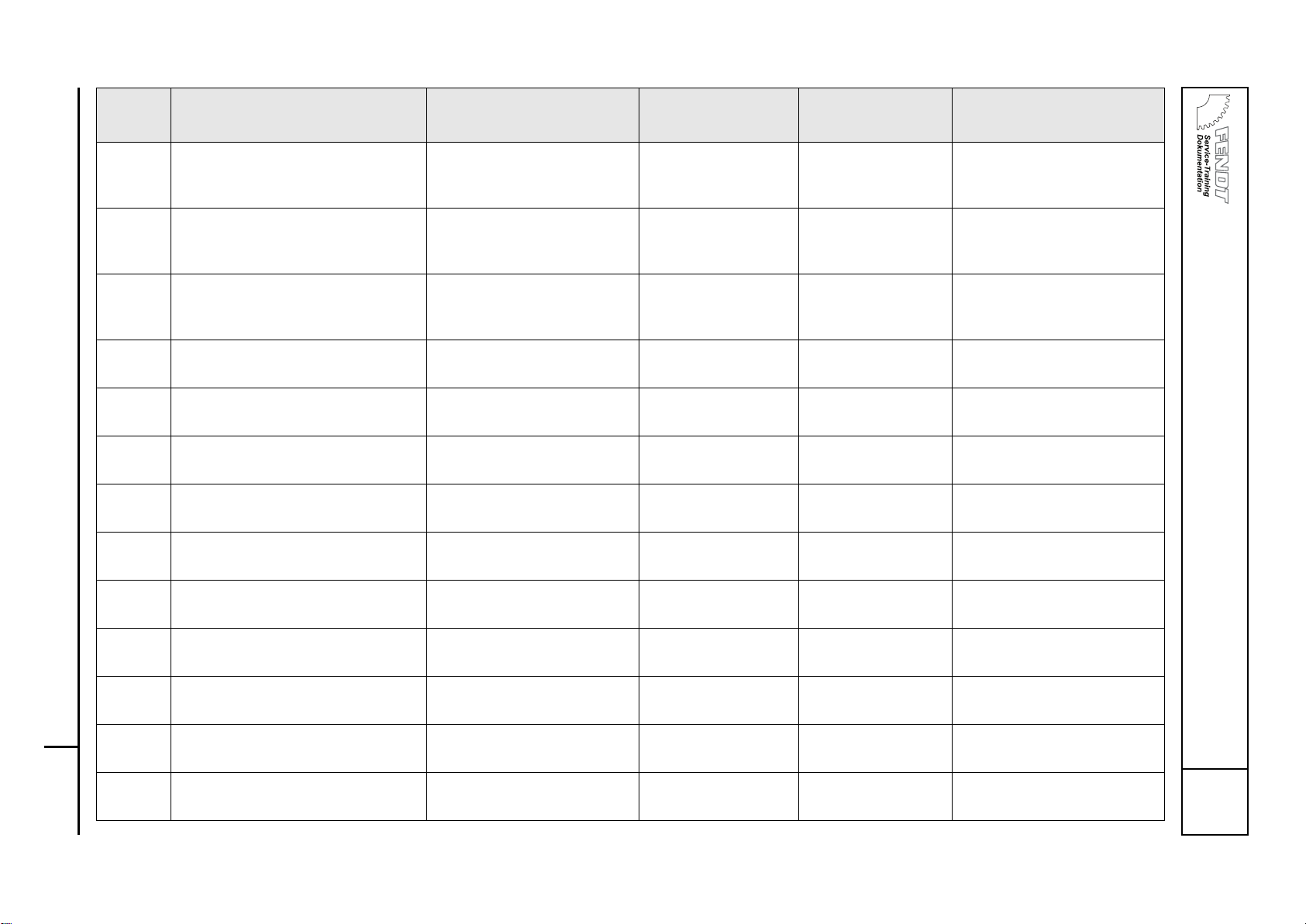

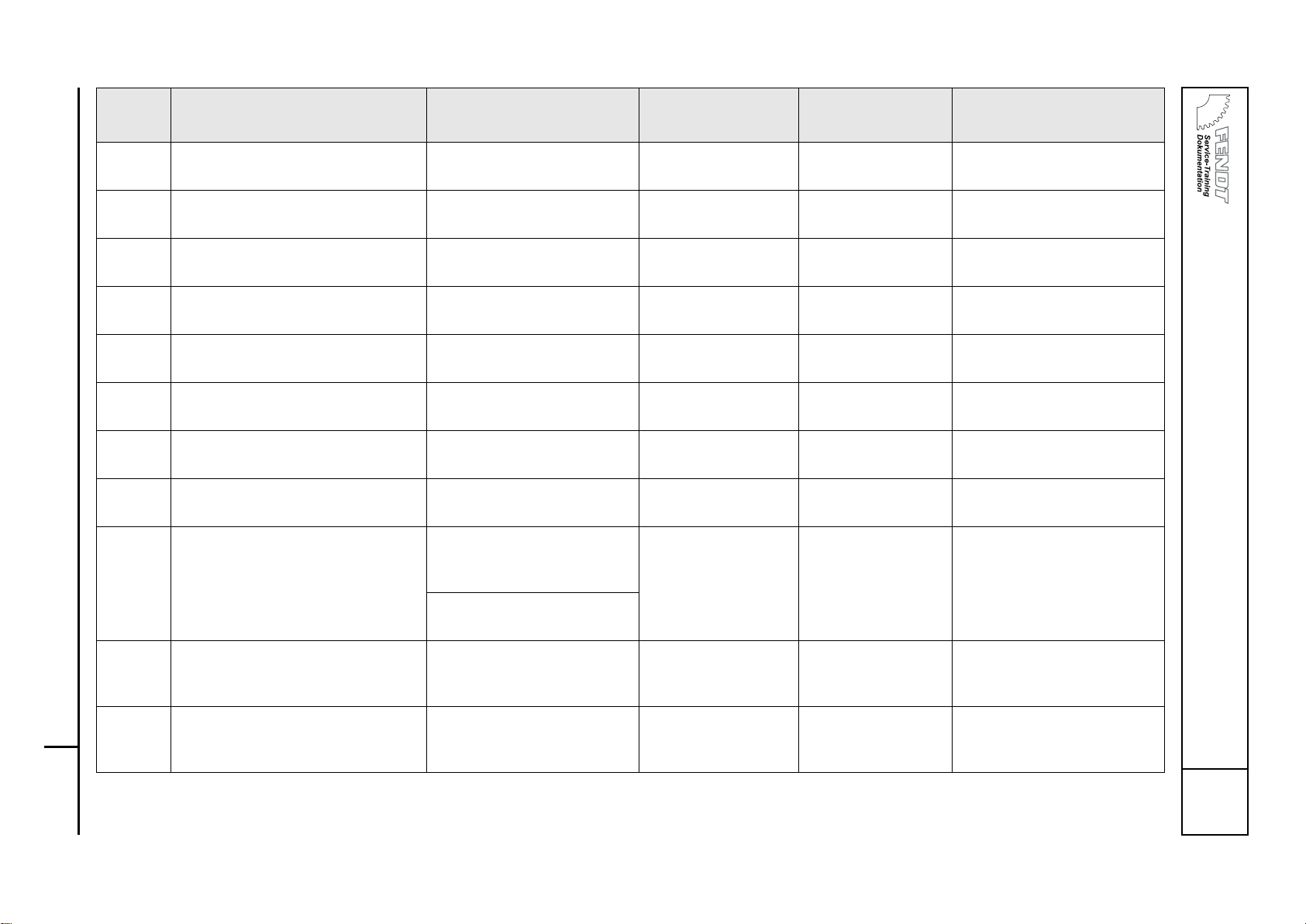

0.0.1A A002,

Y015,

Y016,

Y017,

Y018,

Y019

ECU, enhanced control,

electric auxiliary control

valves

Bus fault No functions available,

no display

Power supply for CAN

bus is in circuit board

A013; fuses F040, F041

0.0.1B A002 ECU, enhanced control TeachIn bus faulty -

Master (Variotronic TI)

('Teach-in data transfer

fault')

Emergency mode

0.0.1E ECU, Neumaier Bus fault Neumaier

reversing system

Neumaier System

doesn't work

(Neumaier Service

Manual)

0.0.1F A034 Joystick Joystick bus fault ('Drive

switch data transfer

fault')

Emergency operation,

no auxiliary valve

operation

Power supply for CAN

bus is in circuit board

A013; fuse F047

JOYSTICK CAN JOYSTICK

0.0.20 A007 Instrument cluster CAN Bus fault between

A007 instrument cluster

and tractor electronics

No functions available,

no display

Power supply for CAN

bus is in circuit board

A013; fuses F040, F041

0.1.50 A007 Instrument cluster VDO instrument cluster

EEPROM not

programmed

Malfunctions in

instrument cluster

EOL reprogramming

necessary

0.1.51 B012 Engine oil pressure

sensor

Sensor fault, wiring fault No monitoring 'Instrument cluster'

circuit diagram

12 V supply fault A013 fuse 24

0.1.54 B019 Compressed air tank

pressure sensor

Sensor fault, wiring fault No display 'Instrument cluster'

circuit diagram

12 V supply fault A013 fuse 25

0.1.55 S036 Hydraulic oil level

sensor

Sensor fault, wiring fault No monitoring 'Spool valves 1' circuit

diagram

0.1.56 B005,

A021,

A022

Temperature sensor

engine temp. (=water),

(ECU,EDC / EMR)

Sensor fault, wiring fault No monitoring 'Instrument cluster'

circuit diagram

Fault

code

Id code Brief description Description Consequences Link FENDIAS / Note

Page 7

all Vario tractors

Tractor / General system

Vario Tractors - Fault Codes

B

Faults

12/1999

0000 000001

B

f

3/58

Capitel Docu-No.

Index

Date Version

Page

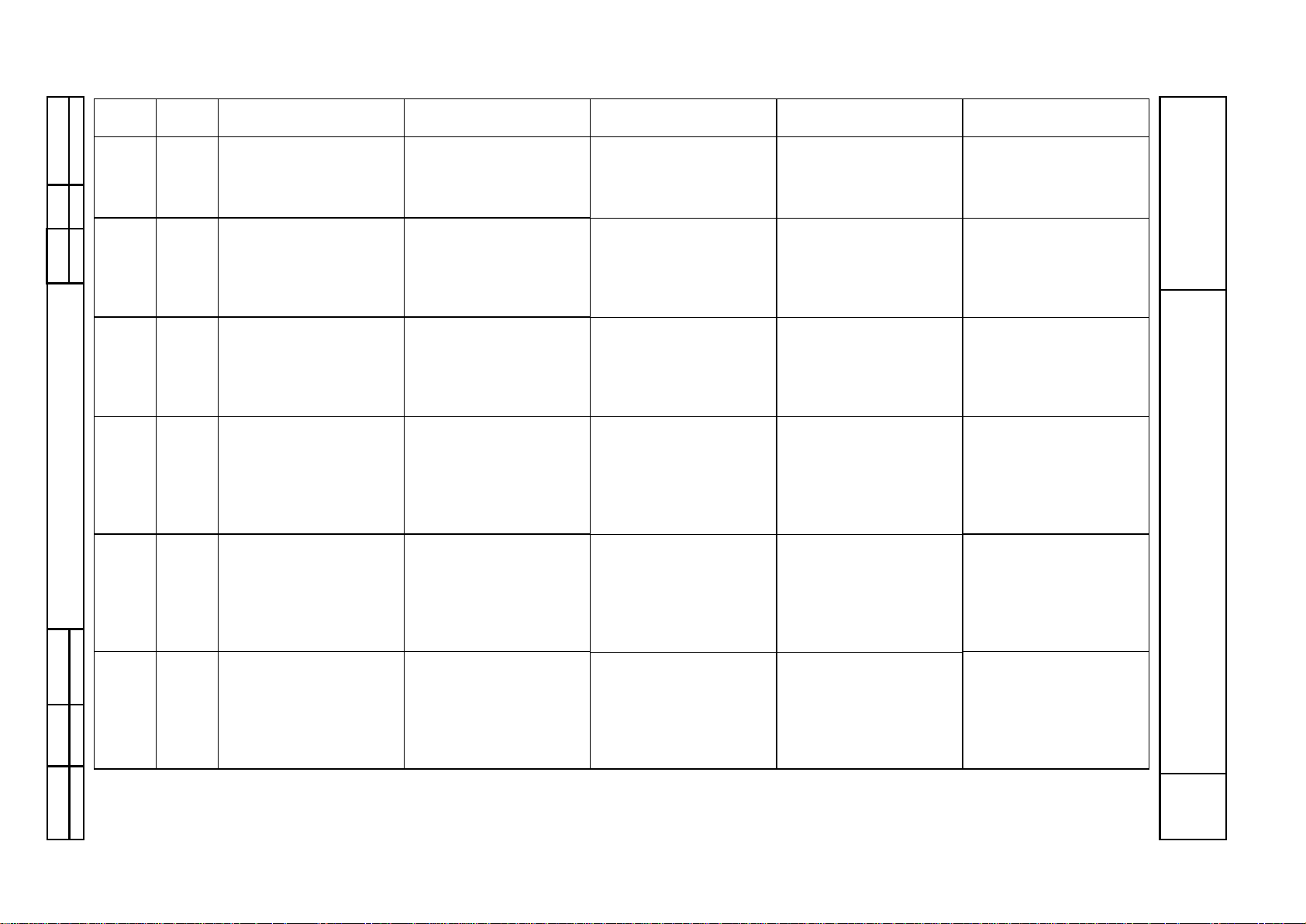

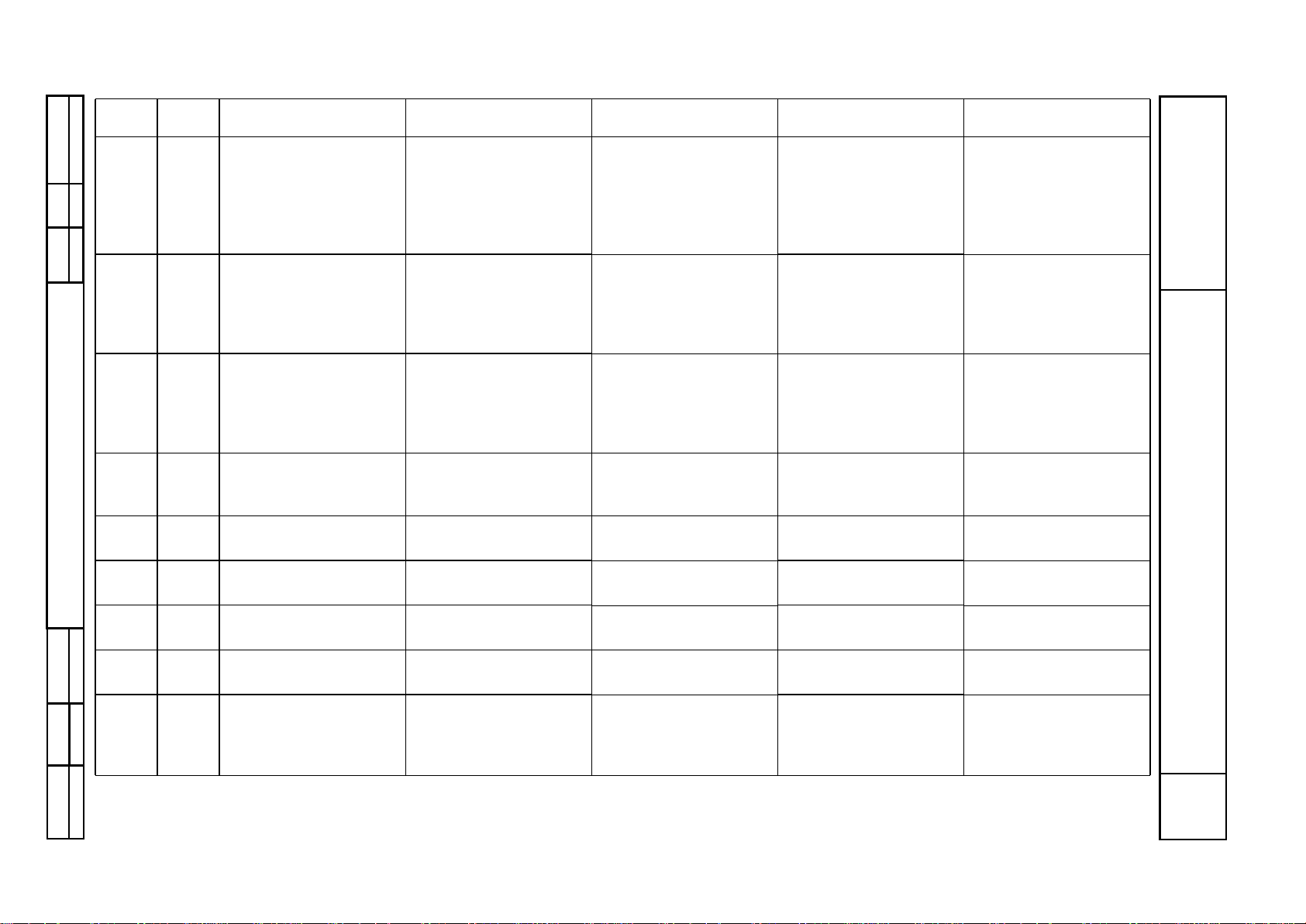

Vario Tractors - Fault Codes

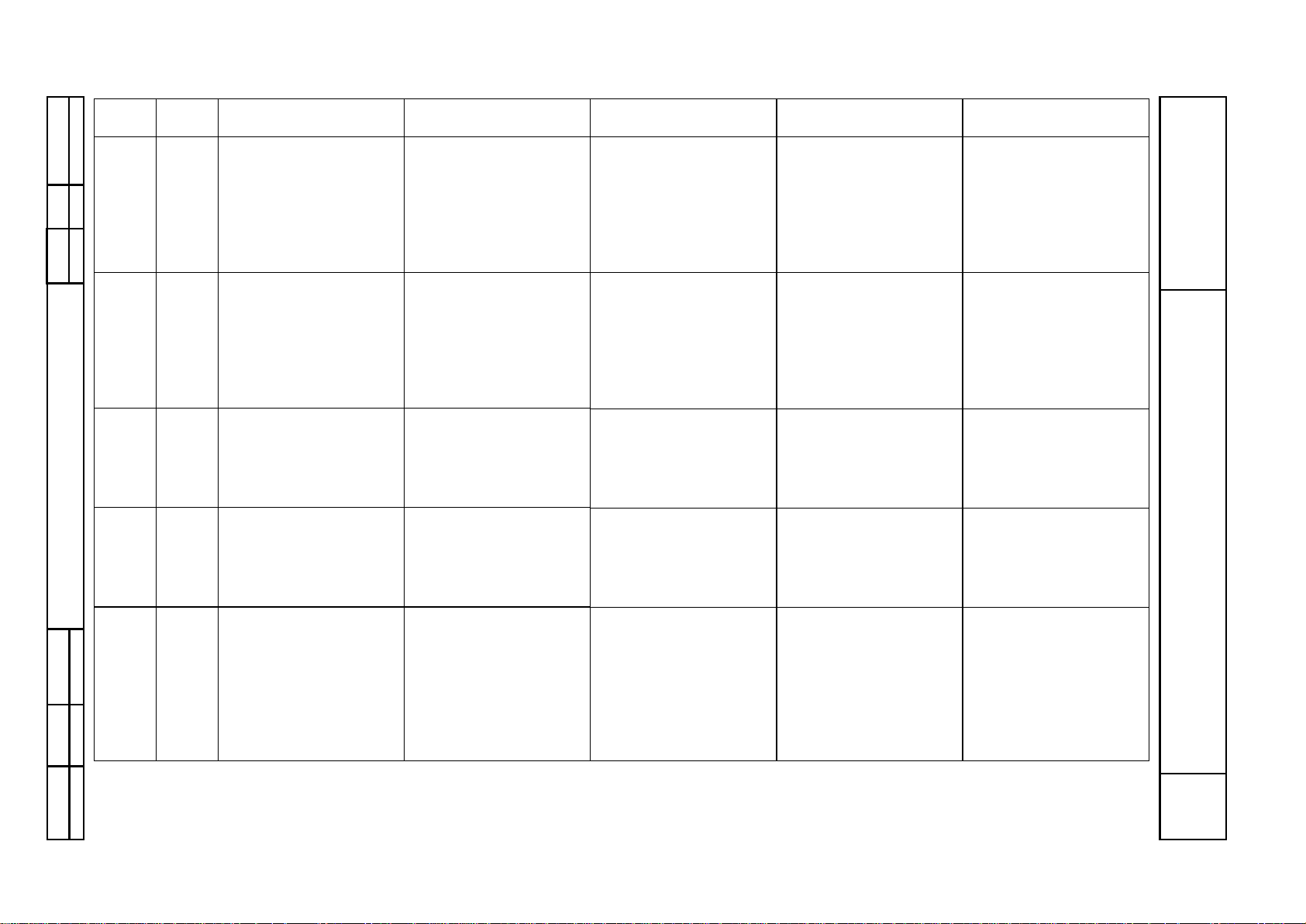

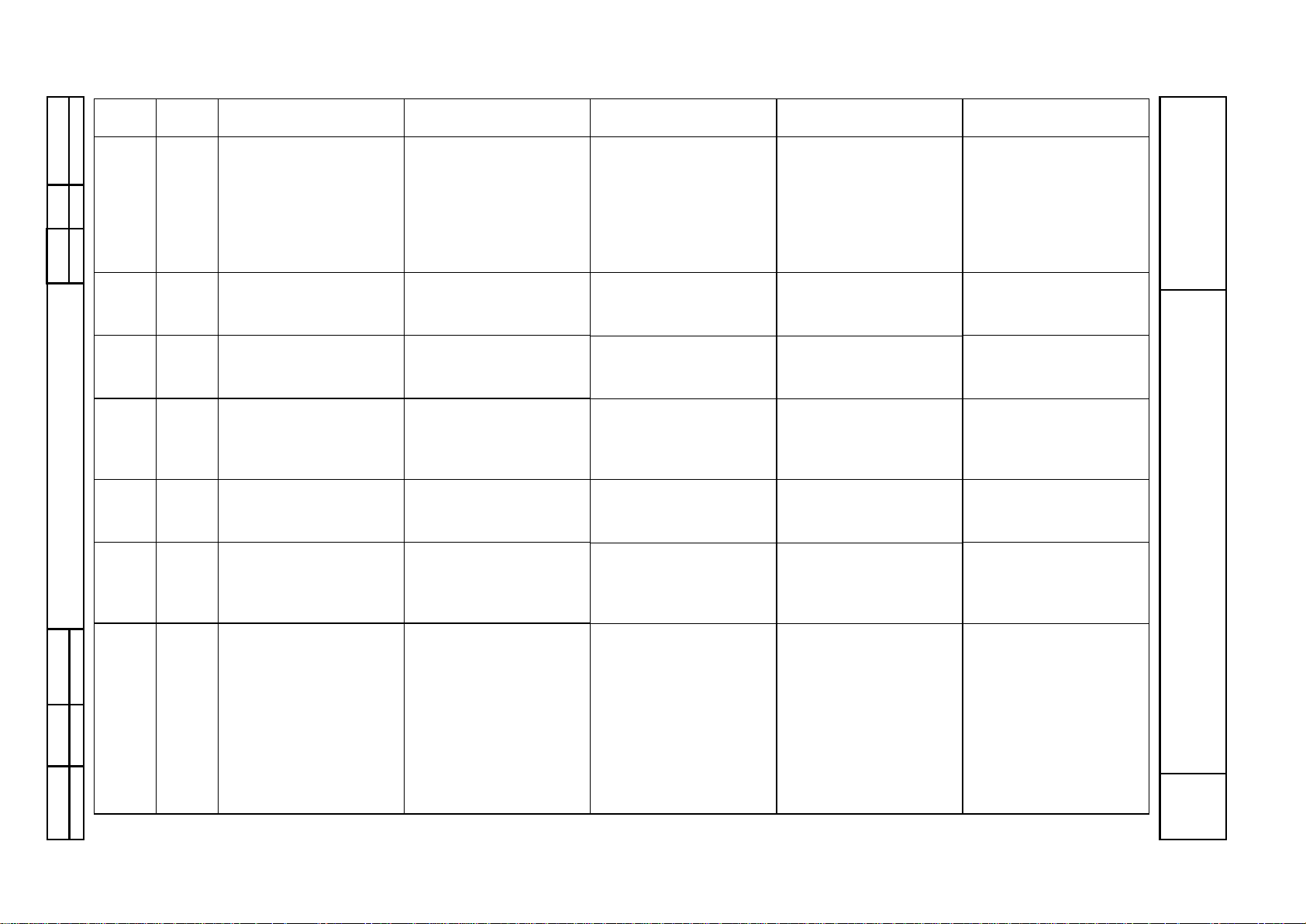

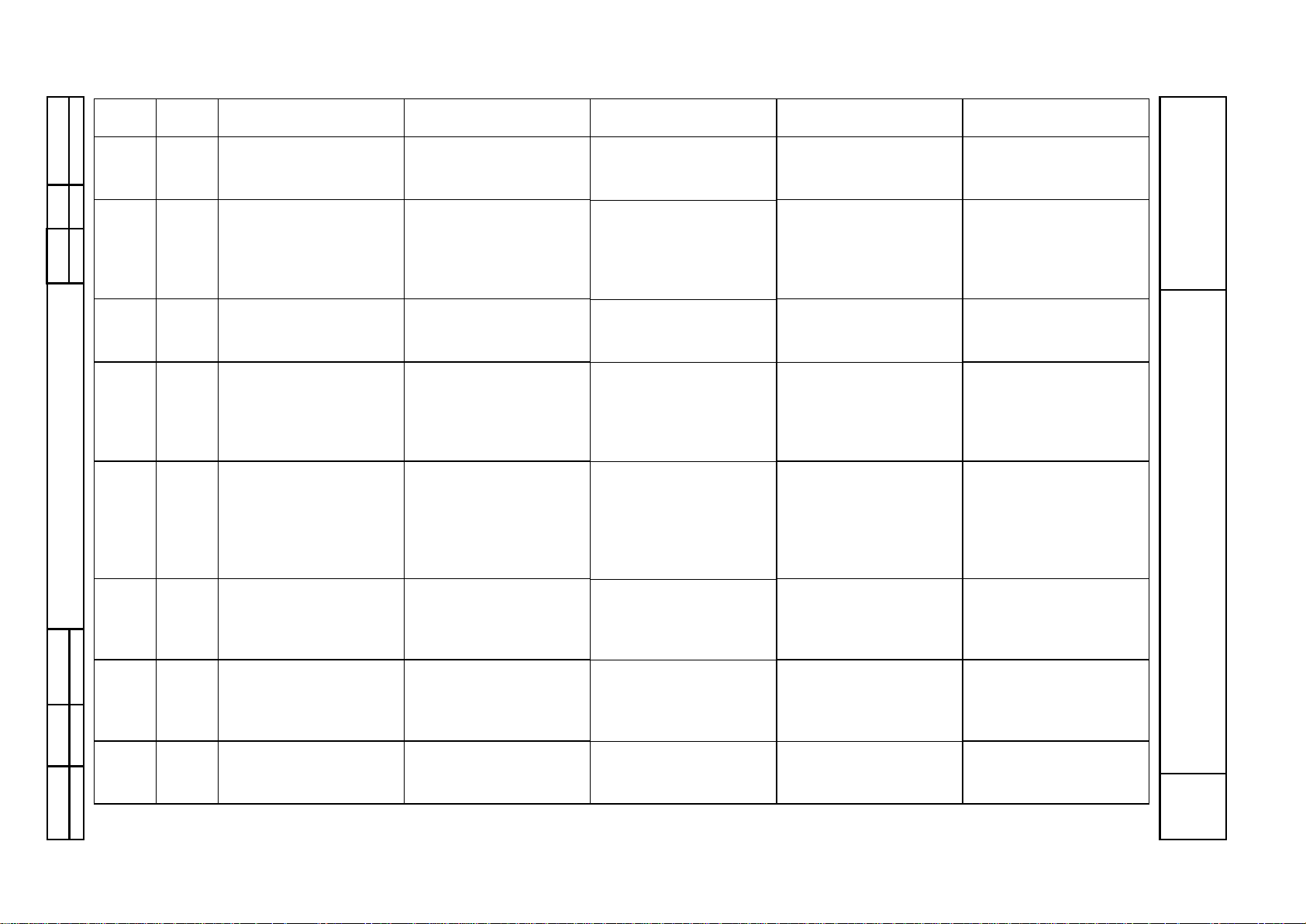

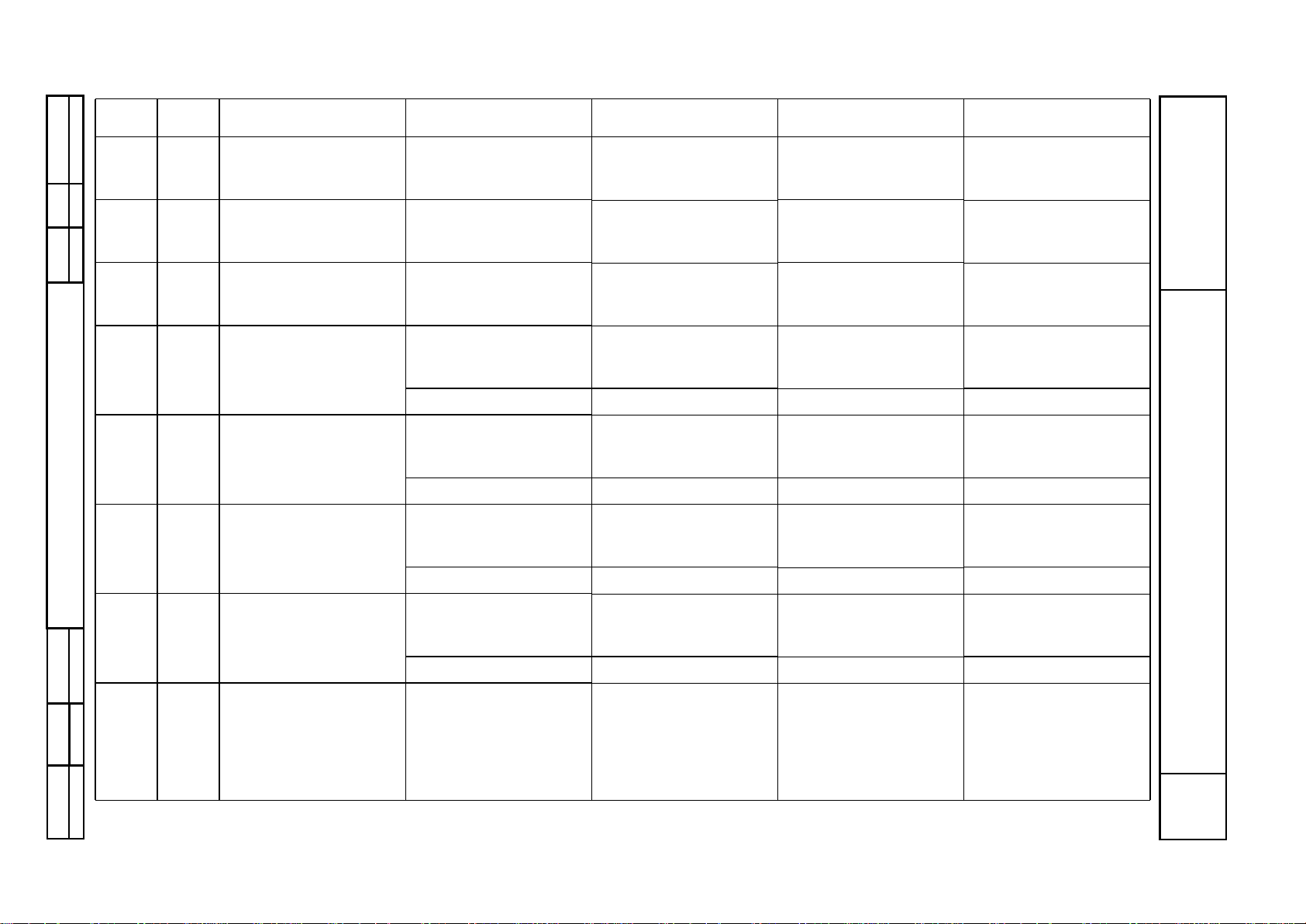

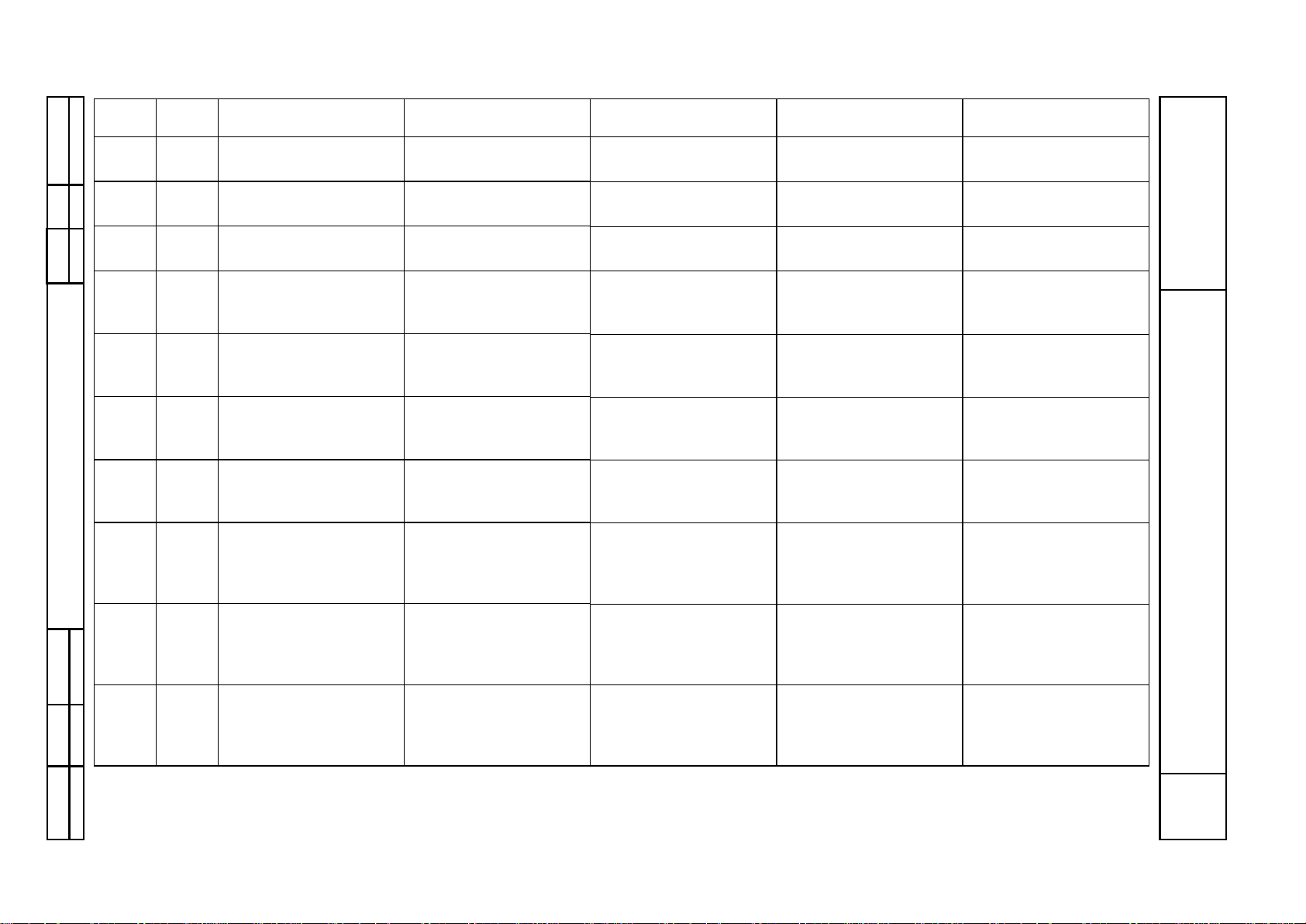

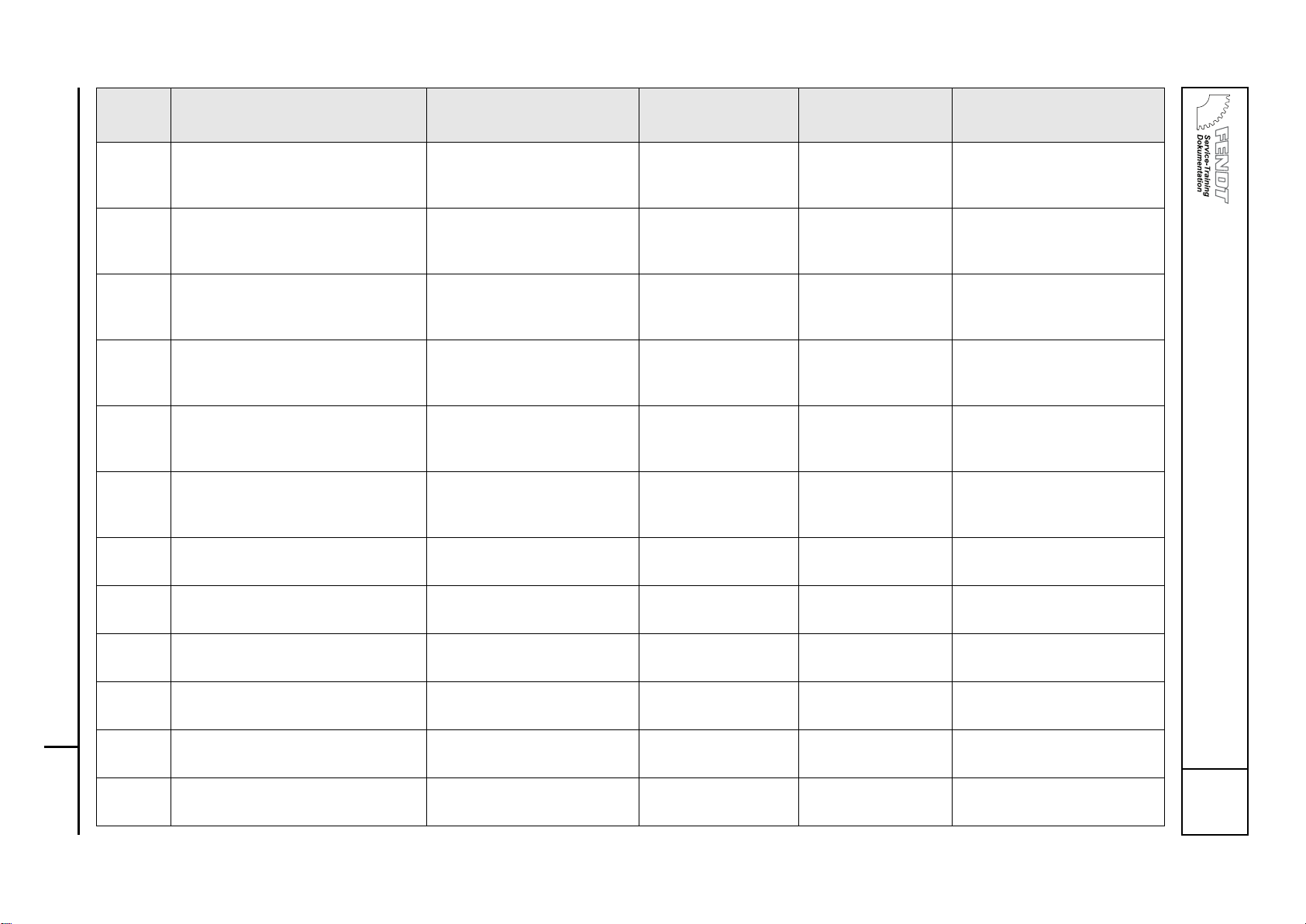

0.1.57 B006,

A022

Sensor, charge air

temperature,

ECU, EMR

Sensor fault, wiring fault No monitoring Circuit diagram:

"Instrument cluster"

(F400, F700); "EDC

control" (F900); "EMR

engine control (F7/800

Vario)

For EDC/EMR EDC level converter /

SERDIA diagnostics

0.1.59 B007;

B034

Fuel level sensor Sensor fault, wiring fault No display 'Instrument cluster'

circuit diagram

1.1.01,

poss.

B038

or

B055

EDC / EMR foot throttle

rotary position sensor

(yellow), combi-sensor

Signal too high, signal

too low, signal missing

for longer than 2000 ms

Chapter 2000 Reg.B

(EDC fault or EMR fault)

'EDC Engine control',

'EMR Engine control'

circuit diagram

TRANSMISSION,

AUTOMATIC MAXIMUM

OUTPUT CONTROL

1.1.03 B029,

B038

or

B055

EST foot throttle rotary

position sensor EST

(red), EDC foot throttle

rotary position sensor

(yellow), combi-sensor

B029 and B038 do not

match, no match B055 combi-sensor (PIN 3 to

PIN 6)

Restricted operating

mode, Chapter 2000

Reg.B (EDC fault or

EMR fault)

'EDC Engine control',

'EMR Engine control'

circuit diagram

TRANSMISSION,

AUTOMATIC MAXIMUM

OUTPUT CONTROL,

calibration code '4005'

1.1.04 A002 ECU, enhanced control Tractor Management

System (TMS)

checksum error

Tractor Management

System (TMS) doesn't

function

EOL reprogramming

necessary

1.1.05 A021;

A022

EDC control module Engine configuration

could not be read from

the EDC / EMR - control

unit

TMS is disengaged 'EDC Engine control',

'EMR Engine control'

circuit diagram

1.1.7E B035 Hand throttle rotary

position sensor

Signal out of range Restricted operating

mode, Chapter 2000

Reg.B (EDC fault or

EMR fault)

'EDC Engine control',

'EMR Engine control'

circuit diagram

TRANSMISSION,

AUTOMATIC MAXIMUM

OUTPUT CONTROL

8.5 V supply fault Fuse 26

1.1.7F A004 Control console Electrical fault in hand

throttle memory keys

(EDC/EMR). No

communication with

control console.

Last speed setting is

retained. Engine speed

can be changed using

hand throttle or

accelerator.

JOYSTICK, CANJOYSTICK

Fault

code

Id code Brief description Description Consequences Link FENDIAS / Note

Page 8

all Vario tractors

Tractor / General system

Vario Tractors - Fault Codes

B

Faults

12/1999

0000 000001

B

f

4/58

Capitel Docu-No.Index

Date Version

Page

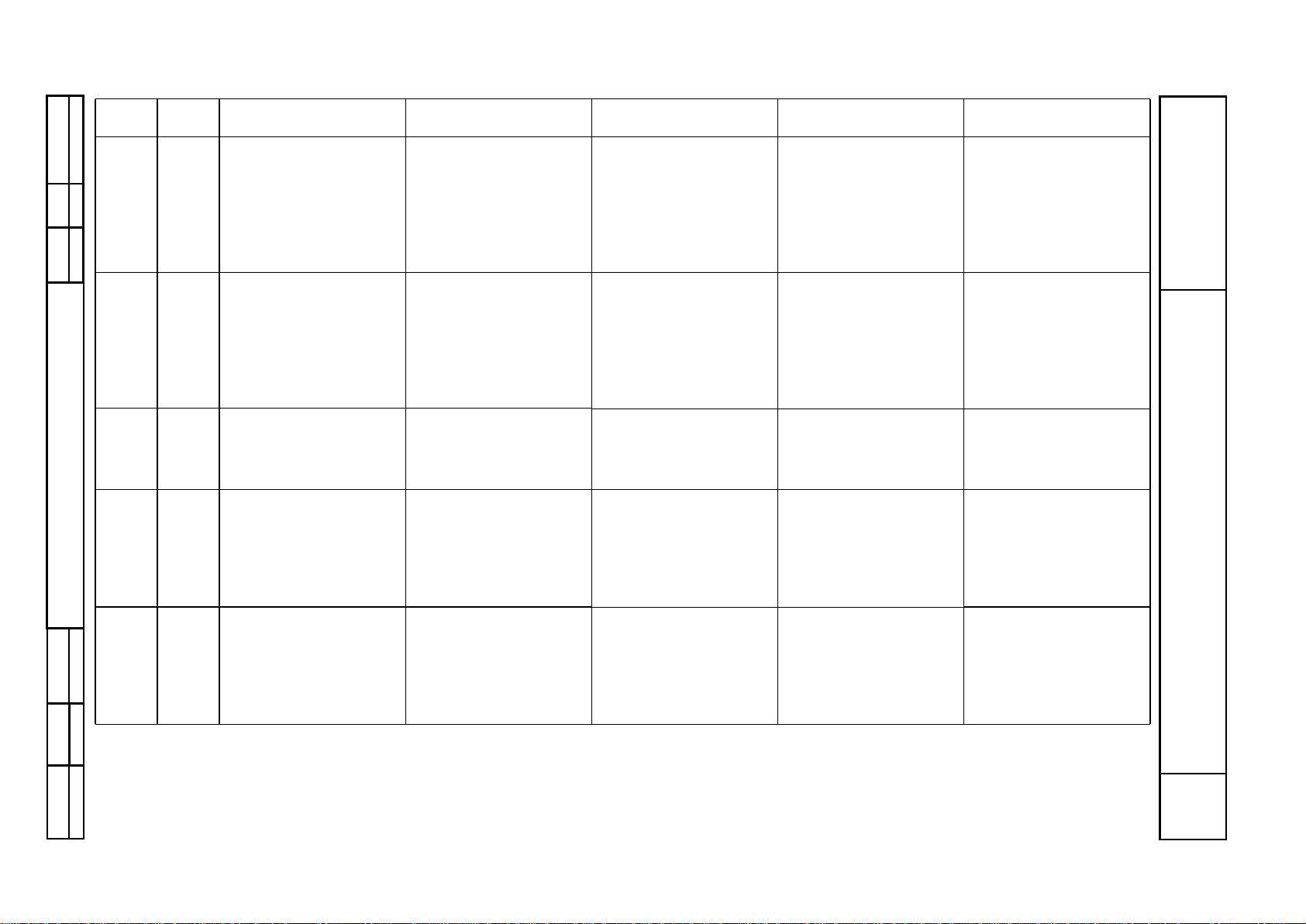

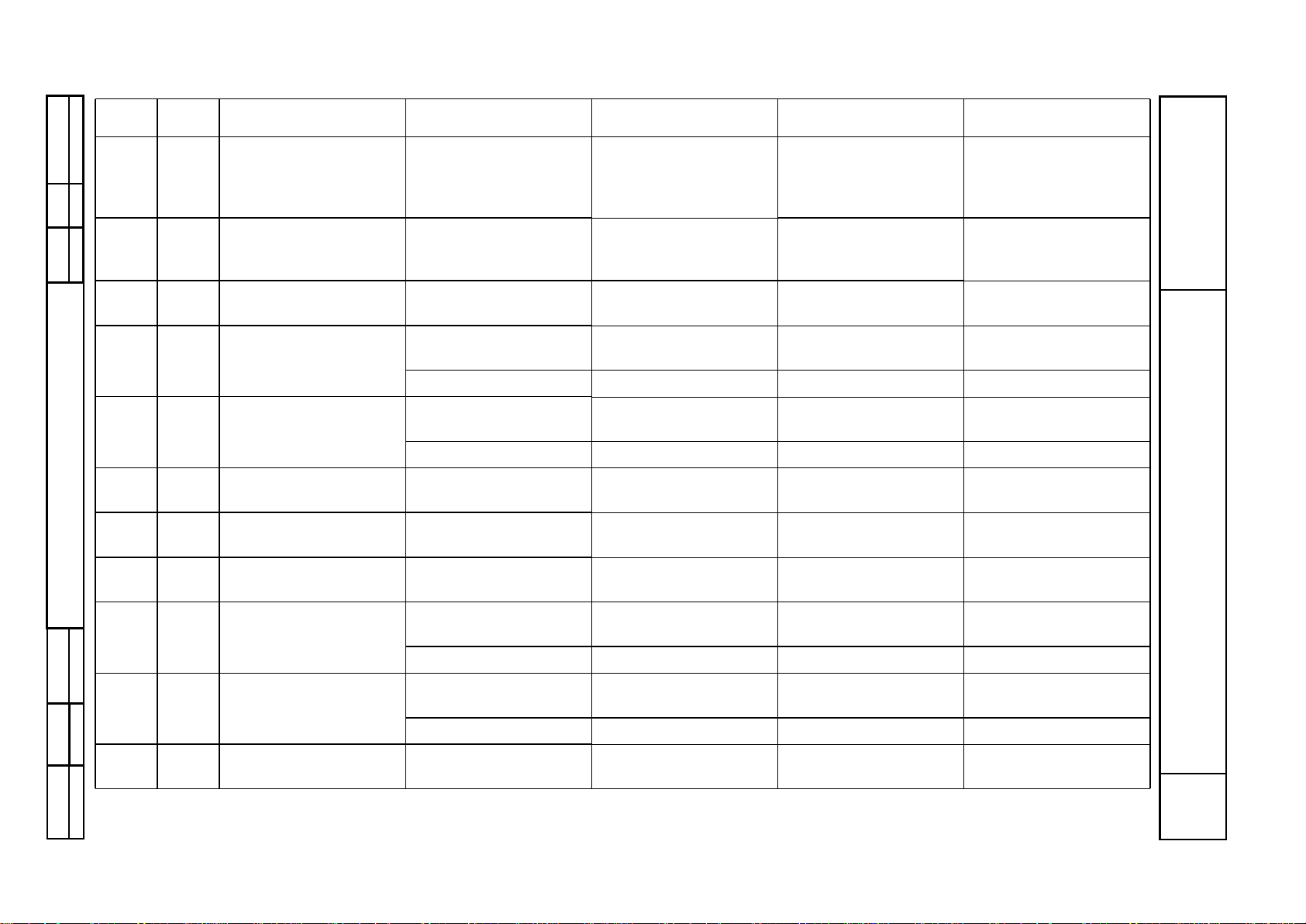

Vario Tractors - Fault Codes

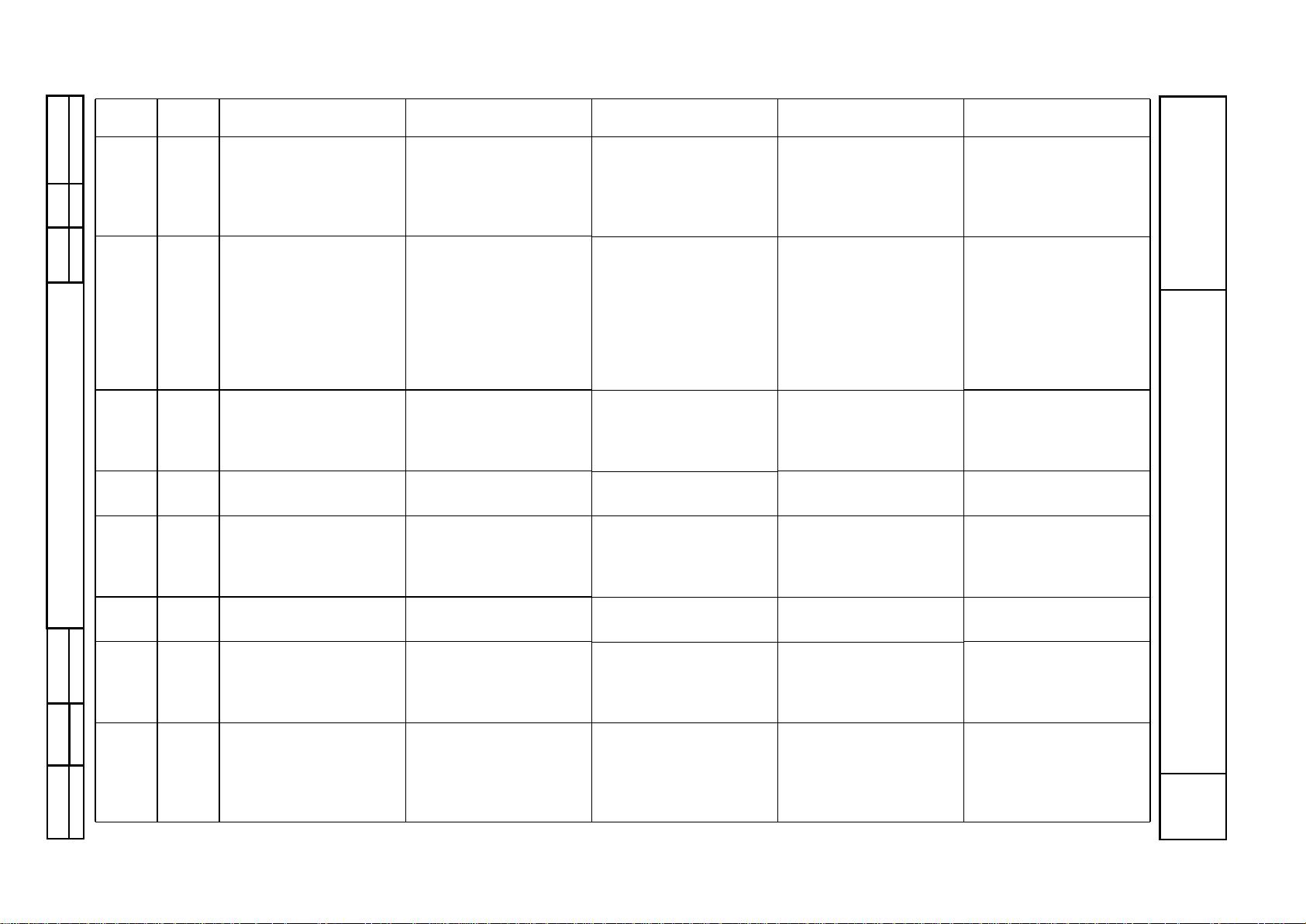

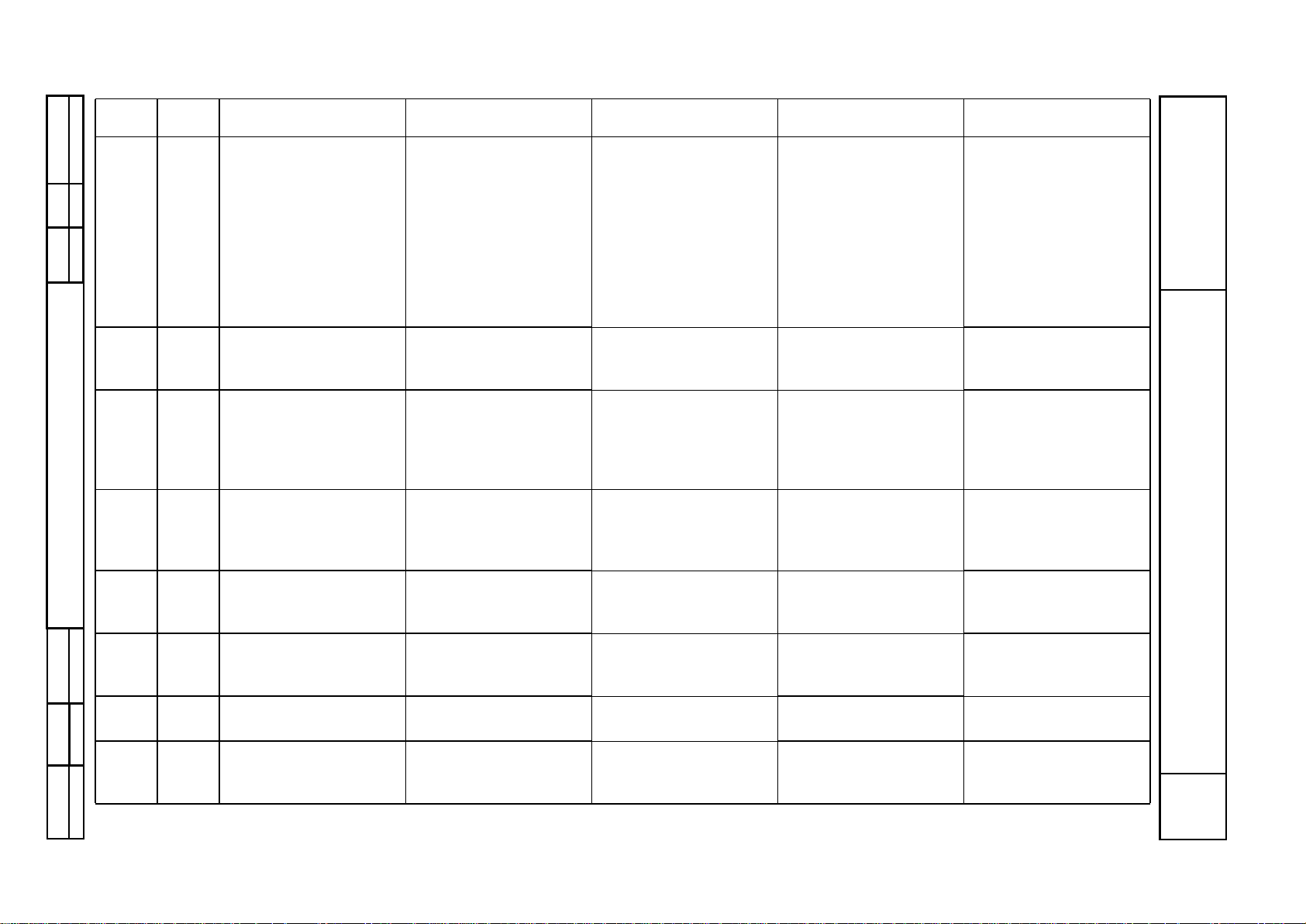

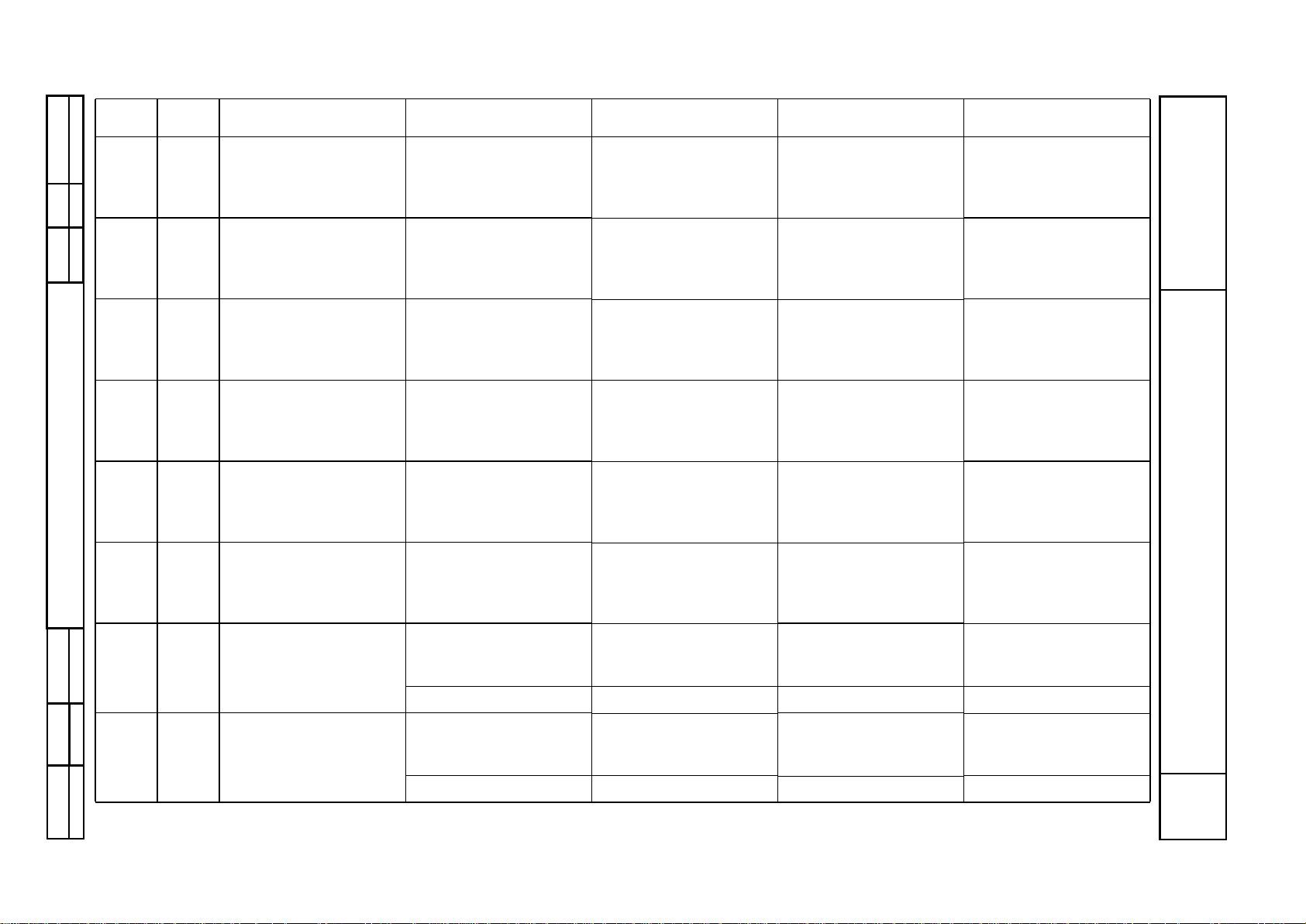

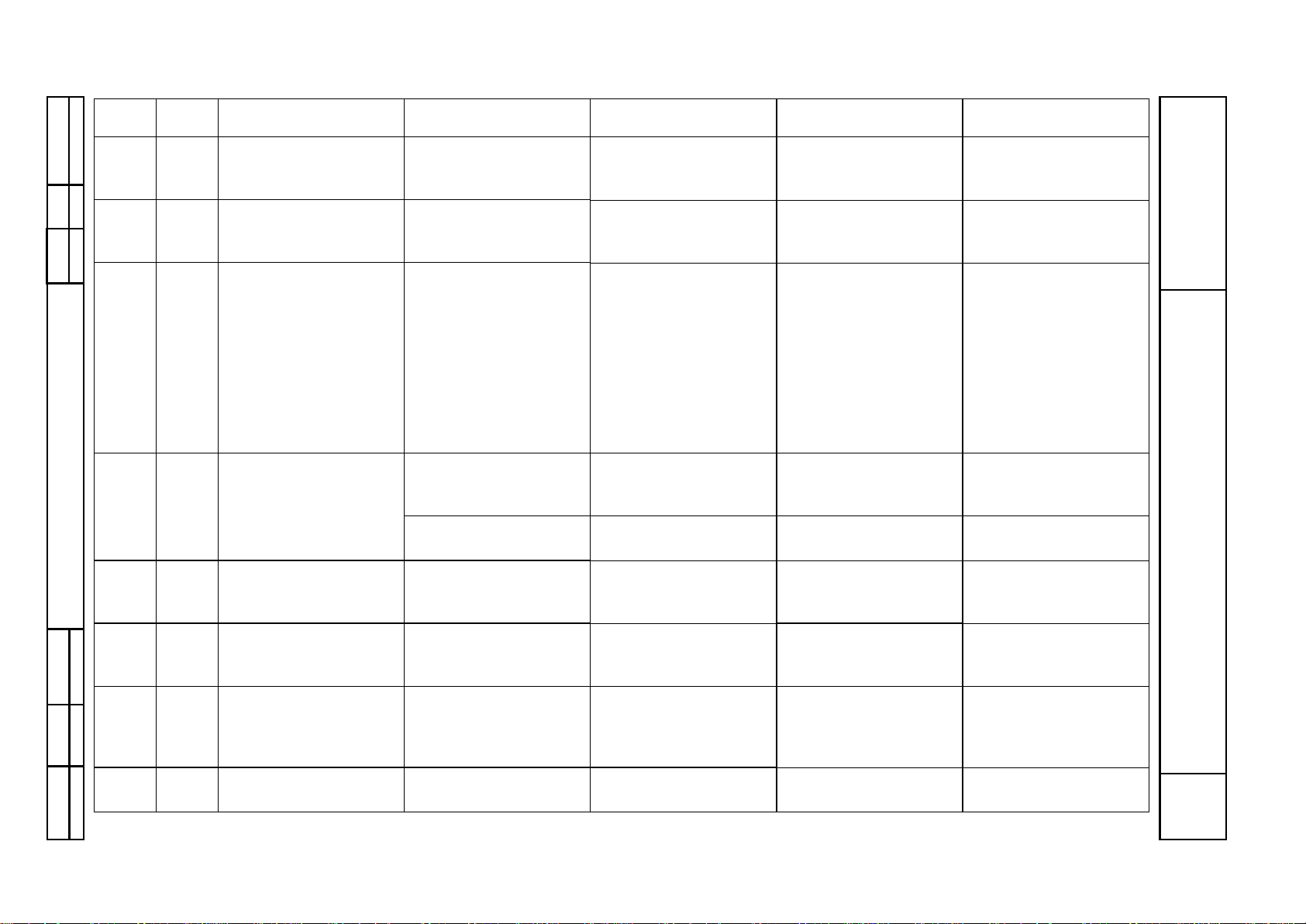

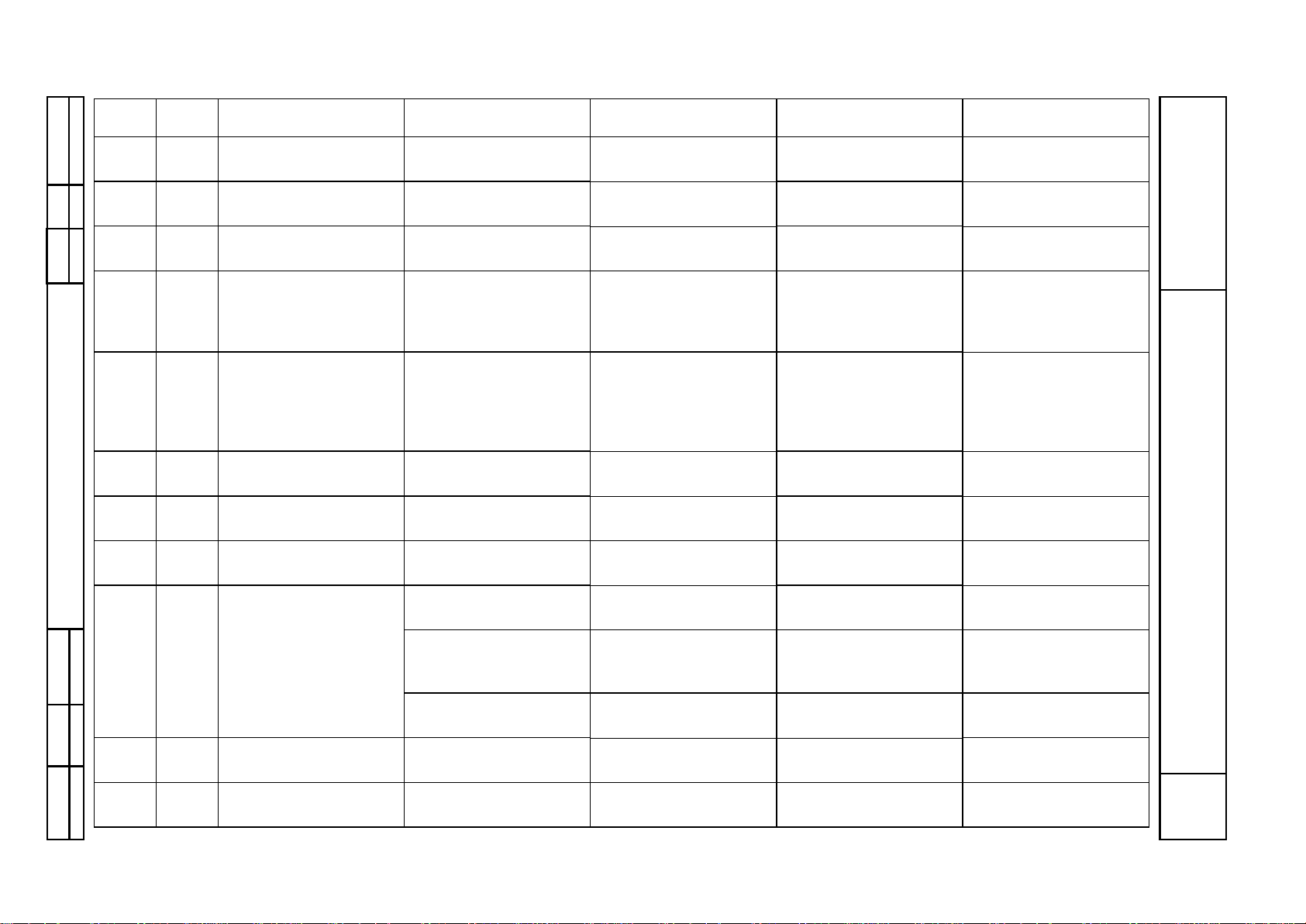

1.1.9E A002,

A004

ECU, enhanced control

Control console

(B035 - sensor, hand

throttle)

CAN connection

(enhanced control Bus);

A002 - ECU (enhanced

control) to A004 - ECU

(control console) faulty

Restricted operating

mode, Chapter 2000

Reg.B (EDC fault or

EMR fault)

'EDC Engine control',

'EMR Engine control'

circuit diagram

JOYSTICK, CANJOYSTICK

1.1.9F A034 Drive switch

(memory buttons)

A034 - Drive switch

(memory buttons) faulty

/ CAN connection

(enhanced control BUS):

A002 ECU (enhanced

control) to A034 - Drive

switch faulty

Restricted operating

mode, Chapter 2000

Reg.B (EDC fault or

EMR fault)

'EDC Engine control',

'EMR Engine control',

'Transmission Bus',

'Enhanced control Bus'

circuit diagram

JOYSTICK, CANJOYSTICK

1.1.A0 A021 EDC control module EDC control module

(A021) cannot be

identified, EOL

programming error

Torque is limited

according to fault

grading. Chapter 2000

Reg.B (EDC fault or

EMR fault)

'EDC Engine control',

'EMR Engine control'

circuit diagram

EDC - level converter or

Serdia diagnostics

1.1.A1 A002,

A021,

A022

ECU (enhanced

control),

EDC engine control

module,

EMR engine control

module

CAN enhanced control

module (A002) - Engine

control module

(A021/A022) connection

fault

Chapter 2000 Reg.B

(EDC fault or EMR fault)

"Transmission Bus"

circuit diagram

EDC - level converter or

Serdia diagnostics

1.1.B0 CAN-bus

communication

restricted

EOL reprogramming

necessary.

1.1.E0 A002,

B035

A002 - ECU (enhanced

control) ;

Sensor hand throttle

EDC / EMR

EEPROM checksum is

wrong

Restricted operating

mode, Chapter 2000

Reg.B (EDC fault or

EMR fault)

'EDC Engine control',

'EMR Engine control'

circuit diagram

New end-of-line

programming required

or load new data record

Fault

code

Id code Brief description Description Consequences Link FENDIAS / Note

Page 9

all Vario tractors

Tractor / General system

Vario Tractors - Fault Codes

B

Faults

12/1999

0000 000001

B

f

5/58

Capitel Docu-No.

Index

Date Version

Page

Vario Tractors - Fault Codes

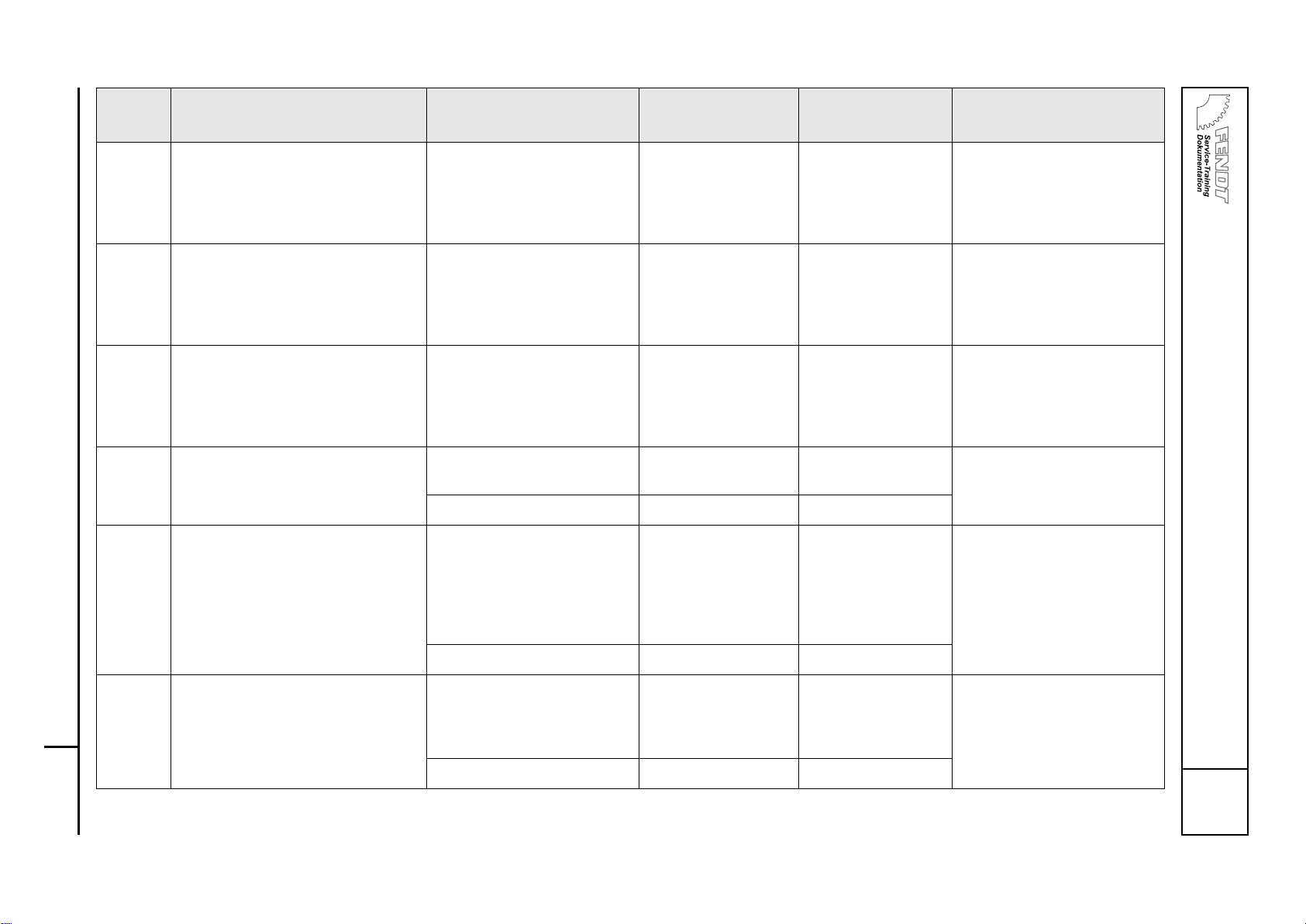

1.2.01 B041 Sensor, EMR (camshaft) Signal error, gap to

camshaft sprocket too

wide, cable connection

broken

B042 - EMR sensor

(crankshaft) takes over

rpm control, no effect on

tractor driving mode.

Note: If both sensors

fail (B041, B042), the

diesel engine dies

see also Chapter 2000

Reg. B - EMR

troubleshooting plan

SERDIA diagnostics

1.2.02 B042 Sensor, EMR

(crankshaft)

Signal error, gap to

flywheel too wide, cable

connection broken

B041 - EMR sensor

(camshaft ) takes over

rpm control, no effect on

tractor driving mode.

Note: If both sensors

fail (B041, B042), the

diesel engine dies

see also Chapter 2000

Reg. B - EMR

troubleshooting plan

SERDIA diagnostics

1.2.04 B041,

B042

Sensor, EMR camshaft /

crankshaft

Overspeed shutoff Engine stop; tractor in

'Push' mode, check

B041/B042 wiring,

Y035 - check EMR

actuator

see also Chapter 2000

Reg. B - EMR

troubleshooting plan

SERDIA diagnostics

1.2.05 B038

or

B055

Sensor, foot throttle

EMR;combi-sensor

Signal too high / signal

too low

Error message, no effect

on tractor driving mode.

see also Chapter 2000

Reg. B - EMR

troubleshooting plan

TRANSMISSION,

AUTOMATIC MAXIMUM

OUTPUT CONTROL

SERDIA diagnostics

calibration code "4005"

1.2.07 B053 Sensor, charge air

temperature / boost

pressure (EMR)

Boost pressure signal

error. Signal out of range

The A022 - ECU, EMR

uses a substitute value

to calculate the quantity

injected, or reduced

output of the tractor.

Check the sensor cable

connection, replace the

sensor

see also Chapter 2000

Reg. B - EMR

troubleshooting plan

SERDIA diagnostics

Fault

code

Id code Brief description Description Consequences Link FENDIAS / Note

Page 10

all Vario tractors

Tractor / General system

Vario Tractors - Fault Codes

B

Faults

12/1999

0000 000001

B

f

6/58

Capitel Docu-No.Index

Date Version

Page

Vario Tractors - Fault Codes

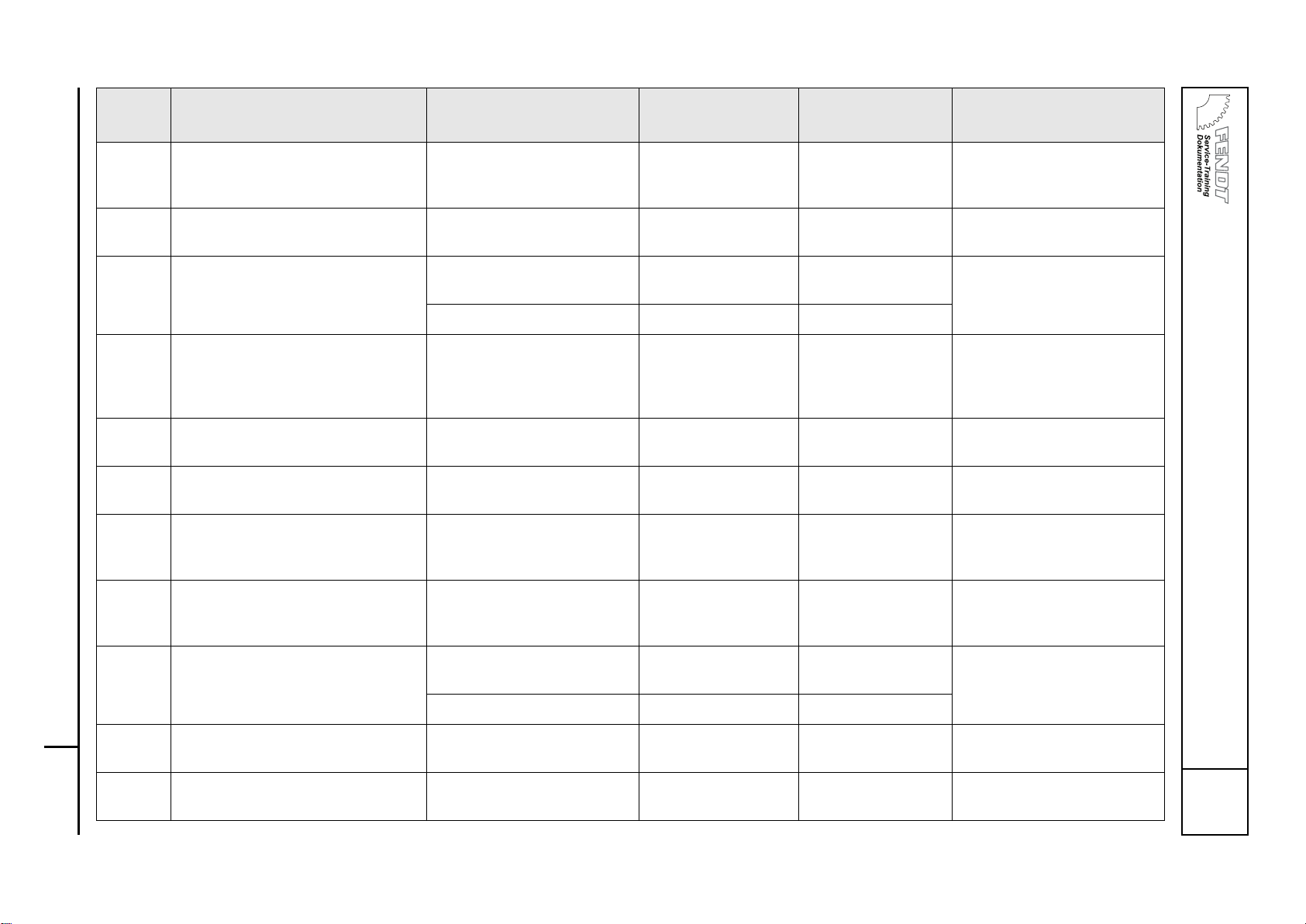

1.2.09 B048 Sensor, water

temperature (EMR)

Signal out of range if necessary, reduce

output, stop engine,

check sensor cable

connection, replace

sensor

see also Chapter 2000

Reg. B - EMR

troubleshooting plan

SERDIA diagnostics

1.2.10 B053 Sensor, charge air

temperature / boost

pressure (EMR)

Charge air temperature

signal error, signal too

high, signal too low

The A022 - ECU, EMR

uses a substitute value

to calculate the quantity

injected, or reduced

output of the tractor.

Check the sensor cable

connection, replace the

sensor

see also Chapter 2000

Reg. B - EMR

troubleshooting plan

SERDIA diagnostics

1.2.13 G001,

G003,

G001,

A021

Battery 1,

battery 2,

alternator, engine

control module (EDC)

Fault in EDC control

module power supply

No engine

powerChapter 2000

Reg.B (EDC fault)

"Power supply" circuit

diagram

1.2.17 Engine speed too high

(EDC)

Poor driving (e.g. driving

downhill)

Chapter 2000 Reg.B

(EDC fault)

1.2.18 A020 Pump control unit

(injection pump) (EDC)

needle movement

sensor

Injection start system

deviation

Reduced power,

Chapter 2000 Reg.B

(EDC fault)

Check fuel supply,

primary pressure,

interior pressure of

pump

EDC level converter

1.2.1A B026 Needle movement

sensor NBF (EDC)

Signal fault Chapter 2000 Reg.B

(EDC fault)

'EDC control' circuit

diagram

EDC level converter

1.2.1F A021 Engine control unit

(EDC)

CAN message: fault

between engine control

module and connected

electrical system

Chapter 2000 Reg.B

(EDC fault)

'EDC control module',

'transmission bus' circuit

diagram

1.2.21 A002 Enhanced control

module, transmission

bus (EDC)

Fendt ECU not

connected or CAN

connection to

transmission bus

interrupted.

Chapter 2000 Reg.B

(EDC fault) Chapter

9000 Reg.E (Can Bus)

'EDC control module',

'transmission bus',

'enhanced control bus'

circuit diagrams

Fault

code

Id code Brief description Description Consequences Link FENDIAS / Note

Page 11

all Vario tractors

Tractor / General system

Vario Tractors - Fault Codes

B

Faults

12/1999

0000 000001

B

f

7/58

Capitel Docu-No.

Index

Date Version

Page

Vario Tractors - Fault Codes

1.2.23 A002 Enhanced control

module (EDC)

CAN communication

fault between enhanced

control module (A002)

and EDC

Chapter 2000 Reg.B

(EDC fault) Chapter

9000 Reg.E (Can Bus)

'Transmission bus',

'EDC engine control'

circuit diagram

1.2.25 K020 Ub30 EDC relay Contact does not open,

ground contact

Battery can discharge,

Chapter 2000 Reg.B

(EDC fault)

'EDC control' circuit

diagram

1.2.2A A002,

A021

Enhanced control

module,

EDC control module,

transmission bus,

enhanced control bus

(EDC)

CAN message fault from

enhanced control

module (A002) to EDC

control module (A021),

'Engine brake function'

Engine brake

non-operational,

Chapter 2000 Reg.B

(EDC fault)

'EDC engine control',

'transmission bus',

'engine brake' circuit

diagrams

TRANSMISSION

CRUISE CONTROL

1.2.2B A002,

A021

Enhanced control

module,

EDC control module,

transmission bus,

enhanced control bus

(EDC)

CAN message fault from

enhanced control

module (A002) to EDC

control module (A021),

'Engine brake function'

Engine brake

non-operational,

Chapter 2000 Reg.B

(EDC fault)

'EDC engine control',

'transmission bus',

'engine brake' circuit

diagrams

TRANSMISSION

CRUISE CONTROL

1.2.2C A002,

A021

Enhanced control

module,

EDC control module,

transmission bus,

enhanced control bus

(EDC)

CAN message fault from

enhanced control

module (A002) to EDC

control module (A021),

'Engine brake function'

Engine brake

non-operational,

Chapter 2000 Reg.B

(EDC fault)

'EDC engine control',

'transmission bus',

'engine brake' circuit

diagrams

TRANSMISSION

CRUISE CONTROL

1.2.2D A002,

A021

Enhanced control

module,

engine control module,

transmission bus (EDC)

CAN signal fault from

enhanced control

module (A002) to EDC

control module (A021)

Chapter 2000 Reg.B

(EDC fault), Chapter

9000 Reg.E (Can Bus)

'EDC engine control',

'transmission bus' circuit

diagram

1.2.2E A002,

A021

Enhanced control

module,

engine control module,

transmission bus (EDC)

CAN signal fault from

enhanced control

module (A002) to EDC

control module (A021)

Chapter 9000 Reg.E

(Can Bus)

'EDC engine control',

'transmission bus' circuit

diagram

Fault

code

Id code Brief description Description Consequences Link FENDIAS / Note

Page 12

all Vario tractors

Tractor / General system

Vario Tractors - Fault Codes

B

Faults

12/1999

0000 000001

B

f

8/58

Capitel Docu-No.Index

Date Version

Page

Vario Tractors - Fault Codes

1.2.31 A022,

B048

ECU, EMR2 ;

Sensor, water

temperature

Coolant temperature

warning threshold

exceeded

After a delay period (and

coolant temperature

remains too high),

reduce engine output -clean the radiator , check

coolant level, check

B048 sensor

see also Chapter 2000

Reg. B - EMR

troubleshooting plan

SERDIA diagnostics

1.2.32 A022,

B053

ECU, EMR2 ;

Sensor, charge air

temperature / boost

pressure

Charge air temperature

warning threshold

exceeded

After a delay (and if the

charge air temperature

remains too high),

engine power is reduced

Clean radiator , test B053

- Sensor

see also Chapter 2000

Reg. B - EMR

troubleshooting plan

SERDIA diagnostics

1.2.35 A022,

B041,

B042

ECU, EMR2 ;

Sensor, EMR (camshaft)

Sensor, EMR

(crankshaft)

Engine speed too high

(for example in 'push'

operation)

The control rod is

brought to zero delivery

position. When speed

falls below the recovery

threshold, control

passes back to the A022

- ECU

see also Chapter 2000

Reg. B - EMR

troubleshooting plan

SERDIA diagnostics

1.2.38 A021 Engine control module

(EDC)

Fault in operation of

EDC control module,

'Engine stop'

Reduced power,

Chapter 2000 Reg.B

(EDC fault)

"EDC engine control",

"power supply" circuit

diagram

EDC level converter

1.2.41 A022 ;

B048

ECU, EMR2 ;

Sensor, water

temperature

Coolant temperature

has gone over shutoff

threshold

Clean radiator, check

coolant lever, test

sensor

also refer to Chapter

2000 Reg. B - EMR

troubleshooting,

Chapter 9000 Reg. E

SERDIA diagnostics

1.2.42

(DEUTZ

EMR)

A022,

B053

ECU, EMR2 ;

Sensor, charge air

temperature / boost

pressure

Charge air temperature

has gone below shutoff

threshold

Clean radiator, test

sensor

see also Chapter 2000

Reg. B - EMR

troubleshooting plan

SERDIA diagnostics

1.2.42

(MAN

EDC)

A020 Pump control unit

(injection pump) (EDC)

Injection pump (pump

control unit), fuel

temperature too high

(overheating)

Chapter 2000 Reg.B

(EDC fault)

'EDC control' circuit

diagram

EDC level converter

Fault

code

Id code Brief description Description Consequences Link FENDIAS / Note

Page 13

all Vario tractors

Tractor / General system

Vario Tractors - Fault Codes

B

Faults

12/1999

0000 000001

B

f

9/58

Capitel Docu-No.

Index

Date Version

Page

Vario Tractors - Fault Codes

1.2.46 Bus

system

Enhanced control bus,

transmission bus, EDC

bus

CAN-bus message fault restricted driving mode,

Chapter 2000 Reg.B

(EDC fault), Chapter

9000 Reg.E (Can Bus)

"EDC engine control",

"transmission bus",

"enhanced control bus"

circuit diagrams

1.2.50 A022,

Y035

ECU EMR2, EMR

actuator ('Rotary

magnet and position

sensor')

Feedback fault from

position sensor

Emergency shutoff,

engine does not start

check actuator (SERDIA

diagnostics), check

wiring from actuator

see also Chapter 2000

Reg. B - EMR

troubleshooting plan

SERDIA diagnostics

1.2.52 A022,

Y035

ECU EMR2, EMR

actuator ('Rotary

magnet and position

sensor')

Feedback fault from

position sensor

(reference coil)

Emergency shutoff,

engine does not start,

check actuator, check

wiring from actuator,

check A022 - ECU EMR

see also Chapter 2000

Reg. B - EMR

troubleshooting plan

SERDIA diagnostics

1.2.53 A022,

Y035

ECU EMR2, EMR

actuator ('Rotary

magnet and position

sensor')

Difference between

target control travel

(ECU EMR2) andactual

control travel (actuator)

greater than 10%

Error message

(disappears when

difference is less than

10%), check actuator,

check whether control

rod functions smoothly

see also Chapter 2000

Reg. B - EMR

troubleshooting plan

SERDIA diagnostics

1.2.67 A022 ECU, EDC ECU EMR internal error

(ERROR Hand Step 1)

Check ECU EMR2, if

necessary load a new

data record (important:

save old data record!!), if

necessary replace ECU

EMR2

see also Chapter 2000

Reg. B - EMR

troubleshooting plan

1.2.68 A022 ECU, EDC ECU EMR internal error

(ERROR CAN Step 1)

Check ECU EMR2, if

necessary load a new

data record (important:

save old data record!!), if

necessary replace ECU

EMR2

see also Chapter 2000

Reg. B - EMR

troubleshooting plan

Fault

code

Id code Brief description Description Consequences Link FENDIAS / Note

Page 14

all Vario tractors

Tractor / General system

Vario Tractors - Fault Codes

B

Faults

12/1999

0000 000001

B

f

10/58

Capitel Docu-No.Index

Date Version

Page

Vario Tractors - Fault Codes

1.2.70 A022 ECU, EDC CAN Bus controller fault possible reduced engine

running characteristics

--- check transmission

bus terminating resistors

(A013 - circuit board,

A009 - actuator unit),

check ECU EMR2

also refer to Chapter

2000 Reg.B (EMR

Troubleshooting),

Chapter 9000 Reg.E

(Can Bus)

1.2.71 A022,

X810

ECU, EMR2 ;

diagnostics socket

CAN interface fault possible reduced engine

running characteristics

--- check transmission

bus terminating resistors

(A013 - circuit board,

A009 - actuator unit),

check ECU EMR2

see also Chapter 2000

Reg. B - EMR

troubleshooting plan

SERDIA diagnostics

1.2.74 A022;

A002

CAN bus, wiring (EMR) Cable broken, short

circuit or serious CAN

bus fault; CAN bus

passive

Running of engine may

be reduced

see also Chapter 2000

Reg. B - EMR

troubleshooting plan

'Transmission Bus'

circuit diagram

1.2.76 A022 ECU EMR2 Parameter settings

incorrect

Emergency, engine

does not start ---

Switch ignition OFF then

ON, check again, if error

reappears --> replace

ECU EMR2

see also Chapter 2000

Reg. B - EMR

troubleshooting plan

load new data record

1.2.77 A022 ECU EMR2 continuous monitoring of

program memory

delivers an error

Emergency, engine

does not start ---

Switch ignition OFF then

ON, check again, if error

reappears --> replace

ECU EMR2

see also Chapter 2000

Reg. B - EMR

troubleshooting plan

Fault

code

Id code Brief description Description Consequences Link FENDIAS / Note

Page 15

all Vario tractors

Tractor / General system

Vario Tractors - Fault Codes

B

Faults

12/1999

0000 000001

B

f

11/58

Capitel Docu-No.

Index

Date Version

Page

Vario Tractors - Fault Codes

1.2.78 A022 ECU EMR2 continuous monitoring of

program memory

delivers an error

Emergency, engine

does not start ---

Switch ignition OFF then

ON, check again, if error

reappears --> replace

ECU EMR2

see also Chapter 2000

Reg. B - EMR

troubleshooting plan

1.2.80 A022,

Y035

ECU EMR2,

EMR actuator

Voltage supply to EMR

actuator out of allowed

range

Error message

(disappears again when

the current is in the

normal range), turn

ignition OFF and ON

again, recheck, if error

occurs again --> replace

ECU EMR2

also refer to

Chapter 2000 Reg. B EMR Troubleshooting,

checking cable

harness

SERDIA diagnostics

1.2.81 B038

or B

055

EDC foot throttle rotary

position sensor (yellow),

combi-sensor

Signal fault Chapter 2000 Reg.B

(EDC fault)

'EDC control' circuit

diagram

TRANSMISSION

AUTOMATIC MAXIMUM

OUTPUT CONTROL

1.2.82 A020 Pump control unit

(injection pump) (EDC)

Fault in high-pressure

solenoid valve actuation

time

Engine stalls, Chapter

2000 Reg.B (EDC fault)

'EDC control' circuit

diagram

EDC level converter

1.2.83 A022 ECU EMR2 Reference voltage 1 for

Y035 - actuator out of

allowed range

Error message

(disappears when

current is back in normal

range), substitute value

5 VDC, check voltage

supply to ECU EMR2,

switch ignition OFF then

ON, if error reappears

--> replace ECU EMR2

see also Chapter 2000

Reg. B - EMR

troubleshooting plan

SERDIA diagnostics

Fault

code

Id code Brief description Description Consequences Link FENDIAS / Note

Page 16

all Vario tractors

Tractor / General system

Vario Tractors - Fault Codes

B

Faults

12/1999

0000 000001

B

f

12/58

Capitel Docu-No.Index

Date Version

Page

Vario Tractors - Fault Codes

1.2.84

(DEUTZ

EMR)

A022 ECU EMR2 Reference voltage 2 for

Y035 - actuator out of

permissible range

Error message

(disappears when

current is back in normal

range), substitute value

5 VDC, check voltage

supply to ECU EMR2,

switch ignition OFF then

ON, if error reappears

--> replace ECU EMR2

see also Chapter 2000

Reg. B - EMR

troubleshooting plan

SERDIA diagnostics

1.2.84

(MAN

EDC)

B025 EDC speed sensor Signal fault Reduced power,

Chapter 2000 Reg.B

(EDC fault)

'EDC control' circuit

diagram

EDC level converter

1.2.85

(DEUTZ

EMR)

A022 ECU EMR2 Reference voltage 4 for

Y035 - actuator out of

permissible range

Error message

(disappears when

current is back in normal

range), substitute value

5 VDC, check voltage

supply to ECU EMR2,

switch ignition OFF then

ON, if error reappears

--> replace ECU EMR2

see also Chapter 2000

Reg. B - EMR

troubleshooting plan

SERDIA diagnostics

1.2.85

(MAN

EDC)

B028 Boost pressure sensor

(EDC)

Signal fault Reduced power,

Chapter 2000 Reg.B

(EDC fault)

'EDC control' circuit

diagram

EDC level converter

1.2.86 A022 ECU EMR2 Temperature in ECU

EMR2 too high

Error message

(disappears when

temperature is back in

normal range), switch

ignition OFF then ON, if

error reappears -->

replace ECU EMR2

see also Chapter 2000

Reg. B - EMR

troubleshooting plan

SERDIA diagnostics

Fault

code

Id code Brief description Description Consequences Link FENDIAS / Note

Page 17

all Vario tractors

Tractor / General system

Vario Tractors - Fault Codes

B

Faults

12/1999

0000 000001

B

f

13/58

Capitel Docu-No.

Index

Date Version

Page

Vario Tractors - Fault Codes

1.2.87

(DEUTZ

EMR)

A022 ECU EMR2 Atmospheric pressure

sensor in ECU EMR2

faulty

Error message

(disappears when

pressure is back in

normal range), switch

ignition OFF then ON, if

error reappears -->

replace ECU EMR2

see also Chapter 2000

Reg. B - EMR

troubleshooting plan

SERDIA diagnostics

1.2.87

(MAN

EDC)

B027 Water temperature

sensor (EDC)

Signal fault Reduced power,

Chapter 2000 Reg.B

(EDC fault)

'EDC control' circuit

diagram

EDC level converter

1.2.89 A020 Pump control unit

(injection pump)

Electronic volume

controller fault

Engine won't start,

Chapter 2000 Reg.B

(EDC fault)

'EDC control' circuit

diagram

1.2.90 A022 ECU EMR2 Incorrect parameter

(EEPROM reading, or

checksum error)

Engine does not start,

switch ignition OFF then

ON, if error reappears

--> replace ECU EMR2

see also Chapter 2000

Reg. B - EMR

troubleshooting plan

load new data record

1.2.91 B025 EDC speed sensor Signal fault Reduced power,

Chapter 2000 Reg.B

(EDC fault)

'EDC control' circuit

diagram

EDC level converter

1.2.92 A020

A021

Engine control module,

pump control unit

(injection pump) (EDC)

Engine stop via 'Injected

volume = 0' faulty, see

Chapter 2710 Reg. A

'Engine stop'

Reduced power,

Chapter 2000 Reg.B

(EDC fault)

'EDC control' circuit

diagram

1.2.93 A022 ECU EMR2 internal processing error

in ECU EMR2 (batch

overflow)

Emergency shutoff,

engine does not start,

switch ignition OFF then

ON, if error reappears

--> load new data record

in ECU EMR2

(important: save old data

record!!) if error

reappears --> replace

ECU EMR2

see also Chapter 2000

Reg. B - EMR

troubleshooting plan

SERDIA diagnostics

Fault

code

Id code Brief description Description Consequences Link FENDIAS / Note

Page 18

all Vario tractors

Tractor / General system

Vario Tractors - Fault Codes

B

Faults

12/1999

0000 000001

B

f

14/58

Capitel Docu-No.Index

Date Version

Page

Vario Tractors - Fault Codes

1.2.94 A022 ECU EMR2 internal processing error

in ECU EMR2

Emergency shutoff,

engine does not start,

switch ignition OFF then

ON, if error reappears

--> load new data record

in ECU EMR2

(important: save old data

record!!) if error

reappears --> replace

ECU EMR2

see also Chapter 2000

Reg. B - EMR

troubleshooting plan

SERDIA diagnostics

1.2.96 A021 Engine control module

monitoring unit (EDC)

Fault in EDC control

module monitoring unit

(A021)

Engine stalls, Chapter

2000 Reg.B (EDC fault)

'EDC control' circuit

diagram

1.2.99 A020

A021

Engine control module

and pump control unit

(injection pump) (EDC)

Engine stop via power

monitor within EDC

control module, Chapter

2710 Reg.A 'Engine

Stop'.

Reduced power,

Chapter 2000 Reg.B

(EDC fault)

'EDC control' circuit

diagram

1.2.9B A020,

A021

Engine control module,

pump control unit

(injection pump) (EDC)

Engine stop via engine

stop solenoid valve,

Chapter 2710 Reg.A

Engine Stop

Reduced power,

Chapter 2000 Reg.B

(EDC fault)

'EDC control' circuit

diagram

1.2.A2 K021 Relay "solenoid valve

shut-off" (EDC)

Engine stop via relay

K021, Chapter 2710

Reg.A Engine Stop

Reduced power,

Chapter 2000 Reg.B

(EDC fault)

'EDC control' circuit

diagram

1.2.A6 A021,

A020

Engine control module,

pump control unit

(injection pump) (EDC)

Engine stop, fault in

signal processing in

EDC control module

Reduced power,

Chapter 2000 Reg.B

(EDC fault)

'EDC control' circuit

diagram

1.2.A8 A021 Engine control module

(EDC)

Fault in barometric

pressure sensor

Chapter 2000 Reg.B

(EDC fault)

EDC level converter

1.2.A9 A020 Pump control unit

(injection pump) (EDC)

Fault identified during

self-diagnostic test

Reduced power, engine

won't start, Chapter

2000 Reg.B (EDC fault)

Fault

code

Id code Brief description Description Consequences Link FENDIAS / Note

Page 19

all Vario tractors

Tractor / General system

Vario Tractors - Fault Codes

B

Faults

12/1999

0000 000001

B

f

15/58

Capitel Docu-No.

Index

Date Version

Page

Vario Tractors - Fault Codes

1.2.B1 A021,

A020

Engine control module,

pump control unit

(injection pump) (EDC)

EDC CAN message:

fault between EDC

control module and

pump control unit

Reduced power,

Chapter 2000 Reg.B

(EDC fault)

'EDC control' circuit

diagram

1.2.B2 A020 Pump control unit

(injection pump) (EDC)

Fault identified during

self-diagnostic test

Reduced power,

Chapter 2000 Reg.B

(EDC fault)

1.2.B3 A020 Pump control unit

(injection pump) (EDC)

Fault in pump control

unit power supply.

Chapter 2710 Reg.A

'Engine stop'.

Engine stalls, engine

won't start, Chapter

2000 Reg.B (EDC fault)

'EDC control' circuit

diagram

1.2.B4 A020

A021

Engine control module,

pump control unit

(injection pump) (EDC)

CAN message: fault

between pump control

unit and engine control

module

Engine idling, Chapter

2000 Reg.B (EDC fault)

'EDC control' circuit

diagram

1.2.B5 A020 Pump control unit

(injection pump) (EDC)

Fault during pump

control unit

self-diagnostic test

(EEPROM checksum)

Reduced power,

Chapter 2000 Reg.B

(EDC fault)

1.2.B6 A020 Pump control unit

(injection pump) (EDC)

Fault during pump

control unit

self-diagnostic test

(EEPROM status)

Reduced power,

Chapter 2000 Reg.B

(EDC fault)

1.2.B7 A020,

B025

Pump control unit

(injection pump), engine

speed sensor (EDC)

Fault in speed signal to

pump control unit, signal

processing fault in pump

control unit

Reduced power,

Chapter 2000 Reg.B

(EDC fault)

'EDC control' circuit

diagram

EDC level converter

1.2.B9 A020 Pump control unit

(injection pump) (EDC)

Fault during injection

pump self-diagnostic

test (RAM fault)

Engine stops. Chapter

2000 Reg.B (EDC fault)

Fault

code

Id code Brief description Description Consequences Link FENDIAS / Note

Page 20

all Vario tractors

Tractor / General system

Vario Tractors - Fault Codes

B

Faults

12/1999

0000 000001

B

f

16/58

Capitel Docu-No.Index

Date Version

Page

Vario Tractors - Fault Codes

1.2.C1 A020 Pump control unit

(injection pump) (EDC)

Fault during pump

control unit

self-diagnostic test

(solenoid valve output

stage)

Chapter 2000 Reg.B

(EDC fault)

Fault only when

starting - check

batteries

Fault during operation

-check primary pressure

and interior pressure of

pump

1.2.C3 A021,

A020

Engine control module,

pump control unit

(injection pump) (EDC)

CAN message: fault

between engine control

module and pump

control unit when engine

starts

Engine idling (720 rpm),

Chapter 2000 Reg.B

(EDC fault)

'EDC control' circuit

diagram

1.2.C4 A020 Pump control unit

(injection pump) (EDC)

Fault in CAN

communication to pump

control unit

Engine idling (720 rpm),

Chapter 2000 Reg.B

(EDC fault)

'EDC control' circuit

diagram

1.2.C5 A021,

A020

Engine control module,

pump control unit

(injection pump) (EDC)

Fault in engine stop via

engine stop solenoid

valve, Chapter 2710

Reg.A Engine Stop

Reduced power,

Chapter 2000 Reg.B

(EDC fault)

'EDC control' circuit

diagram

1.2.C7 A020 Pump control unit

(injection pump) (EDC)

Pump speed sensor

fault (IWZ signal)

Engine stops. Chapter

2000 Reg.B (EDC fault)

Fault only when

starting - check

batteries

1.2.C8 A021,

B026,

B028

EDC CAN BUS,

engine control module,

needle movement

sensor, boost pressure

sensor (EDC)

Engine control module:

injection quantity

calculation inaccurate

Engine stalls, Chapter

2000 Reg.B (EDC fault)

'EDC control' circuit

diagram

EDC level converter

1.2.C9 A020 Pump control unit

(injection pump) (EDC)

Fault during pump

control unit

self-diagnostic test

(solenoid valve output

stage)

Chapter 2000 Reg.B

(EDC fault)

Fault only when

starting - check

batteries

1.2.CA A020 Pump control unit

(injection pump) (EDC)

Injection controller out of

range

Reduced power,

Chapter 2000 Reg.B

(EDC fault)

Check primary pressure

and interior pressure of

pump

Check EDC level

converter, needle

movement sensor

Fault

code

Id code Brief description Description Consequences Link FENDIAS / Note

Page 21

all Vario tractors

Tractor / General system

Vario Tractors - Fault Codes

B

Faults

12/1999

0000 000001

B

f

17/58

Capitel Docu-No.

Index

Date Version

Page

Vario Tractors - Fault Codes

1.2.CB A021,

A020

Engine control module,

pump control unit

(injection pump) (EDC)

Fault in CAN

communication to pump

control unit

Engine idling,

Chapter 2000 Reg.B

(EDC fault)

'EDC control' circuit

diagram

1.2.CD A021,

A020

Engine control module,

pump control unit

(injection pump) (EDC)

Fault in propagation time

of CAN communication

between pump control

unit and EDC control

module

Reduced power,

Chapter 2000 Reg.B

(EDC fault)

1.2.DE A002,

A021

Enhanced control

module, engine control

module (EDC)

Propagation time of

CAN communication

missing

Restricted operating

mode, Chapter 2000

Reg.B (EDC fault)

1.2.E0 A021,

A002

Engine control module,

enhanced control

module (EDC)

Fault during CAN

communication between

EDC control module and

enhanced control

module

Chapter 2000 Reg.B

(EDC fault) Chapter

9000 Reg.E (Can Bus)

'EDC engine control',

'transmission bus' circuit

diagram

1.2.E1 Fault in speed signal

(B014 - sensor,

accumulator shaft, B015

- sensor - bevel pinion)

or PTO is driving engine

(running on)

Fault display,

Chapter 2000 Reg.B

(EDC fault)

2.1.E0 A002,

A034

ECU, enhanced control

Joystick

CAN communication

fault between ECU

enhanced control and

drive switch

Emergency operation -check enhanced control

bus (Chapter 9000

Reg.E)

2.1.EE ISO/LBS implement Fault in LBS ECU Mounted implement can

no longer be operated

via joystick controls or

terminal.

2.1.EF ISO/LBS implement Limited operation of

implement, depending

on manufacturer

For fault description,

please see implement

manufacturer's literature

Fault

code

Id code Brief description Description Consequences Link FENDIAS / Note

Page 22

all Vario tractors

Tractor / General system

Vario Tractors - Fault Codes

B

Faults

12/1999

0000 000001

B

f

18/58

Capitel Docu-No.Index

Date Version

Page

Vario Tractors - Fault Codes

3.1.01 A004 Control console Internal RAM, EEPROM

faults

Functions switched off: button panel, - digital /

analogue inputs, - LED

actuation

Fit new control console

3.1.02 A004 Control console Internal RAM, EEPROM

faults

Functions switched off: button panel, - digital /

analogue inputs, - LED

actuation

Fit new control console

3.1.03 A004 Control console Internal RAM, EEPROM

faults

Functions switched off: button panel, - digital /

analogue inputs, - LED

actuation

Fit new control console

3.1.04 A004 Control console Internal RAM, EEPROM

faults

Functions switched off: button panel, - digital /

analogue inputs, - LED

actuation

Fit new control console

3.1.05 A004 Control console Internal 8.5 V fault,

keypad fault

Functions switched off: button panel, - digital /

analogue inputs, - LED

actuation

Fit new control console

3.1.06 A004 Control console External 8.5 V fault Functions switched off: -

button panel, - digital /

analogue inputs, - LED

actuation

Fit new control console

4.1.01 A003,

A034

Acceleration ramp I-IV Signal fault Continuation in

emergency mode

possible

TRANSMISSION manu.

adjustment

8.5 V supply fault A013 fuse 5 Joystick

4.1.03 Neumaier reverse drive

facility clutch pedal

potentiometer

Signal fault Continuation in

emergency mode

possible

(Neumaier Service

Manual) calibration code

"4011"

8.5 V supply fault A013 fuse 9

Fault

code

Id code Brief description Description Consequences Link FENDIAS / Note

Page 23

all Vario tractors

Tractor / General system

Vario Tractors - Fault Codes

B

Faults

12/1999

0000 000001

B

f

19/58

Capitel Docu-No.

Index

Date Version

Page

Vario Tractors - Fault Codes

4.1.04 B017 Clutch pedal rotary

position sensor

Signal fault Loss of enhanced

control / function in final

speed control; cruise

control does not

function, TMS is

switched off

'Transmission control'

circuit diagram

TRANSMISSION,

OPERATING RANGE

8.5 V supply fault A013 fuse 8

4.1.05 B039 High pressure sensor II

(push detection)

Signal fault Loss of enhanced

control functions during

drive operation ( no

'active parking function')

TRANSMISSION,

TURBOCLUTCH

12 V supply fault A013 fuse 2

4.1.06

(with

mech.

engine

control)

B018 Target engine speed

position sensor

Signal fault Continuation in

emergency mode

possible

'Transmission control'

circuit diagram

TRANSMISSION,

AUTOMATIC MAXIMUM

OUTPUT CONTROL

8.5 V supply fault A013 fuse 14

4.1.06

(for

EDC or

EMR)

B029

or

B055

EST foot throttle rotary

position sensor (red),

combi-sensor

Signal fault Restricted operation (no

hand throttle, no

memory keys)

'EDC control' circuit

diagram

TRANSMISSION,

AUTOMATIC MAXIMUM

OUTPUT CONTROL

8.5 V supply fault A013 fuse 17

4.1.07 B008 Transmission drive

pressure high-pressure

sensor

Signal fault Shifting from driving

mode 1 to 2 not

possible, TMS is

switched off

'Transmission control'

circuit diagram

TRANSMISSION,

TURBOCLUTCH

8.5 V supply fault A013 fuse 3

4.1.08 B016 Actual speed range

position sensor

Signal fault Not possible to change

between driving modes;

current driving mode is

maintained

'Transmission control'

circuit diagram

TRANSMISSION,

OPERATING RANGE

8.5 V supply fault A013 fuse 13

Fault

code

Id code Brief description Description Consequences Link FENDIAS / Note

Page 24

all Vario tractors

Tractor / General system

Vario Tractors - Fault Codes

B

Faults

12/1999

0000 000001

B

f

20/58

Capitel Docu-No.Index

Date Version

Page

Vario Tractors - Fault Codes

4.1.20 A002,

A034

ECU, enhanced control

Joystick

Accelerator pedal

release pot. ('Slide

switch') not calibrated or

EEPROM checksum

error

Driving in accelerator

pedal mode not possible

JOYSTICK, CAN JOYSTICK calibration

code" 4010"

4.1.21 S045 'Reverse operation

sensor' solenoid switch

Signal fault TRANSMISSION,

FUNCTION OVERVIEW

4.1.22 A034 Joystick Accelerator pedal

release pot. ('Slide

switch') faulty

Accelerator pedal mode

not functioning

JOYSTICK, CAN JOYSTICK

4.1.23 A003,

A034

Joystick 'cruise control

ON'

Signal fault Continuation in

emergency mode

possible

'Transmission control'

circuit diagram

TRANSMISSION,

CRUISE CONTROL

4.1.24 S015 Hand brake solenoid

switch

Signal fault Hand brake automatic

mode not available

'Transmission control'

circuit diagram

TRANSMISSION,

OPERATING RANGE

4.1.25 A003,

A034

Joystick 'Rapid

reversing'

Signal fault Continuation in

emergency mode

possible

'Transmission control'

circuit diagram

TRANSMISSION manu.

adjustment

4.1.26 A034 Joystick Joystick signal

'accelerator pedal mode'

faulty

Accelerator pedal mode

not functioning

JOYSTICK, CAN JOYSTICK

4.1.27 A034 Joystick Rapid reverse button

(F/R rocker) fault

F/R rocker in the armrest

not functioning

(joystick lock) JOYSTICK, CAN -

JOYSTICK

4.1.28 A009 Transmission control

unit, F/R incremental

encoder

Signal fault Continuation in

emergency mode

possible

'Transmission control'

circuit diagram

TRANSMISSION,

TRANSMISSION

CONTROL

4.1.29 A003,

A034

Joystick 'Rest position' Signal fault Continuation in

emergency mode

possible

'Transmission control'

circuit diagram

TRANSMISSION manu.

adjustment

4.1.2A B015 Bevel pinion direction

(=direction of travel) Hall

sensor

Signal fault Continuation in

emergency mode

possible

'Transmission control'

circuit diagram

TRANSMISSION,

CRUISE CONTROL

Fault

code

Id code Brief description Description Consequences Link FENDIAS / Note

Page 25

all Vario tractors

Tractor / General system

Vario Tractors - Fault Codes

B

Faults

12/1999

0000 000001

B

f

21/58

Capitel Docu-No.

Index

Date Version

Page

Vario Tractors - Fault Codes

4.1.2B A003,

A034

Button for driving mode

selection

Signal fault Actual driving mode is

maintained; switching is

not possible

'Transmission control'

circuit diagram

TRANSMISSION,

OPERATING RANGE

4.1.2C A003,

A034

Button to toggle

between 'Neutral /

Active stationary mode'

Signal fault Continuation in

emergency mode

possible

'Transmission control'

circuit diagram

TRANSMISSION,

OPERATING RANGE

4.1.2D S014

or

S061

'Rapid reversing' control

on control stalk

Signal fault Rapid reversing still

possible via joystick

'Transmission control'

circuit diagram

TRANSMISSION manu.

adjustment

4.1.2E A003,

A034

'v+ transmission control'

(joystick forwards)

Signal fault Continuation in

emergency mode

possible

'Transmission control'

circuit diagram

TRANSMISSION manu.

adjustment

4.1.2F A003 'v- transmission control'

(joystick to rear)

Signal fault Continuation in

emergency mode

possible

'Transmission control'

circuit diagram

TRANSMISSION manu.

adjustment

4.1.30 MS 'Emergency mode hatch'

solenoid switch

Signal fault Continuation in

emergency mode

possible

Service Training ML 200

(X 990.005.023.027en)

4.1.31 B014 Hall sensor for

accumulator shaft

direction (partially also

defined by 'Hydrostat')

Signal fault Continuation in

emergency mode

possible

'Transmission control'

circuit diagram

TRANSMISSION,

CRUISE CONTROL

4.1.32 A003,

A034

'Activating key' within

joystick

Signal fault Continuation in

emergency mode

possible

'Transmission control'

circuit diagram

TRANSMISSION manu.

adjustment

4.1.33 'Automatic maximum

output control' key on

membrane keypad

Signal fault Function not available Service Training ML 200

(X 990.005.023.027en)

4.1.34 'Cruise control' key on

membrane keypad

Signal fault Function not available Service Training ML 200

(X 990.005.023.027en)

4.1.35 'Store reverse

transmission ratio' key

on membrane keypad

Signal fault Function not available Service Training ML 200

(X 990.005.023.027en)

Fault

code

Id code Brief description Description Consequences Link FENDIAS / Note

Page 26

all Vario tractors

Tractor / General system

Vario Tractors - Fault Codes

B

Faults

12/1999

0000 000001

B

f

22/58

Capitel Docu-No.Index

Date Version

Page

Vario Tractors - Fault Codes

4.1.36 'Rear PTO automatic'

key on membrane

keypad

Signal fault Function not available see Service Training ML

200 (X

990.005.023.027en)

4.1.37 'Front PTO automatic'

key on membrane

keypad

Signal fault Function not available Service Training ML 200

(X 990.005.023.027en)

4.1.38 'Store forward

transmission ratio' key

on membrane keypad

Signal fault Function not available Service Training ML 200

(X 990.005.023.027en)

4.1.41 B011 Engine speed Hall

sensor 2

Signal fault Continuation in

emergency mode

possible

'Transmission control'

circuit diagram

TRANSMISSION,

CRUISE CONTROL

12 V supply fault A013 fuse 2

4.1.42 B014 Hall sensor for

accumulator shaft speed

(partially also defined by

'Hydrostat')

Signal fault Continuation in

emergency mode

possible

'Transmission control'

circuit diagram

TRANSMISSION,

CRUISE CONTROL

8.5 V supply fault A013 fuse 16

4.1.44 B010 Engine speed Hall

sensor 1

Signal fault Continuation in

emergency mode

possible

'Transmission control'

circuit diagram

TRANSMISSION,

CRUISE CONTROL

12 V supply fault A013 fuse 4

4.1.45 B015 Bevel pinion speed

(=travel speed) Hall

sensor

Signal fault Continuation in

emergency mode

possible

'Transmission control'

circuit diagram

TRANSMISSION,

CRUISE CONTROL

8.5 V supply fault A013 fuse 7

4.1.50 S017 'Transmission oil filter

clogged' switch

Filter clogged No further indication of

clogging

'Transmission control'

circuit diagram

TRANSMISSION,

TRANSMISSION

OIL/FILTER switch

function not active

under 50° oil

temperature

Fault

code

Id code Brief description Description Consequences Link FENDIAS / Note

Page 27

all Vario tractors

Tractor / General system

Vario Tractors - Fault Codes

B

Faults

12/1999

0000 000001

B

f

23/58

Capitel Docu-No.

Index

Date Version

Page

Vario Tractors - Fault Codes

4.1.53 B009 Thermo switch 'Transmission oil

temperature more than

110°C'

Continuing to drive will

cause transmission

damage!

'Transmission control'

circuit diagram

TRANSMISSION,

TRANSMISSION

OIL/FILTER

4.1.56 S017 'Transmission oil filter

clogged' switch

Signal fault No further display! 'Transmission control'

circuit diagram

TRANSMISSION,

TRANSMISSION

OIL/FILTER

4.1.58 Transmission slip

monitor

Transmission output

speed deviates by more

than 30% from setpoint

may occur at extremely

low temperatures in

isolated cases; repeated

occurrence under

normal conditions

results in a rise in oil

temperature and

transmission

damage;TMS is

switched off

Fault not active if turboclutch function is

on - clutch is depressed

TRANSMISSION,

TRANSMISSION

ADJUSTMENT ('ideal

ratio / actual ratio'

comparison)

4.1.59 'Emergency operation'

actuation

Emergency operation

activated manually

without apparent reason

Fault code will not be

stored

Fault in emergency

mode

4.1.61 Y002 'Shifting from speed

range 2 to 1' solenoid

valve

Actuation fault Continuation in

emergency mode

possible

'Transmission control'

circuit diagram

TRANSMISSION,

OPERATING RANGE

4.1.62 Y003 'Shifting from speed

range 1 to 2' solenoid

valve

Actuation fault Continuation in

emergency mode

possible

TRANSMISSION,

OPERATING RANGE

4.1.63 Y005 'Speed governor'

solenoid valve (=limiting

angle of rotation of

actuator shaft)

Actuation fault Possible to continue at

max. 30 km/h

'Transmission control'

circuit diagram

TRANSMISSION,

FUNCTION OVERVIEW

4.1.64 Y004 Turboclutch solenoid

valve

PWM actuation fault 'Transmission control'

circuit diagram

TRANSMISSION,

TURBOCLUTCH

Fault

code

Id code Brief description Description Consequences Link FENDIAS / Note

Page 28

all Vario tractors

Tractor / General system

Vario Tractors - Fault Codes

B

Faults

12/1999

0000 000001

B

f

24/58

Capitel Docu-No.Index

Date Version

Page

Vario Tractors - Fault Codes

4.1.65 Y006;

Y051

'Engine brake' solenoid

valve;

Relay cardan brake

Actuation fault

4.1.66 K051,

Y053

Relay, active parking

function,

solenoid valve, active

parking function

Relay faulty, solenoid

valve faulty, signal

transmission faulty

No active parking

function

"Engine brake and

active parking function"

circuit diagram

4.1.67 K051 Relay, active parking

function

Relay test not required,

relay contacts (Pin 3 / 5)

stuck.

No active parking

function.

'Engine brake and active

parking function' circuit

diagram

4.1.70 A004 'Cruise control 1' key Key fault Cruise control cannot be

activated

'Transmission control'

circuit diagram

TRANSMISSION,

CRUISE CONTROL

Bus fault from A004 to

transmission control

module

TRANSMISSION,

CRUISE CONTROL

4.1.71 A004 'Cruise control 2' key Key fault Cruise control cannot be

activated

'Transmission control'

circuit diagram

TRANSMISSION,

CRUISE CONTROL

Bus fault from A004 to

transmission control

module

TRANSMISSION,

CRUISE CONTROL

4.1.72 S017 'Transmission oil filter

clogged' switch

Signal fault No further display or

monitoring, possibly

transmission damage

'Transmission control'

circuit diagram

TRANSMISSION,

TRANSMISSION

OIL/FILTER

4.1.73 B033 'Discharge oil

temperature' sensor

Signal fault No further display or

monitoring, possibly

transmission damage

'Transmission control'

circuit diagram

TRANSMISSION,

TRANSMISSION

OIL/FILTER

4.1.74 S015 'Hand brake ON/OFF

sensor' solenoid switch

Signal fault TMS is switched off 'Transmission control'

circuit diagram

TRANSMISSION manu.

adjustment

4.1.75 S045 'Reverse operation

sensor' solenoid switch

Signal fault 'Transmission control'

circuit diagram

TRANSMISSION,

FUNCTION OVERVIEW

4.1.76 S047 Engine brake

plunger-operated switch

Signal fault TMS is switched off 'Transmission control'

circuit diagram

TRANSMISSION,

CRUISE CONTROL

Fault

code

Id code Brief description Description Consequences Link FENDIAS / Note

Page 29

all Vario tractors

Tractor / General system

Vario Tractors - Fault Codes

B

Faults

12/1999

0000 000001

B

f

25/58

Capitel Docu-No.

Index

Date Version

Page

Vario Tractors - Fault Codes

4.1.77 A034 Joystick Switch, acceleration

ramp I ... IV faulty

Only acceleration rate III

available

JOYSTICK, CAN JOYSTICK

4.1.78 S053 Seat switch Signal fault from seat

switch

Selection of direction of

travel is disabled in

accelerator pedal mode

when vehicle is

stationary (the tractor

driver must re-activate

the selection of direction

of travel)

TRANSMISSION manu.

adjustment

4.1.7E B035 Setpoint engine speed

EDC/EMR rotary

position sensor, 'hand

throttle potentiometer'

Signal fault 'EDC control' circuit

diagram

TRANSMISSION,

AUTOMATIC MAXIMUM

OUTPUT CONTROL,

calibration code '4002'

4.1.7F A003,

A034

Memory key MIN/ MAX

setpoint engine speed

EDC/EMR

Signal fault 'EDC control' circuit

diagram

Joystick

4.1.81 B010

B011

Engine speed Hall

sensor 1/2

Plausibility error

(=speeds do not match)

Continuation in

emergency mode

possible

'Transmission control'

circuit diagram

TRANSMISSION,

CRUISE CONTROL

4.1.82 B014

B015

B016

Drive collector shaft rpm

Hall sensor / driving

mode detection bevel

pinion sensor

Plausibility error

(=speeds do not match)

Continuation in

emergency mode

possible

'Transmission control'

circuit diagram

possible fault;

Potentiometer range

change B016,

Hydrostat.- bevel pinion

sensor

4.1.83 B014

B015

Accumulator shaft/bevel

pinion speed Hall sensor

Plausibility error

(=speeds do not match)

Continuation in

emergency mode

possible

'Transmission control'

circuit diagram

possible fault;

Potentiometer range

change B016,

Hydrostat.- bevel pinion

sensor

4.1.84 A003

or

A034

Joystick switch (V, R,

VR, cruise control,

default position)

Plausibility error

(=signals do not match

logically)

Continuation in

emergency mode

possible

'Transmission control'

circuit diagram

TRANSMISSION manu.

adjustment; joystick

Fault

code

Id code Brief description Description Consequences Link FENDIAS / Note

Page 30

all Vario tractors

Tractor / General system

Vario Tractors - Fault Codes

B

Faults

12/1999

0000 000001

B

f

26/58

Capitel Docu-No.Index

Date Version

Page

Vario Tractors - Fault Codes

4.1.85 B010 Engine speed Hall

sensor 1

Engine speed sensor

does not supply

plausible speed curves.

Output speed increase

or decrease is outside

limits.

Continuation in

emergency mode

possible

'Transmission control'

circuit diagram

TRANSMISSION,

AUTOMATIC MAXIMUM

OUTPUT CONTROL

4.1.86 B008,

B039

High pressure sensor I

(transmission drive

pressure) ; High

pressure sensor II (push

detection)

Plausibility error

between B008 sensor

and B039 sensor

Loss of enhanced

control when driving

('Active parking function

not functioning'), TMS is

switched off

TRANSMISSION,

CRUISE CONTROL

4.1.87 S061 Switch, rapid reverse on

the steering wheel

adjustment

Plausibility error at the F

/ R switch, rapid reverse

F / R switch not

functioning, rapid

reverse on the steering

wheel adjustment lever,

S061- switch,

Check rapid reverse

Chapter 9000 Reg. E

TRANSMISSION manu.

adjustment

4.1.88 A034 Joystick Plausibility error at the

ON / OFF key of the

accelerator pedal mode

Key not functioning Joystick

4.1.90 A001

A004

Cruise control 1 - data

communication

Data communication

fault

Key not available TRANSMISSION manu.

adjustment

4.1.91 A001

A004

Cruise control 2 - data

communication

Data communication

fault

Key not available TRANSMISSION manu.

adjustment

4.1.92 A001

A002

Brake pedal left / right,

data communication

Data communication

fault

Automatic cruise control

not available

TRANSMISSION manu.

adjustment

4.1.93 A001

A002

Brake pedal left, data

communication

Data communication

fault

Automatic cruise control

not available

TRANSMISSION manu.

adjustment

4.1.94 A034 Joystick CAN communication

fault between A002 ECU, enhanced control

and A034 - joystick

Joystick functions

limited.

Joystick

Fault

code

Id code Brief description Description Consequences Link FENDIAS / Note

Page 31

all Vario tractors

Tractor / General system

Vario Tractors - Fault Codes

B

Faults

12/1999

0000 000001

B

f

27/58

Capitel Docu-No.

Index

Date Version

Page

Vario Tractors - Fault Codes

4.1.A0 A009 Transmission control

unit

Actuation fault in

transmission control

module

Continuation in

emergency mode

possible

4.1.A1 A009 Transmission control

unit

Turn angle is not

reached within 2

seconds.

Continuation in

emergency mode

possible

Mechanical test: Check

smooth adjustment

action in emergency

operation

TRANSMISSION,

TRANSMISSION

ADJUSTMENT refer to

Service Information

26/04

4.1.A2 A009

A001

or

A002

Transmission control

unit

CAN-bus actuation fault Continuation in

emergency mode

possible

Chapter 9000 Reg. E Testing CAN - BUS

TRANSMISSION,

TRANSMISSION

CONTROL

4.1.A3 A009 Transmission control

unit

Fault or logical error in

incremental sensor

signal (actual position

signal)

Continuation in

emergency mode

possible

TRANSMISSION,

TRANSMISSION

CONTROL

4.1.A4 A009 Transmission control

unit

Fault or logical error in

ECU signal.

Continuation in

emergency mode

possible

TRANSMISSION,

TRANSMISSION

CONTROL

4.1.A5 A009 Transmission control

unit

Initial reference (=zero

position) could not be

reached during ignition

'ON'

Continuation in

emergency mode

possible

TRANSMISSION,

TRANSMISSION

ADJUSTMENT refer to

Service Information

26/04

4.1.A6 A009 Transmission control

unit

Reference point signal

fault during operation

Continuation in

emergency mode

possible

TRANSMISSION,

TRANSMISSION

CONTROL

4.1.B0 all Bus users Initialisation error Restricted CAN-bus

data communication

Chapter 9000 Reg. E Testing CAN BUS

4.1.B1 Y001

Y002

Speed range control Illogical speed range

operation (=fatal error)

Continuation in

emergency mode

possible

Fault

code

Id code Brief description Description Consequences Link FENDIAS / Note

Page 32

all Vario tractors

Tractor / General system

Vario Tractors - Fault Codes

B

Faults

12/1999

0000 000001

B

f

28/58

Capitel Docu-No.Index

Date Version

Page

Vario Tractors - Fault Codes

4.1.B2 A002 ECU, enhanced control Fault in EPROM

programming (driving

mode selector I / II)

Range cannot be

changed while driving.

EOL reprogramming

necessary

4.1.B3 A002 ECU, enhanced control Fault in EPROM

programming (rapid

reversing ramp

parameters)

Rapid reversing possible

with standard values.

EOL reprogramming

necessary

4.1.B4 B010 Sensor, engine 1 Input parameter values

for plausibility

monitoring are incorrect.

Standard parameters

are stored, plausibility

monitoring system

remains functional.

EOL reprogramming

necessary

4.1.B5 A002 ECU, enhanced control Checksum error ramp

parameter, rapid reverse

for Tractor Management

System (TMS)

EOL reprogramming

necessary

4.1.B6 Equipment 'Neumaier

reverse drive facility'

Neumaier reverse drive

facility has failed or is

faulty

(Neumaier Service

Manual)

4.1.E0 Y004 Turboclutch

characteristic

Wrong characteristic

stored

Continuation in

emergency mode

possible

EOL reprogramming

necessary

4.1.E1 A002 ECU, enhanced control Pressure regulator

control parameters in

tractive power control

(ML - transmission

adjustment) not

plausible or read

incorrectly

EOL reprogramming

necessary

4.1.E2 A002 ECU, enhanced control Pressure regulator

control parameters in

tractive power control

not plausible (B008 /

B039) or read

incorrectly.

EOL reprogramming

necessary

Fault

code

Id code Brief description Description Consequences Link FENDIAS / Note

Page 33

all Vario tractors

Tractor / General system

Vario Tractors - Fault Codes

B

Faults

12/1999

0000 000001

B

f

29/58

Capitel Docu-No.

Index

Date Version

Page

Vario Tractors - Fault Codes

4.1.E3 A002 ECU, enhanced control Checksum error

parameter for

accelerator pedal mode

TMS is switched off EOL reprogramming

necessary

4.1.E4 A002 ECU, enhanced control Checksum error

parameter for active

parking function

EOL reprogramming

necessary

4.1.E8 Equipment 'Neumaier

reverse drive facility'

Checksum error on

clutch pedal

potentiometer on

Neumaier reverse drive

facility or clutch

calibration faulty

(Neumaier Service

Manual) calibration code

'4011'

4.1.E9 B016 Values for shift from

range II to I outside

tolerances

Shifting only possible

when stationary

Calibration code '4003'

4.1.EA A002 Internal fault (RAM /

EEPROM)

Continuation in

emergency mode

possible

EOL reprogramming

necessary

4.1.EB B016 Speed range operation No calibration or drifted

values

Continuation in

emergency mode

possible

TRANSMISSION,

OPERATING RANGE;

calibration code '4003'

4.1.EC B029,

B038

or

B055

Specified engine speed

rotary position sensor

('accelerator pedal')

combi-sensor

No calibration or drifted

values

Continuation in

emergency mode

possible

TRANSMISSION,

AUTOMATIC MAXIMUM

OUTPUT CONTROL,

calibration code '4005'

4.1.ED B017 Clutch pedal rotary

position sensor

No calibration or drifted

values

Continuation in

emergency mode

possible

TRANSMISSION,

OPERATING RANGE;

calibration code '4001'

4.1.EE A002 Transmission

characteristic

No calibration or drifted

values

Continuation in

emergency mode

possible

TRANSMISSION,

AUTOMATIC MAXIMUM

OUTPUT CONTROL,

calibration code '4007'

Fault

code

Id code Brief description Description Consequences Link FENDIAS / Note

Page 34

all Vario tractors

Tractor / General system

Vario Tractors - Fault Codes

B

Faults

12/1999

0000 000001

B

f

30/58

Capitel Docu-No.Index

Date Version

Page

Vario Tractors - Fault Codes

4.1.EF A002 Turboclutch

characteristic

No calibration or drifted

values

Continuation in

emergency mode

possible

TRANSMISSION,

TURBOCLUTCH

FUNCTION, calibration

code '4009'

4.1.FF A001

A002

Transmission e-box Internal fault (RAM /

EEPROM)

Continuation in

emergency mode

possible

5.1.00 A002 ECU, enhanced control EEPROM checksum

error

Run new EOL

programming.

5.1.31 A004 4WD 100% key Key/A004 signal fault Other functions remain

active

'4WD / Diff. Lock' circuit

diagram

4WD ENHANCED

CONTROL

Bus fault A004 / A002

5.1.32 A004 4WD automatic key Key/A004 signal fault Other functions remain

active

'4WD / Diff. Lock' circuit

diagram

4WD ENHANCED

CONTROL

Bus fault A004 / A002

5.1.33 Y009 4WD clutch solenoid

valve

Actuation fault 4WD engages '4WD / Diff. Lock' circuit

diagram

4WD ENHANCED

CONTROL

5.1.34 B047 Proximity sensor steering angle sensor 1

Signal / switch fault 4WD/diff. lock automatic

system out of order

'4WD / Diff. Lock' circuit

diagram

4WD ENHANCED

CONTROL

5.1.35 B047 Proximity sensor steering angle sensor 2

Signal / switch fault 4WD/diff. lock automatic

system out of order

'4WD / Diff. Lock' circuit

diagram

4WD ENHANCED

CONTROL

5.1.51 A004 Diff. lock 100% key Key/A004 signal fault Other functions remain

active

'4WD / Diff. Lock' circuit

diagram

DIFFERENTIAL LOCK

ENHANCED CONTROL

Bus fault A004 / A002

5.1.52 A004 Diff. lock automatic

system key

Key/A004 signal fault Other functions remain

active

'4WD / Diff. Lock' circuit

diagram

DIFFERENTIAL LOCK

ENHANCED CONTROL

Bus fault A004 / A002

5.1.53 Y010 Diff. lock solenoid valve Actuation fault Diff. lock disengages '4WD / Diff. Lock' circuit

diagram

DIFFERENTIAL LOCK

ENHANCED CONTROL

Fault

code

Id code Brief description Description Consequences Link FENDIAS / Note

Page 35