Page 1

FMM250 - Umschlag.fm Seite 1 Montag, 29. Juni 2009 8:30 08

FEIN Service

USA

FEIN Power Tools Inc.

1030 Alcon Street

Pittsburgh, PA 15220

Telephone: (412) 922-8886

Toll Free: 1-800-441-9878

www.feinus.com

Canada

FEIN Canadian Power Tool

Company

323 Traders Boulevard East

Mississauga, Ontario L4Z 2E5

Telephone.:(905) 8901390

Toll Free: 1-800-265-2581

FEIN Canadian Power Tool

Company

2810 De Miniac

St. Laurent, Quebec H4S 1K9

Telephone: (514) 331-7390

Toll Free: 1-800-789-8181

www.fein.com

Headquarter

C. & E. FEIN GmbH

Hans-Fein-Straße 81

D-73529 Schwäbisch Gmünd-Bargau

www.fein.com

© C. & E. FEIN GmbH. Printed in Germany. Abbildungen unverbindlich. Technische Änderungen vorbehalten. 3 41 01 091 21 0 BY 2009.06 DE.

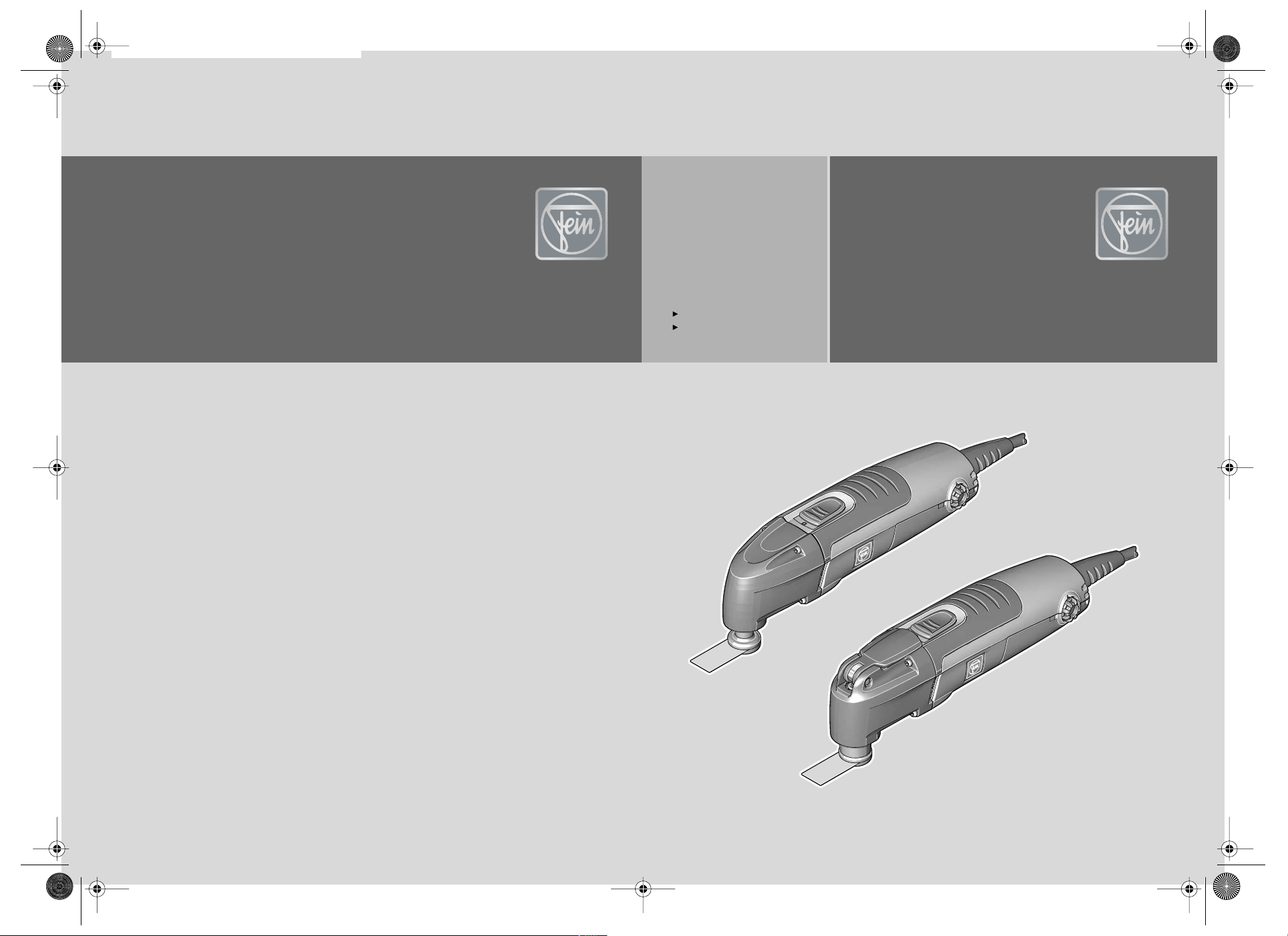

FMM250

FMM250Q

7 229 36

7 229 37

ULTIMASTER

M

Page 2

3 41 01 091 21 0.book Seite 2 Montag, 29. Juni 2009 8:32 08

2

English _____________ Instruction manual_________________

Français ____________ Mode d'emploi____________________

Español _____________ Instrucciones de uso _______________

3

17

32

Page 3

3 41 01 091 21 0.book Seite 3 Montag, 29. Juni 2009 8:32 08

For your safety.

WARNING

the warnings and instructions may result in

electric shock, fire and/or serious injury.

Save all warnings and instructions for future

reference.

Do not use this power tool before you

have thoroughly read and completely

understood this Instruction Manual, including

the figures, specifications, safety regulations

and the signs indicating DANGER, WARNING and CAUTION.

Only carry out such operations with this

power tool as intended for by FEIN. Only use

application tools and accessories that have

been released by FEIN.

Please also observe the relevant national

industrial safety regulations.

Non-observance of the safety instructions in

the said documentation can lead to an electric

shock, burns and/or severe injuries.

This Instruction Manual should be kept for

later use and enclosed with the power tool,

should it be passed on or sold.

SAVE THESE INSTRUCTIONS.

Read all safety warnings and all

instructions. Failure to follow

General Safety Rules.

1) Work area safety

a) Keep work area clean and well lit. Clut-

tered or dark areas invite accidents.

b)Do not operate power tools in explosive at-

mospheres, such as in the presence of

flammable liquids, gases or dust. Power

tools create sparks which may ignite the

dust or fumes.

c) Keep children and bystanders away while

operating a power tool. Distraction can

cause you to lose control.

2) Electrical safety

a) Power tool plugs must match the outlet.

Never modify the plug in any way. Do not

use any adapter plugs with earthed

(grounded) power tools. Unmodified plugs

and matching outlets will reduce risk of

electric shock.

en

b)Avoid body contact with earthed or

grounded surfaces such as pipes, radiators,

ranges and refrigerators. There is an in-

creased risk of electric shock if your body

is earthed or grounded.

c) Do not expose power tools to rain or wet

conditions. Water entering a power tool

will increase the risk of electric shock.

d)Do not abuse the cord. Never use the cord

for carrying, pulling or unplugging the

power tool. Keep cord away from heat, oil,

sharp edges or moving parts. Damaged or

entangled cords increase the risk of electric shock.

e) When operating a power tool outdoors, use

an extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces the risk of electric shock.

f) If operating a power tool in a damp location

is unavoidable, use a residual current device (RCD) protected supply. Use of an

RCD reduces the risk of electric shock.

3) Personal safety

a) Stay alert, watch what you are doing and

use common sense when operating a power

tool. Do not use a power tool while you are

tired or under the influence of drugs, alcohol or medication. A moment of inatten-

tion while operating power tools may result in serious personal injury.

b)Use safety equipment. Always wear eye

protection. Safety equipment such as dust

mask, non-skid safety shoes, hard hat, or

hearing protection used for appropriate

conditions will reduce personal injuries.

c) Avoid accidental starting. Ensure the switch

is in the off-position before plugging in.

Carrying power tools with your finger on

the switch or plugging in power tools that

have the switch on invites accidents.

d)Remove any adjusting key or wrench before

turning the power tool on. A wrench or a

key left attached to a rotating part of the

power tool may result in personal injury.

3

Page 4

3 41 01 091 21 0.book Seite 4 Montag, 29. Juni 2009 8:32 08

4

en

e) Do not overreach. Keep proper footing and

balance at all times. This enables better

control of the power tool in unexpected

situations.

f) Dress properly. Do not wear loose clothing

or jewelry. Keep your hair, clothing and

gloves away from moving parts. Loose

clothes, jewelry or long hair can be caught

in moving parts.

g) If devices are provided for the connection of

dust extraction and collection facilities, ensure these are connected and properly

used. Use of these devices can reduce

dust-related hazards.

4) Power tool use and care

a) Do not force the power tool. Use the correct

power tool for your application. The cor-

rect power tool will do the job better and

safer at the rate for which it was designed.

b)Do not use the power tool if the switch does

not turn it on and off. Any power tool that

cannot be controlled with the switch is

dangerous and must be repaired.

c) Disconnect the plug from the power source

and/or the battery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools. Such

preventive safety measures reduce the

risk of starting the power tool accidentally.

d)Store idle power tools out of the reach of

children and do not allow persons unfamiliar with the power tool or these instructions

to operate the power tool. Power tools are

dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalign-

ment or binding of moving parts, breakage

of parts and any other condition that may

affect the power tools operation. If damaged, have the power tool repaired before

use. Many accidents are caused by poorly

maintained power tools.

f) Keep cutting tools sharp and clean. Prop-

erly maintained cutting tools with sharp

cutting edges are less likely to bind and are

easier to control.

g) Use the power tool, accessories and tool

bits etc., in accordance with these instructions and in the manner intended for the

particular type of power tool, taking into

account the working conditions and the

work to be performed. Use of the power

tool for operations different from those

intended could result in a hazardous situation.

5) Service

a) Have your power tool serviced by a quali-

fied repair person using only identical replacement parts. This will ensure that the

safety of the power tool is maintained.

Special safety instructions.

This double-insulated power tool is equipped

with a polarized plug (one contact is wider than

the other). The plug will only fit into the polarized socket outlet in one position. Turn the plug

if it does not fit completely into the socket outlet. If the plug still does not fit, have a qualified

electrician install a polarized socket outlet. Do

not modify or alter the plug under any circumstances. Double-insulated power tools nei-

ther require a three-core power cable nor a

power connection with ground contact.

Operate the power tool only off of power supplies whose voltage and frequency values correspond with the values on the type plate of the

power tool.

When operating the power tool in a damp environment, it must be connected via a groundfault circuit interrupter (g.f.c.i.). Using special

rubber protective gloves and footwear

increase your own safety.

Use clamping devices or other suitable means

to secure the workpiece to a firm surface.

Holding the workpiece by hand or pressing it

against your body is not sufficient and can

lead to loss of control.

Before mounting or replacing application tools

or accessories, pull the power plug. This pre-

ventive safety measure rules out the danger of

injuries through accidental starting of the

power tool.

Page 5

3 41 01 091 21 0.book Seite 5 Montag, 29. Juni 2009 8:32 08

Hold the power tool by the insulated gripping

surfaces when performing operations where

the application tool could contact hidden wiring or its own power cord. Contact with a

“live” wire will also make exposed metal

parts of the power tool “live” and shock the

operator.

Use appropriate detectors to determine if utility

lines are hidden in the work area or call the

local utility company for assistance. Contact

with electric lines can lead to fire and electric

shock. Damaging a gas line can lead to explosion. Penetrating a water line causes property

damage or may cause an electric shock.

Do not direct the power tool against yourself,

other persons or animals. Danger of injury

from sharp or hot application tools.

For all work or when changing application

tools, always wear protective gloves. Danger

of injury from the sharp edges of the application tools. Application tools can become very

hot while working. Danger of burns!

Handling hazardous dusts

WARNING

sanding, polishing, sawing or for other work

procedures where material is removed, dusts

develop that are both hazardous to one’s health

and can spontaneously combust or be explosive.

Contact with or inhaling some dust types can

trigger allergic reactions to the operator or

bystanders and/or lead to respiratory infections, cancer, birth defects or other reproductive harm.

Examples of such materials and therein contained chemicals, where hazardous dusts can

develop when working them, are:

– Asbestos and materials containing asbestos;

– Lead-containing coatings, some wood types

such as beech and oak;

– Minerals and metal;

– Silicate particles from bricks, concrete and

other materials containing stone;

– Solvent from solvent-containing paint/var-

nish;

– Arsenic, chromium and other wood pre-

servatives;

When working with power

tools, such as when grinding,

en

Grasp the power tool in such a safe manner

that your body never comes into contact with

the application tool, especially while working

with application tools such as saw blades or

other blades pointed toward the grasping

range. Touching sharp tips or cutting edges

can lead to injuries.

The power tool is not permitted for operations

or working with water supply. Water penetrat-

ing the motor casing can lead to electric

shock.

Do not rivet or screw any name-plates or signs

onto the power tool. If the insulation is dam-

aged, protection against an electric shock will

be ineffective. Adhesive labels are recommended.

Clean the ventilation openings on the power

tool at regular intervals. The motor blower

draws dust into the housing. An excessive

accumulation of metallic dust can cause an

electrical hazard.

– Materials for pesticide treatment on boot

and ship hulls.

To minimise the unwanted intake of these

materials:

– Use dust extraction matched appropriately

for the developing dust.

– Use personal protective equipment, such as

a P2 filter-class dust protection mask.

– Provide for good ventilation of the work-

place.

The risk from inhaling dusts depends on the

frequency how often these materials are

worked. Materials containing asbestos may

only be worked by specialists.

CAUTION

Hot mixtures of sanding dust and paint/varnish remainders or other chemical materials

in the filter bag or the vac filter can self-ignite

under unfavourable conditions, such as sparking from sanding metal, continuous sunlight

or high ambient temperatures. To prevent

this:

Wood and light-metal dust can

cause spontaneous combustion

or explosions.

5

Page 6

3 41 01 091 21 0.book Seite 6 Montag, 29. Juni 2009 8:32 08

6

en

– Avoid overheating the material being

sanded and the power tool.

– Empty the dust collector/container in time.

– Observe the material manufacturer’s work-

ing instructions.

Observe the relevant regulations in your

country for the materials being worked.

Hand/arm vibrations

WARNING

While working with this power

tool, hand/arm vibrations

occur. These can lead to health impairments.

WARNING

The vibration emission value

during actual use of the power

tool can differ from the declared value depending on the ways in which the tool is used.

WARNING

It is necessary to identify

safety measures to protect the

operator that are based on an estimation of

exposure in the actual conditions of use.

The vibration emission level given in this

information sheet has been measured in

accordance with a standardised test given in

EN 60745 and may be used to compare one

tool with another. It may be used for a preliminary assessment of exposure.

Emission values for sound and vibration (Two-figure – specifications as per ISO 4871)

Sound emission

Measured A-weighted sound power level LwA

(re 1 pW), in decibels: 85

Measuring uncertainty KwA, in decibels: 3

A-weighted emission pressure power level

measured at the workplace LpA (re 20 µPa), in

decibels: 74

Measuring uncertainty K

, in decibels: 3

pA

REMARK: The sum of the measured emission

value and respective measuring inaccuracy

represents the upper limit of the values that

can occur during measuring.

Wear ear protection!

Measured values determined in accordance

with the corresponding product standard.

The declared vibration emission level represents the main applications of the tool. However if the tool is used for different applications,

with different accessories or poorly maintained,

the vibration emission may differ. This may significantly increase the exposure level over the

total working period.

An estimation of the level of exposure to vibration should also take into account the times

when the tool is switched off or when it is running but not actually doing the job. This may

significantly reduce the exposure level over the

total working period.

Identify additional safety measures to protect

the operator from the effects of vibration such

as: maintain the tool and the accessories, keep

the hands warm, organisation of work patterns.

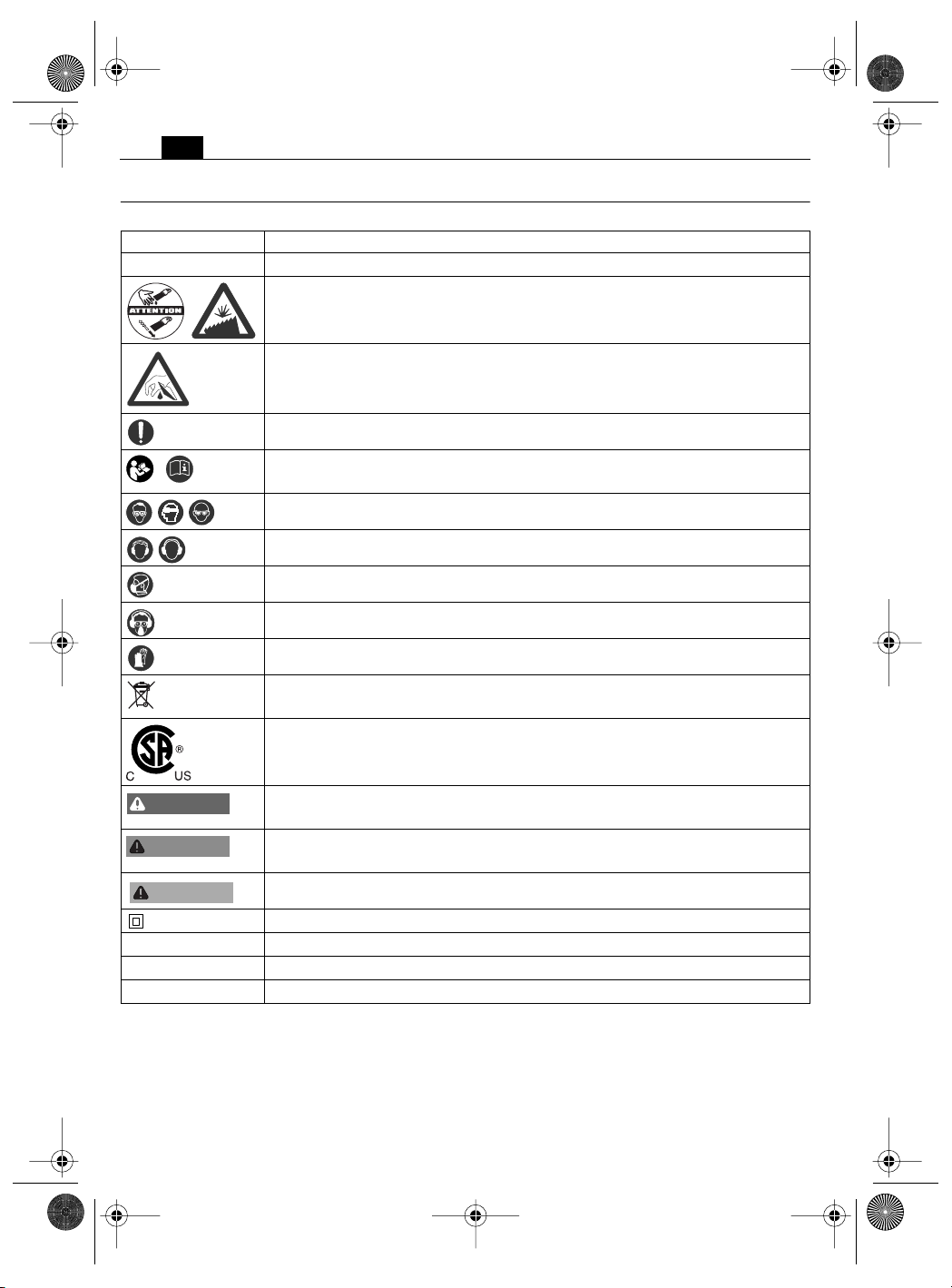

Vibrations

Classification of FEIN

application tools accord-

Weighted

acceleration*

ing to vibration class

VC0

VC1

VC2

VC3

VC4

VC5

< 2.5 m/s

< 8 ft/s

< 5 m/s

< 16 ft/s

< 7 m/s

< 23 ft/s

< 10 m/s

< 33 ft/s

< 15 m/s

< 50 ft/s

> 15 m/s

> 50 ft/s

2

2

2

2

2

2

2

2

2

2

2

2

*These values are based on a work cycle consisting of no-load and full-load operation of

the same duration.

For information on the vibration class

assigned to the application tool, please see the

enclosed data sheet 3 41 30 335 06 0.

Page 7

3 41 01 091 21 0.book Seite 7 Montag, 29. Juni 2009 8:32 08

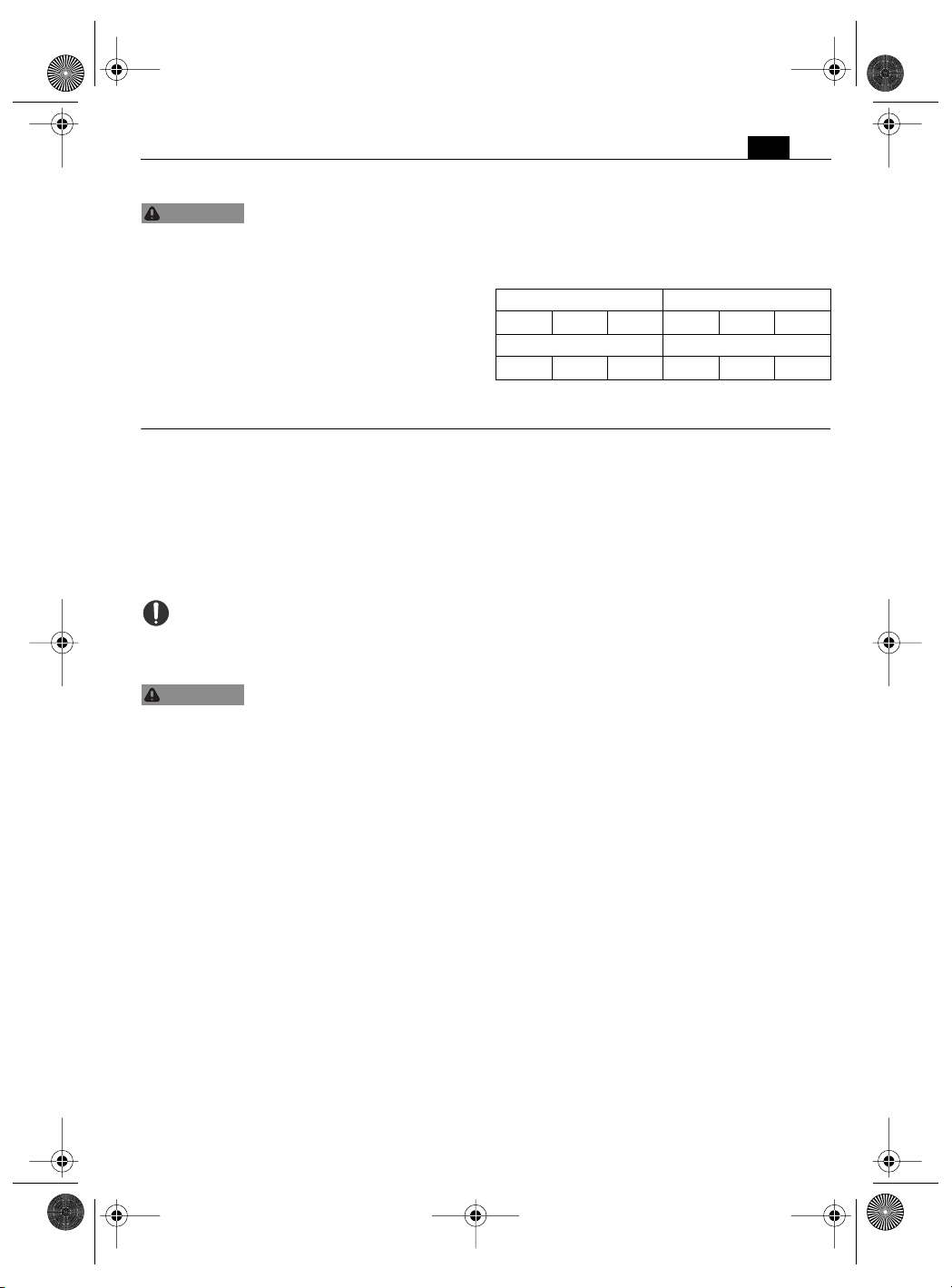

Extension cord

WARNING

If the use of an extension cable

is required, its length and conductor cross-section must be adequate for the

applicational case, in order to prevent a voltage drop in the extension cable, power loss and

overheating of the power tool. Otherwise, the

extension cable and power tool are liable to

electrical danger, and the working efficiency is

impaired.

Recommended dimensions of extension cords

at an operating voltage of 120 V – single-phase

a. c., with only one power tool FMM250/

FMM250Q connected:

Cord Size in A.W.G. Wire Sizes in mm

18 16 14 0.75 1.5 2.5

Cord Length in Feet Cord Length in Meters

25 100 150 30 60 120

Intended use of the power tool.

This power tool is intended for commercial

or private use for dry sanding of small surfaces, corners and edges, for scraping, for

sawing thin steel sheet, wood and plastic

components using the application tools and

accessories recommended by FEIN.

Operation of the power tool off power generators.

Operate the power tool only off

a.c. generators with sufficient power

output that do not have any distortion of the

voltage curve.

WARNING

load speed exceeds the voltage value on the

type plate of the power tool is prohibited.

Operating the power tool off

power generators whose no-

With the respective accessories, the power

tool can also be used for polishing, cutting,

separating and as a rasp.

en

7

2

Page 8

3 41 01 091 21 0.book Seite 8 Montag, 29. Juni 2009 8:32 08

8

en

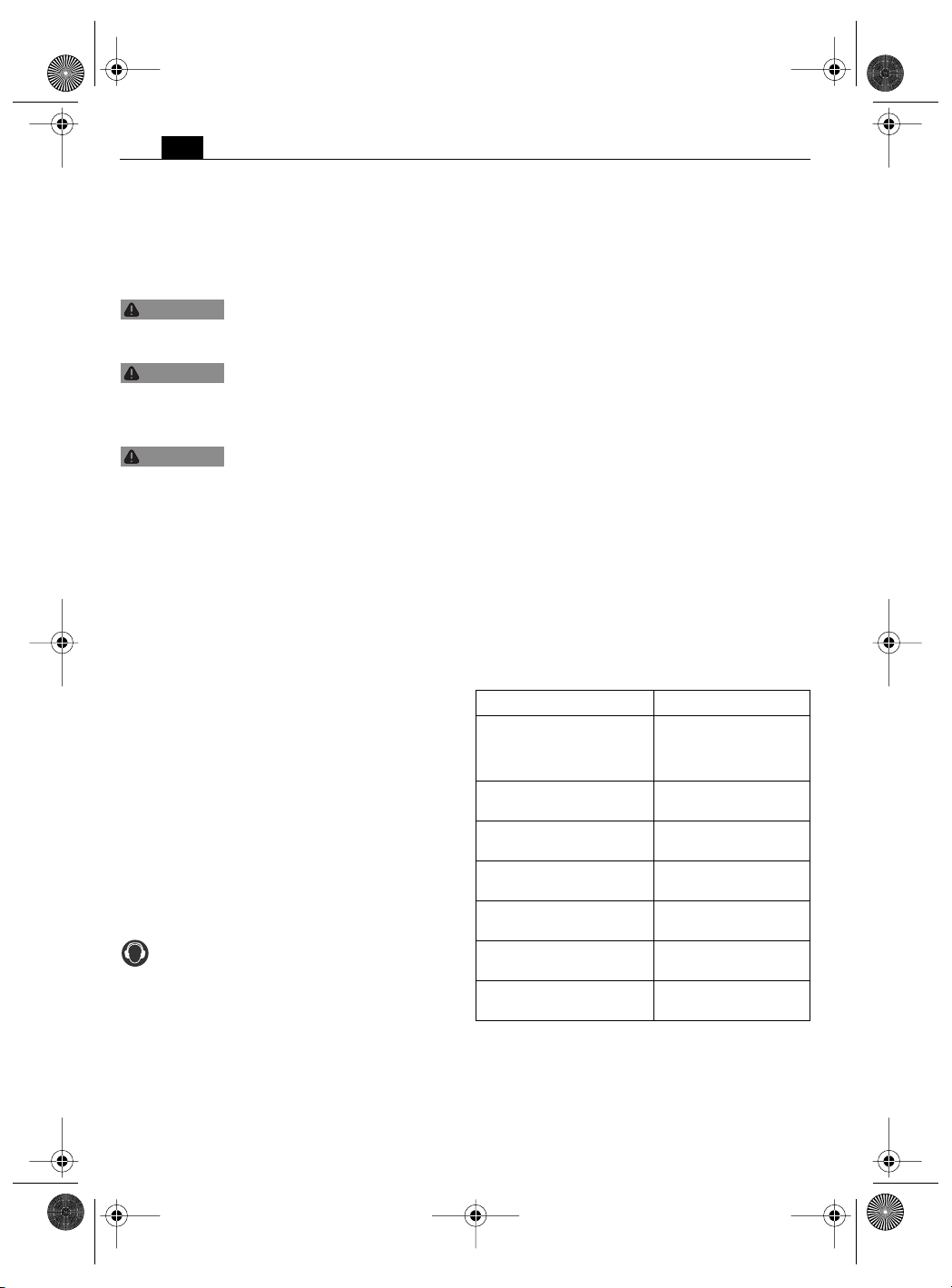

Symbols.

Symbol Explanation

➤

Action to be taken by the user

Danger of sharp application tools moving back and forth.

Warning against sharp edges of application tools, such as the cutting

edges of the cutter blades.

Follow the instructions in the adjacent text!

Be absolutely sure to read the enclosed documentation such as the

Instruction Manual and the General Safety Instructions.

Use eye-protection during operation.

Use ear protection during operation.

Use a dust mask during operation.

Use eye-protection, ear protection and dust mask during operation.

Use protective gloves during operation.

Worn out power tools and other electrotechnical and electrical products

should be sorted separately for environment-friendly recycling.

This symbol confirms the certification of this product for the USA and

Canada.

DANGER

WARNING

This sign warns of a directly imminent, dangerous situation. A false reaction can cause a severe or fatal injury.

This sign indicates a possible dangerous situation that could cause severe

or fatal injury.

CAUTION

This sign warns of a possible dangerous situation that could cause injury.

Product with double or reinforced insulation

~ or a. c. Alternating current

1 ~ Alternating current single-phase

Ø Diameter of a round part

Page 9

3 41 01 091 21 0.book Seite 9 Montag, 29. Juni 2009 8:32 08

Character Unit of measure, national Explanation

n

o

/min Revolution speed at no-load

W Unit of measure for electrical power

Hz Frequency

V Unit of measure for the electric voltage

A Unit of measure for the electric current intensity

° Unit of measure for the angle width

lbs Unit of measure for the mass

ft, in Unit of measure for length, width, height or depth

m, s, kg, A, mm, V, W,

Hz, N, °C, dB, /min, m/s

Basic and derived units of measure from the interna-

2

tional system of units SI.

en

9

Page 10

3 41 01 091 21 0.book Seite 10 Montag, 29. Juni 2009 8:32 08

10

en

Technical description and specifications.

WARNING

Before mounting or replacing application tools or accessories, pull the power

plug. This preventive safety measure rules out the danger of injuries through

accidental starting of the power tool.

Only part of the accessories described or shown in this instruction manual will be included

with your power tool.

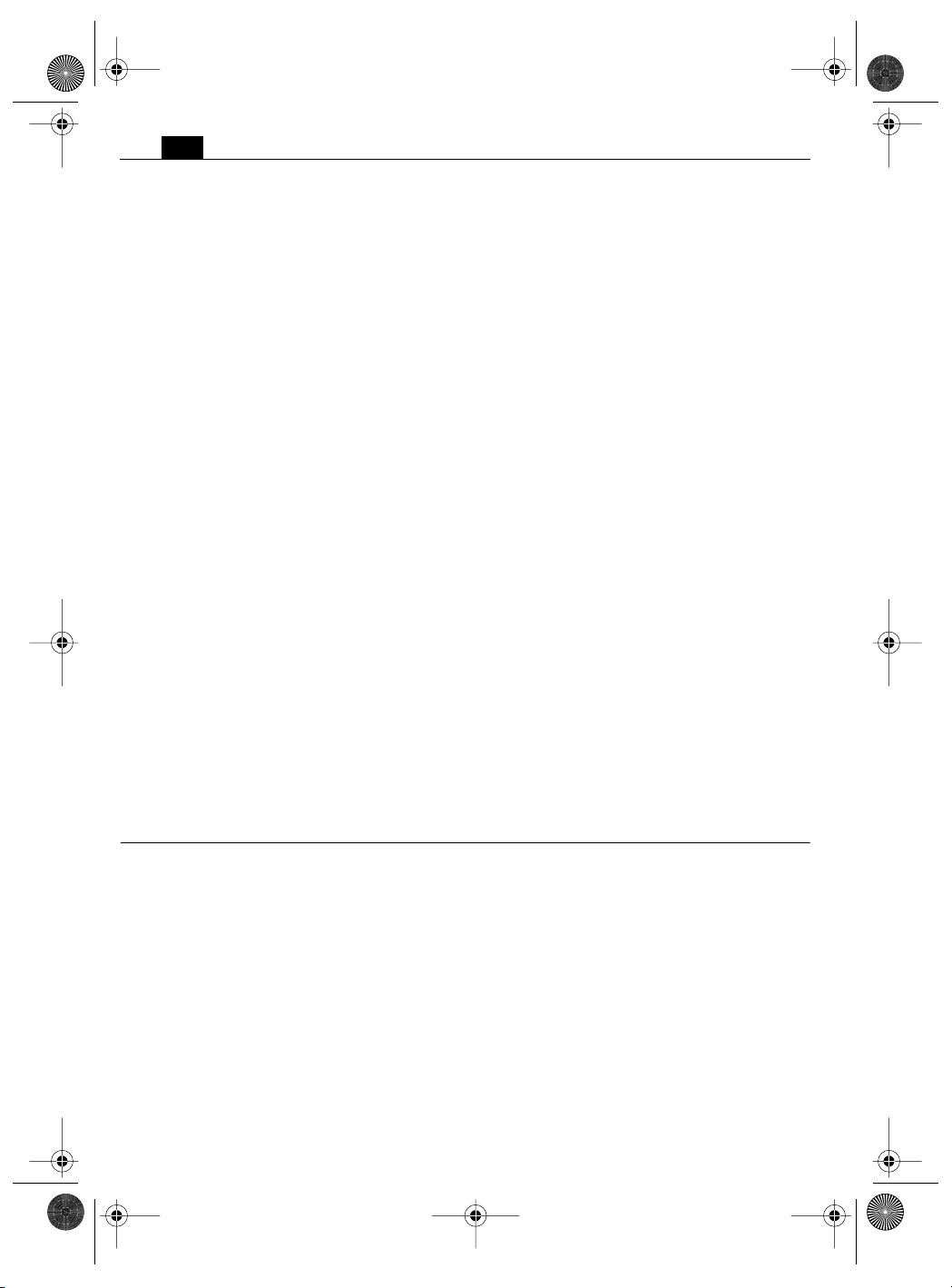

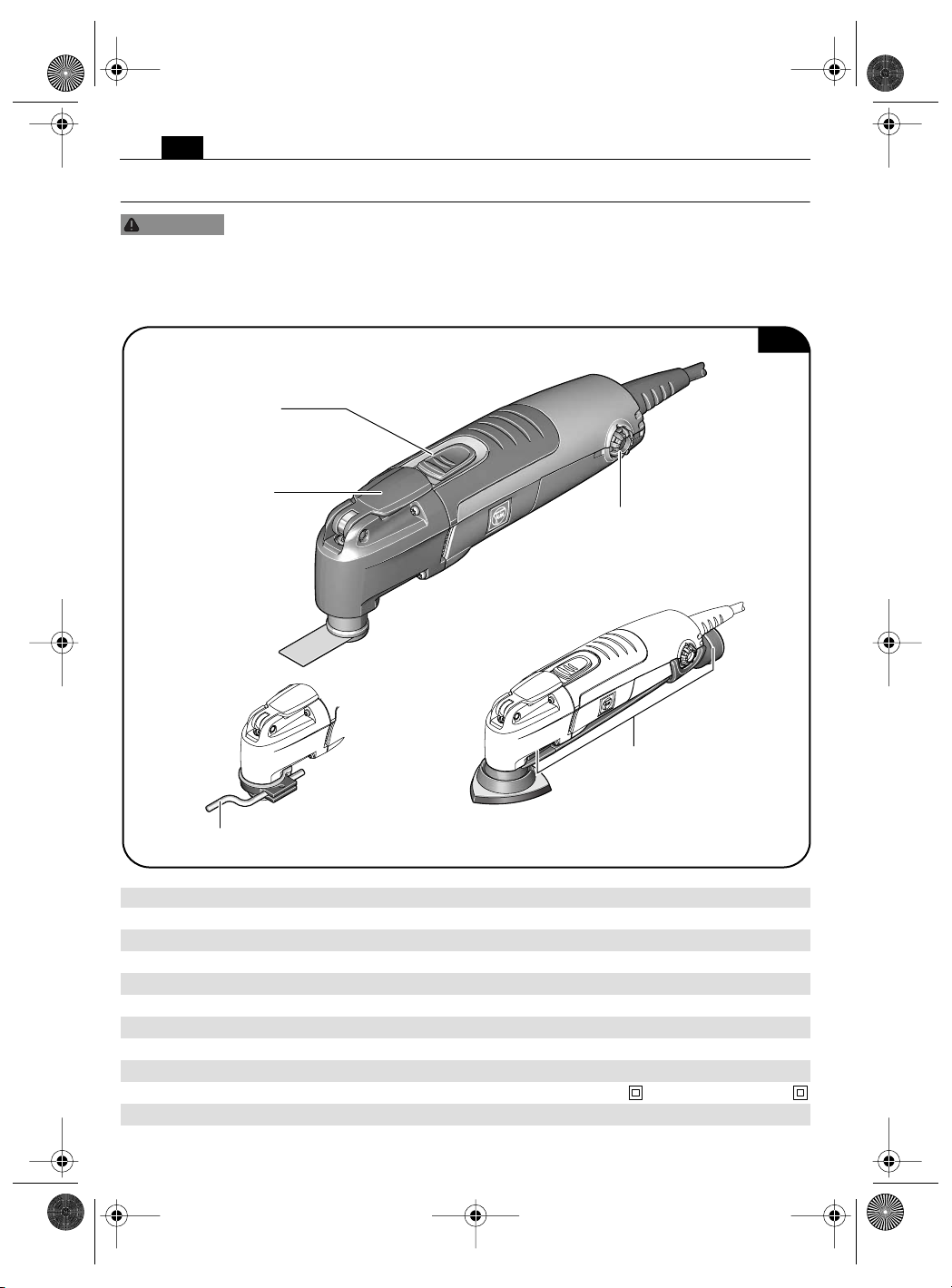

Fig. 1

Multimaster FMM250Q

On/Off switch

Quick-clamping

lever

Dial control for adjustment of

oscillating frequency

Suction device

Depth

stop

Type MULTIMASTER FMM250 MULTIMASTER FMM250Q

Reference number 7 229 36 7 229 37

Rated voltage 120 V/60 Hz 120 V/60 Hz

Power Input 250 W 250 W

Output 140 W 140 W

Current 2.3 A 2.3 A

Power supply type 1 ~ 1 ~

Oscillating frequency 11 000–20 000/min 11 000–20 000/min

Weight according to EPTA-Procedure 01/2003 1.2 kg (2.8 lbs) 1.4 kg (3.2 lbs)

Class of protection II II

Oscillating angle 1.6 ° 1.6 °

Page 11

3 41 01 091 21 0.book Seite 11 Montag, 29. Juni 2009 8:32 08

Assembly instructions.

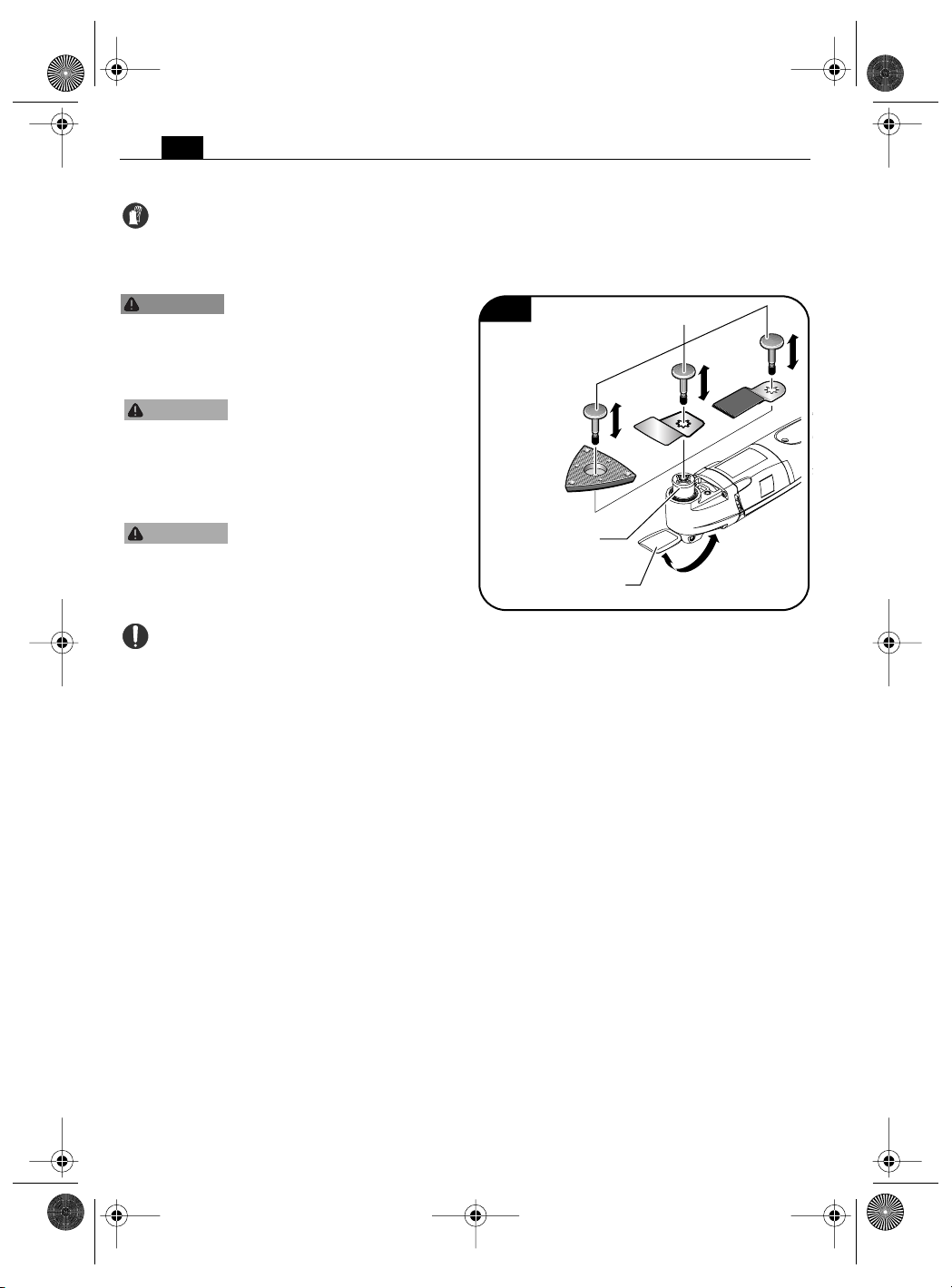

Mounting the suction device (Figure 2).

WARNING

accidental starting of the power tool.

➤ Mount the suction device step by step as shown in the figures.

➤ For connection with a FEIN Dustex or a vacuum cleaner, various hose adapters are

available as an accessory.

➤ To remove the suction device again, push the clamp at the mark to the rear (➑).

Before mounting or replacing application tools or accessories, pull the power

plug. This preventive safety measure rules out the danger of injuries through

➊

➋

➌

Suction device

en

11

Fig. 2

➍➎➏

➐

➑

Page 12

3 41 01 091 21 0.book Seite 12 Montag, 29. Juni 2009 8:32 08

12

en

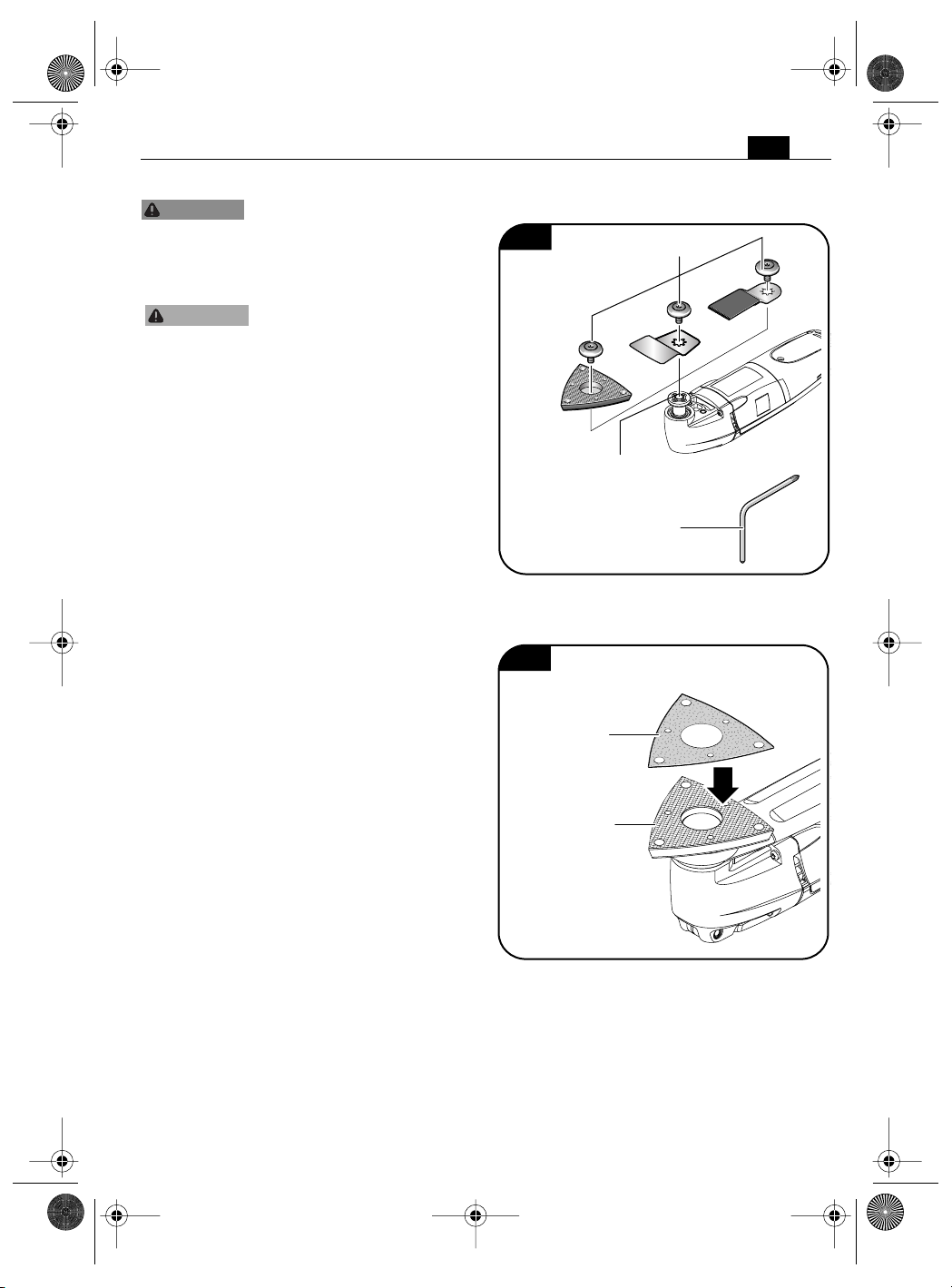

Changing the tool.

The application tool can be fastened offset at convenient working positions at 45° steps

(or at 30° steps for the triangle-shaped sanding pad).

M

ULTIMASTER FMM250Q (Figure 3).

WARNING

ries, pull the power plug. This preventive

safety measure rules out the danger of injuries

through accidental starting of the power tool.

CAUTION

protective gloves. Danger of injury from the

sharp edges of the application tools. Application tools can become very hot while working. Danger of burns!

CAUTION

from the snapping back quick-clamping lever.

The quick-clamping lever pivots back powerfully due to the spring force.

Firmly press in the fastening element to

the stop. Then lock the rapid-clamping

lever.

➤ Loosen the quick-clamping lever and

swivel it to the stop.

➤ Pull out the fastening element.

➤ Clean the tool holder, the application

tool and the fastening element.

➤ Place the application tool exactly onto

the star-shaped tool holder. Pay attention that the application tool has a flush

fit.

➤ Insert the fastening element to the

stop into the tool holder.

➤ Swivel the quick-clamping lever back

until it engages.

Before mounting or replacing

application tools or accesso-

For all work or when changing

application tools, always wear

Protect your hand and fingers

from being bruised/crushed

Fig. 3

Fastening element

Tool holder

Quick-clamping

lever

180°

Page 13

3 41 01 091 21 0.book Seite 13 Montag, 29. Juni 2009 8:32 08

MULTIMASTER FMM250 (Figure 4).

WARNING

Before mounting or replacing

application tools or accesso-

ries, pull the power plug. This preventive

safety measure rules out the danger of injuries

through accidental starting of the power tool.

CAUTION

For all work or when changing

application tools, always wear

protective gloves. Danger of injury from the

sharp edges of the application tools. Application tools can become very hot while working. Danger of burns!

➤ Unscrew the clamping screw.

➤ Clean the tool holder, the application

tool and the clamping screw.

➤ Place the application tool exactly onto

the star-shaped tool holder. Pay attention that the application tool has a flush

fit.

➤ Tighten the clamping screw using the

supplied Allen key.

Attaching/replacing the sanding sheet (Figure 5).

➤ Align the sanding sheet and press it

onto the sanding plate by hand.

➤ Firmly press the power tool with the

sanding sheet against a flat surface and

briefly switch the power tool on. This

provides for good adhesion and prevents

premature wear.

The sanding sheet can be pulled off again and

then remounted offset by 120° when only

one tip of the sanding sheet is worn.

Fig. 4

Fig. 5

Clamping screw

Tool holder

Allen key

Sanding

sheet

Sanding

pad

en

13

Page 14

3 41 01 091 21 0.book Seite 14 Montag, 29. Juni 2009 8:32 08

14

en

Working instructions.

WARNING

Before mounting or replacing application tools or accessories, pull the power

plug. This preventive safety measure rules out the danger of injuries through

accidental starting of the power tool.

Do not use accessories which are not specifically designed and recommended by the power tool

manufacturer. Safe operation is not ensured merely because an accessory fits your power tool.

For each job, use only the FEIN application tool released and intended for the respective

application.

Connecting the dust extraction

(Figure 2, ➐).

CAUTION

to be connected to an external dust extraction

via the extraction adapter.

When working materials that

produce dust, the power tool is

Switching ON and OFF (Figure 1).

WARNING

CAUTION

First check that the power

cable and power plug are not

damaged.

Always hold the power tool

firmly. Otherwise, you could

The vacuum cleaner must be suitable for the

material being worked.

When vacuuming dry dusts that are particularly hazardous to one’s health or carcinogenic, a specialty vacuum cleaner is to be

used.

Switching ON:

➤ Push the switch towards the front (I).

Switching OFF:

➤ Push the switch towards the back (0).

lose control over the power tool.

Setting the oscillating frequency

(Figure 1).

The oscillating frequency can be set infinitely

variable with the dial control.

Increasing the oscillating frequency:

➤ Turn dial control in counterclockwise

direction.

The oscillating frequency depends on the

application and the application tool. Example:

– High oscillating frequency:

Sanding, sawing, using as a rasp, polishing

stone and metal.

– Low oscillating frequency:

Polishing of varnish and veneers, removal of

grout, teak decks from boats.

Decreasing the oscillating frequency:

➤ Turn dial control in clockwise direc-

tion.

Securing the work piece.

CAUTION

tightly in a clamping device or vice, is more

secure than if held by hand.

Secure the workpiece firmly.

A work piece that is gripped

Page 15

3 41 01 091 21 0.book Seite 15 Montag, 29. Juni 2009 8:32 08

Sanding

Typical application: Dry sanding of wood and

metal, especially of smaller surfaces, corners

and edges, as well as hard to reach locations.

Work with the complete surface of the sanding plate, not only with the tip. Select a high

oscillating frequency. Sand with continuous

motion and light pressure. Applying excessive

pressure does not increase material removal;

only the sanding sheet wears more quickly.

Sawing

Typical application: Sawing of thin steel sheet,

wood and plastic components.

Select a high oscillating frequency.

Round saw blades can be clamped offset again

to provide uniform wear.

en

15

Scraping

Typical application: Scraping off old coats of

varnish or adhesives, removing bonded carpeting, e. g., on stairs/steps or other small/

medium-sized surfaces.

Select a medium to high oscillating frequency.

Storage

(M

ULTIMASTER FMM250Q - Figure 3).

WARNING

replacing accessories or placing down the

power tool, pull the plug from the socket outlet.

This safety measure prevents accidental starting of the power tool.

➤ Engage the quick-clamping lever.

➤ Fully insert the fastening element into

the tool holder in order to protect it

against damage and contamination.

Before carrying out adjustments on the power tool,

Page 16

3 41 01 091 21 0.book Seite 16 Montag, 29. Juni 2009 8:32 08

16

en

Maintenance.

WARNING

accidental starting of the power tool.

Before mounting or replacing application tools or accessories, pull the power

plug. This preventive safety measure rules out the danger of injuries through

Service

WARNING

nel. Incorrectly mounted leads and components

can cause serious injuries. Have the required

service carried out only through a FEIN customer service agent.

Have maintenance carried out

only through qualified person-

Cleaning

WARNING

tool from the power supply in order to avoid

accidents.

WARNING

such as when working metals, this dust can

settle in the interior of the power tool. This can

impair the total insulation of the power tool.

Therefore, regularly blow out the interior of the

power tool from outside via the ventilation

openings with dry, oil-free compressed air;

always wear eye protection when doing this.

For additional protection, connect a residual

current device (RCD) on the line side.

Do not attempt to clean clogged or dirty

ventilation openings of the power tool

with pointed metal objects; use non-

metal tools or objects for this.

Do not use cleaning agents and solvents

that can cause damage to plastic parts.

These include: Gasoline, carbon-tetrachloride, chloric solvents, ammonia and domestic

cleaning agents that contain ammonia.

When the power tool’s power cable is

damaged, it must be replaced by a qualified person using a specially prepared power

cable, available from your FEIN customer service agent.

Prior to any cleaning or maintenance, disconnect the power

When using in environments

with conductive dust in the air,

Accessories.

Only use accessories recommended by FEIN.

Warranty and liability.

The warranty for the product is valid in accordance with the legal regulations in the country

where it is marketed.

In addition, FEIN also provides a guarantee in

accordance with the FEIN manufacturer’s

guarantee. For further details on this, please

contact your specialist dealer, your national

FEIN representative, or the FEIN customer

service centre.

Environmental protection,

disposal.

Packaging, worn out power tools and accessories should be sorted for environmentfriendly recycling. Further information can be

obtained from your specialist dealer.

Provided Accessories.

Fig. 6

Allen key

FMM250

Page 17

3 41 01 091 21 0.book Seite 17 Montag, 29. Juni 2009 8:32 08

Pour votre sécurité.

AVERTISSEMENT

tes les instructions. Ne pas suivre les

avertissements et instructions peut donner

lieu à un choc électrique, un incendie et/ou

une blessure sérieuse.

Conserver tous les avertissements et toutes les

instructions pour pouvoir s’y reporter ultérieurement.

Ne pas utiliser cet outil électroportatif,

avant d’avoir soigneusement lu et complètement compris cette notice d’utilisation y compris les figures, les spécifications, les règles de

sécurité ainsi que les indications marquées par

DANGER, AVERTISSEMENT et ATTENTION.

N’effectuer avec cet outil électrique que des

travaux pour lesquels il a été conçu par FEIN.

N’utiliser que des outils de travail et accessoires autorisés par FEIN.

Le non-respect des instructions de sécurité se

trouvant dans la documentation mentionnée

peut entraîner un choc électrique, un incendie

et/ou de graves blessures.

Veuillez également tenir compte des règlementations nationales de protection du travail.

Bien garder cette notice d’utilisation en vue

d’une utilisation ultérieure ; elle doit être jointe

à l’outil électroportatif en cas de transmission ou

de vente à une tierce personne.

GARDER PRECIEUSEMENT CES INSTRUCTIONS DE SECURITE.

Lire tous les avertissements de sécurité et tou-

Instructions générales de sécurité.

1) Place de travail

a) Maintenez l’endroit de travail propre et bien

éclairé. Un lieu de travail en désordre ou

mal éclairé augmente le risque d’accidents.

b) N’utilisez pas l’appareil dans un environne-

ment présentant des risques d’explosion et

où se trouvent des liquides, des gaz ou poussières inflammables. Les outils électropor-

tatifs génèrent des étincelles risquant d’enflammer les poussières ou les vapeurs.

c) Tenez les enfants et autres personnes éloi-

gnés durant l’utilisation de l’outil électroportatif. En cas d’inattention vous risquez de

perdre le contrôle sur l’appareil.

fr

2) Sécurité relative au système électrique

a) La fiche de secteur de l’outil électroportatif

doit être appropriée à la prise de courant.

Ne modifiez en aucun cas la fiche. N’utilisez

pas de fiches d’adaptateur avec des appareils avec mise à la terre. Les fiches non

modifiées et les prises de courant appropriées réduisent le risque de choc électrique.

b)Evitez le contact physique avec des surfa-

ces mises à la terre tels que tuyaux, radiateurs, fours et réfrigérateurs. Il y a un ris-

que élevé de choc électrique au cas où votre corps serait relié à la terre.

c) N’exposez pas l’outil électroportatif à la

pluie ou à l’humidité. La pénétration d’eau

dans un outil électroportatif augmente le

risque d’un choc électrique.

d)N’utilisez pas le câble à d’autres fins que

celles prévues, n’utilisez pas le câble pour

porter l’appareil ou pour l’accrocher ou encore pour le débrancher de la prise de courant. Maintenez le câble éloigné des sources de chaleur, des parties grasses, des

bords tranchants ou des parties de l’appareil en rotation. Un câble endommagé ou

torsadé augmente le risque d’un choc

électrique.

e) Au cas où vous utiliseriez l’outil électropor-

tatif à l’extérieur, utilisez une rallonge

autorisée homologuée pour les applications

extérieures. L’utilisation d’une rallonge

électrique homologuée pour les applications extérieures réduit le risque d’un

choc électrique.

f) Si l’usage d’un outil dans un emplacement

humide est inévitable, utiliser une alimentation protégée par un dispositif à courant

différentiel résiduel (RCD). L’usage d’un

RCD réduit le risque de choc électrique.

3) Sécurité des personnes

a) Restez vigilant, surveillez ce que vous faites.

Faites preuve de bon en utilisant l’outil électroportatif. N’utilisez pas l’appareil lorsque

vous êtes fatigué ou après avoir consommé

de l’alcool, des drogues ou avoir pris des mé-

17

Page 18

3 41 01 091 21 0.book Seite 18 Montag, 29. Juni 2009 8:32 08

18

fr

dicaments. Un moment d’inattention lors

de l’utilisation de l’appareil peut entraîner

de graves blessures sur les personnes.

b)Portez des équipements de protection. Portez

toujours des lunettes de protection. Le fait de

porter des équipements de protection personnels tels que masque

anti-poussières, chaussures de sécurité

antidérapantes, casque de protection ou

protection acoustique suivant le travail à

effectuer, réduit le risque de blessures.

c) Evitez une mise en service par mégarde. As-

surez-vous que l’interrupteur est effectivement en position d’arrêt avant de retirer la

fiche de la prise de courant. Le fait de por-

ter l’appareil avec le doigt sur l’interrupteur ou de brancher l’appareil sur la

source de courant lorsque l’interrupteur

est en position de fonctionnement, peut

entraîner des accidents.

d)Enlevez tout outil de réglage ou toute clé

avant de mettre l’appareil en fonctionnement. Une clé ou un outil se trouvant sur

une partie en rotation peut causer des

blessures.

e) Ne surestimez pas vos capacités. Veillez à

garder toujours une position stable et équilibrée. Ceci vous permet de mieux contrôler

l’appareil dans des situations inattendues.

f) Portez des vêtements appropriés. Ne portez

pas de vêtements amples ni de bijoux.

Maintenez cheveux, vêtements et gants

éloignés des parties de l’appareil en rotation. Des vêtements amples, des bijoux ou

des cheveux longs peuvent être happés

par des pièces en mouvement.

g) Si des dispositifs servant à aspirer ou à re-

cueillir les poussières doivent être utilisés,

vérifiez que ceux-ci soient effectivement

raccordés et qu’ils sont correctement utilisés. L’utilisation de tels dispositifs réduit

les dangers dus aux poussières.

4) Utilisation et emploi soigneux de l’outil électroportatif

a) Ne surchargez pas l’appareil. Utilisez l’outil

électroportatif approprié au travail à effectuer. Avec l’outil électroportatif approprié,

vous travaillerez mieux et avec plus de sécurité à la vitesse pour laquelle il est prévu.

b)N’utilisez pas un outil électroportatif dont

l’interrupteur est défectueux. Un outil

électroportatif qui ne peut plus être mis

en ou hors fonctionnement est dangereux

et doit être réparé.

c) Retirer la fiche de la prise de courant avant

d’effectuer des réglages sur l’appareil, de

changer les accessoires, ou de ranger l’appareil. Cette mesure de précaution empêche

une mise en fonctionnement par mégarde.

d)Gardez les outils électroportatifs non utili-

sés hors de portée des enfants. Ne permettez pas l’utilisation de l’appareil à des personnes qui ne se sont pas familiarisées

avec celui-ci ou qui n’ont pas lu ces instructions. Les outils électroportatifs sont dan-

gereux lorsqu’ils sont utilisés par des personnes non initiées.

e) Prenez soin des outils électroportatifs. Véri-

fiez que les parties en mouvement fonctionnent correctement et qu’elles ne soient pas

coincées, et contrôlez si des parties sont

cassées ou endommagées de telle sorte

que le bon fonctionnement de l’appareil

s’en trouve entravé. Faites réparer les parties endommagées avant d’utiliser l’appareil. De nombreux accidents sont dus à

des outils électroportatifs mal entretenus.

f) Maintenez les outils de coupe aiguisés et

propres. Des outils soigneusement entretenus avec des bords tranchants bien

aiguisés se coincent moins souvent et peuvent être guidés plus facilement.

g) Utilisez les outils électroportatifs, les ac-

cessoires, les outils à monter etc. conformément à ces instructions et aux prescriptions en vigueur pour ce type d’appareil. Tenez compte également des conditions de

travail et du travail à effectuer. L’utilisation

des outils électroportatifs à d’autres fins

que celles prévues peut entraîner des situations dangereuses.

5) Service

a) Ne faites réparer votre outil électroportatif

que par un personnel qualifié et seulement

avec des pièces de rechange d’origine. Ceci

permet d’assurer la sécurité de l’appareil.

Page 19

3 41 01 091 21 0.book Seite 19 Montag, 29. Juni 2009 8:32 08

Instructions particulières de sécurité.

Cet outil électrique à double isolation est

équipé d’une fiche polarisée (un contact est

plus large que l’autre). La fiche ne peut être

introduite dans la prise polarisée que dans une

seule position. Tourner la fiche au cas où celleci n’entrerait pas complètement dans la prise

de courant. Au cas où la fiche n’entrerait toujours pas, faire appel à un électricien autorisé

à effectuer l’installation d’une prise de courant

polarisée. Ne modifier la fiche en aucun cas.

Les outils électriques à double isolation n’ont

pas besoin d’un câble de secteur à 3 brins ni

d’une connexion au secteur mise à la terre.

N’exploiter l’outil électrique qu’aux alimentations en courant dont les valeurs de tension et

de fréquence correspondent aux valeurs indiquées sur la plaque signalétique de l’outil électrique.

Au cas où il faudrait utiliser l’outil électrique

dans un emplacement humide, celui-ci doit être

branché au moyen d’un dispositif à courant différentiel réduit (RCC). L’utilisation de gants de

protection spécifiques en caoutchouc et de

chaussures de protection augmente la sécurité personnelle.

Utiliser des dispositifs de serrage ou d’autres

moyens appropriés pour sécuriser la pièce à

travailler sur un support stable. Bloquer la

pièce avec la main ou la presser contre le

corps ne suffit pas et peut entraîner une perte

de contrôle.

Avant de commencer les travaux de montage

ou avant de changer les outils de travail et les

accessoires, retirer la fiche de secteur. Cette

mesure de sécurité préventive exclut un danger de blessure causé par un démarrage non

intentionné de l’outil électrique.

Ne tenir l’outil électrique que par les surfaces

isolées des poignées lors des travaux pendant

lesquels l’outil de travail risquerait de toucher

des câbles électriques invisibles ou son propre

câble. Le contact de l’accessoire coupant avec

un fil « sous tension » peut également mettre

« sous tension » les parties métalliques exposées de l’outil électrique et provoquer un

choc électrique sur l’opérateur.

Utiliser des détecteurs appropriés afin de déceler des conduites cachées ou consulter les services locaux d’alimentation autorisés. Un

contact avec des fils électriques peut provoquer un incendie ou un choc électrique. Un

endommagement d’une conduite de gaz peut

provoquer une explosion. La perforation

d’une conduite d’eau provoque des dégâts

matériels et peut provoquer un choc électrique.

Ne pas diriger l’outil électrique vers soi-même

ou vers d’autres personnes ou des animaux. Il

y a un danger de blessure causé par des outils

de travail tranchants ou chauds.

Pour tous les travaux ou pour remplacer les

outils de travail, toujours porter des gants de

protection. Les bords tranchants des outils de

travail présentent des risques de blessure !

Les outils de travail peuvent devenir très

chauds lors du travail, danger de brûlure !

Tenir l’outil électrique fermement, en faisant

attention à ce votre corps ne puisse jamais

entrer en contact avec l’outil de travail, en particulier lorsque vous travaillez avec des outils

dirigés vers la poignée tels que lames de scie

ou outils de coupe. Le contact avec les bords

ou coins tranchants peut entraîner des blessures.

L’outil électrique n’est pas agréé pour les travaux avec alimentation en eau. L’eau qui pénè-

tre dans le carter-moteur peut entraîner un

choc électrique.

Il est interdit de visser ou de riveter des plaques ou des repères sur l’outil électrique. Une

isolation endommagée ne présente aucune

protection contre un choc électrique. Utiliser

des autocollants.

Nettoyer régulièrement les ouies de ventilation

de l’outil électroporatif. La ventilation du

moteur aspire de la poussière dans le carter.

De la poussière de métal en trop grande

quantité peut causer des dangers électriques.

fr

19

Page 20

3 41 01 091 21 0.book Seite 20 Montag, 29. Juni 2009 8:32 08

20

fr

Maniement de poussières nocives

AVERTISSEMENT

ponçage, polissage, sciage ou d'autres opérations enlevant du matériau, des poussières

sont générées qui peuvent être nocives pour la

santé, auto-inflammables ou explosives.

Toucher ou aspirer certaines poussières peut

causer des réactions allergiques et/ou des

maladies respiratoires, un cancer, des malformations à la naissance ou autres anomalies de

reproduction auprès de l’utilisateur ou de

personnes se trouvant à proximité.

Quelques exemples de tels matériaux et des

produits chimiques qu’ils contiennent dont

l’usinage génère des poussières nocives :

– l’amiante et les matériaux contenant de

l’amiante ;

– peintures contenant du plomb, certains

bois tels que le bois de chêne et de hêtre ;

– minéraux et métal ;

– les particules de silicate contenues dans les

briques, le béton et autres matériaux conte-

nant de la roche ;

– les solvants contenus dans les vernis et

peintures ;

– l’arsenic, le chrome et d’autres lazures ;

– produits pour la lutte contre les vermines

sur la coque de bateaux et de bâtiments.

Lors du travail avec des

outils, par ex. lors du

Pour minimiser la résorption indésirable de

ces matériaux :

– Utiliser une aspiration adaptée à la pous-

sière générée.

– Utilisez des équipements personnels de

protection tels que par exemple un masque

anti-poussière de la classe filtre P2.

– Veillez à bien aérer la zone de travail.

Le risque causé par l’inhalation des poussières

dans les poumons dépend de la fréquence à

laquelle ces matériaux sont usinés. Les matériaux contenant de l’amiante ne doivent être

usinés que par des personnes qualifiées.

ATTENTION

Les poussières de bois et

les poussières de métaux

légers peuvent causer une auto-inflammation

ou une explosion.

Des mélanges chauds de poussières de ponçage contenant des résidus de vernis, de polyuréthane ou de produits chimiques dans le sac

à poussières en papier ou dans le filtre de

l’aspirateur peuvent s’enflammer dans des

conditions infavorables tels que projection

d’étincelles lors du ponçage de métaux, soleil

directe permanent ou température ambiante

élevée. Pour prévenir ces conditions :

– Evitez la surchauffe des matériaux usinés et

de l’outil électrique.

– Videz le bac de récupération des poussières

à temps.

– Respectez les indications de travail du fabri-

cateur du matériau.

Respectez les règlements en vigueur dans

votre pays spécifiques aux matériaux à traiter.

Vibrations mains-bras

AVERTISSEMENT

avec cet outil électrique. Celles-ci peuvent entraîner des effets néfastes sur la santé.

AVERTISSEMENT

de l’outil électrique peut dévier des valeurs

indiquées, en fonction de l’utilisation de l’outil

électrique.

Des vibrations mains-bras

sont générées lors du travail

La valeur réelle des vibrations lors de l’utilisation

AVERTISSEMENT

Pour protéger l’opéra-

teur, des mesures de

sécurité doivent être déterminées sur la base

de la sollicitation vibratoire estimée pendant

l’utilisation effective.

L’amplitude d’oscillation indiquée dans ces instructions d’utilisation a été mesurée conformément à la norme EN 60745 et peut être utilisée

pour une comparaison d’outils électriques. Elle

est également appropriée pour une estimation

préliminaire de la sollicitation vibratoire.

Page 21

3 41 01 091 21 0.book Seite 21 Montag, 29. Juni 2009 8:32 08

L’amplitude d’oscillation représente les utilisations principales de l’outil électrique. Si

l’outil électrique est cependant utilisé pour

d’autres applications, avec d’autres outils de

travail ou avec un entretien non approprié,

l’amplitude d’oscillation peut être différente.

Ceci peut augmenter considérablement la sollicitation vibratoire pendant toute la durée du

travail.

Pour une estimation précise de la sollicitation

vibratoire, il est recommandé de prendre

pendant lesquels l’appareil est éteint ou en

fonctionnement, mais pas vraiment utilisé.

Ceci peut réduire considérablement la sollicitation vibratoire pendant toute la durée du

travail.

Déterminez des mesures de protection supplémentaires pour protéger l’utilisateur des

effets de vibrations, tels que par exemple :

Entretien de l’outil électrique et des outils de

travail, maintenir les mains chaudes, organisation des opérations de travail.

aussi en considération les espaces de temps

Valeurs d’émission pour bruit et vibration (Indication à deux chiffres suivant ISO 4871)

Emission acoustique

Mesure réelle (A) du niveau d’intensité acoustique pondéré LwA (re 1 pW), en décibel : 85

Incertitude KwA, en décibel : 3

Mesure réelle (A) du niveau de pression

Vibration

Classement des outils

FEIN suivant la classe

Accélération réelle

mesurée*

de vibrations

VC0 < 2,5 m/s

acoustique sur le lieu de travail LpA

(re 20 µPa), en décibel : 74

VC1 < 5 m/s

Incertitude KpA, en décibel : 3

REMARQUE : La somme de la valeur d’émis-

VC2 < 7 m/s

sion mesurée et de l’incertitude constitue la

limite supérieure des valeurs qui peuvent

VC3 < 10 m/s

apparaître pendant des mesurages.

Porter une protection acoustique !

Valeurs de mesure mesurées conformément

VC4 < 15 m/s

VC5 > 15 m/s

à la norme correspondante du produit.

fr

< 8 ft/s

< 16 ft/s

< 23 ft/s

< 33 ft/s

< 50 ft/s

> 50 ft/s

21

2

2

2

2

2

2

2

2

2

2

2

2

* Ces valeurs sont basées sur un cycle de

travail consistant en un service à vide et un

service à pleine charge d’une même durée.

Pour le classement de l’outil de travail suivant

la classe de vibrations, voir la feuille jointe

3 41 30 335 06 0.

Page 22

3 41 01 091 21 0.book Seite 22 Montag, 29. Juni 2009 8:32 08

22

fr

Câble de rallonge

AVERTISSEMENT

Au cas où une rallonge

serait nécessaire, la longueur ainsi que la section du conducteur de celleci doivent être appropriées à l’utilisation afin

d’éviter une baisse de tension dans la rallonge,

une perte de puissance et une surchauffe de l’outil

électrique. Sinon la rallonge et l’outil électrique

présentent des dangers électriques et l’efficacité

du travail est entravée.

Dimensions recommandées de la rallonge pour

une tension de service de 120 V – courant alternatif monophasé lors d’un branchement d’un outil

électrique FMM250/FMM250Q :

Dimension du conducteur

en format américain

(A.W.G.)

Section du conducteur en

2

mm

18 16 14 0,75 1,5 2,5

Longueur du câble en

pieds

Longueur du câble en m

25 100 150 30 60 120

Conception de l’outil électrique.

Cet outil électrique est conçu pour un usage

industriel ou privé, pour le ponçage à sec de

petites surfaces, coins et bords, pour le grattage, pour scier des plaques en tôle, en bois et

en matières plastiques de faible épaisseur avec

les outils de travail et les accessoires autorisés

par FEIN.

Fonctionnement de l’outil électrique avec des générateurs de courant.

Ne faire fonctionner l’outil électrique

que sur des générateurs de courant alternatif d’une puissance suffisante, ne présentant

aucune déviation de la courbe de tension.

AVERTISSEMENT

trique sur des générateurs de courant dont la

tension à vide dépasse la valeur de tension

indiquée sur la plaque signalétique de l’outil

électrique.

Il est interdit de faire

fonctionner l’outil élec-

Muni de certains accessoires, cet outil électrique peut également être utilisé pour le polissage, le râpage, le découpage et le

tronçonnage.

Page 23

3 41 01 091 21 0.book Seite 23 Montag, 29. Juni 2009 8:32 08

Symboles.

Symbol Explication

➤

Action de l’utilisateur

Danger provoqué par des outils de travail tranchants en mouvement.

Attention aux bords tranchants des outils de travail tels que les lames

des couteaux.

Suivre les indications données dans le texte ci-contre !

Lire impérativement les documents ci-joints tels que la notice d’utilisation et les instructions générales de sécurité.

Lors des travaux, porter une protection oculaire.

Lors des travaux, porter une protection acoustique.

Lors des travaux, porter une protection anti-poussière.

Lors du travail, utiliser des lunettes de sécurité, des protections auditives et une protection anti-poussières.

Lors des travaux, utiliser un protège-main.

fr

23

Trier les outils électriques ainsi que les autres produits électrotechniques et électriques et les rapporter à un centre de recyclage respectant les directives concernant la protection de l’environnement.

Ce symbole confirme la certification de ce produit aux Etats-Unis et

au Canada.

DANGER

Cette indication met en garde contre une situation dangereuse imminente. Une mauvaise manipulation peut entraîner de graves blessures

ou la mort.

AVERTISSEMENT

Cette indication indique une situation potentiellement dangereuse qui

peut entraîner de graves blessures ou la mort.

ATTENTION

Cette indication met en garde contre une situation potentiellement

dangereuse qui peut entraîner des blessures.

Produit avec double isolation ou isolation renforcée

~ ou a. c. Courant alternatif

1 ~ Courant alternatif, monophasé

Ø Diamètre d’un élément rond

Page 24

3 41 01 091 21 0.book Seite 24 Montag, 29. Juni 2009 8:32 08

24

fr

Signe Unité nationale Explication

n

/min Vitesse circonférentielle en marche à vide

0

W Unité de mesure pour la puissance électrique

Hz Fréquence

V Unité de mesure pour la tension électrique

A Unité de mesure pour l’intensité du courant électrique

° Unité de mesure pour la largeur d’angle

lbs Unité de mesure pour la masse

ft, in Unité de mesure pour longueur, largeur, hauteur ou profondeur

m, s, kg, A, mm, V, W,

Hz, N, °C, dB, /min, m/s

Unités de base et unités dérivées du système internatio-

2

nal SI.

Page 25

3 41 01 091 21 0.book Seite 25 Montag, 29. Juni 2009 8:32 08

fr

25

Description technique et spécification.

AVERTISSEMENT

sécurité préventive exclut un danger de blessure causé par un démarrage non intentionné de

l’outil électrique.

Il se peut que seule une partie des accessoires décrits ou représentés dans cette notice d’utilisation soit fournie avec l’outil électrique.

Multimaster FMM250Q

Interrupteur

Marche/Arrêt

Levier de

serrage rapide

Avant de commencer les travaux de montage ou avant de changer les outils

de travail et les accessoires, retirer la fiche de secteur. Cette mesure de

Fig. 1

Molette de réglage de la

fréquence d’oscillation

Dispositif d’aspiration

Butée de profondeur

Type

MULTIMASTER FMM250 MULTIMASTER FMM250Q

Référence 7 229 36 7 229 37

Tension nominale 120 V/60 Hz 120 V/60 Hz

Puissance absorbée 250 W 250 W

Puissance utile 140 W 140 W

Consommation en courant 2,3 A 2,3 A

Type de raccord au réseau 1 ~ 1 ~

Fréquence d’oscillations 11 000–20 000/min 11 000–20 000/min

Poids suivant EPTA-Procedure 01/2003 1,2 kg (2,8 lbs) 1,4 kg (3,2 lbs)

Classe de protection II II

Angle d’oscillation 1,6 ° 1,6 °

Page 26

3 41 01 091 21 0.book Seite 26 Montag, 29. Juni 2009 8:32 08

26

fr

Indications de montage.

Montage du dispositiration (Figure 2).

AVERTISSEMENT

sécurité préventive exclut un danger de blessure causé par un démarrage non intentionné de

l’outil électrique.

➤ Monter le dispositif d’aspiration petit à petit conformément aux indications figurant sur

la figure.

➤ Pour le branchement sur l’aspirateur FEIN ou sur des aspirateurs domestiques, diffé-

rents embouts sont disponibles (accessoires).

➤ Pousser l’agrafe vers l’arrière à l’endroit marqué pour enlever de nouveau le dispositif

d’aspiration (➑).

Avant de commencer les travaux de montage ou avant de changer les outils

de travail et les accessoires, retirer la fiche de secteur. Cette mesure de

➊

➋

➌

Fig. 2

Dispositif

d’aspiration

➍➎➏

➐

➑

Page 27

3 41 01 091 21 0.book Seite 27 Montag, 29. Juni 2009 8:32 08

Changement d’outil.

Dans la position de travail la plus favorable, l’outil de travail peut être serré décalé en pas

de 45° (ou en pas de 30° pour le plateau de ponçage triangulaire).

M

ULTIMASTER FMM250Q (Figure 3).

AVERTISSEMENT

avant de changer les outils de travail et les

accessoires, retirer la fiche de secteur. Cette

mesure de sécurité préventive exclut un danger de blessure causé par un démarrage non

intentionné de l’outil électrique.

ATTENTION

écrasés par le levier à serrage rapide lorsqu’il

revient en arrière. Celui-ci contient un ressort

qui lui donne beaucoup de force.

ATTENTION

toujours porter des gants de protection. Les

bords tranchants des outils de travail présentent des risques de blessure ! Les outils de travail peuvent devenir très chauds lors du

travail, danger de brûlure !

Montez l’élément de fixation à fond.

Ensuite, fermez le levier de serrage

rapide.

➤ Desserrer le levier de serrage rapide et

le faire pivoter au maximum.

➤ Retirer l’élément de fixation.

➤ Nettoyer le porte-outil, l’outil de tra-

vail et l’élément de fixation.

➤ Monter l’outil de travail exactement

dans le porte-outil en forme d’étoile.

Veiller à ce que l’outil de travail ne

dépasse pas.

➤ Monter l’élément de fixation à fond

dans le porte-outil.

➤ Rabattre le levier de serrage rapide

jusqu’à ce qu’il s’encliquette.

Avant de commencer les

travaux de montage ou

Faire attention que votre main

et vos doigts ne soient pas

Pour tous les travaux ou pour

remplacer les outils de travail,

Fig. 3

Elément de fixation

Porte-outil

Levier de

serrage rapide

180°

fr

27

Page 28

3 41 01 091 21 0.book Seite 28 Montag, 29. Juni 2009 8:32 08

28

fr

MULTIMASTER FMM250 (Figure 4).

AVERTISSEMENT

Avant de commencer les

travaux de montage ou

avant de changer les outils de travail et les

accessoires, retirer la fiche de secteur. Cette

mesure de sécurité préventive exclut un danger de blessure causé par un démarrage non

intentionné de l’outil électrique.

ATTENTION

Pour tous les travaux ou pour

remplacer les outils de travail,

toujours porter des gants de protection. Les

bords tranchants des outils de travail présentent des risques de blessure ! Les outils de travail peuvent devenir très chauds lors du

travail, danger de brûlure !

➤ Desserrer la vis de serrage.

➤ Nettoyer le porte-outil, l’outil de tra-

vail et la vis de serrage.

➤ Monter l’outil de travail exactement

dans le porte-outil en forme d’étoile.

Veiller à ce que l’outil de travail ne

dépasse pas.

➤ Serrer la vis de serrage à l’aide de la clé

mâle pour vis à six pans creux jointe.

Fig. 4

Vis de serrage

Porte-outil

Clé mâle coudée pour

vis à six pans creux

Montage/Changement de la feuille abrasive (Figure 5).

➤ Bien placer la feuille abrasive et

l’appuyer manuellement sur le plateau de

Fig. 5

ponçage.

➤ Appuyer fortement l’outil électrique

avec la feuille abrasive sur une surface

plane et mettre brièvement l’outil électrique en marche. Ceci permet d’obtenir

une bonne adhérence et empêche une

usure précoce.

Il est possible de retirer la feuille abrasive et

de la remonter tournée de 120°, si seule une

pointe de la feuille abrasive est usée.

Feuille

abrasive

Plateau de

ponçage

Page 29

3 41 01 091 21 0.book Seite 29 Montag, 29. Juni 2009 8:32 08

fr

29

Indications pour le travail.

AVERTISSEMENT

sécurité préventive exclut un danger de blessure causé par un démarrage non intentionné de

l’outil électrique.

Ne pas utiliser des accessoires qui n’ont pas été spécialement conçus ou autorisés par le fabricant de

l’outil électrique. Le seul fait qu’un accessoire va sur votre outil électrique ne garantit pas une utili-

sation sans risque.

N’utiliser que des outils de travail FEIN conçus et autorisés pour l’utilisation correspondante.

Raccordement de l’aspiration de

poussières (Figure 2, ➐).

ATTENTION

l’outil électrique doit être raccordé à un dispositif d’aspiration externe par l’intermédiaire

d’un adaptateur d’aspiration.

Mise en fonctionnement/Arrêt

(Figure 1).

AVERTISSEMENT

et la fiche sont en parfait état.

ATTENTION

sinon de perdre le contrôle de l’outil électrique.

Avant de commencer les travaux de montage ou avant de changer les outils

de travail et les accessoires, retirer la fiche de secteur. Cette mesure de

L’aspirateur doit être approprié au matériau

travaillé.

Lors du travail de matériaux

générant des poussières,

Le cas échéant, utiliser un aspirateur spécial

pour les poussières particulièrement sèches,

nocives pour la santé ou cancérigènes.

Mise en fonctionnement :

➤ Pousser vers l’avant l’interrupteur (I).

Vérifier d’abord que le

câble de raccordement

Arrêt :

➤ Pousser vers l’arrière l’interrup-

teur (0).

Toujours bien tenir l’outil électroportatif. Vous risquez

Réglage de la fréquence d’oscillation

(Figure 1).

Il est possible de régler la fréquence d’oscillation en continu au moyen de la molette de

réglage.

Augmentation de la fréquence d’oscillations :

➤ Tourner la molette de réglage dans le

sens inverse des aiguilles d’une montre.

Bloquer la pièce à travailler.

ATTENTION

par un dispositif de serrage est fixée de manière

plus sûre que si elle est tenue par la main.

Bloquer la pièce à travailler.

Une pièce à travailler serrée

Réduction de la fréquence d’oscillations :

➤ Tourner la molette de réglage dans le

sens des aiguilles d’une montre.

La fréquence d’oscillations dépend de l’utilisation et de l’outil de travail, p. ex. :

– Fréquence d’oscillations élevée :

ponçage, sciage, râpage, polissage de surfaces en pierre et en métal.

– Fréquence d’oscillations basse :

polissage de vernis, enlever matériau isolant, ponts en teck de bateaux.

Page 30

3 41 01 091 21 0.book Seite 30 Montag, 29. Juni 2009 8:32 08

30

fr

Ponçage

Utilisation typique : Ponçage à sec de bois et

métal, spécialement de petites surfaces, coins

et bords ainsi que d'endroits difficilement

accessibles.

Travailler avec toute la surface du plateau de

ponçage, pas seulement avec la pointe. Choisir

Gratter

Utilisation typique : Grattage de vieux vernis

ou colles, enlèvement de moquettes collées,

p. ex. sur des escaliers ou autres surfaces de

petites ou moyennes dimensions.

Choisir une fréquence d’oscillations moyenne

à élevée.

une fréquence d’oscillations élevée. Poncer par

un mouvement continu et en appliquant une

légère pression. Une pression trop élevée

n’augmente pas l’enlèvement de matière mais

l’usure de la feuille abrasive.

Sciage

Utilisation typique : sciage de plaques en tôle,

en bois et en matières plastiques de faible

épaisseur.

Choisir une fréquence d’oscillations élevée.

Il est possible d’enlever les lames rondes et de

les refixer tournées pour garantir une usure

régulière.

Stockage

(M

ULTIMASTER FMM250Q - Figure 3).

AVERTISSEMENT

tuer des réglages sur l’appareil, de changer les

accessoires, ou de ranger l’outil électroportatif. De telles mesures de sécurité préventives

réduisent le risque de démarrage accidentel

de l’outil.

➤ Faire encliqueter le levier de serrage

rapide.

➤ Monter l’élément de fixation à fond

dans le porte-outil afin de le protéger de

Retirer la fiche de la prise

de courant avant d’effec-

dommages et d’encrassement.

Entretien.

AVERTISSEMENT

sécurité préventive exclut un danger de blessure causé par un démarrage non intentionné de

l’outil électrique.

Avant de commencer les travaux de montage ou avant de changer les outils

de travail et les accessoires, retirer la fiche de secteur. Cette mesure de

Service après-vente

AVERTISSEMENT

des personnes qualifiées. Les câbles et éléments mal montés peuvent présenter des risques graves. Ne faire effectuer le service

d’entretien nécessaire que par une station de

service après-vente FEIN.

Ne faire effectuer les tra-

vaux d’entretien que par

Nettoyage

AVERTISSEMENT

électrique de l’alimentation en courant avant

d’effectuer un nettoyage ou des travaux

d’entretien ou de maintenance.

Afin d’éviter des acci-

dents, débranchez l’outil

AVERTISSEMENT

S’il y a de la poussière

conductrice dans l’air

lors de l’utilisation de l’appareil, p. ex. lors du

traitement de métaux, cette poussière peut se

poser à l’intérieur de l’outil électrique. La double isolation de l’outil électrique peut ainsi être

endommagée. Soufflez alors régulièrement de

l’extérieur de l’air comprimé sec exempt

d’huile dans l’intérieur de l’outil électrique à

travers les ouïes de ventilation ; utilisez toujours une protection oculaire. Pour une protection supplémentaire, placez un dispositif à

courant différentiel résiduel (RCD) en amont.

N’essayez pas de nettoyer les ouïes de

ventilation à l’aide d’objets métalliques

pointus ; utilisez des outils non-métalliques.

Page 31

3 41 01 091 21 0.book Seite 31 Montag, 29. Juni 2009 8:32 08

N’utilisez pas de détergents ou de solvants qui peuvent endommager les parties

en matière plastique. Dont : l’essence, le

tétrachlorure de carbone, solvants chlorés,

l’ammoniaque et produits de nettoyage

domestiques contenant de l’ammoniaque.

Si un câble d’alimentation de l’outil élec-

trique est endommagé, il doit être remplacé par une personne qualifiée par un câble

d’alimentation spécialement préparé qui est

disponible auprès du service après-vente de

FEIN.

Accessoires.

N’utiliser que des accessoires autorisés par

FEIN.

Garantie.

Pour le produit, la garantie vaut conformément à la réglementation légale en vigueur

dans le pays où le produit est mis sur le marché.

Outre les obligations de garantie légale, les

appareils FEIN sont garantis conformément à

notre déclaration de garantie de fabricant.

Pour plus de précisions, veuillez vous adresser à votre revendeur spécialisé, à votre

représentant FEIN dans votre pays ou auprès

du service après-vente FEIN.

Accessoires fournis.

Fig. 6

Clé mâle coudée pour

vis à six pans creu

fr

FMM250

31

Protection de l’environnement,

élimination.

Rapporter les emballages, les outils électriques hors d’usage et les accessoires à un centre de recyclage respectant les directives

concernant la protection de l’environnement.

Pour plus de précisions, veuillez vous adresser à votre revendeur spécialisé.

Page 32

3 41 01 091 21 0.book Seite 32 Montag, 29. Juni 2009 8:32 08

32

es

Para su seguridad.

ADVERTENCIA

instrucciones. En caso de no atenerse a las

advertencias de peligro e instrucciones

siguientes, ello puede ocasionar una descarga

eléctrica, un incendio y/o lesión grave.

Guardar todas las advertencias de peligro e

instrucciones para futuras consultas.

No utilice esta herramienta eléctrica sin

haber leído antes a fondo y haber entendido íntegramente estas instrucciones de uso,

inclusive las figuras, especificaciones, reglas de

seguridad y las indicaciones de PELIGRO,

ADVERTENCIA y ATENCIÓN.

Solamente use esta herramienta eléctrica para

realizar los trabajos que FEIN ha previsto para

la misma. Únicamente utilice las herramientas

y accesorios de aplicación autorizados por

FEIN.

Observe también las disposiciones nacionales

de protección laboral pertinentes.

En caso de no atenerse a las instrucciones de

seguridad mencionadas en la documentación

previamente citada, ello puede provocar una

electrocución, incendio y/o lesión grave.

Este manual de instrucción debe mantenerse

para futuro uso, junto con la herramienta

eléctrica y entregarlo al prestar o vender la

herramienta.

GUARDAR ESTAS INSTRUCCIONES EN

UN LUGAR SEGURO.

Lea íntegramente estas

advertencias de peligro e

Instrucciones generales de

seguridad.

1) Seguridad en el puesto de trabajo

a) Mantenga limpio y bien iluminado su puesto

de trabajo. El desorden y una iluminación

deficiente en las áreas de trabajo pueden

provocar accidentes.

b)No utilice la herramienta eléctrica en un en-

torno con peligro de explosión, en el que se

encuentren combustibles líquidos, gases o

material en polvo. Las herramientas eléctri-

cas producen chispas que pueden llegar a

inflamar los materiales en polvo o vapores.

c) Mantenga alejados a los niños y otras per-

sonas de su puesto de trabajo al emplear la

herramienta eléctrica. Una distracción le

puede hacer perder el control sobre el

aparato.

2) Seguridad eléctrica

a) El enchufe del aparato debe corresponder a

la toma de corriente utilizada. No es admisible modificar el enchufe en forma alguna.

No emplear adaptadores en aparatos dotados con una toma de tierra. Los enchufes

sin modificar adecuados a las respectivas

tomas de corriente reducen el riesgo de

una descarga eléctrica.

b)Evite que su cuerpo toque partes conecta-

das a tierra como tuberías, radiadores, cocinas y refrigeradores. El riesgo a quedar

expuesto a una sacudida eléctrica es mayor si su cuerpo tiene contacto con tierra.

c) No exponga las herramientas eléctricas a la

lluvia y evite que penetren líquidos en su interior. Existe el peligro de recibir una des-

carga eléctrica si penetran ciertos líquidos

en la herramienta eléctrica.

d)No utilice el cable de red para transportar o

colgar el aparato, ni tire de él para sacar el

enchufe de la toma de corriente. Mantenga

el cable de red alejado del calor, aceite, esquinas cortantes o piezas móviles. Los ca-

bles de red dañados o enredados pueden

provocar una descarga eléctrica.

e) Al trabajar con la herramienta eléctrica en

la intemperie utilice solamente cables de

prolongación homologados para su uso en

exteriores. La utilización de un cable de

prolongación adecuado para su uso en exteriores reduce el riesgo de una descarga

eléctrica.

f) Si fuese imprescindible utilizar la herra-

mienta eléctrica en un entorno húmedo, es

necesario conectarla a través de un fusible

diferencial. La aplicación de un fusible di-

ferencial reduce el riesgo a exponerse a

una descarga eléctrica.

Page 33

3 41 01 091 21 0.book Seite 33 Montag, 29. Juni 2009 8:32 08

3) Seguridad de personas

a) Esté atento a lo que hace y emplee la herra-

mienta eléctrica con prudencia. No utilice

la herramienta eléctrica si estuviese cansado, ni tampoco después de haber consumido alcohol, drogas o medicamentos. El

no estar atento durante el uso de una herramienta eléctrica puede provocarle serias lesiones.

b)Utilice un equipo de protección y en todo

caso unas gafas de protección. El riesgo a

lesionarse se reduce considerablemente

si, dependiendo del tipo y la aplicación de

la herramienta eléctrica empleada, se utiliza un equipo de protección adecuado

como una mascarilla antipolvo, zapatos de

seguridad con suela antideslizante, casco,

o protectores auditivos.

c) Evite una puesta en marcha fortuita del

aparato. Cerciorese de que el aparato esté

apagado antes de conectarlo a la toma de

corriente. Transportar el aparato sujetán-

dolo por el interruptor de encendido/apagado, o si conecta el enchufe en la toma de

corriente con el aparato encendido, puede

dar lugar a un accidente.

d)Retire las herramientas de ajuste o llaves

fijas antes de conectar la herramienta eléctrica. Una herramienta o llave colocada en

una pieza rotante puede producir lesiones

al ponerse a funcionar.

e) Sea precavido. Trabaje sobre una base

firme y mantenga el equilibrio en todo momento. Ello le permitirá controlar mejor la

herramienta eléctrica en caso de presentarse una situación inesperada.

f) Lleve puesta una vestimenta de trabajo

adecuada. No utilice vestimenta amplia ni

joyas. Mantenga su pelo, vestimenta y

guantes alejados de las piezas móviles. La

vestimenta suelta, las joyas y el pelo largo

se pueden enganchar con las piezas en

movimiento.

g) Siempre que sea posible utilizar unos equi-

pos de aspiración o captación de polvo,

asegúrese de que éstos estén apropiadamente conectados y que sean utilizados correctamente. El empleo de estos equipos

reduce los riesgos derivados del polvo.

es

4) Trato y uso cuidadoso de herramientas eléctricas

a) No sobrecargue el aparato. Use la herra-

mienta prevista para el trabajo a realizar.

Con la herramienta adecuada podrá trabajar mejor y más seguro dentro del margen

de potencia indicado.

b)No utilice herramientas con un interruptor

defectuoso. Las herramientas que no se

puedan encender o apagar son peligrosas

y deben hacerse reparar.

c) Saque el enchufe de la red antes de realizar

un ajuste en el aparato, cambiar de accesorio o al guardar el aparato. Esta medida

preventiva reduce el riesgo a encender accidentalmente el aparato.

d)Guarde las herramientas fuera del alcance

de los niños y de las personas que no estén

familiarizadas con su uso. Las herramien-

tas utilizadas por personas inexpertas son

peligrosas.

e) Cuide sus herramientas eléctricas con es-

mero. Controle si funcionan correctamente,

sin atascarse, las partes móviles del aparato, y si existen partes rotas o deterioradas que pudieran afectar al funcionamiento

de la herramienta. Si la herramienta eléctrica estuviese defectuosa haga repararla

antes de volver a utilizarla. Muchos de los

accidentes se deben a aparatos con un

mantenimiento deficiente.

f) Mantenga las herramientas cortantes lim-

pias y afiladas. Las herramientas cortantes

mantenidas correctamente se dejan guiar

y controlar mejor.

g) Utilice herramientas eléctricas, accesorios,

útiles, etc. de acuerdo a estas instrucciones

y en la manera indicada específicamente

para este aparato. Considere en ello las condiciones de trabajo y la tarea a realizar. El

uso de herramientas eléctricas para trabajos diferentes de aquellos para los que han

sido concebidas puede resultar peligroso.

5) Servicio

a) Únicamente haga reparar su herramienta

eléctrica por un profesional, empleando exclusivamente piezas de repuesto originales.

Solamente así se mantiene la seguridad de

la herramienta eléctrica.

33

Page 34

3 41 01 091 21 0.book Seite 34 Montag, 29. Juni 2009 8:32 08

34

es

Instrucciones de seguridad especiales.