Felton Feltonmix U, Feltonmix H, Feltonmix E Installation Manual

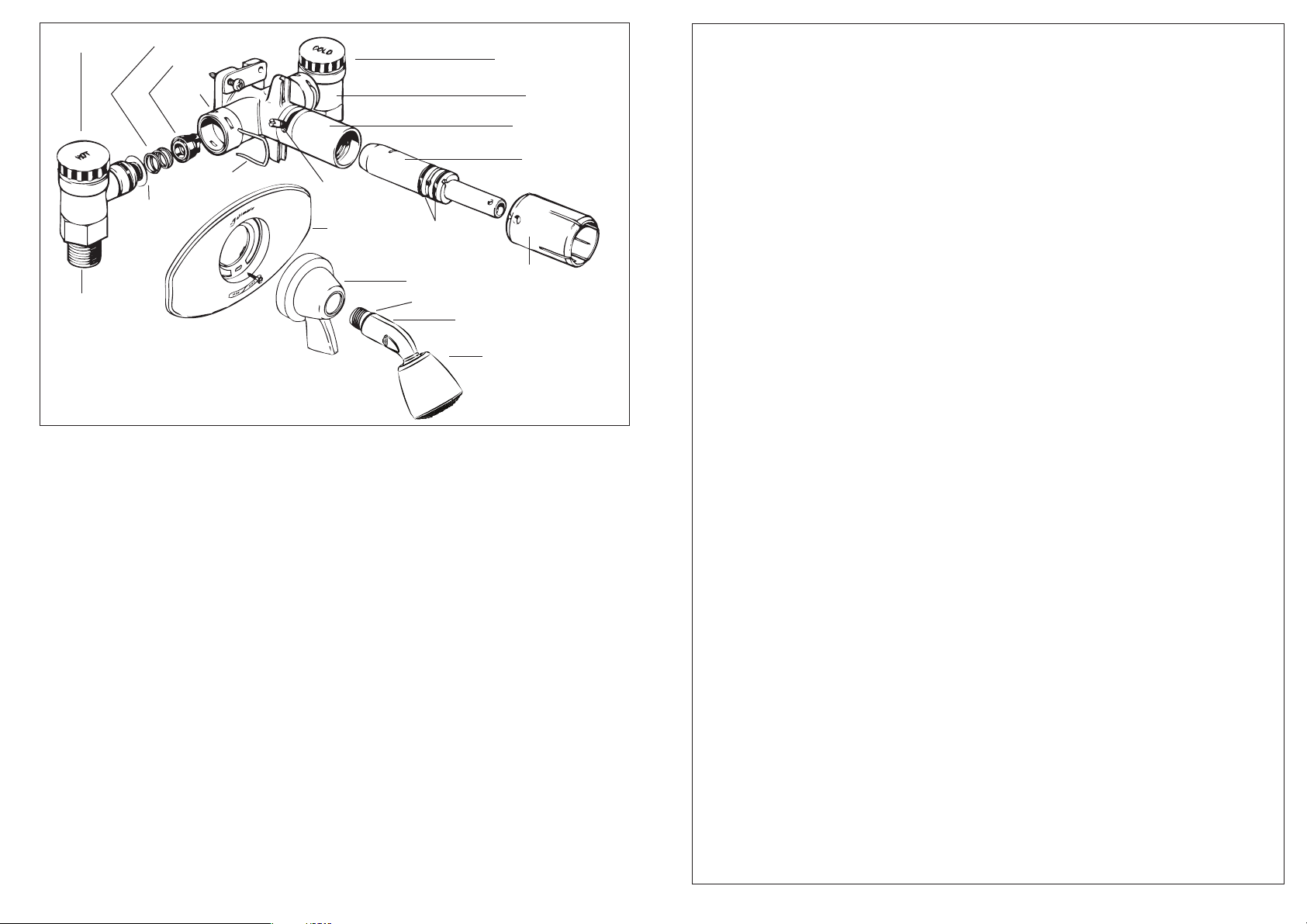

Red Knob ‘HOT’

Compression Spring

Shut-off Seals

Clip

Groove

Blue Knob ‘COLD’

ISOLATOR

Feltonmix

Stainless

Steel Clip

Filters

Isolator

O-Ring

Brass Nipple

SERVICE NOTES

To Replace Seals and Springs

A rubber shut-off seal and spring is fi tted in each

of the two inlets of the valve body and two O-ring

seals fi tted to the rotor located inside the valve

body.

1. Unscrew shower head and stem from valve

body.

2. Using both hands support the handle top and

bottom and withdraw from valve body.

3. Remove wallplate by unscrewing the two

1

⁄

x 7 fi xing screws.

1

8

4. Turn off water supply at either the mains or

the shower mixer isolators.

5. Gently prise stainless steel retaining clips on

valve body outwards with screwdriver and

remove clips completely. Pull isolators clear

of valve body.

6. Unscrew mixer retaining screws and remove

mixer from wall.

7. Remove grub screw from control sleeve.

8. Withdraw rotor from body using a suitable

tool through cross hole in rotor.

9. Using seal extractor tool supplied with the

replacement seal pack, insert end marked

'REMOVE' fully into hole in centre of seal

and withdraw seal and spring.

240613DT

Use only GENUINE FELTONMIX Replacement Parts

MIXER BODY

Rotor

Grub Screw

Wallplate

10.

11. Fit seal in inlet bore with turning motion until

12. Discard O-Ring seals on rotor. Replace with

13. Discard isolator O-Rings and fi t new O-Rings

14. Re-assemble in reverse manner. Insert rotor

Filters

Each isolator is fi tted with a fi lter. These fi lters can

be easily prised out, cleaned and snapped back

into place.

Rotor O-Ring Seals

Handle

Shower Stem O-Ring

Fit blade of seal extractor tool end marked

'REPLACE' into slots in bore of new seal and

spring.

lugs on seal engage in slots in bore of inlet.

Push fully home.

new O-Ring seals.

supplied.

in body. Fit isolators to mixer body. Insert

stainless steel retaining clips through slots

In valve body and press fully home

Control Sleeve

Shower Head Stem

Shower Head

The Perfect Shower Every Time

SHOWER MIXING VALVES

Felton Industries Ltd warrant to the purchaser of this shower mixer

that it is free from defects in materials and workmanship. Accordingly

we undertake to repair or replace and part which we are satisfi ed is

defective for up to fi ve years after installation date. This warranty is

valid only when the mixer is installed by a qualifi ed plumber, to the

following instructions.

Felton Industries Limited is an IS09002 Registered Supplier, and

Feltonmix

AS/NZS 3718:2005, Licence No. WMKA25208 and New Zealand

Standard 4611: 1982, Licence No. 2491.

Three models are available to suit different conditions. Filters are fi tted

to protect parts from damage caused by water born particles. Removal

of these fi lters may void the warranty.

The maximum hot water temperature should not exceed 80ºC

Feltonmix

For use on unequal supply pressures. Mains pressure cold i.e.

supplies from 150 kPa to maximum 500kPa ; low pressure hot i.e.

minimum of 20 kPa to maximum 150 kPa fl ow pressure.

Feltonmix

For use on equal high supply pressures. Mains pressure hot and cold

i.e. supplies from 150 kPa to maximum 500kPa fl ow pressure.

Feltonmix

For use on equal low supply pressures. Hot and cold supply from

minimum 20 kPa to maximum 150 kPa.

Note: A pressure reducing valve in compliance with AS 1357 may

need to be fi tted to maintain supply pressure below 500 kPa.

®

shower valves are manufactured to WaterMark standard

®

Type U - Blue Rotor.

®

Type H - Pink Rotor.

®

Type E - Green Rotor.

Installation Instructions

45 mm

from back

of mixer

to front of

shower

wall Lining.

Warning:

Do not overtighten. Light pressure is suffi cient

to clamp the wallplate fi rmly.

5. Rotate slotted sleeve on valve body

(projecting from central hole of wallplate

anticlockwise and fi t handle to sleeve,

locating a

t the 4 o’clock position. Handle

should recess into the wallplate and match

its contours. Ensure that handle has about

10 mm of engagement.

64 mm

Height

of

recess.

1. Provide a stud or other suitable fi xing in the

shower wall on which to mount the shower valve

Shower head at about eye level (between 1.5 and

1.8 metres) is a good guide. Ensure distance from

mounting face to front of wall lining is 45mm.

2. Flush out pipework. Mount shower valve

assembly and secure with two wood screws

provided. It is important that the pipes which are

now connected directly to the isolator valves on

each side of the shower valve assembly line up

correctly with the isolators and do not place any

unnecessary strain on the valve assembly. Ensure

isolators are open, (turn anticlockwise).

Do not apply heat to pipes connected to the mixer

as internal damage may occur.

Note: When tightening crox nuts it is important to

hold the hexagon face to prevent any strain on the

isolator. Do not attempt to tighten or rem

the brass nipple from the isolator. This has

been installed with correct pre-loading at the

factory and any alteration may cause damage

to the isolator.

3. Cut an access hole in the wallboard to suit the

shape of the wallplate using the template provided.

4. Position the wallplate over the valve outlet and

fi t the two 1

wallplate slot and into the valve body lugs. Tighten

screws alternately until wallplate is fi rmly clamped

to the wall.

FELTONMIX® Shower Valves

Types U, E and H

1

/8 x 7 screws provided through each

6. Screw showerhead into valve assembly

until full home. If necessary unscrew the

showerhead part of a turn to bring it to the

correct position. The O-ring seal fi tted to the

showerhead stem will ensure a watertight

seal. Tape or hemp on the thread is not

necessary or desirable.

7. CHECK OPERATION. When installed check

that the handle swins from right to left from

OFF to HOT. Total movement is about 130°.

ove

TROUBLE SHOOTING

Insuffi cient Water Flow:

Check that the correct model (Type U,

Type E or Type H) has been installed for

the supply conditions. Check fi lters for

foreign

matter.

Insuffi cient Hot Water:

Check that isolators are fully open

(unscrewed anticlockwise) Check that

suffi cient water pressure is reaching the

valve. A minimum of 20 kPa (3 p.s.i.) fl ow

pressure is recommended.

Inadequate hot water temperature and/or

fl ow may also be experienced if a

To protect your investment, use only Genuine Feltonmix Spare Parts. Substitutes

may damage the Feltonmix product. Authorised parts carry the description

GENUINE SPARE PARTS MANUFACTURED BY FELTONMIX LTD, AUCKLAND, N.Z.

tempering valve is fi tted and is not

installed strictly in accordance with the

manufacturer’s instructions.

Valve does not shut off properly:

Check seals.

Water leaks from behind handle:

If water is leaking from under slotted

sleeve when shower is on it will be

necessary to replace O-ring seals on rotor.

(see a/so Service Notes)

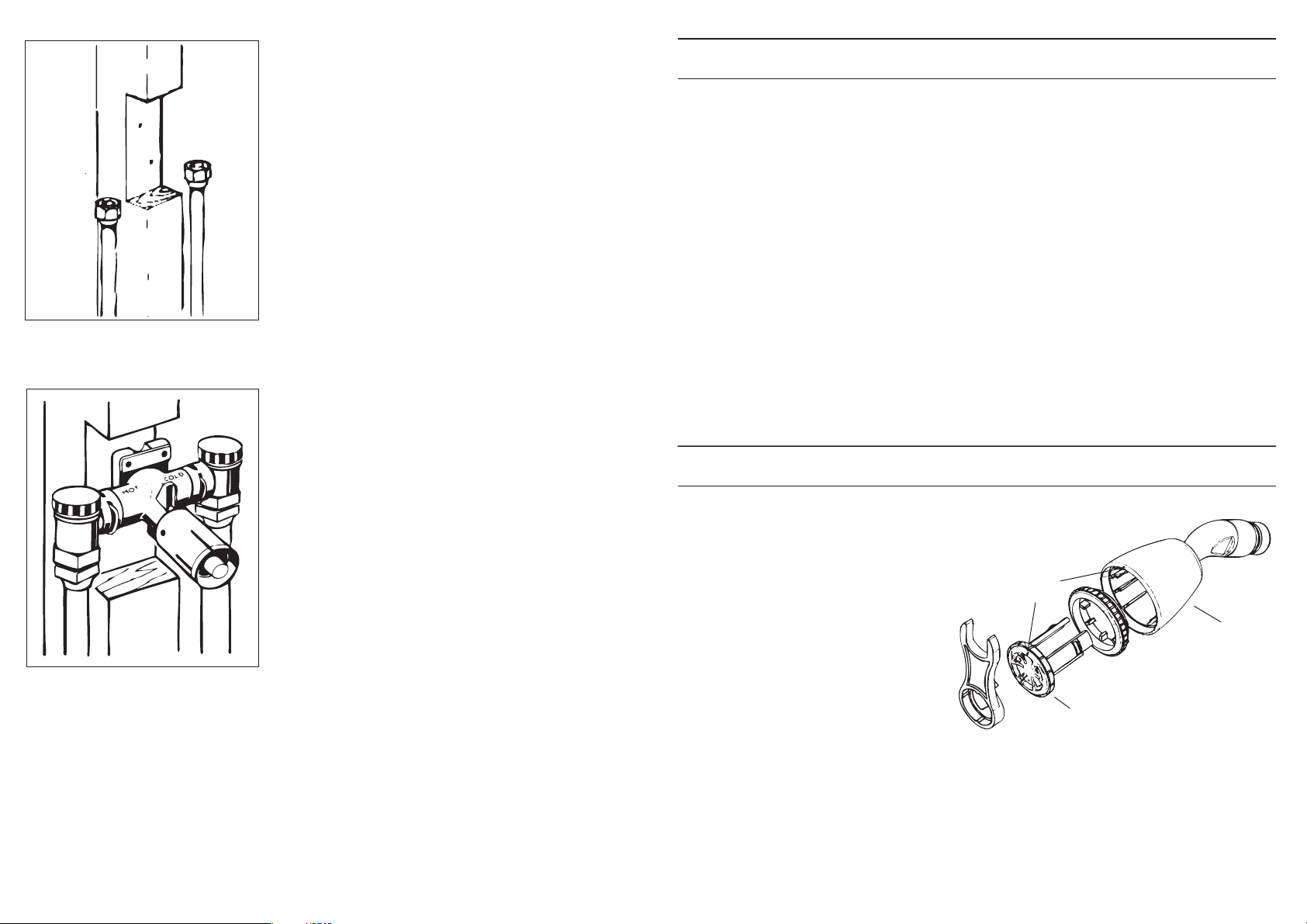

SHOWER HEAD

Your Feltonmix shower head is manufactured

from self-cleaning plastic materials and cleaning

with a soft nylon brush and bathroom cleaners is

usually suffi cient.

If dismantling is required, insert the two leg’s

of the Feltonmix spanner into the face

of the rose. Turn the rose approximately

thirty degrees and withdraw it from the

shower head body.

When assembling ensure that the sharp

outer edge of the soft spray ring is

located at the front edge of its support

ring. Align the assembly pips on the front face

of the rose and lip of the body. Push them together

until they click twice.

Manufac

tured by

FELTON INDUSTRIES LTD

Freephone 0800 PH FELTON (0800 743 358)

Free Fax 0800 FAX FELTON (0800 329 335)

www.felton.co.nz

Assembly

pips

Body

Rose

Loading...

Loading...