® U.S Registered Trademark

Copyright © 2007 Honeywell Inc. • All Rights Reserved MU2B-0328GE51 R0207A

Smart DCM/SN

ELECTRONIC PRESSURE SWITCHES AND TRANSMITTERS

OPERATING INSTRUCTIONS

GENERAL

Honeywell FEMA's Smart DCM Electronic Pressure Switches

and Smart SN Electronic Pressure Transmitters are microprocessor-controlled pressure measurement devices for

relative pressure measurements (-1…+1 bar / 0…40 bar).

With their high-performance stainless steel sensor material,

they are suitable for a wide range of liquid media or gases in

industrial applications. They are screwed (G1/2”) directly into

the line / vessel to be monitored.

BEFORE PROCEEDING!

VALIDITY

These Operating Instructions pertain to measuring systems

containing Smart SN Pressure Transmitters / DCM Pressure

Switches. Device software must be version 1.30 or higher.

QUALIFIED PERSONNEL AND USAGE

Use only these Operating Instructions (and the corresponding

Mounting Instructions) to set up and operate the device. Only

qualified personnel are permitted to install, commission,

operate, and maintain the device. This device may be used

only in applications and under operating conditions described

in these Operating Instructions.

TECHNICAL DATA

Materials

Parts contacting medium Stainless steel (1.4571)

Chemical resistance 4C4 as per EN 60721-3-4

HMI PA66 GF25

Total weight 300 g without, 350 g with HMI

Ambient (operating) temperature and humidity

Versions (non-HMI) -20...+80 °C

Versions (HMI) -20...+70 °C

Humidity 0...95% r.h., non-condensing

Temperature of medium -30...+100 °C (≤ 16 bar models)

-40...+100 °C (> 16 bar models)

Storage temperature

Versions (non-HMI) -40...+80 °C (≤ 16 bar)

-40...+100 °C (> 16 bar)

Versions (HMI) -30...+80 °C

Climate class

Indoors 4K4H as per EN 60721-3-4

Outdoors 3K8H as per EN 60721-3-3

Mechanical stability

Vibration 20 g as per IEC 68-2-6 (up to

2000 Hz)

Mechanical shock 100 g as per IEC 68-2-27

Device resistance / accuracy (combined non-linearity,

hysteresis, and repeatability at 20 °C)

P ≤ 16 bar P > 16 bar

overpressure safety 2x P

nominal

2x P

nominal

burst pressure 4x P

nominal

10x P

nominal

sensor type piezo thin-film

accuracy

max. ±0.8% FS

±0.5% FS (typ.)

max. ±1% FS

±0.6% FS (typ.)

Pressure meas. range 0…40 bar (rel.), -1…1 bar (vac.)

Cycle time 100 ms

EMC according to EN 61326

Protection class 2 as per EN 61010

Protection rating (non-HMI) IP67 as per EN 60529-2

Protection rating (HMI) IP65 as per EN 60529-2

Process connection G1/2" external thread

Electrical connection 4-prong A-coded M12x1 plug

Switch

Output, high level V

SUPPLY

minus 2 V (min.)

Output, low level GND plus 0.5 V (max.)

Reaction time max. 300 ms

WARN output voltage passive: V

SUPPLY

- 2 V

active: ≤ 0.5 V

Transmitter (analog) output

Current (2-wire) 4…20 mA

Voltage / current (3-wire) 0/2...10 V, 0/4...20 mA

V

SUPPLY

(2-wire) 18…35 Vdc

V

SUPPLY

(3-wire) 18…35 Vdc, 24 Vac +10%/-20%,

max. 50 mA

Current output (max. load) (V

SUPPLY

- 16 V) / 22 mA

(max. error ±0.25% FS)

Voltage output (min. load) 15 kΩ (max. error ±0.25% FS)

Transient response approx. 200 ms

Span, offset, and long-term drift (within temperature

compensation range of 0…80 °C)

max. typical

temp. effect on span ±0.3% FS / 10 K ±0.2% FS / 10 K

temp. effect on offset ±0.3% FS / 10 K ±0.2% FS / 10 K

long-term drift* ±0.3% FS / year ±0.2% FS / year

SMART DCM SWITCH – OPERATING INSTRUCTIONS

MU2B-0328GE51 R0207A

2

DCM SWITCH

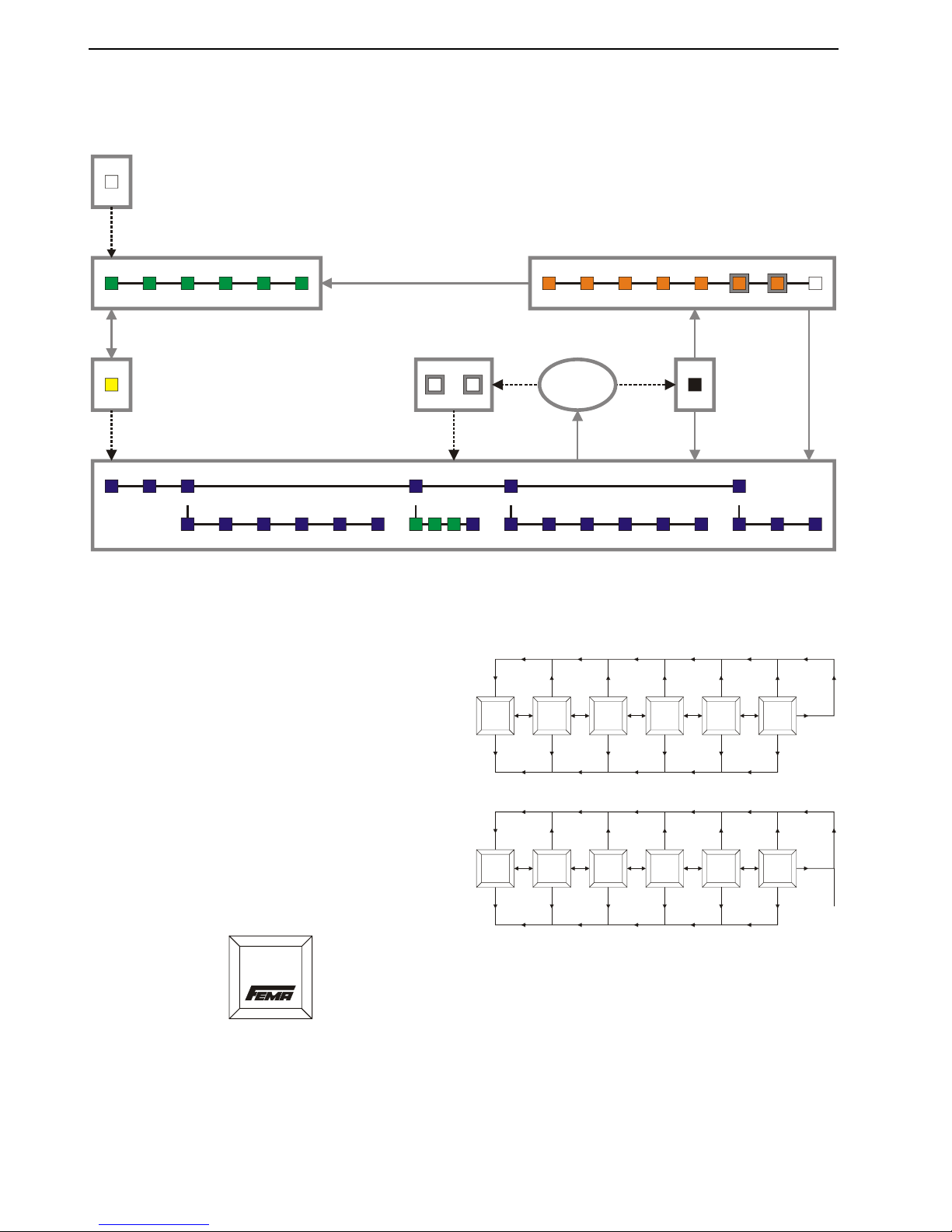

SEQUENCE OF SCREENS

MONITOR FUNCTION

OUTPUTSET-PT RESET-PT

AUTO-0 SET ZERO RESET 0

PRESSURE,

STATE

SET-PT.

WELCOME

RESET-PT. MONITOR FUNCTION DROP-IN DROP-OUT

MESSAGE MESSAGE

DROP-IN DROP-OUT

PEAKS

UNIT LANGUAGE BACKLIGHT REFRESH ROTATE CONTRAST

DISPLAY

CLEARMIN. MAX. TEMP. SIMUL. SET CODE RESET

EXTRAS

ENTER

CODE

GO TO

CONFIRM

A

LL

SETTINGS

PLAUSIBLE

?

NO

Y

ES

SET-PT. RESET-PT. MONITOR F UNCTION DROP-IN DROP-OUT CODE SIMUL. STORING...

DISPLAY LEVEL

PARAMETRIZATION LEVEL

CODE

ERROR

START

CONFIRMATION LEVEL

Fig. 1. Sequence of screens - Overview (DCM)

Devices equipped with an HMI (Human-Machine-Interface)

feature pushbuttons and a display, allowing easy

configuration by means of a menu structure. The menu

structure is divided into the following segments:

• The START SCREEN;

• The DISPLAY LEVEL (where information including the

current pressure and parameterized values are shown but

cannot be edited);

• The CODE area (where you will have to enter the correct

four-digit CODE in order to proceed any further);

• The PARAMETRIZATION LEVEL (where you can edit

various different parameters);

• A ERROR-CHECKING area (where the device will check

the plausibility of your values and, if necessary, redirect

you back to the PARAMETRIZATION LEVEL); and

• The CONFIRMATION LEVEL (where you can review your

edited values before permanently storing them).

START SCREEN

Within 10 seconds of powering-up the device, an initial screen

– the START SCREEN - will appear briefly (see Fig. 2).

Startup

Fig. 2. Start screen

You will then be automatically directed to the DISPLAY

LEVEL.

DISPLAY LEVEL

In the DISPLAY LEVEL, you can view the current pressure as

well as the various different user-settings currently in force.

Reset-pt.

Monitor Function

Drop in

delay

0s

Drop

out delay

0s

4.00bar Window N.C.

MENU MENU MENU MENU MENU

-0.90

bar

Closed

MENU

NEXT

PREVIOUS

NEXT

NEXT

NEXT

NEXT

NEXT

PREVIOUS

PREVIOUS

PREVIOUS

PREVIOUS

PREVIOUS

Set-pt.

5.00bar

MENU

NEXT

PREVIOUS

ESCAPE ESCAPE ESCAPE ESCAPE ESCAPE ESCAPE

Fig. 3. DISPLAY LEVEL

ENTERING THE ENTRY CODE

In order to gain access to the PARAMETRIZATION LEVEL

(where you can edit values), it is first necessary to show that

you have the requisite authorization by entering the correct

four-digit ENTRY CODE (default: 0000).

CODE

NOT

V

ALID

Put code

0000

OK

-

+

0

Put code

0000

-

+

8

Put code

0000

-

+

9

Put code

0009

-

+

0

Put code

0009

-

+

1

Put code

0009

-

+

4

Put code

0009

-

+

5

ESCAPE

OK OK

LEFT LEFT LEFT

OK OK OK OK

Put code

0000

-

+

1

OK

LEFT

LEFT LEFT LEFT LEFT

Fig. 4. Entering the ENTRY CODE

SMART DCM SWITCH – OPERATING INSTRUCTIONS

MU2B-0328GE51 R0207A

3

PARAMETRIZATION LEVEL

Once you have successfully entered the ENTRY CODE and

thus gained access to the PARAMETRIZATION LEVEL, you

can edit values and reconfigure the device.

NOTE: The currently set option (e.g. "yes," "no," "window

monitor", etc.) is always marked in the display

screen with a small dot to the left (see Fig. 5).

Monitor

Max.

OK

Window

ESCAPE

Monitor

Max.

Window

ESCAPE

OK

DOT

Fig. 5. Dot indicating present setting

SET-PT.

In this screen, you can select the set-point. This is defined as

the pressure at which you want the device to switch.

The default setting is 60% of full-scale.

ERROR MESSAGE: "VALUE OUT OF RANGE"

If you have entered a set-point outside of the device's

specified pressure measurement range or which is for any

other reason not rational, this error message will appear,

whereupon you should then enter a correct value.

RESET-PT.

In this screen, you can select the reset-point. This is defined

as the pressure at which you want the device to switch back.

The default setting is 40% of full-scale.

ERROR MESSAGE: "VALUE OUT OF RANGE"

If you have entered a reset-point outside of the device's

specified pressure measurement range or which is for any

other reason not rational, this error message will appear,

whereupon you should then enter a correct value.

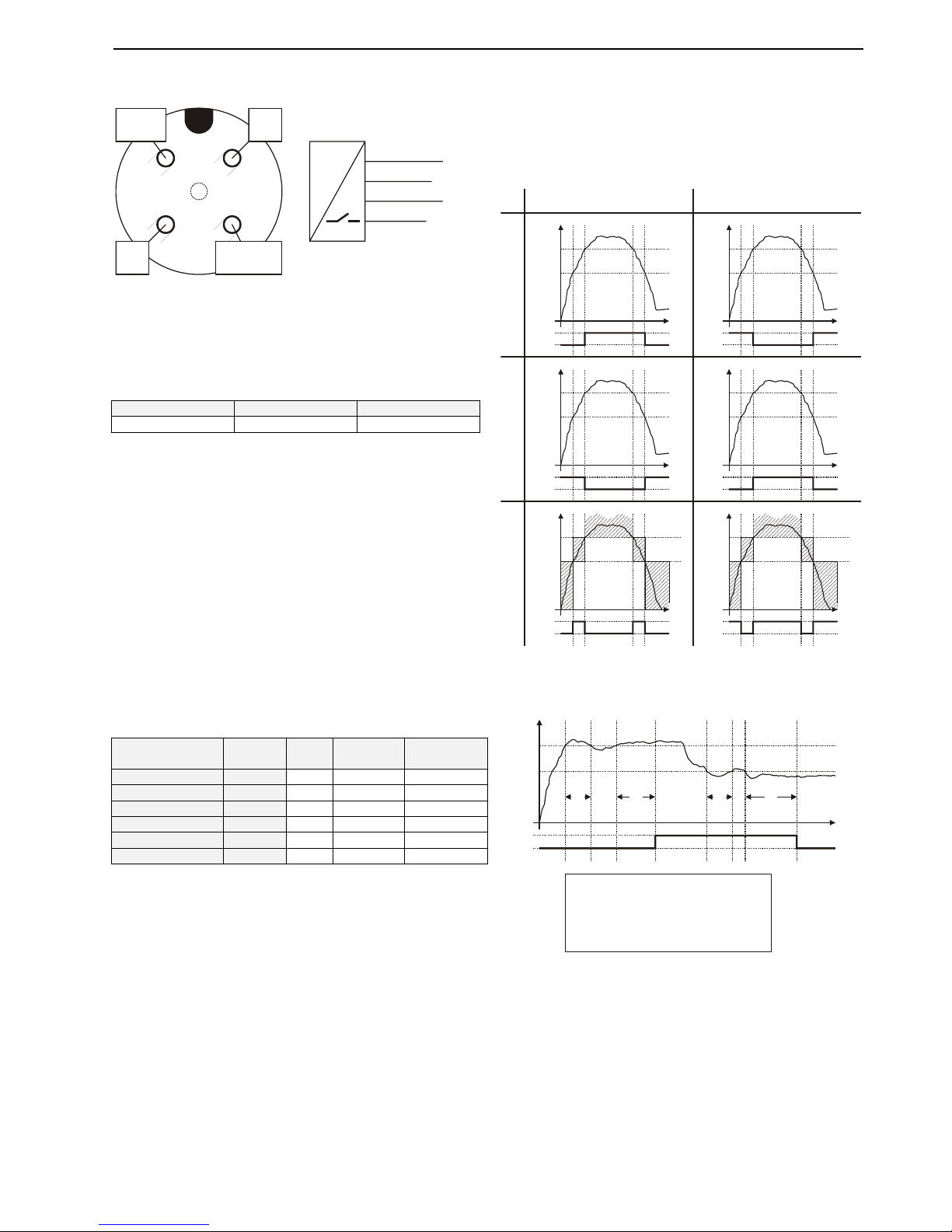

OUTPUT

MONITOR

Here, you can choose between three types of monitors: min.,

max., and window.

• Min.;

• Max.;

• Window;

See Fig. 7 on page 5 for an explanation of the meanings of

these different settings.

The default setting is "Max."

FUNCTION

Here, you can choose the type of action you want the DCM

Switch to have:

• N.O.: Normally-open switch (meaning: when the switch is

activated, it will CLOSE); or

• N.C.: Normally-closed switch (meaning: when the switch

is activated, it will OPEN).

See Table 2 and Fig. 7 on page 5 for more information.

The default setting is "N.O."

AUTO ZERO

The purpose of the auto zero function is to allow the user to

adjust the device to local ambient atmospheric pressure and

to compensate for drift. To use this function properly, the

device must be mounted in the application and the pressure

sensor exposed to local ambient atmospheric pressure (i.e.

0 bar relative pressure).

• Yes: The device takes the current local ambient

atmospheric pressure as its zero.

• No: The device setting remains unchanged.

The default setting is "No".

SET ZERO

The difference between the pressure value you enter in this

screen and the pressure which the device is currently

measuring will be taken as the offset. This offset can be reset

to zero using the reset zero option (see section "Reset Zero"

below).

The default setting is the pressure which the device is

currently measuring (meaning that the offset is then zero).

ERROR MESSAGE: "VALUE OUT OF RANGE"

If you have set a zero outside the permissible range (±25%

full-scale), this error message will appear, whereupon you

should then enter a correct value.

RESET ZERO

Here, you can reset the zero:

• Yes: The pressure offset will be set to zero.

• No: The device setting remains unchanged.

The default setting is "No".

DROP-IN

Here, you can select the drop-in value. See also Fig. 8.

Possible values range from 0 to 99 seconds.

The default setting is "0" seconds.

DROP-OUT

Here, you can select the drop-out value. See also Fig. 8.

Possible values range from 0 to 99 seconds.

The default setting is "0" seconds.

PEAKS

Here, you can view the historical max. and min. measured

pressures as well as the max. measured temperature

(historical = measured since the device has been put into

operation / since the last time the peaks were cleared).

If desired, by proceeding to "Clear" and choosing "yes," you

can also permanently erase all such values. All such peaks

will then be erased and the recording of peaks will be reinitiated.

DISPLAY

Here, you can select/alter various modes of displaying screen

information.

UNIT

Here, you can choose the units in which the device displays

pressures:

• bar: All pressures will be displayed in bars.

• Pa: All pressures will be displayed in Pascals.

• Psi: All pressures will be displayed in pounds / in2.

The default setting is "bar".

LANGUAGE

English is the only supported language.

SMART DCM SWITCH – OPERATING INSTRUCTIONS

MU2B-0328GE51 R0207A

4

BACKLIGHT

Here, you can select how the device's screen backlight

should operate:

• Always: The backlight will remain ON at all times.

• Demand: The backlight will come ON whenever the

device's keys are operated, and remain ON for 25 s.

• Never: The backlight is shut OFF permanently.

The default setting is "Never".

REFRESH

Here, you can set how often (in seconds) the screen contents

should be refreshed (i.e. refilled with freshly-measured data).

Possible values range from 1 to 9 seconds.

The default setting is "1" sec.

ROTATE

Here, you can permanently rotate (by 0°, 90°, 180°, or 270°)

the orientation in which the screen's contents are displayed.

This is for easier viewing / enhanced legibility.

The default setting is "0" degrees (i.e. screen contents vertical

when device mounted in upright position).

CONTRAST

Here, you can choose the degree of contrast with which the

screen's contents are displayed:

• Min.: The contrast is decreased to its minimum value;

• Mean: The contrast is set to its mean value;

• Max.: The contrast is increased to its maximum value.

The default setting is "Mean".

EXTRAS

SIMUL. (= SIMULATION MODE)

The simulation mode allows the user to test the device within

the application without actually applying pressure.

When the simulation mode is initiated, the device's diagnostic

features are not active, and use of the device in an active

safety application is impossible.

After leaving the simulation mode and returning to the normal

operating mode, the device is again ready for use in safety

applications.

• Yes: The simulation mode is started.

• No: The device remains in its normal operating mode.

The default setting is "No".

WARNING

After you have completed testing in the simulation mode, do

not forget to return to this screen and re-instate the active

operating mode.

SET CODE

Here, you can change the ENTRY CODE. After leaving the

PARAMETRIZATION LEVEL and proceeding through the

CONFIRMATION LEVEL, the new ENTRY CODE will then be

in effect.

RESET

Here, you can re-instate all factory (i.e. default) settings:

• Yes: All factory settings are re-instated.

• No: currently-set values are retained.

PLAUSIBILITY CHECK

Upon attempting to leave the PARAMETRIZATION LEVEL,

the device will determine two checks to determine the

plausibility of your values.

ERROR MESSAGE: "MIN. DISTANCE BETW. SET-PT. AND

RESET-PT. IS 0.5% FS. PLEASE CORRECT PARAMS"

The difference between the set-point and the reset-point will

be checked. If the distance is too small (i.e. less than 0.5% of

the full-scale), this error message will appear.

ERROR MESSAGE: "OFFSET MUST BE BETWEEN -25%FS &

+25%FS. PLEASE CORRECT"

The offset will also be checked. If the offset is not within 25%

of the full-scale, this error message will appear.

CONFIRMATION LEVEL

Here, you have the opportunity of once again viewing all of

the device's settings (including any changes you may have

made) in a quick overview. If you reject any settings, you will

be automatically redirected to the PARAMETRIZATION

LEVEL. If you accept all settings, these values will be

permanently stored, and you will be automatically redirected

to the DISPLAY LEVEL.

IMPORTANT

You should be completely satisfied with the correctness of the

settings displayed in the CONFIRMATION LEVEL. As soon

as you complete the CONFIRMATION LEVEL, all of these

settings will become effective.

SMART DCM SWITCH – OPERATING INSTRUCTIONS

MU2B-0328GE51 R0207A

5

OUTPUT DESCRIPTION

1

2

4

3

L+

L-

OC PNP

1

2

3

4

P

L+

L-

OC PNP

WARN

WARN

Fig. 6. Pin assignment of A-coded M12 plug

NOTE: The unit and any field devices (actuators, sensors,

etc.) to which it is electrically connected must be

provided with a common ground via pin 3.

The initial conditions of the device's signal outputs are as

follows:

Table 1. DCM Switch signal outputs after power-up

WARN (pin 2) POWER OUTPUT (pin 4)

passive -- open

NOTE: The WARN output (pin 2) is an auxiliary output

used for signaling errors. It cannot be used to drive

high loads.

DCM SWITCH BEHAVIOR IN OVERCURRENT

CONDITIONS

In order to prevent damage of the device electronics, the

device measures the current flowing into the load.

If the current flowing from the switch output to the load

exceeds 250 mA, the load is automatically disconnected and

the WARN output is set to < 0.5 V for 5 sec. The load is then

reconnected, the current is measured again, and the WARN

output is set to the power supply voltage. If the current is still

greater than 250 mA, the load is disconnected and the WARN

output is set to < 0.5 V… in a loop.

Table 2. DCM Switch functions and definitions

definition function

equa-

tion

"active" = "inactive" =

max. monitor N.O.

1 closed open

max. monitor N.C.

1 open closed

min. monitor N.O.

1 open closed

min. monitor N.C.

1 closed open

window monitor N.O.

2 closed open

window monitor N.C.

2 open closed

Equation 1 (min./max. monitor):

active x ≥ USP

y

n+1

= inactive x ≤ LSP

y

n

otherwise

Equation 2 (window monitor):

active LSP ≤ x ≤ USP

inactive x ≤ LSP minus (0.5%

±

range)

Inactive x ≥ LSP plus (0.5%

±

range)

y

n+1

=

yn otherwise

Where

y

n

is the analog output value as determined in the

previous cycle,

y

n+1

is the analog output value as determined in the current

cycle, and

x is the current measured pressure.

USP

USP

USP

LSP

LSP

LSP

NORMALLY-OPEN NORMALLY-CLOSED

time

time

time

p

p

p

closed

closed

closed

open

open

open

time

time

time

p

p

p

closed

closed

closed

open

open

open

USP

USP

USP

LSP

LSP

LSP

MAX. MONITORMIN. MONITORWINDOW MONITOR

Fig. 7. DCM Switch output (max./min./window monitor)

USP

LSP

time

p

closed

open

N.O. MAX. MONITOR (OR N.C. MIN. MONITOR)

T

1

T

3

T

2

T

4

LEGEND:

T less than drop-in time

T greater than or equal to drop-in time

T less than drop-out time

T greater than or equal to drop-out time

1

2

3

4

Fig. 8. Drop-in / drop-out time

SMART SN TRANSMITTER – OPERATING INSTRUCTIONS

MU2B-0328GE51 R0207A

6

SN TRANSMITTER

SEQUENCE OF SCREENS

MODE FUNCTION

OUTPUTSTART-PT END-PT

AUTO-0 SET ZERO RESET 0

PRESSURE,

STATE

START-PT.

WELCOME

END-PT. MODE FUNCTION ATTENUATION

MESSAGE MESSAGE

ATTENUATION

PEAKS

UNIT LANGU AGE BACKLIGHT REFRESH ROTATE CONTRAST

DISPLAY

CLEARMIN. MAX. TEMP. SIMUL. SET CODE RESET

EXTRAS

ENTER

CODE

GO TO

CONFIRM

A

LL

SETTINGS

PLAUSIBLE

?

NO YES

START-PT. END-PT. MODE FUNCTION ATTENUATION CODE SIMUL. STORING...

DISPLAY LEVEL

PARAMETRIZATION LEVEL

CODE

ERROR

START

CONFIRMATION LEVEL

Fig. 9. Sequence of screens – Overview (SN)

Devices equipped with an HMI (Human-Machine-Interface)

feature pushbuttons and a display, allowing easy

configuration by means of a menu structure. The menu

structure is divided into the following segments:

• The START SCREEN;

• The DISPLAY LEVEL (where information including the

current pressure and parameterized values are shown but

cannot be edited);

• The CODE area (where you will have to enter the correct

four-digit CODE in order to proceed any further);

• The PARAMETRIZATION LEVEL (where you can edit

various different parameters);

• A ERROR-CHECKING area (where the device will check

the plausibility of your values and, if necessary, redirect

you back to the PARAMETRIZATION LEVEL); and

• The CONFIRMATION LEVEL (where you can review your

edited values before permanently storing them).

START SCREEN

Within 10 seconds of powering-up the device, an initial screen

– the START SCREEN - will appear briefly (see Fig. 10).

Startup

Fig. 10. Start screen

You will then be automatically directed to the DISPLAY

LEVEL.

DISPLAY LEVEL

In the DISPLAY LEVEL, you can view the current pressure as

well as the various different user-settings currently in force.

Function

A

tt. filter

Non-inv. 10%

MENU

NEXT

PREVIOUS

End

pressure

10.00bar

Mode

2-wire

4..20mA

Start

pressure

0.00bar

MENU

NEXT

PREVIOUS

ESCAPE ESCAPE

MENU

NEXT

PREVIOUS

ESCAPE

NEXT

PREVIOUS

ESCAPE

MENU

NEXT

PREVIOUS

ESCAPE

MENU

0.22

bar

4.35mA

MENU

NEXT

PREVIOUS

Fig. 11. DISPLAY LEVEL (example: SN 2-Wire)

Function

Att. filter

Non-inv. 10%

MENU

NEXT

PREVIOUS

End

pressure

10.00bar

Mode

3-wire

0..10V

Start

pressure

0.00bar

MENU

NEXT

PREVIOUS

ESCAPE ESCAPE

0.22

bar

0.21V

MENU

NEXT

PREVIOUS

MENU

NEXT

PREVIOUS

ESCAPE

NEXT

PREVIOUS

ESCAPE

MENU

NEXT

PREVIOUS

ESCAPE

MENU

Fig. 12. DISPLAY LEVEL (example: SN 3-Wire)

ENTERING THE ENTRY CODE

In order to gain access to the PARAMETRIZATION LEVEL

(where you can edit values), it is first necessary to show that

you have the requisite authorization by entering the correct

four-digit ENTRY CODE (default: 0000).

SMART SN TRANSMITTER – OPERATING INSTRUCTIONS

MU2B-0328GE51 R0207A

7

CODE

NOT

V

ALID

Put code

0000

OK

-

+

0

Put code

0000

-

+

8

Put code

0000

-

+

9

Put code

0009

-

+

0

Put code

0009

-

+

1

Put code

0009

-

+

4

Put code

0009

-

+

5

ESCAPE

OK OK

LEFT LEFT LEFT

OK OK OK OK

Put code

0000

-

+

1

OK

LEFT

LEFT LEFT LEFT LEFT

Fig. 13. Entering the ENTRY CODE

PARAMETRIZATION LEVEL

Once you have successfully entered the ENTRY CODE and

thus gained access to the PARAMETRIZATION LEVEL, you

can edit values and reconfigure the device.

NOTE: The currently set option (e.g. "yes," "no,"

"4…20 mA", etc.) is always marked in the display

screen with a small dot to the left (see Fig. 5).

Function

N.O.

OK

N.C.

ESCAPE

Function

N.O.

N.C.

ESCAPE

OK

DOT

Fig. 14. Dot indicating present setting

START-PT.

In this screen, you can select the start-point. This is defined

as the pressure at which you want the device to begin

providing an analog output signal.

The default setting is "0".

ERROR MESSAGE: "VALUE OUT OF RANGE"

If you have entered a start-point outside of the device's

specified pressure measurement range or which is for any

other reason not rational, this error message will appear,

whereupon you should then enter a correct value.

END-PT.

In this screen, you can select the end point. This is defined as

the pressure at which you want the device to stop providing

an analog output signal.

The default setting is 100% of full-scale.

ERROR MESSAGE: "VALUE OUT OF RANGE"

If you have entered an end-point outside of the device's

specified pressure measurement range or which is for any

other reason not rational, this error message will appear,

whereupon you should then enter a correct value.

OUTPUT

MODE

Here, you can set the device's mode. Four different modes

are possible:

• 0…10V: the voltage range is set to 0…10 V;

• 0…20mA: the current range is set to 0…20 mA;

• 2…10V: the voltage range is set to 2…10 V;

• 4…20mA: the current range is set to 4…20 mA (default).

NOTE: The only mode supported by the SN 2-Wire Trans-

mitter is "4…20 mA". However, it can be inverted

to "20…4 mA" (see section "Function" below).

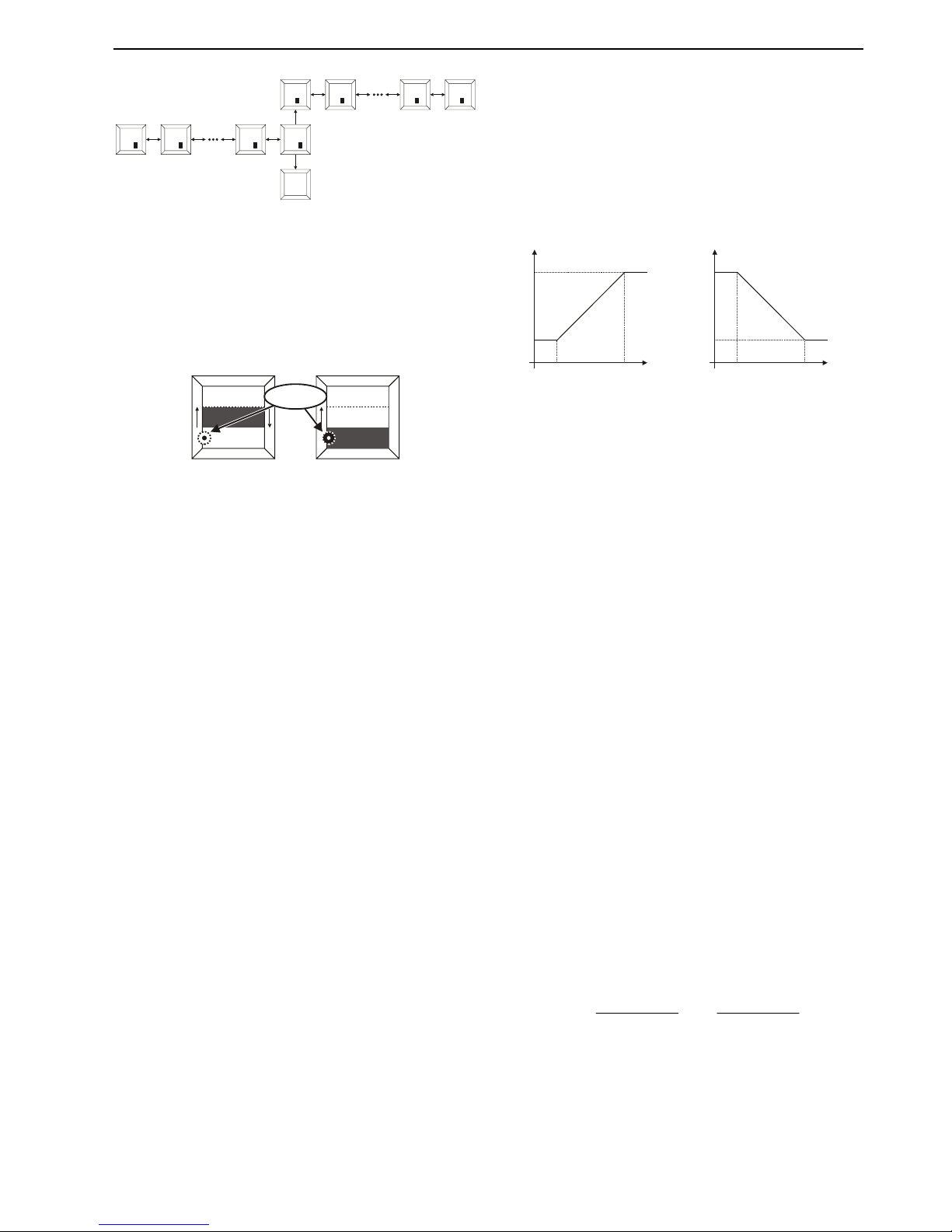

FUNCTION

Here, you can invert the device's function (see also Fig. 15):

• Non-invert.: the mode (current range or voltage range, as

the case may be) is set to 0/4…20 mA or 0/2…10 V (as

the case may be) (default);

• Inverted: the mode (current range or voltage range, as the

case may be) is set to 20…0/4 mA or 10…0/2 V (as the

case may be).

The default setting is "non-invert."

U/I

MAX MAX

U/I

MAX MAX

U/I

MIN MIN

U/I

MIN MIN

output U/I output U/I

NORMAL OPERATION INVERTED OPERATION

pressure pressure

pressure

start

pressure

start

pressure

end

pressure

end

Fig. 15. SN Transmitter output (normal/inverted)

AUTO ZERO

The purpose of the auto zero function is to allow the user to

adjust the device to local ambient atmospheric pressure and

to compensate for drift. To use this function properly, the

device must be mounted in the application and the pressure

sensor exposed to local ambient atmospheric pressure (i.e.

0 bar relative pressure).

• Yes: The device takes the current local ambient

atmospheric pressure as its zero.

• No: The device setting remains unchanged.

The default setting is "No".

SET ZERO

The difference between the pressure value you enter in this

screen and the pressure which the device is currently

measuring will be taken as the offset. This offset can be reset

to zero using the reset zero option (see section "Reset Zero"

below).

The default setting is the pressure which the device is

currently measuring (meaning that the offset is then zero).

ERROR MESSAGE: "VALUE OUT OF RANGE"

If you have set a zero outside the permissible range (±25%

full-scale), this error message will appear, whereupon you

should then enter a correct value.

RESET ZERO

Here, you can reset the zero:

• Yes: The pressure offset will be set to zero.

• No: The device setting remains unchanged.

The default setting is "No".

ATT. FILTER

Here, you can attenuate (dampen) the outputted portion of

the peak. Possible values range from 0 to 99%. The default

setting is "10" percent.

The formula for calculating the attenuation is as follows:

1

100

)

100

1(

−

+−=

nnn

y

nattenuatio

x

nattenuatio

y

SMART SN TRANSMITTER – OPERATING INSTRUCTIONS

MU2B-0328GE51 R0207A

8

Where

y

n

is the analog output value

x

n

is the measured offset-compensated pressure in this

cycle

y

n-1

is the analog output value generated in the previous

cycle

PEAKS

Here, you can view the historical max. and min. measured

pressures as well as the max. measured temperature

(historical = measured since the device has been put into

operation / since the last time the peaks were cleared).

If desired, by proceeding to "Clear" and choosing "yes," you

can also permanently erase all such values. All such peaks

will then be erased and the recording of peaks will be reinitiated.

DISPLAY

Here, you can select/alter various modes of displaying screen

information.

UNIT

Here, you can choose the units in which the device displays

pressures:

• bar: All pressures will be displayed in bars.

• Pa: All pressures will be displayed in Pascals.

• Psi: All pressures will be displayed in pounds / in2.

The default setting is "bar".

LANGUAGE

English is the only supported language.

BACKLIGHT

Here, you can select how the device's screen backlight

should operate:

• Always: The backlight will remain ON at all times.

• Demand: The backlight will come ON whenever the

device's keys are operated, and remain ON for 25 sec.

• Never: The backlight is shut OFF permanently.

The default setting is "Never"

NOTE: The only backlight option supported by the SN 2-

Wire Transmitter is "Never."

REFRESH

Here, you can set how often (in seconds) the screen contents

should be refreshed (i.e. refilled with freshly-measured data).

Possible values range from 1 to 9 seconds.

The default setting is "1" sec.

ROTATE

Here, you can permanently rotate (by 0°, 90°, 180°, or 270°)

the orientation in which the screen's contents are displayed.

This is for easier viewing / enhanced legibility.

The default setting is "0" degrees (i.e. screen contents vertical

when device mounted in upright position).

CONTRAST

Here, you can choose the degree of contrast with which the

screen's contents are displayed:

• Min.: The contrast is decreased to its minimum value;

• Mean: The contrast is set to its mean value;

• Max.: The contrast is increased to its maximum value.

The default setting is "Mean".

EXTRAS

SIMUL. (= SIMULATION MODE)

The simulation mode allows the user to test the device within

the application without actually applying pressure.

When the simulation mode is initiated, the device's diagnostic

features are not active, and use of the device in an active

safety application is impossible.

After leaving the simulation mode and returning to the normal

operating mode, the device is again ready for use in safety

applications.

• Yes: The simulation mode is started.

• No: The device remains in its normal operating mode.

The default setting is "No".

WARNING

After you have completed testing in the simulation mode, do

not forget to return to this screen and re-instate the active

operating mode.

SET CODE

Here, you can change the ENTRY CODE. After leaving the

PARAMETRIZATION LEVEL and proceeding through the

CONFIRMATION LEVEL, the new ENTRY CODE will then be

in effect.

RESET

Here, you can re-instate all factory (i.e. default) settings:

• Yes: All factory settings are re-instated.

• No: currently-set values are retained.

PLAUSIBILITY CHECK

Upon attempting to leave the PARAMETRIZATION LEVEL,

the device will perform two checks to determine the

plausibility of your values.

ERROR MESSAGE: "MIN. DISTANCE BETW. START-PT. AND

END-PT. IS 50% FS. PLEASE CORRECT PARAMS"

The difference between the set-point and the reset-point will

be checked. If the distance is too small (i.e. less than 50% of

the full-scale), this error message will appear.

ERROR MESSAGE: "OFFSET MUST BE BETWEEN -25%FS &

+25%FS. PLEASE CORRECT"

The offset will also be checked. If the offset is not within 25%

of the full-scale, this error message will appear.

CONFIRMATION LEVEL

Here, you have the opportunity of once again viewing all of

the device's settings (including any changes you may have

made) in a quick overview. If you reject any settings, you will

be automatically redirected to the PARAMETRIZATION

LEVEL. If you accept all settings, these values will be

permanently stored, and you will be automatically redirected

to the DISPLAY LEVEL.

IMPORTANT

You should be completely satisfied with the correctness of the

settings displayed in the CONFIRMATION LEVEL. As soon

as you complete the CONFIRMATION LEVEL, all of these

settings will become effective.

SMART SN TRANSMITTER – OPERATING INSTRUCTIONS

MU2B-0328GE51 R0207A

9

OUTPUT DESCRIPTION

PTS...V3PTH... PTS...A3 PTS...A2

1

2

4

3

1

2

3

4

P

U/I

L+/

~

L-/

~

WARN

WARN

U/I

OUT

L+/

~

L-/

~

1

2

4

3

1

2

3

4

P

U

WARN

WARN

U

OUT

L+/

~

L-/

~

L+/

~

L-/

~

1

2

4

3

1

2

3

4

P

I

WARN

WARN

I

OUT

L+/

~

L+/

~

L-/

~

L-/

~

1

2

4

3

L+

L-

n.c.

n.c.

1

2

3

4

P

I

L+

n.c.

n.c.

L-

Fig. 16. Pin assignment of A-coded M12 plug

NOTE: The unit and any field devices (actuators, sensors,

etc.) to which it is electrically connected must be

provided with a common ground via pin 3.

The initial conditions of the device's signal outputs are as

follows:

Table 3. SN Transmitter signal outputs after power-up

device

output

signal range

WARN power

output

(pin 4)

2-Wire 4…20 mA not used < 3.6 mA not used

4…20 mA passive -- 0 mA

2…10 V passive -- 2 V

0…20 mA passive -- 0 mA

3-Wire

0…10 V passive -- 0 V

The output limits of the device's outputs at overpressure and

underpressure are as follows:

Table 4. SN Transmitter output limits at over- /

underpressure

device

output signal

range

min. output

limit

max. output

limit

2-Wire 4…20 mA 3.8 mA 20.5 mA

4…20 mA 3.8 mA 20.5 mA

2…10 V 1.8 V 10.5 V

0…20 mA 0 mA 20.5 mA

3-Wire

0…10 V 0 V 10.5 V

Table 5. SN Transmitter parameters

parameter description range

analog

start-pt.

pressure mapped to

upper limit of output

range

min. pressure (analog

end minus 50%FS)

analog endpt.

pressure mapped to

lower limit of output

range

max. pressure (analog

start plus 50%FS)

offset

user-adjustable offset to

compensate for local

atmospheric pressure

and drift

±25%FS

definition selection of output signal

0…20 mA, 4…20 mA

0…10 V, 2…10 V

function

selecting normal /

inverted output

characteristics

non-inverted; inverted

attenuation

weight (in %) of previous

value in attenuation filter

0.95

SMART DCM SWITCH / SN TRANSMITTER – OPERATING INSTRUCTIONS

MU2B-0328GE51 R0207A

10

REMARKS AS PER EN 61010-1

PREREQUISITES FOR MOUNTING

The unit is not suitable for mounting in explosive environments.

The unit may be operated only within the specified technical

limits.

CONNECTION

In the case of units with stationary mounting, the following

requirements must be observed:

Minimum cross-sectional diameter of wiring: 0.75 mm2

POWER FAILURE

In the event of a power failure, the device will cease

operation. After power is returned, the device will, after a brief

(2-3 sec) initialization period, resume normal functioning.

Because its memory is stored on EPROM, no reparametrization is necessary.

CLEANING AGENTS

All commercial cleaning agents approved for use in the food

industry and for stainless steel 1.4571 are permitted.

MISUSE OF UNIT

Installing/operating this device contrary to these Operating

Instructions can impair its proper functioning / result in

malfunctioning and device damage - result in danger of injury.

RECALIBRATION

It is not possible to recalibrate the device in the field, nor does

it contain any field-reparable parts. For recalibration or repair,

contact FEMA.

SAFETY FUNCTION (D.C. SUPPLY,

ONLY)

SN TRANSMITTER

Measuring pressures is the safety function of the directcurrent-driven devices. It is applicable for 2-wire (4…20 mA)

and 3-wire versions (0/4…20 mA and 0/2…10 V with auxiliary

WARN output) and ensures an accuracy of 5% of the

measured value within this range.

The safety function ensures that, in the worst-case scenario,

the diagnosis function responds within 45 seconds.

The transmitter's output is updated according to Fig. 15 on

page 7. The X-axis of the characteristic indicates the

measured pressure after application of the offset compensation and the attenuation filter. The Y-axis displays the

generated output in the range according to the output

definition (see Fig. 15 on page 7 and Table 5 on page 9).

DCM SWITCH

Measuring pressures is the safety function of the directcurrent-driven devices. The device will act within an accuracy

of 5% as a Max., Min., or Window monitor (switch output and

auxiliary WARN output), depending upon the device settings.

The switch output is in the "open" state (see Table 7)

whenever the prerequisites for the "open" state are fulfilled.

ERROR STATES

While the device is in operation, it provides continuous

supervision. The diagnostics detect errors in the application

(e.g. when the desired output signal is not reached), in the

electronics (e.g. in the event of miswiring or defective

circuitry), as well as sensor defects and runtime errors in the

software.

If an error occurs, it will be signalized on the signal output

and/or WARN output within a maximum of 45 seconds, and

the display illumination will turn RED and remain RED until

the error has been eliminated.

There are two classes of errors: recoverable errors and

unrecoverable errors.

RECOVERABLE ERRORS

Recoverable errors can be solved by a software reset:

After the error is recognized, it is reported at the signal output

and the WARN output for 5 seconds. After that, the device

performs an automatic software reset (i.e. the signal output

will go into the start-up condition and the device will be reinitialized). The device will then resume normal operation.

UNRECOVERABLE ERRORS

If (after an automatic software reset) the error is still detected

or it recurs during the next 10 minutes of operation, the error

is reclassified as unrecoverable. This means that it cannot be

resolved without interaction of the user. If, however, the error

does not recur within 10 minutes, the device will resume

normal operation.

Unrecoverable errors can be resolved only by means of a

hardware reset. A hardware reset is performed by

disconnecting the device from the power supply for at least 10

seconds.

SMART DCM SWITCH / SN TRANSMITTER – OPERATING INSTRUCTIONS

MU2B-0328GE51 R0207A

11

REMEDYING AN UNRECOVERABLE ERROR SETTING

If an unrecoverable error is indicated, you can try to solve the

issue by powering down the device and eliminating the error

conditions (e.g. miswiring, overtemperature, overpressure).

A hardware reset is performed by disconnecting the device

from the power supply for at least 10 seconds.

NOTE: If the error persists, contact FEMA.

OUTPUT LEVELS AND OUTPUT BEHAVIOR

SN TRANSMITTER

2-WIRE VERSION

The 2-wire version signalizes an error via the current loop

signal.

3-WIRE VERSION

NOTE: If either analog range 0…10 V or analog range

0…20 mA is used, then the WARN output must

also be used.

The 3-wire version signalizes an error via the signal output

(pin 4) and the WARN output (pin 2).

If (due to miswiring or electronic failure) the signal output

cannot reach the desired "high" failure state, it will automatically go to the "low" failure state.

Table 6. SN Transmitter error reporting

error reporting

device

output

signal

range

primary,

"high" failure

state

secondary,

"low" failure

state

WARN

output

(pin 2)

2-wire 4…20 mA

loop current >

21 mA

loop current <

3.6 mA

NOTE 1

0…20 mA

output >

21 mA

output = 0 mA

NOTE 2

< 0.5 V

4…20 mA

output >

21 mA

output <

3.6 mA

< 0.5 V

0…10 V output > 11 V

output = 0 V

NOTE 2

< 0.5 V

3-wire

2…10 V output > 11 V output < 1.5 V < 0.5 V

NOTE 1: The 2-Wire Transmitter has no WARN output.

NOTE 2: This a valid signal; it is therefore necessary to use

the WARN output.

DCM SWITCH

Table 7. DCM Switch error reporting

error reporting

device

output

signal

range

primary,

"high" failure

state

secondary,

"low" failure

state

WARN

output

(pin 2)

switch

open /

closed

open open* < 0.5 V

*It is still necessary to use the WARN output to cover blocked

closed output transistor error.

SMART DCM SWITCH / SN TRANSMITTER – OPERATING INSTRUCTIONS

Manufactured for and on behalf of the Environmental and Combustion Controls Division of Honeywell Technologies Sàrl, Ecublens, Route du Bois 37, Switzerland by its Authorized Representative:

Fema Controls

Honeywell GmbH

P.O. Box 1254

D-71099 Schönaich

phone: (49) 7031-637-02

fax: (49) 7031-637-850

http:/honeywell.de/fema

Subject to change without notice. Printed in Germany

MU0B-0560GE51 R0207A

ERROR MESSAGES

Table 8 lists all error messages which can appear in the display screen during operation.

Table 8. SN Transmitter / DCM Switch error messages

screen

contents

description / cause

recoverable /

unrecoverable

remedy

0 No error. -- No action necessary.

1 Electronics failure. R/U If unrecoverable: Contact FEMA.

4 Electronics failure or sensor failure. R/U If unrecoverable: Contact FEMA.

5 Electronics failure or miswiring. R/U

Check wiring (current meter used for current

output? Voltmeter used for voltage output?).

Correct detected errors and perform a hardware reset as described above. If

unrecoverable: Contact FEMA.

6 Device memory check failure. R/U

Hardware reset as described above. Contact

FEMA.

7 Device program flow failure. R/U If unrecoverable: Contact FEMA.

8 Environment too hot or electronics failure. U

Eliminate overtemperature conditions. Perform

hardware reset as described above. Contact

FEMA.

10 Electronics failure. U Contact FEMA.

11 Electronics failure or data processing error. U Contact FEMA.

12 Data processing error. R/U If unrecoverable: Contact FEMA.

13

Pressure exceeds overpressure, resulting in

sensor failure.

U

Eliminate overpressure conditions. Perform

hardware reset as described above. If this

does not help: Contact FEMA.

15 Device memory check failure. R/U

Perform hardware reset as described above. If

this does not help: Contact FEMA.

16 Electronics (microcontroller) failure. R/U If unrecoverable: Contact FEMA.

17 Damage to application state data. R/U

Perform hardware reset as described above. If

this does not help: Contact FEMA.

18 Electronics error. R/U If unrecoverable: Contact FEMA.

19 Electronics or data processing error. R/U If unrecoverable: Contact FEMA.

20 Electronics or sensor error. R/U If unrecoverable: Contact FEMA.

21 Electronics error. R/U If unrecoverable: Contact FEMA.

22 Electronics or data processing error. U Contact FEMA.

® U.S Registered Trademark

Copyright © 2007 Honeywell Inc. • All Rights Reserved MU2B-0328GE51 R0207A

Smart SN, DCM

ELEKTRONISCHE DRUCKSCHALTER UND -TRANSMITTER

BEDIENUNGSANLEITUNG

ALLGEMEINES

Druckschalter der Baureihe Smart DCM sowie Drucktransmitter der Baureihe Smart SN von Honeywell FEMA sind

mikroprozessor-gesteuerte Druckmessgeräte zur Messung

von Relativdrücken von -1…+1 bar und 0…40 bar. Sie sind

bestens geeignet für vielfältige Einsatzbereiche, u.a. zur

genauen Erfassung, Überwachung und Regelung von

Systemdrücken. Der M12x1 Winkelstecker ist im Lieferumfang enthalten. Die Geräte werden direkt in die Druckleitung oder den Druckbehälter eingeschraubt (G1/2").

BITTE BEACHTEN!

GÜLTIGKEIT

Diese Bedienungsanleitung bezieht sich auf Meßsysteme, die

Smart DCM Druckschalter bzw. Smart SN Drucktransmitter

beinhalten. Geräte-Software Version 1.30 oder höher ist

Voraussetzung.

VERWENDUNG

Bei der Konfiguration und Inbetriebnahme des Geräts darf

nur diese Bedienungsanleitung (sowie die dazugehörigen

Montageanleitungen) verwendet werden. Nur qualifizierte

Fachkräfte dürfen das Gerät einbauen, einstellen, in Betrieb

nehmen und warten. Das Gerät ist ausschließlich unter den

vorliegenden Bedingungen und zu den vorgesehenen

Zwecken zu betreiben.

TECHNISCHE DATEN

Werkstoffe

Mediumberührte Teile Edelstahl (1.4571)

Chemische Beständigkeit 4C4 gemäß EN 60721-3-4

HMI PA66 GF25

Gesamtgewicht 300 g ohne, 350 g mit HMI

Umgebungstemperatur und -feuchtigkeit (bei Betrieb)

Versionen ohne HMI -20...+80 °C

Versionen mit HMI -20...+70 °C

Rel. Luftfeuchtigkeit 0...95%, nicht-kondensierend

Mediumtemperatur -30...+100 °C (≤ 16 bar-Modelle)

-40...+100 °C (> 16 bar-Modelle)

Lagertemperatur

Versionen ohne HMI -40...+80 °C (≤ 16 bar)

-40...+100 °C (> 16 bar)

Versionen mit HMI -30...+80 °C

Klimaklasse

Innenräume 4K4H gemäß EN 60721-3-4

Im Freien 3K8H gemäß EN 60721-3-3

Mechanische Festigkeit

Schwingungen 20 g gem. IEC 68-2-6 (bis

2000 Hz)

Mechan. Erschütterungen 100 g gemäß IEC 68-2-27

Druckbeständigkeit / Genauigkeit (kombinierte

Nichtlinearität, Hyst. und Reproduzierbarkeit bei 20 °C)

Druckbereich P ≤ 16 bar P > 16 bar

Überdruckbeständigkeit 2x P

nominal

2x P

nominal

Berstbeständigkeit 4x P

nominal

10x P

nominal

Fühlertyp Piezo Dünnfilm

Genauigkeit

max. ±0,8% FS

±0,5% FS (typ.)

max. ±1% FS

±0,6% FS (typ.)

Druckmessbereich 0…40 bar, -1…1 bar

Taktzeit 100 ms

EMV gemäß EN 61326

Schutzklasse 2 gemäß EN 61010

Schutzart (ohne HMI) IP67 gemäß EN 60529-2

Schutzart (mit HMI) IP65 gemäß EN 60529-2

Prozessanschluss G1/2" Außengewinde

Elektrischer Anschluß 4-poliger M12x1-Stecker, "A"

Schalter

Ausg., oberer Wert (min.) V

VERSORG

- 2 V

Ausg., unterer Wert (max.) GND plus 0,5 V

Antwortzeit max. 300 ms

WARN-Ausg.-Spannung passiv: V

VERSORG

- 2 V

aktiv: ≤ 0,5 V

Transmitter (analog) Ausgang

Strom (2-Leiter) 4…20 mA

Spannung/Strom (3-Leiter) 0/2...10 V, 0/4...20 mA

Spannungsvers. (2-Leiter) 18…35 Vdc

Spannungsvers. (3-Leiter) 18…35 Vdc, 24 Vac +10%/-20%,

max. 50 mA

Stromausg. (max. Bürde) (V

VERSORG

- 16 V) / 22 mA

(max. Fehler ±0,25% FS)

Spann.-Ausgang (min. Last) 15 kΩ (max. Fehler ±0,25% FS)

Sprungantwort ca. 200 ms

Messbereich, Kalibrierung und Langzeitdrift (innerhalb

Temperaturkompensationsbereich von 0…80 °C)

max. typisch

Temp.-Einfluss auf Messb. ±0,3% FS / 10 K ±0,2% FS / 10 K

Temp.-Einfluss auf Kalib. ±0,3% FS / 10 K ±0,2% FS / 10 K

Langzeitdrift ±0,3% FS p.a. ±0,2% FS p.a.

SMART DCM SCHALTER – BEDIENUNGSANLEITUNG

MU2B-0328GE51 R0207A

14

DCM SCHALTER

MENÜNAVIGATION

MONITOR FUNCTION

OUTPUTSET-PT RESET-PT

AUTO-0 SET ZERO RESET 0

PRESSURE,

STATE

SET-PT.

WELCOME

RESET-PT. MONITOR FUNCTION DROP-IN DROP-OUT

MESSAGE MESSAGE

DROP-IN DROP-OUT

PEAKS

UNIT LANGUAGE BACKLIGHT REFRESH ROTATE CONTRAST

DISPLAY

CLEARMIN. MAX. TEMP. SIMUL. SET CODE RESET

EXTRAS

ENTER

CODE

GO TO

CONFIRM

A

LL

SETTINGS

PLAUSIBLE

?

NO

Y

ES

SET-PT. RESET-PT. MONITOR F UNCTION DROP-IN DROP-OUT CODE SIMUL. STORING...

DISPLAY LEVEL

PARAMETRIZATION LEVEL

CODE

ERROR

START

CONFIRMATION LEVEL

Abb. 1. Menünavigation - Übersicht (DCM)

Geräte, die mit einem HMI-Kopf ausgestattet sind, vereinfachen die Konfiguration mit Hilfe der Drucktasten und einer

Anzeige. Die am Rande angezeigten Begriffe und Symbole

erleichtern die Navigation durchs Menü.

Das Menü läßt sich in folgende Bereiche aufteilen:

• STARTANZEIGE;

• DISPLAY-BEREICH (Informationsanzeige einschließlich

des aktuellen Drucks, sowie verschiedener Einstellwerte.

Editieren ist hier nicht möglich);

• CODE-BEREICH (Eingabe des vierstelligen CODEs, um

in die nächste Ebene zu gelangen);

• PARAMETRISIERUNGSBEREICH (Änderung

verschiedener Einstellwerte);

• PRÜFBEREICH (Überprüfung auf korrekte Eingabe und

ggfls. Zurückstufung in den PARAMETRISIERUNGSBEREICH); und

• BESTÄTIGUNGSBEREICH (Nochmalige Bestätigung der

Einstellwerte, bevor sie dauerhaft gespeichert werden).

STARTANZEIGE

Binnen 10 Sekunden nach Einschalten des Geräts erscheint

als erstes die STARTANZEIGE (siehe Abb. 2).

Startup

Abb. 2. Startanzeige

Danach gelangen Sie automatisch in den DISPLAYBEREICH.

DISPLAYBEREICH

Im DISPLAYBEREICH können Sie den aktuellen Druck sowie

diverse andere Einstellwerte sehen.

Reset-pt.

Monitor Function

Drop in

delay

0s

Drop

out delay

0s

4.00bar Window N.C.

MENU MENU MENU MENU MENU

-0.90

bar

Closed

MENU

NEXT

PREVIOUS

NEXT

NEXT

NEXT

NEXT

NEXT

PREVIOUS

PREVIOUS

PREVIOUS

PREVIOUS

PREVIOUS

Set-pt.

5.00bar

MENU

NEXT

PREVIOUS

ESCAPE ESCAPE ESCAPE ESCAPE ESCAPE ESCAPE

Abb. 3. DISPLAYBEREICH

EINGABE DES ZUGANGSCODES

Um in den PARAMETRISIERUNGSBEREICH zu gelangen

und dort Einstellwerte ändern zu können, müssen Sie sich

zuerst mit der erforderlichen Autorisierung ausweisen. Dies

geschieht durch Eingabe des vierstelligen ZUGANGSCODEs

(Standardwert: 0000).

CODE

NOT

V

ALID

Put code

0000

OK

-

+

0

Put code

0000

-

+

8

Put code

0000

-

+

9

Put code

0009

-

+

0

Put code

0009

-

+

1

Put code

0009

-

+

4

Put code

0009

-

+

5

ESCAPE

OK OK

LEFT LEFT LEFT

OK OK OK OK

Put code

0000

-

+

1

OK

LEFT

LEFT LEFT LEFT LEFT

Abb. 4. Eingabe des ZUGANGSCODEs

SMART DCM SCHALTER – BEDIENUNGSANLEITUNG

MU2B-0328GE51 R0207A

15

PARAMETRISIERUNGSBEREICH

Nach Eingabe des richtigen ZUGANGSCODE und Gelangen

in den PARAMETRISIERUNGSBEREICH können Sie

Einstellwerte ändern sowie das Gerät umkonfigurieren.

HINWEIS: Die aktuelle Einstellung (z.B. "Ja", "Nein",

"Window-Wächter" usw.) ist an einem kleinen

Punkt zu erkennen (siehe Abb. 5).

Monitor

Max.

OK

Window

ESCAPE

Monitor

Max.

Window

ESCAPE

OK

DOT

Abb. 5. Kennzeichnung der akt. Einstellung

SET-PT. (SCHALTPUNKT)

In diesem Menüfenster können Sie den Schaltpunkt

einstellen. Der Schaltwert ist der Druck, bei dem das Gerät

schalten soll.

Die Werkseinstellung beträgt 60% von FS.

FEHLERMELDUNG: "VALUE OUT OF RANGE"

Falls Sie einen Schaltwert gewählt haben, der außerhalb des

zulässigen Druckmessbereichs oder inkorrekt ist, erscheint

diese Fehlermeldung, worauf hin Sie einen richtigen Wert

eingeben sollen.

RESET-PT. (RÜCKSCHALTPUNKT)

In diesem Menüfenster können Sie den Rückschaltpunkt einstellen. Der Rückschaltpunkt ist der Druck, bei dem das Gerät

zurückschalten soll.

Die Werkseinstellung beträgt 40% von FS.

FEHLERMELDUNG: "VALUE OUT OF RANGE"

Falls Sie einen Rückschaltwert gewählt haben, der außerhalb

des zulässigen Druckmessbereichs oder inkorrekt ist,

erscheint diese Fehlermeldung, worauf hin Sie einen richtigen

Wert eingeben sollen.

OUTPUT (AUSGABE)

MONITOR (ÜBERWACHUNGSMÖGLICHKEITEN)

Hier können Sie zwischen drei Überwachungsmöglichkeiten

wählen: "min.", "max." und "window".

• Min.;

• Max.;

• Window;

Siehe Abb. 7 auf S. 17 für eine Erklärung der Bedeutungen

der verschiedenen Einstellungen.

Die Werkseinstellung ist "Max."

FUNCTION (FUNKTION)

Hier können Sie das gewünschte Verhalten des DCM

Schalters wählen:

• N.O.: Schließer (d.h. bei Betätigung des Schalters

schließt er); oder

• N.C.: Öffner (d.h. bei Betätigung des Schalters öffnet er).

Siehe Tabelle 2 sowie Abb. 7 auf S. 17 für mehr

Informationen.

Die Werkseinstellung ist "N.O."

AUTO ZERO

Die "auto zero"-Funktion ermöglicht es dem Anwender, das

Gerät entsprechend den lokalen atmosphärischen Druckverhältnissen einzustellen sowie die Drift auszugleichen. Um

diese Funktion richtig anzuwenden, sollte das Gerät am

Einsatzort eingebaut und der Druckfühler dem örtlichen

Umgebungsdruck ausgesetzt sein (d.h. 0 bar Relativdruck).

• "Yes": Das Gerät übernimmt den örtlichen Umgebungsdruck als seinen Nullwert.

• "No": Die Geräteeinstellung bleibt unverändert.

Die Werkseinstellung ist "No".

SET ZERO (NULLABGLEICH)

Der Unterschied zwischen dem Druckwert, den Sie in diesem

Menüfenster eingeben, und dem aktuell gemessenen Druck

stellt den Offset (Nullabgleich) dar. Dieser Nullabgleich kann

mit dem "reset zero"-Option (siehe unten) wieder auf Null

gestellt werden.

Die Standardeinstellung ist der aktuell gemessene Druck (d.h.

der Nullabgleich beträgt dann Null).

FEHLERMELDUNG: "VALUE OUT OF RANGE"

Falls Sie einen "Nullabgleich" gewählt haben, der außerhalb

des zulässigen Bereichs (±25% FS) liegt, erscheint diese

Fehlermeldung, worauf hin Sie einen richtigen Wert eingeben

sollen.

RESET ZERO

Hier können Sie den Nullwert wieder einstellen:

• "Yes": Der Nullabgleich wird auf "Null" gesetzt.

• "No": Die Geräteeinstellung bleibt unverändert.

Die Werkseinstellung ist "No".

DROP-IN (EINSCHALTVERZÖGERUNG)

Hier können Sie die Einschaltverzögerung einstellen. Siehe

Abb. 8.

Sie ist wählbar zwischen 0…99 Sekunden.

Die Werkseinstellung beträgt "0" Sekunden.

DROP-OUT (AUSSCHALTVERZÖGERUNG)

Hier können Sie die Ausschaltverzögerung einstellen. Siehe

Abb. 8.

Sie ist wählbar zwischen 0…99 Sekunden.

Die Werkseinstellung beträgt "0" Sekunden.

PEAKS (SPITZENWERTE)

Hier können Sie die historischen Maximal- und Minimaldrücke

sehen sowie die Maximaltemperatur (historisch = gemessen

seit Inbetriebnahme bzw. seit dem letzten Löschen der

Spitzenwerte).

Falls erwünscht, können Sie zu "Clear" ("Löschen") vorgehen

und "Yes" wählen; sämtliche gespeicherte Spitzenwerte

werden dadurch gelöscht und die Aufzeichnung von

Spitzenwerten wird wieder neu begonnen.

DISPLAY

Hier können Sie verschiedene Anzeigemodi auswählen.

SMART DCM SCHALTER – BEDIENUNGSANLEITUNG

MU2B-0328GE51 R0207A

16

UNIT (EINHEITEN)

Hier können Sie die Einheiten, in denen das Gerät den Druck

anzeigt, wählen:

• bar: Der Druck wird in bar angezeigt.

• Pa: Der Druck wird in Pascal angezeigt.

• Psi: Der Druck wird in pounds / in2 angezeigt.

Die Werkseinstellung ist "bar".

LANGUAGE (SPRACHE)

Die unterstützte Menüsprache ist ENGLISCH.

BACKLIGHT (HINTERGRUNDBELEUCHTUNG)

Hier können Sie die Hintergrundbeleuchtung einstellen:

• "Always": Die Hintergrundbeleuchtung bleibt immer EIN.

• "Demand": Die Hintergrundbeleuchtung geht an, sobald

eine Taste betätigt wird und erlischt nach 25 Sek.

• "Never": Die Hintergrundbeleuchtung ist dauerhaft AUS.

Die Werkseinstellung ist "Never".

REFRESH (AKTUALISIEREN)

Hier können Sie die Aktualisierungsrate (in Sekunden) des

Displayinhalts einstellen.

Mögliche Werte sind 1…9 Sekunden.

Die Werkseinstellung beträgt "1" Sek.

ROTATE (DREHEN)

Hier können Sie (zur besseren Lesbarkeit) die Ausrichtung

des Displays dauerhaft um 0°, 90°, 180° oder 270° drehen.

Die Werkseinstellung ist "0" Grad (d.h. senkrechte

Ausrichtung bei aufrechter Einbaulage).

CONTRAST (KONTRAST)

Hier können Sie den Kontrast des Displays einstellen:

• "Min.": Der Kontrast wird auf den Mindestwert eingestellt;

• "Mean": Der Kontrast wird auf den Mittelwert eingestellt;

• "Max.": Der Kontrast wird auf den Höchstwert eingestellt.

Die Werkseinstellung ist "Mean".

EXTRAS (ZUSATZFUNKTIONEN)

SIMUL. (SIMULATIONSMODUS)

Der Simulationsmodus ermöglicht es dem Anwender, die

reibungslose Funktion des Geräts zu prüfen, ohne das

System unter Druck zu setzen.

Nach Aufrufen des Simulationsmodus sind die Diagnostikfunktionen nicht wirksam, und das Gerät kann nicht in einer

echten Sicherheitsanwendung eingesetzt werden.

Nach Verlassen des Simulationsmodus und Rückkehr in die

normale Betriebsart kann das Gerät wieder in

Sicherheitsanwendungen eingesetzt werden.

• "Yes": Der Simulationsmodus wird aufgerufen.

• "No": Das Gerät bleibt in seiner normalen Betriebsart.

Die Werkseinstellung ist "No".

VORSICHT

Nach Abschluß Ihres Tests im Simulationsmodus müssen Sie

darauf achten, zu diesem Menüfenster zurückzukehren und

die normale Betriebsart wieder zu aktivieren.

SET CODE (CODE EINSTELLEN)

Hier können Sie den ZUGANGSCODE neu definieren. Nach

Verlassen des PARAMETRISIERUNGSBEREICHS und

Durchlauf durch den BESTÄTIGUNGSBEREICH wird der

neue ZUGANGSCODE dann wirksam.

RESET

Hier können Sie das Gerät wieder auf Werkseinstellung (d.h.

Standardwerte) zurücksetzen:

• "Yes": Alle Werkseinstellungen werden wieder wirksam.

• "No": Die aktuellen Einstellungen werden beibehalten.

PLAUSIBILITÄTSPRÜFUNG

Beim Versuch, den PARAMETRISIERUNGSBEREICH zu

verlassen, wird das Gerät eine automatische Prüfung durchführen, um die Plausibilität der Einstellungen zu prüfen.

FEHLERMELDUNG: "MIN. DISTANCE BETW. SET-PT. AND

RESET-PT. IS 0.5% FS. PLEASE CORRECT PARAMS"

Die Differenz zwischen dem Schaltpunkt und dem Rückschaltpunkt wird geprüft. Falls die Distanz nicht groß genug

ist (d.h. weniger als 0,5% des FS), erscheint diese Fehlermeldung.

FEHLERMELDUNG: "OFFSET MUST BE BETWEEN -25%FS &

+25%FS. PLEASE CORRECT"

Der Offset wird ebenfalls geprüft. Falls der Offset nicht

innerhalb 25% des FS ist, erscheint diese Fehlermeldung.

BESTÄTIGUNGSBEREICH

Hier haben Sie die Gelegenheit, sämtliche Geräteeinstellungen (einschl. der Werte, die Sie geändert haben)

nochmals Revue passieren zu lassen. Falls Sie irgendwelche

Einstellungen ablehnen, gelangen Sie automatisch wieder in

den PARAMETRISIERUNGSBEREICH. Falls Sie jedoch alle

Einstellungen annehmen, werden sie dauerhaft gespeichert,

und Sie gelangen automatisch zum DISPLAYBEREICH.

WICHTIG

Sie sollten von der Richtigkeit aller Einstellungen überzeugt

sein, die im BESTÄTIGUNGSBEREICH angezeigt werden.

Nach Durchlauf des BESTÄTIGUNGSBEREICHS werden

diese Einstellungen wirksam.

SMART DCM SCHALTER – BEDIENUNGSANLEITUNG

MU2B-0328GE51 R0207A

17

BESCHREIBUNG DES AUSGANGS

1

2

4

3

L+

L-

OC PNP

1

2

3

4

P

L+

L-

OC PNP

WARN

WARN

Abb. 6. Stiftbelegung des A-codierten M12-Steckers

HINWEIS: Das Gerät und sämtliche elektrisch an-

geschlossene Feldgeräte (z.B. Stellmotoren,

Fühler usw.) müssen über Stift 3 mit einer

gemeinsamen Masse versehen werden.

Die Anfangsbedingungen der Signalausgänge des Geräts

sind wie folgt:

Tabelle 1. DCM Signalausgänge nach Einschaltung

WARN (Stift 2) STROMVERS. AUSGANG (St. 4)

passiv -- offen

HINWEIS: Der WARN-Ausgang (Stift 2) ist ein Nebenausgang

zur Anzeige von Signalfehlern. Er läßt sich nicht

zum Antrieb von hohen Lasten verwenden.

DCM SCHALTVERHALTEN BEI ÜBERSTROM

Um eine Beschädigung der Geräteelektronik zu verhindern,

mißt das Gerät den Eingangsstrom (der Strom, der in die Last

einfließt).

Falls der Strom, der vom Schaltausgang an die Last fließt,

einen Wert von 250 mA überschreitet, wird die Last

automatisch getrennt und der WARN-Ausgang auf < 0.5 V für

5 sec gestellt. Die Last wird dann wieder zugeschaltet

(verbunden/angeschlossen), der Strom neu gemessen, und

der WARN-Ausgang auf die Spannungsversorgung gestellt.

Falls der Strom immer noch höher als 250 mA ist, wird die

Last getrennt und der WARN-Ausgang auf < 0.5 V… in eine

Schleife gestellt.

Tabelle 2. DCM Funktionen und Definitionen

Definition

Funk-

tion

Gleic

hung

"aktiv" = "inaktiv" =

max. monitor N.O.

1 geschl. offen

max. monitor N.C.

1 offen geschlossen

min. monitor N.O.

1 offen geschlossen

min. monitor N.C.

1 geschl. offen

window monitor N.O.

2 geschl. offen

window monitor N.C.

2 offen geschlossen

Gleichung 1 (min./max. monitor):

aktiv x ≥ USP

y

n+1

= inaktiv x ≤ LSP

y

n

sonst

Gleich 2 (window monitor):

aktiv LSP ≤ x ≤ USP

inaktiv x ≤ LSP minus (0,5%

±

FS)

inaktiv x ≥ LSP plus (0,5%

±

FS)

y

n+1

=

y

n

sonst

Wobei

y

n

den analogen Ausgangswert des vorigen Zyklus'

darstellt,

y

n+1

den analogen Ausgangswert des jetzigen Zyklus'

darstellt und

x der aktuell gemessene Druck ist.

USP

USP

USP

LSP

LSP

LSP

NORMALLY-OPEN NORMALLY-CLOSED

time

time

time

p

p

p

closed

closed

closed

open

open

open

time

time

time

p

p

p

closed

closed

closed

open

open

open

USP

USP

USP

LSP

LSP

LSP

MAX. MONITORMIN. MONITORWINDOW MONITOR

Abb. 7. DCM Ausgang (max./min./window-Wächter)

USP

LSP

time

p

closed

open

N.O. MAX. MONITOR (OR N.C. MIN. MONITOR)

T

1

T

3

T

2

T

4

LEGEND:

T less than drop-in time

T greater than or equal to drop-in time

T less than drop-out time

T greater than or equal to drop-out time

1

2

3

4

Abb. 8. Verzögerungszeiten

SMART SN TRANSMITTER – BEDIENUNGSANLEITUNG

MU2B-0328GE51 R0207A

18

SN TRANSMITTER

MENÜNAVIGATION

MODE FUNCTION

OUTPUTSTART-PT END-PT

AUTO-0 SET ZERO RESET 0

PRESSURE,

STATE

START-PT.

WELCOME

END-PT. MODE FUNCTION ATTENUATION

MESSAGE MESSAGE

ATTENUATION

PEAKS

UNIT LANGU AGE BACKLIGHT REFRESH ROTATE CONTRAST

DISPLAY

CLEARMIN. MAX. TEMP. SIMUL. SET CODE RESET

EXTRAS

ENTER

CODE

GO TO

CONFIRM

A

LL

SETTINGS

PLAUSIBLE

?

NO YES

START-PT. END-PT. MODE FUNCTION ATTENUATION CODE SIMUL. STORING...

DISPLAY LEVEL

PARAMETRIZATION LEVEL

CODE

ERROR

START

CONFIRMATION LEVEL

Abb. 9. Menünavigation - Übersicht (SN)

Geräte, die mit einem HMI-Kopf ausgestattet sind, vereinfachen die Konfiguration mit Hilfe der Drucktasten und einer

Anzeige. Die am Rande angezeigten Begriffe und Symbole

erleichtern die Navigation durchs Menü.

Das Menü läßt sich in folgende Bereiche aufteilen:

• STARTANZEIGE;

• DISPLAY-BEREICH (Informationsanzeige einschließlich

des aktuellen Drucks, sowie verschiedener Einstellwerte.

Editieren ist hier nicht möglich);

• CODE-BEREICH (Eingabe des vierstelligen CODEs, um

in die nächste Ebene zu gelangen);

• PARAMETRISIERUNGSBEREICH (Änderung

verschiedener Einstellwerte);

• PRÜFBEREICH (Überprüfung auf korrekte Eingabe und

ggfls. Zurückstufung in den PARAMETRISIERUNGSBEREICH); und

• BESTÄTIGUNGSBEREICH (Nochmalige Bestätigung der

Einstellwerte, bevor sie dauerhaft gespeichert werden).

STARTANZEIGE

Binnen 10 Sekunden nach Einschalten des Geräts erscheint

als erstes die STARTANZEIGE (siehe Abb. 10).

Startup

Abb. 10. Startanzeige

Danach gelangen Sie automatisch in den DISPLAYBEREICH.

DISPLAYBEREICH

Im DISPLAYBEREICH können Sie den aktuellen Druck sowie

diverse andere Einstellwerte sehen.

Function

A

tt. filter

Non-inv. 10%

MENU

NEXT

PREVIOUS

End

pressure

10.00bar

Mode

2-wire

4..20mA

Start

pressure

0.00bar

MENU

NEXT

PREVIOUS

ESCAPE ESCAPE

MENU

NEXT

PREVIOUS

ESCAPE

NEXT

PREVIOUS

ESCAPE

MENU

NEXT

PREVIOUS

ESCAPE

MENU

0.22

bar

4.35mA

MENU

NEXT

PREVIOUS

Abb. 11. DISPLAYBEREICH (Beispiel: SN 2-Leiter)

Function

Att. filter

Non-inv. 10%

MENU

NEXT

PREVIOUS

End

pressure

10.00bar

Mode

3-wire

0..10V

Start

pressure

0.00bar

MENU

NEXT

PREVIOUS

ESCAPE ESCAPE

0.22

bar

0.21V

MENU

NEXT

PREVIOUS

MENU

NEXT

PREVIOUS

ESCAPE

NEXT

PREVIOUS

ESCAPE

MENU

NEXT

PREVIOUS

ESCAPE

MENU

Abb. 12. DISPLAYBEREICH (Beispiel: SN 3-Leiter)

EINGABE DES ZUGANGSCODES

Um in den PARAMETRISIERUNGSBEREICH zu gelangen

und dort Einstellwerte ändern zu können, müssen Sie sich

zuerst mit der erforderlichen Autorisierung ausweisen. Dies

geschieht durch Eingabe des vierstelligen ZUGANGSCODEs

(Standardwert: 0000).

SMART SN TRANSMITTER – BEDIENUNGSANLEITUNG

MU2B-0328GE51 R0207A

19

CODE

NOT

V

ALID

Put code

0000

OK

-

+

0

Put code

0000

-

+

8

Put code

0000

-

+

9

Put code

0009

-

+

0

Put code

0009

-

+

1

Put code

0009

-

+

4

Put code

0009

-

+

5

ESCAPE

OK OK

LEFT LEFT LEFT

OK OK OK OK

Put code

0000

-

+

1

OK

LEFT

LEFT LEFT LEFT LEFT

Abb. 13. Eingabe des ZUGANGSCODEs

PARAMETRISIERUNGSBEREICH

Nach Eingabe des richtigen ZUGANGSCODE und Gelangen

in den PARAMETRISIERUNGSBEREICH können Sie

Einstellwerte ändern sowie das Gerät umkonfigurieren.

HINWEIS: Die aktuelle Einstellung (z.B. "Ja", "Nein",

"4…20 mA" usw.) ist an einem kleinen Punkt zu

erkennen (siehe Abb. 14).

Function

N.O.

OK

N.C.

ESCAPE

Function

N.O.

N.C.

ESCAPE

OK

DOT

Abb. 14. Kennzeichnung der akt. Einstellung

START-PT. (STARTPUNKT)

In dieser Anzeige können Sie den Startpunkt einstellen. Der

Startwert ist der Druck, bei dem das Gerät anfangen soll,

einen analogen Ausgang zu liefern.

Die Werkseinstellung ist "0".

FEHLERMELDUNG: "VALUE OUT OF RANGE"

Falls Sie einen Startwert gewählt haben, der außerhalb des

zulässigen Druckmessbereichs oder inkorrekt ist, erscheint

diese Fehlermeldung, worauf hin Sie einen richtigen Wert

eingeben sollen.

END-PT. (ENDPUNKT)

In dieser Anzeige können Sie den Endpunkt einstellen. Der

Endpunkt ist der Druck, bei dem das Gerät kein analoges

Ausgangssignal mehr liefern soll.

Die Werkseinstellung beträgt 100% von FS.

FEHLERMELDUNG: "VALUE OUT OF RANGE"

Falls Sie einen Endwert gewählt haben, der außerhalb des

zulässigen Druckmessbereichs oder inkorrekt ist, erscheint

diese Fehlermeldung, worauf hin Sie einen richtigen Wert

eingeben sollen.

OUTPUT (AUSGANG)

MODE (MODUS)

Hier können Sie zwischen vier verschiedenen Betriebsmodi

wählen:

• 0…10V: Spannungsbereich = auf 0…10 V;

• 0…20mA: Strombereich = 0…20 mA;

• 2…10V: Spannungsbereich = 2…10 V;

• 4…20mA: Strombereich = 4…20 mA (Werkseinstellung).

HINWEIS: Der SN 2-Leiter Transmitter unterstützt nur den

"4…20 mA" Modus. Dies kann jedoch in

"20…4 mA" invertiert werden siehe Abschnitt

"Function (Funktion)" unten).

FUNCTION (FUNKTION)

Hier können Sie die Gerätefunktion invertieren (siehe auch

Abb. 15):

• "Non-invert.": der Modus (Strom- bzw. Spannungsbereich)

wird auf 0/4…20 mA bzw. 0/2…10 V eingestellt

(Werkseinstellung);

• "Inverted": der Modus (Strom- bzw. Spannungsbereich)

wird auf 20…0/4 mA bzw. 10…0/2 V eingestellt.

Die Werkseinstellung ist "non-invert."

U/I

MAX MAX

U/I

MAX MAX

U/I

MIN MIN

U/I

MIN MIN

output U/I output U/I

NORMAL OPERATION INVERTED OPERATION

pressure pressure

pressure

start

pressure

start

pressure

end

pressure

end

Abb. 15. SN Transmitter Ausgang (normal/invertiert)

AUTO ZERO

Die "auto zero"-Funktion ermöglicht es dem Anwender, das

Gerät entsprechend den lokalen atmosphärischen Druckverhältnissen einzustellen sowie den Drift auszugleichen. Um

diese Funktion richtig anzuwenden, sollte das Gerät am

Einsatzort eingebaut und der Druckfühler den örtlichen

Umgebungsdruck ausgesetzt sein (d.h. 0 bar Relativdruck).

• "Yes": Das Gerät übernimmt den örtlichen Umgebungsdruck als seinen Nullwert.

• "No": Die Geräteeinstellung bleibt unverändert.

Die Werkseinstellung ist "No".

SET ZERO (NULLABGLEICH)

Der Unterschied zwischen dem Druckwert, den Sie in diesem

Menüfenster eingeben, und dem aktuell gemessenen Druck

stellt den Offset (Nullabgleich) dar. Dieser Nullabgleich kann

mit dem "reset zero"-Option (siehe unten) wieder auf Null

gestellt werden.

Die Standardeinstellung ist der aktuell gemessene Druck (d.h.

der Nullabgleich beträgt dann Null).

FEHLERMELDUNG: "VALUE OUT OF RANGE"

Falls Sie einen " Nullabgleich " gewählt haben, der außerhalb

des zulässigen Bereichs (±25% FS) liegt, erscheint diese

Fehlermeldung, worauf hin Sie einen richtigen Wert eingeben

sollen.

RESET ZERO

Hier können Sie den Nullwert wieder einstellen:

• "Yes": Der Nullabgleich wird auf "Null" gesetzt.

• "No": Die Geräteeinstellung bleibt unverändert.

Die Werkseinstellung ist "No".

ATT. FILTER (DÄMPFUNG)

Hier können Sie den ausgegebenen Anteil der Spitze

dämpfen. Mögliche Werte sind 0…99%. Die Werkseinstellung

ist "10" Prozent.

Die Formel zur Berechnung der Dämpfung lautet wie folgt:

1

100

)

100

1(

−

+−=

nnn

y

Dämpfung

x

Dämpfung

y

SMART SN TRANSMITTER – BEDIENUNGSANLEITUNG

MU2B-0328GE51 R0207A

20

Wobei

y

n

den analogen Ausgangswert darstellt,

x

n

den gemessenen, abgeglichenen Druck des jetzigen

Zyklus' und

y

n-1

den analogen Ausgangswert des vorigen Zyklus'

darstellt.

PEAKS (SPITZENWERTE)

Hier können Sie die historischen Maximal- und Minimaldrücke

sehen sowie die Maximaltemperatur (historisch = gemessen

seit Inbetriebnahme bzw. seit dem letzten Löschen der

Spitzenwerte).

Falls erwünscht, können Sie zu "Clear" ("Löschen") vorgehen

und "Yes" wählen; sämtliche gespeicherte Spitzenwerte

werden dadurch gelöscht und die Aufzeichnung von

Spitzenwerten wird wieder initiiert.

DISPLAY

Hier können Sie verschiedene Anzeigemodi auswählen.

UNIT (EINHEITEN)

Hier können Sie die Einheiten, in denen das Gerät den Druck

anzeigt, wählen:

• bar: Der Druck wird in bar angezeigt.

• Pa: Der Druck wird in Pascal angezeigt.

• Psi: Der Druck wird in pounds / in

2

angezeigt.

Die Werkseinstellung ist "bar".

LANGUAGE (SPRACHE)

Die unterstützte Menüsprache ist ENGLISCH.

BACKLIGHT (HINTERGRUNDBELEUCHTUNG)

Hier können Sie die Hintergrundbeleuchtung einstellen:

• "Always": Die Hintergrundbeleuchtung bleibt immer EIN.

• "Demand": Die Hintergrundbeleuchtung geht an, sobald

eine Taste betätigt wird und erlischt nach 25 Sek.

• "Never": Die Hintergrundbeleuchtung ist dauerhaft AUS.

Die Werkseinstellung ist "Never".

HINWEIS: Die einzige Hintergrundbeleuchtungsoption, die

beim SN 2-Leiter Transmitter unterstützt wird, ist

"Never."

REFRESH (AKTUALISIEREN)

Hier können Sie die Aktualisierungsrate (in Sekunden) des

Displayinhalts einstellen.

Mögliche Werte sind 1…9 Sekunden.

Die Werkseinstellung beträgt "1" Sek.

ROTATE (DREHEN)

Hier können Sie (zur besseren Lesbarkeit) die Ausrichtung

des Displays dauerhaft um 0°, 90°, 180° oder 270° drehen.

Die Werkseinstellung ist "0" Grad (d.h. senkrechte

Ausrichtung bei aufrechter Einbaulage).

CONTRAST (KONTRAST)

Hier können Sie den Kontrast des Displays einstellen:

• "Min.": Der Kontrast wird auf den Mindestwert eingestellt;

• "Mean": Der Kontrast wird auf den Mittelwert eingestellt;

• "Max.": Der Kontrast wird auf den Höchstwert eingestellt.

Die Werkseinstellung ist "Mean".

EXTRAS (ZUSATZFUNKTIONEN)

SIMUL. (SIMULATIONSMODUS)

Der Simulationsmodus ermöglicht es dem Anwender, die

reibungslose Funktion des Geräts zu prüfen, ohne das

System unter Druck zu setzen.

Nach Aufrufen des Simulationsmodus sind die Diagnostikfunktionen nicht wirksam, und das Gerät kann nicht in einer

echten Sicherheitsanwendung eingesetzt werden.

Nach Verlassen des Simulationsmodus und Rückkehr in die

normale Betriebsart kann das Gerät wieder in Sicherheitsanwendungen eingesetzt werden.

• "Yes": Der Simulationsmodus wird aufgerufen.

• "No": Das Gerät bleibt in seiner normalen Betriebsart.

Die Werkseinstellung ist "No".

VORSICHT

Nach Abschluß Ihres Tests im Simulationsmodus müssen Sie

darauf achten, zu diesem Menüfenster zurückzukehren und

die normale Betriebsart wieder zu aktivieren.

SET CODE (CODE EINSTELLEN)

Hier können Sie den ZUGANGSCODE neu definieren. Nach

Verlassen des PARAMETRISIERUNGSBEREICHS und

Durchlauf durch den BESTÄTIGUNGSBEREICH wird der

neue ZUGANGSCODE dann wirksam.

RESET

Hier können Sie das Gerät wieder auf Werkseinstellung (d.h.

Standardwerte) zurücksetzen:

• "Yes": Alle Werkseinstellungen werden wieder wirksam.