Page 1

Quick Start Guide

Tec 4

www.felixprinters.com/support

support@felixprinters.com

Zeemanlaan 15

3401 MV IJsselstein

The Netherlands

Page 2

FELIXprinters Quick Start Guide for the FELIX Tec 4

General safety

Keep children under the age of 14 out of reach of the printer.

FELIXprinters are only suitable for professional use.

Considerations when in operation

Do not lean on the printer.

Be careful with long hair and loose clothes.

Do not transport the printer while working.

Make sure all moving parts can move without any obstructions.

Do not remove any objects from the hot plate while printing.

Caution with any moving parts that move in the X, Y and Z

direction. At the end of each moving part there is a pinching

hazard.

Electronic safety

Only use the power supplies and cables supplied by FELIXprinters. Always turn off and unplug the printer before doing

maintenance or modications.

The power supply meets all CE mark regulations and is

protected against short-circuit, overload, over voltage and over

temperature.

Printer placement

Place the FELIXprinter on a stable table/desk.

This will keep it safe from small children.

Use the FELIXprinter in a dry environment.

Ventilate

Good ventilation while printing is advised though printing

pure PLA is considered safe. When printing ABS, small

concentrations of Styrene vapour can be released. This

can (in some cases) cause headaches, fatigue, dizziness,

confusion, drowsiness, malaise, difculty in concentrating,

and a feeling of intoxication.

We recommend using lament types shown on the FELIXprinters website. Examples PLA, PETG, ABS, PVA etc. Other

types may be toxic. Please follow instructions from the

lament supplier.

Caution with heater elements

There is a potential risk of injury, as the print head can reach

temperatures of up to 275°C and the heated bed of up to

100°C. Don’t place objects on the heated bed that are not

being printed, not even when the printer is turned off.

We do not recommend to leave the printer unattended for

a very long period of time. If you do, it is recommended to

leave it in a properly conditioned room with distance from

highly amable objects.

Safety

Page 2

Page 3

FELIXprinters Quick Start Guide for the FELIX Tec 4

Thank you for choosing FELIX Tec 4.

This quick start guide contains the following information for you to familiarize yourself with your 3D printer, to use it to

its best advantages and to benet fully from all the functions and the technical developments it incorporates.

It is well worth taking a few minutes to read this guide to familiarize yourself with the information and guidelines it

contains about the machine and its functions.

More manuals and tutorials can be found on www.felixprinters.com/support

Page 3

Chapter 1 – Unboxing

1.1 What’s in the Box?

1.2 Unboxing

1.3 Installing the Handle

1.4 Installing Accesoires and Cables

Chapter 2 – Prepare

2.1 Level Build Platform

2.2 Calibrate Z-Probe

2.3 Change lament

Chapter 3 – Print

3.1 Ensure a Succesfull Print

3.2 Printing via SD Card

3.3 Remove a 3D Printed Object

3.4 Remove Support Material

INTRODUCTION & CONTENT

Chapter 4 – Software and maintenance

4.1 Print your own 3D Models

4.2 Calibrate XY Offset

4.3 Calibrate Z Offset

Require additional support?

Have a look at www.felixprinters.com/support

or at our user forum.

Page 4

FELIXprinters Quick Start Guide for the FELIX Tec 4

Page 4

FELIX Tec 4

System Specications

• Printer dimensions (L, W, H) 410 x 450 x 520 mm

• Weight 9 kg

• Power requirements: 220 V

Capabilities

• Build volume Single mode (L, W, H) 205 x 255 x 225 mm

• Build volume Dual mode (L, W, H) 205 x 240 x 225 mm

• Layer height range 0.05 - 0.25 mm

• Bed temperature: max. 90 °C

Extruders

• Diameter nozzle: 0.35 mm (optional 0.5mm)

• Max temperature: 275 °C

Website

www.FELIXprinters.com

Print materials

• Open source 1.75 mm filaments

• Tolerance: ± 0.15 mm

• PLA, PVA, ABS-X, PETG, PolyFlex, Wood, Glass

Connectivity

• Stand-alone micro-SD card printing

• USB cable connection

• Optional WiFi - The Element by Printr (external)

Software

• Optimized for Simplify3D and Repetier-Host

Contact

info@FELIXprinters.com

Zeemanlaan 15, 3401 MV IJsselstein, The Netherlands

Specs

Page 5

FELIXprinters Quick Start Guide for the FELIX Tec 4

The Basics

Nozzles / Extruders

Flexible BuildPlate

Build Platform

Power Switch

Power Connection

USB Computer Cable

SD Card Slot

Filament tubes

Filament guide

Thumb screws

Filament

Filament spool holder

Display unit

Page 5FELIXprinters Quick Start Guide for the FELIX Tec 4

Page 6

FELIXprinters Quick Start Guide for the FELIX Tec 4

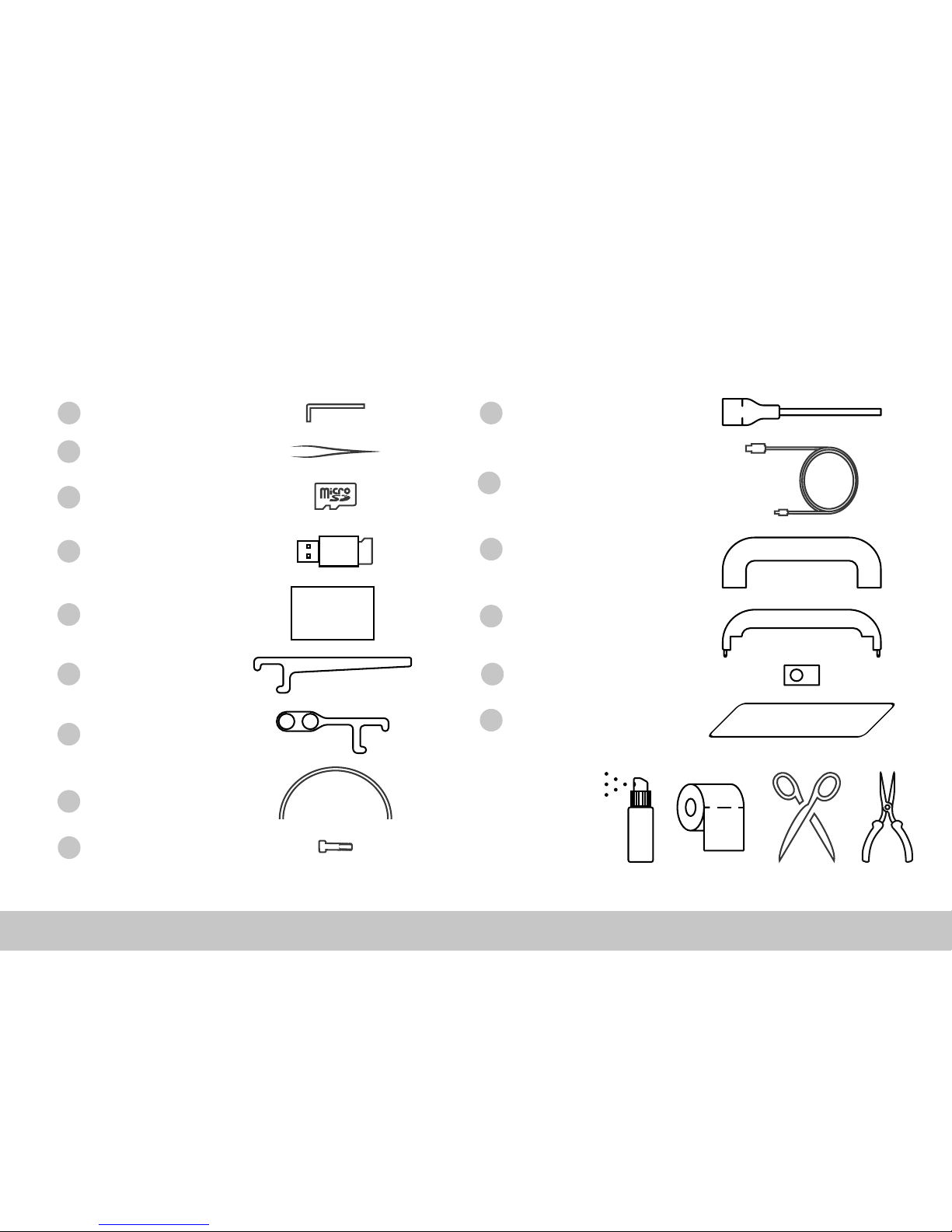

1.1 What’s in the Box?

*We recommend to use the following tools: Spray Container with Alcohol, Paper Cloth, Scissors and Long Nose Pliers

1 x Allen Key

2 x Spool Holder

1 x Filament Guide

1 x USB-SD Adapter

1 x Handle Cover

1 x USB Cable

1 x Power Cable

1 x Handle

1 x Tweezers

1 x Micro SD Card

2 x Filament Tubes

Chapter 1: Unboxing

Page 6FELIXprinters Quick Start Guide for the FELIX Tec 4

Recommended

tools:

A

B

C

D

F

G

H

I

M

L

K

J

2 x T-nut M8N

2 x M8x16 Screw

Calibration

Card

E

1 x Calibration Card

1 x Flexible BuildPlateN

Page 7

FELIXprinters Quick Start Guide for the FELIX Tec 4

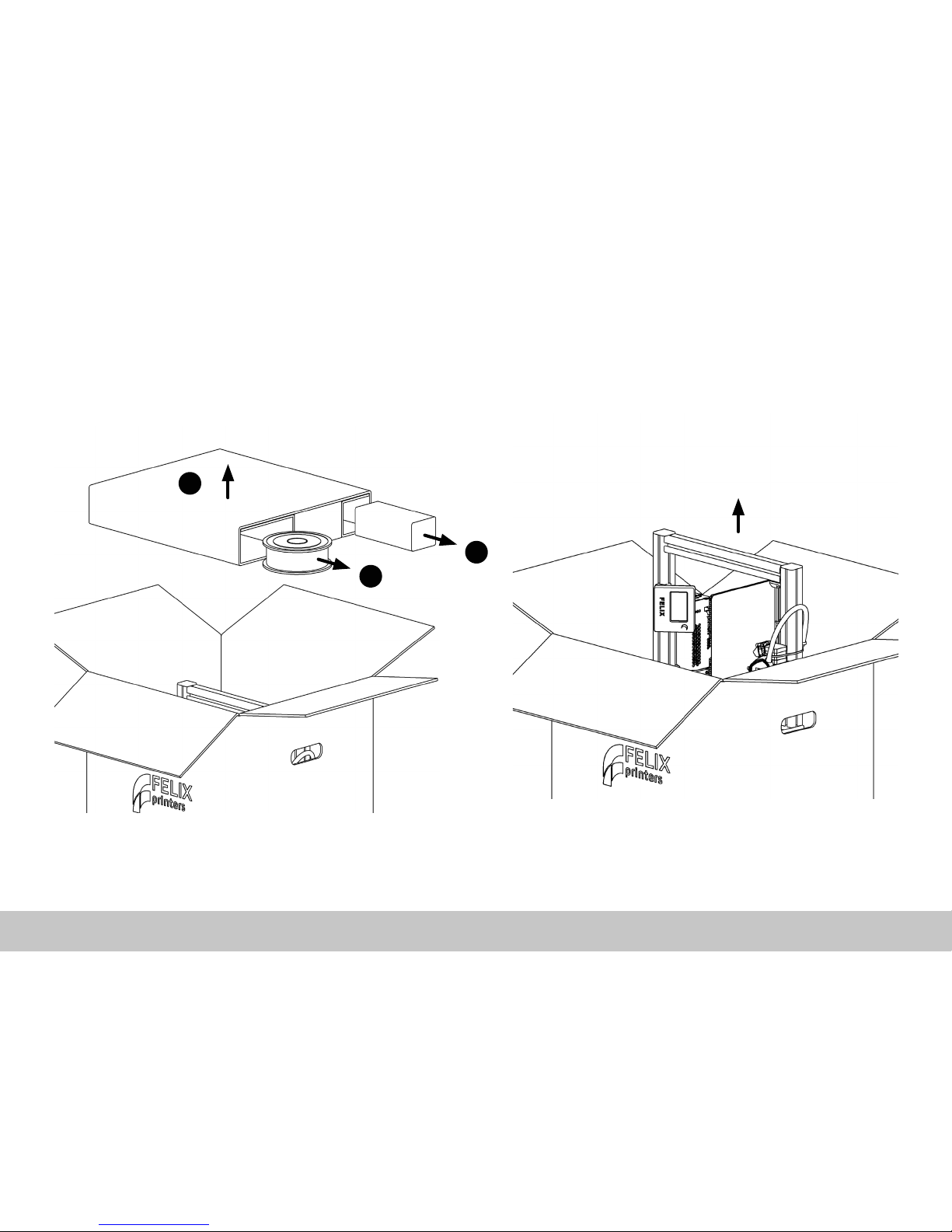

1.2 Unboxing

Chapter 1: Unboxing

Page 7Page 7FELIXprinters Quick Start Guide for the FELIX Tec 4

Open the box, remove the bumper and take out the

miscellaneous parts from the bumper.

Carefully remove the FELIX Tec 4 from the box.

1

2

2

Page 8

FELIXprinters Quick Start Guide for the FELIX Tec 4

Page 8

Chapter 1: Unboxing

Remove the foam protection from the printer frame. Remove the ve red protective cable ties using cutting

pliers or a scissor.

4 5

1

2

3

Page 9

FELIXprinters Quick Start Guide for the FELIX Tec 4

1.3 Installing the Handle

Page 9

Chapter 1: Unboxing

1. Put the T-nut upright into the T-slot of the prole.

2. Twist the T-nut 90 degrees in place.

3. Repeat this for both T-nuts.

1. Fix the handle against the vertical prole with the

two hexagon screws. Use a hex key size 5.

2. Press the handle cover on the handle

1

1

2

1

2

Page 10

FELIXprinters Quick Start Guide for the FELIX Tec 4

1.4 Installing Accesoires and Cables

Chapter 1: Unboxing

Page 10

≈ 12 cm

≈ 20 cm

1. Place the rear of the Flexible BuildPlate on the edge.

2. Lower the front of the Flexible BuildPlate and make

sure all edges are inside the build platform.

Install the lament guide and spool holder(s) by placing

one edge in the T-slot and twisting it in place.

1

2

Page 11

FELIXprinters Quick Start Guide for the FELIX Tec 4

Page 11

Chapter 1: Unboxing

E1:190°C E2:190°C B:55°C

X: 0.00mm

Y: 0.00mm

Z: 0.00mm

Printer Ready

Rotate the button to navigate

Push to enter the Main Menu

Current Temperature

Extruder 1 Extruder 2

Build PLT.

Status

1. Make sure the power switch is turned off.

2. Insert the power cable.

3. Insert the USB cable when printing via computer.

The unboxing is done, you can now switch on the

printer!

2

1

3

Page 12

FELIXprinters Quick Start Guide for the FELIX Tec 4

E1:21°C E2:21°C B:21°C

Build PLT.

Levelled Correctly

>>> OK <<<

E1:21°C E2:21°C B:21°C

Max. 10°

Turn back: 45° R

Turn front: 90° L

>Measure Again

Cancel

E1:21°C E2:21°C B:21°C

Measuring...

Please Wait...

E1:21°C E2:21°C B:21°C

Back

>Control

Print

Settings

Chapter 2: Preparation

Page 12

2.1 Level Build Platform

Enter the main menu by pressing the button,

select Control.

Scroll down and select Level Build Platform.

Shown are the correction values. These values

will be used to level the build platform by turing

the two thumbscrews.

Turn the front thumbscrew 90° to the left (counterclockwise), and turn the back thumbscrew

45° to the right (clockwise). Now select Measure

Again.

If the thumbscrews are adjusted correctly, the

process will nish automatically. If not repeat

steps 3 and 4 untill levelled correctly

1

2

4 5 6

Next the printer will start measuring the angle of

the build platform, this may take a few seconds.

E1:21°C E2:21°C B:21°C

Back

Preheat/Cool

Remove Build PLT.

Change Filament

>Level Build PLT.

2

3

Page 13

FELIXprinters Quick Start Guide for the FELIX Tec 4

www.felixprinters.com

Calibration Card

E1:21°C E2:21°C B:21°C

Z-Probe

Calibrated!

>>> OK <<<

E1:21°C E2:21°C B:21°C

Back

>Control

Print

Settings

Chapter 2: Preparation

Page 13

2.2 Calibrate Z-Probe

Enter the main menu by pressing the button,

select Control.

Next, scroll down and select Calibrate Z-Probe.

Scroll left to increase the friction, and scroll right

to decrease the friction on the Calibration Card.

When satised, press the button to continue.

You’ve now calibrated the Z-Probe. This will inuence the distance between the Flexible BuildPlate and the nozzle. This is important for the

rst layer to stick during printing.

1

3 4 5

Place the Calibration Card between the left

nozzle and the Flexible BuildPlate. Press the rotary button to continue.

E1:21°C E2:21°C B:21°C

Preheat/Cool

Remove Build PLT.

Change Filament

Level Build PLT.

>Calibrate Z-Probe

2

Always make sure the

exterior of the nozzles are

clean before calibrating the

Z-Probe

!

Page 14

FELIXprinters Quick Start Guide for the FELIX Tec 4

Chapter 2: Preparation

Page 14

2.3 Change Filament

Take the lament tubes and push the ends in

the lament guide and print-head. These will be

used to feed the lament to the print-head

Take the end of the lament, and create a clean

end, by cutting the lament with a scissor.

Place the lament into the print-head. We will

feed the lament completely through the extrud-

ers on the next page.

3

4 5

Place the lament spools on the spool holders.

1 2

Clean and replace the dust

lter periodically to improve

the lifetime of the extruders

and nozzles.

i

Page 15

FELIXprinters Quick Start Guide for the FELIX Tec 4

E1:21°C E2:21°C B:21°C

Change Filament

Back

>PLA

PETG

PV A

E1:21°C E2:21°C B:21°C

Back

Preheat/Cool

Remove Build PLT.

>Change Filament

Level Build PLT.

Chapter 2: Preparation

Page 15

Enter the main menu by pressing the button,

select Control.

Scroll down and select Change Filament.

Select the material you want to load. If you’re

not sure, check the side of the lament spool for

more information. Press to continue.

Feed the lament through the extruder by

rotating the button clockwise until a small thread

comes out of the nozzle. Use the tweezers to

remove the thread of lament.

6 2

9 10

Select the extruder which you want to load. For

single head printers only extruder 1 can be used.

7 8

E1:21°C E2:21°C B:21°C

Back

>Control

Print

Settings

E1:21°C E2:21°C B:21°C

Change Filament

Back

>Extruder 1

Extruder 2

When changing to a new

material with a lower tem-

perature, purge the extruder

with the previous tempera-

ture to prevent clogging.

i

Page 16

FELIXprinters Quick Start Guide for the FELIX Tec 4

3.1 Ensure a Succesfull Print

Clean Nozzles

Remove plastic residue from the nozzle using the

tweezer. Select Preheat/Cool in the Control Menu to

make the residue soft and easy to remove.

Clean Build Platform

Degrease the Flexible BuildPlate using alcohol,

methylated spirit or acetone and wipe it clean with a

paper towel.

Page 16

Chapter 3: Print

Page 17

FELIXprinters Quick Start Guide for the FELIX Tec 4

22

E1:144°C E2:21°C B:39°C

Benchy Single PLA

00.0%

Heating up...

E1:21°C E2:21°C B:21°C

Back

Benchy Dual PLA-PLA

>Benchy Single PLA

Chapter 3: Print

Page 17

3.2 Printing via SD Card

Enter the main menu and select Print. Select

Benchy Single PLA

for a single colour

sample. If you prefer a dual colour sample

select

Benchy Dual PLA-PLA

.

1

4 5

Insert the FELIX SD card into the slot located

above the power plug. This SD card contains the

Benchy Gcodes which is the rst test print.

3

E1:21°C E2:21°C B:21°C

Back

Control

>Print

Settings

If you want to Stop printing, press the rotary

button and select Cancel Print.

Make sure your rst layer is nished properly

before leaving your printer unattended. Make

sure the material sticks properly to the Flexible

BuildPlate.

E1:185°C E2:21°C B:55°C

Back

>Cancel Print

Pause Print

Change Filament

Z-Offset: 0.00mm

Printing via SD card (instead

of USB cable) improves

reliablity, and is advised for

long print jobs.

i

Page 18

FELIXprinters Quick Start Guide for the FELIX Tec 4

3.3 Remove a 3D Printed Object

Page 18FELIXprinters Quick Start Guide for the FELIX Tec 4 Page 18

Caution: Hot!

Page 18

Chapter 3: Print

Remove the Build Plate

To remove the Flexible BuildPlate lift up the front end using

the notch in the build platform. Now you can easily remove

the Flexible BuildPlate by pulling it fowards.

Remove Printed Objects

To remove printed objects simply bend the Flexible

BuildPlate at both ends.

POP!

1

1

1

2

Page 19

FELIXprinters Quick Start Guide for the FELIX Tec 4

Page 19

3.4 Remove Support Material

Chapter 3: Print

FELIXprinters Quick Start Guide for the FELIX Tec 4

Same Material Support

Remove the same material support structures by pulling on the endes of the structure that are not connected to the 3D model using long nose pliers.

PVA Water Soluble Support

When using PVA Water Soluble Support simply dissolve

the support structure in water overnight. Do not use

warm water since this could warp the 3D model.

Support structures are used

to support 3D geometries

that angle up and outwards

more than 45 degrees.

i

Page 20

FELIXprinters Quick Start Guide for the FELIX Tec 4

Page 20

4.1 Print your own 3D Models

Chapter 4: Software and maintenance

Page 20

Repertier-Host

For experienced users who love to tweak we also

support repertier-host open source 3D software.

www.felixprinters.com/repetier-host

Simplify3D

Simplify3D is the recommended software to operate

the FELIX Tec 4.

www.felixprinters.com/simplify3d

Benchy.STL Benchy.Gcode

3D Model Slicer 3D Printer

Page 21

FELIXprinters Quick Start Guide for the FELIX Tec 4

1

E1:21°C E2:21°C B:21°C

Back

>Calibrate XYe all

>Home All

Chapter 4: Software and maintenance

Page 21

4.2 Calibrate XY Offset (Dual only)

Select: Control -> Calibrate Extruders -> Calibrate XY.

Choose the beste aligning lines for both the X

and Y value. In this example the best aligning

Y value is 3.

Enter both the X and Y values and select

continue.

3 4

To start the XY-Calibration, rst load PLA in both

extruder 1 and 2. Also make sure the build platform is properly levelled.

2

Only perform this calibration

after removal or replacement

of the hot-ends and nozzles.

!

E1:21°C E2:21°C B:21°C

Back

Preheat/Cool

Remove Build PLT.

>Change Filament

Level Build PLT.

E1:21°C E2:21°C B:21°C

Choose the Best

Aligning XY Values

>X Value 8

Y Value 3

Continue

In case the values go out of

range simply select the best

aligning value and repeat

steps 1 to 4 untill both

values are 5.

i

Page 22

FELIXprinters Quick Start Guide for the FELIX Tec 4

E1:21°C E2:21°C B:21°C

Back

>Home Allome all

Home X

Home Y

Home Z>Home All

Chapter 4: Software and maintenance

Page 22

4.3 Calibrate Z Offset (Dual only)

Select: Control -> Move -> Home All. Make

sure the build platform is properly

levelled and the nozzles are clean.

Loosen the right hex screw slightly by turning it

counterclockwise with a hex key size 3.

Adjust the height of the right extruder by turning

the hex screw with a hex key size 2.5. Turn

clockwise to lower the right extruder.

3 4

Turn the printer off and manually move the right

extruder to position A. Now remove the fan cover

by pulling it forward.

1

A

Use the Calibration Card to adjust the right

extruder to the same height as the left extruder.

If satised tighten the hex screw size 3 and put

the fan cover back in it’s original position.

5

2

Only perform this calibration

after removal or replacement

of the hot-ends and nozzles.

!

Page 23

FELIXprinters Quick Start Guide for the FELIX Tec 4

Page 23

Page 24

Quick Start Guide FELIX Tec 4

Zeemanlaan 15

3401 MV IJsselstein

The Netherlands

www.felixprinters.com/support

support@felixprinters.com

Review our products

Help us to improve our products and services. It only takes a few minutes!

www.felixprinters.com/survey

(a small reward is waiting for you)

Manuals & tutorials

www.felixprinters.com/support

FELIX Community

www.felixprinters.com/community

V1-2017

Loading...

Loading...