SERVICE MANUAL

PASSPORT® P-80

(This is the model name for warranty claims)

p/n 069-1003-000

WARRANTY SERVICE PROCEDURES

Warranty field service of the Passport® P-80 will be limited to replacement of defective

PCB Assemblies and all other parts not

repairs can of course be to the component level at the Service Center’s discretion. For

non-warranty component level repairs all parts listed as “REF” in the Parts List must be

sourced from suppliers other than FMIC.

Fender Musical Instruments Corporation, 8860 East Chaparral Road Suite 100 Scottsdale, AZ 85250

ATTENTION:

marked as “REF” in the Parts List. Non-Warranty

Issued: October, 2007

2

PASSPORT

(This is the model name for warranty claims)

October, 2007

IMPORTANT NOTICE

®

P-80

• Copyright © 2007 FMIC. All rights reserved. All

information contained herein is CONFIDENTIAL

and PROPRIETARY and is the property of

Fender® Musical Instruments Corporation. It is

not to be sold or assigned to another party and is

disclosed solely for use by Fender Authorized

Service Centers for purposes of product service

and maintenance. All information is not to be disclosed to others without the expressed permission

of Fender® Musical Instruments Corporation. All

PARTS LIST CODES

The description codes used in the itemized Parts Lists are defined below:

CAPACITOR

CAP AE = Aluminum Electrolytic

CAP CA = Ceramic Axial

CAP CD = Ceramic Disk

CAP CR = Ceramic Radial

CAP MPF = Metalized Polyester Film

CAP MY = Mylar

CAP PFF = Polyester Film/Foil

RESISTOR

RES CC = Carbon Comp

RES CF = Carbon Film

RES FP = Flame Proof

RES MF = Metal Film

RES MOX = Metal Oxide

RES WW = Wire Wound

CODES

CODES

specifications are subject to change without notice. This information and any copies produced

electronically or otherwise must be surrendered

upon demand of Fender® Musical Instruments

Corporation.

• Parts marked with two asterisks (

required use of that specific part. This is necessary for RELIABILITY and SAFETY requirements.

DO NOT USE A SUBSTITUTE!

HARDWARE

BLX = Black Oxide

CR = Chrome Plated

HWH = Hex Washer Head

M = Machine Screw

NI = Nickel Plated

OHP = Oval Head Phillips

PB = Particle Board

PHP = Pan Head Phillips

PHPS = Pan Head Phillips Sems

SMA = Sheet Metal "A" Point

SMB = Sheet Metal "B" Point

SS = Stainless Steel

TF = Thread Forming

ZI = Zinc Plated

CODES

**) indicate the

PASSPORT

(This is the model name for warranty claims)

®

P-80

SPECIFICATIONS

Model Name: PASSPORT P-80

Release Number: PR600

Part Number: (120V, 60Hz) US: 069-1003-000

(240V, 50 Hz) AUS: 069-1003-030

(230V, 50 Hz) UK: 069-1003-040

(230V, 50 Hz) EUR: 069-1003-060

(100V, 50 Hz) JPN: 069-1003-070

Frequency Response: 20 Hz to 40 kHz ± 1 dB (at send output)

30 Hz to 30 kHz ± 1 dB (at speaker output, with processor threshold exceeded)

Distortion: < 0.1%, 20 Hz to 20 kHz, 1dB below rated output

Signal to Noise Ratio: > 80 dB @ 1W, “A” WTD

Power Output: 80W continuous average power, 4

Input Impedance:

(Channels 1-2-3 XLR and 1/4”) “Mic” switch position: 2 k

“Line” switch position: 66 k

(Phono Channel 1/4”) 78 k

Max. Input Level: Mic: -7 dBu

Line: 30 dBu

Stereo: 26 dBu

Return Input Impedance: 47k

Fuse type: T4AH, 250V

Passport System: Width: 610 mm (24 in.)

Height: 541 mm (18 in.)

Depth: 254 mm (10 in.)

Weight: 11.83 kgs (26 lbs)

Speakers: Width: 245 mm (9.65 in.)

Height: 439 mm (17.5 in.)

Depth: 241 mm (9.5 in.)

Weight: 3.3 kgs (7.25 lbs)

Power Tower: Width: 254 mm (10 in.)

Height: 451 mm (18 in.)

Depth: 178 mm (7 in.)

Weight: 5.23 kgs (11.5 lbs)

Tower Footprint: 241 x 298 mm (9.5 x 11.75 in.)

Microphone: Dynamic Cardioid, balanced

Microphone Cable: XL -Male to XL-Female, 6 m (20 feet)

Speaker Cables: 1/4 in. to 1/4 in., 9 m (30 feet)

Ω

Ω

Ω

Ω, both channels driven with THD < 1%

Ω

3

0 dBu is referenced to 0.775 volts rms

Product specifications are subject to change without notice

SERVICE NOTES

The following describes the procedure to dismantle

the P-80 Cabinets.

STEP A: P-80 CABINETS

A1. Unscrew four M4 machine screws on each

side of the left and right hatches.

A2. Unscrew two M3 pan-head machine screws

on the handle cover and detach it.

A3. Place the unit upside down. Unscrew eight M4

self-tapping screws off the foot standers.

A4. Detach the foot standers. There are six M3

self-tapping screws in the middle portion.

A5. Unscrew three M3 self-tapping screws located

on the right-hand-side.

A6. Place the unit in the normal position.

A7. Locate the four M3 and two M4 self-tapping

screws on the top and unscrew them.

A8. Separate the left and right cabinets.

A9. Locate the UHF and VHF antennas on the

right and left cabinets respectively.

A10. De-solder both antennas.

A11. Unscrew three M3 self-tapping screws on left

and right side panels of the tower metal assembly.

A12. Unscrew eight M2.6 and six M3 self-tapping

screws.

A13. Detach the left and right metal side panels.

A14. Detach the 8-pin antenna connector.

A15. Detach the top metal cover.

A16. Unscrew seven M3 self-tapping screw on the

rear panel

A17. Detach all connectors.

A18. The procedure is completed.

STEP B: P-80 MIXER PCB

B1. Detach 14 knobs and their nuts.

B2. Detach the Reverb PCB assembly.

PASSPORT

(This is the model name for warranty claims)

B3. Unscrew nine M3 machine screws from the

mixer PCB assembly.

B4. Detach all connectors.

B5. The procedure is completed.

STEP C: P-80 DSP REVERB PCB

C1. Detach all connectors.

C2. The procedure is completed.

STEP D: P-80 INPUT PCB

D1. Unscrew six screws and nuts from the front

panel.

D2. Detach all connectors.

D3. The procedure is completed.

STEP E: P-80 POWER AMP PCB

E1. Unscrew four screws connecting the heatsink

to the side brackets (two on either side of

tower).

E2. Detach all connectors.

E3. The procedure is completed.

STEP F: P-80 SMPS PCB

F1. Unscrew three screws from the front panel.

F2. Detach all wiring and connectors.

F3. Unscrew six screws from the top cabinet of

the SMPS.

F4. Unscrew three screws from the bottom cabi-

nets of the SMPS.

F5. Detach the spacer from the wiring of the

SMPS.

F6. Unscrew the earthing M4 nut.

F7. Detach the mains connector from the AC inlet.

F8. Unscrew five screws from the SMPS PCB as-

sembly

F9. The procedure is completed.

P-80

®

4

PCB EXCHANGE POLICY

Parts marked with a single asterisk (

Lists are not field replaceable. If a failure due to

one of these components is detected, please con-

*) in the Part

CIRCUIT DESCRIPTION

This section provides concise information about new

or unusual circuitry designs incorporated into this

amplifier model. The purpose is to aid the service

technician by providing insight into the design areas

most likely to become obstacles in troubleshooting.

Information is focused for its effective use while

maintaining the security of Fender® proprietary information wherever possible.

The P-80 consists of the following modules.

1. Mixer Section

2. Digital Reverb Section

3. Signal Processor Circuit and System EQ Circuit

4. Power Amplifier

5. Switch Mode Power Supply Unit (SMPSU)

Mixer Section

The mixer section is mainly made up of operational

amplifiers as gain stages and therefore a technical

description will not be used here. Following is a basic circuit description to familiarize you with the

layout of the circuit.

The Mic/line section is made up of 3 microphone /

line inputs each with a first stage preamplifier for

balanced or unbalanced inputs (locate on the mixer

board). Line inputs can operate as either balanced

or unbalanced if TRS or TR 1/4” jacks are used respectively. Gain selection of 1dB/+30dB is made by

switching a different value resistor in the input

stage. At this point on channel one, the signal is

picked off for the VIP control ducking circuit made

up of U1B. After the input stage there is one knob

for contour control, followed by an auto-pad level

control where the signal splits off into the rev/aux

bus and main signals with the main signals going to

a pan circuit. Here the main signal is split between

5

®

PASSPORT

(This is the model name for warranty claims)

tact the FMIC Customer Service Department to

order the complete PCB Assembly.

left and right channel signal bus. Channel three also

has an additional input via a pair of RCA connectors

where the signals are summed into mono which

may be used as an auxiliary audio signal input. This

circuit consists of an auto-pad level control, low frequency and high frequency tone controls, and a

rev/aux send control.

The audio bus is connected to three FETs that perform ducking of the signals on the bus with the

exception of channel one which is the drive circuit

for the VIP ducking circuit. This function is provided

by U1B.

Bus signals are buffered by U8A and drive the tape

out connections and the main master level control

circuitry made up of U9A. Rev/Aux signals are buffered by U12B and feed the mono aux send output.

The main level control is auto-pad configured and

drives the speaker EQ circuitry made up of U10A.

Note: Channel 1 Mic/Line reverb function will be affected by VIP control making announcements on

Channel 1 dry.

The mixer board also contains part of the signal

processor circuit and the system EQ circuit for the

power amplifier. These circuits are an integral part

of the power amplifier and appear after the return

signal path.

These circuits will all be discussed later in this

document.

Digital Reverb Section

The DSP Reverb PCB module receives the input

REV/AUX signals at pin 4 of connector CN401. The

P-80

DSP Reverb’s IC’s consist of U404 (AL1101 ADC),

U405 (AL1201 DAC), and U406 (AL3201B). The

outputs from U405 are fed to U402B and then buffered by U402A before feeding back to pin 6 of CN

401.

Signal Processor Circuit and System EQ Circuit

The signal processor is partially located on the

mixer board but is an integral part of the power amplifier section. The operation of this circuit is

performed by filtering the signal from U11A which

drives the bases of Q5 and Q7 to control the voltage level at FETs Q4 and Q6 respectively. This in

turn changes the filter characteristics of circuits

which at low levels boosts the low and high frequencies of the signal. At high signal levels with the

gate voltages approaching or at 0v, the circuit lowers the boost of the low frequencies in response.

This circuit is post aux return and therefore does

not modify the response of the signal at the aux

send outputs.

Power Amplifier

Note: In cases where the amplifier circuits are identical between the left and right channel. Only

components related to the left channel will be discussed for simplicity.

The first stage of the power amplifier is made up of

op amp U201A that acts as the input buffer and

muting circuit for minimization of turn on/off pops.

Q202 in balance with the input resistors of this circuit are designed to provide a deep muting effect.

This circuit will be called into action if the temperature of the heat sink also rises above 80 degrees

Centigrade. (Typical HS temperature is around 50

for normal operation). The output of the first stage

feed trimmer resistor VR201 which are part of the

balanced input section of low noise op-amp U203A

which sets the amplifier gain (factory set at approximately 30.5dB). The output of the second

stage directly drives the biased gates of lateral

power FETs Q205 and Q208.

PASSPORT

(This is the model name for warranty claims)

Speaker short circuit protection is provided by

U203B. This is accomplished when the output is

shorted to ground, the normal differential signal applied to U203B is absent at the negative terminal

while at the same time, the second stage is now

forced into open loop gain. The drive signal is integrated into C211 forcing a positive voltage at the

output of U203B that pulls the gate of FET Q207

into conduction from its previous negative bias off

point, nulling the output of U203A. With the output

of U203A minimized the output current of the amplifier is minimized until the short is removed. At this

time, C211 will discharge allowing normal operation

of the amplifier. Note: Some small DC offset will be

present when the amplifier is in the short circuit protect mode.

The power amplifier board also provides the ±15v

for the mixer/reverb boards as well as the supply for

the SMPSU FAN and the LED PCB which indicated

power. The power amplifier board is also connected

to the GM type fuse holder and aux DC power input

connector.

Switch Mode Power Supply Unit (SMPSU)

This unit is not recommended to be serviced in

the field except by replacing the complete module as a total assembly.

The following information is provided to assist in the

trouble shooting of the unit. Please not that the

mains fuse must be replaced with exactly the same

grade of fuse for safety regulations and to avoid risk

of damage and potential fire hazard.

The mains input to the SMPSU allows for operation

from 100V to 240V. The output of the SMPSU is

±36V DC for the main power supply rails of the

power amplifier. The unit also has connectors for

mains power input, mains power switch and chassis, earth and signal grounds.

Service Tip: You can connect to the aux DC input

(with GM fuses installed) to test the output voltage

to the rails before you open the set for service to

get an indication of a possible power supply fault as

it is connected to the rail output. Do not short these

terminals!

P-80

®

6

The SMPSU incorporates protection circuits other

than the fuses including over current protection. All

parts contained in the SMPSU should be considered to be safety parts and should be replaced with

only exact where service can be provided by properly licensed and trained repair technicians. This

includes the dust filter as well as it has a fire hazard

rating. Please be aware that voltages contained

in this module are deadly.

Service Notes on Changes and Updates

7

®

PASSPORT

(This is the model name for warranty claims)

Refer to the mixer schematic diagram of this manual for the following change. A 0.01uF mylar film

capacitor has been added to the VIP ducking circuit

to prevent a slight hum that may be heard as an artifact at the tail of the ducking action. This was

mainly detected on UL voltage settings. This capacitor is added at the junction of R18 (1Mega ohm)

and D16 and the Source (Ground) of FET Q3

(J112). This modification should be performed on

individual units that are listed below by S/N. All

other UL units have been modified by the factory.

P-80

PASSPORT

®

P-80

(This is the model name for warranty claims)

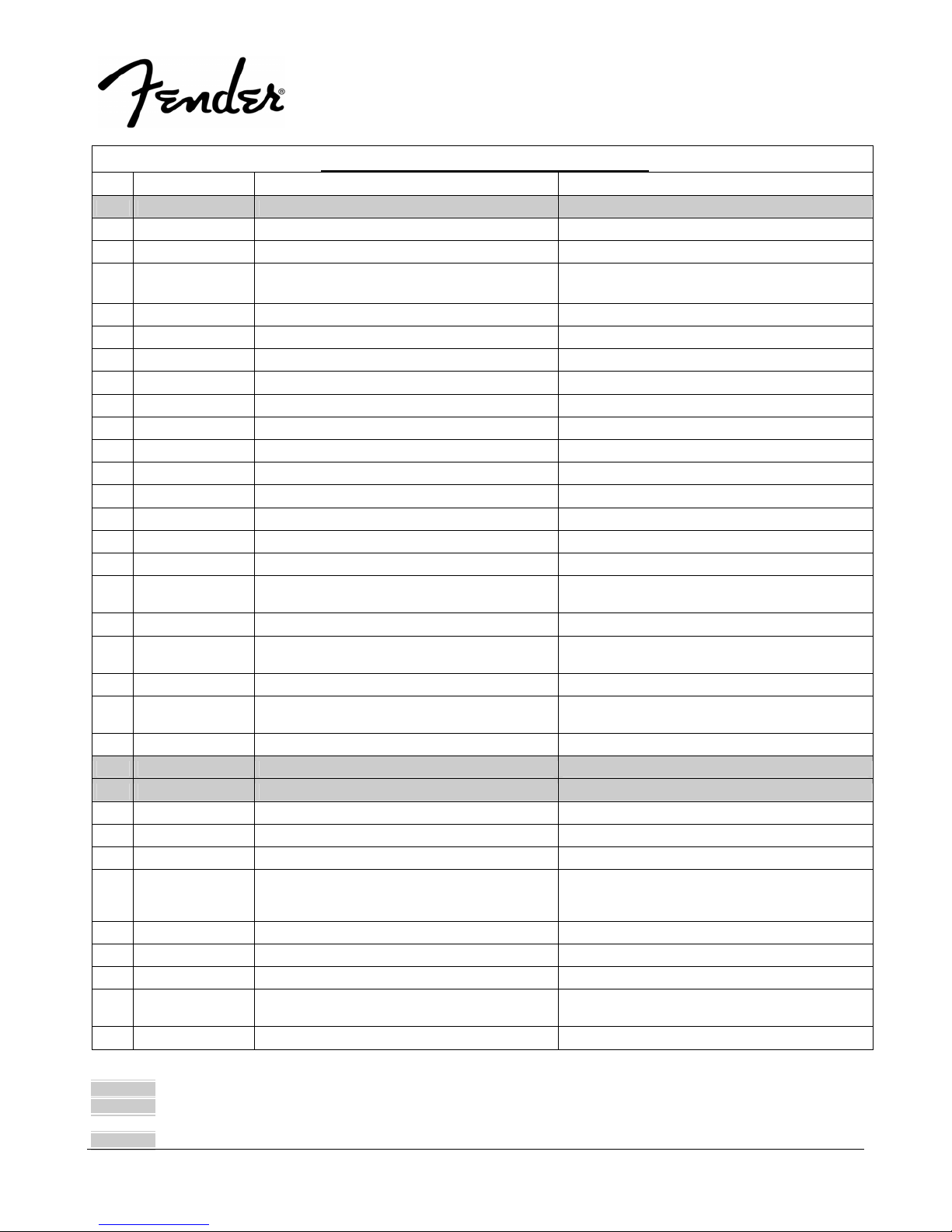

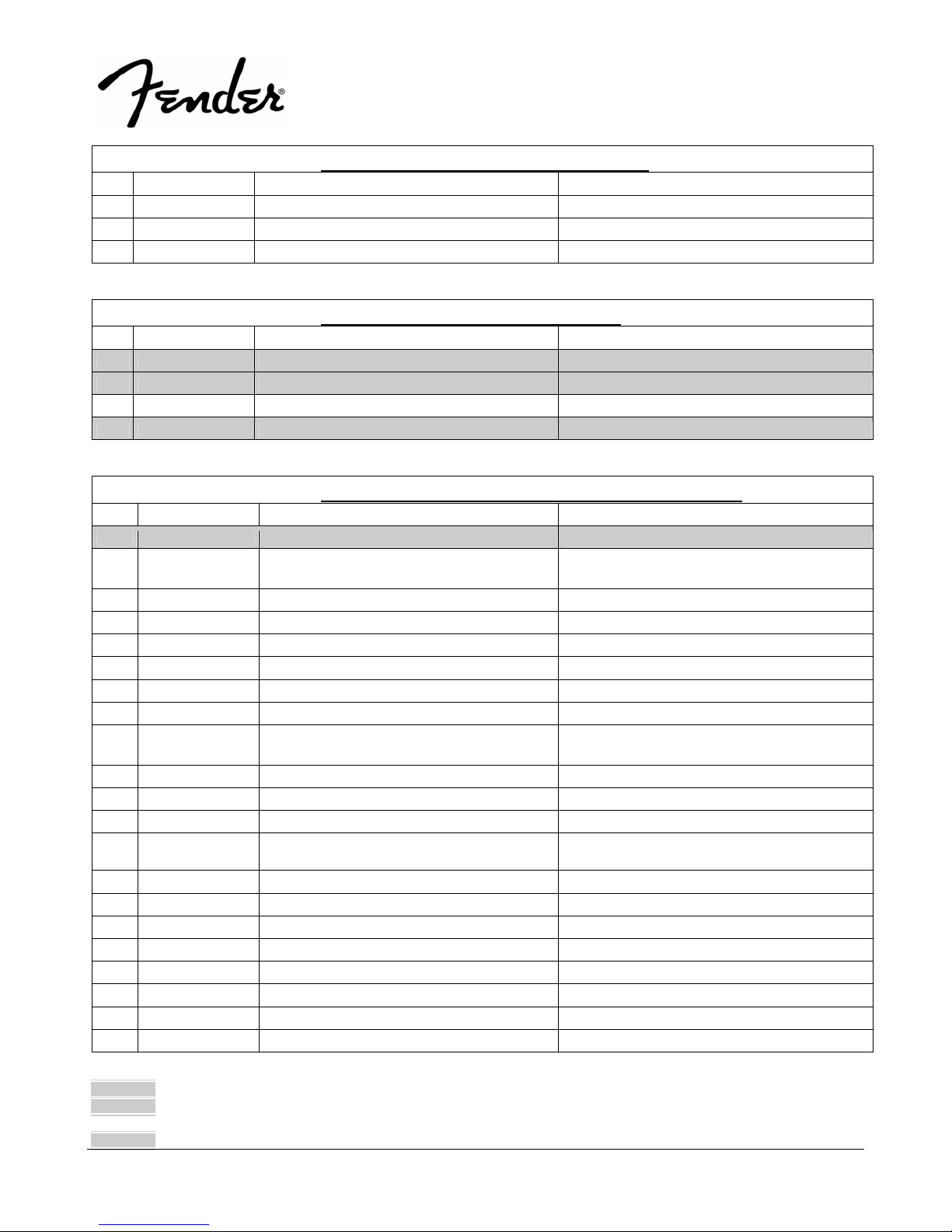

.PARTS LIST:

QTY PART # DESCRIPTION REFERENCE DESIGNATION

1.0 0074726000 PCB ASSY MIXER

1.0 REF FRONT PANEL P80

4.0 REF CC 50V 100P 10% RL 5X3 C3-4 C15-16

11.0 REF CC 50V 27P 10% RL 5X3 C9 C11 C21 C23 C37 C43 C52 C62 C78-80

4.0 REF CM 100V 0.001UF 10% RL 5x7.5 C20 C41 C83-84

1.0 REF CM 100V 0.01UF 10% RL 6x7.5 C87

2.0 REF CM 100V 0.1UF 10% RL 9x11 CENTRALAB C85-86

2.0 REF CM 100V 0.0015UF 10% RL 5X7.5 C7 C18

2.0 REF CM 100V 0.015UF 10% RL 6x9.5 C8 C19

2.0 REF CM 100V 0.0022U 10% 5x7.5 C63 C67

1.0 REF CM 100V 0.022UF 10% RL C42

2.0 REF CM 100V 0.0047UF 10% RL 5.3X7.5 C54-55

2.0 REF CE 25V 47U 20% RLR 5X11 ELNA C47-48

6.0 REF CE 50V 1U 20% RLR 5x11 ELNA C6 C10 C22 C35 C39 C82

4.0 REF CE 50V 2.2uF 20% RL 5x11 C1-2 C13-14

7.0 REF CE 50V 0.47uF 20% RL 5x11 C5 C17 C49 C51 C53 C61 C75

2.0 REF CE 50V 0.47U 20% RLR 5X11

ELNA/NCC/MATSUSHITA

1.0 REF CE 50V 4.7uF 20% RL 5x11 C66

1.0 REF CE 50V 4.7U 20% RLR 5x11

ELNA/NCC/MATSUSHITA

2.0 REF CE 50V 47uF 20% RL 8x12 C76-77

1.0 REF PCB MIXER EF040C S/S 94HB 1OZ REV:A

P50

1.0 REF WAFER JM24182-3P CN8

4.0 0070067000 PJ6-09-5STEREO JACK W/O NUT 5P PJ1-2 PJ4 PJ6

2.0 0070068000 MONO JACK PJ6-09-3 W/O NUT DIAMOND PJ5 PJ7

8.0 REF WASHER METAL M3X0.3X4 WZ MIX/RCA

2.0 REF FIBRE WASHER M3X0.8X8MM MIXER PCB

6.0 REF S-TITE 3X8 (BLK) MIC JACK

15.0 REF SCREW B-TITE BIND HEAD M3X8 CROSS-

RECESS BZ

MIXER- PCB ASSEMBLY

C64-65

C12

LED PCB MIXER PCB

RCA JACK U-BAR

8

3.0 REF SW COVER 2751-11-0 SW-SLIDE

9.0 REF IC TL072CP DUAL FET OP AMP TI U2 U4 U6-12

2.0 REF IC LM833N NS U1 U3

1.0 REF IC TL072CDR DUAL J-FET INPUT OP-AMP

(SMD)

1.0 REF SHIELD PLATE 4132-4741-0 P150

* Non-serviceable part. Replace complete parent assembly. See PCB EXCHANGE POLICY section above.

shaded Unique Fender® part. Order directly from the FMIC Parts Department.

shaded + * Access to this part or assembly is controlled. Please contact the FMIC Customer Service Department.

** Safety Requirement part. Replacement must match Safety Agency…–Value, if specified –Type, if specified –Approval Mark(s) if on part.

shaded + ** Both a unique Fender® part and a Safety Requirement part as defined above.

U13

PASSPORT

®

P-80

(This is the model name for warranty claims)

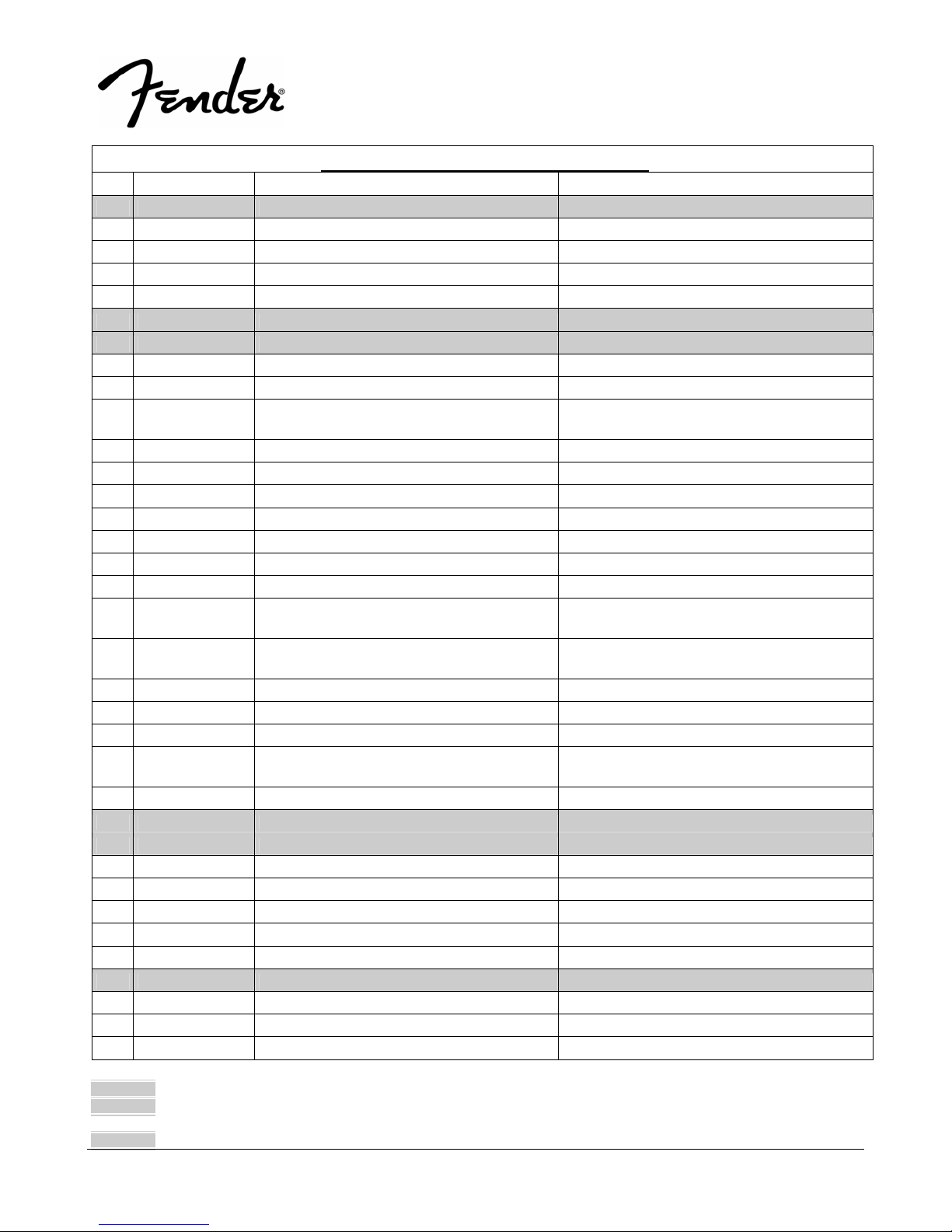

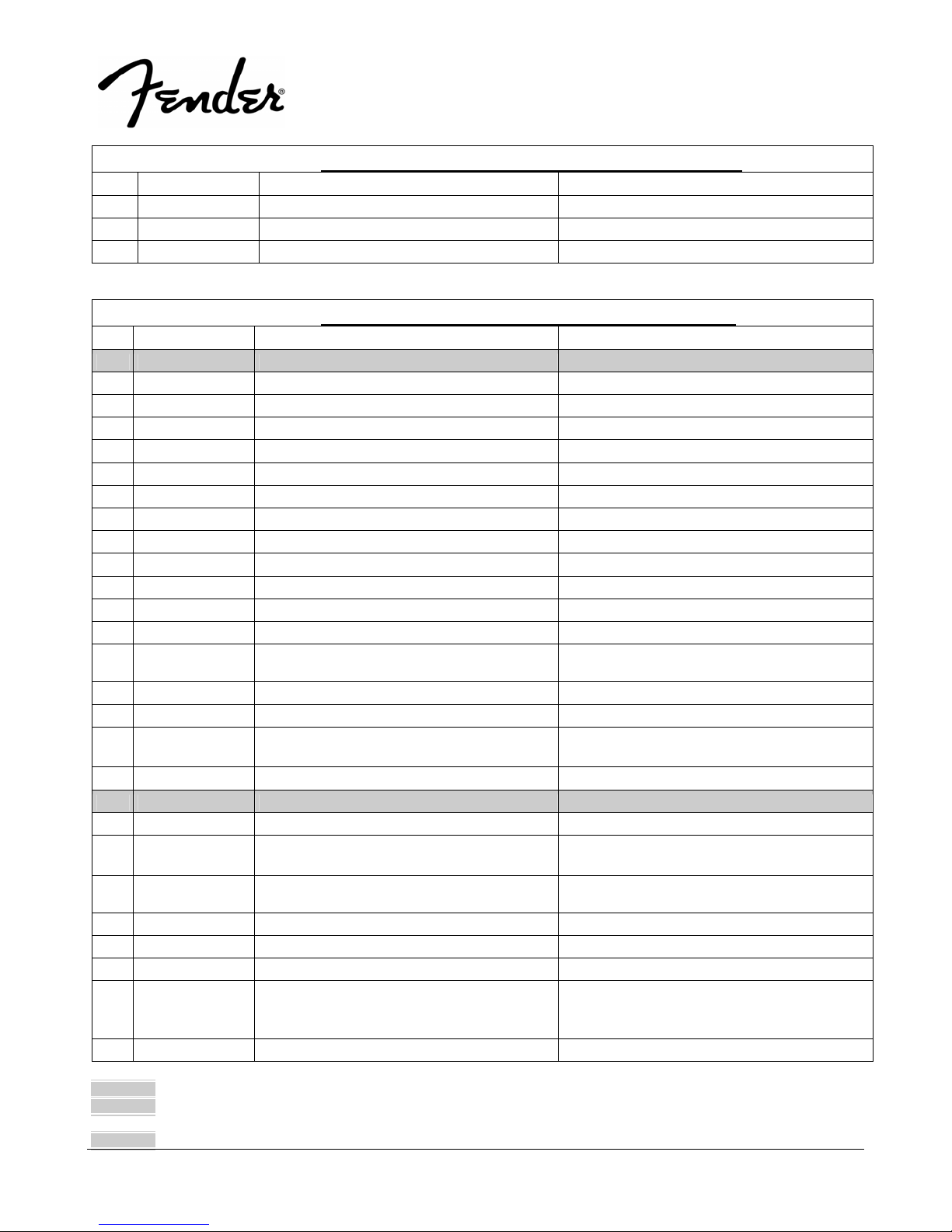

.PARTS LIST:

QTY PART # DESCRIPTION REFERENCE DESIGNATION

1.0 0074733000 MIC JACK BKT 2751-9-0

6.0 REF WASHER M13 4132-5041-0 PHONE JACK

6.0 REF T-NUT M12 4132-5031-0 PHONE JACK

2.0 REF U-BRACKET

4.0 REF CS-0813 PCB SUPPORT

1.0 0070536000 KNOB A 1463-8301-1 P150

13.0 0070537000 KNOB B 1463-8401-1 P150

1.0 REF SHEET FRONT FOR P50

6.0 REF RCF 1/8W 10K 5% AT R11 R65 R80 R90 R129 R138

9.0 REF RCF 1/8W 100K 5% AT R20 R38 R76 R86 R92 R95 R122 R139 R145

6.0 REF RCF 1/8W 1M 5% AT R17 R19 R108 R132-133 R135

2.0 REF RCF 1/8W 110K 5% AT R82 R120

3.0 REF RCF 1/8W 2.2M 5% AT R16 R107 R109

11.0 REF RCF 1/4W 1K 5% ATS R1-3 R6 R15 R25-27 R30 R88 R148

1.0 REF RCF 1/4W 11K 5% ATS R131

6.0 REF RCF 1/4W 12K 5% ATS R9 R14 R33 R37 R102 R105

4.0 REF RCF 1/4W 27K 5% ATS R67 R69 R71 R73

11.0 REF RCF 1/4W 33K 5% ATS R4-5 R7-8 R28-29 R31-32 R93-94 R143

MIXER- PCB ASSEMBLY

9

9.0 REF RCF 1/4W 39K 5% ATS R10 R13 R34 R36 R100-101 R123 R130 R141

3.0 REF RCF 1/4W 470R 5% ATS R22 R24 R136

1.0 REF RCF 1/4W 56K 5% ATS R124

5.0 REF RCF 1/4W 6.8K 5% ATS R83 R103-104 R106 R121

8.0 REF RCF 1/4W 82K 5% ATS R12 R35 R40 R42 R77 R81 R126 R128

1.0 REF RMF 2W 3.3R 5% ATS METAL OXIDE R140

6.0 0070083000 VR RK14K1240 100KBx2 W/C.C (ALPS) VR1 VR6 VR15-16 VR18 VR20

8.0 0070082000 VR RK14K1240 (100KBx2) ALPS VR2-4 VR7-8 VR14 VR21-22

11.0 REF DIODE 1N4148TA NS D1-8 D13 D15-16

1.0 REF TR FET J112 Q4

4.0 REF TR FET J112-TR1-E3 RLT Q1 Q3 Q8-9

1.0 REF TR MPS A56 VCE 80V NS Q5

1.0 REF TR MPS A56 VCE 80V NS RL T Q11

3.0 0070443000 SW-SLIDE 2P2T SS2214RG9 Y.S.C. SW1-2 SW4

1.0 REF CN ASSY UL1007 #26 L=80 15P F/M P2.5 CN1

1.0 REF CN ASSY UL2547 #26 L=170 3P M/M P2.5 CN3

1.0 REF CN ASSY UL2547 #26 L=210 3P M/M P2.5 CN4

* Non-serviceable part. Replace complete parent assembly. See PCB EXCHANGE POLICY section above.

shaded Unique Fender® part. Order directly from the FMIC Parts Department.

shaded + * Access to this part or assembly is controlled. Please contact the FMIC Customer Service Department.

** Safety Requirement part. Replacement must match Safety Agency…–Value, if specified –Type, if specified –Approval Mark(s) if on part.

shaded + ** Both a unique Fender® part and a Safety Requirement part as defined above.

PASSPORT

®

P-80

(This is the model name for warranty claims)

.PARTS LIST:

QTY PART # DESCRIPTION REFERENCE DESIGNATION

1.0 REF CN ASSY UL2547 #26 L=250 3P F/M P2.5 CN5

1.0 REF CN ASSY UL1007 #26 L=180 2P F/M P2.5 CN6

1.0 REF CN ASSY UL1007 #18 L=100 2P F P3.68 CN7

MIXER- PCB ASSEMBLY

.PARTS LIST:

QTY PART # DESCRIPTION REFERENCE DESIGNATION

1.0 0074728000 PCB ASSY RCA

1.0 0074734000 4RCA JACK HSP-204V-03 GP RJ1

1.0 REF WAFER 15P ST. P=2.5 COULOMB CN1

2.0 0070078000 MIC JACK SVP561P-R MJ1-2

RCA- PCB ASSEMBLY

.PARTS LIST:

QTY PART # DESCRIPTION REFERENCE DESIGNATION

1.0 0074508000 PCB ASSY DSP REVERB

19.0 REF CC 50V 0.1uF 10% 0805 1.2X2.0 C405-406 C412-419 C422-427 C431-432 C434

DSP REVERB- PCB ASSEMBLY

10

2.0 REF CC 50V 220pF 10% 0805 1.2x2.0 C407 C409

1.0 REF CC 50V 470pF 10% 0805 1.2X2.0 C408

1.0 REF CC 50V 4700pF 10% 0805 1.2x2.0 C404

1.0 REF CE 50V 1UF 20% RLT 5X11 SHOEI C420

7.0 REF CE 50V 10UF 20% RLT 5X11 SHOEI C401-403 C410-411 C430 C433

2.0 REF CE 50V 47UF 20% RLT 6.3X11 SHOEI C428-429

1.0 REF JM24182-6P WAFER CN401

1.0 REF X'TAL 12.288MHZ +/- 30PPM 49U XL401

1.0 REF IC L78L05ACZ ST U407

3.0 REF IC NJM2068M-#ZZZB DUAL OP AMP U401-403

1.0 REF IC AL3201BG WAVEFRONT DIGITAL RE-

VERB

1.0 REF IC AL1201G WAVEFRONT DAC U405

1.0 REF IC AL1101G WAVEFRONT ADC U404

1.0 REF RMG 1/10W 1K 5% 0805 R417

8.0 REF RMG 1/10W 10K 5% 0805 R408 R410-411 R416 R418-421

1.0 REF RMG 1/10W 100K 5% 0805 R401

3.0 REF RMG 1/10W 220R 5% 0805 R406-407 R413

4.0 REF RMG 1/10W 2.2K 5% 0805 R402-405

2.0 REF RMG 1/10W 4.7K 5% 0805 R409 R412

U406

* Non-serviceable part. Replace complete parent assembly. See PCB EXCHANGE POLICY section above.

shaded Unique Fender® part. Order directly from the FMIC Parts Department.

shaded + * Access to this part or assembly is controlled. Please contact the FMIC Customer Service Department.

** Safety Requirement part. Replacement must match Safety Agency…–Value, if specified –Type, if specified –Approval Mark(s) if on part.

shaded + ** Both a unique Fender® part and a Safety Requirement part as defined above.

PASSPORT

(This is the model name for warranty claims)

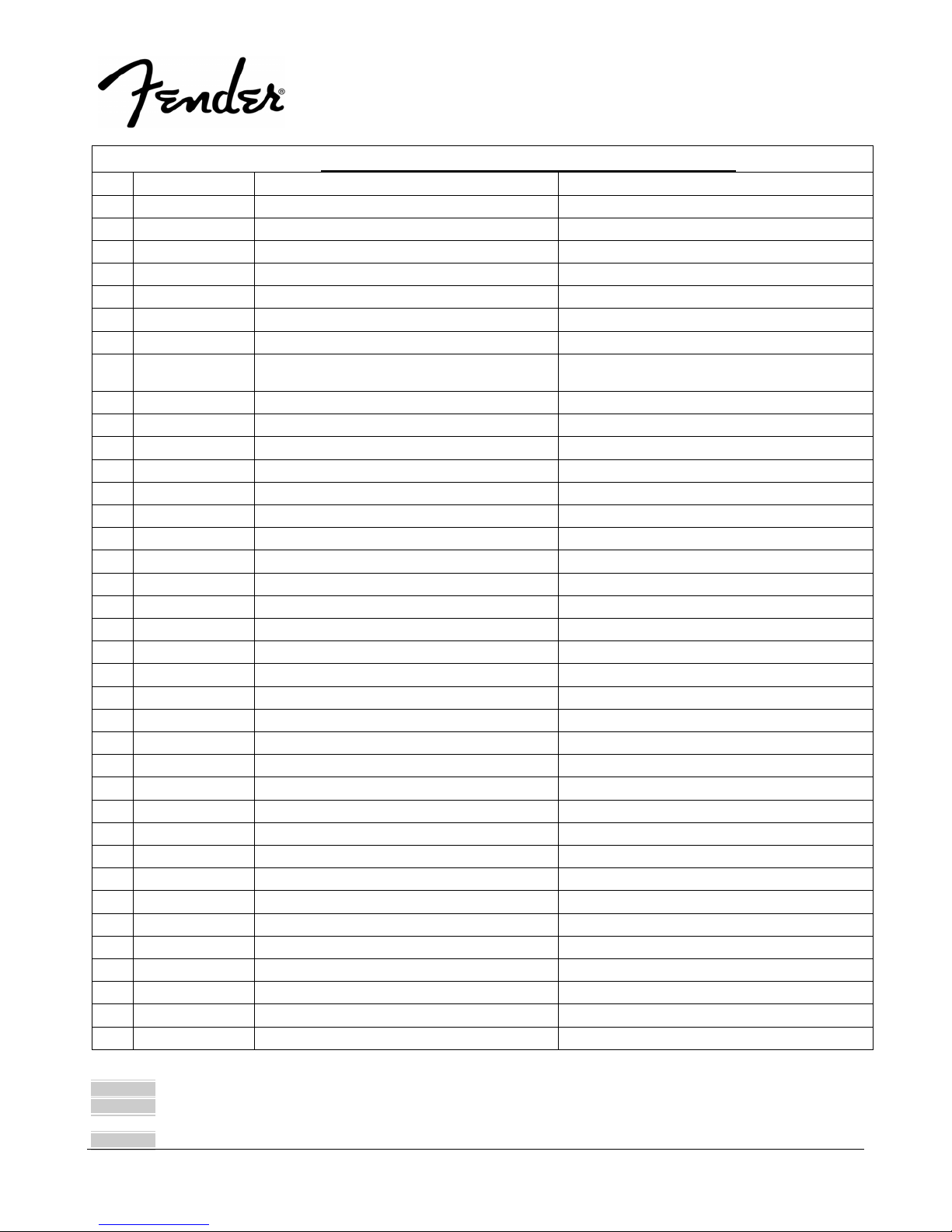

.PARTS LIST:

QTY PART # DESCRIPTION REFERENCE DESIGNATION

1.0 REF RMG 1/10W 47K 5% 0805 R415

1.0 REF RMG 1/8W 10R 5% 1206 R414

1.0 REF CN ASSY UL1007 #26 L=180 2P F/M P2.5 CN402

.PARTS LIST:

QTY PART # DESCRIPTION REFERENCE DESIGNATION

1.0 0074727000 PCB ASSY POWER AMP

5.0 REF CC 50V 0.1U 20% RLF C215-216 C219-220 C224,

1.0 REF CC 50V 0.22UF 20% RLF MONO C208

2.0 REF CC 50V 47P 10% RL 5X3 C203 C207

1.0 REF CC 1KV 1000PF 10% RL Y5P 5X5 C214

1.0 REF CM 100V 0.022UF 10% RL C210

1.0 REF CM 100V 0.22UF 10% RL 11.5x13 C211

1.0 REF CE 16V 22uF 20% RL 5x11 C206

2.0 REF CE 50V 1UF 20% RLT 5X11 SHOEI C202 C209

1.0 REF CE 50V 10UF 20% RLT 5X11 SHOEI C223

2.0 REF CE 50V 100uF 20% RL 8x12 C217-218

2.0 REF CE 50V 2.2uF 20% RL 5x11 C201 C225

5.0 REF CE 50V 47UF 20% RLT 6.3X11 SHOEI C205 C212-213 C221-222

1.0 REF PCB POWER AMP/LED D/S FR4 10Z REV:C

P80

1.0 REF JM2422-2M WAFER CN201

2.0 REF JM2422-4M WAFER CN202-203

5.0 REF JM24182-2P WAFER CN205A CN206 CN208-209 CN402A

DSP REVERB- PCB ASSEMBLY

POWER AMP- PCB ASSEMBLY

®

P-80

11

1.0 REF WAFER JM24182-3P CN204

2.0 0070311000 MONO JACK PJ6-09-3 W/O NUT DIAMOND PJ201-202

2.0 REF METAL WASHER M3X0.5X8MM BZ 2SK1058/J162

7.0 REF WASHER SPRING M3X0.9X5.5 BZ HEAT SINK REAR PANEL

2.0 REF SCREW MACHINE PAN M3X10 CROSS-

RECESS BZ

2.0 REF SCREW BH M3X 5 MM BZ CROSS PCB/BRASS

4.0 REF SCREW TAP-BT BH M2.6X 6 MM BZ CROSS FUSE HOLDER

6.0 REF SCREW D3X6 S-TITE BH,BK REAR PANEL

8.0 REF SCREW B-TITE PH M3X 12 MM YZ CROSS

W/ WASHER

1.0 REF SCREW B-TITE BIND HEAD M3X8 CROSS- HEAT SINK

* Non-serviceable part. Replace complete parent assembly. See PCB EXCHANGE POLICY section above.

shaded Unique Fender® part. Order directly from the FMIC Parts Department.

shaded + * Access to this part or assembly is controlled. Please contact the FMIC Customer Service Department.

** Safety Requirement part. Replacement must match Safety Agency…–Value, if specified –Type, if specified –Approval Mark(s) if on part.

shaded + ** Both a unique Fender® part and a Safety Requirement part as defined above.

H.S/BRASS

2SK1058/J162 MTG. BKT

TH/SW BKT U202

PASSPORT

(This is the model name for warranty claims)

.PARTS LIST:

QTY PART # DESCRIPTION REFERENCE DESIGNATION

RECESS BZ

1.0 REF MICA T-400 8302 18X12.7M T0220 U202

2.0 REF MICA T-400 T03P 25X20M T O-3P 2SK1058/J162

1.0 REF IC TL072CP DUAL FET OP AMP TI U201

1.0 REF IC LM317HVT/NOPB REGULATOR U202

1.0 REF IC BA4560 ROHM U203

1.0 REF ANTENNA WASHER HEAT SINK

2.0 REF 2666-12 METAL WASHER M12 X0.5X16MM

NI

2.0 REF 2666-11 HEXAGON NUT M12 PHONE JACK

1.0 REF 2688-15-0 TH/SW BKT HEAT SINK

2.0 REF MTG. BKT 4312-4711-0 P150 HEAT SINK

2.0 REF BRASS TUBE 2751-10-0 L=9mm PCB/H.S

1.0 REF BUSHING TO-220A U202

2.0 REF 1800-FI GM FUSE HOLDER

2.0 REF RCF 1/8W 10K 5% AT R205 R227

2.0 REF RCF 1/8W 100K 5% AT R206 R221

2.0 REF RCF 1/8W 1M 5% AT R218 R220

1.0 REF RCF 1/8W 2.2M 5% AT R202

2.0 REF RCF 1/8W 3.3M 5% AT R215 R217

3.0 REF RCF 1/8W 390R 5% AT R207 R224-225

1.0 REF RCF 1/4W 1K 5% ATS R212

2.0 REF RCF 1/4W 1.5K 5% ATS R232 R234

3.0 REF RCF 1/4W 15K 5% ATS R211 R223 R226

2.0 REF RCF 1/4W 2K 5% ATS R213 R238

4.0 REF RCF 1/4W 39K 5% ATS R201 R203-204 R208

1.0 REF RCF 1/4W 390K 5% ATS R216

2.0 REF RCF 1/4W 4.7K 5% ATS R233 R237

1.0 REF RCF 1/4W 56K 5% ATS R222

1.0 REF RMF 1/8W 240R 1% AT R209

1.0 REF RMF 1/8W 5.1K 1% AT R231

1.0 REF RMF 1/4W 1.3K 1% AT R210

2.0 REF RMF 2W 3.3K 5% ATS METAL OXIDE R214 R219

2.0 REF RMF 2W 3.3R 5% ATS METAL OXIDE R235-236

3.0 REF RWR 5W 100R 5% AL R239-241

3.0 REF RWR 5W 68R 5% AL R228-230

1.0 REF SVR B1K H3 VZ067TL7B 6.3X 6.8 HDK VR201

2.0 REF DZ 1/2W 15V 5% TEMIC AT Z204-205

POWER AMP- PCB ASSEMBLY

PHONE JACK

®

P-80

12

* Non-serviceable part. Replace complete parent assembly. See PCB EXCHANGE POLICY section above.

shaded Unique Fender® part. Order directly from the FMIC Parts Department.

shaded + * Access to this part or assembly is controlled. Please contact the FMIC Customer Service Department.

** Safety Requirement part. Replacement must match Safety Agency…–Value, if specified –Type, if specified –Approval Mark(s) if on part.

shaded + ** Both a unique Fender® part and a Safety Requirement part as defined above.

13

PASSPORT

(This is the model name for warranty claims)

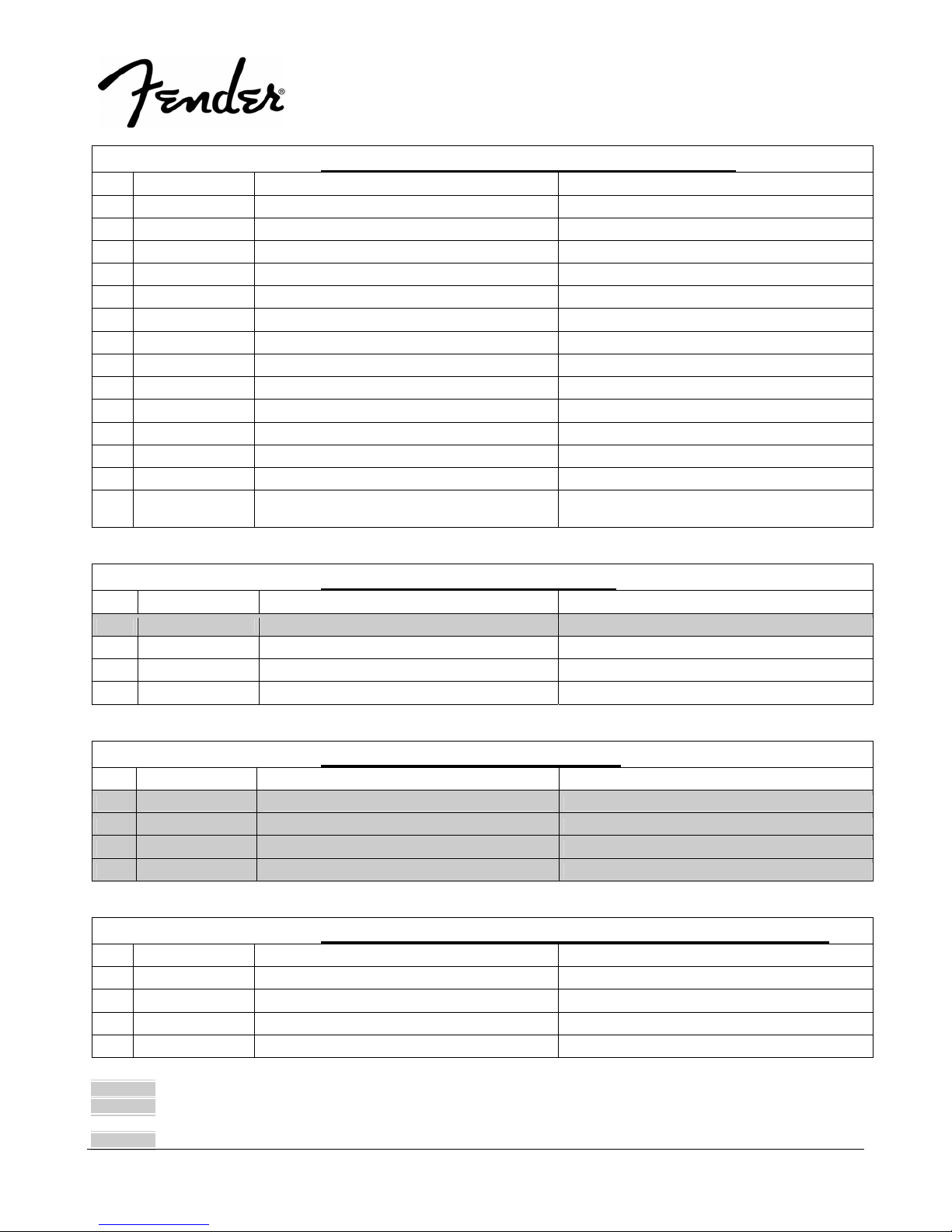

.PARTS LIST:

QTY PART # DESCRIPTION REFERENCE DESIGNATION

1.0 REF DZ 1/2W 33V TEMIC AT Z201

1.0 REF DZ 1W 12V AT TEMIC Z206

2.0 REF DZ 1W 15V AT TEMIC Z202-203

7.0 REF DIODE 1N4148TA NS D201-207

1.0 REF TR BD140-10 HFE 63-160 Q204

1.0 REF TR 9013H Q203

2.0 REF TR FET J112-TR1-E3 RLT Q202 Q207

1.0 REF TR MPSA06 VCE 80V NS RLT Q201

1.0 REF TR FET 2SK1058-E HITACH IDS=7A Q208

1.0 REF TR FET 2SJ162-E HITACH IDS=7A Q205

1.0 REF THERMAL SW 17AM203A5-4 CN207

1.0 REF HEAT SINK PD150 ROK 2SK1058/J16

1.0 REF CN ASSY UL1007 #26 L=100 2P M P2.5 CN207

1.0 REF CN ASSY UL1007 PCE98-033 3 #18

L=90/150/170 4P

.PARTS LIST:

QTY PART # DESCRIPTION REFERENCE DESIGNATION

1.0 0074725000 PCB ASSY LED

1.0 REF PCB POWER AMP 2751-3/-6 REV:D

1.0 REF LED RED/GREEN L-937EGW 3MM LED201

1.0 REF CN ASSY UL1007 #26 L=220 2P F/M P2.5 CN205

.PARTS LIST:

QTY PART # DESCRIPTION REFERENCE DESIGNATION

1.0 0699000000 MICROPHONE P51 FENDER

1.0 063679000 MANUAL MULTIPLE P-80 6 LANGUAGES

2.0 0070587000 SPK CABLE MONO 90 ANGLE PLUG L=30FT

1.0 0074365014 PASSPORT MICROPHONE CABLE

.PARTS LIST:

QTY PART # DESCRIPTION REFERENCE DESIGNATION

8.0 REF WASHER METAL M4X0.8X10 BZ

8.0 REF SPRING WASHER M4X0.8X6.5 MM BZ

8.0 REF SCREW S-TITE 4X16 PH BLK ZINC

8.0 REF C-PIN 4132-4691-0 P-150

* Non-serviceable part. Replace complete parent assembly. See PCB EXCHANGE POLICY section above.

shaded Unique Fender® part. Order directly from the FMIC Parts Department.

shaded + * Access to this part or assembly is controlled. Please contact the FMIC Customer Service Department.

** Safety Requirement part. Replacement must match Safety Agency…–Value, if specified –Type, if specified –Approval Mark(s) if on part.

shaded + ** Both a unique Fender® part and a Safety Requirement part as defined above.

POWER AMP- PCB ASSEMBLY

CN202

LED- PCB ASSEMBLY

PACKING MATERIALS

LATCH LOCKER CASING MATERIALS

®

P-80

14

PASSPORT

®

P-80

(This is the model name for warranty claims)

.PARTS LIST:

QTY PART # DESCRIPTION REFERENCE DESIGNATION

4.0 REF LATCH BKT 4132-4681-0 P-150

4.0 REF TORSION SPRING-LATCH 2751-5-0

4.0 REF LATCH 1464-3500-0 P150

4.0 0070564000 LOCKER-LATCH 1464-3600-1 P150 QUICK REPAIR ASSEMBLY

LATCH LOCKER CASING MATERIALS

.PARTS LIST:

QTY PART # DESCRIPTION REFERENCE DESIGNATION

1.0 0074729000 SW MODE POWER SUPPLY

2.0 0070483000 **FUSE S505-4A TIME DELAY 250V 5x20mm

UL/CSA/SEMKO

1.0 0070267000 **SWITCH ROCKER 2PIT SW301

1.0 REF ANTENNA FM 75OHM D1.2X240 PD150 UHF

GND

1.0 REF ANTENNA FM 75OHM D1.2X120 PD150

PLUS

1.0 REF HALO BUSHING 0813C

4.0 REF METAL WASHER M3X0.5X8MM BZ PANEL/MTG.BK

3.0 REF METAL WASHER M3X0.5X8MM BZ PANEL/PARTIT

3.0 REF METAL WASHER M3X0.5X8MM BZ PANEL/SMPS

2.0 REF WASHER SPRING M3X0.9X5.5 BZ FUSE COVER

6.0 REF WASHER SPRING M3X0.9X5.5 BZ REAR PANEL

2.0 REF SCREW FLAT-CS M3X 5 MM B Z CROSS HANDLE COVER

2.0 REF ME 4*16 6.8MM BK/RH JH1303-01 HANDLE/CONSO

2.0 REF SCREW TAP-BT BH M2.6X 6 MM BZ CROSS DOOR

8.0 REF TTS SCREW M2.6x8 BH BZ

2.0 REF SCREW D3X6 S-TITE BH,BK FUSE COVER

3.0 REF SCREW D3X6 S-TITE BH,BK PANEL/SMPS

6.0 REF SCREW D3X6 S-TITE BH,BK REAR PANEL

3.0 REF SCREW D3X6 S-TITE BH,BK SIDE PLATE-A

3.0 REF SCREW D3X6 S-TITE BH,BK SIDE PLATE-B

2.0 REF S-TITE 3X8 (BLK) HINGE

4.0 REF S-TITE 3X8 (BLK) PANEL/MTG.BK

3.0 REF S-TITE 3X8 (BLK) PANEL/PARTIT

2.0 REF SCREW B-TITE BIND HEAD M3X8 CROSSRECESS BZ

4.0 REF B-TITE 3X10MM (BLK.ZN) HANDLE BKT

8.0 REF SCREW TAP-C2 BH M4X 10 M M BZ CROSS FOOT STAND

6.0 REF SCREW B-TITE BIND M4X14 CS-RECESS

BZ

* Non-serviceable part. Replace complete parent assembly. See PCB EXCHANGE POLICY section above.

shaded Unique Fender® part. Order directly from the FMIC Parts Department.

shaded + * Access to this part or assembly is controlled. Please contact the FMIC Customer Service Department.

** Safety Requirement part. Replacement must match Safety Agency…–Value, if specified –Type, if specified –Approval Mark(s) if on part.

shaded + ** Both a unique Fender® part and a Safety Requirement part as defined above.

CASING MATERIALS

POWER INLET

CONSOLE

CONSOLE

PANEL/PARTIT

SUPPORT RIB

15

PASSPORT

®

P-80

(This is the model name for warranty claims)

.PARTS LIST:

QTY PART # DESCRIPTION REFERENCE DESIGNATION

1.0 REF COVER-TOP EFPAPD150+05CS17

1.0 REF PANEL-REAR AUSTRALIA EF043C

1.0 REF PLATE-SIDE EFPAPD150+05CS17

1.0 REF SIDE PLATE-B 4132-4881-1

1.0 REF BKT-SOCKET 4132-4891-0 P150

2.0 REF HANDLE BKT 4132-4901-1 P150

1.0 REF COMPRESSION SPRING 2751-6-0

1.0 REF COVER-10P SK 4132-5131-0 CN606

1.0 REF COVER SHIELDING

1.0 0074737000 HANDLE NK740C

2.0 REF ENCLOSURE SIDE NK740C

2.0 REF FOOT STAND NK740C

1.0 REF RIB-INSIDE NK740C

1.0 0070570000 DOOR 1464-3700-1 P150

1.0 0070571000 LOCKER-DOOR 1464-3800-0 P150

2.0 REF HINGE 1464-4200-0 P150

2.0 REF SPRUE CAP(GREY)1464-4810 -0 P150

2.0 REF NAME PLATE

1.0 REF GASKET-HANDLE 2751-2-A

1.0 REF GASKET-TOP 2751-3-A

1.0 REF GASKET-BOTTOM 2751-4-A

CASING MATERIALS

.PARTS LIST:

QTY PART # DESCRIPTION REFERENCE DESIGNATION

1.0 REF 2617-12 REV:A WIRELESS PCB

1.0 REF T'NAL 2225A-20D 2x10 PIN NELTRON

3.96mm CARD EDGE

3.0 REF METAL WASHER M3X0.5X8MM BZ U601 PCB

3.0 REF WASHER SPRING M3X0.9X5.5 YZ U601 PCB

1.0 REF M3 NUT NI U601

2.0 REF SCREW MACHINE PAN M3X12 CROSSRECESS BZ

3.0 REF SCREW M3X10 (BLK) REG PCB

1.0 REF MICA T-400 T03P 25X20M T O-3P U601

1.0 REF ANT WIRE 2751-13-0 CN603

1.0 REF BUSHING TO-220A U601

1.0 REF SPONGE BAR 2751-12-0 CONSOLE

1.0 REF RUBBER CABLE BUSHING BLK 6MM SIDE PLATE-B

* Non-serviceable part. Replace complete parent assembly. See PCB EXCHANGE POLICY section above.

shaded Unique Fender® part. Order directly from the FMIC Parts Department.

shaded + * Access to this part or assembly is controlled. Please contact the FMIC Customer Service Department.

** Safety Requirement part. Replacement must match Safety Agency…–Value, if specified –Type, if specified –Approval Mark(s) if on part.

shaded + ** Both a unique Fender® part and a Safety Requirement part as defined above.

REG CASING MATERIALS

CN606

CN606

PASSPORT

(This is the model name for warranty claims)

.PARTS LIST:

QTY PART # DESCRIPTION REFERENCE DESIGNATION

1.0 REF UL1533#26 G/B PCE99-0229 L=60MM 8 POS

HOUSING

1.0 REF UL1007#26 R/B PCE99-0200 L=280MM 2

POS HOUSING

1.0 REF CONN WIRE 8P #26 UL1533 PCE99-0228

G/B L=253MM

.PARTS LIST:

QTY PART # DESCRIPTION REFERENCE DESIGNATION

1.0 0074731000 SPEAKER BOX QUICK REPAIR ASSY

1.0 0074730000 SPEAKER STAND PLUG

2.0 0070371000 P150 SPK 6.5" S-6-4 4OHM 1525-0920-0

1.0 0074732000 REAR PHONE JACK 5 PIN

0.4 REF SHRINKAGE TUBE ID=4MM UL

1.0 REF WASHER METAL M9X0.5X14 BZ

4.0 REF SCREW BH M6X 25 MM BZ CROSS

2.0 REF SCREW B-TITE FLAT-CS M3X10 CS-

RECESS BZ

8.0 REF SCREW TAP-C2 BH M4X 10 MM BZ CROSS

1.0 REF SCREW B-TITE BIND M4X14CS-RECESS BZ

1.0 0070552000 GRILLE 4132-4781-0 P150

0.147 REF O RING 4152-2091-0 NK110C

1.0 REF SPRUE CAP(GREY)1464-4810-0 P150

1.0 REF GASKET SPEAKER 2751-7-A L=1080mm

1.0 REF SPRUE CAP(RED)

1.0 REF SPEAKER BOX REAR NK740C

1.0 REF SPEAKER WIRE 400mm BLK-B LK/RED

REG CASING MATERIALS

CN607B

CN601

CN607A

SPEAKER CASING MATERIALS

®

P-80

16

.PARTS LIST:

QTY PART # DESCRIPTION REFERENCE DESIGNATION

1.0 0074735000 TOWER SIDE CABINET A

1.0

* Non-serviceable part. Replace complete parent assembly. See PCB EXCHANGE POLICY section above.

shaded Unique Fender® part. Order directly from the FMIC Parts Department.

shaded + * Access to this part or assembly is controlled. Please contact the FMIC Customer Service Department.

** Safety Requirement part. Replacement must match Safety Agency…–Value, if specified –Type, if specified –Approval Mark(s) if on part.

shaded + ** Both a unique Fender® part and a Safety Requirement part as defined above.

0074736000 TOWER SIDE CABINET B

1 0070315000

1 0070316000

1 0070317000 GP BS/IEC POWER CORD (UK/HK) UK,HK

MISCELLANEOUS MATERIALS

GP UL/IEC POWER CORD (UL/CSA VER)

NORTH AMERICA,TAIWAN

GP CE/IEC POWER CORD (EURO VER)

CONT.EUR/ASIA EXPT HK,CHINA, AUSTRALIA,

JAPAN

1 0070318000

1 0070319000

1 0070320000 GP JIS/IEC POWER CORD W/ GND PIN JAPAN

GP CCEE POWER CORD (CHINA) GREAT

WALL STD.

GP SAA/IEC POWER CORD (AUST/NZ) AUSTRALIA/NEW ZEALAND

17

®

PASSPORT

(This is the model name for warranty claims)

P-80

* Non-serviceable part. Replace complete parent assembly. See PCB EXCHANGE POLICY section above.

shaded Unique Fender® part. Order directly from the FMIC Parts Department.

shaded + * Access to this part or assembly is controlled. Please contact the FMIC Customer Service Department.

** Safety Requirement part. Replacement must match Safety Agency…–Value, if specified –Type, if specified –Approval Mark(s) if on part.

shaded + ** Both a unique Fender® part and a Safety Requirement part as defined above.

18

PASSPORT

(This is the model name for warranty claims)

®

P-80

Service Diagram List

Service Diagram (Schematic) ............BLOCK DIAGRAM

Service Diagram (Schematic) ............MIXER

Service Diagram (PCB Assembly) ............MIXER PCB

Service Diagram (Schematic) ............INPUT

Service Diagram (PCB Assembly) ............RCA/XLR INPUT PCB

Service Diagram (Schematic) ............REVERB

Service Diagram (PCB Assembly) ............REVERB PCB

Service Diagram (Schematic) ............SMPS

Service Diagram (PCB Assembly) ............SMPS PCB

Service Diagram (Schematic) ............AMP

Service Diagram (PCB Assembly) ............AMP PCB

Service Diagram (PCB Assembly) ............LED PCB

Service Diagram (Test Point Information) ............TP1-TP20

Service Diagram ............WIRING DIAGRAM

Service Diagram (Exploded View) ............LATCH ASSY

Service Diagram (Exploded View) ............MIXER ASSY

Service Diagram (Exploded View) ............SPEAKER ASSY

Service Diagram (Exploded View) ............TOWER HOUSING ASSY

Service Diagram (Exploded View) ............PACKING ASSY

Power

Aux

LED

PCB

DC--DC

-34V

GND

+34V

Out

Protect

Speaker

Power

Switch

Input

Mains

GND+15V-15V

SMPSU

GND -34V GND +34V

Out

Speaker

Short

Power Amp

-15V

GND

+15V

Auto

Response

EQ

Speaker

Right

Master

VIP Ducking

Mixer Board

Rev/Aux

Level

Contour

Rev/Aux

Level

Contour

Rev/Aux

EQ LOW EQ HI

Left

Master

+15VGND

-15V

IN

Reverb Board

OUT

Master

Reverb

Effects

Control

Gain Switch

Gain Switch

Gain Switch

Level

1/1+2

Switch

CH1

RCA/XLR

Input Board

Line1

RL

CH2

2

Line3

Line2

Aux Send

Foot Switch

Aux Return

1

CH3

Tape

Input

Output

PASSPORT

Block Diagram

1

TP15

C67

222

R105

C62

27p

R101

39k

-15V

2

R100

39k

C61

0.47u/50V

R24

470

Q1

D

G

R19

1M

C12

4u7/50V

5

C18

152

LM833

R33

12k

D6

1N4148

D5

1N4148

+15V - 15V

+30dB

1

SW2A

SS2214RG9

2

4

5

123456789

12k

1

U11A

TL072

3

82k

R40

R38

100k

J112

S

VR7A

100KB

LEVEL MIC/LINE2

R37

12k

C22

1u/50V

R36

39k

C19

153

EQ

VR6A

R34

39k

C17

0.47u/50V

U3A

LM833

+15V

84

3

C13

2u2/50V

0dB

3

R28

33k

R25

1k

1011121314

R102

12k

R104

C63

222

C64

8 4

+15V

R103

6k8

C23

27p

7

13

2

6

1n

C20 102

C21 27p

R35

82k

1

2

100KB W/CC

3

-15V

2

1

R32

33k

-15V

2

C14

2u2/50V

R29

33k

SS2214RG9

R26

1k

15

TO

RCA

PRE

R94

10k

123

R90

IN

CN3

R93

33k

2

LEFT

13

VR18A

100KB W/CC

33k

CN3

1

2

3

CON3

-15V

+15V

3

2

8 4

TL072

U13A

1

R131 11k

R20

100k

1k

R148

VR2A

100KB

31

LEVEL MIC/LINE1

R14

12k

C10

1u/50V

R13

39k

C8

153

VR1A

EQ

100KB W/CC

C7

152

R9

12k

R10

39k

C5

0.47u/50V

+15V

1

U1A

LM833

D2

1N4148

84

3

D1

1N4148

+15V -15V

C1

2u2/50V

0dB

123

+30dB

R4

33k

SW1A

SS2214RG9

R1

1k

14

2

13

C55

472

C54

472

R92

C53

0.47u/50V

C52

27p

-15V

-15V

NC

R86

100k

R82

110k

C11

27p

2

1n

C83 102

R12

82k

13

2

-15V

R8

2

C2

2u2/50V

R5

33k

R2

1k

3

TP11

R95

100k

VR20A

13

100KB W/CC

100k

1

3

2

R143

0.47u/50V

-15V

R83

7

5

6

C9 27p

1

U2A

TL072

2

33k

C4

-15V

+30dB

4

SW1B

SS2214RG9

1

C80

27p

1

U10A

TL072

-15V

+15V

-15V

+15V

8 4

3

2

2

SYSTEM EQSYSTEM EQ

U9A

TL072

+15V

+15V

8 4

33k

C51

TP14

R88

1k

1

U8A

TL072

+15V

8 4

3

2

C49

0.47u/50V

6k8

R22

470

Q3

J112

S

D

G

2

VR4A

100KB

3

1

C87

REV/AUX

Q11

D15

8 4

C6

D4

MPSA 56

1N4148

+15V

1u/50V

R11

1N4148

R7

33k

C3

100p

R6

1k

R3

1k

103

R17

1M

-15V

R16

CN4

CON3

CN4

CON3

3

3

2

2

1

1

2

VR3A

100KB

31

VIP

10K

-15V +15V

15478

PJ6-09-5

PJ1

D16

1N4148

2M2

R15

1k

7

102

C84

6

U1B

1

2

CN604B

WE2

LINE 1

TO WIRE DOCKING

U2B

TL072

3

100p

D3

1N4148

0dB

6

5

CN1

CON15

6k8

0.47u/50V

R106

6k8

C65

0.47u/50V

-15V

R108

1M

R107

2M2

VR8A

100KB

3

U4B

TL072

5

1

U4A

3

C16

100p

D7

1N4148

+30dB

0dB

4

SW2B

5

TP12

AMP

123

CN5

CON3

AUDIO OUT

GND

CN8

WF8

123

TP1

Q5

MPSA 56

C66

4u7/50V

R109

2M2

G

D

S

Q4

J112

82k

R42

2

1

REV/AUX

C48

47u/25V

C47

47u/25V

-15V +15V

TL072

8 4

+15V

D8

1N4148

+15V

-15V

R31

33k

C15

100p

6

R30

1k

1k

R27

15478

1

2

CN605B

PJ6-09-5

LINE 2

PJ2

PJ5 PJ6-09-3

541

R136

470

C79

27p

R124

56k

R123

R122

100k

-15V

C78

27p

R120

110k

R121

6k8

R77

82k

R76

100k

C43

27p

-15V

R73

27k

223

C42

2

VR16A

EQ/LOW

31

100KB W/CC

R69

27k

C39

1u/50V

3

2

VR14A

100KB

1

LEVEL/STEREO

-15V

R67

27k

1u/50V

C35

WF2

AUX SEND

6

39k

1

2

2

R141

39k

R71

C41

321

EQ/HI

C37

27p

D13

1N4148

8

PJ6

PJ6-09-5

MONO

AUX RET

STEREO

745

1

10k

R138

7

U12B

TL072

5

U12A

TL072

+15V

8 4

3

R126

C75

0.47u/50V

1

U7A

3

27k

1n

102

VR15A

100KB W/CC

1

U6A

3

2

-15V

82k

TL072

8 4

+15V

TL072

8 4

+15V

R64

10k

87451

PJ6-09-5

STEREO

PJ4

PJ7

FOOT

SWITCH

541

R145

100k

R133

R132

TP13

CN7

CON2

1

2

TO START GROUND

12

PJ6-09-3

-15V

R139

100k

R135

1M

1M

1M

REV OUT

6

CN401

6

CN2

R140

3R3 2W

31

1

2

CN6

CON2

POWER IN

+15V

C77

47u/50V

104

C85

C76

47u/50V

104

C86

+15V -15V

C82

1u/50V

Q9

J112

G

D

S

Q8

J112

G

D

S

REV IN

DGND

-15V

REVERB

+15V

AGND

+15V

R80

OUTPUT GROUND

SW4

SS2214RG9

2

PCB

12345

CON6

12345

CON6

-15V

VR21A

100KB

3

1

2

39k

R130

MASTER REV

R129

10k

R128

82k

R81

82k

2

VR22A

100KB

10k

3

1

REV/AUX

11

PASSPORT

Mixer Schematic Diagram

2

Mixer PCB

3

PASSPORT

Mixer PCB

RCA HSP-206V-03

RJ1A

L

14

15TAPE OUT

RCA HSP-206V-03

RJ1B

R

13

2

MIC 1

SVP561P-R

+

G

MJ1

2

3

1

3

1

CN1

WF15

4

MIC 2

SVP561P-R

G

MJ2

2

+

3

1

5

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

TO

MIX

AMP

RCA HSP-206V-03

RJ1E

L

RJ1F

RCA HSP-206V-03

R

12

11

PASSPORT

Input Schematic Diagram

4

C415

C414

0.1uF

0.1uF

+5V

R415

10K

C417

10R

0.1uF

C420

1uF/50V

C416

0.1uF

+5V

16

12

14

11

15

13

10

9

C419

0.1uF

C418

0.1uF

14

13

11

16

15

9

10

12

R414

+5V

Vdd

Gnd

DigIn

Reset

BitClk

Bypass

15

16

14

INR-

INR+

INL+1INL-2AGND3REF+4REF-5VD6DGND7FORMAT

U404

+5V

9

10

13

12

11

VA

MID

DOUT

AGND

DGND

R408

WDCLK

AL1101 AD C

+5V

8

C405

0.1uF

C406

0.1uF

1K

R416

U406

10K

XL401

Dig Out1Int/Ext2Xtal In3Xtal Out4Prog0/SData5Prog1/SClk6Prog27Prog3

12.288MHz

SysClk

TP19

TP20

WordClk

AL3201B

8

+5V

R419

10K

C410

10uF/25V

R418

10K

R421

10K

R420

C404

R406

220R

4700pF

R407

220R

C403

10uF/25V

7

U403B

-2+

R402

6

1

C401

+5-

R404

NJM2068

2.2K

U401A

NJM2068

3

10uF/25V

R403

2.2K

C402

10uF/25V

1

R409

4.7K

R405

R401

-2+

2.2K

U403A

100K

NJM2068

3

1K

R417

2.2K

C407 220pF

U402A

C408 470pF

R410

10K

5

6

-

+

U402B

7

3

2

-

+

NJM2068

1

C430

10uF/25V

MID

OUTR-

OUTR+

OUTL-1OUTL+2AGND3REF+4REF-5VD6DIN7FORMAT

U405

C411

10uF/25V

10K

R412

4.7K

R411

10K

C409

220pF

NJM2068

R413

C412

VA

DEM

AGND

DGND

WDCLK

AL1201 DA C

220

0.1uF

8

C413

0.1uF

TP18

+15V

C426

C423

C422

U407

1

78L05

3

CN402

U403C

0.1uF

U402C

0.1uF

U401C

0.1uF

TP17

Vout

GND

Vin

1

2

CON2

NJM2068

C427

NJM2068

C425

NJM2068

C432

C424

0.1uF

C433

10uF/25V

C434

0.1uF

2

-15V

4 8

0.1uF

4 8

0.1uF

4 8

0.1uF

C431

C428

AUDIO IN

AGND

AUDIO OUT

+15V

-15V

TP16

CN401

AGND

6

12345

6PIN

47uF/25V

0.1uF

C429

47uF/25V

PASSPORT

Reverb Schematic Diagram

5

g

Digital Reverb PCB Component Side

Di

ital Reverb PCB Copper Side

RCA/XLR Input PCB

PASSPORT

Digital Reverb / RCA/XLR Input PCB

6

TP3

2200U/50V

R4*20

L5

2200U/50V

+15V

-34V

D9 OPEN

OPEN

T2

R31

R30

+34V

TP2

A

C7

104

R40

2.2K/2 W

C2 6

2200U/50V

R4*20

L6

R39

2.2K/2 W

C6

104

C3 0

C2 5

2200U/50V

C2 4

C2 8

222/500V

D7 T O-220 10A/400V ER1004

be ad co r e

R25

4R7/0. 5W

222/500V

C2 7

TO-220/10A /400V ER1004

D6

R24

4R7/0. 5W

@0.5*27TS

T1

R19

D3

47K/2W

FR107

C17

be ad co r e

222M/1K V

EE42/42/20

BC1beadc ore

+5V

R36

OPEN

R38

OPEN

C3 3

OPEN

C3 2

OPEN

BC4 OPEN

C2 9

OPEN

OPEN

D10

C3 4 OPEN

C2 3

be ad co r e

OPEN

L4

+34V

C3 6 OPEN

OPEN

R29

OPEN

OPEN

D4

OPEN

D5

OPEN

R23

OPEN

OPEN

C2 2

OPEN

23

C2 1

12N60/STP 13N60/24N60

BC2 6mm bead core

be ad co r e

47R

-15V

R35

OPEN

+15V

R33

C3 1

OPEN

R37

OPEN

EARTH

D8 OPEN

C3 5 OPEN

U4

U8 OPEN

4

1

C2 0

OPEN

OPEN

L3

OPEN

be ad co r e

C16

101/1KV

-34V

Q1

OPEN

R18

D2

OPEN

R9

R32

OPEN

R34

OPEN

+34V

OPEN

4.2K 1%

C4

OPEN

ZD3

5C2

D11

UF1003

C15 331

OPEN

C5 104

U6 OPEN

EARTH

A

VR1

R28

39K 1%

R2

4.7K

U8817C

R21

U7

X00602MA/ST

R22

39R

R41

270R

ZD4

2.0A

R14

0.2/2W

R6

10K

ZD1

18V/0.5W

750R

R16

R26

R27

1K

C1 9

22U/50V

U5

R20

4.7K

R42

4.7K

R5

5.1K

PC817

102

2.4K 1%

ZD2

Z22C D O-35

C1 8

U3

PC817

47UF/25V

D12

CY4

102/400V

TP1

R13

C1 4

180U/400V

C1 3

180U/400V

V+

V-

2

BD1

1

CY3

4

AC

AC

6A/600V

3

33K/1W

BC3 6mm bead core

222/400V

C1 2

R12

56K/1W

1

0.22R

T1/2

R11

@0.5*15TS

HER105

D1

C11

bea d cor e

47U

L7

400A

8

7

6

0.1UF

C10

0.1UF

U1

C9

TTC03-103 10K

NTC2

CY2

CX1 0.22UF /275V

471/250V

R15

470K

R1

470K

CY1

471/250V

MO V1

10D471

T12.7 22Ts

L1

1

2

CX3

0.22UF

CO N 1

NTC1

2.5R/8 A

EE25V@ 0.6

CX2

0.1UF /275V

L2

U2

C3

104

R4

1

2

3

UC3843 ST

4 5

R8

12K

R10

12K 1%

2

1

3.96

CO N 1~

10k

C8

C2

102/50V

220PF /50V

OPEN

R7

222J/100V

C1

4.2K 1%

R3

R43

Q2

1K

2N3904

L

be ad cor e

S1

1

2

3

F1

CO N

IEC SOCKET

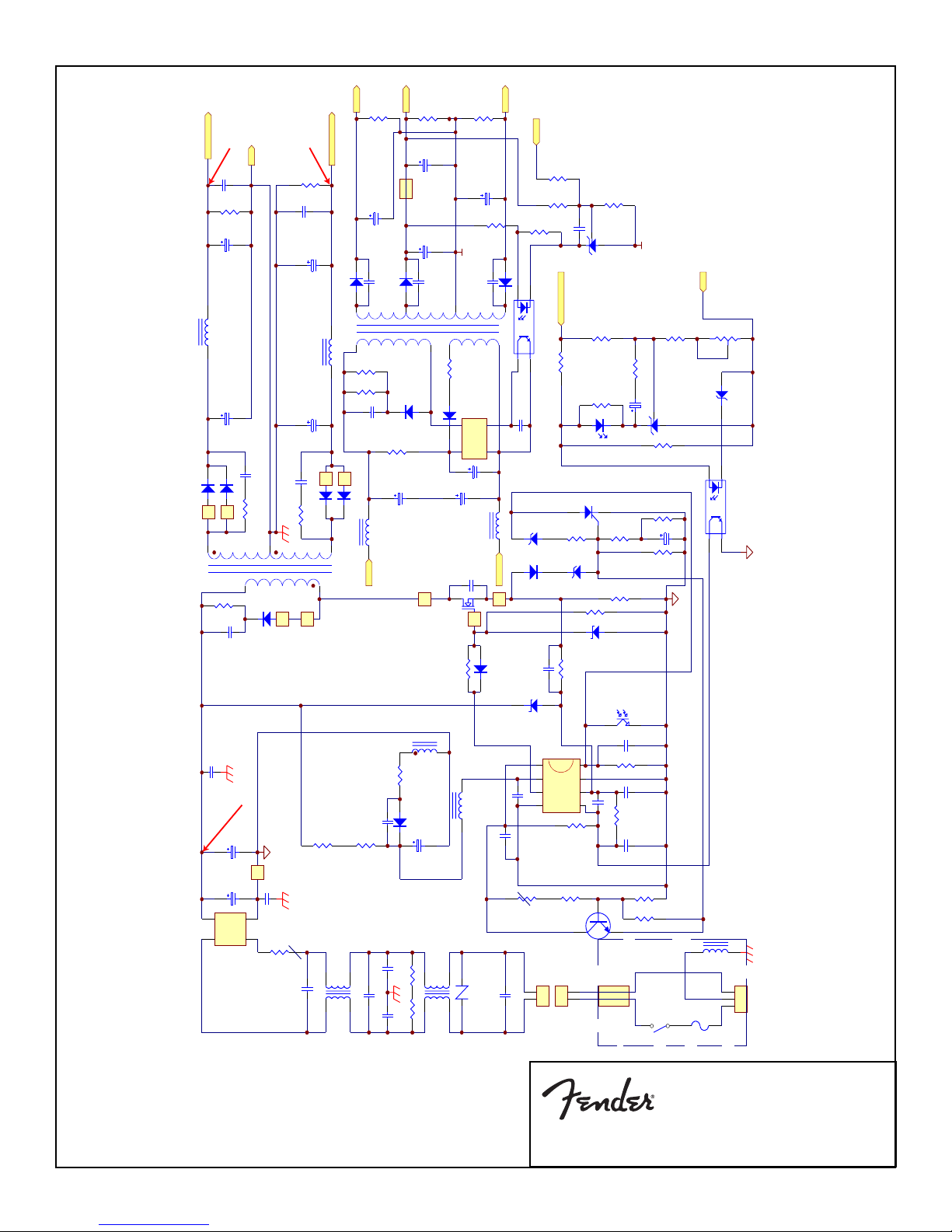

PASSPORT

SMPS Schematic Diagram

7

PASSPORT

SMPS PCB

8

+36V

Q204

R230

R241

U202

LM317HV

BD140

1

2

CN208

R237

4K7

R238

2K

CE

Z206

12V 1W

C205

47u/25V

68R/5W

100R/5W

C224

100n

3

Vin

Vout

2

R210

1K3 1%

ADJ

1

R209

240 1%

C223

10u/50V

CON2

Q203

9013H

C225

2u2/50V

B

R227

10K

R211

15K

D207

1N4148

START GROUND

CN201

WF2

PJ6-09- 3

PJ201

145

1

2

R SPKR OUT

TP10

PJ202 PJ6-09-3

START GROUND

145

SPKR OUT

+36V

L SPKR OUT

DGS

R219

3K3 2W

D205

1N4148

TP7

C217

100u/50V

C215

100n

Q208

2SK1058

C212

47u/25V

Z204

15V

TP9

C211

CN402

1

2

WF2

R228

-15V

TP5

CN209

LED201

2751-6

1

2

CN206

WF2

R240

1

2

1

2

LED PCB

100R/5W

R229

68R/5W

Z203

15V 1W

+15V

C221

47u/25V

C220

100n

R213

WF2

CON2

LED

209EGW

TP6

2K

R239

100R/5W

68R/5W

Z202

15V 1W

C222

47u/25V

C219

100n

1

2

WF2

CN205A

CN205

G

R

R204

THERMAL SWITCH

TH201

17AM203A5-4

CON2

CN207

2

1

85C

Z201

33V

R203

39K

-15V

1K

R212

R201

39K

+15V

R202

C201

2u2/50V

+15V BOOTST RAP

39K

Q201

MPSA06

D201

1N4148

2M2

224

D204

1N4148

D

G

Q207

J112

S

R226

R225

390

15K

1

R232

1K5

_

2

R231

5K1 1%

-36V

123

4

CN202

WF4

EXIT/DC

10A

F202

10A

F201

123

4

CN203

WF4

TP8

(OPTION)

-36V

C218

100u/50V

C216

100n

Q205

2SJ162

S

D

G

C214

R215

7

R216

390K

4 8

_

+

U203

BA4560

5

6

223

C210

R217

3M3

R218

1M

C209

1u/50V

D202

1N4148

D203

1N4148

R222

56K

R235

3R3 2W

R234

1K5

U203

BA4560

+

3

C206

22u/16V

VR201

NV26TLI 1K

1

S

G

R208

D

Q202

J112

-15V

39K

C203 47p

2

R205

10K

C202

1000pF

3M3

R221

100K

R224

390

220n

C208

47p

C207

4K7

R233

U201A

TL072

+15V

3

390

R207

R206

100K

1u/50V

TP4

R214

3K3 2W

47u/25V

D206

C213

1N4148

Z205

15V

HI-PA AGND

-15V BOO T STRAP

R220

1M

R223

15K

R236

3R3 2W

LO-PA GND

123

CN204

WF3

AUDIO IN

PASSPORT

AMP Schematic Diagram

9

Amplifier PCB Component Side

Amplifier PCB Copper Side

LED PCB Component Side

LED PCB Copper Side

PASSPORT

Amplifier / LED PCB

10

TP1 DC300V

TP2 DC34V

TP3 DC-34V

TP4

TP5 DC-15V

TP6 DC15V

TP7 DC34V

TP8 DC-34V

TP9 DC8V

PASSPORT

Test Point Information

11

TP10

TP11

PASSPORT

Test Point Information

12

TP12

TP13

PASSPORT

Test Point Information

13

TP14

TP15

PASSPORT

Test Point Information

14

TP16

TP17 DC8V

TP18 DC5V

TP19

PASSPORT

Test Point Information

15

TP20

PASSPORT

Test Point Information

16

SMPS PCB

AF_CH1

GND

GND

GND

AF_CH2

P-80 Wiring Diagram

RCA/XLR Input PCB

AUT_CH1

GND

white

GND

AUT_CH2

black

red

balck

Mixer PCB

CN7

CN605B CN604B

CN1

CN6

CN2

CN5

AMP PCB

CN209

VCC

CN203

CN402A CN208

CN201

CN205A CN205

CN204CN206

FAN

LED PCB

Reverb PCB

CN401

CN402

PASSPORT

Wiring Diagram

17

The following shows the legend of the mating connections

P-80 Wiring Diagram

CN604B

CN605B

CN205A CN205

PCB-P8011+MIXE PCB-P8011+RCA

1 GND 1 GND

2 MIC1+ 2 MIC1+

3 MIC1- 3 MIC14 MIC2+ 4 MIC2+

5 MIC2- 5 MIC26 OPEN 6 OPEN

7 OPEN 7 OPEN

8 OPEN 8 OPEN

9 OPEN 9 OPEN

10 RCA IN2 10 RCA IN2

11 STEREO R 11 STEREO R

12 STEREO L 12 STEREO L

13 TAPE OUT R 13 TAPE OUT R

14 TAPE OUT L 14 TAPE OUT L

15 GND 15 GND

PCB-P8011+MIXE PCB-P8011+DREV

1 -15V 1 -15V

2 AGND 2 AGND

3 +15V 3 +15V

4 AUDIO IN 4 AUDIO IN

5 AGND 5 AGND

6 AUDIO OUT 6 AUDIO OUT

PCB-P8011+MIXE PCB-P8011+PWRM

1 AUDIO OUT 1 AUDIO IN

2 GND 2 GND

3 OPEN 3 OPEN

PCB-P8011+MIXE PCB-P8011+PWRM

CN6 CN209

CN7

CN406

CN201

CN402 CN402A

2 -15V 2 -15V

1 +15V 1 +15V

PCB-P8011+MIXE PCB-P8011+SMPS

1 GND 1 GND

2 GND 2 GND

PCB-P8011+MIXE WIRELESS PCB

1 AF_CH1 3 AF_CH1

2 GND 4 GND

PCB-P8011+MIXE WIRELESS PCB

1 AF_CH2 8 AF_CH2

2 GND 7 GND

PCB-P8011+PWAM PCB-P8011+LED

2 GND 2 GND

1 +15V 1 +15V

PCB-P8011+PWAM WIRELESS PCB

2 +8V 6 +8V

1 GND 5 GND

PCB-P8011+PWRM PCB-P8011+SMPS

1 GND 1 GND

2 GND 2 GND

PCB-P8011+PWRM PCB-P8011+SMPS

1 +34V 1 +34V

2 GND 2 GND

3 GND 3 GND

4 -34V 4 -34V

PCB-P8011+DREV PCB-P8011+PWAM

2 +8V 2 +8V

1 GND 1 GND

CN1CN1

CN401CN2

CN204CN5

CN203CN203

PASSPORT

Wiring Diagram

18

2

5

3

No. DESCRIPTION PART NUMBER QTY

1 LATCH ARM 4153-2730+0 1

2 LATCH BRACKET 4133-9540+0 1

3 LATCH “C” PINS 4133-9430+0 2

4

4 LATCH SPRING 4133-9550+0 1

5 LATCH SAFETY CATCH 4153-2740+1 1

Remark:

Each unit contains 4 latch assemblies.

1

3

LATCH ASSEMBLY EXPLODED VIEW

No. DESCRIPTION PART NUMBER QTY

1 REAR PANEL P-80 4133-946D+0 1

2 AUX POWER CON BRACKET 4133-9510+0 1

3 GM FUSE HOLDER HOUSING 4153-1160+0 1

4 AUX POWER CONNECTOR 7010-0140+0 1

5 2.6x6 MM SCREW TF 2934-2606+3000 2

6 FUSE COVER P-80 4135-5511+0 1

7 POWER AMP HEAT SINK 5400-1881+1 1

8 MOUNTING BRACKET 4133-9490+0 2

9 POWER AMP PCB ASSEMBLY

P-80

10 BRASS TUBE STANDOFF 4133-9580+0 2

11 THERMAL MOUNTING

BRACKET

12 3x12MM SCREW PHPS 2944-3008+3000 9

13 SMPSU MODULE P-80 1

14 M3 METAL WASHER 2600-3005+0803 4

15 3x6MM SCREW PHPS 2944-3006+3000 11

16 M3 METAL SPRING WASHER 2607-3009+0553 12

17 3x8MM SCREW PHPS 2954-3008+3000 4

PCB-P8011+PWRM 1

4133-9090+0 1

POWER MODULE ASSEMBLY EXPLODED VIEW

PASSPORT

Latch Exploded View

19

No. DESCRIPTION PART NUMBER QTY

1 FRONT PANEL OVERLAY P-80 4155-0141+0 1

2 FRONT PANEL P-80 1466-7601+0 1

3 SHIELD PLATE 4133-9550+0 1

4 MIXER PCB ASSEMBLY P-80 PCB-P8011+MIXER 1

5 REVERB PCB ASSEMBLY P-80 PCB-p8011+DREV 1

6 RCA/XLR PCB ASSEMBLY 1723-080A+0000 1

7 XLR MIC JACK (RCA/XLR ASSY) 2113-1223+0 2

8 MIC JACK BRACKET (RCA/XLR) 4133-9570+0 1

9 SWITCH COVER 3100-4531+0 3

10 3X8MM SCREW TF 2954-3008+3000 14

11 M3 FIBER WASHER 2601-3008+0801 2

12 PCB STANDOFF 4153-1220+0 4

13 MIXER CONTROL KNOB 4153-2830+1 13

14 MASTER CONTROL KNOB 4153-2820+1 1

15 LED PCB ASSEMBLY PCB-P150D11+LED 1

16 3X8MM SCREW PHPS 2944-3008+3000 6

17 “U” BAR P-80 4153-2983+0 2

18/19 M3 METAL WASHER 2600-3003+0402 8

20 M12 HEX T-NUT 4133-9660+0 7

21 M13 METAL WASHER

4133-9650+0 7

MIXER ASSEMBLY EXPLODED VIEW

PASSPORT

Mixer Exploded View

20

4

5

6

3

2

10

9

1

11

3

10

10

12

13

14

10

7

11

8

SPEAKER ASSEMBLY EXPLODED VIEW

No. DESCRIPTION PART NUMBER QTY

1 BAFFLE GASKET 4153-2880+0 1

2 SPEAKER GRILLE 4133-9440+0 1

3 6.5” SPEAKER DRIVE UNIT 1525-1150+0 2

4 SPEAKER BOX 4153-3022+1 1

5 RED SPRUE CAP 4153-2902+0 1

6 NATURAL SPRUE CAP 4153-2810+0 1

7 SPEAKER STAND PLUG 1463-9100+1 1

8 6X25MM SCREW TF 2904-6025+3000 4

9 4x14mm SCREW PHPS 2954-4014+3000 1

10 4x10mm SCREW TF 2954-4010+3000 8

11 3X10MM SCREW FLAT HEAD 2951-3010+3000 2

12 M12 WASHER 4133-2810+0 1

13 12MM HEX NUT 4133-2820+0 1

14 SPEAKER STAND “O” RING 4152-2091+0 1

EACH UNIT CONTAINS TWO SPEAKER ASSEMBLIES.

PASSPORT

Speaker Exploded View

21

TOWER HOUSING ASSEMBLY EXPLODED VIEW

No. DESCRIPTION PART NUMBER QTY

1 TOWER SIDE CABINET 4153-2703+0 2

2 MIXER MODULE ASSEMBLY P-80 1

3 POWER MODULE ASSEMBLY P-80 1

4 SIDE PLATE(B) 4133-9480+1 1

5 HANDLE COVER 4153-2694+0 1

6 PARTITION 413-9450+3 1

7 COMPARTMENT DOOR 4153-2750-1 1

8 DOOR LATCH 4153-2760+0 1

9 3X8MM TF SCREW 2954-3008+3000 4

10 DOOR HINGE 4153-2780+0 2

11 COMPRESSION SPRING 4133-9560+0 1

12 FOOT STAND 4153-2714+0 2

13 SUPPORT RIB 4153-2724+0 1

14 HANDLE BRACKET 4133-9520+1 2

15 TOP GASKET 4153-2860+1 1

16 HANDLE GASKET 4153-2850+1 1

17 BOTTOM GASKET 4153-2870+1 1

18 SPEAKER LATCH ASSEMBLY SS-P15011+LALK 4

No. DESCRIPTION PART NUMBER QTY

19 M2.6x8 MM SCREW PHPS 2944-2608+0000 8

20 4X10 MM SCREW TF 2954-4010+3000 8

21 4X14 MM SCREW TF 2954-4014+3000 6

22 3X6 MM FLAT HEAD SCREW 2901-3005+3000 2

23 2.6X6 MM SCREW TF 2934-2606+3000 2

24 3X8 MM SCREW PHPS 2944-3008+3000 9

25 3X6 MM SCREW PHPS 2944-3006+3000 12

26 SIDE PLATE (A) 4133-9470+1 1

27 M3 METAL FLAT WASHER 2600-3005+0803 10

28 LOGO NAME PLATE 4153-2842+0 2

29 SPRUE CAP (GRAY) 4153-2810+0 2

30 4x16 MM SCREW TF 2910-4016+3000 2

31 4X16 MM SCREW PHPS 2940-4016+3000 8

32 M4 METAL SPRING WASHER 2607-4008+0653 8

33 M4 METAL WASHER 2600-4008+1003 8

34 M3 METAL SPRING WASHER 2607-3009+0553 3

35 HALO BUSHING 0813C 2113+9535+0 1

PASSPORT

Tower Housing Exploded View

22

No. DESCRIPTION PART NUMBER QTY

1 GIFT BOX P-80 1434-2103+0-3 1

8

2 MAIN UNIT POLY BAG 1497-2542+0 1

3 PADDED SIDE CARTON LINER 1434-2300+2-2 2

4 INNER SPACER BRACE 1434-4300+0-1 4

5 PE FOAM 1493-0641+0 2

6 WIRES POLY BAG 1497-2092+0 2

7 MAIN UNIT P-80 1

8 PADDED LINER 1434-2200+0-1 2

9 PE FOAM (TOP LINER) 1493-0631+0 1

10 9M SPEAKER CABLE 7010-0000+0 2

11 MAINS POWER CABLE REGIONAL 7011-6210+0 1

12 OWNER’S MANUAL P-80 4301-7169+1 1

13 PE FOAM (BOTTOM LINER)

1493-0651+0 1

6

UL

11

6

9

12

4

4

3

2

10

10

5

7

5

4

4

3

8

13

1

PACKING ASSEMBLY EXPLODED VIEW

23

PASSPORT

Packing Exploded View

Loading...

Loading...