Page 1

Brisa

™

assembly and operation instructions

electric table base

model 2B-C48-__-___

__ = color combination (shroud/feet)

___ = SLV, BLK or WHT (column and frame)

Page 2

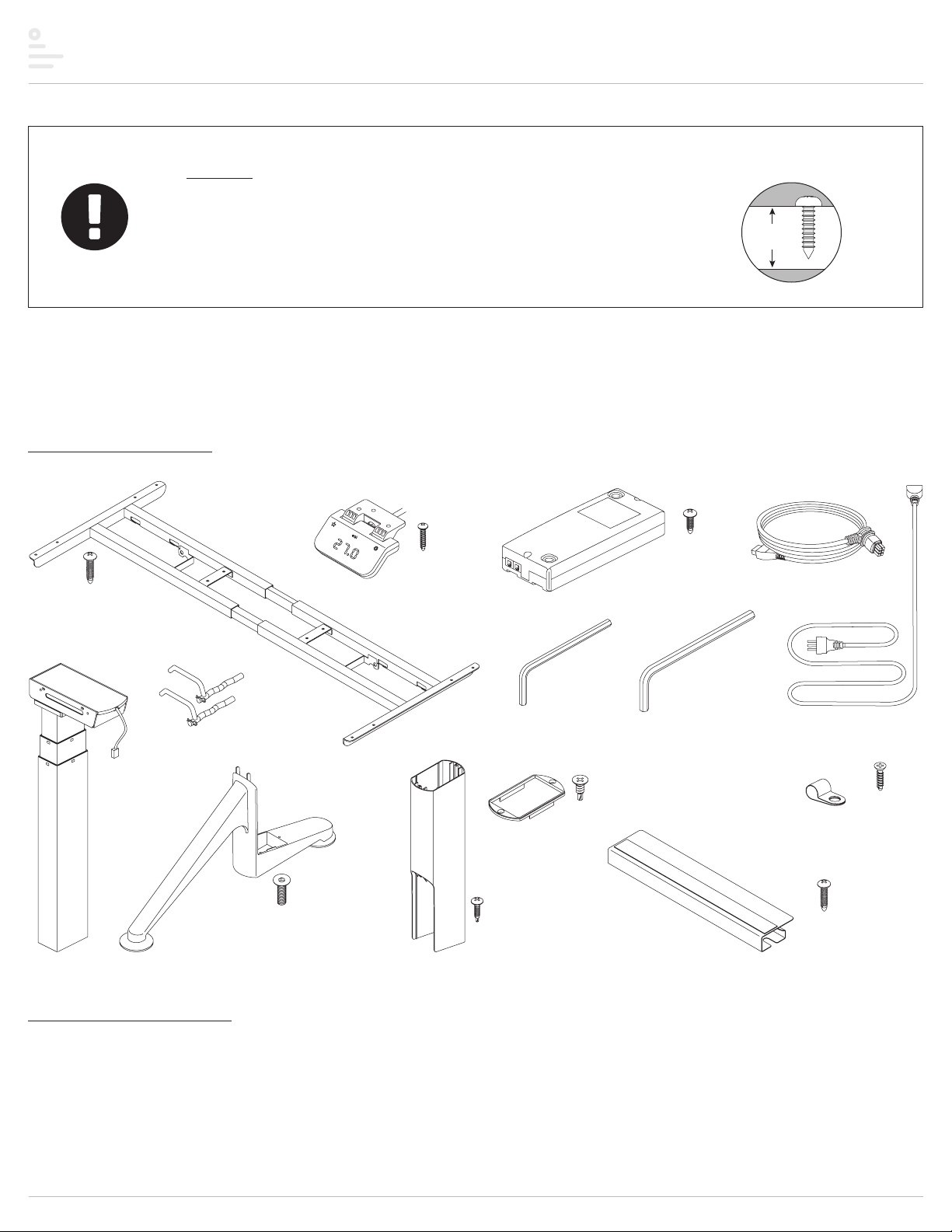

Brisa™ electric table base components and tools

work

surface

C48 frame (1)

control unit (1)

motor cable (2)keypad (1)

caution

• When drilling holes for the wood screws, guard against drilling through the

top of the worksurface.

• Always check that screws used to attach components to the worksurface

are not too long for the thickness of the surface.

Please review these instructions before beginning the installation. Use the illustrations below to check that the all components needed for your

installation were provided with your order. Do not discard the packaging until the product works to your satisfaction.

components and tools

round head (12)

M4.8x22

#2 Phillips

legs with

motor (2)

cam locks (2)

with cotter pin

feet (2)

M6x22 socket

flat head (8)

round head (3)

shroud (2)

M3x18.5

#1 Phillips

leg caps (2)

M4x15

#2 Phillips

round head (2)

4mm

Allen key (1)

#8-18x½"

#2 Phillips

flat head (4)

M5x15

#2 Phillips

round head (2)

5mm

Allen key (1)

cord-organizing

trough (2)

power cable (1)

cord clips (10)

M3.5x16

#2 Phillips

flat head (10)

M4.8x22

#2 Phillips

round head (6)

additional tools required

• power drill with assorted drill bits

• Phillips screwdriver

• Phillips #1 and #2 bits

Page 2

Page 3

Brisa™ electric table base assembly

1" with 24" table

step 1: position frame on table

With the table top facing down on a soft, clean surface, arrange the frame as shown below. The short end of the top supports must be toward the rear.

• Position the frame side to side.

— Loosen all eight set screws using the 5mm Allen key. Expand or compress the frame so that the top supports are 1" from the edges of the table. There are scribe

marks on the expanding portion of the cross channels; center the longest scribe mark. Then tighten the eight set screws.

• Position the frame front to back.

— With tables that are 24" deep, position the rearmost hole on the top supports 1" from the rear edge of the table. With 30" tables, position the rearmost holes 4" from

the rear edge of the table. This position of the frame will center the feet front to rear when they are installed in step 5.

short end toward rear

1"

top

support

center longest

scribe mark

step 2: screw frame to table

• Use the M4.8x22 #2 Phillips round head screws

(12 screws total).

• Screw through the top supports and cross

supports, as shown.

rear

M10 x 25

socket set screw

front

4" with 30" table

cross channel

loosen

set screws

feet

will be

centered

front

to rear

1"

M4.8x22

#2 Phillips

round head (12)

top support

cross support

Page 3

Page 4

Brisa™ electric table base assembly

step 3: attach legs to frame

• Remove the cotter pin from each cam lock and save it for use later in this step.

• Position each leg.

— First lower the protrusions on the motor housing into the notches.

— Then push the protrusions back toward the top supports into the narrower part of the notches.

• Route the motor cable on each leg under the frame support, as shown.

• Install the cam lock. With the lever arm upward, insert the long end of the cam lock first, as shown.

• After the cam lock is installed, rotate its lever arm toward the leg until the lever is horizontal. This locks the

leg in place.

• Install the cotter pin to secure the cam lock.

• Check to be sure each leg is securely locked in position.

cam lock

cotter pin

WARNING: The cam locks must be in the locked position at all times to secure the

legs in place.

position leg

install cam lock,

long end first

route motor

cable under

frame support

step 4: attach leg caps to shrouds

• Secure a leg cap to the top of each shroud with the self-tapping #8-18x½” #2 Phillips flat head screws.

leg cap

remove and save

rotate lever

to lock leg

secure

with cotter pin

#8-18x½"

#2 Phillips

flat head

Page 4

shroud

Page 5

Brisa™ electric table base assembly

step 5: insert shroud assemblies over legs

• Slide the shroud assemblies over the legs with the cutout

portion of the shroud toward the front, as shown.

• Lower the shroud all the way down to the motor end of

the legs.

cutout

faces front

shroud assembly

installed

shroud

step 6: attach feet to legs

• Attach the feet to the legs using the 4mm Allen key

and four M6x22 socket flat head screws per foot.

• The angled part of the foot faces front, as shown.

angled part

toward front

4mm Allen key

M6x22

socket flat head

Page 5

Page 6

Brisa™ electric table base assembly

step 7: attach shrouds to feet

• Raise each shroud up to the foot. Be sure the edges of the shroud are flush with the edges of the foot.

• Attach the shroud with one M4x15 #2 Phillips pan head screw per foot. The screw is self-tapping; use sucient torque to tighten it securely, but be careful not to strip

the shroud extrusion.

M4x15

#2 Phillips

round head (2)

shroud flush

with foot

Page 6

Page 7

Brisa™ electric table base assembly

step 8: attach cord-organizing troughs

• Two troughs may be installed to help organize the cords and

cables.

• Peel the backing from the double-sided tape on the bottom of

the troughs. Center the troughs at the rear of the table against

the frame cross channel.

• Secure each trough with three M4.8x22 #2 Phillips round head

screws.

M4.8x22

#2 Phillips

round head

trough

rear of

table

double-sided tape

installed troughs

step 9: attach keypad

• Install the keypad on the left or right side of the table, according to user preference.

• Position the back of the keypad 11/8" from the front edge of the table, as shown below.

• Attach the keypad using the three M3x18.5 #1 Phillips round head screws.

M3x18.5

#1 Phillips

round head

keypad

11/8"

11/8"

Page 7

Page 8

Brisa™ electric table base assembly

step 10: attach control unit

• Place the control unit between the cross channels. Position it so that the

cable from the keypad can reach the control unit and the motor cables can

extend from the control unit to both motors.

• Attach the control unit using the two M5x15 #2 Phillips round head screws.

control

unit

M5x15 #2 Phillips

round head

step 11: make connections and organize cables and cords

While making the following connections, organize the cables and cords using the troughs and the provided

cord clips. The cables and cords must not dangle under the table where they may present a hazard

to the user or may accidentally be pulled from their connections.

• Connect the cable from the keypad to one of the end ports on the control unit,

as shown.

• Connect the motor cables to the ports on top of the control unit and to the short

cable from each table leg.

• Connect the power cord to the control unit.

• Plug the power cord into an AC outlet. Be sure the cord can reach the outlet

when the table is raised to its highest position.

CAUTION: Do not operate the table until after initializing the system.

See step 12 on the next page.

trough

motor

cable

keypad

cable

cord clip

motor

cable

power cord

M3.5x16

#2 Phillips

flat head

Page 8

Page 9

Brisa™ electric table base assembly

keypad

step 12: use keypad to initialize the system

• Press and hold the star and gear buttons simultaneously for more than six

seconds. The legs will begin to move down at half the speed of normal operation.

• Continue to press the star and gear buttons. The legs will move down to the

lowest position, then rebound approximately 1/16" (2mm) and stop.

• Release the star and gear buttons at the same time. This completes the

initialization procedure.

star

button

IMPORTANT: The initialization procedure above must be completed

before operating the table.

NOTE: The unit must be re-initialized anytime power is cut to the unit.

step 13: test operation

• The keypad works like a lever switch. Press the lever down or lift it up to test operation.

— Release the lever to stop movement of the table. The table must stop prior to reversing direction.

• End your test with the legs lowered and then unplug the power cord.

• If there are problems with operation, check that all cable and cord connections are secure. If problems continue, call ESI Customer Service.

gear

button

move lever to

test operation

step 14: turn the table upright

With the assistance of a helper, turn the table upright and place it in its final position. IMPORTANT: There must be 1" (25mm) of clearance on all sides

of the worksurface (and other moving parts) to ensure free, unobstructed movement.

• If necessary, adjust the leveling glides on the feet to level the worksurface.

• Plug the power cord into an AC outlet.

• Re-initialize the table as described in step 12. IMPORTANT: Be sure there are no obstacles under the table that would prevent it from reaching its lowest position.

• See the operating procedures beginning on page 10.

Page 9

Page 10

Brisa™ electric table base operation

star

button

lift up or press downkeypad lever

LED height display

(inches or centimeters)

general operation

• Move the table by lifting the lever up to raise it or pressing the lever down

to lower it.

• The table will continue to move up or down until you release the lever or

until the maximum or minimum height is reached.

Table movement stops when you release the lever.

NOTE: The table must stop prior to reversing directions.

memory stop positions

Two memory stop positions can be used to save specific heights of the

worksurface. To set a specific position:

• Raise or lower the table to the first position you want to save.

• Touch the star button for more than three seconds and then release.

— The LED display flashes and stop position #1 is saved.

• Raise or lower the table to the second position you want to save.

• Touch the star button for more than three seconds.

— The LED display flashes and stop position #2 is saved.

If you try to set a third memory position, you will reset position #2.

To move the worksurface to a memory stop position:

• Lift or press the lever until the table stops. Release the lever.

— If you continue to lift or press the lever after it stops, the table will

continue to move up or down.

If you release the memory button before the saved position is reached, table

movement will stop.

To delete a memory stop position:

• Move the worksurface to the memory stop position you wish to delete.

• Touch the star button for more than three seconds.

— The LED display flashes. Release the star button.

— The stop position is deleted.

To delete both memory stop positions at the same time:

• Touch the star button for more than eight seconds.

— The LED display flashes and will show “CLr”.

— Release the star button. Both stop positions are deleted.

gear

button

CAUTION: The initialization procedure

must be completed before operating

the table. See Step 12 on page 9.

top height limit

To set the top height limit (the maximum height of the table):

• Use the lever to move the table to the desired maximum height.

• Touch the gear button six times. The display reads “F01”.

• Lift or press the lever until the display reads “F03”.

• Touch the gear button for three seconds. The display reads “–L–”.

— Release the gear button. The top height limit is set.

If there is a memory stop position higher than the top height limit, the

memory stop will be erased.

To erase the top height limit:

• Use the lever to move the table to any position.

• Touch the gear button six times. The display reads “F01”.

• Lift or press the lever until the display reads “F04”.

• Touch the gear button for three seconds. The display reads “–C–”.

— Release the gear button. The top height limit is erased.

If there was a memory stop position higher than the top height limit, the

memory stop needs to be set again.

bottom height limit

To set the bottom height limit (the minimum height of the table):

• Use the lever to move the table to the desired minimum height.

• Touch the gear button six times. The display reads “F01”.

• Lift or press the lever until the display reads “F05”.

• Touch the gear button for three seconds. The display reads “–L–”.

— Release the gear button. The bottom height limit is set.

If there is a memory stop position lower than the bottom height limit, the

memory stop will be erased.

To erase the bottom height limit:

• Use the lever to move the table to any position.

• Touch the gear button six times. The display reads “F01”.

• Lift or press the lever until the display reads “F06”.

• Touch the gear button for three seconds. The display reads “–C–”.

— Release the gear button. The bottom height limit is erased.

If there was a memory stop position lower than the bottom height limit, the

memory stop needs to be set again.

Page 10

Page 11

Brisa™ electric table base operation

height display units

To change the height display from inches to centimeters:

• Touch the gear button six times. The display reads “F01”.

• Lift or press the lever once. The display should continue to read “FO1”.

• Touch the gear button for three seconds. The height of the table is now

displayed in centimeters

— Release the gear button. The height display change from inches to

centimeters is complete.

To change the height display from centimeters to inches:

• Touch the gear button six times. The display reads “F01”.

• Lift or press the lever until the display reads “F02”.

• Touch the gear button for three seconds. The height of the table is now

displayed in inches.

— Release the gear button. The height display change from centimeters to

inches is complete.

adjusting the height readout

To set the display height of the table to account for dierent

worksurface thicknesses:

• Use the lever to move the table to the lowest position.

• Measure and record the height of the top of the worksurface in inches or

centimeters.

• Touch the gear button six times. The display reads “F01”.

• Lift or press the lever until the display reads “F09”.

• Touch the gear button once. The display reads “058”. The first number (“0”)

flashes.

• If necessary, lift the lever to increase the first number to match your

measurement.

— If the display height is in centimeters, the first number remains zero

(assuming the table is in the lowest position).

— If the display height is in inches, the first number will be the “tens”

column. (Example: If your measurement is 24”, the first number will

be “2”.) Lift the lever to increase the first number to “2”.

• Touch the gear button once. The second number (“5”) flashes.

• If necessary, lift or press the lever to increase or decrease the second

number to match your measurement.

• Touch the gear button once. The third number (“8”) flashes.

• If necessary, lift or press the lever to increase or decrease the third number

to match your measurement.

— If the display height is in inches, the third number will be either “0” or “5”.

(The “5” equals ½” — see note below.)

• Touch the gear button for three seconds. The height adjustment is complete.

In inch format, the minimum adjustable amount (third digit) is 0.5”. (The third

digit will be either 0 or 5.) In centimeter format, the minimum adjustable

amount (third digit) is 1 cm. (The third digit will be 0 through 9.)

leveling

To correct the gravity reference:

• Touch the gear button six times. The display reads “F01”.

• Lift or press the lever until the display reads “F12”.

• Touch the gear button for three seconds. Current mounting position angle

is displayed.

• Gravity reference is complete.

gyro anti-collision sensitivity adjustment

The default anti-collision sensitivity is G-1. To increase or decrease the

sensitivity of the table to obstacles in the path of its movement:

• Touch the gear button six times. The display reads “F01”.

• Lift or press the lever until the display reads “F10”.

• Touch the gear button once. The display reads “G-4”.

• Lift or press the lever to increase or decrease the sensitivity level.

— There are five levels of sensitivity: “G-0”, “G-1”, G-2”, “G-3” and “G-4”.

— “G-4” is the highest level of sensitivity and “G-0” is no gyro sensitivity.

• Touch the gear button for three seconds. The anti-collision sensivity

adjustment is complete.

If the legs do not move when general operation is attempted, the gyro

sensitivity adjustment may be too high.

error codes

Error

Code

E01 Leg malfunction

E03

E04

E06

E12 Gyro error

Description Troubleshooting

1. Check that the leg cables are securely plugged

into the leg and control unit.

2. Inner parts of leg are broken. Replace the leg.

Table top

overload

Control unit

malfunction

Communication

interruption

1. Remove some weight from the table.

1. Re-initialize the system.

1. Check the cable connection between the keypad

and control unit. Verify that the cable is securely

plugged into the control unit.

2. If the problem is not resolved, replace the keypad

or control unit.

1. Communication is abnormal; power ON to

normalize communication.

2. Table is tilted; straighten table or wait one minute

before operating table.

IMPORTANT: The table should be re-initialized after every 1,000 cycles; every six months; or if power is cut or cable is unplugged accidentally.

When re-initializing, be sure there are no obstacles under the table that would prevent it from reaching its lowest position

Page 11

Page 12

Brisa

™

electric table base

Please contact Customer Service with any questions or

comments at 800.833.3746 or visit our website at esiergo.com

LIMITED WARRANTY

ESI warrants this product to be free from defects in manufacturing for a period of 15 years on structural parts and 7 years on electrical parts from the date of original purchase. This warranty

extends only to the original purchaser, and does not apply if the product has been damaged or fails to function properly as a result of misuse, abuse, modification, alteration, or improper cleaning or

maintenance. This warranty does not apply to damage in shipment caused by carriers, damage caused during installation, normal wear and tear, or excessive use (meaning consistent use in excess

of an eight hour shift). ANY IMPLIED WARRANTIES OF MERCHANTABILIT Y OR FITNESS FOR A PARTICULAR PURPOSE ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF ORIGINAL RETAIL

PURCHASE. ESI’s sole obligation under this warranty or any implied warranty, and the purchaser’s sole remedy, is limited to the repair or replacement, at ESI’s option, of the product or any defec tive

part. Costs (such as installation, labor fees or express shipping) incurred due to replacement of products are not covered under warranty. IN NO EVENT SHALL FELLOWES, ITS AFFILIATES, SUBSIDIARIES,

RELATED ENTITIES OR THEIR RESPECTIVE OFFICERS, DIRECTORS, OR EMPLOYEES, BE LIABLE FOR INCIDENTAL, CONSEQUENTIAL, PUNITIVE, EXEMPLARY, OR SPECIAL DAMAGES.

To make a warranty claim, contact ESI at 800-833-3746 or customerservice@esiergo.com. You must provide proof of purchase, such as the original purchase order number.

The duration, terms and conditions of this warranty are valid worldwide, except where dierent limitations, restrictions or conditions may be required by local law.

BR Rev B 5/2019© 2019 Fellowes, Inc.

Loading...

Loading...