Felker Super Tile Master STM-1000, Super Tile Master STM-1500, Super Tile Master STM-2000 Operating Instructions And Parts List Manual

OPERATING INSTRUCTIONS AND PARTS LIST

INSTRUCCIONES DE OPERACIÓN Y LISTA DE PIEZAS

Super Tile Master

MODELS: STM-1000

STM-1500

STM-2000

CONTENTS / CONTENIDO

ENGLISH ……………………………….……. 2-3

ESPAÑOL ………………………………..….. 4-5

PARTS LISTS/LISTA DE PIEZAS ………… 6-8

WIRING DIAGRAMS…………………………8-9

DIAGRAME DE CABLADO ELÉCTRICO….8-9

WARRANTY/GARANTÍA .……………………11

0AF04023

Copyright © Sept. 17, 2003

Electrolux Professional Outdoor Products, Inc.

Printed in U.S.A.

17400 West 119th Street

Olathe, Kansas 66061

Customer Service ...…….800-365-4003

Corp. Office ............…….913-928-1000

Cust. Service FAX…...….800-825-0028

Corp. Office FAX ....….....913-438-7951

ENGLISH

FAILURE TO COMPLY WITH THESE WARNINGS COULD RESULT

IN SERIOUS BODILY INJURY.

SAFETY WARNINGS FOR THE OPERATION OF THE SAW

DO

carefully read and understand all the instructions

DO

DO

DO

DO

DO

DO

DO

operating the saw.

before

always keep guards in place.

always wear safety approved hearing, eye, head

and respiratory protection.

keep all parts of our body away from the blade and

all other moving parts.

inspect the blade, flanges and shafts for damage

before installing the blade.

use only blades marked with maximum operating

speed greater than the blade shaft speed.

use caution and follow the instructions when

setting up or transporting the saw.

DO NOT

DO NOT

DO NOT

DO NOT

DO NOT

DO NOT

DO NOT

DO NOT

DO NOT

allow other persons to be near the saw when

cutting.

use damaged equipment or blades.

operate the saw if you are uncertain of how to

run the machine.

replace the motor with any motor that does

not have a special grounding connection.

leave the saw unattended while the motor is

running.

operate the saw while under the influence of

drugs or alcohol.

operate the saw in areas of combustible

material. Sparks from the saw could cause a

fire or an explosion.

operate the saw without all guards in place.

Symbol Definitions

Use in Well Ventilated Area

Machinery Hazard – Keep Hands & Feet Clear

Always Wear Approved Equipment

Wear Eye Protection

Wear Head Protection

Read Operating Instructions Before Using Saw

Do Not Use in Flammable Areas

Do Not Operate Without All Guards in Place

Wear Hearing Protection

Wear Breathing Protection

2

ASSEMBLY of BASIC & DELUXE MODELS

1. Put the stand on the floor and keep the stand from

rolling with the floor lock.

2. Place the frame on the stand so that the cutting

head support bar is the maximum distance from

the end of the stand with the floor lock.

3. Place the pan on the frame and lock the pan in

place with the four safety locks.

WARNING: Always keep the pan lock ed in

place because an overhanging load could tilt the

pan.

4. Place one of the conveyor carts on the rails. ONLY

the Deluxe Model includes two carts – the

standard large cart and an additional small cart

(Saw must have Inner Rail kit) for small tiles.

5. Assem ble the cutting head on the saw frame. Be

sure the blade will line up with the center of the

slot in the conveyor cart. Next, tighten the

fasteners so that the c utting head is held securely

on the base pivot bar, but can be adjusted up or

down.

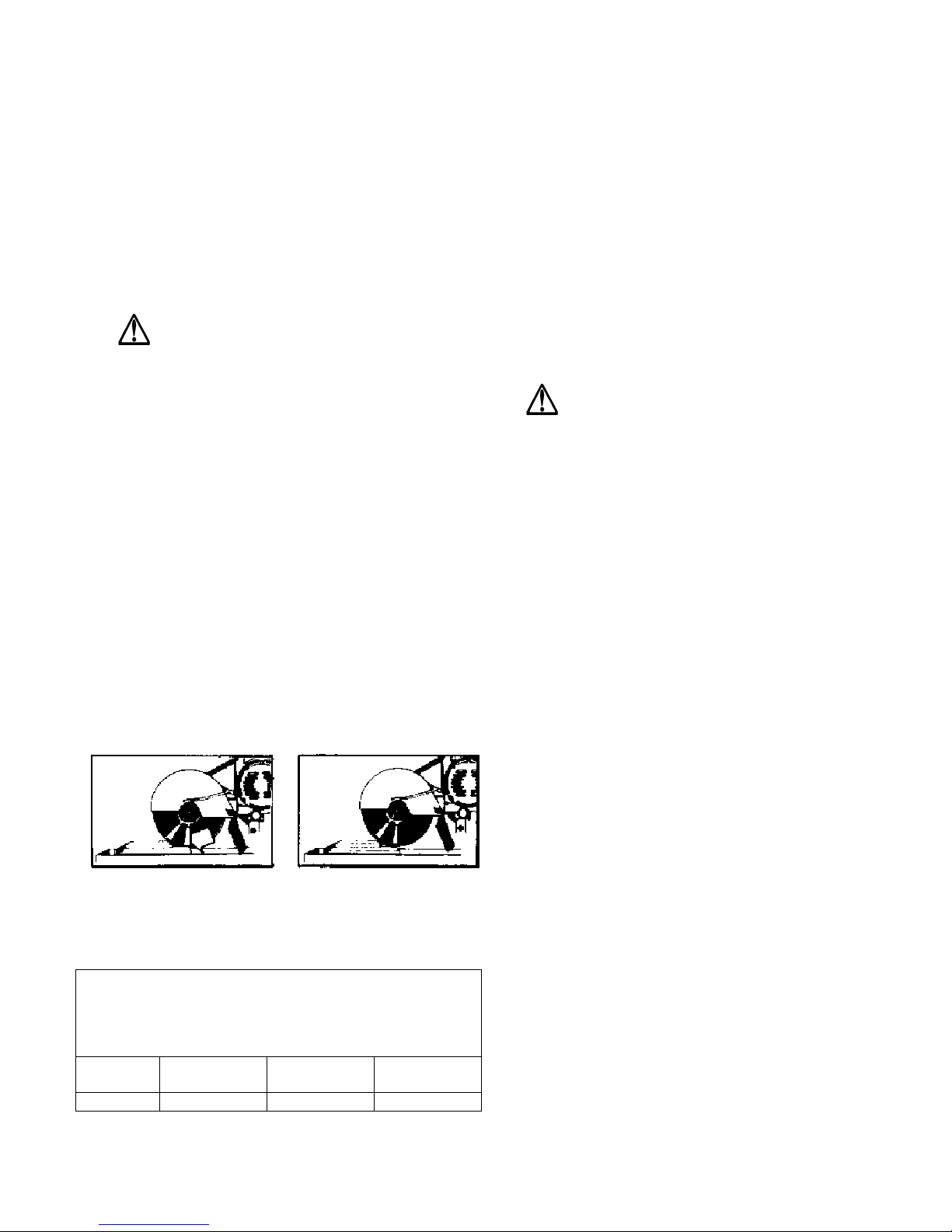

6. Adjust the cutting head so the blade-cutting rim is

through the conveyor top, then tighten the

adjustment control knob mounted on the belt

guard. When it is necessary to make cuts in the

center of the tile, the cutting head may be raised,

and operated by hand.

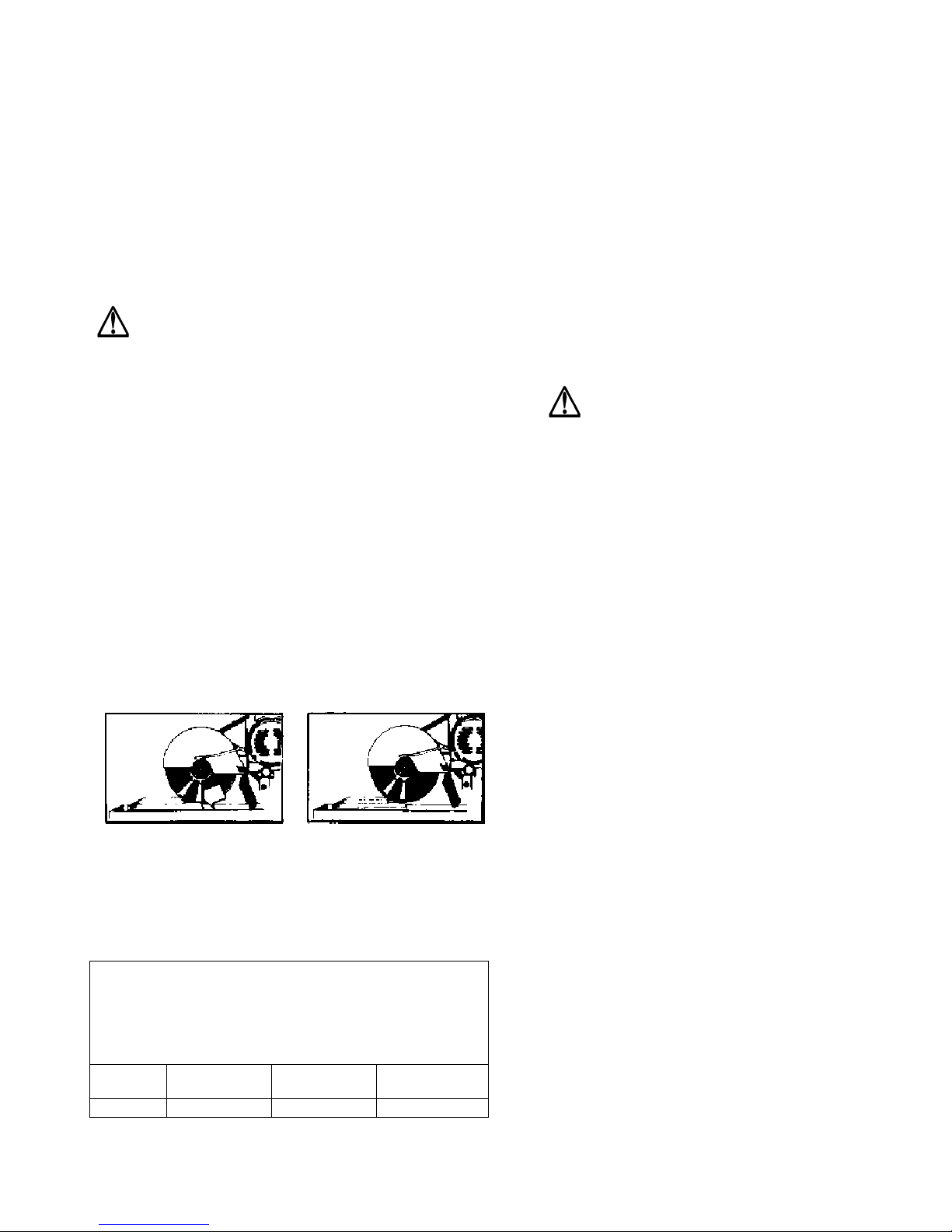

Correct position for a diamond

blade. The blade is positioned so

that it is at least 1/4” below the top

surface of the c onveyor cart.

Good motor performance depends on proper voltage.

Extension cords that are too long and/or small reduce

voltage to the motor under load. Use extension cords no

smaller than indicated below.

Motor

HP

50’ Cord

115V 230V

1-1/2 & 2 #10 #14 #10 #14 #8 #14

Wrong – The blade is positioned

incorrectly in this illustration, as it is above

the conveyor cart surface. Setting the

blade too shallow may cause it to grab.

75’ Cord

115V 230V

100’ Cord

115V 230V

OPERATION

1. Be sure you are using the correct blade for the

material. For best results, always use genuine

FELKER diamond blades that have been specially

developed for ceramic wall tile, quarry tile, marble,

granite, slate and many other hard materials.

2. Use a wrench to tighten the flange nut securely,

but first make sure the blade flanges are clean.

Never use wing nuts, and never merely handtighten the hex nut.

3. The water supply should be adequate, with

plentiful supply flow of water at all times.

WARNING: Keep water clean and make

certain the WATER LEVEL IS ALWAYS ABOVE

THE PUMP INTAKE. Wet-cut diamond blades

must be used with a plentiful flow of water at all

times.

4. Keep the V-belt tight for proper power

transmission and longer belt life. Do not over

tighten. Change V-belts in sets only.

5. Keep the conveyor cart clean and free of cuttings.

The small conveyor cart on the Deluxe Model

should be used for tiles up to 12”. The standard

large conveyor cart is to be used for tiles above

12”. The large car t will diagonally cut up to 24” x

24” square tiles or rip 36” tiles. An additional

support is furnished which can be mounted to the

side of the large cart for supporting oversized

materials. The backstop can be lowered if the

material overhangs the cart on the operator’s end.

In addition, an extra support can be mounted on

the operator’s end of the cart, if required.

Felker’s Super Tile Master tile saws feature an

exclusive, patented, adjustable tray that is guided

to maintain squareness accurately. The

adjustable tray permits the operator to adjust the

saw to the most convenient and comfortable

operating position whether the operator is cutting

4” x 4” or 24” x 24” ceramic tile units.

The stop bar on the water tray will automatically

stop the tray when it has reached either the

maximum forward or maxim um rear position. The

adjustable water tray is easily removed from the

saw frame for transporting or cleaning.

3

Use en lugar bien ventilado

ESPAÑOL

NO RESPETAR ESTA S ADVERTENCIAS PUEDE TENER

RESULTADOS FATALES O GRAVES DAÑOS CORPORALES.

CONSIDERACIONES DE SEGURIDAD PARA EL US O DEL A CORTADORA

HAGA

Si Lea cuidadosamente y comprenda todas las instrucciones

antes de usar la cortadora.

Si Mantenga siempre las protecciones en su lugar.

Si Siempre use protecciones de seguridad confirmada para

el oído, vista, cabeza y respiración.

Si Mantenga todas las partes de su cuerpo alejadas del

disco y de otras piezas móviles.

Si Verifique que el disco, bridas y eje del siaco no estén

dañados antes de instalar el disco.

Si Use sólo siscos que indiquen una velocidad máxima de

operación mayor que la velocidad del eje del disco.

Si Tenga cuidado y siga las instrucciones al preparar o

transportar la cortadora.

NO permita que otras personas se acerquen al usar la

cortadora.

NO use equipo o discos dañados.

NO deje sola una cortadora funcionando.

NO use una cortadora sin estar seguro de cómo utilizarala.

NO cambie el motor por ptro que no tenga un conector de

tierra de protección.

NO use la cotadora bajo la influencia de drogas o del alcohol.

NO use la cortadora en zonas con material combustible.

Chispas de la cortadora pueden provocar un incendio o

una explosiõn.

NO use la cortadora si la protección del disco no está en su

lugar.

NO HAGA

Definicións de los símbolos

Maquinaria peligrosa – Mantenga alejados y manos

Siempre use equipamento aprobado

Use protección visual

Use protección para la cabeza

Lea las instrucciones de operación antes de usar la cortadora

No use en lugares con productos inflammables

No use sin todas las protecciones en su lugar

Use protección auditiva

Use protección respiratoria

4

MONTAJE

1. Ponga el soporte de la cortadora en el suelo bloquee

el soporte con la traba para evitar que se mueva.

2. Ponga el chasís en el soporte de manera que la barra

de fijación del cabezal de corte quede a la mayor

distancia posible del extremo del soporte con la traba.

3. Ponga el depósito de agua en el chasís y asegure el

depósito con las cuatro trabas de seguridad.

PRECAUCIÓN: Siempre mantenga el depósito

con las trabas pues una carga que sobresalga del

chasís puede inclinar o volcar el depósito.

4. Ponga uno de los carros de corte en los rieles. La

cortadora incluye dos carros – uno para baldosas

grandes y el otro para baldosas pequeñas.

5. Monte el cabezal de corte en el chasís de la cortadora.

Asegure que el disco esté en línea con el centro de la

ranua del carro de corte. Enseguida apriete las tuercas

de manera que el cabezal de corte esté sujeto con

firmeza en la barra basculante, pero pueda ser ajustado

hacia arriba o abajo.

6. Ajuste el cabezal de corte de maners que el borde

cortante del disco quede bajo el nivel superior del carro

de corte, luego apriete la perilla de ajuste ubicada en el

protector de correa. Cuando sea necesario hac er cortes

al centro de una baldosa, se puede levantar el cabezal

de corte, y utilizarlo manualmente.

Correcto: esta es la posición del

disco diamantado. El disco se

coloca de manera que entre por lo

menos 1/4” (6mm) bajao el nivel

superior del carro de corte.

Unbuen rendimiento del motor depende de un voltaje

adecuado. Cables de extensión demasiado largos o de

un calibre muy pequeño reducen el voltaje en el motor

bajo carga. Use cables de extensión de un calibre no

menor al indicdo en esta talba.

Potencia

del motor

Cable 50’ (15m)

115V 230V

1-1/2 y 2 #10 #14 #10 #14 #8 #14

Incorrecto: en sata figura aparece el

disco en una ubicación incorrecta,

pues está sobre el nivel del carro de

corte. Un disco muy superficial puede

atascarse.

Cable 75’ (23m)

115V 230V

Cable 100’ (30m)

115V 230V

OPERACIÓN

1. Asegure que se usa el disco adecuado para el

material. Para el mejor resultado., siempre use discos

diamantados auténticos de FELKER que sean

especialmente diseñados para azulejo cerámico mural,

bladosa de cantera, mámol, granito, pizarra y muchos

otros materiales duros.

2. Use una llave para apretat las tuercas de bridas con

firmeza, controlando antes que las bridas de disco

estén limpias. Nunca use tuercas de mariposa, y nunca

apriete solamente a mano la tuerca hexagonal.

3. El suministro de agua debe ser adecuado, con un

caudal abundante en ambos lados del disco.

ADVENTENCIA: Mantenga el agua limpia y

asegure que EL NIVEL DEL AGUA ESTÉ SIEMPRE

SOBRE LA ENTRADA DE LA BOMBA. Los discos

diamantados de corte húmendo deben utilizarse

siempre con un flujo abundante de agua.

4. Mantenga tensa la correa V para tener una transmisión

adecuada de la fuerza y una máxima duración de la

correa. No la apriete demasiado. Cambie las correas V

sólo por juegos completos.

5. Mantenga el carro de corte limpio y libre de rebarbas.

Se debe utilizar el carro de corte peueño para baldosas

hasta 12” (30 cm). Se utiliza el carro de corte grande

en baldosas sobre 12” (30 cm). El carro de corte

grande corta en diagonal baldosas cuadradas de 24” x

24” (60x60 cm) o hiende baldosas hasta 36” (90 cm).

Se suministra un soporte adicional para montar al

costado del carro de corte grande para soportar

materiales de gran tamaño. Se puede bajar el tope

trasero si el material sobresale edl carro al extremo del

operario. Además, se puede montar el soporte

adicional en el costado del operario, si fuera necesario.

Las cortdoras de baldosa Super Tile Master de Felker

ienen una carro de corte ajustable exclusivo, patentado

, con guías para mantener una escuadra precisa. El

carro ajustable permite al operario ajustar la cortadora

a la posición de trabajo más conveniente y cómoda, ya

sea para cortar baldosas cerámicas de 4” x 4” (10x10

cm) o 24” x 24” (60x60 cm).

La barra de tope en el depósito de agua detiene

automáticamente el car ro de cor te cuando éste llega

a su posición máxima delantera o posterior. El

depósito de agua ajustable se desmonta con

facilidad del chasís de la cortador a para trans porte o

limpieza.

5

DIAGRAM 1 – Super Tile Master MODELS: STM-1500, STM-2000

6

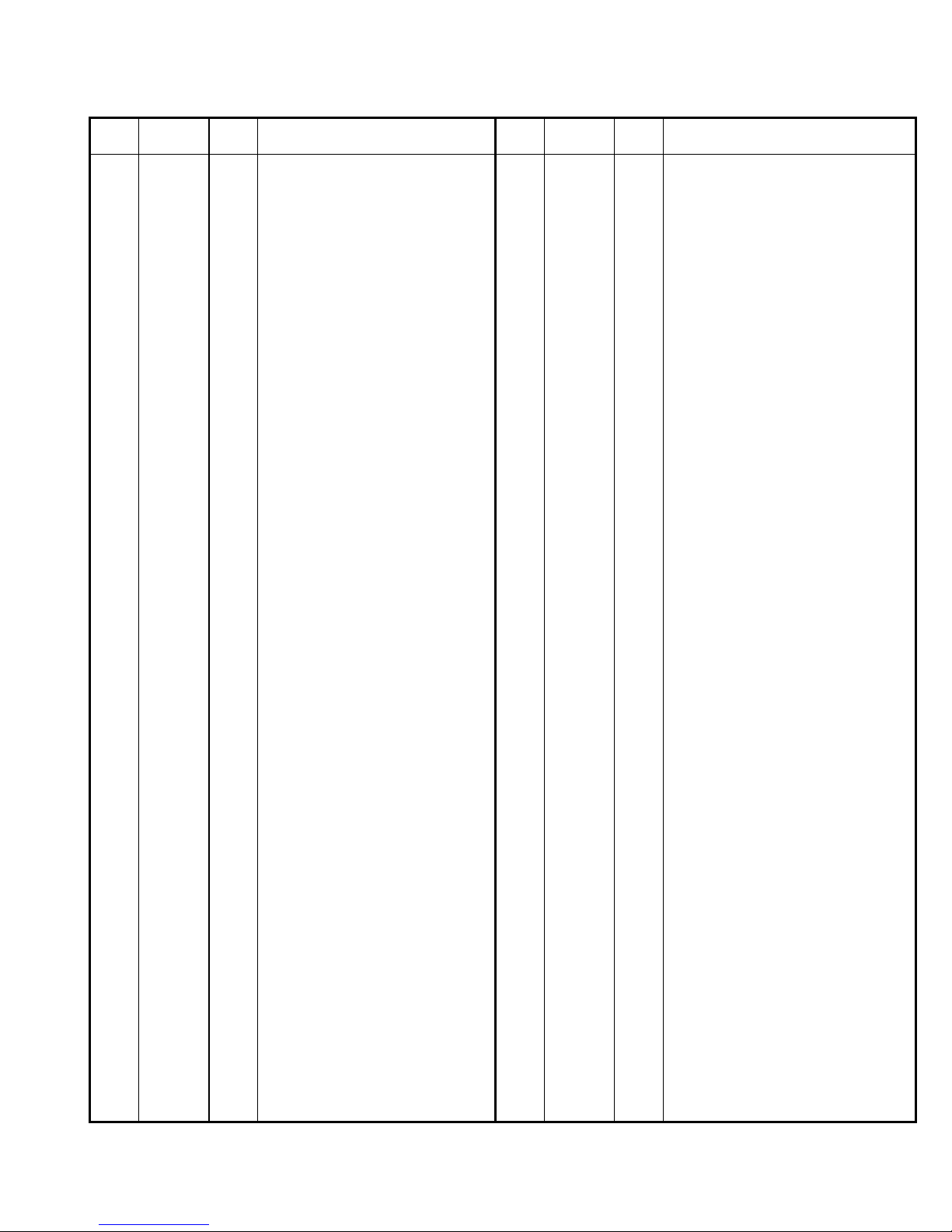

DIAGRAM 1 - PARTS LIST (9/17/03)

DIAG.

LOC.

1

2 161671 2 Rigid Castor 60 020323 1 Capscrew, Hex Hd. 3/8"-16 x 1"

3 161670 2 Swivel Castor 61 169332 1

4 021416 16 Capscrew, Hex Hd, 5/16"-18 x 1" 62 169365 1 Guard, Splash

5 020197 16 Locknut, Fiber, 5/16"-18 63 169366 1

6 161687 4 Floor Lock 64 020739 1 Washer, Flat #10

7 048740 4 Capscrew, Hex Hd, 3/8"-16x1-1/4" 65 020126 1 Bolt, Carriage, 5/16"-18 x 1-3/4"

8 020199 4 Locknut, Fiber, 3/8"-16 66 020245 1 Locknut, Wing, 5/16"-18

9 161600 1 Frame Weldment 67 169548 1 Blade Guard, 10"

10 161658 2 Pan Stop Assy (Incl.11-12) 68 163248 1 Rubber Strip, Sponge

11 051065 4 Plastic Tabs 69 - - - - 12 197044 4 Latch 70 169564 1

13 020489 2

14 161632 1 Lock Bar 72 189661 2 Bearing Cap

15 020373 1

16 020197 1 Locknut, Fiber, 5/16"-18 74 020441 4 Capscrew, 5/16"-18 x 1-3/4”

17 161641 1

18 169486 1 Hand Knob, 5/16"-18 x 1" 76 052006 1 Shaft, Blade

19 020763 1 Washer, Flat, SAE 5/16" 77 071110 1 Washer, Spring

20 043260 2 Set Collar 78 071081 2 Bearing, Blade Shaft

21 161661 1 Pan 79 169522 1 Flange, Inner

22 030386 1 Drain Plug 80 169523 1 Flange, Outer

23 161624 2 Rail, Large Outer 81 020176 1 Nut, Thin Hex, 5/8"-18

24 161626 2

25 020301 16 Capscrew, Hex Hd, .25-20 x 5/8” - - 175056 1

26 020195 16 Locknut, Fiber 1/4"-20

27 169635 2

28 161316 1

- - 050216 1 Water Pump Assembly, 230V/50/1 83 020741 4 Washer, Flat, 1/4"

29 197237 1 Hose Barb 1/4" NPT x 1/4" OD 84 020489 2

30 161134 1 Valve, Flow Control 85 021416 4 Capscrew, Hex Hd, 5/16"-18 x 1"

31 - - - - - - - - - - - - - 86 020742 4 Washer, Flat, 5/16"

32 161663 1

33 161751 1 Back Stop 88 020060 2 Key, 3/16" Sq. x 1"

34 048740 2 Capscrew, Hex Hd, 3/8"-16x1-1/4" 89 030906 1 Pulley, 2G3V2.25 - .875 w/SS

35 020743 2 Washer, Flat, 3/8" (For 1-1/2HP & 2HP)

36 161662 1 Cart Weldment 90 161696 1

37 030822 4 Wheel, Cart

38 020763 4 Washer, Flat, SAE 5/16" 91 058020 2 V-Belt, 3VX280

39 032366 4 Nut, KEPS, 5/16"-18 92 169499 1 Mounting Bracket, Belt Guard

40 161622 2 Cutting Board, Cart 93 020370 4 Capscrew, 1/4”-20 x 3/4”

41 020411 12

42 020739 12 Washer, Flat #10 95 020195 4 Locknut, Fiber, 1/4”-20

43 020194 12 Locknut, Fiber, #10-24 - - 1

44 161666 1

45 161667 1 Extension Cart Weldment 97 169343 1 Decal: Warning/Caution

46 161623 1 Cutting Board, Ext. 98 021416 1 Capscrew, Hex Hd, 5/16"-18 x 1"

47 020411 4

48 020739 4 Washer, Flat #10 100 020197 1 Locknut, Fiber, 5/16"-18

49 020194 4 Locknut, Fiber, #10-24 101 021423 2 Capscrew, Hex Hd, 1/4"-20 x 1/2"

50 020323 2 Capscrew, Hex Hd, 3/8"-16 x 1" 102 020762 2 Washer, Flat, 1/4"

51 020743 2 Washer, Flat, 3/8" 103 169573 1 Cart Assy, Conveyor (Incl104-108)

52 161707 1 Miter Guide Assy. (Incl. 53-58)

53 161650 1 Miter Guide Weldment 104 169576 1 Cart, Conveyor w/ V-Top

54 161655 1 Locking Bolt - - 030049 1

55 050106 1

56 050105 1

57 050103 1 Knob, Metal

58 161043 2 Knob

PART

NO.

161634 1 Stand Weldment 59 161693 1

QTY.

REQ.

Screw, Hex Hd, Self-Tapping 1/4"-20x3/4"

Capscrew, Hex Hd, 5/16"-18 x 1-1/2"

Wrench, Blade Shaft 15/16" x 9/16" Box

Rail, Small Inner (Optional)

Support, Inner Rail (Optional)

Water Pump Assembly, 115V/60/1

Conveyor Cart Assy (Incl. 33-43)

Machine Screw, Hex Hd, #10-24 x 3/4"

Extension Cart Assembly

Machine Screw, Hex Hd, #10-24 x 3/4"

Spring

Stop

DESCRIPTION

DIAG.

LOC.

71 171032 1 Motor Base

73 020785 4 Lockwasher, Split, 5/16”

75 052004 1

82

- - 161706 1 Motor & Switch Assy, 2 HP

87 020197 4 Locknut, Fiber, 5/16"-18

94 020262 4 Washer, Flat, 1/4”

96 171013 1 Belt Guard

99 020763 1 Washer, Flat, SAE, 5/16"

105 032366 4 Nut, KEPS, 5/16"-18

106 030822 4 Wheel, Cart

PART

NO.

542000605

240/50/1 (542000607 w/ Decals)

QTY.

REQ.

1

DESCRIPTION

Rip Guide Assembly

Blade Guard Assy 10" (Incl. 23-31, 82)

Screw, Pan Hd, Self-Tapping, #8 x 3/8"

- - - - -

Water Tube Assy, 1/4"Y x 72"

Blade Shaft Assy (Incl. 58-63)

Motor & Switch Assy, 1.5 HP, 115V-230/60/1

Motor & Switch Assy, 2 HP, 115-230V/60/1

(542000716 Modified w/ Ammeter Assy)

Screw, Hex Washer Hd, 1/4"-20 x 3/4"

Pulley, Blade Shaft 2G3V2.00 - .625 w/SS

(For 1-1/2 HP & 2 HP)

Belt Guard Assy (Incl. 96-102)

in Optional Deluxe Package

Wheels-Set of 4 (Incl. Items 105 & 106)

7

0

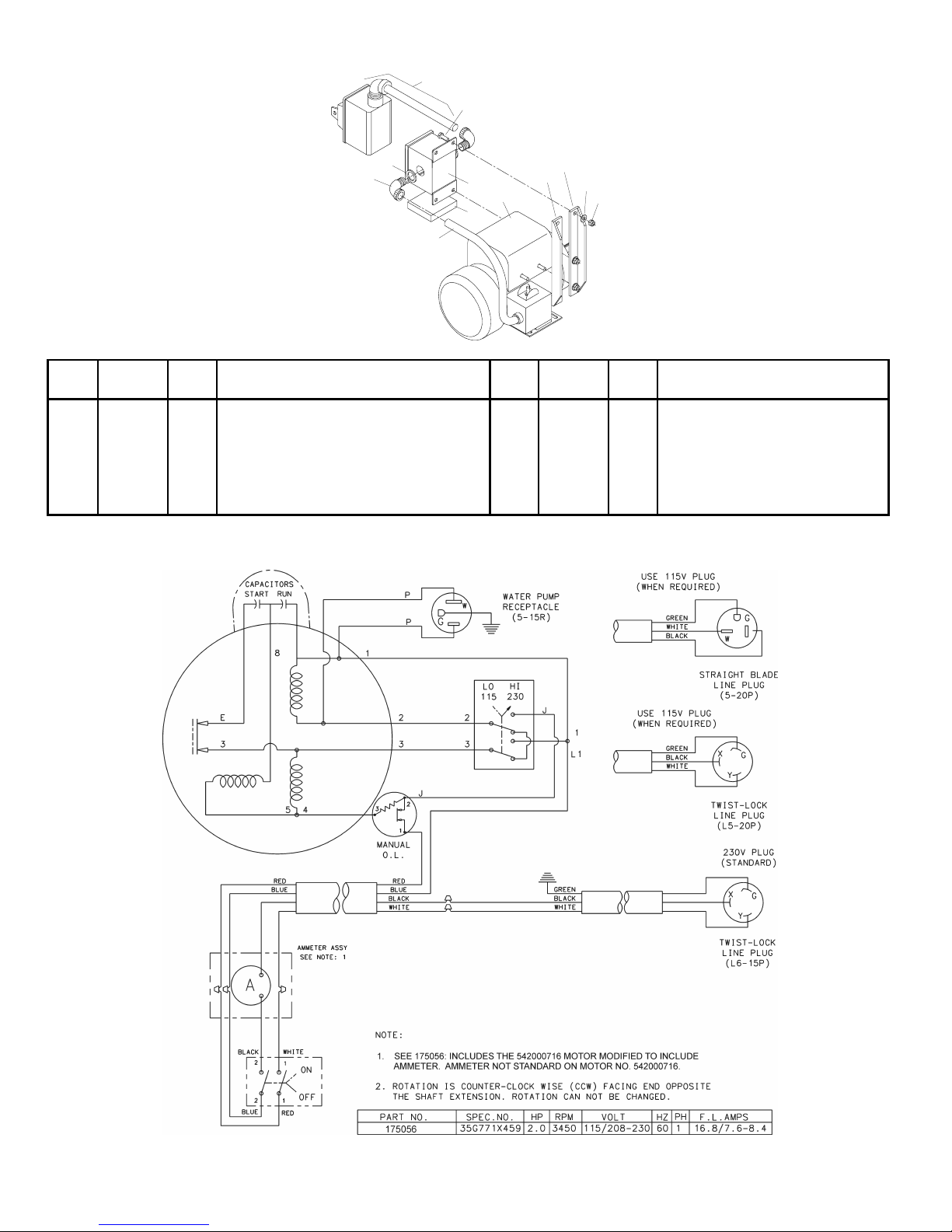

DIAGRAM 2 – STM-2000 2 HP

with Ammeter

(9/17/03)

1a

8

5

4

11

3

1

2

7

6

9

1

DIAG.

LOC.

- - 175056 1 2 HP Motor-Ammeter (Incls 1-11) 6 175086 1 Mounting Bar, L.H.

1

1a 1 Switch Assy – ONLY 8 020370 6 Capscrew, 1/4”-20 x 3/4”

2 175085 1 Mounting Pad – Foam Rubber 9 020742 6 Washer, Flat 1/4”

3 175079 1 Ammeter & Enclosure 10 020195 6 Locknut, Fiber, 1/4”-20

4

5 176953 2 Locknut, 3/4” Conduit

PART

NO.

542000716

542182212

QTY.

REQ.

1 2 HP Motor & Switch 115/230V/60/1 7 175087 1 Mounting Bar, R.H.

2

Connector, 90° Strain Relief

DESCRIPTION

DIAG.

LOC.

11 180817 2 ft Cable, 12-5 SOW-A/SO

PART

NO.

QTY.

REQ.

DESCRIPTION

WIRING DIAGRAM STM-2000 with Ammeter (9/17/03)

8

WIRING DIAGRAM STM-1500 (P/N 542000605) (9/17/03)

WIRING DIAGRAM STM-2000 (P/N 542000607) (9/17/03)

9

NOTES:

10

Felker’s New Equipment Warranty

Except as noted below. Felker warrants that its new equipment will be free from manufacturing defects for a

period of two (2) years from date of purchase by the original consumer purchaser.

The above warranty is subject to the following new equipment exceptions:

1. The warranty time period for the following new equipment is limited as follows:

Gas-powered Quickie Super saws – Three (3) months

Mix Master, Mortar Master, Stone Mate, Land Shark, Power Kat - One (1) year

Tile Mitersaw, Little Jack, Jack Junior and Slammer Jack tools – Six (6) months

FTS-70 - Ninety (90) days

2. To the extent the following components are part of any the new equipment, Felker’s warranty on the

component parts is limited to the manufacturer’s warranty period set out below:

Manufacturer.....Warranty Period

GAS and DIESEL ENGINES

Briggs & Stratton....................2 years

Koler Gas................................2 years

Robin Gas................ 2 yrs./2,000 hrs.

Honda Gas..............................2 years

Wisconsin Gas. .......1 year/2,000 hrs.

Hatz Diesel..............................1 year

3. Felker’s obligation under this warranty is expressly limited to the replacement or repair at Felker, Olathe,

KS 66061, or at a service facility designated by Felker, of such parts as inspection shall disclose to have been

defective. This warranty does not cover labor, except for gas powered Quickie Super saws and does not cover

maintenance items such as belts, air filters, bearings and wheels. Purchaser will be responsible for paying for

shipping costs to and from the location where the equipment is to be repaired or replaced. Motors and engines

are to be serviced by the nearest factory authorized service center. These service centers are designated by the

manufacturer of the engine/motor. Under no circumstances will Felker be responsible for incidental or

consequential damages.

4. Felker’s warranty does not apply to defects caused by damage, abuse, modifications, low voltage, acts of

God, unreasonable use, faulty repairs made by others or defects caused by failure to provide reasonable

maintenance. All warranties are void if the equipment or any of its components are altered or modified by the

purchaser, or of the product is used in a manner or with a blade not recommended by the manufacturer.

5. The forgoing express warranties are in lieu of all other warranties. FELKER EXPRESSLY DISC LAIM S

ALL OTHER WARRANTIES, INCLUDING, WITHOUT LIMITATION, THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

Please record the Date of Purchase and the Serial Number of your saw in the space below. (The serial number

is located on the side of the motor.) When ordering service items, please have this information available.

Manufacturer.....Warranty Period

ELECTRIC MOTORS

Baldor.......................................1 year

Leeson......................................1 year

Bosch...................................6 months

Milwaukee............................Lifetime

Black & Decker........................1 year

DM100................................6 months

AIR MOTORS and VAC. PUMPS

Gast..........................................1 year

Manufacturer.....Warranty Period

TRANSMISSIONS

Eaton.....................................3 years*

Sunstrand................3 yrs./1,000 hrs.*

(* from date of manufacture)

HYDRAULIC PUMPS

Fenner-Stone............................1 year

John S. Barnes Co....................1 year

WATER PUMPS

Jasbsco.....................................1 year

Beckett.....................................1 year

Serial Number:

Date of Purchase:

Model Number: Where Purchased:

11

Felker Corporate Office

17400 West 119th Street

Olathe, Kansas 66061

Customer Service ……….……………. 800-365-4003

Corp. Office ...………………………..... 913-928-1000

Cust. Service FAX …………………… 800-825-0028

Corp. Office FAX ..………………….... 913-438-7951

Cust. Service, Int'l. …………………… 913-928-1300

Int'l. E-mail ......……………….…. rcoats@db-inc.com

Western Division Center

17311 South Edwards Road

Ceritios, CA 90703-2427

Felker Latin America, Mexico, Caribbean,

Central and South Ame rica

17400 West 119th Street

Olathe, Kansas 66061

Phone ……………………………….…. 913-928-1255

FAX ………………………………….…. 913-438-7938

E-mail ……………………………. hleon@db-inc.com

Felker Canada

17400 West 119th Street

Olathe, Kansas 66061

Customer Service …………….…….... 800-365-4003

E-mail …………………………… rbaker@db-inc.com

Felker Hong Kong, China

Diamant Boart Pte Ltd.

Unit E, 13/F., Infotech Centre,

21 Hung To Road, Kwun Tong,

Hong Kong

Phone ……………………..…………. 852-2516-6602

FAX ………………………..…………. 852-2516-6605

E-mail …………………….... Targethk.netvigator.com

Felker Japan, Korea, Taiwan

1803-36 Oyama-Machi

Machida-Shi, Tokyo 194-0212

Japan

Phone ………………………………… 8142-797-0212

FAX …………………………………… 8142-798-7515

E-mail ………………… fwnh9794@mb.infoweb.ne.jp

Felker Australia, New Zealand/Dembicon Pty. Ltd

29 Kinkaid Avenue

North Plympton, Adelaide SA 5037

Australia

Phone ………………….…………..…... 61-83751000

FAX …………………….………….…… 61-83710990

E-mail ……………….. enquiries@dembicon.com.au

Internet ……………….……. www.dembicon.com.au

Felker Brazil

Pix Do Brasil

Rua José de Oliveira Coutinho

São Paulo, Brazil CEP 01144-020

Phone ………………………………. 55 11 3611-8383

FAX ………………………….……... 55 11 3619-3022

E-mail …………………………. pixbrasil@uol.com.br

Felker Singapore, Thailand, Vietnam,

Malaysia, Indonesia

Phone ………………………………….. 65-9628-6175

FAX ……………………………………… 65-234-2896

e-mail …………………………. reeh@singnet.com.sg

European Headquarters

DB Construction Business Group

Avenue Du Pont De Luttre, 74

1190 Brussels, Belgium

Phone ……………………………….. (32-2) 348-3669

FAX ………………………………….. (32-2) 348-3136

Internet …………………….. www.diamant-boart.com

Loading...

Loading...