Page 1

poor installation.

®

be responsible for any damages that may occur due to misuse or

in ground hum or intermittent signal. Fishman Transducers will not

NOTE: Always handle the pickup with care. Mishandling may result

MENT DUE TO IMPROPER INSTALLATION.

NOT BE RESPONSIBLE FOR ANY DAMAGES TO YOUR INSTRU-

STRONGLY RECOMMENDED. FISHMAN TRANSDUCERS WILL

INSTALLATION BY A QUALIFIED PROFESSIONAL REPAIRMAN IS

WARNING

available from Fishman.

guide, “The Finer Points of Piezo Installation” by Ken Parker, is

If you are new to under saddle piezo installations, a comprehensive

PIEZO INSTALLATION

information.

Fishman SMART SWITCH. Call Fishman at 978-988-9665 for more

through a single stereo instrument cable), you must first install a

electret microphone through the Fishman Blender System (routed

If you plan to mix the ACOUSTIC MATRIX with an onboard mini

SMART SWITCH

cating LED and a PHASE SWITCH.

varying body sizes. Other features include a battery function indipreamp will function at optimum performance levels in guitars of

LIMITED WARRANTY

INSTALLATION BY A QUALIFIED PROFESSIONAL REPAIRMAN IS STRONGLY

RECOMMENDED. FISHMAN TRANSDUCERS WILL NOT BE RESPONSIBLE FOR ANY

DAMAGES THAT MAY RESULT FROM IMPROPER INSTALLATION.

The FISHMAN ACOUSTIC MATRIX PROFESSIONAL is warranted to function for a period of

One (1) Year from the date of purchase. If the unit fails to function properly within the

warranty period, free repair and the option of replacement or refund in the event that

FISHMAN is unable to make repair are FISHMAN’s only obligations. This warranty does not

cover any consequential damages or damage to the unit due to misuse, accident, or neglect.

FISHMAN retains the right to make such determination on the basis of factory inspection.

Products returned to FISHMAN for repair or replacement must be shipped in accordance with

the Return Policy, as follows. This warranty remains valid only if repairs are performed by

FISHMAN. This warranty gives you specific legal rights and you may also have other rights

which may vary from state to state.

RETURN POLICY

To return products to FISHMAN TRANSDUCERS, you must follow these steps...

1. Call FISHMAN TRANSDUCERS at 978-988-9199 for a Return Authorization Number

(“RAN” ).

2. Enclose a copy of the original Bill of Sale as evidence of the date of purchase, with the

product in its original packaging and a protective carton or mailer.

3. FISHMAN TRANSDUCERS’ technicians will determine whether the item is covered by war-

ranty or if it instead has been damaged by improper customer installation or other causes

not related to defects in material or workmanship.

4. Warranty repairs or replacements will be sent automatically free of charge.

5. If FISHMAN TRANSDUCERS determines the item is not covered by warranty, we will notify

you of the repair or replacement cost and wait for your authorization to proceed.

340-D Fordham Road Wilmington MA 01887 USA

FISHMAN TRANSDUCERS

Phone 978-988-9199 • Fax 978-988-0770

www.fishman.com

®

009-067-001 2-97

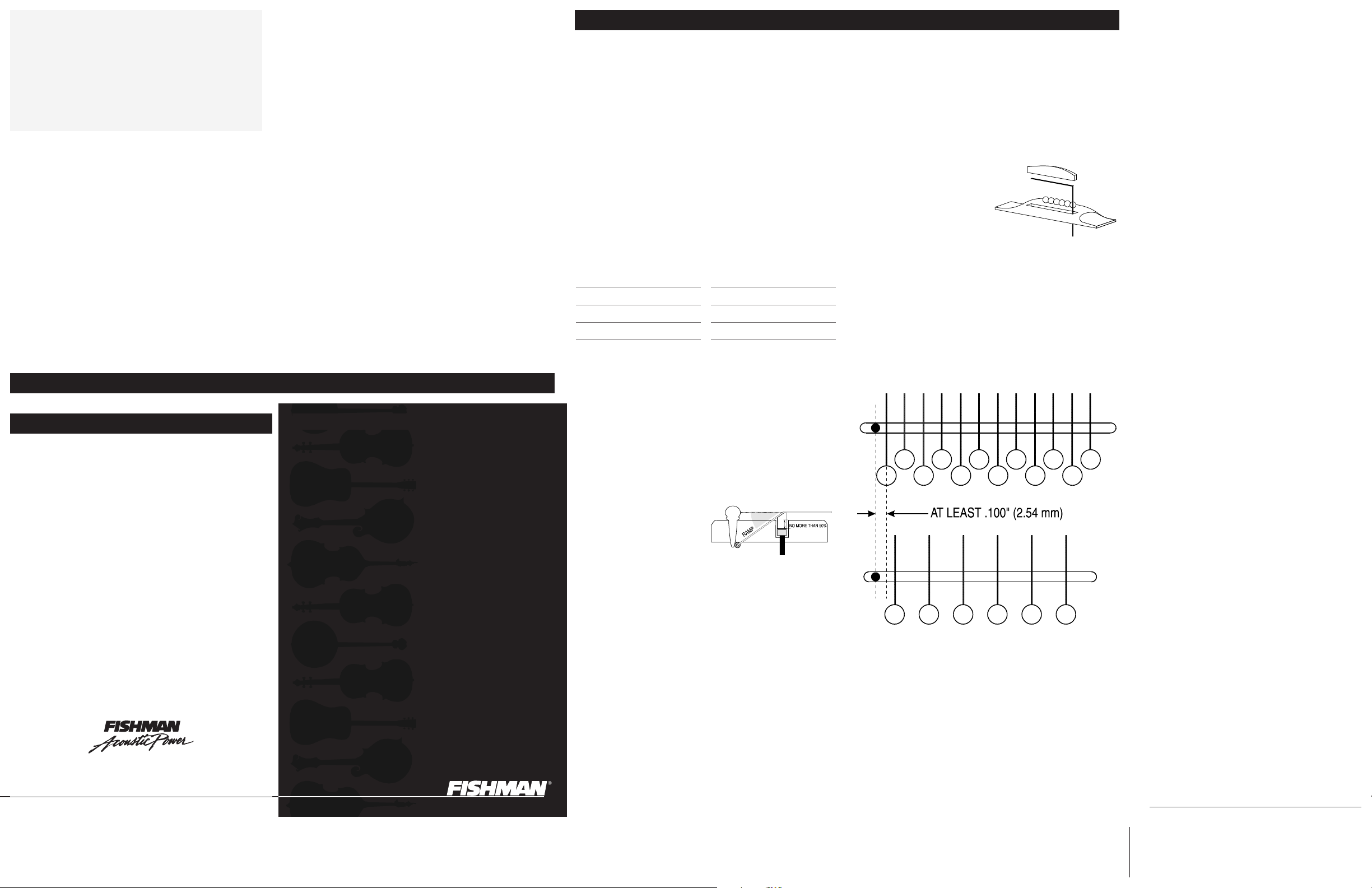

ACOUSTIC MATRIX PROFESSIONAL

INSTALLATION GUIDE

ACOUSTIC

MATRIX

PROFESSIONAL

ACTIVE ACOUSTIC GUITAR SYSTEM

WIDE FORMAT:

.125” (3.2 mm) Width

NARROW FORMAT:

.093” (2.3 mm) Width

WARNING

INSTALLATION BY A QUALIFIED PROFESSIONAL REPAIRMAN IS

STRONGLY RECOMMENDED. FISHMAN TRANSDUCERS WILL

NOT BE RESPONSIBLE FOR ANY DAMAGES THAT MAY RESULT

FROM IMPROPER INSTALLATION.

adjust the amount of soundhole resonance or “bottom” so that the

on the back of the preamp. This internal trim feature can be used to

well as a “set it and forget it” SUB-BASS energy trim control located

PARTS LIST

tures BASS, TREBLE, MIDRANGE and BRILLIANCE controls as

• Slider Bezel

MATRIX PROFESSIONAL system. This low-profile “slider” unit fea-

• Preamp

The four-band equalizer / preamp is the brain of the ACOUSTIC

• Acoustic Matrix Pickup

• 1/4" Stereo Jack, with hardware

THE PREAMP

• 4-40 Screws (4), 3/16" length, with

Star Washers

• 4-40 Screws (4), 7/16" length

• 1/4" Aluminum Hex Standoffs (4),

your instrument.

9/16" length

the transducer helps preserve the beauty and structural integrity of

• 3/16" Brass Hex Jack Screws (4),

The incredibly small size and convenient under the saddle design of

1/2" length

• (3) Adhesive-backed Plastic

ance.

Wire Guides

traditional ceramic based transducers); providing superb string bal-

• Preamp Cutout Template

entire saddle rather than small sections of it (as is the case with

• (5) Slider Knobs

• Back Plate with Battery Clip

This continuous strip design allows it to sense the motion of the

continuous strips of sensing material that are fully EMI shielded.

The ACOUSTIC MATRIX transducer is a multi-layer configuration of

known materials.

exhibits a sensitivity and dynamic range that far surpasses all other

sensing material available exclusively from Fishman. This material

WIDE FORMAT

The ACOUSTIC MATRIX pickup is made with a unique co-polymer

Width: .125" (3.2 mm)

THE TRANSDUCER

Height: .053" (1.35 mm)

Length: 2.650" (67.3 mm)

contact our PRODUCT INFORMATION LINE at 978-988-9665.

Sensing Area: 2.670" (67.8 mm)

these instructions carefully. If you have any questions or problems,

Thank you for your purchase of a FISHMAN product. Please read

Max. recommended string spacing:

NOTE: The overall length of the Matrix pickup is 2.700" (68.58mm).

We recommend a saddle slot length of at least 2.875" (73mm).

The actual sensing area of the pickup is 2.670" long and can accommodate string spacings of up to 2.500" (63.5 mm). Poor string balance may result with string spacings greater than this.

DO NOT trim the end of the pickups length as ground hum will occur.

Custom pickup lengths are available from Fishman.

PICKUP DIMENSIONS

2.500" (63.5 mm)

TOOLS

• Caliper

• Router with 1/8" (3 mm)

(or .9375" Plunging Cutter

for Narrow Format)

• 400 Grit Sandpaper or Scraper

• Flex Shaft Tool with 1" (25.4 mm)

Diameter Saw Blade or Router

with 1/4" (6.30 mm) cutter.

• Soldering Iron (30 watt max)

• Rosin Core Solder

• Wire Strippers

• #1 Phillips Screwdriver

• Variable Speed Drill

• Center Punch

• 1/8" Twist Drill

• 15/32" Spade Bit Drill

• 1/2" Open End Wrench

• 3/32" Allen Wrench

NARROW FORMAT

Width: .09375" (2.4 mm)

Height: .043" (1.1 mm)

Length: 2.650" (67.3 mm)

Sensing Area: 2.670" (67.8 mm)

Max. recommended string spacing:

PART I - PREPARATION

2.500" (63.5 mm)

MECHANICAL FACTORS AFFECTING

PICKUP PERFORMANCE

BREAK ANGLE

There must be an adequate

amount of downbearing pressure on the pickup in order

for it to perform optimally.

The pickup will "see" an acceptable amount of downbearing pressure

when there is a 20° (minimum) break angle across the saddle.

A pickup in a Guitar with less than a 20° break angle will often have

string balance problems as well as poor tone. For such instruments,

an adequate break angle can be realized by "ramping" the string slots

or (in extreme cases) raising the saddle height and resetting the neck

angle.

THE 50/50 RULE

For adequate coupling between string, saddle and pickup, we recommend that the saddle slot depth (with pickup installed) should equal no

more than 50% of the total height of the saddle.

ADJUSTING FOR TOO DEEP A SADDLE SLOT

If the slot (with pickup installed) measures more than 50% of the total

saddle height, the pickup performance will often suffer. To correct for

too deep a slot, place a wood shim under the pickup. Determine the

proper thickness of the shim by subtracting 1/2 of the total saddle

height from the slot depth (with pickup installed). Then, remove an

amount of material equal to the thickness of the shim from the bottom

of the saddle.

EXCEPTION: Pickups in guitars with a very steep string break angle

(25° or more), will generally perform well, even if the saddle slot depth

measures more than 50% of the total saddle height.

COMPENSATED SADDLES

We do not recommend compensating the saddle under the "B" string.

Doing so may twist the saddle and cause uneven pickup response.

PREPARE THE SADDLE SLOT

1. Rout a .125" (3.2 mm) wide saddle slot

for the Acoustic Matrix Wide Format

pickup.

OR

Rout a .09375" (2.3 mm) wide

slot for the Acoustic Matrix

Narrow Format pickup.

2.

Be certain that the bottom of the slot is

Deepen an existing slot only enough to obtain a clean, flat surface.

FLAT.

LOCATE THE WIRE HOLE

1. Locate the center of the wire hole no less than .100" (2.5 mm) from

the closest string.

2. Mark the location where the wire will enter the saddle slot. Center

the mark between the walls (width) of the slot.

3. Drill a .09375" hole.

4. Clear wood chips and foreign materials from the saddle slot.

5. Carefully insert (do not bend) the pickup.

PREPARE THE SADDLE

We recommend synthetic materials such as Micarta or Corian as

excellent saddle materials for the Acoustic Matrix. Organic materials

such as bone or ivory are not as consistent and may result in poor

string balance.

1. Prepare a .125" wide saddle (.09375" for Narrow Format)

tom of the saddle must be

2. Remove only enough material from the width of the saddle to pro-

vide a sliding fit in the slot. To test the fit, the saddle should slide

easily in the slot, but should not fall out when overturned. To maintain your current action, the new saddle must be .053" shorter in

height (.043" for Narrow Format pickups) than your current saddle.

FLAT.

The bot-

Page 2

PART I - PREPARATION Cont’d.

PREAMP CUT-OUT

For guitars with non-laminated sides, we strongly recommend gluing a

thin plywood patch inside the guitar before cutting out the cavity. This

will prevent cracking and splintering of the cut-out area during cutting,

and provide adequate structural support for the preamp.

1. Choose the preamp location on the side of the instrument.

Note that the bezel has the ability to conform to most curved surfaces on standard size guitars.

2. Tape the enclosed Cutout Template to the desired location.

Use the flex shaft tool (with 1/2" blade) or the router (with 1/4" cutter) to make the cut-out.

3. Drill the screw mounting holes using the 1/8" drill.

PART II - INSTALLATION

a complete stop before removing it from the hole.

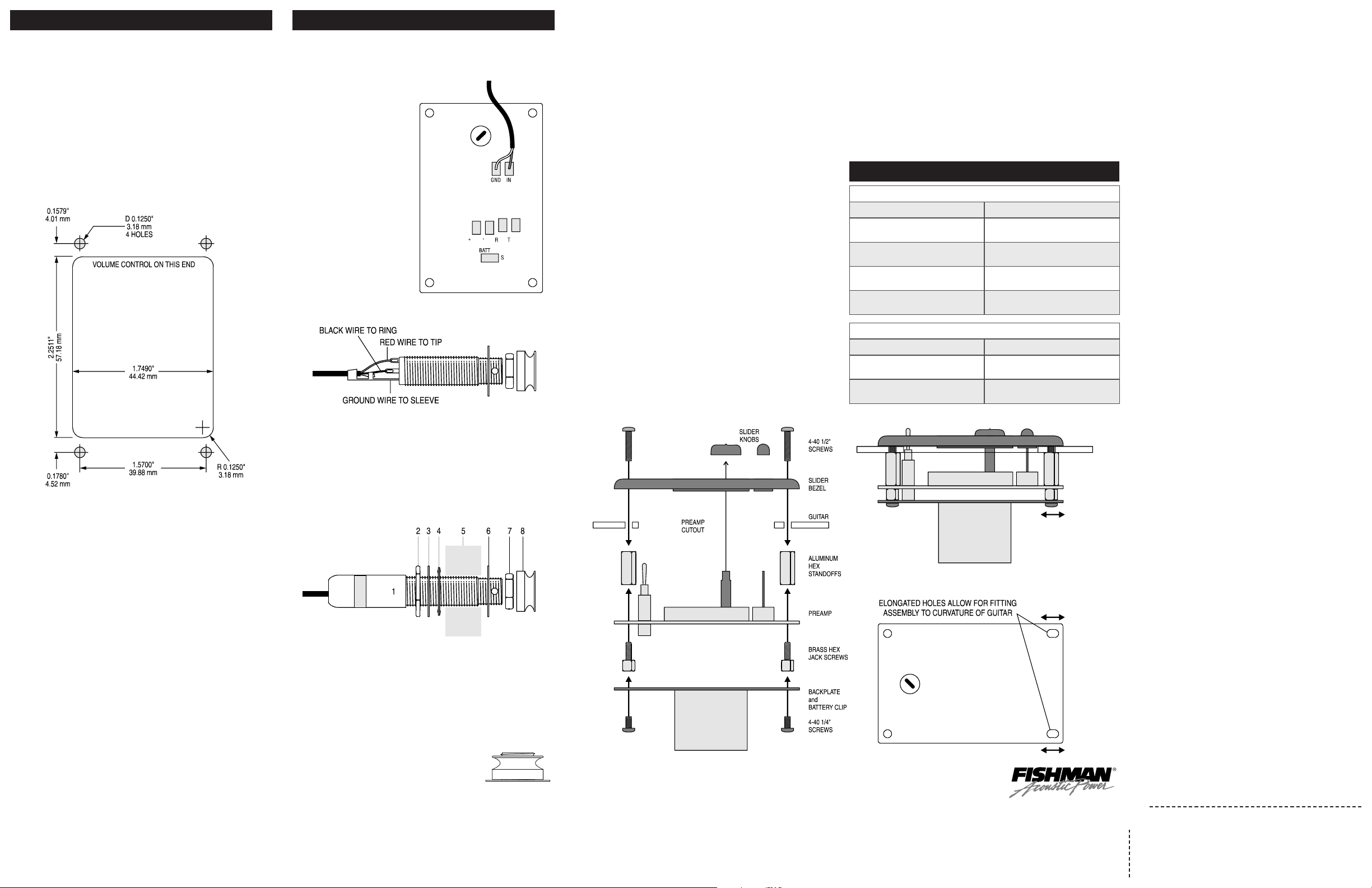

SOLDER THE WIRE CONNECTIONS

1. Insert the pickup in the sad-

dle slot then strip and tin

the wire ends.

2. Solder the "hot" wire from

the pickup (inner conductor)

to the pad marked "IN" on

the preamp circuit board.

Solder the "ground" wire

from the pickup (shield) to

the pad marked "GND" on

the preamp circuit board.

3. Strip and tin the wire ends

of the preamp output cable.

Solder the RED wire to TIP,

the BLACK wire to RING

and the ground wire to the

SLEEVE of the 1/4" jack.

MOUNT THE PREAMP

The hardware supplied will accommodate guitars with laminated sides

that are between .100" and .175" thick. If your guitar has sides less

than .100" thick, the slider knobs will not fit in the bezel properly.

To make up the difference, use #4-40 washers to shim the preamp

inside the instrument or contact Fishman for longer standoffs.

1. Fasten the 3/16" brass hex screws and the 1/4" hex standoffs to

the preamp as shown. Note that the mounting holes on the volume

control side of the circuit board are slotted to allow for fitting the

preamp to the curved surface of the guitar side.

2. Temporarily fit the preamp and bezel together on the guitar, with

the standoffs finger tight. Fasten the bezel with the #4-40 1/2"

screws to check the standoff alignment. Align the standoffs if necessary. Remove the preamp from the guitar. Tighten the aligned

standoffs secure.

3. Mount the backplate to the preamp with the 3/16" #4-40 screws.

Install the battery and string up the guitar.

4. Plug the guitar into an amplifier and set all the slider's tone con-

trols to their center positions. On the back of the preamp, there is

a recessed Sub-Bass control which is preset at the factory to full

boost. This can be used to roll-off the amount of “bottom end”

which can cause feedback (especially in larger dreadnought-style

guitars). Turn the trim pot counter clockwise for less bass.

5. Re-install the preamp into the guitar. Be sure that the low battery

LED lines up with the corresponding hole in the bezel.

6. Attach the adhesive backed plastic wire guides to the sides or the

kerfing of the instrument.

7. Insert a 9 Volt Alkaline battery into the battery clip.

IMPORTANT: Although the supplied battery holder should provide

adequate capacity to grip the battery at all times, we strongly recommend removal of the battery when shipping your instrument.

FAILURE

TO REMOVE BATTERY COULD RESULT IN DAMAGE TO YOUR

INSTRUMENT.

age as a result of shipping or handling.

Fishman will not be held responsible for any such dam-

The output jack of the Acoustic Matrix Professional System is also the

power switch for the battery.

When a cable is first plugged into this jack, the BATT/LOW LED will flash

momentarily to indicate that the power is on.

When the battery power is low, this light will remain lit.

Adjust the volume of the preamp and your amplifier as desired.

Using your ears as a guide, set the PHASE switch for proper phase

relationship with the sound source (amps, monitors, etc.).

This relationship is most audible at louder volumes and will change from

room to room and with your position on stage.

Saddle is too tight/loose in slot

Bottom of saddle slot is not flat Rout out saddle slot

OPERATION

Be sure to unplug the output jack when not in use

to avoid battery drain.

TROUBLESHOOTING

SYMPTOM: Weak string or strings

PROBLEM SOLUTION

Saddle should have a precise, sliding

Bottom of saddle is not flat Flatten bottom of saddle

Less than adequate

downbearing pressure

SYMPTOM: Hum

PROBLEM

Saddle fit is too tight

Pickup tube is torn

Observe the 50/50 rule - In extreme belly up

cases, a neck reset may be necessary

Sand off side of the side of the saddle

fit in the slot

SOLUTION

to provide a sliding fit

Replace the pickup

PREPARE THE ENDPIN BLOCK

TOOLS

• Masking Tape • X-Acto Fine-toothed Saw

• Variable Speed Drill • Center Punch

• 1/8" Twist Drill • 15/32" Spade Bit Drill

• 1/2" Open End Wrench • 3/32" Allen Wrench

The objective of this method is to drill a hole in the endblock, with the

endpin in place. You may remove a loose endpin and refasten it in the

endblock with cyanoacrylate glue before starting this procedure.

1. Apply masking tape around the endblock area to protect the instru-

ment.

2. Locate an X-Acto saw blade 1/16" away from the body and saw off

the endpin.

3. Centerpunch a guide hole in the center of the trimmed endpin.

4. Drill a 1/8" pilot hole through the endblock.

5. Line up a 15/32" Spade bit in the pilot hole and begin drilling.

Maintain a perpendicular plunge in relation to the instrument. Use

steady (but not heavy) pressure, especially as the drill exits inside

the guitar.

IMPORTANT: To avoid damage to the instrument, let the drill come to

FASTEN THE JACK IN THE ENDPIN HOLE

Follow this sequence when installing the endpin jack:

1 - Shielding Cap

2 - First Large Hex Nut

3 - Large Dress Washer

4 - Star Washer

5 - Guitar Endblock

6 - Small Dress Washer

7 - Small Dress Nut

Strap Button

The jack should protrude at least 5/16" and no more than 11/32" outside of the body for proper fit. After fitting the small dress washer and

nut over the end of the jack, insert the 3/32" allen wrench through the

cross drilled hole on the end of the jack. Tighten the nut with the 1/2"

open end wrench while holding the jack in place with the allen wrench.

Thread and hand tighten the the strap button.

NOTE: With the strap button in place, the end of

the jack should protrude slightly to allow proper

plug fit.

(optional)

8 -

Loading...

Loading...