Fein WSG10-115T, WSG14-125T, WSG14-150T, WSG14-70ET, WSS14-125T Instruction Manual

© C. & E. FEIN GmbH. Printed in Germany. Abbildungen unverbindlich. Technische Änderungen vorbehalten. 3 41 01 121 21 0 BY 2011.09 DE.

FEIN Service

USA

FEIN Power Tools Inc.

1030 Alcon Street

Pittsburgh, PA 15220

Telephone: (412) 922-8886

Toll Free: 1-800-441-9878

www.feinus.com

Canada

FEIN Canadian Power Tool

Company

323 Traders Boulevard East

Mississauga, Ontario L4Z 2E5

Telephone.:(905) 8901390

Toll Free: 1-800-265-2581

FEIN Canadian Power Tool

Company

2810 De Miniac

St. Laurent, Quebec H4S 1K9

Telephone: (514) 331-7390

Toll Free: 1-800-789-8181

www.fein.com

Headquarter

C. & E. FEIN GmbH

Hans-Fein-Straße 81

D-73529 Schwäbisch Gmünd-Bargau

www.fein.com

WSG10-115T 7 221 55

WSG14-125T 7 221 56

WSG14-150T 7 221 57

WSG14-70ET 7 221 58

WSS14-125T 7 221 54

3 41 01 121 21 0 - Umschlag.fm Seite 1 Montag, 12. September 2011 9:07 09

2

English _____________ Instruction manual_________________

Français ____________ Mode d’emploi ___________________

Español _____________ Instrucciones de uso _______________

3

30

58

3 41 01 121 21 0.book Seite 2 Montag, 22. August 2011 1:11 13

3

en

For your safety.

Read all safety warnings and all

instructions. Failure to follow

the warnings and instructions may result in

electric shock, fire and/or serious injury.

Save all warnings and instructions for future

reference.

Do not use this power tool before you

have thoroughly read and completely

understood this Instruction Manual, including

the figures, specifications, safety regulations

and the signs indicating DANGER, WARNING and CAUTION.

Only carry out such operations with this

power tool as intended for by FEIN. Only use

application tools and accessories that have

been released by FEIN.

Please also observe the relevant national

industrial safety regulations.

Non-observance of the safety instructions in

the said documentation can lead to an electric

shock, burns and/or severe injuries.

This Instruction Manual should be kept for

later use and enclosed with the power tool,

should it be passed on or sold.

SAVE THESE INSTRUCTIONS.

General Safety Rules.

1) Work area safety

a) Keep work area clean and well lit. Clut-

tered or dark areas invite accidents.

b)Do not operate power tools in explosive at-

mospheres, such as in the presence of

flammable liquids, gases or dust. Power

tools create sparks which may ignite the

dust or fumes.

c) Keep children and bystanders away while

operating a power tool. Distractions can

cause you to lose control

2) Electrical safety

a) Power tool plugs must match the outlet.

Never modify the plug in any way. Do not

use any adapter plugs with earthed

(grounded) power tools. Unmodified plugs

and matching outlets will reduce risk of

electric shock.

b)Avoid body contact with earthed or

grounded surfaces such as pipes, radiators,

ranges and refrigerators. There is an in-

creased risk of electric shock if your body

is earthed or grounded.

c) Do not expose power tools to rain or wet

conditions. Water entering a power tool

will increase the risk of electric shock.

d)Do not abuse the cord. Never use the cord

for carrying, pulling or unplugging the

power tool. Keep cord away from heat, oil,

sharp edges or moving parts. Damaged or

entangled cords increase the risk of electric shock.

e) When operating a power tool outdoors, use

an extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces the risk of electric shock.

f) If operating a power tool in a damp location

is unavoidable, use a residual current device (RCD) protected supply. Use of an

RCD reduces the risk of electric shock.

3) Personal safety

a) Stay alert, watch what you are doing and

use common sense when operating a power

tool. Do not use a power tool while you are

tired or under the influence of drugs, alcohol or medication. A moment of inatten-

tion while operating power tools may result in serious personal injury.

b)Use safety equipment. Always wear eye

protection. Safety equipment such as dust

mask, non-skid safety shoes, hard hat, or

hearing protection used for appropriate

conditions will reduce personal injuries.

c) Avoid accidental starting. Ensure the switch

is in the off-position before plugging in.

Carrying power tools with your finger on

the switch or plugging in power tools that

have the switch on invites accidents.

d)Remove any adjusting key or wrench before

turning the power tool on. A wrench or a

key left attached to a rotating part of the

power tool may result in personal injury.

WARNING

3 41 01 121 21 0.book Seite 3 Montag, 22. August 2011 1:11 13

4

en

e) Do not overreach. Keep proper footing and

balance at all times. This enables better

control of the power tool in unexpected

situations.

f) Dress properly. Do not wear loose clothing

or jewellery. Keep your hair, clothing and

gloves away from moving parts. Loose

clothes, jewellery or long hair can be

caught in moving parts.

g) If devices are provided for the connection of

dust extraction and collection facilities, ensure these are connected and properly

used. Use of these devices can reduce

dust-related hazards.

4) Power tool use and care

a) Do not force the power tool. Use the correct

power tool for your application. The cor-

rect power tool will do the job better and

safer at the rate for which it was designed.

b)Do not use the power tool if the switch does

not turn it on and off. Any power tool that

cannot be controlled with the switch is

dangerous and must be repaired.

c) Disconnect the plug from the power source

and/or the battery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools. Such

preventive safety measures reduce the

risk of starting the power tool accidentally.

d)Store idle power tools out of the reach of

children and do not allow persons unfamiliar with the power tool or these instructions

to operate the power tool. Power tools are

dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalign-

ment or binding of moving parts, breakage

of parts and any other condition that may

affect the power tools operation. If damaged, have the power tool repaired before

use. Many accidents are caused by poorly

maintained power tools.

f) Keep cutting tools sharp and clean. Prop-

erly maintained cutting tools with sharp

cutting edges are less likely to bind and are

easier to control.

g) Use the power tool, accessories and tool

bits etc., in accordance with these instructions and in the manner intended for the

particular type of power tool, taking into

account the working conditions and the

work to be performed. Use of the power

tool for operations different from those

intended could result in a hazardous situation.

5) Service

a) Have your power tool serviced by a quali-

fied repair person using only identical replacement parts. This will ensure that the

safety of the power tool is maintained.

Special safety instructions.

Safety Warnings common for Grinding,

Sanding, Wire Brushing or Abrasive

Cutting Off Operations

This power tool is intended to function as a

grinder, sander, wire brush or cut-off tool.

Read all safety warnings, instructions, illustrations and specifications provided with this

power tool. Failure to follow all instructions

listed below may result in electric shock, fire

and/or serious injury.

This power tool is not recommended for polishing. Operations for which the power tool was

not designed may create a hazard and cause

personal injury.

Do not use accessories which are not specifically designed and recommended by the tool

manufacturer. Just because the accessory can

be attached to your power tool, it does not

assure safe operation.

The rated speed of the accessory must be at

least equal to the maximum speed marked on

the power tool. Accessories running faster

than their rated speed can break and fly apart.

The outside diameter and the thickness of your

accessory must be within the capacity rating of

your power tool. Incorrectly sized accessories

cannot be adequately guarded or controlled.

3 41 01 121 21 0.book Seite 4 Montag, 22. August 2011 1:11 13

5

en

The arbor size of wheels, flanges, backing pads

or any other accessory must properly fit the

spindle of the power tool. Accessories with

arbor holes that do not match the mounting

hardware of the power tool will run out of

balance, vibrate excessively and may cause

loss of control.

Do not use a damaged accessory. Before each

use inspect the accessory such as abrasive

wheels for chips and cracks, backing pad for

cracks, tear or excess wear, wire brush for

loose or cracked wires. If power tool or accessory is dropped, inspect for damage or install

an undamaged accessory. After inspecting and

installing an accessory, position yourself and

bystanders away from the plane of the rotating

accessory and run the power tool at maximum

no-load speed for one minute. Damaged acces-

sories will normally break apart during this

test time.

Wear personal protective equipment. Depending on application, use face shield, safety goggles or safety glasses. As appropriate, wear

dust mask, hearing protectors, gloves and

workshop apron capable of stopping small

abrasive or workpiece fragments. The eye

protection must be capable of stopping flying

debris generated by various operations. The

dust mask or respirator must be capable of filtrating particles generated by your operation.

Prolonged exposure to high intensity noise

may cause hearing loss.

Keep bystanders a safe distance away from

work area. Anyone entering the work area must

wear personal protective equipment. Frag-

ments of workpiece or of a broken accessory

may fly away and cause injury beyond immediate area of operation.

Hold the power tool by insulated gripping surfaces only, when performing an operation

where the cutting accessory may contact hidden wiring or its own cord. Cutting accessory

contacting a “live” wire may make exposed

metal parts of the power tool “live” and could

give the operator an electric shock.

Position the cord clear of the spinning accessory. If you lose control of the power tool,

the cord may be cut or snagged and your

hand or arm may be pulled into the spinning

accessory.

Never lay the power tool down until the accessory has come to a complete stop. The spin-

ning accessory may grab the surface and pull

the power tool out of your control.

Do not run the power tool while carrying it at

your side. Accidental contact with the spin-

ning accessory could snag your clothing, pulling the accessory into your body.

Regularly clean the power tool’s air vents. The

motor’s fan will draw the dust inside the

housing and excessive accumulation of powdered metal may cause electrical hazards.

Do not operate the power tool near flammable

materials. Sparks could ignite these materials.

Do not use accessories that require liquid coolants. Using water or other liquid coolants

may result in electrocution or shock.

Kickback and related warnings

Kickback is a sudden reaction to a pinched or

snagged rotating wheel, backing pad, brush or

any other accessory. Pinching or snagging

causes rapid stalling of the rotating accessory

which in turn causes the uncontrolled power

tool to be forced in the direction opposite of

the accessory’s rotation at the point of the

binding.

For example, if an abrasive wheel is snagged

or pinched by the workpiece, the edge of the

wheel that is entering into the pinch point can

dig into the surface of the material causing the

wheel to climb out or kick out. The wheel

may either jump toward or away from the

operator, depending on direction of the

wheel’s movement at the point of pinching.

Abrasive wheels may also break under these

conditions.

Kickback is the result of power tool misuse

and/or incorrect operating procedures or

conditions and can be avoided by taking

proper precautions as given below.

3 41 01 121 21 0.book Seite 5 Montag, 22. August 2011 1:11 13

6

en

Maintain a firm grip on the power tool and position your body and arm to allow you to resist

kickback forces. Always use auxiliary handle, if

provided, for maximum control over kickback

or torque reaction during start-up. The opera-

tor can control torque reactions or kickback

forces, if proper precautions are taken.

Never place your hand near the rotating accessory. Accessory may kickback over your

hand.

Do not position your body in the area where

power tool will move if kickback occurs. Kick-

back will propel the tool in direction opposite

to the wheel’s movement at the point of snagging.

Use special care when working corners, sharp

edges, etc. Avoid bouncing and snagging the

accessory. Corners, sharp edges or bouncing

have a tendency to snag the rotating accessory and cause loss of control or kickback.

Do not attach a saw chain woodcarving blade

or toothed saw blade. Such blades create fre-

quent kickback and loss of control over the

power tool.

Safety warnings specific for grinding

and abrasive cutting-off operations

Use only wheel types that are recommended for

your power tool and the specific guard

designed for the selected wheel. Wheels for

which the power tool was not designed cannot be adequately guarded and are unsafe.

The guard must be securely attached to the

power tool and positioned for maximum safety,

so the least amount of wheel is exposed

towards the operator. The guard helps to pro-

tect operator from broken wheel fragments,

accidental contact with wheel and sparks that

could ignite clothing.

Wheels must be used only for recommended

applications. For example: do not grind with the

side of cut-off wheel. Abrasive cut-off wheels

are intended for peripheral grinding, side

forces applied to these wheels may cause

them to shatter.

Always use undamaged wheel flanges that are

of correct size and shape for your selected

wheel. Proper wheel flanges support the

wheel thus reducing the possibility of wheel

breakage. Flanges for cut-off wheels may be

different from grinding wheel flanges.

Do not use worn down wheels from larger

power tools. Wheels intended for larger

power tools are not suitable for the higher

speed of a smaller tool and may burst.

Additional safety warnings specific for

abrasive cutting off operations

Do not “jam” the cut-off wheel or apply excessive pressure. Do not attempt to make an

excessive depth of cut. Overstressing the

wheel increases the loading and susceptibility

to twisting or binding of the wheel in the cut

and the possibility of kickback or wheel

breakage.

Do not position your body in line with and

behind the rotating wheel. When the wheel, at

the point of operation, is moving away from

your body, the possible kickback may propel

the spinning wheel and the power tool

directly at you.

When wheel is binding or when interrupting a

cut for any reason, switch off the power tool

and hold the power tool motionless until the

wheel comes to a complete stop. Never attempt

to remove the cut-off wheel from the cut while

the wheel is in motion otherwise kickback may

occur. Investigate and take corrective action

to eliminate the cause of wheel binding.

Do not restart the cutting operation in the

workpiece. Let the wheel reach full speed and

carefully reenter the cut. The wheel may bind,

walk up or kickback if the power tool is

restarted in the workpiece.

Support panels or any oversized workpiece to

minimize the risk of wheel pinching and kickback. Large workpieces tend to sag under

their own weight. Supports must be placed

under the workpiece near the line of cut and

near the edge of the workpiece on both sides

of the wheel.

Use extra caution when making a “pocket cut”

into existing walls or other blind areas. The

protruding wheel may cut gas or water pipes,

electrical wiring or objects that can cause

kickback.

3 41 01 121 21 0.book Seite 6 Montag, 22. August 2011 1:11 13

7

en

Safety warnings specific for sanding

operations

Do not use excessively oversized sanding disc

paper. Follow manufacturers recommendations, when selecting sanding paper. Larger

sanding paper extending beyond the sanding

pad presents a laceration hazard and may

cause snagging, tearing of the disc, or kickback.

Safety warnings specific for wire

brushing operations

Be aware that wire bristles are thrown by the

brush even during ordinary operation. Do not

overstress the wires by applying excessive load

to the brush. The wire bristles can easily pen-

etrate light clothing and/or skin.

If the use of a guard is recommended for wire

brushing, do not allow any interference of the

wire wheel or brush with the guard. Wire

wheel or brush may expand in diameter due

to work load and centrifugal forces.

Additional safety warnings

Use elastic spacers/liners when these are provided with the grinding accessory.

Make absolutely sure that the accessory is

mounted in accordance with the manufacturer’s instructions. The mounted accessory

must be able to rotate freely. Incorrectly

mounted accessories can loosen during operation and fly off.

Handle accessories carefully and store them

according to the manufacturer’s instructions.

Damaged accessories can form cracks and

break off during operation.

When using application tools with a threaded

insert, take care that the thread in the application tool is long enough to hold the spindle

length of the power tool. The thread in the

application tool must match the thread on the

spindle. Incorrectly mounted application tools

can loosen during operation and cause injuries.

Beware of any concealed electric cables, gas or

water conduits; check the working area with a

metal detector, for example, before commencing work.

Use a stationary extraction system, blow out

ventilation slots frequently and connect a

residual current device (RCD) on the line side.

When working metal under extreme operating conditions, it is possible for conductive

dust to settle in the interior of the power

tool. The total insulation of the power tool

can be impaired.

This double-insulated power tool is equipped

with a polarized plug (one contact is wider than

the other). The plug will only fit into the polarized socket outlet in one position. Turn the plug

if it does not fit completely into the socket outlet. If the plug still does not fit, have a qualified

electrician install a polarized socket outlet. Do

not modify or alter the plug under any circumstances. Double-insulated power tools nei-

ther require a three-core power cable nor a

power connection with ground contact.

Operate the power tool only off of power supplies whose voltage and frequency values correspond with the values on the type plate of the

power tool.

When operating the power tool in a damp environment, it must be connected via a groundfault circuit interrupter (g.f.c.i.). Using special

rubber protective gloves and footwear

increase your own safety.

Recommendation: The tool should always be

supplied with power via a residual current

device (RCD) with a rated current of 30 mA or

less.

Use clamps or another practical way to secure

and support the workpiece to a stable platform.

Holding the work by hand or against your

body leaves it unstable and may lead to loss of

control.

Before mounting or replacing application tools

or accessories, pull the power plug. This pre-

ventive safety measure rules out the danger of

injuries through accidental starting of the

power tool.

3 41 01 121 21 0.book Seite 7 Montag, 22. August 2011 1:11 13

8

en

Use appropriate detectors to determine if utility

lines are hidden in the work area or call the

local utility company for assistance. Contact

with electric lines can lead to fire and electric

shock. Damaging a gas line can lead to explosion. Penetrating a water line causes property

damage or may cause an electric shock.

Do not direct the power tool against yourself,

other persons or animals. Danger of injury

from sharp or hot application tools.

Do not rivet or screw any name-plates or signs

onto the power tool. If the insulation is dam-

aged, protection against an electric shock will

be ineffective. Adhesive labels are recommended.

Always work using the auxiliary handle. The

auxiliary handle ensures reliable guidance of

the power tool.

Before putting into operation, check the main

connection and the main plug for damage.

Handling hazardous dusts.

When working with power

tools, such as when grinding,

sanding, polishing, sawing or for other work

procedures where material is removed, dusts

develop that are both hazardous to one’s health

and can spontaneously combust or be explosive.

Contact with or inhaling some dust types can

trigger allergic reactions to the operator or

bystanders and/or lead to respiratory infections, cancer, birth defects or other reproductive harm.

Examples of such materials and therein contained chemicals, where hazardous dusts can

develop when working them, are:

– Asbestos and materials containing asbestos;

– Lead-containing coatings, some wood types

such as beech and oak;

– Minerals and metal;

– Silicate particles from bricks, concrete and

other materials containing stone;

– Solvent from solvent-containing paint/var-

nish;

– Arsenic, chromium and other wood pre-

servatives;

– Materials for pesticide treatment on boot

and ship hulls;

To minimise the unwanted intake of these

materials:

– Use dust extraction matched appropriately

for the developing dust.

– Use personal protective equipment, such as

a P2 filter-class dust protection mask.

– Provide for good ventilation of the work-

place.

The risk from inhaling dusts depends on the

frequency how often these materials are worked. Materials containing asbestos may only

be worked by specialists.

Wood and light-metal dust can

cause spontaneous combustion

or explosions.

Hot mixtures of sanding dust and paint/varnish remainders or other chemical materials

in the filter bag or the vac filter can self-ignite

under unfavorable conditions, such as sparking from sanding metal, continuous sunlight

or high ambient temperatures. To prevent

this:

– Avoid overheating the material being san-

ded and the power tool.

– Empty the dust collector/container in time.

– Observe the material manufacturer’s wor-

king instructions.

Observe the relevant regulations in your

country for the materials being worked.

WARNING

CAUTION

3 41 01 121 21 0.book Seite 8 Montag, 22. August 2011 1:11 13

9

en

Hand/arm vibrations

While working with this power

tool, hand/arm vibrations

occur. These can lead to health impairments.

The vibration emission value

during actual use of the power

tool can differ from the declared value

depending on the ways in which the tool is

used.

It is necessary to identify

safety measures to protect the

operator that are based on an estimation of

exposure in the actual conditions of use.

The vibration emission level given in this

information sheet has been measured in

accordance with a standardised test given in

EN 60745 and may be used to compare one

tool with another. It may be used for a preliminary assessment of exposure.

The declared vibration emission level represents the main applications of the tool. However if the tool is used for different

applications, with different accessories or

poorly maintained, the vibration emission

may differ. This may significantly increase the

exposure level over the total working period.

An estimation of the level of exposure to

vibration should also take into account the

times when the tool is switched off or when

it is running but not actually doing the job.

This may significantly reduce the exposure

level over the total working period.

Identify additional safety measures to protect

the operator from the effects of vibration

such as: maintain the tool and the accessories,

keep the hands warm, organisation of work

patterns.

WARNING

WARNING

WARNING

3 41 01 121 21 0.book Seite 9 Montag, 22. August 2011 1:11 13

10

en

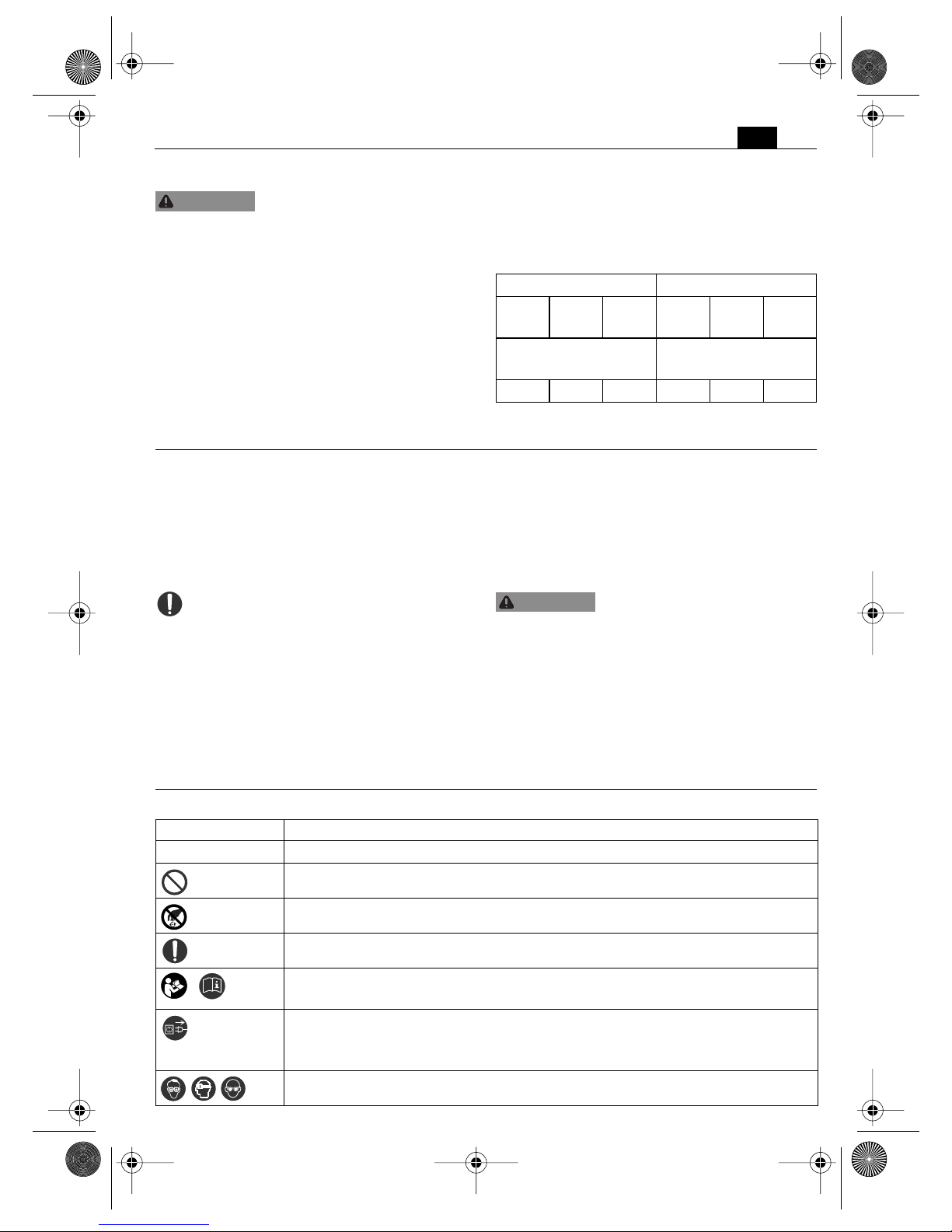

Emission values for sound and vibration (Two-figure – specifications as per ISO 4871)

Sound emission WSG10-115T WSG14-125T WSG14-150T WSG14-70ET WSS14-125T

A-weighted emission pressure power level measured

at the workplace LpA

(re 20 µPa),

in decibels 85 85 85 85 85

Measuring uncertainty KpA,

in decibels 33333

Measured A-weighted

sound power level LwA

(re 1 pW), in decibels 96 96 96 96 96

Measuring uncertainty

KwA, in decibels 33333

C-weighted peak sound

pressure level measured at

the workplace L

pCpeak

,

in decibels

99 99 101 101 99

Measuring uncertainty

K

pCpeak

, in decibels

33333

Vibrations

Vibration emission value

(triax vector sum) determined according to EN 60745

Mean vibrational value for

angle grinding , in

m/s

2

ft/s

2

5.0

15

5.0

15

4.5

13.5

4.5

13.5

5.0

15

Mean vibrational value for

sanding with sanding sheet

, in

m/s

2

ft/s

2

2.5

7.5

2.5

7.5

2.5

7.5

2.5

7.5

2.5

7.5

Measuring uncertainty K, in

m/s

2

ft/s

2

1.5

4.5

1.5

4.5

1.5

4.5

1.5

4.5

1.5

4.5

REMARK: The sum of the measured emission value and respective measuring inaccuracy represents the upper limit of the values that can occur during measuring.

Wear ear protection!

Measured values determined in accordance with the corresponding product standard.

h,AG

h,DS

3 41 01 121 21 0.book Seite 10 Montag, 22. August 2011 1:11 13

11

en

Extension cord

If the use of an extension cable

is required, its length and conductor cross-section must be adequate for the

applicational case, in order to prevent a voltage drop in the extension cable, power loss and

overheating of the power tool. Otherwise, the

extension cable and power tool are liable to

electrical danger, and the working efficiency is

impaired.

Recommended dimensions of extension cords

at an operating voltage of 120 V – single-phase

a. c., with only one power tool WSG10/WSG14/

WSS14 connected:

Intended use of the power tool.

Hand-guided angle grinder for dry grinding/

roughing and cutting of metal and stone in

weather-protected environments with the

application tools and accessories recommended by FEIN.

Operation of the power tool off power generators.

This machine is also intended to be pow-

ered by a. c. generators with sufficient

power output that correspond with

ISO 8528, design class G2. Compliance with

this Standard in particular is not given when

the so-called distortion factor exceeds 10%.

When in doubt, inform yourself about the

generator in use.

Operating the power tool off

power generators whose noload speed exceeds the voltage value on the

type plate of the power tool is prohibited.

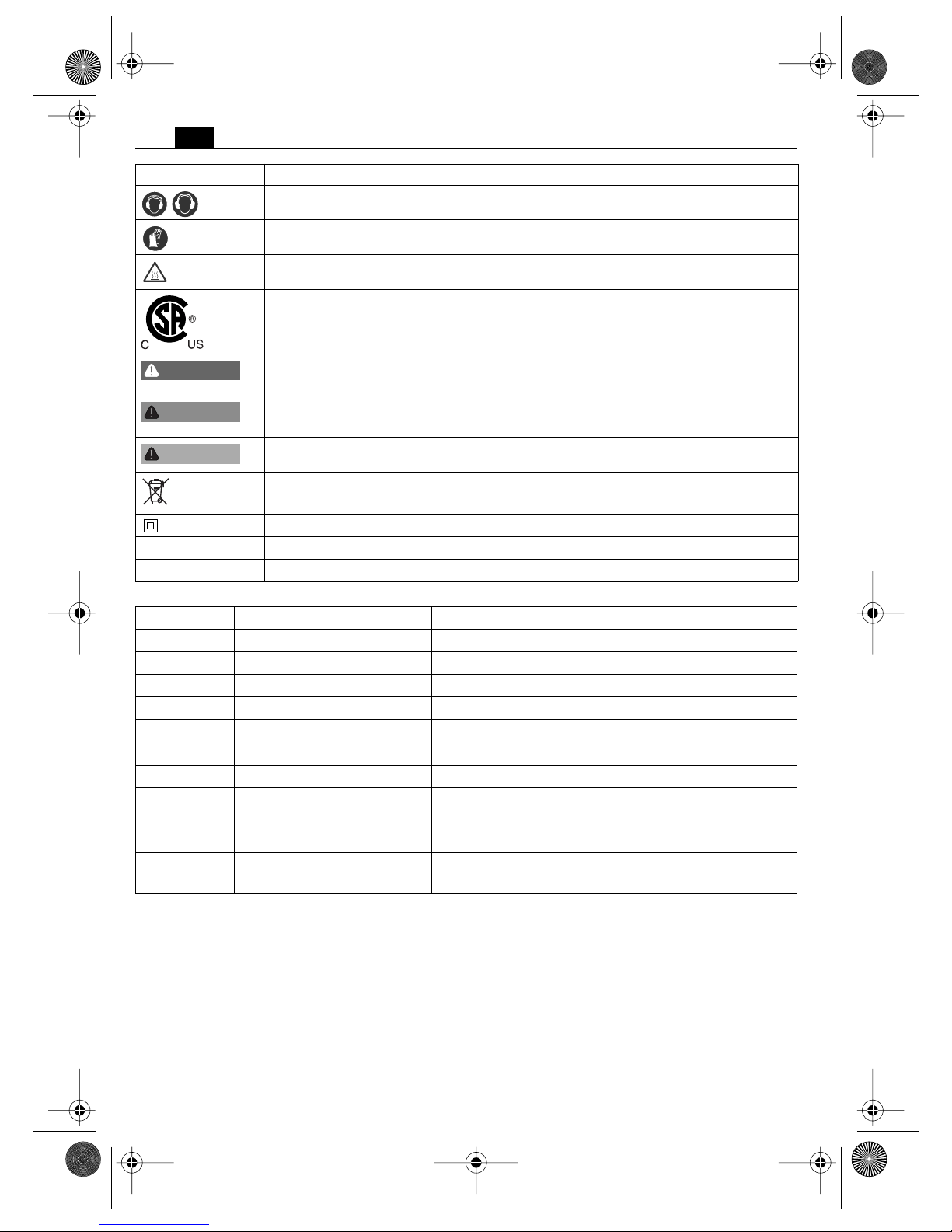

Symbols.

WARNING

Max. cable length, ft Max. cable length, m

≤ 100 100

–200

200

–300

≤ 30 30

– 6060–100

Min. conductor size

(A.W.G.)

Min. conductor

cross-section, mm

2

16 14 12 1.5 2.5 4

WARNING

Symbol, character Explanation

➤

Action to be taken by the user

General prohibition sign. This action is forbidden!

Do not touch the rotating grinding wheels.

Observe the instructions in the text or graphic opposite!

Be absolutely sure to read the enclosed documentation such as the Instruction Manual and the General Safety Instructions.

Before commencing this working step, pull the mains plug out of the

socket. Otherwise there will be danger of injury if the power tool should

start unintentionally.

Use eye-protection during operation.

3 41 01 121 21 0.book Seite 11 Montag, 22. August 2011 1:11 13

12

en

Use ear protection during operation.

Use protective gloves during operation.

An exposed surface is very hot if touched and therefore dangerous.

This symbol confirms the certification of this product for the USA and Canada.

This sign warns of a directly imminent, dangerous situation. A false reaction

can cause a severe or fatal injury.

This sign indicates a possible dangerous situation that could cause severe

or fatal injury.

This sign warns of a possible dangerous situation that could cause injury.

Worn out power tools and other electrotechnical and electrical products

should be sorted separately for environment-friendly recycling.

Product with double or reinforced insulation

~ or a. c. Alternating current

1 ~ Alternating current single-phase

Symbol, character Explanation

DANGER

WARNING

CAUTION

Character Unit of measure, national Explanation

n rpm; /min Rated speed

P W Unit of measure for electrical power

° Unit of measure for the angle width

U V Unit of measure for the electric voltage

f Hz Unit of measure for the frequency

I A Unit of measure for the electric current intensity

m kg, lbs Unit of measure for the mass

l ft, in Unit of measure for length, width, height, depth,

diameter or thread

Ø ft, in Diameter of a round part

m, s, kg, A, mm, V, W, Hz,

N, °C, dB, min, m/s

2

Basic and derived units of measure from the international system of units SI.

3 41 01 121 21 0.book Seite 12 Montag, 22. August 2011 1:11 13

13

en

Technical description and specifications.

Before mounting or replacing application tools or accessories, pull the power

plug. This preventive safety measure rules out the danger of injuries through

accidental starting of the power tool.

Only part of the accessories described or shown in this instruction manual will be included

with your power tool.

WARNING

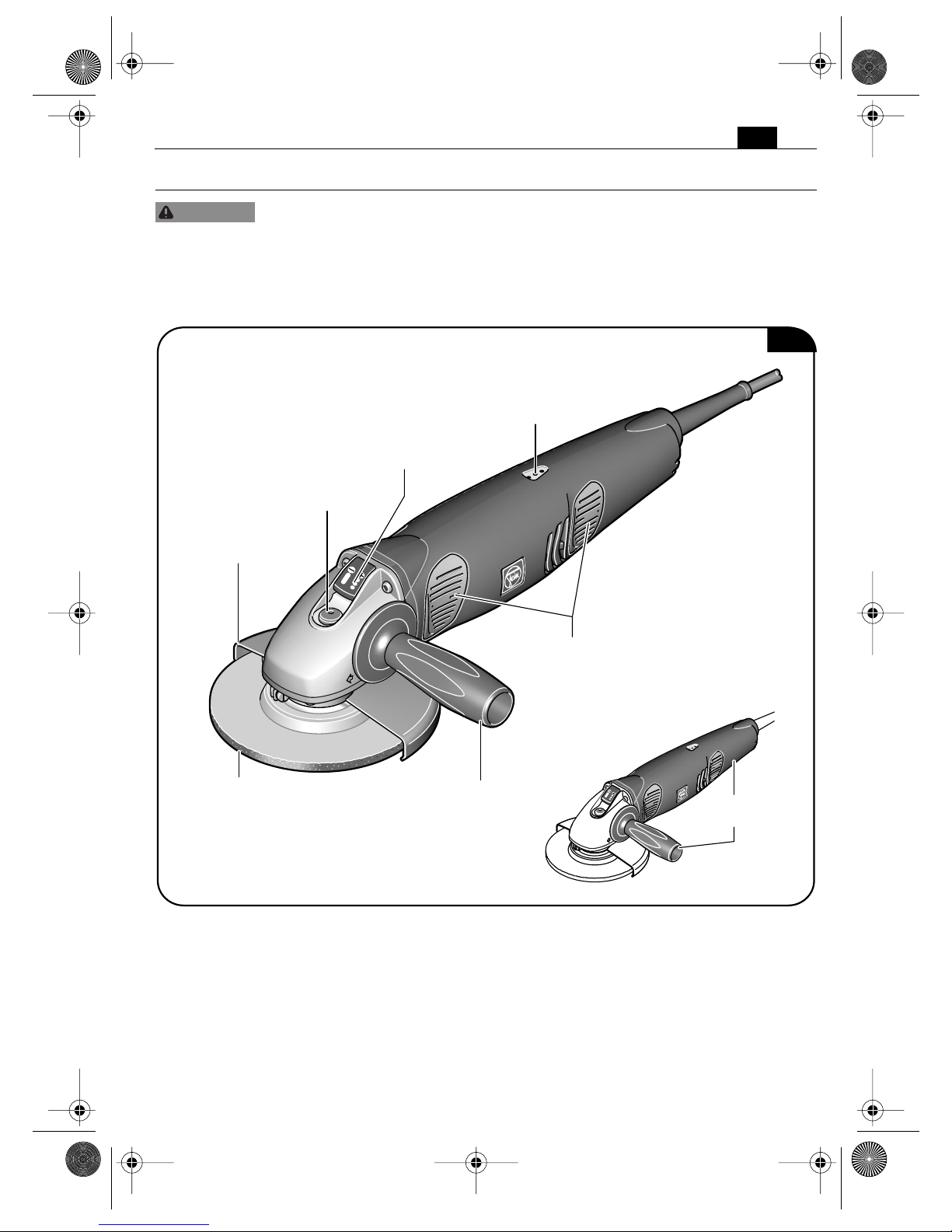

Grinding disc

Auxiliary handle

Fig. 1

Wheel guard

Locking button

WSG10-115T

WSG14-125T

WSG14-150T

WSG14-70ET

Speed regulation

button

(WSG14-70ET)

Speed display

(WSG14-70ET)

Pressing surface (4x)

Gripping surface

3 41 01 121 21 0.book Seite 13 Montag, 22. August 2011 1:11 13

14

en

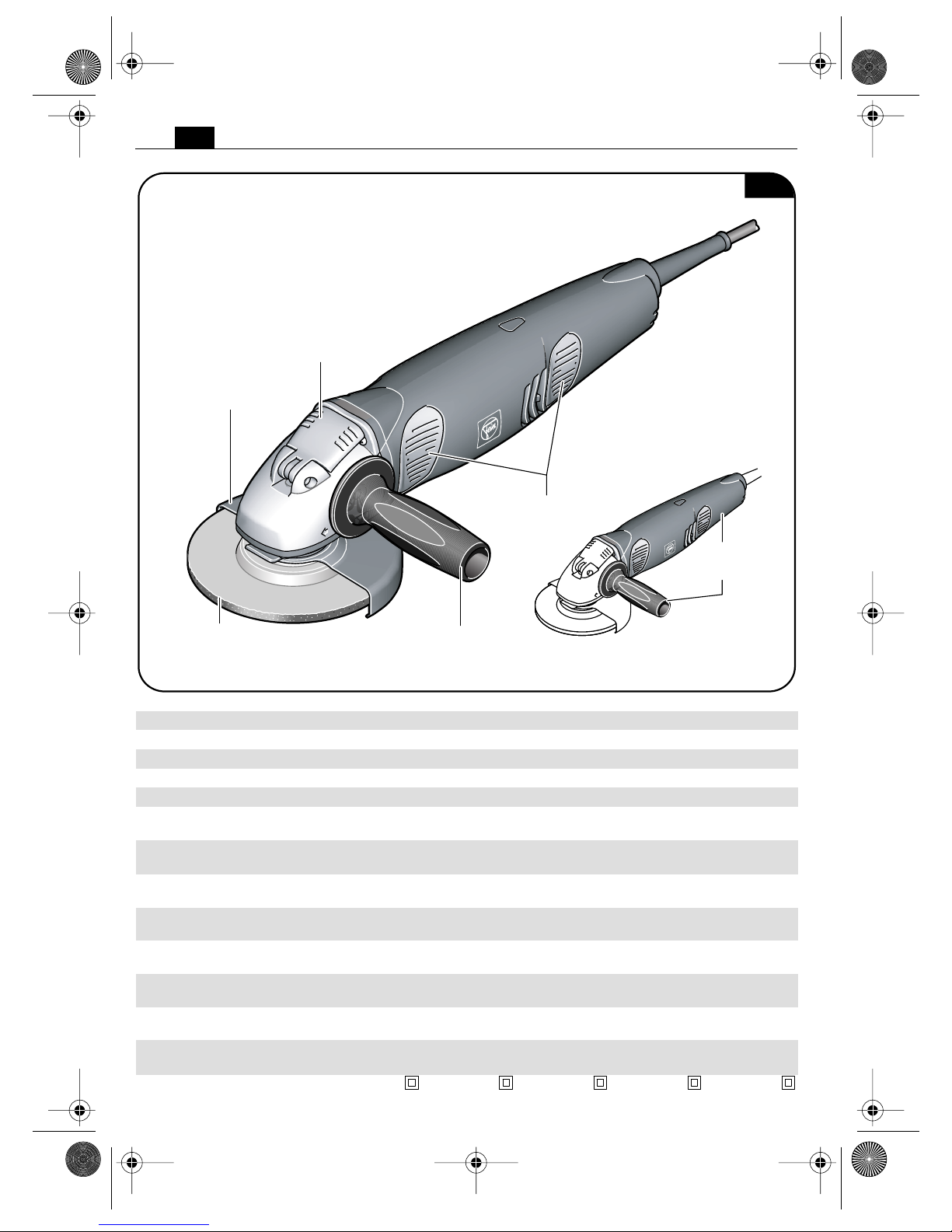

WSS14-125T

Grinding disc

Auxiliary handle

Fig. 2

Wheel guard

Rapid-clamping lever

Pressing

surface (4x)

Gripping

surface

Type WSG10-115T WSG14-125T WSG14-150T WSG14-70ET WSS14-125T

Reference number 7 221 55 7 221 56 7 221 57 7 221 58 7 221 54

Power input 800 W 1200 W 1200 W 1200 W 1200 W

Output 550 W 750 W 750 W 750 W 750 W

Power supply type 1 ~ 1 ~ 1 ~ 1 ~ 1 ~

Rated speed 10000/min 10000/min 7000/min 2500–

7000/min

10000/min

max. diameter of grinding/cutting

disc

4 1/2 in

115 mm

5 in

125 mm

6 in

150 mm

5 in

125 mm

5 in

125 mm

Diameter of mounting hole 7/8 in

22.23 mm

7/8 in

22.23 mm

7/8 in

22.23 mm

7/8 in

22.23 mm

7/8 in

22.23 mm

Thickness of grinding/cutting disc 1/16 in–1/4 in

1–6 mm

1/16 in–1/4 in

1–6 mm

1/16 in–1/4 in

1–6 mm

1/16 in–1/4 in

1–6 mm

1/16 in–1/4 in

1–6 mm

max. diameter of backing pad 4 1/2 in

115 mm

4 1/2 in–5 in

115/125 mm

6 in

150 mm

5 in

125 mm

4 1/2 in–5 in

115/125 mm

Thread for clamping flange 5/8 in–

11 UNC

5/8 in–

11 UNC

5/8 in–

11 UNC

5/8 in–

11 UNC

–

Length of mounting thread 3/4 in

20 mm

3/4 in

20 mm

3/4 in

20 mm

3/4 in

20 mm

–

Weight according to

EPTA-Procedure 01/2003

4.4 lbs

(2.0 kg)

5.0 lbs

(2.3 kg)

5.3 lbs

(2.4 kg)

5.3 lbs

(2.4 kg)

5.3 lbs

(2.4 kg)

Class of protection II II II II II

3 41 01 121 21 0.book Seite 14 Montag, 22. August 2011 1:11 13

15

en

Assembly instructions.

Before mounting or replacing application tools or accessories, pull the power

plug. This preventive safety measure rules out the danger of injuries through

accidental starting of the power tool.

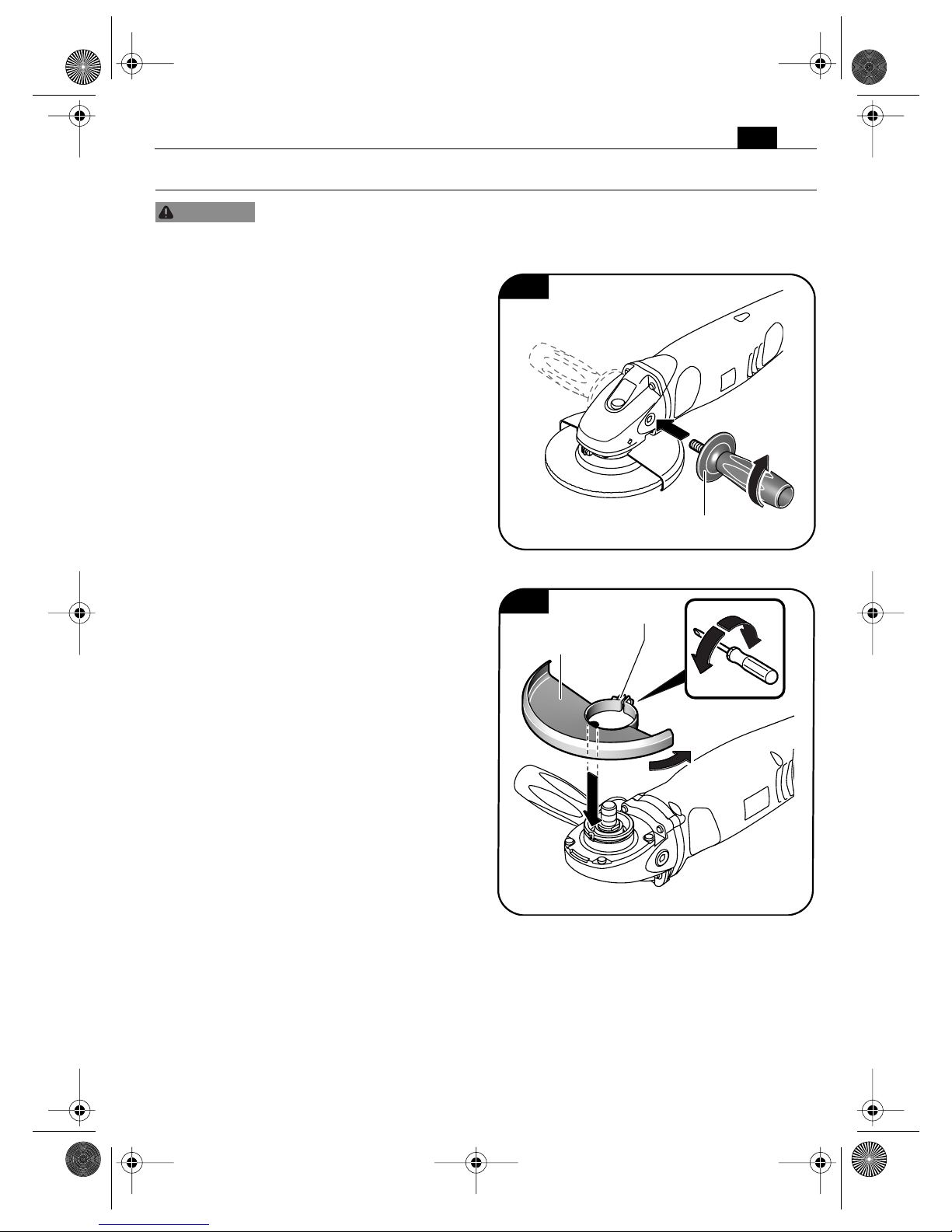

Mounting the auxiliary handle

(Figure 3).

➤ Screw the auxiliary handle tightly onto

the left or right side of the power tool,

depending on the working method.

Mounting the guard (Figure 4)

WSG14-150T/WSG14-70ET.

➤ Loosen the tightening screw.

➤ Insert the clip of the wheel guard into

the groove on the power tool.

➤ Turn the wheel guard to the required

working position and clamp the wheel

guard using the tightening screw.

WARNING

Fig. 3

Auxiliary handle

Fig. 4

Wheel guard

Clamping screw

3 41 01 121 21 0.book Seite 15 Montag, 22. August 2011 1:11 13

16

en

Changing the tool.

Before mounting or replacing application tools or accessories, pull the power

plug. This preventive safety measure rules out the danger of injuries through

accidental starting of the power tool.

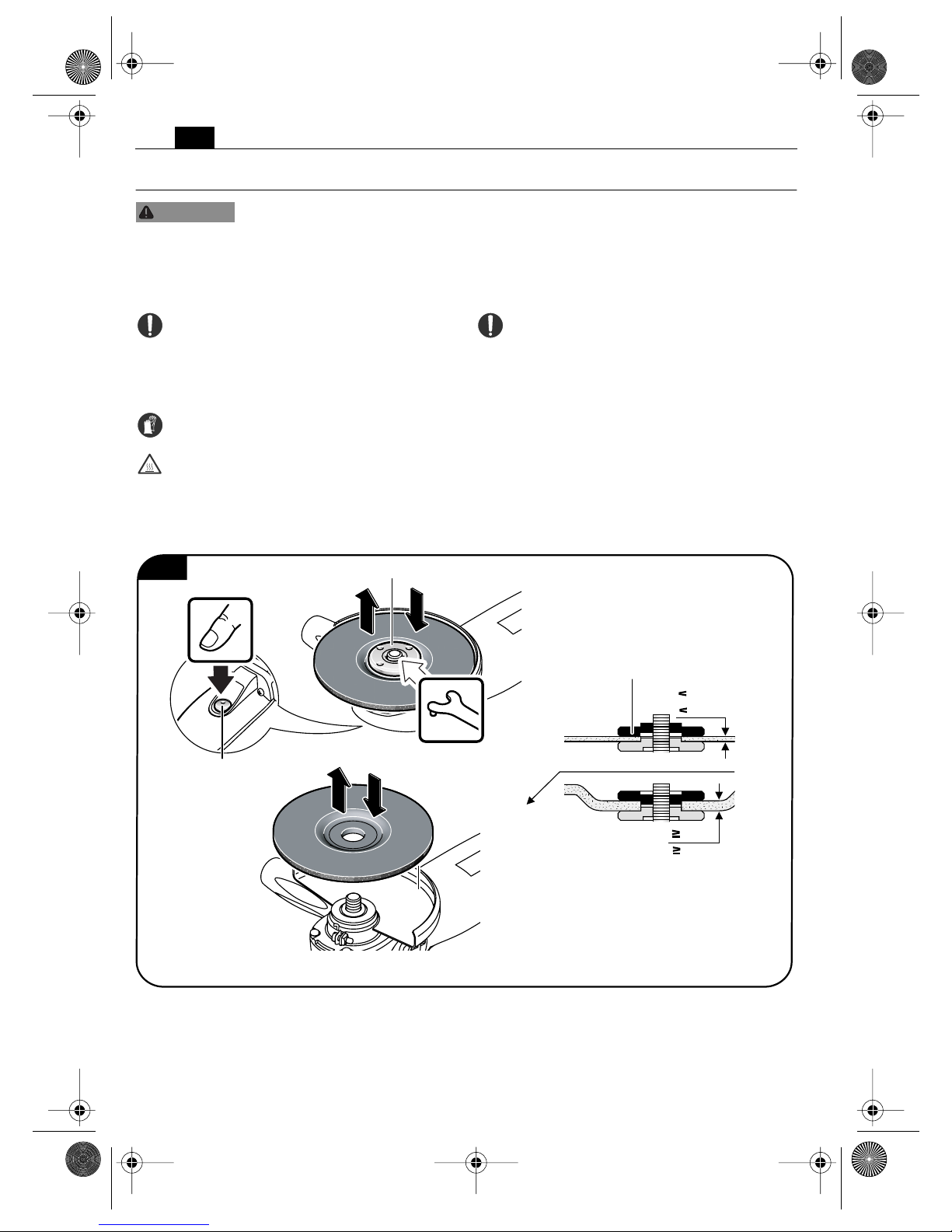

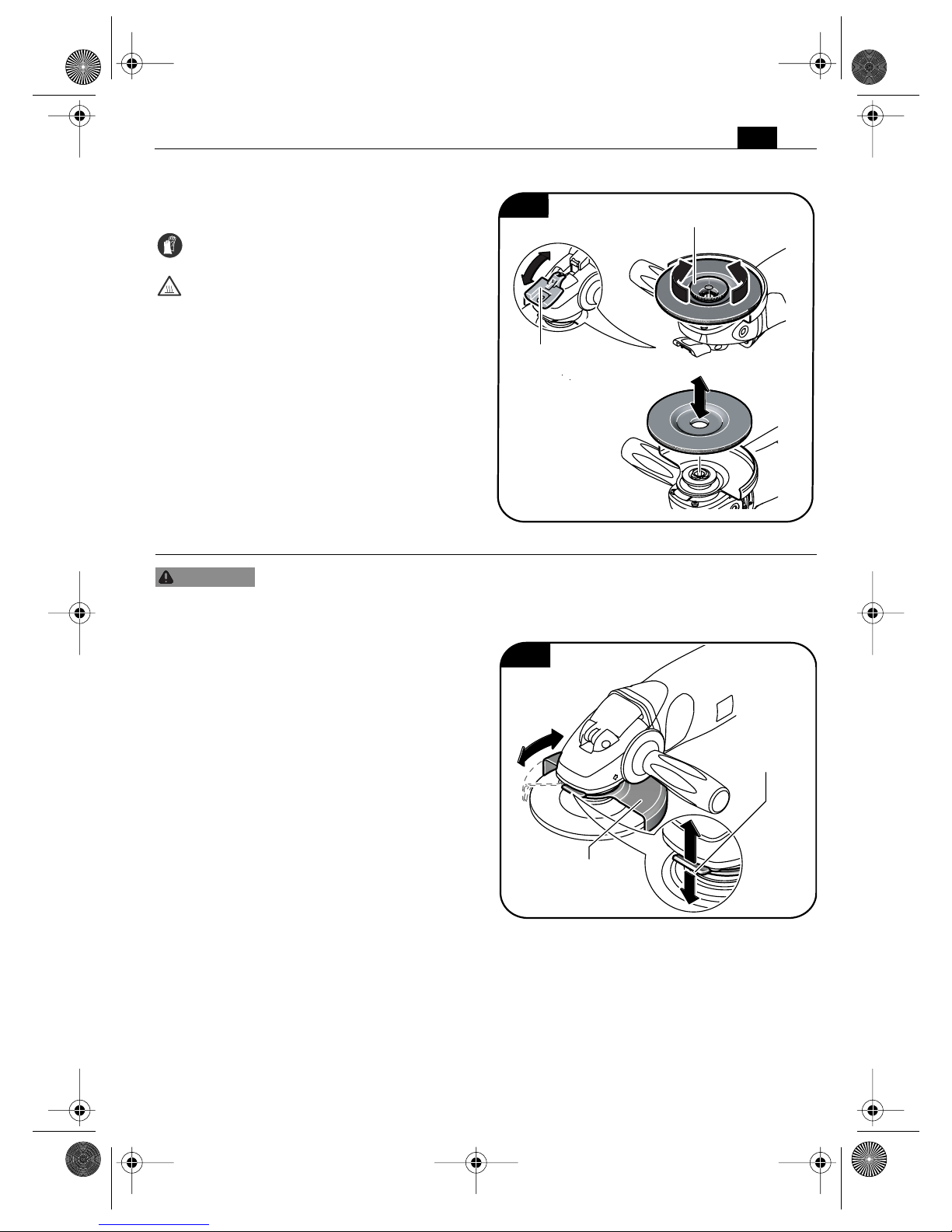

Mounting a grinding disc (Figure 5) WSG10-115T/WSG14-125T/WSG14-150T/

WSG14-70ET.

Only press the locking button when the

motor is not running.

➤ Press the locking button and keep it

pressed down. Undo the threaded flange

using the face spanner.

➤ Completely unscrew the threaded

flange.

➤ Change the used accessory or insert a

new one.

In so doing, make sure that the grinding

tool is centred properly between the

inner and threaded flange.

➤ Screw the threaded flange in again by

hand.

➤ Press the locking button and keep it

pressed down. Screw the threaded

flange tightly using the face spanner.

Note: Pay attention to the mounting direction

of the inner flange, which can vary depending

on the thickness of the grinding disc

(Figure 5).

WARNING

6 mm

1/4 in

6 mm

1/4 in

Fig. 5

Locking button

Threaded flange

Inner flange

3 41 01 121 21 0.book Seite 16 Montag, 22. August 2011 1:11 13

17

en

Mounting a grinding disc (Figure 6) WSS14-125T.

➤ Loosen the quick-clamping lever and

swivel it to the stop.

➤ Completely unscrew the clamping unit

by hand.

➤ Change the used accessory or insert a

new one.

➤ Turn the clamping unit in when the

rapid-clamping lever is open. Manually

tighten the clamping unit until a ratcheting noise starts.

➤ Swivel the quick-clamping lever back

until it engages.

Adjustments.

Before mounting or replacing application tools or accessories, pull the power

plug. This preventive safety measure rules out the danger of injuries through

accidental starting of the power tool.

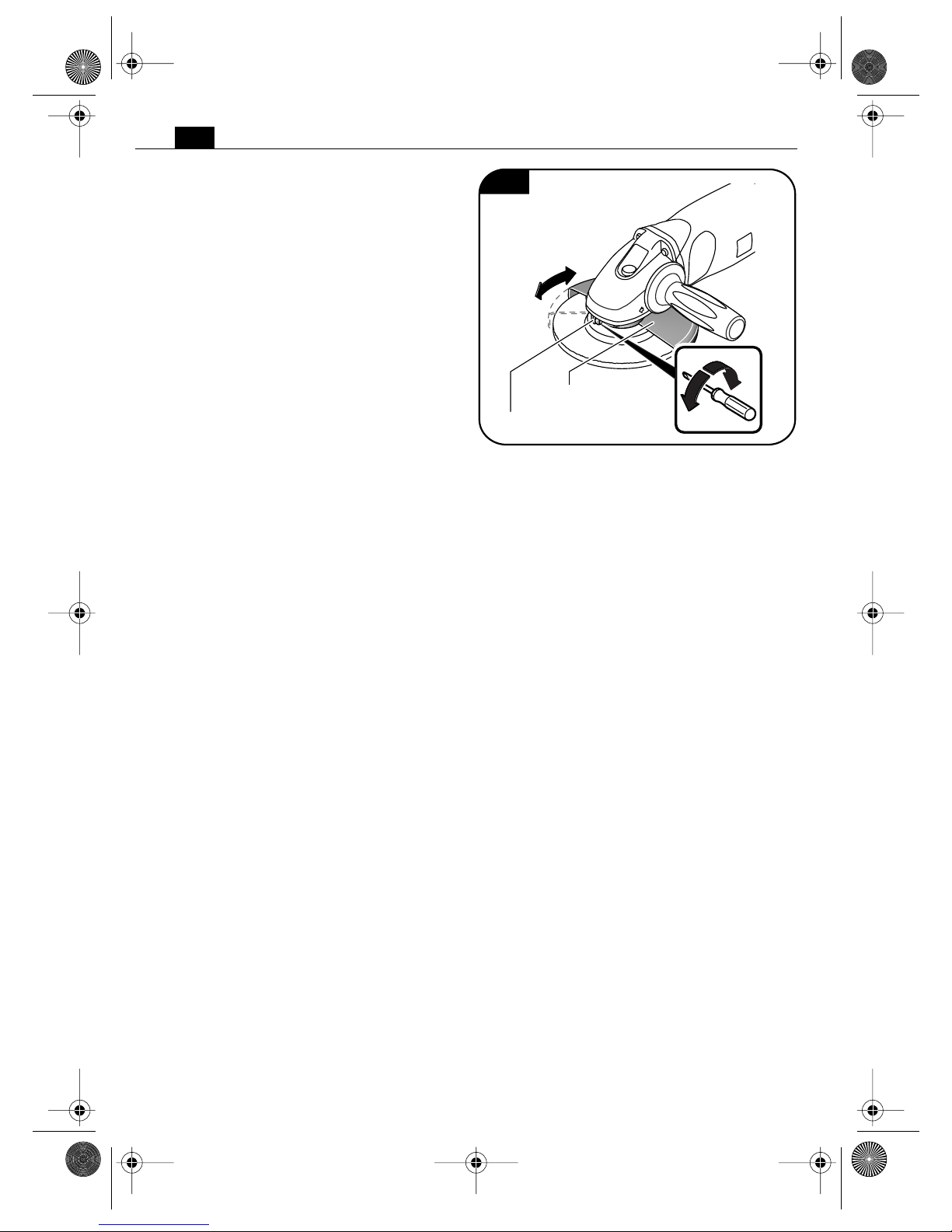

Adjusting the guard (Figure 7)

WSS14-125T/WSG14-125T/

WSG10-115T.

➤ Unclamp the clamping lever.

➤ Swivel the guard into the required

working position.

➤ Notch in the clamping lever.

Fig. 6

Clamping unit

Rapid-clamping

lever

WARNING

Fig. 7

Wheel guard

Clamping lever

3 41 01 121 21 0.book Seite 17 Montag, 22. August 2011 1:11 13

18

en

Adjusting the guard (Figure 8)

WSG14-150T/WSG14-70ET.

➤ Loosen the tightening screw.

➤ Turn the wheel guard to the required

working position and clamp the wheel

guard using the tightening screw.

Fig. 8

Wheel guard

Clamping screw

3 41 01 121 21 0.book Seite 18 Montag, 22. August 2011 1:11 13

19

en

Working instructions.

Before mounting or replacing application tools or accessories, pull the power

plug. This preventive safety measure rules out the danger of injuries through

accidental starting of the power tool.

For each job, use only the FEIN application tool released and intended for the respective

application.

First check that the mains supply lead and mains plug are

not damaged.

Always hold the power tool

firmly. Otherwise, you could

lose control over the power tool.

WSG10T/WSG14T: Press the locking but-

ton only when the motor is stopped.

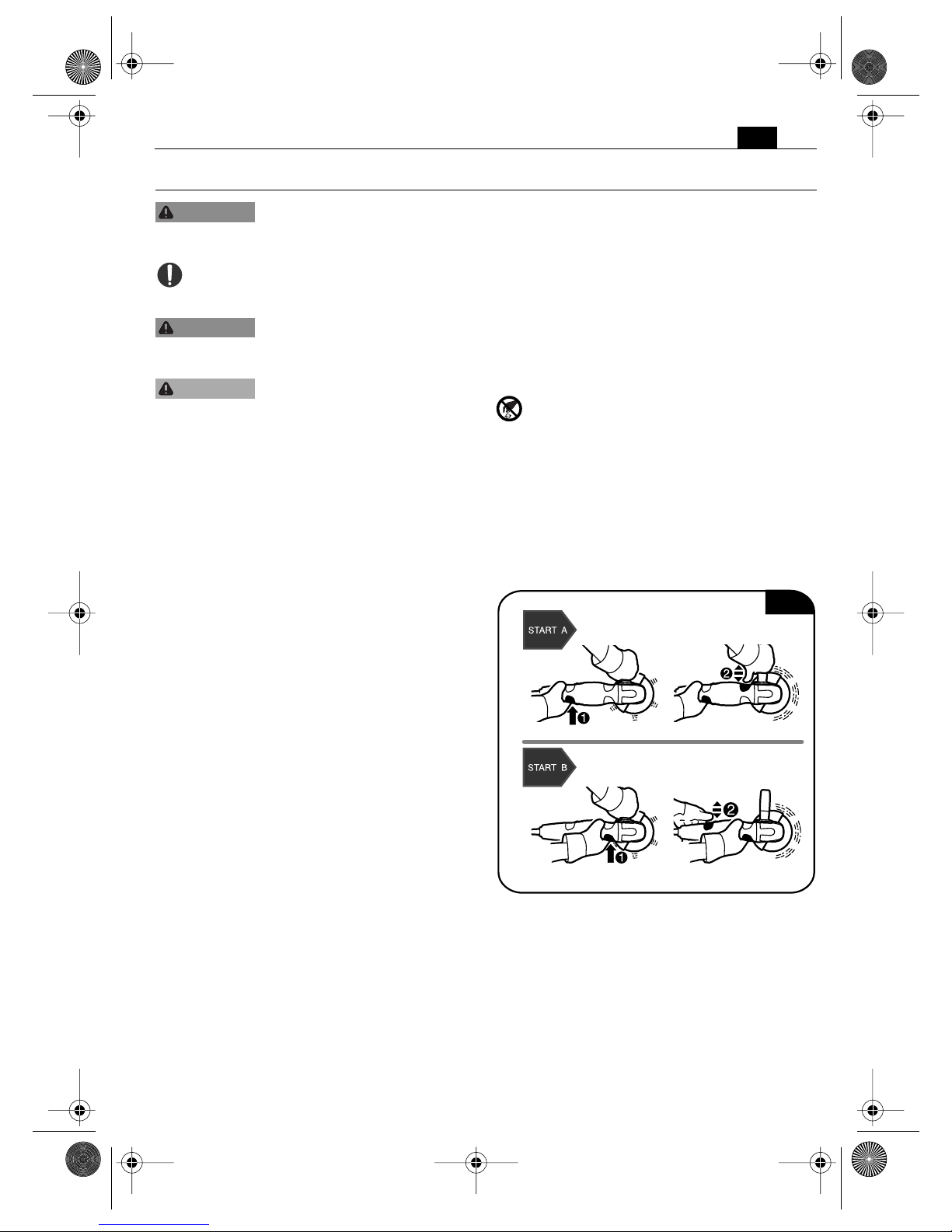

Starting (Figure 9).

After inserting the mains plug, the angle grinder can be started in any working position by

pressing the pressing surfaces twice in succession.

➤ Hold the angle grinder in the required

working position, either at the

back (START A) or front (START B);

lightly press at least one of the 4 pressing

surfaces, and keep it/them pressed.

Please note: The accessory begins to move

with short, low-power impulses. The angle

grinder thereby indicates that the first pressing surface has been activated.

For the working position holding the power

tool at the back (START A):

➤ Briefly press one of the front switch-

pads (close to the auxiliary handle) with

your thumb.

For the working position holding the power

tool at the front (START B):

➤ Briefly press one of the rear switch-

pads.

The angle grinder starts gently and rea-

ches its working speed after a short time.

Please note: The angle grinder does not start

up:

– when the switchpads at the front and rear

are pressed at the same time

– when the rapid-clamping lever is not tilted

back and engaged

– if one or more of the pressing surfaces is/

are pressed while the mains plug is inserted

WARNING

WARNING

CAUTION

➊

➋

➋

Fig. 9

3 41 01 121 21 0.book Seite 19 Montag, 22. August 2011 1:11 13

20

en

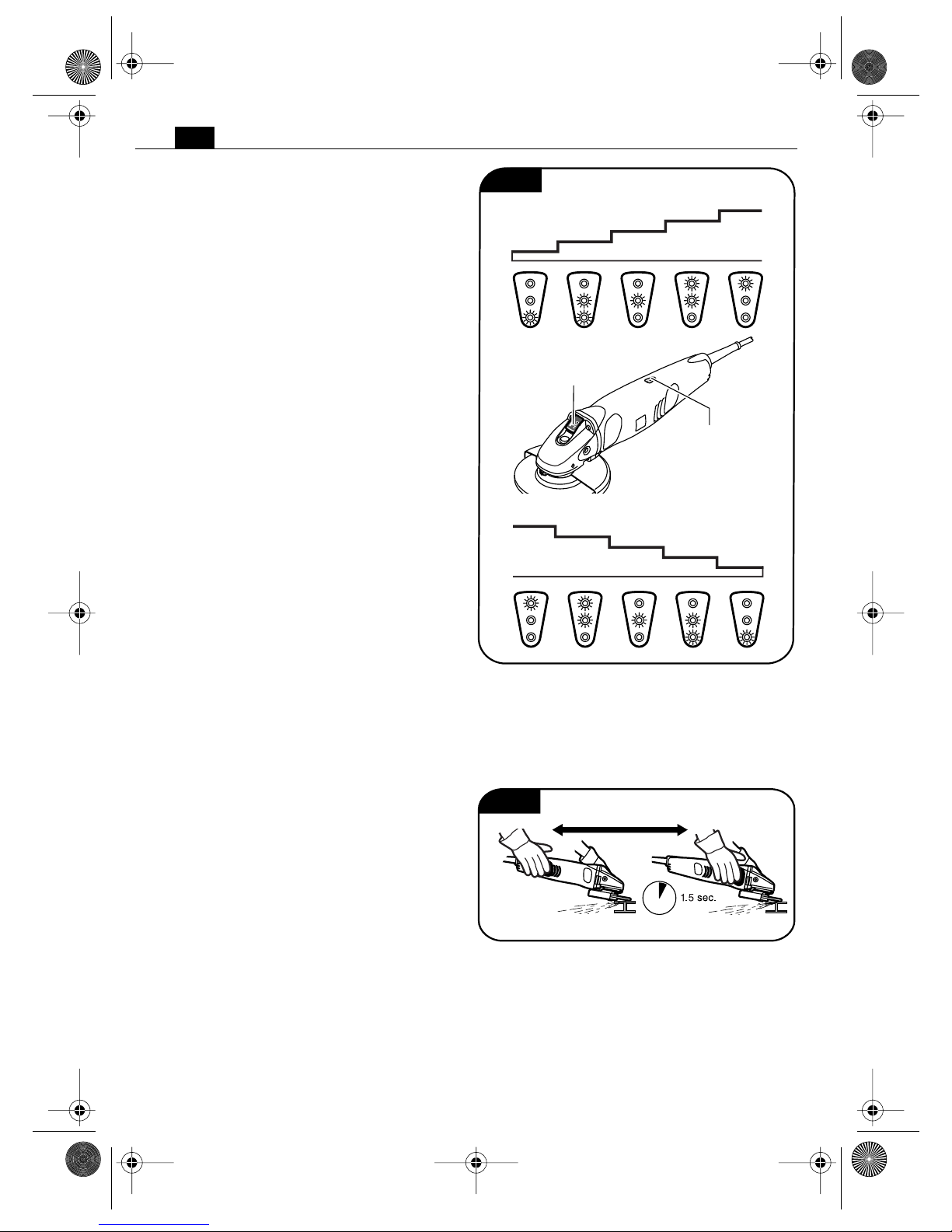

Setting the speed (Figure 10)

WSG14-70ET.

The speed can be set to different levels.

To increase the speed:

➤ Briefly press button.

Reducing the speed:

➤ Keep button pressed down.

The speed set is shown by the symbols on the

speed display.

The last speed setting used is stored in the

power tool after stopping the motor or after

pulling out the mains plug from the mains

socket.

➤ The speed can be preset when the

mains plug is inserted, also when the

motor is at a standstill.

Operation (Figure 11).

➤ Continuously press one of the 4

switchpads. The angle grinder is kept at

working speed.

Notes: The switchpads actuate easily in order

to prevent tense working postures. Changing

the working posture is possible at any time by

changing the switching position. The angle

grinder can be brought up to the working

speed again within 1.5 seconds by pressing

one of the 4 switchpads.

The self-start lock prevents the angle grinder

from automatically restarting again, even after

a brief interruption of the power supply, e.g.,

from a pulled mains plug.

2500/min

3000/min

5000/min

5900/min 7000/min

3500/min

4200/min

2500/min

3000/min

3500/min

5000/min

5900/min7000/min

4200/min

Fig. 10

Speed regulation

button

Speed display

Fig. 11

3 41 01 121 21 0.book Seite 20 Montag, 22. August 2011 1:11 13

21

en

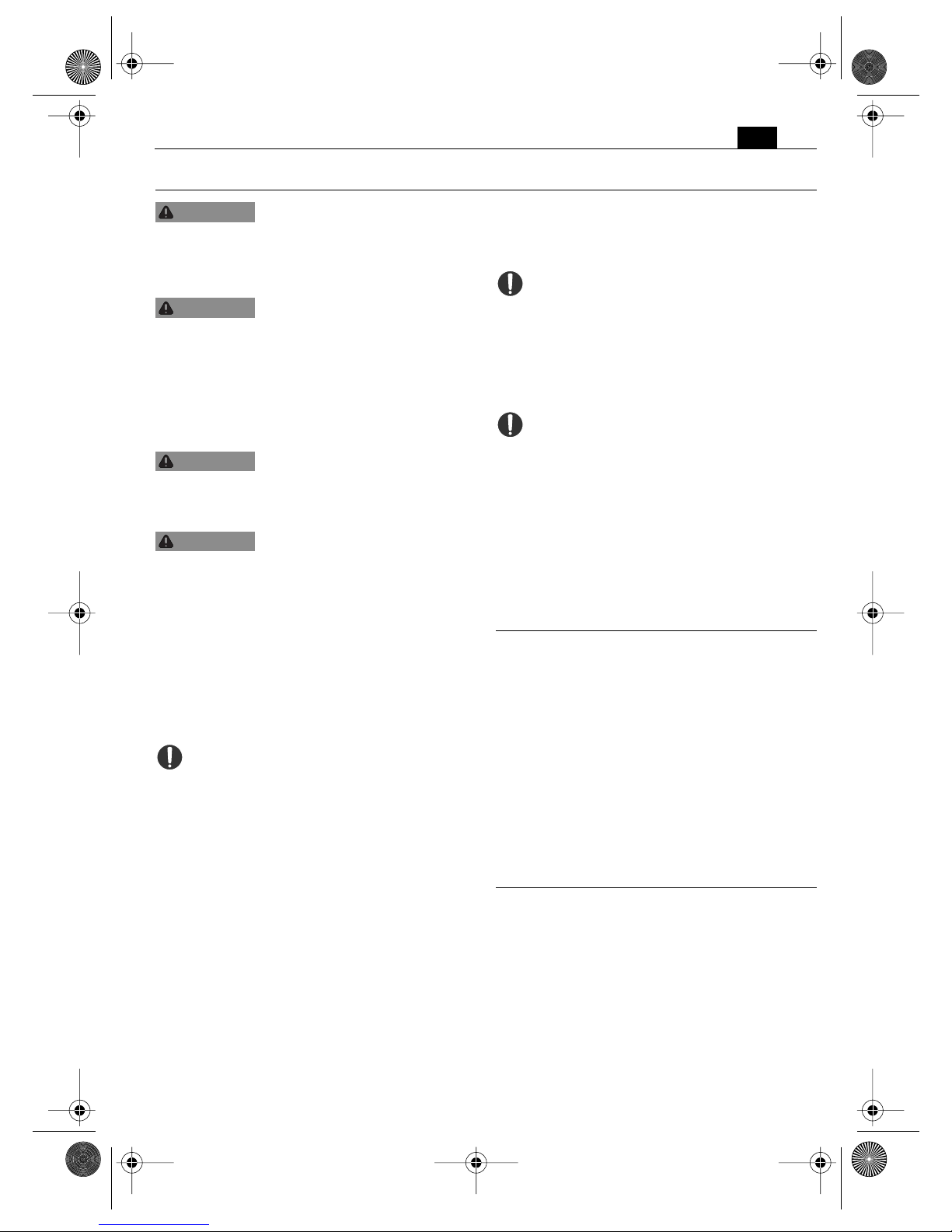

Stopping (Figure 12).

➤ Let go of all the pressing surfaces. The

accessory begins to slow down.

Securing the work piece.

➤ Secure the workpiece adequately. A

workpiece that is not properly secured

can, for example, cause the accessory to

jam and kick back, fall and cause other

hazards.

Using the cut-off wheel guard (FIgure 13).

For cut-off grinding operations, always

work with the cut-off wheel guard

mounted.

➤ Before beginning to work, push the

cut-off wheel guard onto the already

mounted wheel guard for roughing.

Fig. 12

Fig. 13

Cut-off wheel

guard

Wheel guard

for roughing

3 41 01 121 21 0.book Seite 21 Montag, 22. August 2011 1:11 13

22

en

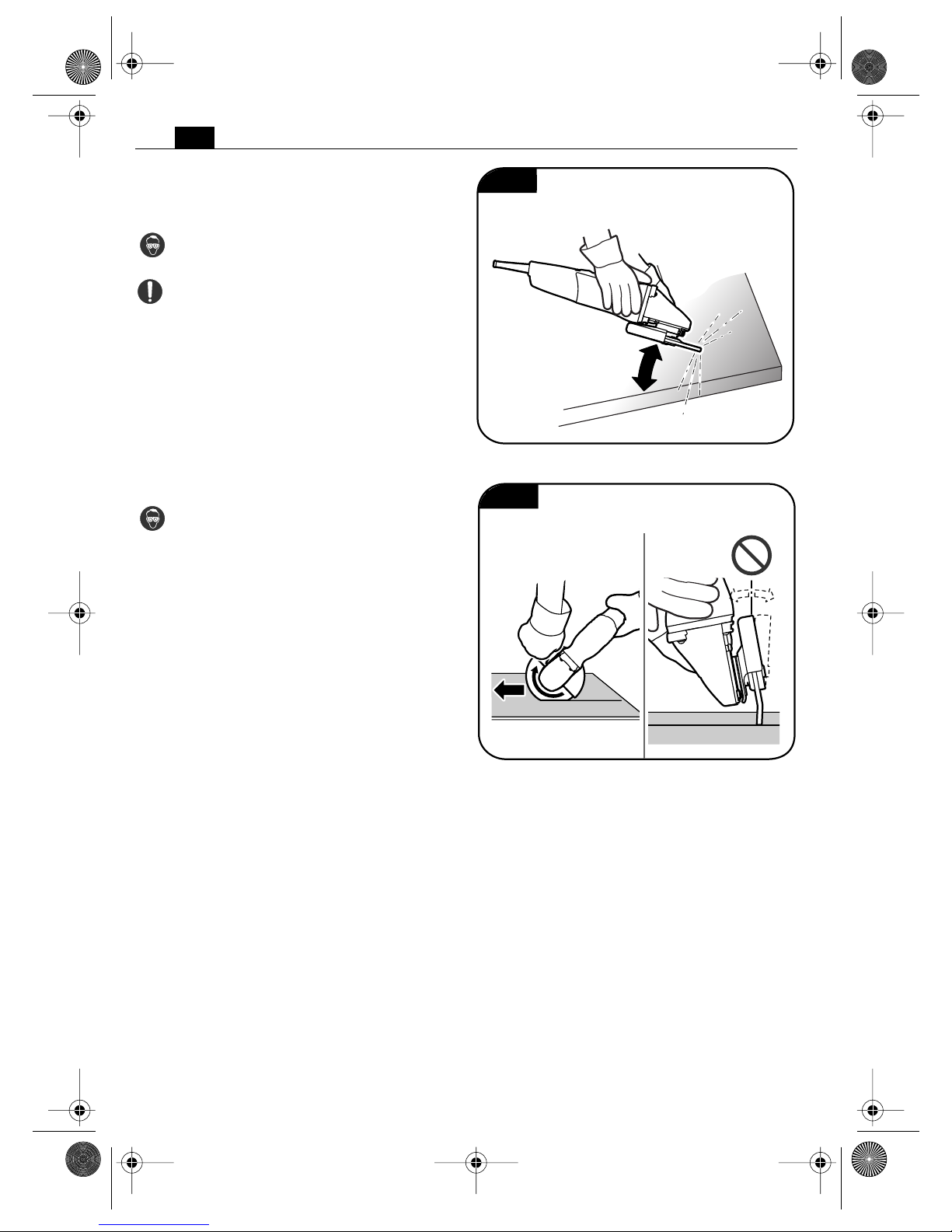

Grinding (Figure 14).

➤ Keep to an angle of tilt of 20 – 40°. In

this way you will obtain a good removal.

➤ Press the power tool on evenly and

move it over the surface.

➤ Do not allow the surface of the work-

piece to become too hot.

Cutting (Figure 15).

➤ Always work against the direction of

rotation so that the cutting wheel does

not jump out of the cut.

20°– 40°

Fig. 14

Fig. 15

3 41 01 121 21 0.book Seite 22 Montag, 22. August 2011 1:11 13

23

en

Maintenance.

Before mounting or replacing application tools or accessories, pull the power

plug. This preventive safety measure rules out the danger of injuries through

accidental starting of the power tool.

Service

Have maintenance carried out

only through qualified personnel. Incorrectly mounted leads and components

can cause serious injuries. Have the required

service carried out only through a FEIN customer service agent.

Cleaning

Prior to any cleaning or main-

tenance, disconnect the power

tool from the power supply in order to avoid

accidents.

When using in environments

with conductive dust in the air,

such as when working metals, this dust can

settle in the interior of the power tool. This can

impair the total insulation of the power tool.

Therefore, regularly blow out the interior of the

power tool from outside via the ventilation

openings with dry, oil-free compressed air;

always wear eye protection when doing this.

For additional protection, connect a residual

current device (RCD) on the line side.

Do not attempt to clean clogged or dirty

ventilation openings of the power tool

with pointed metal objects; use nonmetal tools or objects for this.

Do not use cleaning agents and solvents

that can cause damage to plastic parts.

These include: Gasoline, carbon-tetrachloride, chloric solvents, ammonia and domestic

cleaning agents that contain ammonia.

WSS14-125T: Unscrew the clamping unit by

hand to protect it from damage and dirt.

When the power tool’s power cable is

damaged, it must be replaced by a qualified person using a specially prepared power

cable, available from your FEIN customer

service agent.

If required, you can change the following parts

yourself: Application tools, auxiliary handle,

clamping unit or flanges, wheel guard

(WSG14-150T, WSG14-70ET).

Warranty and liability.

The warranty for the product is valid in

accordance with the legal regulations in the

country where it is marketed.

In addition, FEIN also provides a guarantee in

accordance with the FEIN manufacturer’s

guarantee. For further details on this, please

contact your specialist dealer, your national

FEIN representative, or the FEIN customer

service center.

Environmental protection,

disposal.

Packaging, worn out power tools and accessories should be sorted for environmentfriendly recycling. Further information can be

obtained from your specialist dealer.

WARNING

WARNING

WARNING

WARNING

3 41 01 121 21 0.book Seite 23 Montag, 22. August 2011 1:11 13

24

en

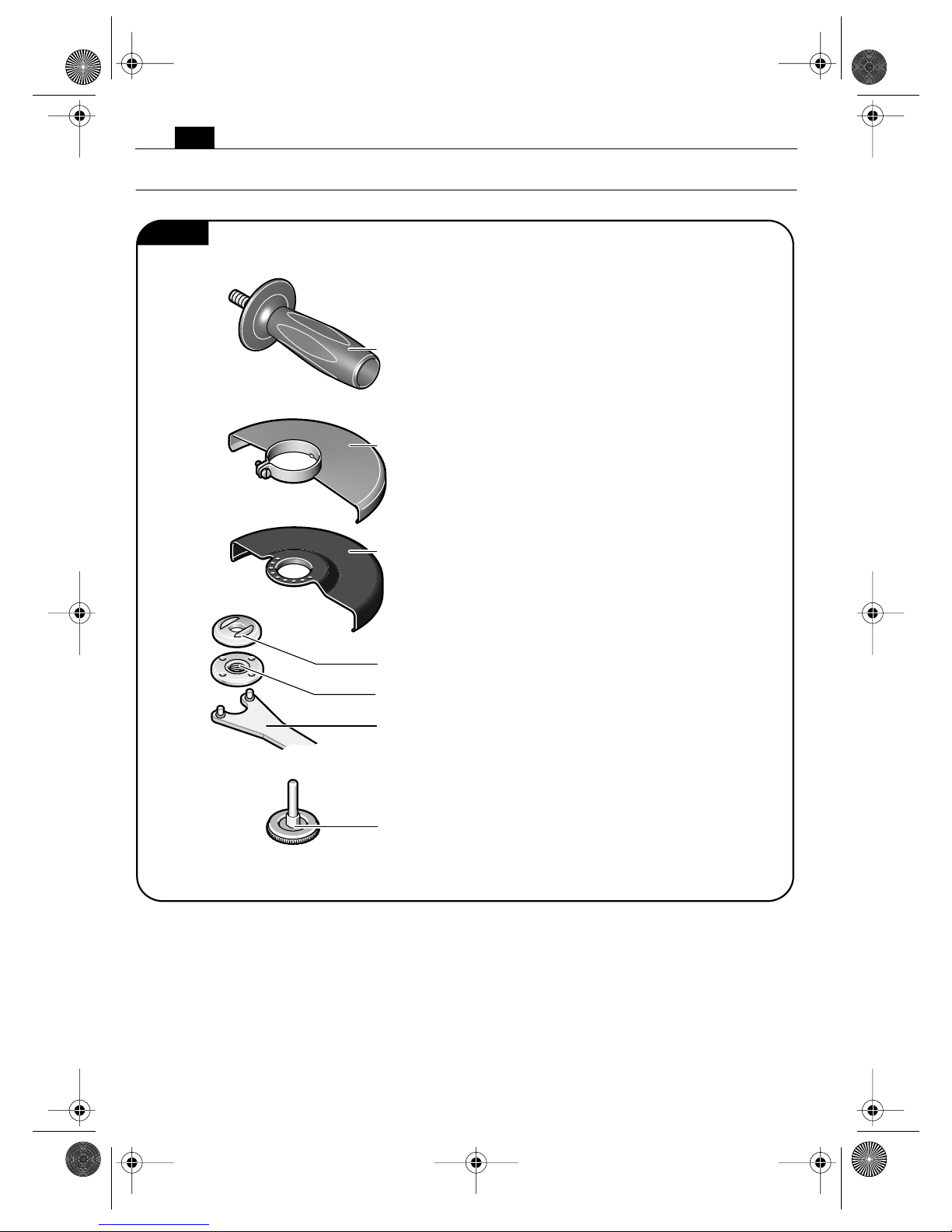

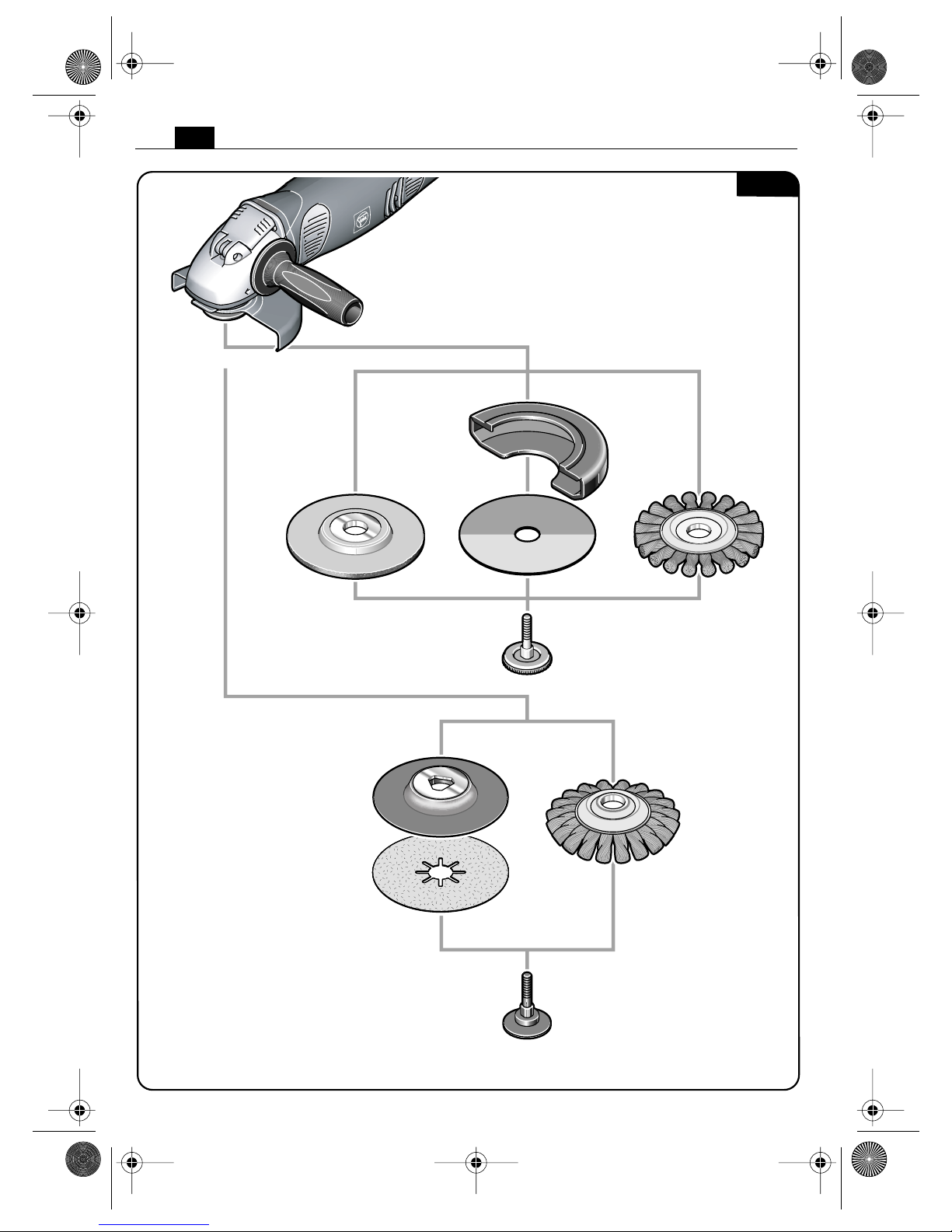

Provided Accessories (Figure 16).

WSG14-125T

WSG14-150T

WSG14-70ET

WSG10-115T

WSG14-150T

WSG14-70ET

WSS14-125T

WSG14-125T

WSG10-115T

WSS14-125T

Auxiliary handle

Fig. 16

Wheel guard

Wheel guard

Clamping unit

Threaded flange

Inner flange

Face spanner

3 41 01 121 21 0.book Seite 24 Montag, 22. August 2011 1:11 13

25

en

Selection of accessories (Figures 17–20).

The accessories must be intended for the power tool type.

A Grinding disc, flap disc

(use only with mounted wheel guard)

B Cut-off disc

(use only with mounted cut-off wheel guard)

C Steel wire brush, fleece backing pad

(use only with mounted wheel guard)

D Backing pad for fibre sanding sheets, fibre sanding sheets

(mount only with the provided backing-pad clamping unit; use only with mounted hand

guard or wheel guard)

E Steel tapered twist brush

(use only with mounted wheel guard)

F Backing pad with Velcro, Velcro sanding sheets, sanding fleece with Velcro attachment,

sponges

(use only with mounted hand guard)

G Steel cup brush, round twist brushes

(use only with mounted hand guard)

H Extraction nozzle for fibre sanding sheets

I Protective suction hood for grinding discs

3 41 01 121 21 0.book Seite 25 Montag, 22. August 2011 1:11 13

26

en

A

ED

BC

WSS14-125T

Fig. 17

3 41 01 121 21 0.book Seite 26 Montag, 22. August 2011 1:11 13

Loading...

Loading...