Page 1

Assembly Manual

FELIX One

www.felixprinters.com

support@felixprinters.com

Zeemanlaan 15

3401 MV IJsselstein

The Netherlands

Version 1.0

2018

Page 2

FELIXprinters Assembly Manual for the FELIX One

Page 3

Dear Customer,

Thank you for choosing FELIXprinters! To get your Felix printer up

and running as fast and painlessly as possible please follow this manual carefully. Please don’t take any shortcuts. It’s better to spend a

few minutes extra on reading, than to wait a week for new parts.

When things are unclear or if you have any remarks or tips, please

contact us at support@FELIXprinters.com. We also recommend

looking on our forum and getting yourself a forum account. You will

benet from the ability to get downloadable and printable upgrades

for your printer. Also it is a great source to obtain and share knowledge about your 3D printer and 3D printing in general.

Have fun building!

Kind regards,

FELIXprinters.

Introduction Table of Content

Required tools 5

Chapter 1: Frame 6

Chapter 2: Z-axis 8

Chapter 3: X-axis 11

Chapter 4: Y-axis 15

Chapter 5: Print Head 19

Chapter 6: Wiring 27

Chapter 7: Upload Firmware 31

Chapter 8: Installing LCD 32

Chapter 9: Functional test 33

Chapter 10: Finishing Touch 35

Chapter 11: Checklist 36

Bill of Material 38

Page 3

FELIXprinters Assembly Manual for the FELIX One

Page 4

Notice

Before starting the assembling: Check the content of the kit if it is complete

according to the bill of material in the appendix of this document.

Page 4

FELIXprinters Assembly Manual for the FELIX One

Page 5

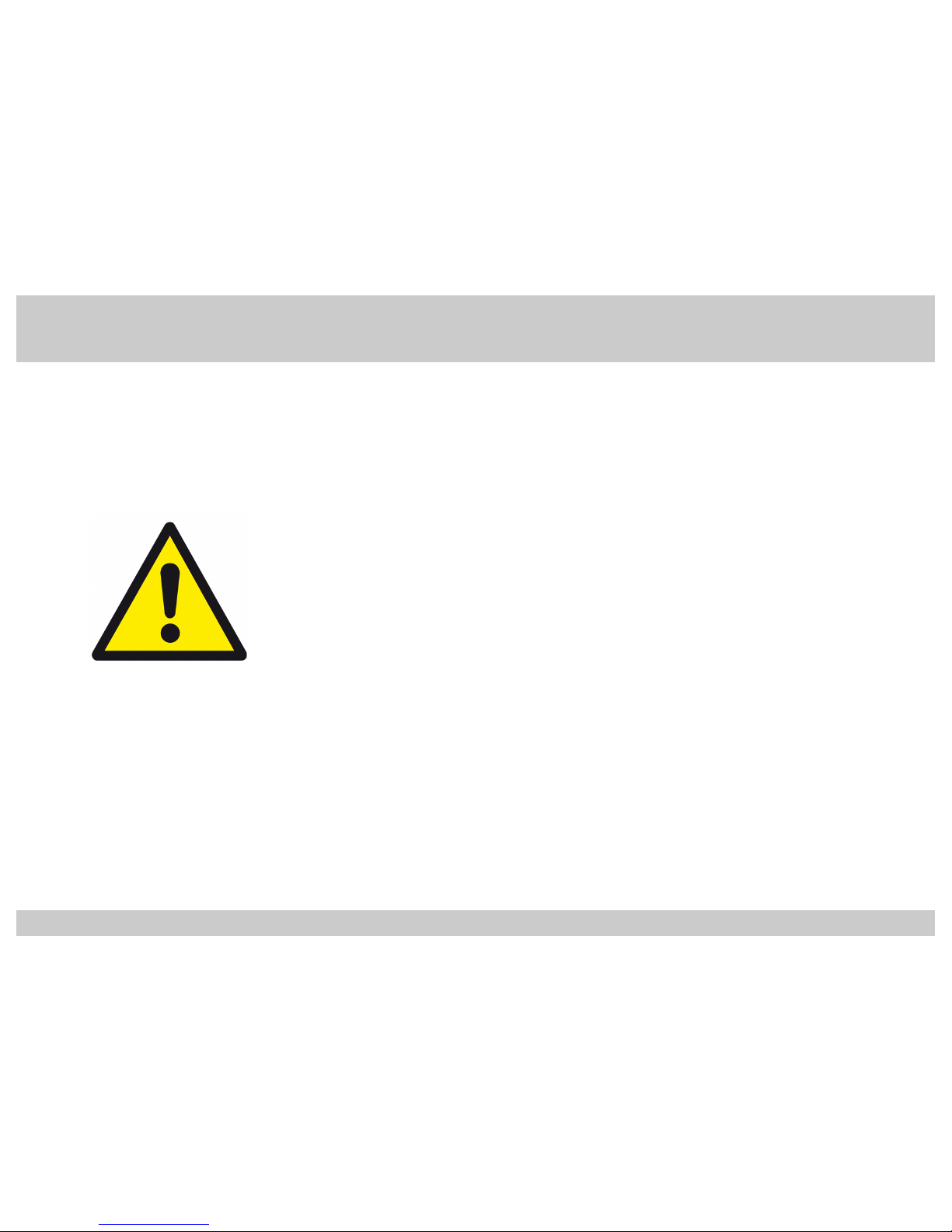

Required Tools:

*Or use a steel hammer with a soft piece

of rubber or plastic to absord the impact.

1,5 2 3 4 52,5

Hexagon

Key 1,5mm

Hexagon

Key 2mm

Hexagon

Key 2,5mm

Hexagon

Key 3mm

Hexagon

Key 4mm

Hexagon

Key 5mm

Tweezer

Wrench

5,5 mm 7,0 mm and 12 mm

5,5

7,0

12

+ -

Slotted Head

Screwdriver

Phillips Head

Screwdriver

Small

Pliers

Knife / Box

Cutter

Rubber

Hammer*

Grease

Lubricant

Tape

Measure

Alcohol

Page 5

FELIXprinters Assembly Manual for the FELIX One

Page 6

Tools:

3

1

Tools:

Chapter 1: Frame

30 Minutes

2

4 5

(1x) Prole 2

(1x) Bolt M8 x 20

(1x) Frame Connector

(1x) Prole 4

(2x) Bolt M8 x 20

(2x) Frame Connector

(1x) Prole 1

5

!! Hole !!

!! Hole !!

!! Hole !!

160mm

Tools:

5

!! Hole !!

!! Hole !!

!! Hole !!

!! Hole !!

!! Hole !!

160mm

Tools:

5

Tools:

5

5

Page 6

FELIXprinters Assembly Manual for the FELIX One

Page 7

Tools:

9

7 8

11

Make sure the proles are

properly aligned. If not

untighten the screws and

readjust the proles.

6

(4x) End Cap Square

(1x) End Cap Rectangle

!! Hole !!

(1x) Prole 2

(1x) Bolt M8 x 20

(1x) Frame Connector

Tools:

5

Tools:

5

(1x) Prole 3

(2x) Bolt M8 x 20

(2x) Frame Connector

Tools:

5

Tools:

5

10

Page 7

FELIXprinters Assembly Manual for the FELIX One

Page 8

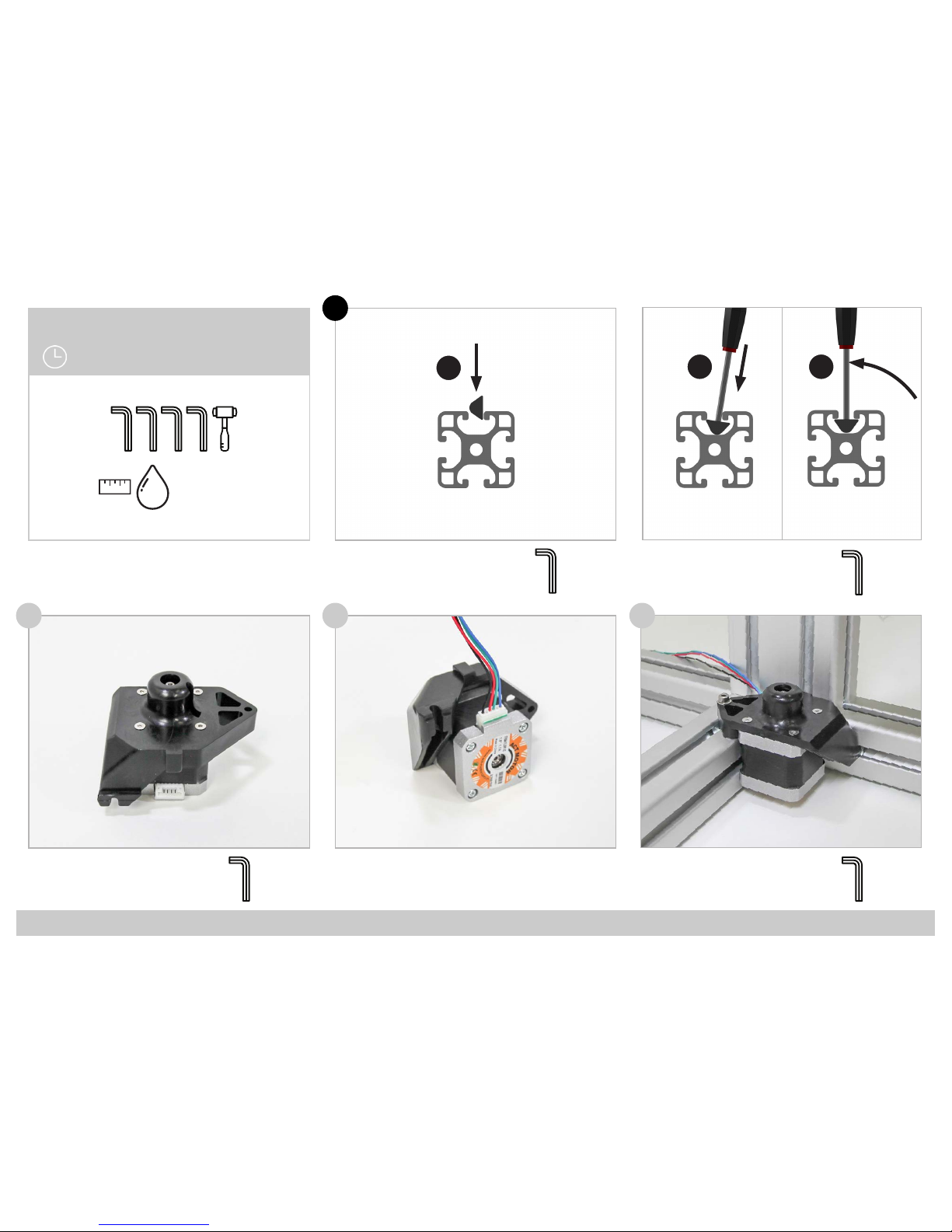

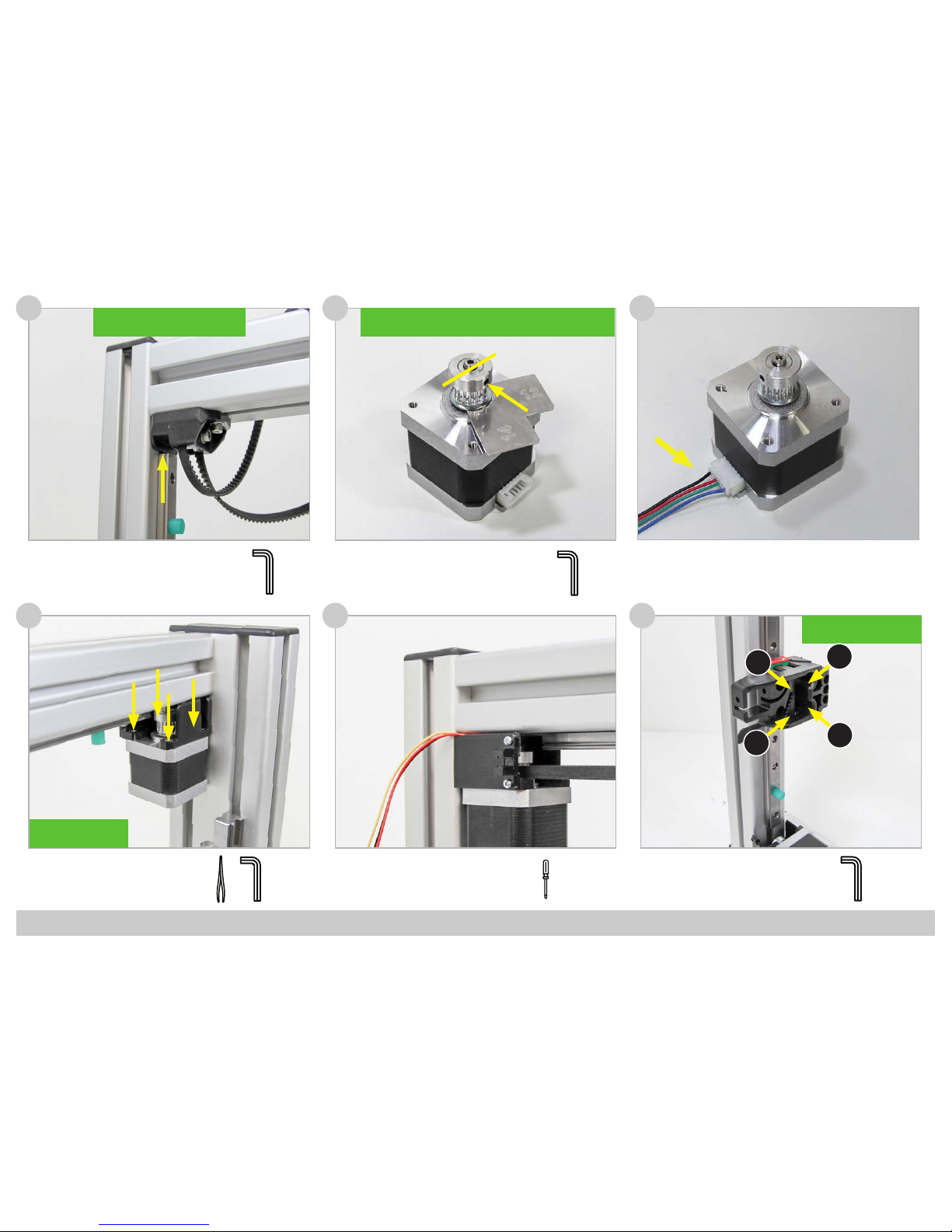

Tools:

12

(4x) CSK Bolt M3 x 8

(1x) Motor

(1x) Z-Axis Motor Bracket

13 14

(1x) Cable Stepper Z

i

(1x) Motor Assembly

(2x) T-Nut M4

(2x) Bolt M4 x 20

(2x) Small Washer M4

Example - Insert T-Nut:

Insert the nut into the slot

Tools:Example - Insert T-Nut:

Insert the key into the

threaded hole and rotate

the nut into position.

2

2

Tools:

2

Tools:

3

Tools:

Chapter 2: Z-Axis

45 Minutes

41,5 2 3

1

2 3

Page 8

FELIXprinters Assembly Manual for the FELIX One

Page 9

Tools:

18

(2x) Bolt M4 x 40

(2x) Locknut M4

16 17

19 20

(4x) Bearing

(2x) Bolt M4 x 25

(2x) Small Washer M4

(3x) Bolt M4 x 20

(1x) Linear Guide HGW15

Use tape measure to allign.

(1x) Z-Axis Lift

(1x) Hexagon Nut

15

(3x) T-Nut M4

16cm

28cm

4cm

!! Don’t let the Carriage run of the Rail !!

Tools:

3

!! Remove Bolts after pulling Locknuts into Z-Axis Lift !!

!! Washer!!

!! Washer!!

Tools:

3

Tools:

3

Tools:

2

Page 9

FELIXprinters Assembly Manual for the FELIX One

Page 10

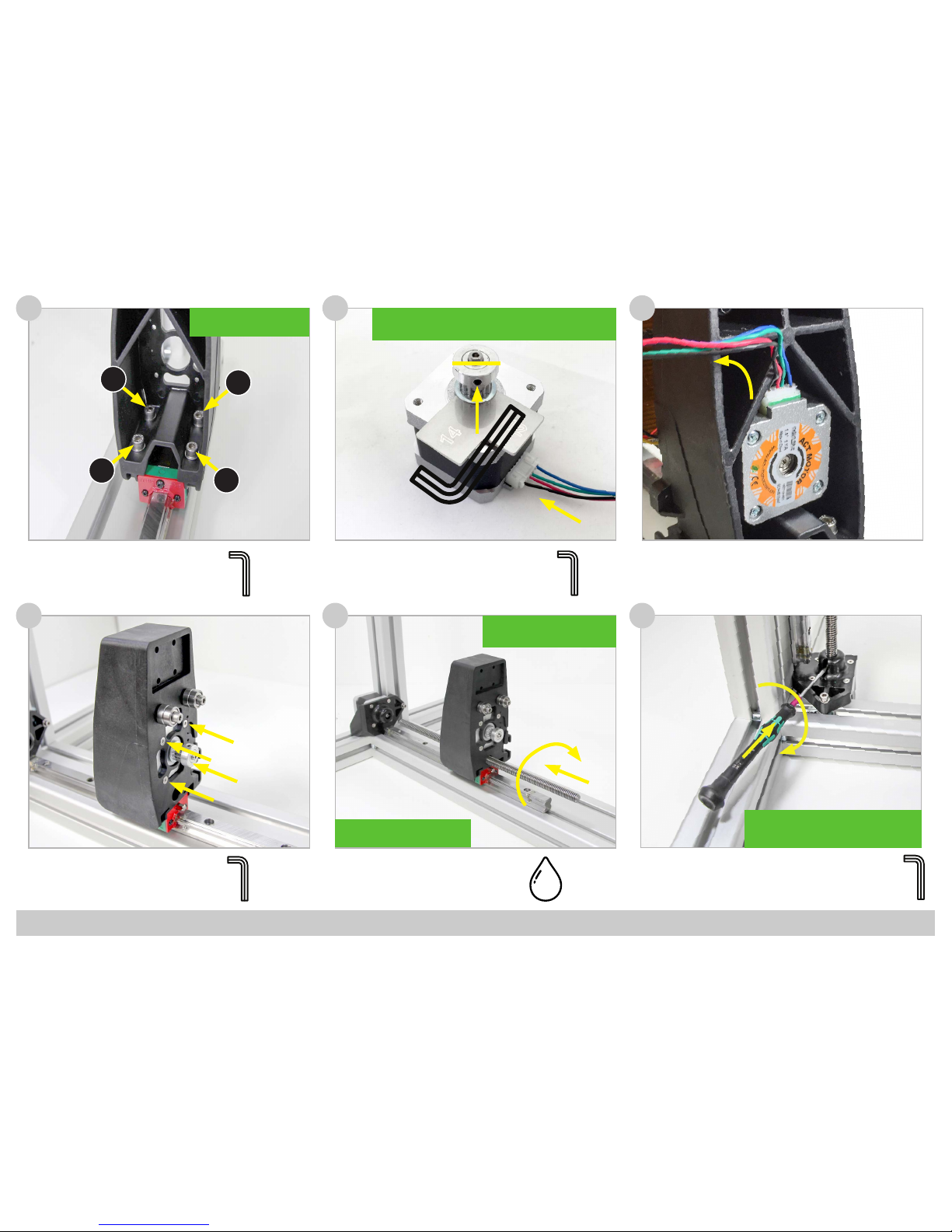

24

(1x) Motor Assembly

(4x) CSK Bolt M3 x 8

22 23

25 26

(1x) Spindle

(1x) Motor

(1x) Pulley

(1x) Set Screw M3 x 6

(1x) Cable Stepper Y

(1x) Cable Stepper Y

21

(1x) Z-Axis Lift Assembly

(4x) Bolt M5 x 16

(4x) Small Washer M5

(1x) Set Screw M3 x 6

Note: use a high quality and sharp 1.5 mm allen

key to properly x the spindle on the motor.

Tools:

4

Tools:

2

Tools:

1,5

Tools:

1,5

!! Make sure the Hexagon Nut

stays in its Socket !!

!! Make sure the at side of the Motor

Axle is Perpendicular to the Set Screw !!

!! Make sure the at side of the Motor Axle is Perpendicu-

lar to the Set Screw !!

Tools:

!! Apply Grease to the Spindle.

Do NOT use Oil as Lubricant !!

!! Tighten in a Crosswise

Pattern !!

4

2

1

3

Page 10

FELIXprinters Assembly Manual for the FELIX One

Page 11

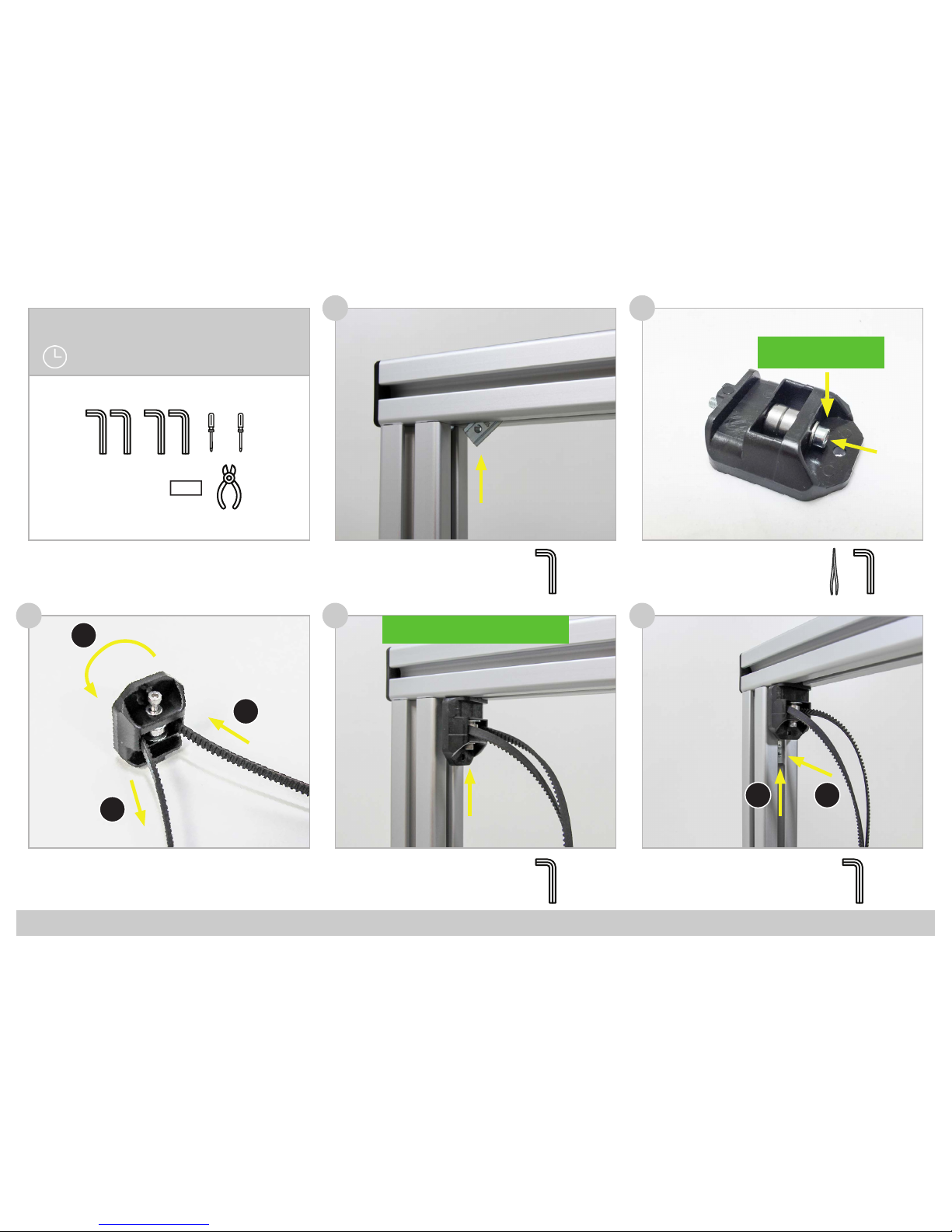

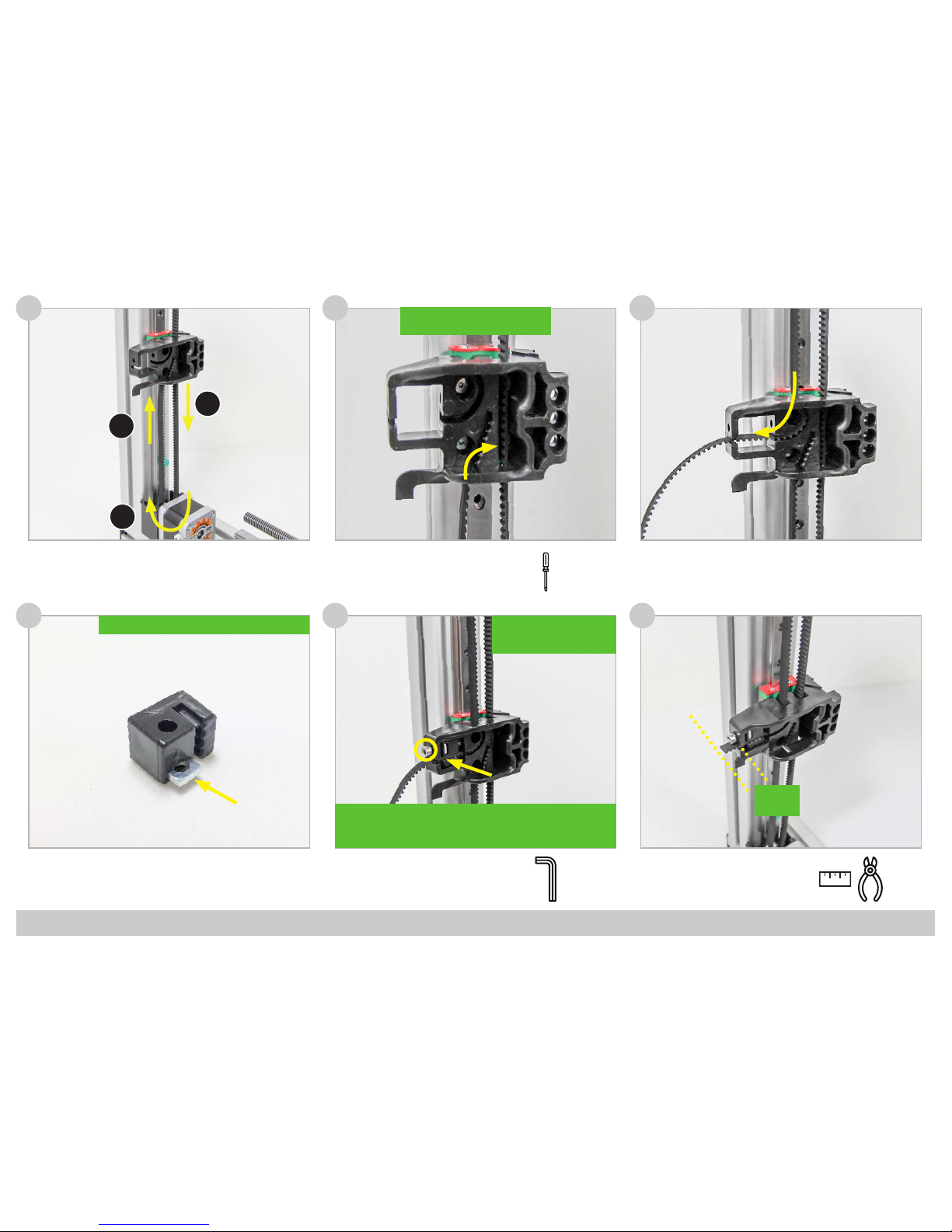

29

(1x) Belt

27 28

30 31

(1x) T-Nut M4

(2x) Bearing

(1x) Small Washer M4

(1x) X-Axis Belt Mount

(1x) Bolt M4 x 40

(1x) T-Nut M4

Tools:

3

!! Washer !!

Tools:

3

Tools:

2

Tools:

2

(1x) X-Axis Belt Mount Assembly

Tools:

Chapter 3: X-Axis

60 Minutes

141,5

2 32,51,5

+

-

12

1

2

3

!! Make sure the short side of the T-nut is

facing the corner of the frame !!

Page 11

FELIXprinters Assembly Manual for the FELIX One

Page 12

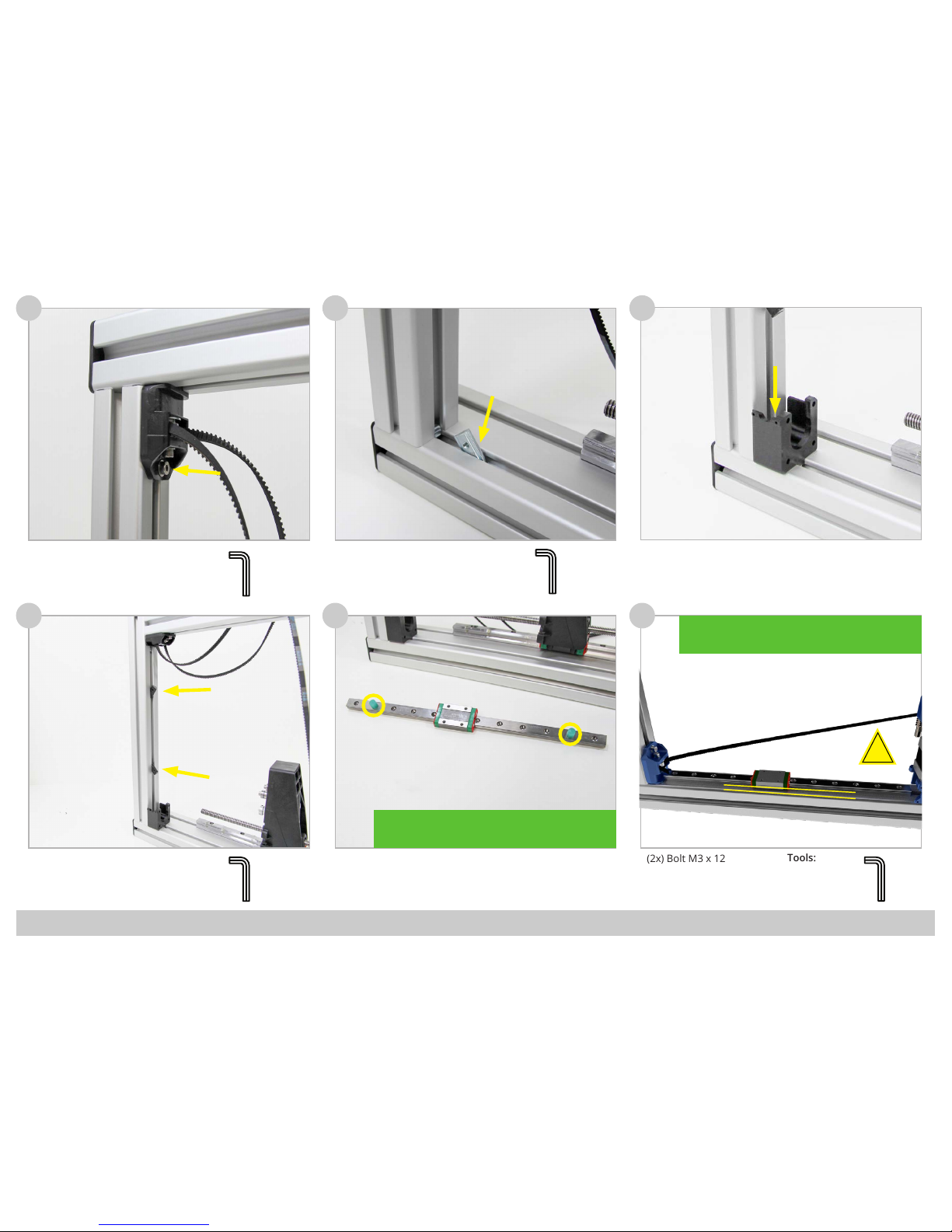

!! Reposition the Safety Plugs as shown !!

Tools:

35

33 34

36 37

(2x) T-Nut M3 (black)

(1x) T-Nut M4

(1x) Bolt M4 x 16

(1x) Small Washer M4

(1x) X-Axis Motor Bracket

32

(1x) Bolt M4 x 16

(1x) Small Washer M4

(2x) Bolt M3 x 12

(1x) Linear Guide MGN12

Tools:

Tools:

3

Tools:

2

2

2,5

(1x) Linear Guide MGN12

!

14 mm

14mm from the side of the rail to side of the

frame!

Page 12

FELIXprinters Assembly Manual for the FELIX One

Page 13

Tools:

41

(1x) Motor Assembly

(4x) CSK Bolt M3 x 8

39 40

42 43

(2x) Small Screw 2,2 x 8

(1x) Opto Sensor X

(1x) Cable Stepper X

38

(4x) CSK M3 x 6

(1x) Extru Base

Tools:

!! Make sure to Position the Rail

against X-Axis Belt Mount !!

Tools:

2,5

(1x) Motor

(1x) Pulley

(1x) Set Screw M3 x 6

Tools:

1,5

!! Make sure the at side of the Motor Axle is Perpendicular

to the Set Screw !!

Tools:

2

!! Use Tweezer to

Position the Bolts !!

+

2

!! Tighten in a Crosswise

Pattern !!

1

3

4

2

Page 13

FELIXprinters Assembly Manual for the FELIX One

Page 14

Tools:

Tools:

47

(1x) Tension Bracket

(1x) Square Nut M4

46

48 49

(1x) Tension Bracket Assembly

(1x) Bolt M4 x 25

44

Tools:

-

!! Use a screwdriver to Push the

Belt completely into the Socket !!

!! Insert the Square Nut into the Tension Bracket !!

3

2 cm

!! Use the Screwdriver to

Push the Belt completely

into the Socket !!

1

2

3

!! Move the carriage to the center of the rail. Tighten the belt using

the size 3 hexagon key until the belts can barely touch eachother

when pressing them together !!

45

Page 14

FELIXprinters Assembly Manual for the FELIX One

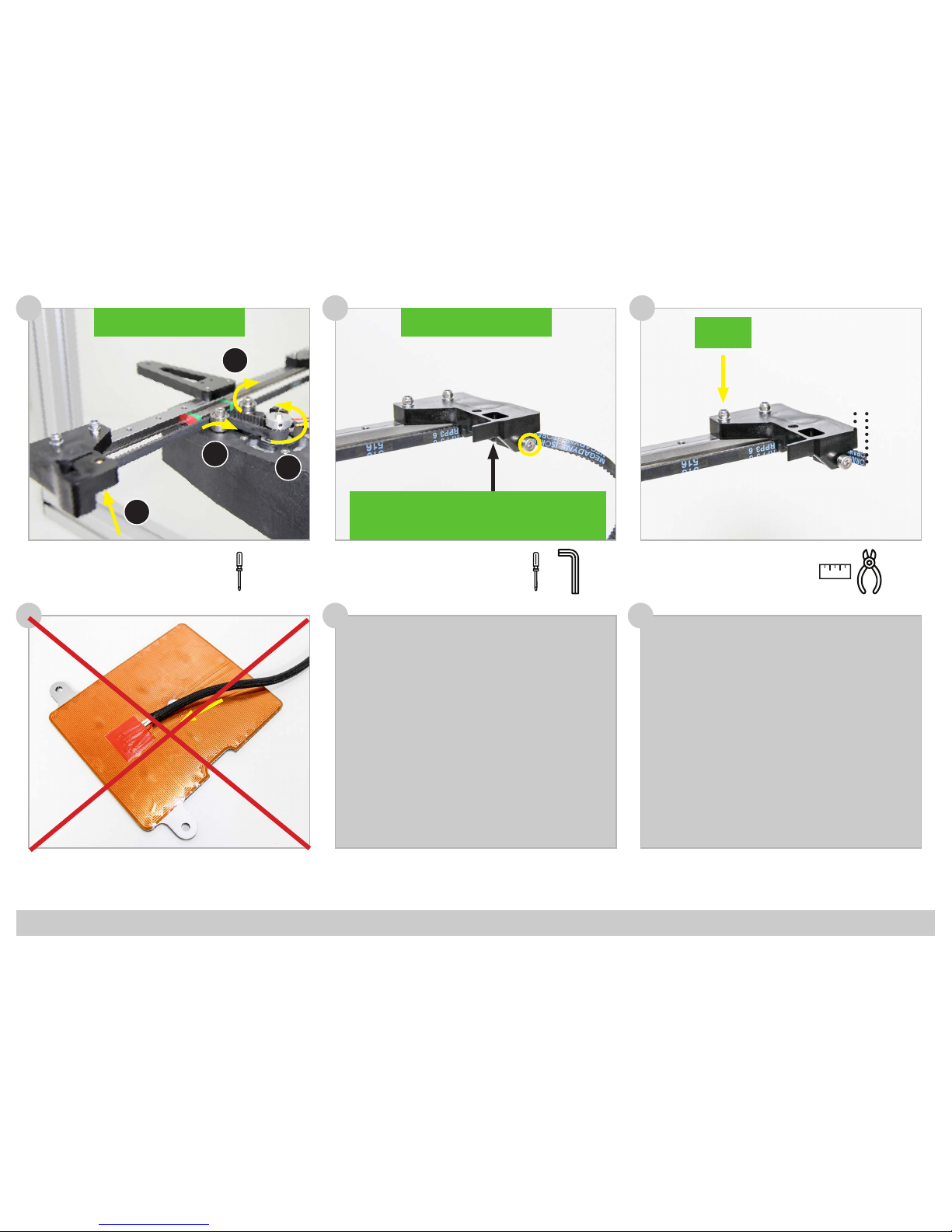

Page 15

Tools:Tools:

52

(2x) Bolt M3 x 12

(1x) Y-Stage Bracket

50 51

53 54

(2x) Small Screw 2,2 x 8

(2x) Thin Nut M4

(1x) Opto sensor Y

(4x) Bolt M3 x 16

(4x) Locknut M3

(4x) Small Washer M3

(1x) Y-Stage Bracket Pt.1

(1x) Y-Stage Bracket Pt.2

(1x) Hiwin Linear Guide MGN12

(4x) Bolt M3 x 16

(4x) Small Washer M3

(1x) Y-Stage Assembly

!! (1x) Thin Nut M4 !!

!! (1x) Thin Nut M4 !!

+

!! Don’t let the Carriage run of the Rail !!

5,5

2,5

!! Endswitch Vane !!

Tools:

2,5

(1x) Tension Bracket

(1x) Bolt M4 x 25

(1x) Square Nut M4

Tools:

3

Tools:

2,5

!! Tighten in a Crosswise

Pattern !!

Tools:

Chapter 4: Y-Axis

30 Minutes

5,5

2,5

+3-

4

1

3

2

1

2

Page 15

FELIXprinters Assembly Manual for the FELIX One

Page 16

58

(1x) Build Platform

(1x) Short Wire Sleeve

56 5755

(1x) Belt Tools:

-

!! Use the Screwdriver to Push the

Belt completely into the Socket !!

Tools:

!! Use the Screwdriver to Push the

Belt completely into the Socket !!

-

3

Tools:

2 cm

2

1

3

4

Tensioning the Belt:

Move the Y-Axis completely to one end. Tighten the belt using the

size 3 hexagon key until the belt can barely touch the rail of the

Y-Axis

59 60

M3 x 25

Page 16

FELIXprinters Assembly Manual for the FELIX One

Page 17

65 66

(1x) Cable ties for mounting

cables on z bracket

64

(1x) Bolt M4 x 16

(1x) Spring

!! Tighten the Bolt against the end of the Thread !!

Tools:

3

End to End

25cm

Tools:

(1x) Cable ties for mounting

cables on z bracket

Tools:

!! Give the Cable enough Slack and tighten the Cable Tie !!

Tools:

62

(2x) Thumb screw

(2x) Spring

(1x) Build Platform Assembly

(2x) Cable Tie

63

!! Repeat for Front and Rear Thumbscrew !! !! Give the Cable enough Slack and tighten the Cable Ties !!

61

Page 17

FELIXprinters Assembly Manual for the FELIX One

Page 18

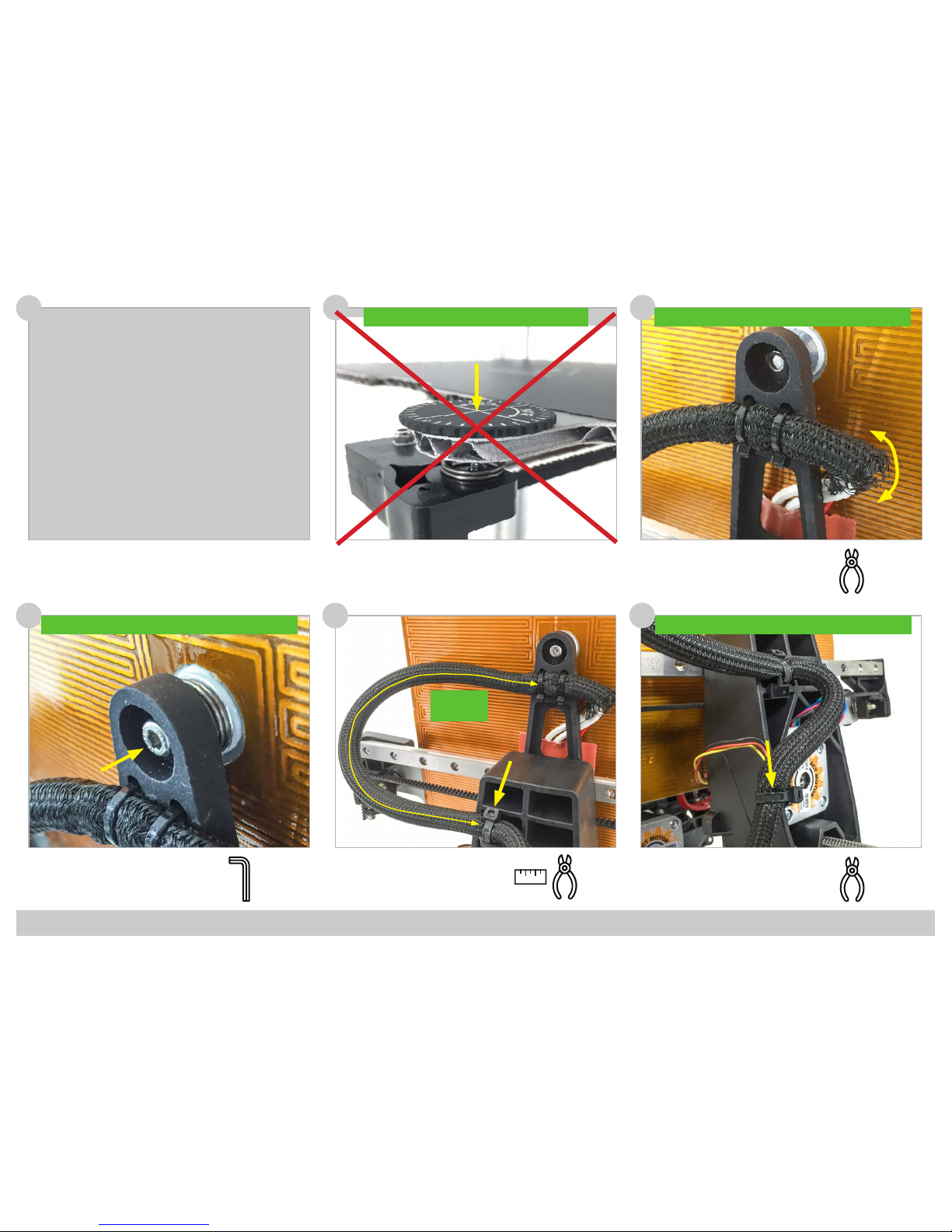

71

(1x) Extru Arm Pt. 2

69 70

72 73

(2x) Large Washer M4

(1x) Bolt M4 x 12

(1x) Thin Nut M4

(1x) Spring

(1x) Extru Arm Pt. 1

(1x) Bearing

(1x) L-Bracket

(1x) Square Nut M4

!! For Dual Head: Repeat this Step !! !! For Dual Head: Repeat this Step !!

!! For Dual Head: Repeat this Step !!

Tools:

3

!! For Dual Head: Repeat this Step !!

(1x) Motor

(1x) Extruder drive wheel

(1x) Set Screw M3 x 6

Tools:

1,5

!! Make sure the at side of the Motor Axle is Perpendicular

to the Set Screw !!

!! Repeat this Step !!

Tools:

Chapter 5: Print Head

90 Minutes

1,5

1,5

32,5

Page 18

FELIXprinters Assembly Manual for the FELIX One

Page 19

77

(1x) L-Bracket

75 76

(3x) Bolt M3 x 16

(1x) L-Bracket Assembly

(1x) Motor

(1x) Square Nut M4

(1x) Extruder Arm Assembly

(1x) Spring Assembly

74

(1x) Bolt M4 x 40

Bolt is used to keep square nut

in place during assembly.

!! Repeat this Step !!

Tools:

3

Tools:

2,5

Motor E1

Motor E1 Motor E1

Page 19

FELIXprinters Assembly Manual for the FELIX One

Page 20

95

Label end of the hot-endcable: 0

96

Make sure the sticker from the fan is at the back.

The fan blows on the side of the sticker

Mount the bolt loosely.

Label end of the wire: 2

Align the print head on the carrier

Tools:

97

2,5

99

100

98

(2x M4) Place nuts for ease of

assembly.

Tools:

2,5

!

Tighten the bolt

!

Page 20

FELIXprinters Assembly Manual for the FELIX One

Page 21

95 96

(2x) Bolt M4 x 40 (used in step 74)

Connect sensor assembly and the

fan + LED onto the main assembly.

Tools:

97

2,5

99

100

98

(2x M4) Place nuts for ease of

assembly.

Tools:

2,5

Page 21

FELIXprinters Assembly Manual for the FELIX One

Page 22

Guide fan wires to front of bracket.

(3x) small cable tie

bundle cables, but do not tighten

too much.

Tools:

2 x

1 x

102101

103

(2x) print head assembly

Bend wires a little bit so they come to the front, while

heads are still parallel to each other.

(2x) M4 x 12

Connect extruder assembly by

placing two bolts.

(2x) normal cable tie

(1x) Long cable sleeve

Mount left motor wire and print head

wires together with cable bundle from

right side.

1. Remove nuts (placed in step 98)

2. (1x) small cable tie

Mount front assembly. Bundle print

head wires, motor wire and sensor

wire. Place cable tie loosely.

Tools:

Tools:

Tools:

2,5

104 105 106

2,5

Page 22

FELIXprinters Assembly Manual for the FELIX One

Page 23

1. Place explate on top of buildplate.

2. Move z-sensor above leveler wheel.

3. Move platform up, until left or right hot-end touches build

plate.

4. Adjust height of z-sensor, until the distance between sensor

and leveler wheel is the thickness of the calibration card.

107

(Detailed Z-height calibration process is explained in the Quick Start Guide)

Page 23

FELIXprinters Assembly Manual for the FELIX One

Page 24

Tools:

110

(1x) Single Cable Clip

108

Tools:

Chapter 6: Wiring

60 Minutes

109

111

112

(2x) Single Cable Clip

(2x) Dual Cable Clip

(2x) Single Cable Clip

(1x) Angled Cable Clip

24cm

End to End

38cm

Tools:

Tools:

Tools:

3

+

Page 24

FELIXprinters Assembly Manual for the FELIX One

Page 25

Tools:

116

114

115

117

113

(1x) Electronic Enclosure

Assembly

Tools:

118

Tools:

3

Tools:

1x Y-stage bracket pt1

1x Y-stage bracket pt2

4x Bolt M3x16

4x Smal washer M3

4x Self locking nut M3

Tools:

1x Bolt M3x8

1x Small t-slot M3

1x Y stage tensioning bracket

1x Thin nut M4

1x Bolt M4x25

Page 25

FELIXprinters Assembly Manual for the FELIX One

Page 26

116

114

115

117

113

Tools:

118

ATTENTION: Bottom of set-screw should NOT touch

plate internally. Keep distance of approx. 0.5mm

!

3x Set screw M4x30

3x Thin nut M4

Large washer

3x spring

2x Small washer

1x Large washer

3x Thin nut M4

!

Tighten the nuts a couple of turns, make sure that

the springs are still able to compress for further

ne-adjustment later.

2x tie-wrap

Page 26

FELIXprinters Assembly Manual for the FELIX One

Page 27

116

114

115

117

113

118

1x 25 cm Cable spiral

Belt

Mount the belt, according to the arrows.

!

+/- 1cm

Page 27

FELIXprinters Assembly Manual for the FELIX One

Page 28

116

114

115

113

1x 25 cm Cable spiral

1x Clamp + Cable tie

Ends of the plastic strip must be cut at an angle

!

!

1x 13 cm Plastic U-prole

The y-axis and the print bed

are nished.

Page 28

FELIXprinters Assembly Manual for the FELIX One

Page 29

Tools:

116

(1x) Electronic Enclosure

Cover Plate

114

115

117

(2x) T-Nut M4

(2x) Bolt M4 x 12

(2x) Power Supply Screw

(1x) Power Supply

(1x) Electronic Enclosure

Pt. 2

(2x) Power Supply Screw

(1x) Electronic Enclosure

Pt. 1

113

(1x) Electronic Enclosure

Assembly

Tools:

118

23cm

Tools:

End to End

25 cm

Tools:

+

Tools:

+

!! Position the narrow edge upwards!!

3

!! Make sure to position the left

T-Nut against the prole !!

!! First slide the Enclosure against

the left T-Nut, next slide the right

T-Nut with Bolt into the Slot.

Finally tighten the Two Bolts !!

3

1

2

Page 29

FELIXprinters Assembly Manual for the FELIX One

Page 30

Important:

1. Set the Blue Potentiometers

to the correct value as shown

in the overview.

2. Tighten the screw terminals

with force to ensure a good

connection.

3. Make sure the Control board

is positioned correctly, so

that the underside doesn’t

touch the power supply.

Overview:

Control Board

119

120

121

Black

Green

Blue

Red

Blue

Green

Red

Black

Main board side

Motor side

Note:

E0 = E1

on control board

Page 30

FELIXprinters Assembly Manual for the FELIX One

Page 31

125

123 124

(1x) Display Assembly

(1x) Control Board

122

(4x) Square Nut M4 Tools:

!! Plug the connector into the

matching socket description !!

end X = Endswitch X (Opto sensor)

end Y = Endswitch Y (Opto sensor)

Z sensor cable has no label.

Page 31

FELIXprinters Assembly Manual for the FELIX One

Page 32

Download the Firmware:

Download the latest FELIX One Firmware version from:

http://www.felixprinters.com/downloads_felixprinters

Upload the Firmware to the Control Board:

1. Unzip the downloaded le to a convenient location.

(Note: if you click on the zip le from within the Windows explorer, it will NOT be unzipped. You just

view the content of the zip. You need to select the les and drag them to the desired location.)

2. Connect your printer to your computer and turn it on. Do not make a connection at this time with

the printer with programs like Repetier-Host or Simplify3D.

3. Start the batch le “upload_automatic.bat”. A script will start in a command window.

4. The script will try to detect what COM port your printer is using. Check if this is correct, and then

proceed by entering ‘Y’ in the command window.

5. The rmware is uploaded when ‘’Programming nished!’’ is displayed, this may take a few minutes.

6. Press any key to continue. The FELIX One rmware is now successfully uploaded.

Note for Experienced Users: Due to compatibility issues with linux based systems, the baudrate for the

FELIX Tec 4 is lowered to 115200. Make sure to adjust the settings in the used software accordingly.

Chapter 7: Upload Firmware

15 Minutes

Page 32

FELIXprinters Assembly Manual for the FELIX One

Page 33

125

123 124

126

(1x) Display Interface PCB

(1x) Display Assembly

122

2x Small screw 2,2 x 8

10

1x Plastic Display-cover

Page 33

FELIXprinters Assembly Manual for the FELIX One

Page 34

127

128

130

(6x) Damping Feet

!! Clean the surface of the

frame rst before apply-

ing the damping feet !!

Tools:

(2x)

(2x) (2x)

128

!

Connecting the display cables

Align the square nuts from step

88 properly before mounting the

cover with the m4x12 bolts.

130

Page 34

FELIXprinters Assembly Manual for the FELIX One

Page 35

Chapter 9: Functional Test

10 Minutes

In order to make sure all motors, sensors and LCD panel are connected properly, the following tests need to be performed

Z-sensor

The z-sensor can be tested by holding a metal object underneath the sensor. Check if the z-sensor LED turns o.

When the z-sensor indication LED on the main board switches o, the sensor is activated.

Y-sensor

Manually move the bed to its end position to activate the y-sensor. Check if the y-sensor LED turns o.

When the y-sensor indication LED on the main board switches o, the sensor is activated.

X-sensor

Manually move the extruder to its end position to activate the x-sensor. Check if the x-sensor LED turns o.

When the x-sensor indication LED on the main board switches o, the sensor is activated.

Check Sensor Connections:

Main board Tec 4

IMPORTANT: Keep hand near ON/OFF switch of printer, in case things go wrong.

Warm up left extruder (E1).

Note: The hot-ends might smell a bit the rst time heating. This is because of a small amount of oil within certain parts.

Click rotary button to enter the main menu --> Control --> scroll down to heater --> Click on E1 and rotate until setpoint

temperature increases to about 100 degC. Then check if temperature for that heater goes up.

Repeat these steps for the right extruder (E2) and for the Bed (55degC).

Check heaters:

Page 35

FELIXprinters Assembly Manual for the FELIX One

Page 36

Check Motor Cable Connections:

IMPORTANT: Keep hand near ON/OFF switch of printer, in case things go wrong.

X-axis motor

To make sure the wires are connected as required it is important to test all connections.

To do so for the x-axis: enter menu by pushing the rottary button --> Control --> Move --> Home X

Y-axis motor

To test the y-axis: enter menu by pushing the rottary button --> Control --> Move --> Home Y

Z-axis motor

NOTE: When doing home z, extruders heatup to 120 DegC to prevent possible lament blobs from scratching the kapton surface layer.

Important: ensure explate is placed on the print bed.

To test the z-axis: enter menu by pushing the rottary button --> Control --> Move --> Home Z

Page 36

FELIXprinters Assembly Manual for the FELIX One

Page 37

Tools:

(1x) Kapton Foil

Tools:

Chapter 10: Finishing Touch

15 Minutes

132

!! Peel o the protective sheet at the

corner and stick the exposed adhesive

to the BuildPlate at one corner !!

!! Continue peeling o the protective sheet and at the

same time stick the foil to the BuildPlate using a soft

object in a zigzag motion to avoid air bubbles !!

1

2

131

Preheat your buildplate to 60 C

degrees to make sure the Kapton

Foil will have good adhesion to the

exible plate.

Tools:

(4x) M4 x 12

(1x) Electronic Enclosure

Cover

133

!! Use the Screwdriver to

center the Square Nut be-

fore inserting the Bolts !!

3

+

134

(1x) Main Fan Cover

Connect the fan cover onto the extruder unit.

3

+

Page 37

FELIXprinters Assembly Manual for the FELIX One

Page 38

Chapter 11: Checklist

Frame:

1. Frame bolts (6x) are properly xed.

2. Frame proles are perpendicular and propely aligned.

3. Damping feet are placed underneath the printer.

X-axis:

1. X-axis rail is properly aligned.

2. Bolts (2x) X-axis rail are properly xed.

3. X-axis belt pushed fully into bracket and tensioner.

4. Belt remains at same height during moving the X-axis.

5. Set screw (1x) for pulley is xed at the correct height with set

screw.

6. X-axis belt tensioned properly

Y-axis:

1. Bolts for stacked bearings (4x) guiding the belt are properly

xed.

2. Y-axis carriage is properly aligned in the Z-axis lift.

3. Bolts (4x) of the Y-axis carriage are properly xed.

4. Y-axis belt pushed fully into bracket and tensioner.

5. Belt remains at same height during moving the Y-axis.

6. Set screw (1x) for pulley is xed at the correct height with set

screw.

7. Y-axis belt tensioned properly.

Z-axis:

1. Z-axis rail is properly aligned.

2. Bolts (3x) Z-axis rail are properly xed.

3. Set screw (1x) Z-axis spindle is properly xed.

4. Bolts (4x) connecting Z-axis carriage to the lift are propely

xed.

5. Z-axis spindle nut is properly tted in the Z-axis lift.

6. Z-axis spindle is greased over its entire length.

Build Platform:

1. Bolt (1x) center of build platform is properly xed.

2. Build surface doesn’t contain air bubbles.

Print Head:

1. Extruder drive wheels properly aligned.

2. Bolts (2x) connecting print head to X-axis carriage are pro-

perly xed.

3. Bolts (2x) sensor bracket are properly xed.

Electrical:

1. Wire harness properly xed without rubbing against parts.

2. Wire harness loop for X, Y, Z-axis are at the correct length

and do not get pulled under full extension.

3. Cables are not under tension and have enough slack.

4. Cable ties neatly cut o.

5. Connectors properly connected in sockets.

6. Potentiometers on control board are set to the correct values.

7. Control board contains the correct Tec 4 rmware version.

8. Wire colors are according to diagram.

Online Test:

1. Build platform heats up to 90 degrees C, move cable harness

to check for wire breakage.

2. Extruders heat up to 90 degrees C, move cable harness to

check for wire breakage.

3. Hot-ends don’t move during loading/unloading lament.

4. Check if lament gets pulled through rmly.

Page 38

FELIXprinters Assembly Manual for the FELIX One

Page 39

Congratulations!

You have nished building the FELIX One.

Continue to the Quick Start Guide to start printing!

Page 39

FELIXprinters Assembly Manual for the FELIX One

Page 40

Bill of Material

Part

Quantity

#140 011.0 Set screw D-916 - M3 x 6-N -

5

#140 012.0 Bolt D-7991- M3 x 6 --- 6N - CSK

5

#140 013.0 Bolt D-7991- M3 x 8 --- 8N - CSK

15

#140 016.0 Hexagon socket head cap screw DIN 912 - M3 x 12

5

#140 017.0 Hexagon socket head cap screw DIN 912 - M3 x 16

14

#140 018.0 Hexagon socket head cap screw DIN 912 M4 x 12

12

#140 019.0 Hexagon socket head cap screw DIN 912 M4 x 16

2

#140 020.0 Hexagon socket head cap screw DIN 912 M4 x 20

7

#140 021.0 Hexagon socket head cap screw DIN 912 M4 x 25

4

#140 022.0 Hexagon socket head cap screw DIN 912 M4 x 40

2

#140 023.0 Hexagon socket head cap screw DIN 912 M5 x 16

5

#140 024.0 WasherD-125A M3

6

Bolts and nuts set

Page 40

FELIXprinters Assembly Manual for the FELIX One

Page 41

Part

Quantity

#140 011.0 Set screw D-916 - M3 x 6-N -

5

#140 012.0 Bolt D-7991- M3 x 6 --- 6N - CSK

5

#140 013.0 Bolt D-7991- M3 x 8 --- 8N - CSK

15

#140 016.0 Hexagon socket head cap screw DIN 912 - M3 x 12

5

#140 017.0 Hexagon socket head cap screw DIN 912 - M3 x 16

14

#140 018.0 Hexagon socket head cap screw DIN 912 M4 x 12

12

#140 019.0 Hexagon socket head cap screw DIN 912 M4 x 16

2

#140 020.0 Hexagon socket head cap screw DIN 912 M4 x 20

7

#140 021.0 Hexagon socket head cap screw DIN 912 M4 x 25

4

#140 022.0 Hexagon socket head cap screw DIN 912 M4 x 40

2

#140 023.0 Hexagon socket head cap screw DIN 912 M5 x 16

5

#140 024.0 WasherD-125A M3

6

#140 025.0 WasherD-125A M4

10

#140 026.0 WasherD-125A M5

5

#140 028.0 Corrosserie ring - M4 - large washer

2

#140 029.0 Prevailing torque type hexagon nut DIN-985 - M3

6

#140 030.0 Prevailing torque type hexagon nut DIN-985 - M4

6

#140 031.0 Hexagon Thin Nut D-439B - M4

8

#140 032.0 Powersupply screw UNC 6/32 x 1/4 Pozi steel

6

#140 037.0 Set screw D-916 - M4 x 30

2

#140 039.0 Spring Extruder & bed

4

#140 040.0 Thin square nut DIN 562 - Steel - M4

9

#110 021.0 t_slot nut - 8 ST M3

3

#140 070.0 Parker 2.2 x 8 - plaatschroef

6

Page 41

FELIXprinters Assembly Manual for the FELIX One

Page 42

Prod. Nr.

Desciption

Total

Image

105 021.0

Electronics bag

150 155.0

Opto sensor X (Straight) , cable and connectorTec4

1

150 156.0

Opto sensor Y (Angled) cable + connector Tec4

1

105 028.0

Z-sensor calibration unit

1

150 159.0

Double fan with cable and connector Tec4

1

Page 42

FELIXprinters Assembly Manual for the FELIX One

Page 43

170 013.0

cable ties, tie wrap - 100mm x 2.5 mm

1

170 021.0

Cable ties for mounting cables on Z bracket

2

170 015.0

Cable sleeve, nylon semi open set 95/ 115 cm

2.1

150 150.0

Stepper Extruder0 cable Tec4

1

150 152.0

Stepper X -axis cable Tec4

1

Page 43

FELIXprinters Assembly Manual for the FELIX One

Page 44

150 153.0

Stepper Y -axis cable Tec4

1

150 154.0

Stepper Z-axis cable Tec4

1

Prod. Nr.

Desciption

Total

Image

105 020.0

Mechanic bag felix Tec4

135 004.0

Pulley motor - FELIX 3 and Pro series

2

135 003.0

Tooth Belt

1

135 005.0

bearing 624, 4x13x6 (packaged per 10)

7

130 016.1

Extruder drive wheel FELIX 3/Tec4

1

Page 44

FELIXprinters Assembly Manual for the FELIX One

Page 45

Prod. Nr.

Desciption

Total

Image

105 020.0

Mechanic bag felix Tec4

135 004.0

Pulley motor - FELIX 3 and Pro series

2

135 003.0

Tooth Belt

1

135 005.0

bearing 624, 4x13x6 (packaged per 10)

7

130 016.1

Extruder drive wheel FELIX 3/Tec4

1

130 035.0

platform support Felix Tec4 (Y-Bracket F3.5)

1

130 041.0

Knurled thumb knob tec4

2

130 043.0

Z-adjustment right hot-end

1

130 042.0

Fan finger guard 40x40 mm tec4

2

130 044.0

Dual Extruder Front Bracket - Tec 4

1

160 017.0

Spacer rail and extruder wheel adjustment for Felix3.X

1

Page 45

FELIXprinters Assembly Manual for the FELIX One

Page 46

Prod. Nr.

Desciption

Total

Image

Parts packet separately in DIY kit

150 023.0

Powersupply - FELIX 3.0

1

130 017.0

Spindle - trapezium - Felix 3

1

105 127.0

Assy build platform Felix Tec4

1

135 001.0

Hiwin linear ball bearing - MGN12H1R0300Z1HM

2

135 002.0

Hiwin linear ball bearing - HGW15CC1R300Z0

1

Page 46

FELIXprinters Assembly Manual for the FELIX One

Page 47

Prod. Nr.

Desciption

Image

105 047.0

Set plastic parts

122 012.0

X_stage_F3_0_belt _mount_v1 - black

1

105 064.0

Y stage bracket prt1 with inserts Felix Tec4 Black

1

105 065.0

Y stage bracket prt2 with inserts Felix Tec4 Black

1

122 015.0

Y_stage_F3_0_tensi oning_bracket_v1 - black

2

122 016.0

z_axis_F3_0_lift_part_v1 - black

1

122 017.0

z_axis_F3_0_motor_bracket_v1 - black

1

Page 47

FELIXprinters Assembly Manual for the FELIX One

Page 48

122 019.1

Extru_F3_1_base - black

1

122 020.1

Extru_F3_1_L_shap e_bracket - black

3

122 021.0

Extru_F3_0_arm_pt1_v1 - black

2

122 022.0

Extru_F3_0_arm_pt2_v1 - black

2

122 025.0

Electronics_enclosure_F3_0 _cap_pt1 - black

1

122 026.0

Electronics_enclosure_F3_0 _cap_pt2 - black

1

Page 48

FELIXprinters Assembly Manual for the FELIX One

Page 49

122 028.0

Electronics_encl osure_F3_0_cover_plate_v1 - black

1

122 031.0

Electronics_enclosure Felix Tec4 Black

1

170 017.0

Sticker on control box, TEC 4

1

122 039.0

Fan Cap airduct Tec4 - Black

2

122 040.0

Fan front cover Tec4 - black

1

122 037.0

Printed parts LCD cabinet Felix Tec4 - Black

1

122 011.0

X_stage_F3_0_motor_bracket_v1 - black

1

Page 49

FELIXprinters Assembly Manual for the FELIX One

Page 50

Prod. Nr.

Desciption

Total

Image

105 124.0

FULL metal hotend FELIX Tec

130 110.0

nozzle_felixprinters (0,35 mm pro1)

1

130 029.0

Hotend bas e Felix Tec4

1

130 030.0

Heat break Felix Tec4

1

150 013.0

Felix 3 & Tec 4 - Heater Cartridge incl. connector

1

130 109.0

Hot End Heated Barrel 1.75 Pro1

1

150 162.0

FELIX 3.1 & Tec4 - Thermistor incl. connector

1

130 031.0

Teflon tube Hot-end (36,5 mm) Felix Tec4

1

140 036.0

Set screw D-916 - M3 x 4

3

Page 50

FELIXprinters Assembly Manual for the FELIX One

Page 51

Prod. Nr.

Desciption

Total

Image

105 051.0

Frame bag Felix3/ Tec4

110 017.0

frame connector set

6

110 018.0

handle PA 160 for Felix3

1

110 019.0

Protective cap, handle PA160, FELIX 3

1

110 022.0

T-slot nuts 8 ST M4

12

110 024.0

t_slot nut - 8 ST M8

2

110 015.0

40x40 protective caps

4

110 016.0

80x40 protective caps

1

110 025.0

damping foot (felix 3)

6

140 035.0

bolkop inbus bol t M8x16 ITEM

2

Page 51

FELIXprinters Assembly Manual for the FELIX One

Page 52

Prod. Nr.

Desciption

Total

Image

105 050.0

Frame profile set Felix3/ Tec

profiel 8 40x40x400 E PT1

1

profiel 8 40x40x400 E PT3

2

profiel 8 40x40x400 E PT4

1

profiel 8 80x40x440 E

1

Page 52

FELIXprinters Assembly Manual for the FELIX One

Page 53

Prod. Nr.

Desciption

Total

Image

105 019.0

Miscellaneous Felix 3.1/ Tec4

150 018.0

USB cable 1.8m

1

170 011.0

Tweezers

1

170 019.1

Teflon Tube for Pro and 3 series - (55cm)

2

170 023.1

Filament dust cleaner

1

180 001.1

PLA sample - 50 gram - Random Colours

1

122 045.0

Filament guide/ dust cleaner holder Fel ix3/ Tec (printed)

1

122 044.0

Filament bracket Felix3/ Tec (printed ) - black

2

Page 53

FELIXprinters Assembly Manual for the FELIX One

Page 54

Prod. Nr.

Desciption

Total

Image

Optional parts depending on region

150 019.0

Power cabl e EU

1

150 020.0

Power cable US

1

150 021.0

Power cable AU

1

150 022.0

Power cable UK

1

Page 54

FELIXprinters Assembly Manual for the FELIX One

Page 55

Prod. Nr.

Desciption

Total

Image

105 031.0

Upgrade Single Tec to Dual Felix Tec 4

150 027.1

Stepper motor Nema 17, 40 mm

1

150 151.0

Stepper Extruder1 cable Tec4

1

130 016.1

Extruder drive wheel FELIX 3/Tec4

1

140 017.0

Hexagon socket head cap screw DIN 912 - M3 x 16

3

105 124.0

Full metal hotend FELIX Tec

1

140 039.0

Spring Extruder & bed

1

140 028.0

Corrosserie ring - M4 - large washer

2

140 018.0

Hexagon socket head cap screw DIN 912 M4 x 12

1

Optional: depending on order

Page 51

Page 55

FELIXprinters Assembly Manual for the FELIX One

Page 56

140 031.0

Hexagon Thin Nut D-439B - M4

1

135 005.0

bearing 624, 4x13x6 (packaged per 10)

1

170 019.1

Teflon Tube for Pro and 3 series - (55cm)

1

170 023.1

Filament dust clean er

1

105 128.0

set Tie wraps 20 pieces in bag

1

Optional: depending on order

Loading...

Loading...