FEMA ELECTRÓNICA - Page 1

FEMA ELECTRÓNICA

INTELLIGENT

PANEL

METERS

Series TAS-1

Intelligent Panel Meters

info@fema.es

www.fema.es

USER’S MANUAL

AC Current

DC Current

AC Voltages

DC Voltages

TAS-1-IAC

TAS-1-IDC

TAS-1-VAC

TAS-1-VDC

User’s Manual Series TAS-1

FEMA ELECTRÓNICA - Page 2

1.1-INDEX

1.- Introduction

1.1.- Index 2

1.2.- If this is the first time you work with a TAS-1 meter 3

1.3.- Frontal View and Rear View of the instrument 3

2.- Quick Reference Guide

2.1.- Connections 4

2.2.- Programming Menu 4

3.- Configuration

3.1.- Input Signal 5

3.2.- Direct Access

3.2.1- Decimal Point Position 5

3.2.2- Adjusting the Low Indication 5

3.2.3- Adjusting the High Indication 5

3.2.4- Alarm Setpoints 5

3.2.5- Correcting a Low Input Signal 5

3.2.6- Correcting a High Input Signal 5

4.- Advanced Configuration

4.1.- Input Signal for : DC V oltage 6

4.2.- Input Signal for : AC Volt age 6

4.3.- Input Signal for : DC Current 6

4.4.- Input Signal for : AC Current 6

4.5.- Alarm Configuration 6

4.6.- Manual Adjustment 7

4.7.- Dealing with Errors 7

4.8.- Advanced Indication 7

4.9.- Blocking the Keypad 7

4.10.- Resetting the system. Default values 7

4.11.- Messages and Errors 8

5.- Configuring with a PC 8

6.- Technical Specifications and Dimensions 9

7.- Available Options .- Installing and Configuring 10

7.1- Analog Output - TSAT Option Board 10

7.1.1- Connections 10

7.1.2- Technical Characteristics 10

7.1.3- S tart-Up 10

7.1.4- Configuration 1 1

7.2- Installing the option boards 1 1

7.3- Modbus Output - R485M Option Board 12

7.3.1- Configuration 12

7.3.2- Accepted Functions 12

7.3.3- Register Map 12

7.3.4- Connections and Bus Terminator 13

7.3.5- Modbus frame structure-I 13

7.3.6- Character Structure 13

7.3.7- Modbus frame structure-II 13

7.4- Peak, V alley, Hold, Tare, Reset - TEK Option Board 14

7.4.1- Available Functions 14

7.4.2- Connections 14

7.4.3- Configuration 14

8.- CE Certificate / Warranty 15

9.- Safety Information 15

User’s Manual Series TAS-1

FEMA ELECTRÓNICA - Page 3

1.2- IF THIS IS THE FIRST TIME YOU WORK WITH A TAS-1 METER...

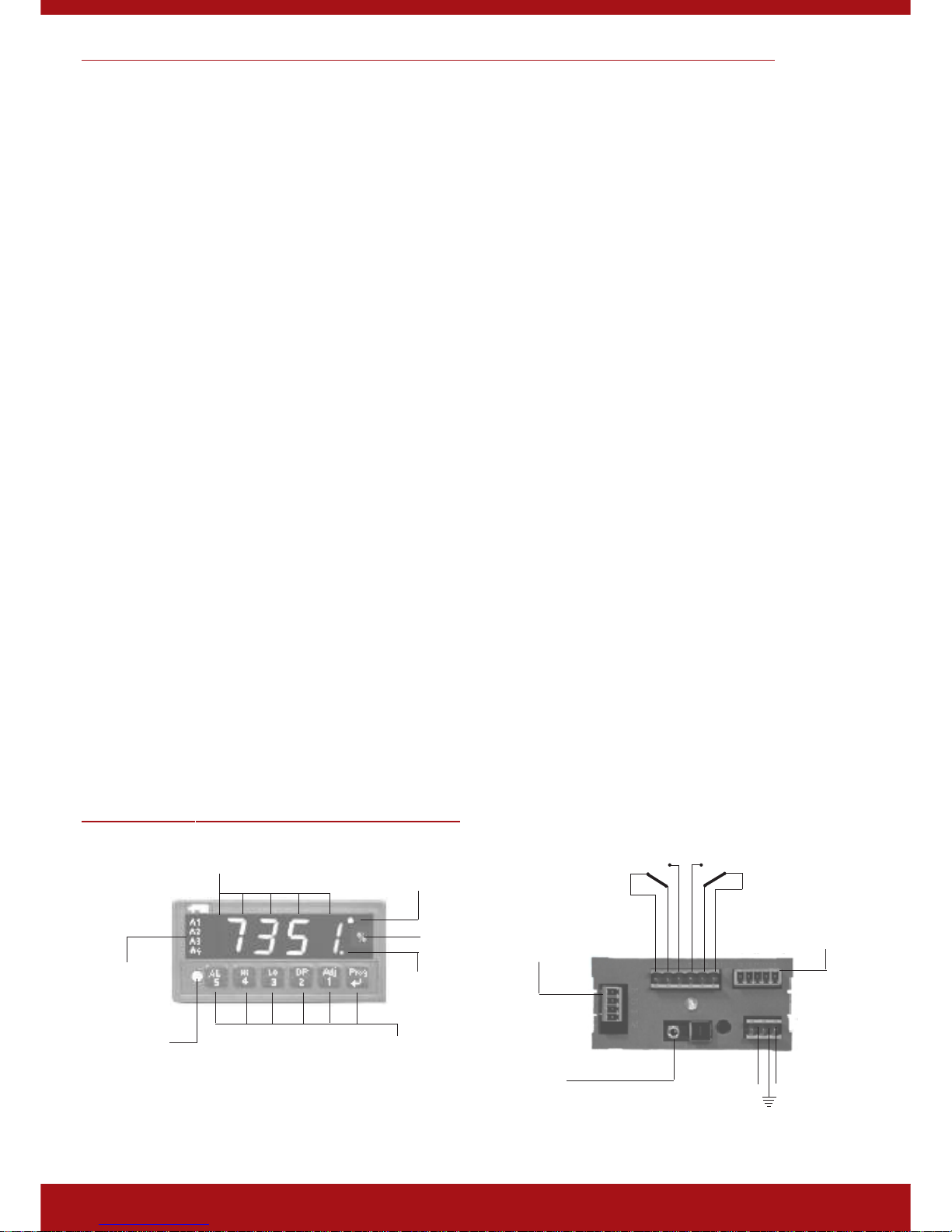

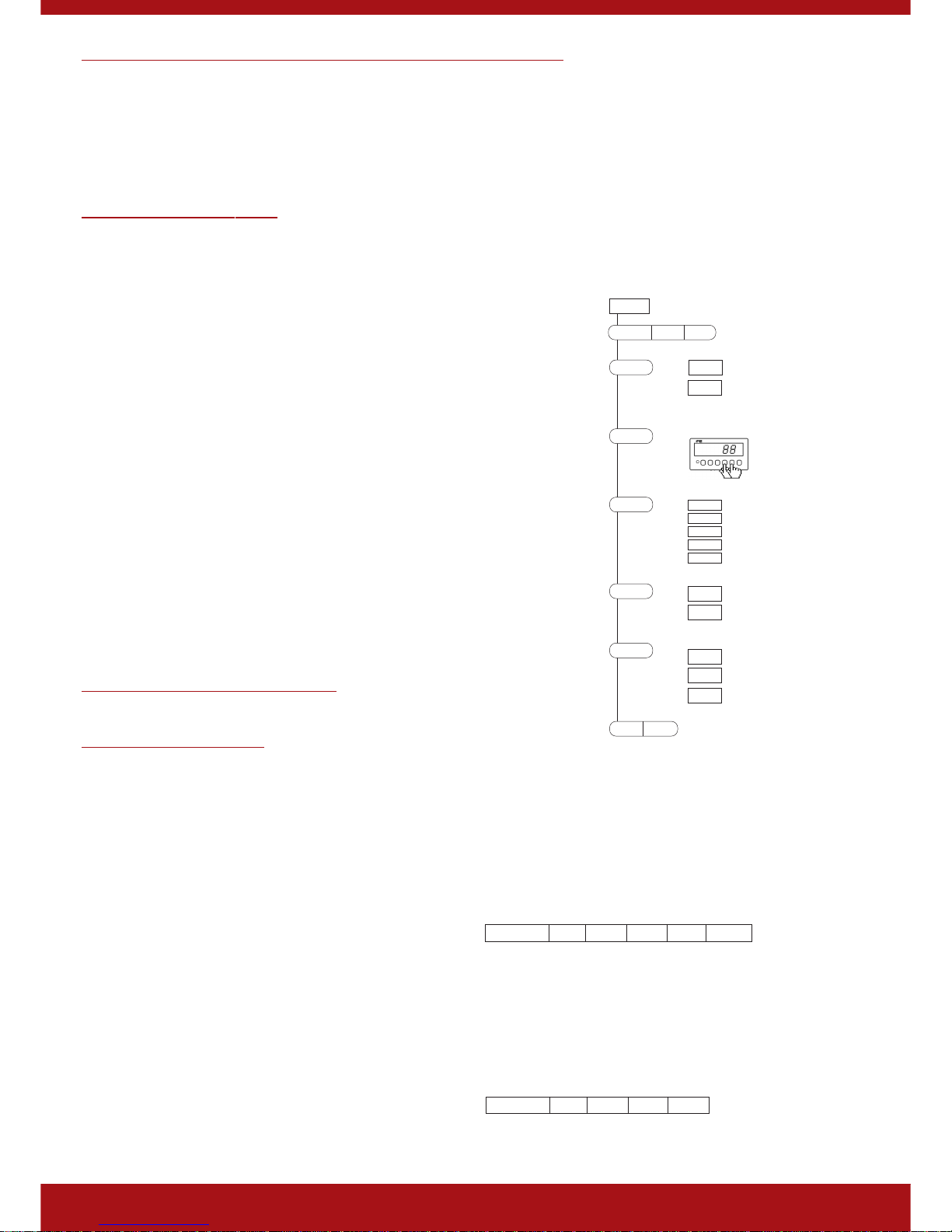

TAS-1 Rear ViewTAS-1 Frontal View

Status Led for

alarms 1,2,3 and 4

Leypad Function Led

Red Led - keypad acting as number

Green Led - keypad acting as direct access

6 pads for programming

double function

Indication

5 displays 7 segments

Units

Activity Led

Decimal

Point

Connector for PC

Configuration

(PCConnector

cable needed)

Power

Input Signal

(3 or 4 pole Terminal

depending on the

unit)

(N)

(+)

(L)

(-)

Relay 1

Output

Relay 2

Output

Output for Optional

Boards

(See pages 10 to 14)

Note .- The 2 relay outputs and the Optional Boards are

OPTIONAL and are NOT INCLUDED with the basic unit.

1.3- FRONTAL VIEW AND REAR VIEW

We strongly recommend you to read the following

paragraphs. Following ideas need to be clearly understood

in order to easily adjust and program the unit.

WHEN POWERING THE INSTRUMENT the meter displays

a message indicating the configured signal input range (see

page 4).

IF THE TAS-1 DETECTS A STRANGE SITUA TION on the

instrument status, or sensor break, etc, the instrument will

show an error message (see page 8 «messages and

errors»).

THE FRONTAL KEYPAD is composed of 5 function/key

pads and 1 programming pad. The pads have two functions,

acting both as number keys (when a number needs to be

entered) and as direct access keys to the following

functions :

Key AL - Access to the ALARM setpoints

Key HI - V alue for the HIGH Indication

Key LO - V alue for the LOWIndication

Key ADJ - Access to the automatic «on the

field» offset correction and High Level

Input Signal correction

Key DP - Decimal Point Position

Key PROG - Allows the introduction of the

PROGRAMMING codes (4 digit

codes, as shown on page 4). These

codes, when validated, activate

different input signal modes, and

advanced configurations for alarms,

indication, etc.

«TIME» MESSAGE .- If while introducing a programming

code or while reconfiguring the unit parameters (such as

the alarm setpoints or others) the user does not interact

with the unit for a period of 5 seconds, the TAS-1 will show

the message «TIME», cancel the ongoing changes, and

roll-back to the previous configuration. This is a security

function which disables the situation where a unit would be

«hanged» for a long time waiting for the operator to finish a

programming.

THE TAS-1 UNITS ARE FULL Y CONFIGURABLE. The unit

is 100% configurable from the frontal keypad. The

programming software also allows an easy configuration

from a PC (PCConnection Cable needed).

OPTIONS .- This manual includes description and operating

instructions for the basic unit and the additional extra

options accepted. These options include Relay Output

Contacts, Analog Outputs, RS485 Outputs, Peak/Valley

memory, etc. If your instrument does not include these

options, they can easily be added.

SIGNAL INPUT RANGES .- To work with an input signal

range not indicated in this manual, select the closest input

signal range accepted, and change the input/indication

parameters with the code 14 1 1 (see later in this manual).

For example, to configure a 0/60 mV input coming from a

10 Amper shunt, we need to :

1.- select the 0/100 mV input signal range

2.- enter on code 14 1 1 for Editing Adjustments

3.- edit 0=0 and 60=10.000

If later on we need to change the 10.000 value for any other

value we can do it directly with the keypad HI.

User’s Manual Series TAS-1

FEMA ELECTRÓNICA - Page 4

Referencia Rápida

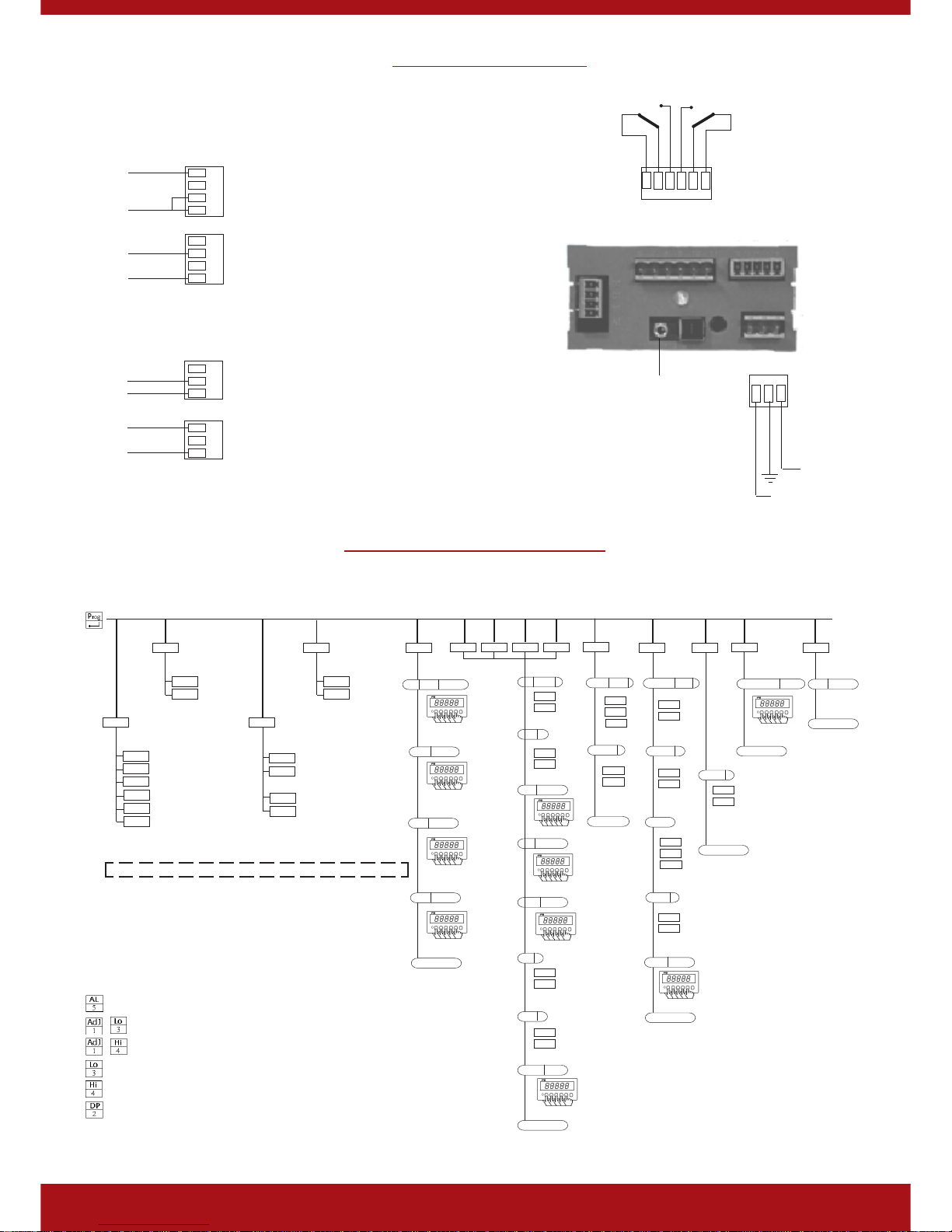

2.1- CONNECTIONS

Input Signal

Relay Outputs

NCNCNO

NO

COMON

COMON

Relay 1Relay 2

Connector for PC

Configuration

(PCConnector cable needed)

Phase (-)

Earth

Neutrum (+)

Power

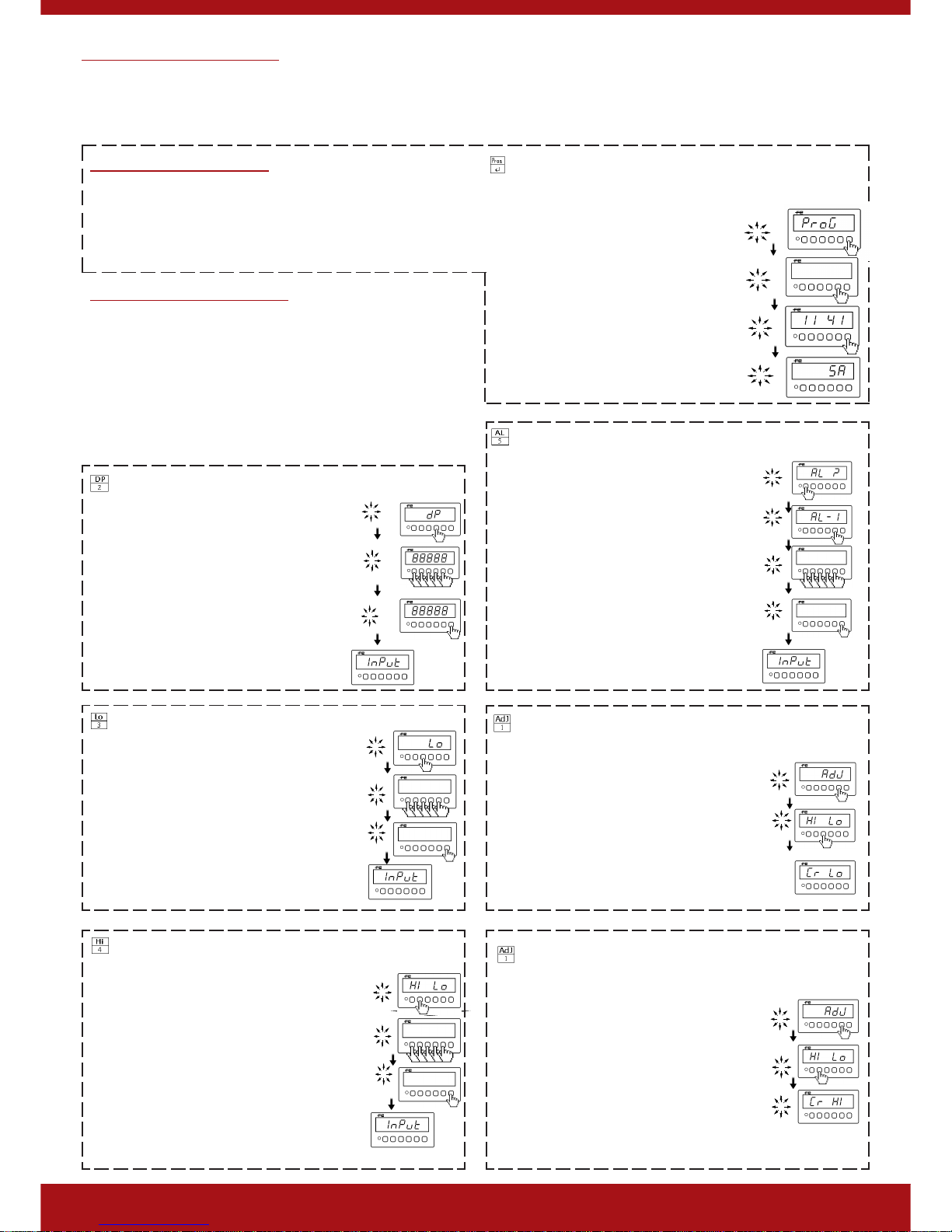

2.2- PROGRAMMING MENU

* IMPORTANT:

Before validating a PASSWORD with the

Keypad Blocking menu, remember the 5 digit

number you are about to enter. The instrument

will not accept any future order until the same

5 digit password is reintroduced.

Reset and Default

Parameters

↵↵

↵↵

↵

14 22

INPUT

Configuration : Direct Access

Adjusting the LOW Indication

Adjusting the HIGH Indication

Decimal Point Position

Alarm Setpoints

Correcting the LOW input signal

Correcting the HIGH input signal

Keypad

Blocking*

14 15 *

↵↵

↵↵

↵

↵↵

↵↵

↵

PASSWORD XXXX

INPUT

↵↵

↵↵

↵

DEF CONFR

Error

Treatment

↵↵

↵↵

↵

↵↵

↵↵

↵

14 14

INPUT

ONERR

OFF

ON

1

1

↵↵

↵↵

↵

Visualization

14 13

DISPLAY NULL

↵↵

↵↵

↵

LAST

1

1

ON

OFF

1

1

OFF

ON

↵↵

↵↵

↵

↵↵

↵↵

↵

3

2

1

FIL 2

FIL 3

FIL 1

FILT

ADQN

AVERA

REAL

1

1

↵↵

↵↵

↵

INPUT

↵↵

↵↵

↵

STEP XXXXX

Alarm 1

Alarm 2

Alarm 3

Alarm 4

13 11

↵↵

↵↵

↵

AL LO

AL HI

1

1

AL 1 ACTIU

↵↵

↵↵

↵

ON

OFF

1

1

13 14

13 12 13 13

↵↵

↵↵

↵

↵↵

↵↵

↵

HIST XXXXX

↵↵

↵↵

↵

DL1 XXXXX

↵↵

↵↵

↵

INV

DIR

1

1

↵↵

↵↵

↵

OFF

ON

1

1

↵↵

↵↵

↵

Editing

Adjustments

14 11

↵↵

↵↵

↵

EDIT IN LO XXXXX

↵↵

↵↵

↵

↵↵

↵↵

↵

DI LO XXXX

INPUT

↵↵

↵↵

↵

IN HI XXXXX

↵↵

↵↵

↵

DI HI XXXXX

1

1

LEFT

CENTR

RIGHT

↵↵

↵↵

↵

↵↵

↵↵

↵

↵↵

↵↵

↵

ALSET HIST

SMODE

ON

OFF

INPUT

Alarms:

Hysteresis and SM

13 15

1

2

3

TAS-1-VDC

11 XX

11 24

11 23

11 22

11 11

11 12

11 13

0/100Vdc

0/650Vdc

0/10Vdc

0/1Vdc

0/100mVdc

0/20mVdc

TAS-1-IDC

TAS-1-VAC

TAS-1-IAC

11 XX

11 35

11 33

0/100mAdc

0/5Adc

11 XX

650Vac

100Vac

100mVac

1Vac

11 32

11 31

11 15

11 14

11 XX

11 41

11 34

0/100mAac

0/5Aac

Input Signal Ranges

0/650 Vac

0/100 Vac

0/1 Vac

0/100 mVac

0/650 Vdc

0/100 Vdc

0/10 Vdc

0/1 Vdc

0/100 mVdc

0/20 mVdc

+

-

+

-

TAS-1-VDC TAS-1-VAC

0/100 mAdc 0/100 mAac

TAS-1-IDC TAS-1-IAC

0/5 Adc 0/5 Aac

+

-

+

-

TIPE

AL-1 XXXXX

LED

TEXT

STRING XXXX

INPUT

User’s Manual Series TAS-1

FEMA ELECTRÓNICA - Page 5

Section 3.1 shows how to enter a code to select an input

signal range. All codes are indicated on page 4.

3- CONFIGURATION

Examples in this page show how to configure a T AS-1-IAC unit

with an input signal of 0/5 Aac and indication 0/2500.0. All other

units and signal ranges follow the same procedures.

Allows to link a current signal at the input terminals

to the High Indication Value memorized on the HI

keypad.

1-Generate the high input level signal

2-Press Adjust Adj

The instrument asks «Hi» or «Lo» ?

3-Press Hi

4-Message «Cr Hi» shows the unit has corrected

the high level value, linking the current input signal

to the high indication value memorized (HI keypad)

1-Generate the low input level signal

2-Press Adjust Adj

The instrument asks «Hi» or «Lo» ?

3-Press Lo

4-Message «Cr Lo» shows the unit has corrected the

low level value, linking the current input signal value to

the low indication value memorized (LO keypad)

3.2.5-CORRECTING THE LOW INPUT SIGNAL (OFFSEET)

Allows offset correction, by linking the current input signal on

terminals to the Low Indication Value memorized.

V

V

1-Press Lo

2- Current value for the low indication is displayed.

Modify it by pressing on 1,2,3,4,5

until we see 00000

3-Validate the changes pressing

↵↵

↵↵

↵

message «INPUT» shows the configuration has been

accepted

3.2.2-ADJUSTING THE LOW INDICA TION V ALUE

For the low input level (0 Aac) we want to

configure a low indication of 0000.0

R

V

R

3.2.1- DECIMAL POINT POSITION

Activate the Decimal Point at position XXXX.X

1- Press DP

2- message «DP» during 1 second

Press 2 to fix decimal point position 2

(To fix at other positions, press 1,2,3,4 or 5)

3- Validate changes pressinf

↵↵

↵↵

↵

message «INPUT» shows the configuration has

been accepted

V

R

R

3.2.4- ALARM SETPOINTS

Fix the setpoint for Alarm1 at 10500

1-Press AL

2-Enter the number of the alarm we want to

modify 1

3-Current value for Alarm1 setpoint is displayed.

Modify it by pressing on 1,2,3,4,5

until we see 10500

4-Validate the changes pressing

↵↵

↵↵

↵

message «INPUT» shows the configuration has

been accepted

V

R

R

V

3.2- DIRECT ACCESS

The frontal keypad hasseveral direct access buttons for a

quick configuration of the instrument :

Pad 1 (ADJ) - Correct the LOW or HIGH input levels

Pad 2 (DP) - Decimal Point Position

Pad 3 (LO) - Set for the LOW indication level

Pad 4 (HI) - Set for the HIGH indication level

Pad 5 (AL) - Alarms Setpoint

CONFIGURING A 0/5 AAC INPUT SIGNAL RANGE

(Code 1 1 41 ; as shown on table on page 4, for a

T AS-1-AAC unit)

1- Press Prog

message «Prog» during 1 second

blank screen

2- Input the code 11 41

3- Validate the code pressing

↵↵

↵↵

↵

4- Message showing the selected range

«5 A» during 1 second

V

R

V

R

The T AS-1 units have several built-in predefined input signal

ranges, selectable with the help of codes (4 digit codes). On

page 4 there is a list of all accessible ranges and the codes

associated.

3.1- INPUT SIGNAL

V

V

V

3.2.6-CORRECTING THE HIGH INPUT SIGNAL

3.2.3- ADJUSTING THE HIGH INDICA TION V ALUE

For the high input level (5 Aac) we want to configure

a high indication of 2500.0

1-Press Hi

2- Current value for the high indication is displayed.

Modify it by pressing on 1,2,3,4,5

until we see 25000

3-Validate the changes pressing

↵↵

↵↵

↵

message «INPUT» shows the configuration has

been accepted

V

R

R

User’s Manual Series TAS-1

FEMA ELECTRÓNICA - Page 6

Input Code Message

0/650 Vdc 11 24

0/100 Vdc 11 23

0/10 Vdc 11 22

0/1 Vdc 11 11

0/100 mVdc 11 12

0/20 mVdc 11 13

4-ADVANCED CONFIGURATION

4.5- ALARM CONFIGURATION

4.2- INPUT SIGNAL : AC VOLTAGE

Codes : 11 XX

Menu : Hysteres and SM

Parameters configured on this menu apply to the 4 alarms

Input Code Message

0/650 Vac 11 32

0/100 Vac 11 31

0/1 Vac 11 14

0/100 mVac 11 15

The alarm configuration menu list several parameters to which we

must assign a value.

Numerical values are assigned with the number pads. Predefined

values (such as ON/OFF) are selected by selecting available

options with keys ‘1’, ‘2’ or ‘3’.

Validate with key ’

↵↵

↵↵

↵’ in order to access next parameter.

Hysteresis is applied to the

process of alarm deactivation*

Band alarm. Hysteresis is applied

to the process of alarm activation

and deactivation*

Hysteresis is applied to the

process of alarm activation.*

*The hysteresis points are defined on parameter HYST

for each alarm.

Security Mode activated on alarms

acting as «minimum»**

Securty Mode deactivated

**Output relay are inactive until the set point is

reached for the first time.

Parameters Values Function

Menu : Alarm Parameters

Alarm Number CODE Menu

Alarm 1 13 11 Alarm Parameters

Alarm 2 13 12 Alarm Parameters

Alarm 3 13 13 Alarm Parameters

Alarm 4 13 14 Alarm Parameters

General 13 15 Hysteresis and SM

Alarm1 working

Alarm1 not working

Alarm1 working as «maximum»

Alarm1 working as «minimum»

Setpoint for Alarm1

(expressed in display points)

Hysteresis value (max. 255)

(expressed in display points)

Delay on relay activation

(expressed in seconds)

Led is active when alarm is active

Led is active when alarm is inactive

Alarm text active

Alarm text inactive

Text associated with alarm led

Parameters Values Description

4.1- INPUT SIGNAL : DC VOLTAGE

Codes : 11 XX

4.3- INPUT SIGNAL : DC CURRENT

Codes : 11 XX

Input Code Message

0/5 Adc 11 35

0/100 mAdc 11 33

4.4- INPUT SIGNAL : AC CURRENT

Codes : 11 XX

Input Code Message

0/5 Aac 11 41

0/100 mAac 11 34

User’s Manual Series TAS-1

FEMA ELECTRÓNICA - Page 7

4.9- BLOCKING THE KEYPAD

Blocks the frontal keypad

Password is made of a numerical

value of 5 digits

Code : 14 15 Function :

Parameters Values Function

* More information on «what is an error», on section 4.7 «Messages

and errors»

4.8-ADVANCED CONFIGURATION

Parameters Values Function

No zeros active to the left

Zeros active to the left

Fixes the least significant digit to zero

Frees the least significant digit

Fast filter on the input signal : 0.25 Seg 98%

Medium filter on the input signal : 0.5 Seg 98%

Slow filter on the input signal: 1 Seg. 98%

Real time indication

Indication of mean values

Time (between 1 and 255 seconds) to calculate

mean values for mean indication

Code : 14 13 Function :

4.10-RESETTING THE SYSTEM. DEFAULT VALUES

4.6- MANUAL ADJUSTMENT

Parameters Values Function

number

number

number

number

Input Low - Low Input Signal

Display Low - Indication for Low Signal

Input High - High Input signal

Display High- Indication for High Signal

Code 14 11 can be used both to modify adjustments and to visualize

current values.

Code : 14 11 Function :

Code : 14 22 Function :

Resets the unit to the default manufacturing values. It is needed to

reconfirm the action by pressing INTRO after the message

Acquisition Mode Real

STEP Value 10

Zero Blanking ON

Least Significant Digit to zero OFF

Display Refresh Filter 2 (0.5 seg.)

Password deactivated

General Default Configuration

Setpoint Histeresis Delay Type Led Text String

Alarm 1 ON 1000 1 0 HI DIR OFF AL-1

Alarm 2 ON 1000 1 0 HI DIR OFF AL-2

Alarm 3 ON 1000 1 0 HI DIR OFF AL-3

Alarm 4 ON 1000 1 0 HI DIR OFF AL-4

Hysteresis CENTER

Security Mode ON

OnError OFF

Input Signal 0/100 VDC

Lo - Low Level Indication 0

HI - High Level Indication 100.00

Decimal Point 0 0 0.0 0

Default Configuration TAS-1-VDC

Input Signal 0/650 VAC

Lo - Low Level Indication 0

HI - High Level Indication 650.0

Decimal Point 0 0 0.0 0

Default Configuration TAS-1-VAC

Input Signal 0/5 ADC

Lo - Low Level Indication 0

HI - High Level Indication 5.000

Decimal Point 0 0.0 0 0

Configuration TAS-1-IDC

Input Signal 0/5 AAC

Lo - Low Level Indication 0

HI - High Level Indication 5.000

Decimal Point 0 0.0 0 0

Configuration TAS-1-IAC

4.7- DEALING WITH ERRORS

Activates all alarms in case of error

state *

Deactivates all alarms in case of error

state*

Code : 14 14 Function :

Parameters Values Function

User’s Manual Series TAS-1

FEMA ELECTRÓNICA - Page 8

4.11-MESSAGES AND ERRORS

5- CONFIGURING WITH A PC

TAS-1 units allow configuration from a PC. You need software SW-TAS1 and the cable PCConnector. Cable is connected to the rear side of the

instrument (stereo jack) and to the 9-pin SUB-D PC Port. Software installs

executable file TAS-1.exe

1.- Select com port. Press «START COMM»

2.- Configuration windows open

These windows contain all information on the unit. Meter and alarms are

shown on the main window. Additional options are shown in the small

window to the right.

To force a writing onto the device press WRITE_D. Some changes

already force a writing (such as changing the input signal), and ask for

a confirmation.

To force a configuration reading of the instrument press READ_D

To save/load configurations on your hard disk, use buttons SAVE_F /

READ_F. Note that the options (right windows) have their own

configuration file independent of the main instrument and so have their

own «SAVE T O FILE» / «LOAD FROM FILE» buttons.

Messages and errors are active when the instrument senses a «not

normal» situation . The instrument identifies the type of «anormality»

and informs with an error or with a message.

Messages

«Messages» are associated with non-critical situations, those

which only affect the measure temporary. The «message»

remains active on display until the situation clears. The

instrument recovers the normal working state when situation

clears.

Errors

«Errors» are associated with critical situtations which disable the

hability to measure the signal.

The «error» remains active on display until the situation disapears. At

this time, the instrument recovers normal functionality.

«Errors» execute actions on alarms, activating or deactivating them

depending on the status of variable OnErr (see page.11). Alarms

recover their normal behaviour when the the error state clears.

Internal Error. Restart the instrument.

** It is possible that no action is performed on alarms

if this error is affecting the internal EPROM

Mathematical Error 0

Parameters introduced for the input signal are not

coherent. (Typical case : the high level value is similar or

very close to low level value, on input signal range or

indication)

Mathematical Error 1: mathematical overflow.

The unit is trying to process values higher than 32000 or

lower than -32000.

COM Selection

«START COM» Button

«WRITE_D» Button

Forces writing

configuration

to the instrument

Options Configuration

Window

Signal/Display

adjustments

Input

Signal

Ranges

The input signal is lower than selected range

The input signal is higher than selected range

Security waiting time exceeded while in configuration

mode. The instrument rolls-back to the previous

configuration

Error when entering a data. Value not accepted.

Reintroduce the value. (Typical case : The value

assigned to hysteresis is higher than 255)

Error on Display Indication

Trying to display a value higher than 32000 or lower

than -19999. Reduce HI and LO levels dividing by

10.

User’s Manual Series TAS-1

FEMA ELECTRÓNICA - Page 9

6- TECHNICAL SPECIFICATIONS

INDICATION

Display 5 Digits, 7 Segments , Red Led High Brightness

Digit Height 14,2 mm. / 0,56’’

Filter Anti-reflexive.

Indication From - 19999 to 32000

Refresh 5 /seg. (Filter selectable)

A/D CONVERTER

Speed 14 Readings / Second

Accuracy 16 BIT + sign (± 65.000 points)

CMRR > 130 dB

POWER

Standard 230 Vac 50/60 Hz. Consumption 3,5W Max

Optional 115 Vac 50/60Hz. Consumption 3.8W Max

Optional 24 Vdc (±10%) isolated. Consumption 4W Max

Isolation 1000 Vdc (Primary - Secondary)

Maximum consumption at 24 Vdc .- 265 mA

Peak current at start-up <600mA

UNIT T AS-1-VDC

Input Signal Ranges 0/650 Vdc, 0/100 Vdc, 0/10 Vdc

0/1Vdc, 0/100 mVdc, 0/20 mVdc

Note .- Although not mentioned above, the unit accepts any signal range

between 0/20mV and 0/650Vdc, including 60mV, 100mV y150mV shunt

signals. For these ranges. select the closest range and readjust with code

14 11

Accuracy 0,1% from reading ± 1 point

Thermal Drift ± 100 ppm/ºC

Input impedance 1 MOhm for Vin>1Vdc

5 MOhm for Vin<1Vdc

Effective Resolution 32.000 points

UNIT T AS-1-V AC

Input Signal Ranges 0/650 Vac, 0/100 Vac

0/1 Vac, 0/100 mVac

Note .- Although not mentioned above, the unit accepts any signal range

between 0/20mVac and 0/650Vac, including 60mV, 100mV y150mV shunt

signals. For these ranges. select the closest range and readjust with code

14 11

Accuracy 0,3% of reading ± 1 point

Thermal Drift ± 150 ppm/ºC

Input impedance 1 MOhm for Vin>1Vdc

5 MOhm for Vin<1Vdc

Effective Resolution 32.000 points

ENVIRONMENTA L DA T A

Working Temperature 0 ... + 50 ºC

Storage Temperature -20 ... + 85 ºC

Humidity 0 ... 85%, non condensaded

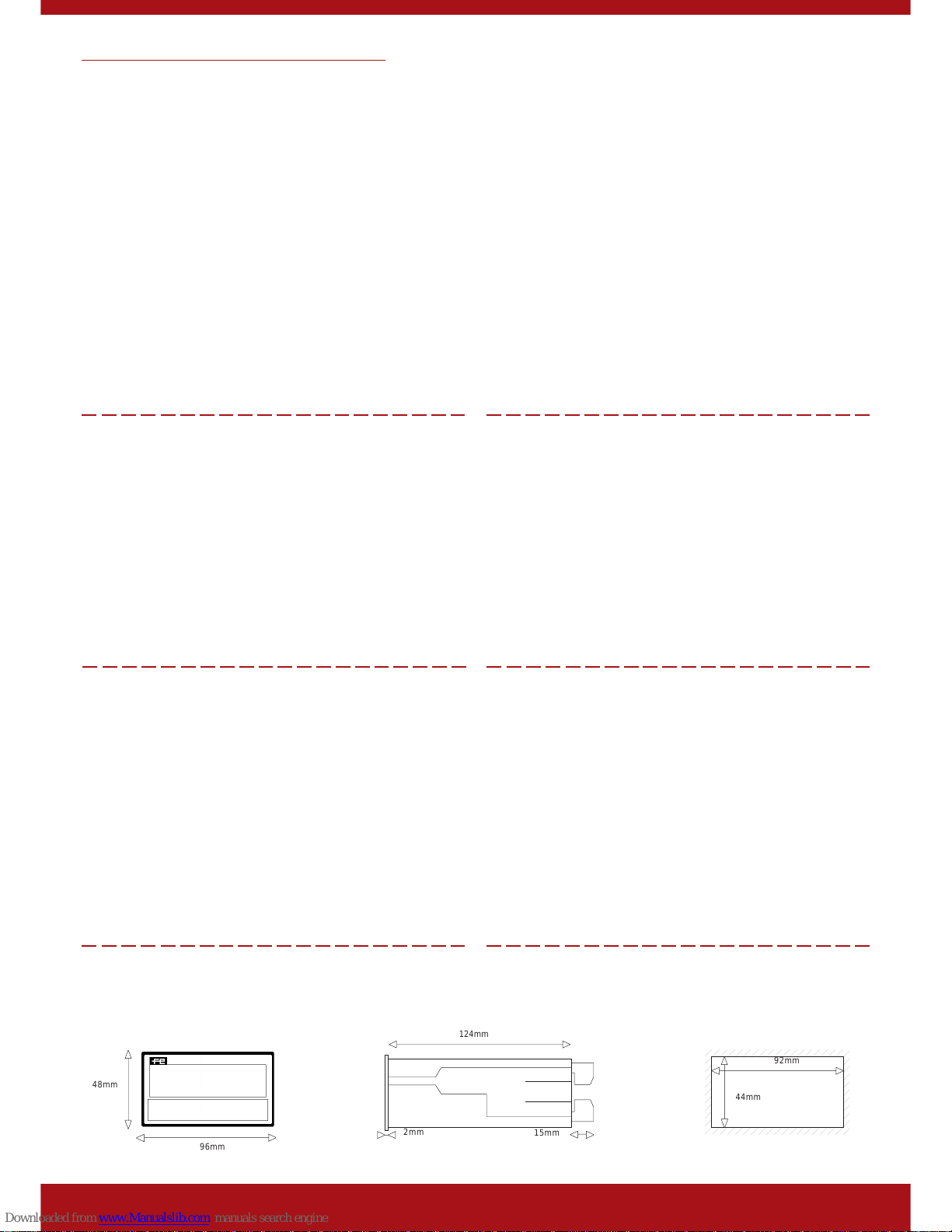

MECAHNICAL DA T A

Dimensions Standard 1/8 DIN

96 x 48 x 124 mm. (3,78" x 1.89" x 4,88")

Front Protection IP65 (NEMA 4)

Weight 0,5 Kgs

ALARMS AND RELAYS (OPTION AL2)

4 alarms on display. Alarms 1 and 2 can control Relays 1 y 2 (Option AL2)

2 Relays ON/OFF 2 A. (non inductive), 250 Vac

Note .- AL2 option not mounted on standard units

ANALÓG OUTPUT Technical data see page 10

RS485 MODBUS OUTPUT Technical data see page 12

PEAK / VALLEY, ETC OPTION Technical data see page 14

UNIT T AS-1-IDC

Input Signal Ranges 0/5 Adc

0/100 mAdc

Note .- Although not mentioned above, the unit accepts any signal range

between 0/100mA and 0/5 Adc. For these ranges. select the closest range

and readjust with code 14 11

Accuracy 0,1% of reading ± 1 point

Thermal Drift ± 150 ppm/ºC

Input impedance 0.02 Ohm for I>100mA

1 Ohm for I<100mA

Effective Resolution 32.000 points

UNIT T AS-1-IAC

Input Signal Ranges 0/5 Aac

0/100 mAac

Note .- Although not mentioned above, the unit accepts any signal range

between 0/100mAac and 0/5 Aac, including X/5 and X/1 Current T ransformer

signals. For these ranges. select the closest range and readjust with code

14 11

Accuracy 0,3% of reading ± 1 point

Thermal Drift ± 200 ppm/ºC

Input impedance 0.02 Ohm for I>100mA

1 Ohm for I<100mA

Effective Resolution 32.000 points

SIZES AND P ANEL CUT-OUT

1234567890123456789

1

23456789012345678

9

1

23456789012345678

9

1

23456789012345678

9

1

23456789012345678

9

1

23456789012345678

9

1

23456789012345678

9

1

23456789012345678

9

1

23456789012345678

9

1

23456789012345678

9

1

23456789012345678

9

1234567890123456789

92mm

44mm

124mm

2mm

15mm

96mm

48mm

User’s Manual Series TAS-1

FEMA ELECTRÓNICA - Page 10

The TSAT board adds analog output capabilities to the TAS-1

instruments. Jumper selectable for voltage ( 0/10 Vdc) and for

current (4/20mA and 0/20mA in modes SINK and SOURCE) adds

a galvanic isolation of 2KVef f.

The analog output adjustment is done via the frontal keypad. The

analog output value is adjusted related to the display indication.

This allows the intelligent use of the correction functions for offsets

and fast readjustment of the TAS-1 series, meaning that when

7.1.3- START-UP

1.- Place jumpers on TSA T board for Vdc or mA output

2.- Plug the TSA T board on the bus pins (Expansion Bus) on

board AL2 or EXP

3.- T o configure the analog output you need to know the analog

output signal and the related display indication

Input Signal Indication Analog Output

4 mA 0 0 Vdc (00000 miliVots)

20 mA 100.00 10 Vdc (10000 miliVolts)

7- AVAILABLE OPTIONS - INSTALLING AND CONFIGURING

7.1- ANALOG OUTPUT - TSAT OPTION BOARD

readjusting the input/display readings, the analog output

does not need to be readjusted most of the times.

in case of trouble with the input signal, such as loop

break or sensor break, the analog output signal will

exhibit always the same behaviour predefined by the

operator on the menu.

7.1.1- CONNECTIONS

Voltage Output .- T erminal 12 (Negative)

T erminal 13 (Positive)

Current Output .- T erminal 13 (Negative)

(Source = Active) T erminal 14 (Positive)

Current Output .- T erminal 12 (Negative)

(Sink=Pasive needs T erminal 13 (Positive)

external power supply)

R

l

-

+

Terminal 12

Terminal 13

Rl

+

-

Vext

Terminal 12

Terminal 13

7.1.2- TECHNICAL CHARACTERISTICS

Output Signals 0/10 Vdc, 0/20 mA and 4/20 mA (and others)

Resolution 12 bits

Accuracy <0.1% FS

Ripple <0.01% FS

Thermal Drift 100 ppm/ºC

Pass Band 1.5 Hz (-3 dB)

Response Time 250 ms (99% of indication)

Isolation Levels 2KVeff (50 Hz, 1 minute)

mA Output RLmax 500 Ohms (Source Mode)

Imax 21.5 mA aprox.

SINK Outputmaximum 40Vdc on terminals

Vdc Output RL min 1 KOhm

Vmax 11 Vdc aprox.

R

l

-

+

Terminal 13

Terminal 14

T erminal 12

T erminal 13

T erminal 14

Jumpers to the left.Output in Vdc

Jumpers to the right.Output in mA

Note .- Analog output units are entered with 3 decimals, this

is, in miliV olt s and microAmperes.

4.- Make connections, power the unit and configure the board

(see next page)

User’s Manual Series TAS-1

FEMA ELECTRÓNICA - Page 11

7.1.4- CONFIGURING THE ANALOG OUTPUT

Entering the Menu

Introduce the programming code «55 11»

Message «IC ANG» Analog Output board recognized

Message «MENU» Entering the programming menu

Message «4_20» or «0 10» Shows the operating mode selected by jumpers

(Vdc or mA)

Adjusting the Analog Output

*Note .- The values for the following 4 parameter are setable using keys 1,2,3,4,5

Parameter «d_LO» (Display Low)

Display value associated with the low level analog

output

Parameter «o_LO» Output Low

Analog output value associated with the «d_LO»

value *

Parameter «d_HI» Display High

Display value associated with the high level

analog output

Parameter «o_HI» Output High

Analog output value associated with the «d_HI»

value*

Note .- values for «d_LO» and «d_HI» are in microVolts or microAmperes

Behaviour when Error

Parameter «OnErr» .- Behaviour of the analog output when an «error»

occurs (section 4.11 describes «errors»)

«DIR» - Analog Output rises up to Full Scale (11Vdc or

21mA aprox)

«INV» .- Analog Output sinks down to zero ( -0.5 Vdc or

0mA aprox)

Exiting the Menu

Mesage «INPUT» Confirms that the parameters have been accepted

Message «ERROR» Informs that at least one of the values is not

correct, and the whole configuration could not

be applied. Repeat the process from the begining.

7.2- INST ALLING THE OPTION BOARDS

The Option Boards are inserted onto the vertical pins of the Expansion

Modules. These modules are AL2 or EXP.

Note .- Both AL2 and EXP are optional themselves and are not included in the

standard units

The board has to be firmly inserted onto the vertical pins of the expansion

module. Once inserted, reconnect the expansion module to the frontal of the instrument and insert the whole into the box.

The instrument automatically recognizes the pressence of an inserted

board.

Note1 : The expansion module is included with those instruments TAS-1 with the

AL2 option built in or the EXP option. The AL2 or the EXP modules can be also added

to those instruments who were acquired without any of these two options.

Note2 : The TEK board can share the expansion bus with the TSAT option of with

the R485M option, or can be directly connected to the bus alone.

Nota3 : Boards TSAT for Analog Output and R485M for Modbus output can not be

integrated simultaneously on the same instrument.

Módulo de Expansión

Option Board (Analog Output,

Modbus or TEK)

Expansion Module

55 11

4_20 ó 0_10

- - - - - - IC ANG Menu

↵↵

↵↵

↵

o_LO

d_LO

d_HI

o_HI

↵↵

↵↵

↵

1

DIR

2

INV

INPUT or ERROR

onErr

IC_OFF

↵↵

↵↵

↵

↵↵

↵↵

↵

↵↵

↵↵

↵

↵↵

↵↵

↵

User’s Manual Series TAS-1

FEMA ELECTRÓNICA - Page 12

The R485M board adds Modbus communication capabilities

to the TAS-1 units, for retransmission of visualized data to a

remote element. The board is isolated and is completely

configurable from frontal keypad.

Protocols ModBus RTU and ModBus ASCII selectable

Bus RS485 Half Duplex (EIA-RS485)

shielded twisted pair cable, in line,

closed with terminator

Speed 2400, 4800, 9600, 19200, 38400 bauds

Addresses from 0 to 99

Distances 1200 meters per BUS segment

4800 meters with repeaters

Isolation 2 KV with inputsignal

3.5 KV with power signal

7.3- MODBUS OUTPUT - R485M OPTION BOARD

↵↵

↵↵

↵

Prot

1

M Asc

Bauds

↵↵

↵↵

↵

↵↵

↵↵

↵

Dir

2

M rtu

1

2400

2

4800

3

9600

4

19200

5

38400

n bit

↵↵

↵↵

↵

1

8 bit

2

7 bit

55 11

- - - - - - IC 485 Menu

↵↵

↵↵

↵

Input IC OFF

t Par

↵↵

↵↵

↵

1

n Par

2

Even

3

Odd

Note2 : The length of all registers is 2 bytes, defined as LSB and MSB.

MSB (Most Significant Byte) is the first to be transmitted

LSB (Least Significant Byte) us the second to be transmitted

7.3.2- ACCEPTED FUNCTIONS

04 Hex Registry read («Input Register» on the standard)

7.3.3- REGISTER MAP

00 00 Hex Display V alue

T ype : Integer

V alue : from -32768 to 32767

00 01 Hex Decimal Point Position

T ype : Integer

Value : 0, 1, 2, 3 or 4

00 02 Hex Status

T ype : Integer

Word composed of 1+4 bits

b0=0 Value contained on register 00 00H is an indication (number)

b0=1 Value contained on register 00 00H is not an indication

Word b4,b3,b2,b1

0.- Reserved 3.- +Ovr 6.- Con 9.- MErr1 12.- Reserved 15.- Others

1.- Low 4.- DErr0 7.- Open 10.- Reserved 13.- Reserved

2.- -Ovr 5.- Brk 8.- MErro0 11.- Reserved 14.- Reserved

00 03 Hex Alarms

T ype : Integer

b0=0 AL1 in OFF state b2=0 AL3 in OFF state

b0=1 AL1 in ON state b2=1 AL3 in ON state

b1=0 AL2 in OFF state b3=0 AL4 in OFF state

b1=1 AL2 in ON state b3=1 AL4 in ON state

Note1 : If there is no numeric value on display (but a text value), register

0000Hex offers value 32767 or -32768. And bit b0 of register 0002Hex

show the display status.

0 = no decimal 2 = 2 digits decimal 4=4 digits decimal

1 = 1 digit decimal 3 = 3 digits decimal 5=5 digits decimal

Not Used b3 b2 b1 b0

Not Used b4 b3 b2 b1 b0

Introduce te programming code «55 1 1»

Message «IC 485» RS485 board recognized

Message «MENU» Entering the programming menu

Parameter «PROT» Protocol

Select Modbus ASCII or Modbus RT U

Parameter «DIR» Address

Input instrument address

Parameter «BAUDS» Speed in Bauds

Parameter «n BIT» Number of Bits

Select 8 or 7 bits per character

Parameter «t P AR» Parity

«Even» «Odd» «nPar»

Message «INPUT» .- confirms that the parameters have been

accepted

Message «ERROR» .- informs that at least one of the values

is not correct, and the whole configuration could not be applied.

Repeat the process from the begining.

7.3.1- CONFIGURATION

User’s Manual Series TAS-1

FEMA ELECTRÓNICA - Page 13

7.3.6- CHARACTER STRUCTURE

Bit structure for the characters on protocolos ModBus RTU and ModBus ASCII

7.3.7- MODBUS FRAME STRUCTURE-II

7.3.5- MODBUS FRAME STRUCTURE-I

T1 = Time between two characters

T2 = Time between end of question and start of response

T3 = Time between end of responde and start of next question

7.3.4- CONNECTIONS AND BUS TERMINATOR

RESPONSE : Communication SLAVE to MASTER

ADDRESS 1 CARACTER Instrument Address

FUNCTION 1 CARACTER Function 04H, register read

LENGTH 1 CARACTER Number of data characters following

DATA X CARACTERES Response data*

CR C 2 CARACTERES Control Checksum

QUESTION : Communicacion MASTER and SLAVE

ADDRESS 1 CHARACTER Instrument Address

FUNCTION 1 CHARACTER Function 04H, register read

READING START REGISTER 2 CHARACTERS Register 00 00H = Display Value

NUMBER OF REGISTERS TO READ X CHARACTERS 02 = 2 registers (4 bytes)

CR C 2 CHARACTERS Control Checksum

ST ART DATA PARITYSTOP TOTAL BITS

RTU18P111

18I 111

18--211

ASCII 1 7 P 1 10

17I 110

17--210

T2 MAX

(RTU and ASCII)

38400 4.3 mSeg

19200 5.7 mSeg

9600 9.2 mSeg

4800 15.5 mSeg

2400 27 mSeg

T1 (min/max)

R T U 0CT / 3CT

ASCII 0CT / ---

T3 (min/max)

RTU 3.5CT / -ASCII --- / ---

Conections .- Cables A

and B as Standard

Modbus

Terminator .- Place jumper

if the BUS ends on this

instrument

Example for a Modbus-RTU frame .- Start Character corresponds with instrument address and final character

corresponds with the CRC Security Code

In Modbus-ASCII Start and End characters are specífic

T erminal 13 A

T erminal 14 B

User’s Manual Series TAS-1

FEMA ELECTRÓNICA - Page 14

The TEK option adds functions for PEAK/V ALLEY memory , or

remote T ARE or remote HOLD to the instruments T AS-1. These

functions are selectable and programmable from frontal keypad,

and are activated connecting two external contacts to the rear

7.4.1- AVAILABLE FUNCTIONS

Functions PEAK, VALLEY, HOLD, T ARE, RESET

T erminals 2 Terminals for 2 Free Potential Contacts

1 Function for each contact

Contact1 PEAK or VALLEY or HOLD or T ARE or RESET

configurable from frontal keypad

Contact2 PEAK or VALLEY or HOLD configurable from

frontal keypad

Contact12 RESET . This function is fixed and is activated

when closing both contacts at same time.

Isolation 2KV to the input signal

3K5V to the power 230Vac and 1 15V ac

1KV to the power 24Vdc

7.4.3- TEK CONFIGURATION

Default Configuration

When entering code «14 22» to apply a unit reset, the TEK option is

configured as follows :

STATE FUNCTION

CONTROL 1 OFF HOLD

CONTROL 2 OFF HOLD

CONTROL12 OFF

Entering the Menu

Introduce the programming code «14 23»

Message «E INP» TEK board recognized

Configuring the external contacts

Parameter «INP_1» Contact 1

ON Active

OFF Not Active

Parameter «FUN_T» Function assigned to Contact1

Parameter «INP_2» Contact 2

ON Active

OFF Nor Active

Parameter «FUN_T» Function assigned to Contact2

Parameter «RES12» RESET12

Function «Reset» when connecting

contacts 1 and 2 simultaneously

ON Active

OFF Nor Active

Exiting the Menu

Mesage «INPUT» .- confirms that the parameters have been accepted

Message «ERROR» .- informs that at least one of the values is not correct,

and the whole configuration could not be applied. Repeat the process from the

begining.

7.4.2- CONNECTIONS

Terminal 12 .- COMMON

Terminal 15 .- CONTACT1

Terminal 16 .- CONTACT2

7.4- PEAK, VALLEY, HOLD, TARE, RESET- OPTIÓN TEK

T erminal 15

T erminal 16

T erminal 12

side terminals. Each contact has assigned one function (which

can be changed) plus a third function associated to both

contacts closing at the same time, to release a RESET for

PEAK/V ALLEY memory . Isolated option.

14 23

E INP

↵↵

↵↵

↵

INP_1

FUN_T

FUN_T

RES12

↵↵

↵↵

↵

1

ON

2

OFF

INP_2

↵↵

↵↵

↵

1

ON

2

OFF

↵↵

↵↵

↵

1

HOLD

2

MMIN

3

MMAX

4

RESET

5

TARE

↵↵

↵↵

↵

1

ON

2

OFF

↵↵

↵↵

↵

1

HOLD

2

MMIN

3

MMAX

INPUT o ERROR

User’s Manual Series TAS-1

FEMA ELECTRÓNICA - Page 15

WARRANTY.

FEMA ELECTRÓNICA, S.A. warrants this product free of manufacture

defects for two years from the date of shipment.

This Warranty is VOID if the unit shows evidence of damages as a result

of misapplication, accident, misuse or if the product has been tampered

or repaired by personnel or companies without the official authorization

of FEMA ELECTRÓNICA, S.A. This Warranty is VOID also for damages

caused by defective or inappropriate applications.

During the warranty FEMA ELECTRONICA, S.A. will repair or replace at

its own discretion the material which results to be faulty.

Attach with the material a copy of the invoice and delivery note, with a

description of the malfunction, and ship it free of charge and properly

packed to your local distributor or to the following address

FEMA ELECTRONICA, S.A.

Altimira 14 (Talleres-14, Nave-2)

P.I. Santiga

P.O. Box 49

E 08210 BARBERÀ DEL VALLÈS

BARCELONA (SPAIN)

LIMITATION OF LIABILITY

FEMA ELECTRONICA, S.A. shall not be responsible for any damage

or loss to other equipment however caused, which may be experienced as a result of the installation or use of this product.

FEMA ELECTRONICA, S.A. liability shall not exceed the purchase

price paid of the product upon which liability is based. In no event

shall FEMA ELECTRONICA, S.A. be liable for consequential, incidental or special damages.

Manufactured by : FEMA ELECTRONICA, S.A.

Address : P.I. Santiga

Altimira 14 (Talleres-14, Nave-2)

08210- Barberà del Vallès (Barcelona-Spain)

Declares that the equipment complies with the following technical specifications.

Product : TAS-1-TP, TAS-1-VDC, TAS-1-VAC, TAS-1-IDC,

TAS-1-IAC

DIRECTIVES

EUROPEAN DIRECTIVE FOR LOW VOLTAGE D73/23/CEE AMENDED BY D93/68/CEE.

Equipments powered from 50 to 1000 Vac. and /or from 75 to 1500 Vdc.

EUROPEAN DIRECTIVE FOR PRODUCT SAFETY D92/59/CEE.

ELECTROTECHNICAL REGULATION FOR LOW VOLTAGE (RBT) ITC 21, ITC

29, ITC 35. For equipments with power supply lower than 50 Vac and/or 75 Vdc.

EUROPEAN DIRECTIVE FOR ELECTROMAGNETIC COMPATIBILITY D89/336/

CEE AMENDED BY D93/68/CEE, ACCORDING TO RD1950/1995 (Dec.1st).

REGULATIONS

ELECTRICAL SECURITY: EN 61010-1

SUCEPTIBILITY: EN 50082-2

IEC 1000-4-2, EN 61000-4-2, IEC 801-2

ENV 50140, EN 61000-4-4, IEC 801-4 (level 3)

ENV 50141, IEC 801-3 (level 3)

ENV 50204 (level 3)

EMISSION: EN 50081-2.

EN 55011, EN 55014, EN 55022

UNE 21352-76: CEI 359-71.

Operating quality expressions for electronic equipments.

UNE 20652-80: CEI 284-68.

Behaviour rules inherent to the handling of electronic equipments and other similar technics.

FEMA ELECTRONICA, S.A.

Barberà del Vallès, 2000

DECLARATION OF CONFORMITY CE

INSTALLATION

PRECAUTIONS.- Installation and use of this unit must be done by qualified

operators. The unit has not AC (mains) switch, neither internal protection

fuse, and it will be in operation as soon as power is

connected. The installation must contain an external

mains switch with protection fuse plus the necessary

devices to protect the operator and the process when

using the unit to control a machine or process where

injury to personnel or damage to equipment or process may occur as a result

of failure of the unit.

External Protection Fuse to be added :

for 230 Vac : 80mA fuse TimeLag as IEC 127/2

for 115 Vac : 125mA fuse TimeLag as IEC 127/2

SAFETY PRESCRIPTIONS.- These instruments have been designed and

tested according to EN-61010-1 rules and are delivered in good

operational conditions. This user manual contains useful information for electrical connections. Do not make wiring signal changes

or connections when power is applied to the unit. Make signal

connections before power is applied and, if reconnection is required,

disconnect the AC (mains) power before such wiring is attempted. Install

the unit in a place with good ventilation to avoid excessive heating, and far

from electrical noise sources or magnetic field generators such as power

relays, electrical motors, speed controls etc...

The unit cannot be installed in open places. Do not use until the installation

is finished.

POWER SUPPLY.- The power supply must be connected to the adequate

terminals (see connection instructions). Characteristics of the power

supply are showed on the characteristics label attached to the instrument.

Please make sure the unit is correctly connected to a power supply of the

correct voltage and frequency. Do not use other power supply otherwise

permanent damage may be caused to the unit. Do not connect the unit to

power sources heavily loaded or to circuits which power loads in cycle ONOFF or to circuits which power inductive loads.

WARNING.- On units with DC power supply, be careful with the polarity

indicated for each terminal.

SIGNAL WIRING.- Certain considerations must be given when installing the

signal input wires. Long wires can act like an antenna and introduce

electrical noise to the unit, therefore :

Do not install the signal input wires in the same conduct with power lines,

heaters, solenoids, SCR controls etc...and always far from these elements.

When shielded wires are used, leave unconnected the shield on the

indicator side and connect the other end of the shield to the ground terminal

of the machine.

SAFETY CONSIDERATIONS

PRESCRIPTIONS.- Before starting any operation of adjustment,

replacement, maintenance or repair, the unit must be disconnected from

any kind of power supply.

Keep the unit clean , to assure good functioning and

performance. To prevent electrical or fire hazard, do not

expose the unit to excessive moisture. Do not operate

the unit in the presence of flammable gases or fumes,

such as environment constitutes a definite safety hazard. The unit is

designed to be mounted on a panel.

If the unit shows signs of damage, or is not able to show the expected

measures, or has been stored in a bad conditions or a protection failure can

occur, then do not attempt to operate and keep the unit out of service.

IN CASE OF FIRE

IN CASE OF FIRE

1.- Disconnect the unit from the power supply.

2.- Give the alarm according to the local rules.

3.- Switch off all the air conditioning devices.

4.- Attack the fire with carbonic snow, do not use

water in any case.

WARNING : In closed areas do not use systems with vaporized liquids.

FEMA ELECTRÓNICA - Page 16

SIGNAL CONVERTERS - ISOLATED

AC ELECTRICAL SIGNALS

DC ELECTRICAL SIGNALS

TEMPERATURES

LOADCELLS

PROCESS SIGNALS

INTEGRATORS ANALOG / FREQUENCY

FREQUENCY SIGNALS

LARGE DISPLA YS

COUNTERS

PROCESS SIGNALS

TEMPERATURES

TACHOMETERS

SERIAL RS REPEATERS

CLOCKS

CHRONOMETERS

P ANEL METERS

AC ELECTRICAL SIGNALS

DC ELECTRICAL SIGNALS

TEMPERATURES

LOADCELLS

PROCESS SIGNALS

TACHOMETERS

COUNTERS

Pol. Ind. Santiga • Altimira, 14 (T14 - N2) • P.O. Box 49

E-08210 BARBERÀ DEL VALLÈS (Barcelona) España

info@fema.es • www.fema.es

• Tel. (+34) 93 729 6004 •

• Fax (+34) 93 729 6003 •

F3108/04

r3108/04

DISTRIBUTED BY :

Loading...

Loading...