Page 1

fellowes.com

Business Wire Binder

Please read these instructions before use.

Veuillez lire ces instructions avant utilisation.

Lea estas instrucciones antes del uso.

Page 2

ENGLISH

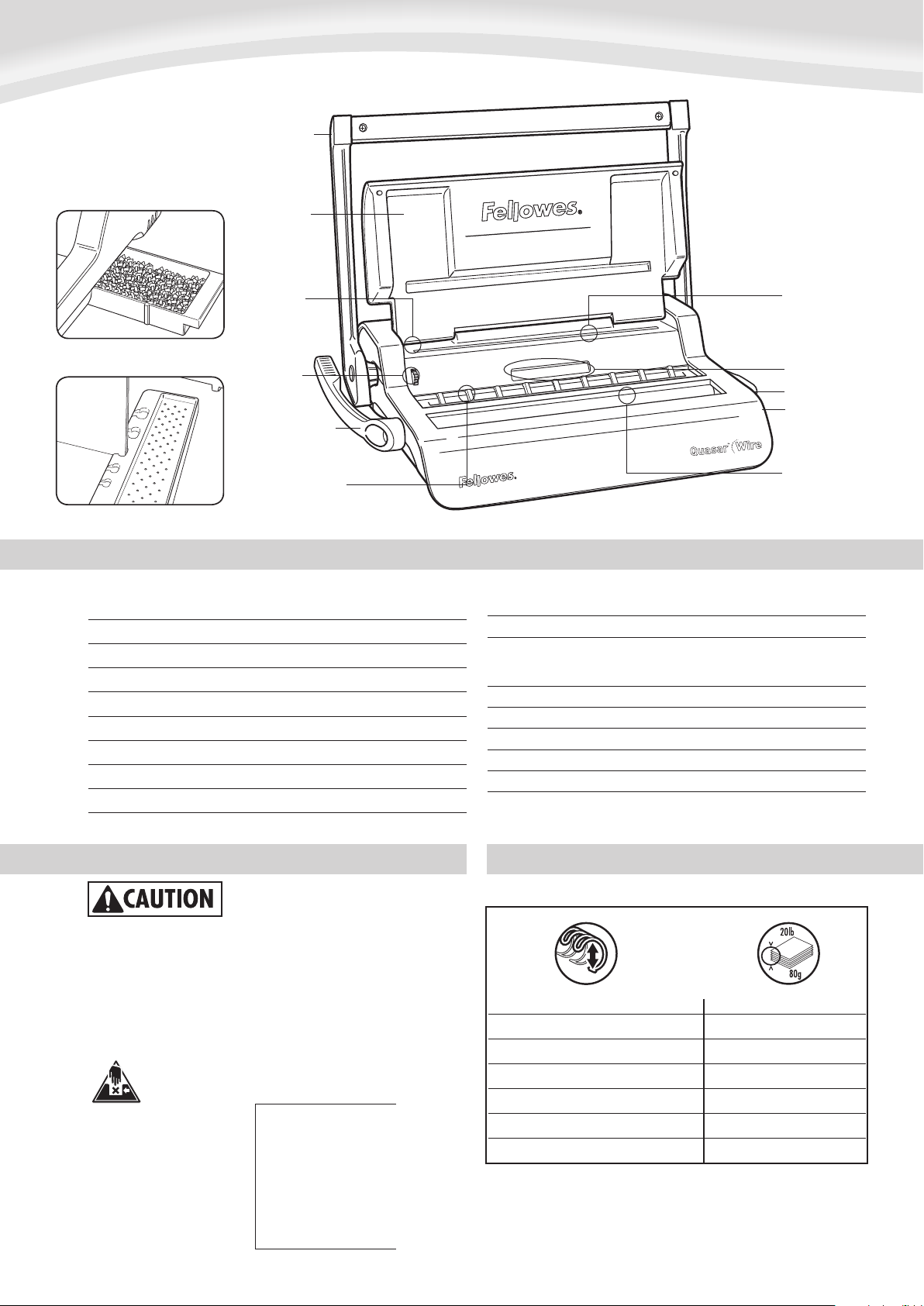

Punch handle

Document

support (lid)

Adjustable

edge guide

Waste tray

Wheel to

adjust edge

guide

Wire closing lever

Wire comb support

Storage and Document Measure

CAPABILITIES

Punching Capacity

Paper sheets

70-80g / 20lb 15 sheet

Transparent covers

100-200 micron / 4-8 mil 2 sheet

200+ micron / 8+ mil 1 sheet

Other standard covers

160-270g / 40-60 lb 2 sheet

270+g / 60+ lb 1 sheet

Waste tray capacity approx. 1500 sheet

Binding Capacity

Max wire comb size 14mm

Max document (80g / 20lb) c. 130 sheet

Technical Data

Paper dimensions A4

Punching slots 34

Slot pitch 3: 1”

Adjustable edge guide yes- rotary

Net weight 7.8 kg / 17.2 lb

Dimensions (LxDxH) 470 x 390 x 130mm / 18.5” x 15.3” x 5.1”

Paper Entry

Window

Waste tray

Storage tray

and Document

measure

Wire closing jaws

IMPORTANT SAFETY INSTRUCTIONS

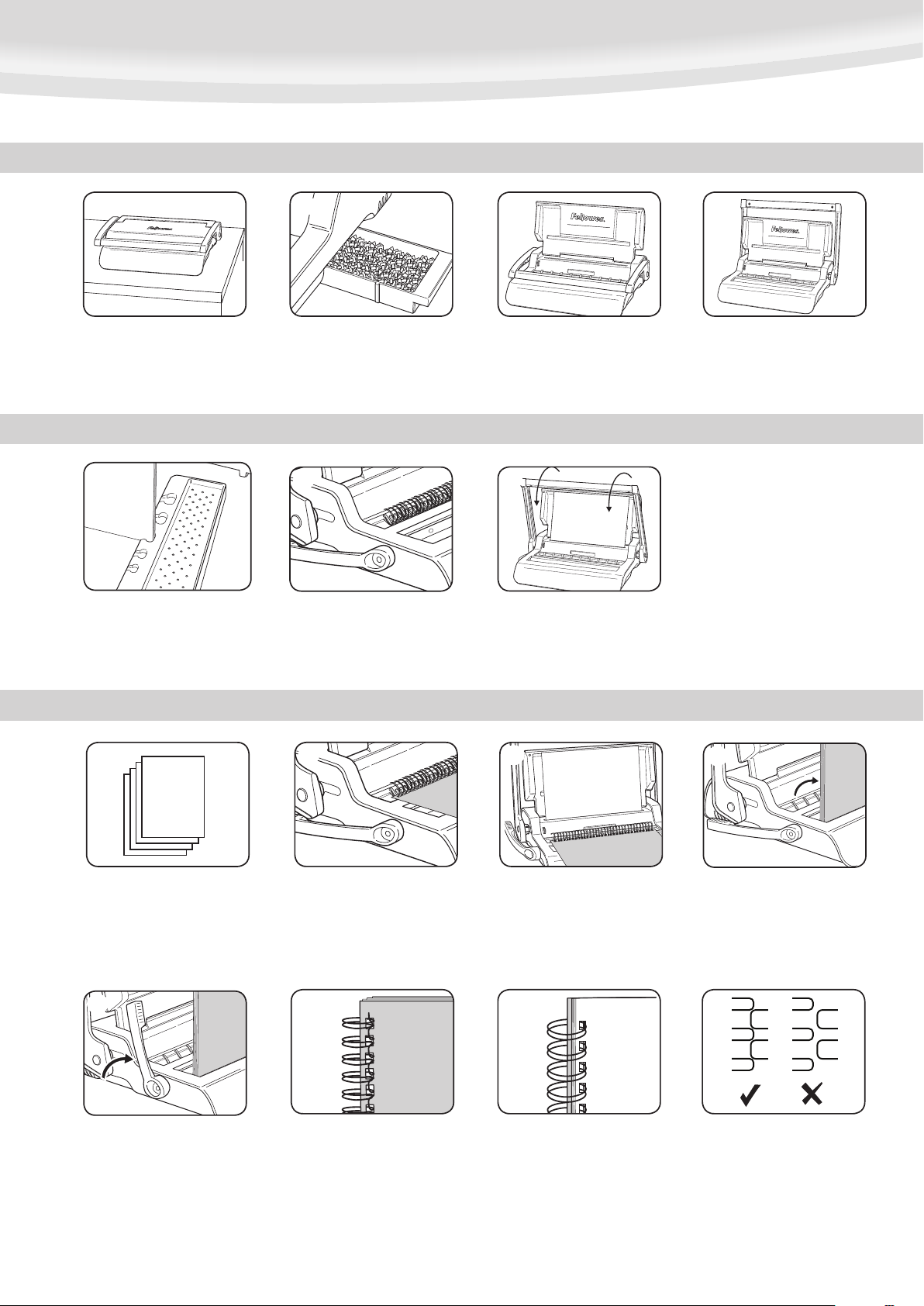

WIRE COMB DIAMETER & DOCUMENT SIZES

Read Before Using!

Please keep for future reference.

When punching;

- always ensure the machine is on a stable surface

- test punch scrap sheets and set the machine before punching final documents

- remove staples and other metal articles prior to punching

- never exceed the machines quoted performance

When binding;

- take care, potential pinch point

Need Help?

Customer Service….

www.fellowes.com

Let our experts help you

with a solution.

Always call Fellowes

before contacting

your place of purchase.

2

mm inch number of sheets

6mm 1/4” 2-35

8mm 5/16” 36-50

10mm 3/10” 51-61

11mm 7/16” 61-80

12mm 1/2” 81-100

14mm 9/16” 100-130

Page 3

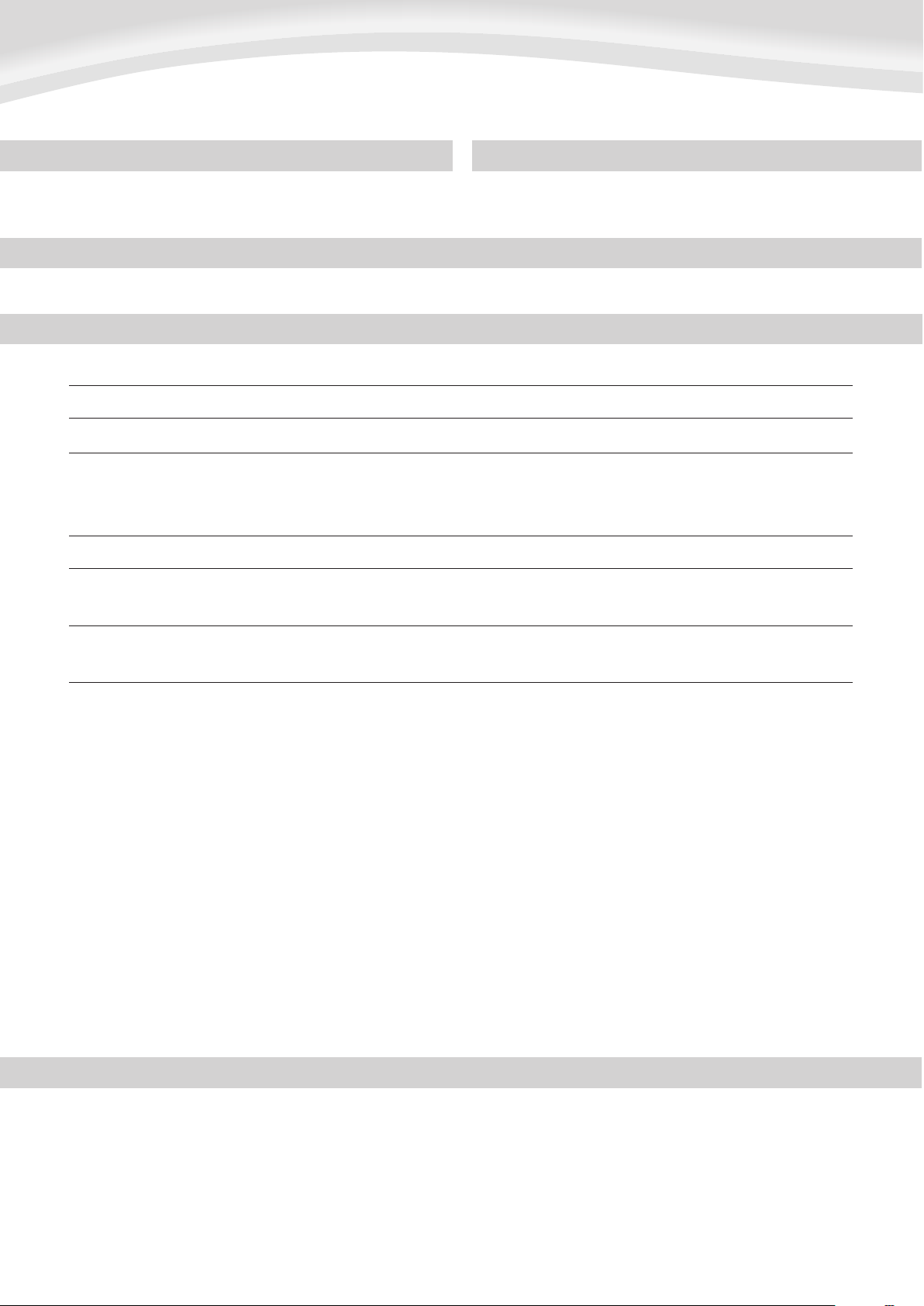

SET UP

30

1. Ensure the machine is on a

stable surface.

BEFORE YOU BIND

1

1. Select the correct wire comb

diameter using the comb

storage tray.

21 3

2. Check waste tray is empty

and correctly fitted.

2

2. Hang the selected wire

comb onto wire comb support.

3. Lift the lid. Ensure the wire

closing lever is pushed backwards.

3

3. Test punch scrap sheets to

check edge guide setting.

4

4. Lift the punch handle to its

upright position.

STEPS TO BIND

1 3

Max 15

(80gsm)

1. Punch sheets in small

batches that do not overload

the machine or user.

5

5. Lift the wire closing lever

forwards. The closing scale guide is

on the moving jaw. Close the jaws

until the wire gauge shows the size

of wire being closed.

2

2. Starting with the rear cover.

Load punched sheets directly onto

the hanging open wire comb.

6 7

6. Check the closed seam. If

the seam is not closed correctly,

the document can be placed

into the jaws and closed again.

3. Punch and hang the front

cover. Punch and hang the

remaining sheets.

7. To hide the seam, turn the

rear cover backwards. The front

cover is now visible. The seam is

hidden inside the document.

4

4. Lift the wire comb upwards off the

hooks. Carefully place into the open

wire closing mechanism. Ensure the

wire comb is open and touching the

bottom of the mechanism.

8

8. Check wire seam closure is

complete. Loose binding allows

sheet loss. Good closure retains

all sheets.

3

Page 4

CORRECTING A BOUND DOCUMENT

REMOVAL OF WASTE CLIPPINGS

Wire binding is a secure binding system. Additional sheets cannot be

added unless the document is disassembled and then re-bound.

STORAGE

Lower the punch handle to the horizontal position. Lower the lid.

TROUBLESHOOTING

Problem

Punched holes are not central

Machine will not punch

Punch holes are not parallel to edge

Partial holes

Damaged hole edges

Waste tray leaks

Cause

Edge guide not set

Blockage

Debris is stuck below dies

Sheets not correctly aligned to punch pattern

Possibly overloading the machine

Waste tray is not correctly inserted or ‘burst

feature’ has activated

The waste tray is located under the machine and is accessed from the

right side. For best results empty the tray regularly.

Solution

Adjust edge guide until hole pattern is correct

Check waste tray in empty. Check for blockage to paper entry

Take stiff cardboard and slide into the paper entry. Move the

cardboard sideways to release any stray clippings into the

waste tray

Adjust edge guide and test punch scrap sheets until correct

Punch plastic covers with paper sheets. Reduce number of

sheets being punched

Check waste tray is empty and ‘burst feature’ is closed

Sheets fall out of document

Wire comb is not closed enough

WARRANTY

Fellowes warrants all parts of the binder to be free of defects in material and workmanship

for 2 years from the date of purchase by the original consumer. If any part is found to be

defective during warranty period, your sale and exclusive remedy will be repair or replacement,

at Fellowes’ option and expense, of the defective part. This warranty does not apply in

cases of abuse, mishandling or unauthorised repair. Any implied warranty, including that of

merchantability or fitness for particular purpose, is hereby limited in duration to the appropriate

Check closure of wire comb. Place into closing mechanism and

improve binding closure.

warranty period set forth above. In no event shall Fellowes be liable for any consequential

damages attributable to this product. This warranty gives you specific legal rights. You may

have other legal rights that vary from this warranty. The duration, terms and conditions of this

warranty are valid worldwide, except where different limitations, restrictions or conditions may

be required by local law. For more details or to obtain services under this warranty, please

contact Fellowes or your dealer.

4

Page 5

FRANÇAIS

ATTENTION

Poignée de

perforation

Support de

document

(couvercle)

Guide latéral

ajustable

Plateau de déchets

Roulette

d’ajustement

du guide latéral

Levier de

fermeture des

mâchoires

Support du peigne

Rangement et mesure de document

CAPACITÉS

Capacité de perforation

Feuilles de papier

70 à 80 g / 20 lb 15 feuilles

Couvertures transparentes

100-200 microns / 4 à 8 mil 2 feuilles

200+ microns / 8+ mil 1 feuille

Autres couvertures standard

160 à 270 g / 40 à 60 lb 2 feuilles

270+ g / 60+ lb 1 feuille

Capacité du plateau de déchets env. 1500 feuilles

Entrée de papier

Fenêtre

Plateau de déchets

Rangement de

peigne et mesure

de document

Mâchoires de

fermeture du

fil métallique

Capacité de reliure

Grosseur maximale du peigne 14 mm

Document maximum (80 g / 20 lb) c. 130 feuilles

Données techniques

Dimensions du papier A4

Fentes de reliure 34

Nombre de fentes 3 : 25,4 mm / 3 : 1 po

Guide de tranche réglable oui - rotatif

Poids net 7,8 kg / 17,2 lb

Dimensions (LxPxH) 470 x 390 x 130 mm / 18,5 po x 15,3 po x 5,1 po

IMPORTANTES INSTRUCTIONS DE SÉCURITÉ

Veuillez conserver à titre de référence.

En perforant :

- assurez-vous que l’appareil est toujours sur une surface stable

- testez la perforation sur des feuilles de rebuts et réglez l’appareil avant de

- retirez les agrafes et autres objets métalliques avant de perforer

- ne dépassez jamais la performance indiquée de l’appareil

En reliant :

- prenez garde, point de

6

perforer les documents finaux

pincement potentiel

À lire avant d’utiliser !

Vous avez be-

soin d’aide ?

Service à la clientèle….

www.fellowes.com

Laissez nos experts vous

aider à trouver une solution.

Appelez toujours Fellowes avant

de contacter l’endroit d’achat.

TAILLES DE DOCUMENTS ET DIAMÈTRE

DU PEIGNE

millimètres pouces nombre de feuilles

6mm 1/4 po 2-35

8mm 5/16 po 36-50

10mm 3/10 po 51-61

11mm 7/16 po 61-80

12mm 1/2 po 81-100

14mm 9/16 po 100-130

Page 6

INSTALLATION

30

1. Assurez-vous que l’appareil

soit toujours sur une surface

stable.

AVANT DE RELIER

1

1. Sélectionnez le bon

diamètre de peigne à l’aide

du plateau de rangement du

peigne.

21 3

2. Vérifiez que le plateau

de déchets est vide et bien

ajusté.

2

2. Accrochez le fil métallique

sélectionné au support

du peigne.

3. Soulevez le couvercle. Veillez

à ce que le levier de fermeture

des mâchoires soit poussé vers

l’arrière.

3

3. Testez la perforation sur des

feuilles de rebut pour vérifier le

réglage du guide de tranche.

4

4. Soulevez la poignée de

perforation à sa position

verticale.

OPÉRATIONS POUR RELIER

1 3

Max 15

(80 g/m2)

1. Perforez les feuilles par

petits lots qui ne surchargent

pas l’appareil ou l’utilisateur.

5

5. Soulevez le levier de fermeture

du fil en le tirant vers l’avant. Le

guide de l’échelle de fermeture

se trouve sur la mâchoire mobile.

Fermez les mâchoires jusqu’à ce

que le calibreur du fil métallique

indique la taille du fil à fermer.

2

2. En commençant par la

couverture arrière, chargez les

feuilles perforées directement sur

le peigne ouvert.

6 7

6. Vérifiez la fermeture du

joint. Si le joint n’est pas bien

fermé, vous pouvez remettre le

document dans les mâchoires

et refermer le joint.

3. Perforez et accrochez la

couverture avant. Perforez et

accrochez les feuilles restantes.

7. Pour dissimuler le joint,

tournez la couverture arrière

vers l’arrière. La couverture

avant est maintenant visible. Le

joint est dissimulé à l’intérieur

du document.

4

4. Soulevez le peigne vers le haut et

décrochez-le. Placez-le délicatement

dans l’ouverture du mécanisme de

fermeture du fil métallique. Veillez à

ce que le peigne soit ouvert et qu’il

touche le fond du dispositif.

8

8. Vérifiez si le joint est bien

fermé. Vous risquez de perdre

des feuilles si la reliure est

lâche. Un joint bien fermé

permet de retenir toutes les

feuilles.

Page 7

CORRIGER UN DOCUMENT RELIÉ

RETRAIT DES ROGNURES

La reliure au fil métallique est un système de reliure sûr. On ne peut

y ajouter des feuilles supplémentaires à moins de désassembler le

document, puis de le relier de nouveau.

RANGEMENT

Abaissez la poignée de perforation à sa position horizontale. Abaissez le couvercle.

DÉPANNAGE

Problème

Les trous perforés ne sont

pas centrés

L’appareil ne perfore pas

Les trous perforés ne sont pas

parallèles à la tranche

Trous partiels

Cause

Le guide de tranche n’est pas réglé

Blocage

Des débris sont coincés sous les

emporte-pièces

Les feuilles ne sont pas alignées correctement

pour le motif de perforations

Le plateau de déchets se trouve sous l’appareil et vous pouvez y avoir accès

du côté droit. Pour les meilleurs résultats, videz régulièrement le plateau.

Solution

Ajustez le guide de tranche jusqu’à ce que le motif des trous

soit exact

Vérifiez que le plateau de déchets est vide. Vérifiez s’il y a un

blocage à l’entrée de papier

Prenez un carton rigide et glissez-le à l’entrée de papier.

Déplacez le carton de côté pour dégager toutes rognures dans

le plateau de déchets

Ajustez le guide de tranche et testez-le sur des feuilles de rebut

jusqu’à ce que ce soit exact

Bords de trous endommagés

Le plateau de déchets fuit

Surcharge possible de l’appareil

Le plateau de déchets n’est pas inséré

correctement ou la « fonction de rafale »

est activée

Des feuilles tombent du document

Le peigne n’est pas suffisamment fermé

GARANTIE

Fellowes garantit que toutes les pièces de la relieuse sont exemptes de tout vice de matériau

ou de fabrication pendant une période de 2 ans à partir de la date d’achat par le consommateur

initial. Si une pièce s’avère défectueuse durant la période de garantie, votre seul et unique

recours sera la réparation ou le remplacement de la pièce défectueuse à la discrétion et aux

frais de Fellowes. Cette garantie ne couvre pas les cas de mauvaise utilisation, mauvaise

manipulation ou réparation non autorisée. Toute garantie implicite, y compris celle de qualité

marchande ou d’adaptation à une utilisation particulière, se limite par la présente à la durée

Perforez les couvertures de plastique avec les feuilles de papier.

Réduisez le nombre de feuilles à perforer

Vérifiez que le plateau de déchets est vide et que la « fonction

de rafale » est fermée

Vérifiez le peigne de fermeture. Remettez le tout dans le

dispositif de fermeture et refermez la reliure de la bonne

façon.

de la période de garantie appropriée établie dans ce document. En aucun cas, Fellowes ne sera

tenue responsable de quelque façon que ce soit de tout dommage consécutif attribuable à ce

produit. Cette garantie vous donne des droits juridiques spécifiques. Vous pourriez aussi avoir

d’autres droits juridiques différents de cette garantie. La durée, les modalités et les conditions de

cette garantie s’appliquent partout au monde sauf dans les cas où différentes limites, restrictions

ou conditions pourraient être exigées par la loi locale. Pour plus de détails ou pour obtenir un

service sous cette garantie, veuillez contacter Fellowes ou votre concessionnaire.

8 10

Page 8

ESPAÑOL

PRECAUCIÓN

Manija de

perforación

Soporte para

documentos

(tapa)

Guía de

bordes

ajustable

Bandeja para desechos

Rueda para

ajustar la guía

de bordes

Palanca de cierre

de alambre

Soporte del peine

de alambre

Almacenamiento y medida

del documento

CAPACIDADES

Capacidad de perforación

Hojas de papel

70-80 g / 20 lb 15 hojas

Tapas transparentes

100-200 micrones / 4-8 mil 2 hojas

más de 200 micrones / 8 mil 1 hoja

Otras tapas estándar

160-270 g / 40-60 lb 2 hojas

más de 270 g / 60 lb 1 hoja

Capacidad de la bandeja para desechos aprox. 1500 hojas

Entrada del papel

Ventana

Bandeja para desechos

Bandeja de

almacenamiento

y medida del

documento

Mordazas de

cierre de alambre

Capacidad de encuadernación

Tamaño máx. del peine de alambre 14mm

Tamaño máx. del documento (80 g [20 lb]) c. 130 hojas

Información técnica

Dimensiones del papel A4

Ranuras de perforación 34

Espaciado 3: 25,4 mm (3: 1 pulg.)

Guía de bordes ajustable sí, giratoria

Peso neto 7,8 kg (17,2 lb)

Dimensiones (LxPxA) 470 x 390 x 130 mm (18,5 x 15,3 x 5,1 pulg.)

INSTRUCCIONES DE SEGURIDAD IMPORTANTES

Consérvelas como referencia futura.

Al perforar;

- siempre asegúrese de que la máquina esté sobre una superficie estable

- perfore hojas a modo de prueba y configure la máquina antes de perforar los

documentos finales

- retire las grapas y otros artículos de metal antes de la perforación

- nunca supere la capacidad indicada de las máquinas

Al encuadernar;

- tenga cuidado; punto posible de

compresión

10

¡Léalas antes de

usar la máquina!

¿Necesita

ayuda?

Servicio de atención al cliente….

www.fellowes.com

Deje que nuestros expertos lo

ayuden y le den una solución.

Siempre llame a Fellowes antes de

comunicarse con su vendedor.

DIÁMETRO DEL PEINE DE ALAMBRE Y

TAMAÑOS DE LOS DOCUMENTOS

mm pulg. número de hojas

6 mm 1/4 pulg. 2-35

8 mm 5/16 pulg. 36-50

10 mm 3/10 pulg. 51-61

11 mm 7/16 pulg. 61-80

12 mm 1/2 pulg. 81-100

14 mm 9/16 pulg. 100-130

Page 9

INSTALACIÓN

30

21 3

1. Asegúrese de que la máquina

esté sobre una superficie

estable.

2. Verifique que la bandeja para

desechos esté vacía y que esté

correctamente colocada.

ANTES DE LA ENCUADERNACIÓN

1

1. Seleccione el diámetro

correcto del peine de

alambre con la bandeja de

almacenamiento del peine.

2

2. Coloque el peine de

alambre seleccionado en el

soporte del peine de alambre.

3. Levante la tapa. Asegúrese

de que la palanca de cierre de

alambre esté colocada hacia atrás.

3

3. Perfore hojas a modo

de prueba para verificar

la configuración de la guía

de bordes.

4

4. Coloque la manija de

perforación en la posición

vertical.

PASOS PARA LA ENCUADERNACIÓN

1 3

Máx. 15

(80 g/m2)

1. Perfore las hojas en lotes

pequeños de modo de no

sobrecargar la máquina ni al

usuario.

5

5. Levante la palanca de cierre de

alambre y colóquela hacia adelante.

La guía de escala de cierre está sobre

la mordaza móvil. Cierre las mordazas

hasta que el indicador de alambre

muestre el tamaño del alambre que

se cierra.

2

2. Comience por la tapa trasera.

Cargue las hojas perforadas

directamente en el peine de

alambre abierto colgante.

6 7

6. Verifique la junta cerrada.

Si la junta no está cerrada

correctamente, es posible

colocar el documento en

las mordazas y cerrarlo

nuevamente.

3. Perfore y coloque la tapa

delantera. Perfore y coloque

las hojas restantes.

7. Para ocultar la junta, coloque

la tapa trasera atrás. Ahora

se ve la tapa delantera. La

junta está oculta dentro del

documento.

4

4. Levante el peine de alambre para

quitarlo de los ganchos. Colóquelo con

cuidado en el mecanismo de cierre de

alambre abierto. Asegúrese de que el

peine de alambre esté abierto y que

toque la parte inferior del mecanismo.

8

8. Verifique que el cierre de la

junta de alambre sea total. Si

la encuadernación está abierta,

pueden perderse hojas. Un buen

cierre retiene todas las hojas.

Page 10

fellowes.com

&,-.CdglddY6kZcjZ!>iVhXV!>aa^cd^h+%&)("&%.*JH6+(%"-.("&+%%

Australia Canada Deutschland France Japan Polska United Kingdom

Benelux China España Italia Korea Singapore United States

Useful Phone Numbers

CORRECCIÓN DE UN DOCUMENTO ENCUADERNADO

EXTRACCIÓN DE LOS RECORTES DESECHADOS

La encuadernación con alambre es un sistema seguro. No se pueden

agregar hojas adicionales a menos que se desarme el documento y

se vuelva a encuadernar.

ALMACENAMIENTO

Baje la manija de perforación a la posición horizontal. Baje la tapa.

SOLUCIÓN DE PROBLEMAS

Problema

Los agujeros perforados no

están centrados

La máquina no perfora

Los agujeros perforados no están

paralelos al borde

Agujeros parciales

Bordes de agujeros dañados

Causa

No se colocó la guía de bordes

Bloqueo

Hay desechos debajo de los troqueles

Las hojas no están correctamente alineadas al

patrón de perforación

Es posible que haya sobrecargado la máquina

La bandeja para desechos está ubicada debajo de la máquina y se obtiene

acceso a ésta desde el lado derecho. Para obtener mejores resultados, vacíe

la bandeja con regularidad.

Solución

Ajuste la guía de bordes hasta que el patrón de los agujeros sea

correcto

Verifique que la bandeja para desechos esté vacía. Verifique

que la entrada del papel no esté bloqueada

Deslice un cartón rígido por la entrada del papel. Mueva el

cartón de manera lateral para liberar los recortes sueltos en la

bandeja para desechos

Ajuste la guía de bordes y perfore hojas a modo de prueba

hasta corregir el problema

Perfore las tapas plásticas con hojas de papel. Reduzca la

cantidad de hojas que perfora

La bandeja para desechos pierde

La bandeja para desechos no está correctamente insertada o se ha activado la ‘función

Verifique que la bandeja para desechos esté vacía y que la

‘función de ráfaga’ no esté activada

de ráfaga’

Las hojas se salen del documento

El peine de alambre no está bien cerrado

Verifique el cierre del peine de alambre. Colóquelo en el

mecanismo de cierre y mejore el cierre de la encuadernación.

GARANTÍA

Fellowes garantiza que todas las otras piezas de la encuadernadora estarán libres de defectos

de material y mano de obra durante 2 años a partir de la fecha en que el consumidor original

haya adquirido el producto. Si se encuentra algún defecto en cualquiera de las piezas durante

el período de garantía, la única y exclusiva solución será la reparación o el cambio de la pieza

defectuosa, a criterio y cuenta de Fellowes. Esta garantía no se aplica en los casos de uso

indebido, manejo inapropiado o reparación no autorizada. Por medio del presente, toda garantía

implícita, incluida la garantía de comerciabilidad o adaptabilidad para un propósito específico,

se limita al período de duración correspondiente de la garantía conferida anteriormente. En

ningún caso, Fellowes será responsable de cualquier daño directo, que pueda atribuírsele a este

producto. Esta garantía le confiere derechos legales. Podría tener otros derechos legales que

difieran de lo expuesto en esta garantía. La duración, los términos y las condiciones de esta

garantía son válidos en todo el mundo, excepto en los lugares donde la legislación local exija

limitaciones, restricciones o condiciones diferentes. Para obtener más detalles o recibir servicio

conforme con esta garantía, comuníquese con Fellowes o con su distribuidor.

12

Page 11

fellowes.com

&,-.CdglddY6kZcjZ!>iVhXV!>aa^cd^h+%&)("&%.*JH6+(%"-.("&+%%

Australia Canada Deutschland France Japan Polska United Kingdom

Benelux China España Italia Korea Singapore United States

Useful Phone Numbers

Help Line

Australia +1-800-33-11-77

Canada +1-800-665-4339

Fellowes

Australia +61-3-8336-9700

Benelux +31-(0)-76-523-2090

Canada +1-905-475-6320

Deutschland +49-(0)-5131-49770

España +34-91-748-05-01

France +33-(0)-1-30-06-86-80

Italia +39-071-730041

Europe 00-800-1810-1810

Mexico +1-800-234-1185

United States +1-800-955-0959

Japan +81-(0)-3-5496-2401

Korea +82-2-3462-2844

Malaysia +60-(0)-35122-1231

Polska +48-(0)-22-771-47-40

Singapore +65-6221-3811

United Kingdom +44-(0)-1302-836836

United States +1-630-893-1600

2006 Fellowes, Inc. Part No. 403054

Loading...

Loading...