RSs 636-1/2

To be handed to the workshop

~

Operating instructions

for the

double insulated and radio suppressed

Electric Nibblers type RSs 636-1, RSs

636-2

and type RSs 736-1 and RSs

736-2

(42

Volt)

1.

Technical

Data

Type

of

current:,...,

(AC

single

phase)

For sheet metal

up

to

Radius

of

Cu

tting

I

In

cisions

Net

Typ

e

sheet

stainle

ss

aluminium

3

)

sm

allest

sp

ee

d

I

Input

Outp

ut

Weig

ht

steel

')

steeJ2)

plastics

cu

rve

f~/

I

m/

per

Wa

tt

s Watts

SWG I

mm

SWG I

mm

SWG I

mm

lll.

I

I

RSs 636-1/2

18

1.3

22 I 0.8

14 2

3/4

RSs 736-

1/2

I

1

)

up

to

28.4 sh. ton/sq. in.

2

)

up to 42.5 sh. t on/sq. in.

3)

up

to 7.8 sh. ton/sq. in.

2.

Construction

This nibbler

is

an

electric

tool

of

Class

II

with

double insulation

and

in accordance

with

the

VDE

regulations 0740.

The

protective

insulation

is

additional

to

the normal insulation.

The

pole housing

is

insulated by

the

motor

housing

made

of

shockproof

Poly

amide

and

the electric parts

of the arma

ture

are protected by a separating in-

sulation against

the

dri

ve s

haft. The

machine is supplied with a two-

core cable wi

thout

earth

wire a

nd must

not

be ea

rth

ed. The high

voltage test is

made with the prescribed test v

olt

age of 4000 Volt

s.

The

machine

is

radio

-suppressed according

to

radio interference degree

N.

Type

RSs

736-1 , 736-2

(42

V)

is

of

the

same design

but

not double

insulated.

In

ord

er to prevent the ove

rbrid

ging

of the insulation no additional

marking

plates and

signs mu

st

be ri veted

or

screwed

on the housing.

We recomme

nd the u

se

of transfers onl y.

3.

Connection

and

Operation

Main v

olt

age must correspond

to the operating v

olt

age marked on

the rating plate. The tool can be plugged into plain

or

saf

ety sockets.

Switch must be in

the

»Off

<<

pos

ition

when

conn

ect

ing.

Type

RSs

636-1 is used to trim straig

ht

or

shaped sheet a

nd

corrugated

she

et

with

corrugations spaced

at

least 70 mm (2

3

/ 4

")

apart

. To cur

holes

or

openings

of any

kind, first drill a

pilot

hole of 18

-25

mm

dia.,

so

that

the anvil can be

introd~ced

.

Cutting dir

ection:

in

line

w

ith

motor axi

s.

Type RSs 636- 2 w

ith

anvil offset t

hrou

gh 90 °, is u

se

d for working

on

corrugated sheet w

ith

closely s

pac

ed corru gations. Cu

tti

ng direc-

tio

n:

at rig

ht angl

es

to mo

tor

axis.

BE 147/e

CX

5.72

Printed

in Germany

I mm

mm

I

20

.I

5.6

I

'

Capac

ity:

minute

mm

1.7 1800 280

15

0

I

I

Steel

sheet (drawn) max. 1.3 mm -

3

/o

•"

Stainl

ess

steel sheet max. 0.8 mm -1/sz"

Aluminium sheet max. 2

mm

-

5

fG

4"

Welding

seams

must

not

be

cut!

lbs I kg

3.5 1.6

No claims can be entertained for damage resulting fr

om

cutting sheett

of heavier

gauges

or

higher strength than thos

e sp

eci

fied here

or

work

with blunt bla

des

or

inadequate lubrication.

N

ever work

with

blunt

blades

and

inserts

U

se

of

blunt cutting edg

es

imposes an excessive load on the anvil

which is likely to fracture.

4.

Maint

enance

and

Lubrication

Before carrying

out any ma

inten

ance

work

alwa

ys reme

mber

to

pull

out

the

plug.

E

ver

y 300

duty

hours the tool should be cleaned thoroughly in

ord

er

to guarantee the safety given

by

the

protective insu

latio

n. For th

is

purpose carbon holders

and

insulated parts must

be

cleaned by means

of

a brush or

by

blowing out the tool

with dry pneumatic a

ir

or

a

hand

blower.

Aft

er checking carbon

brushes

for wear, make sure that they are

refi

tt

ed in their original place and

that th

ey m

ove

easily

in thei

r holder.

They sh

ou

ld be replaced

at

the latest

when

they have worn down to

7 mm (II<"). Please, only use original Fein

car

bon brus hes (Ord

er

Reference EZ 11-62).

After

fitting new

brushes, run

tool unloaded for

about

15

minutes to allow brush

es

to

bed in.

One pair

of

spare carbon brush

es

will be found in the

handle; pleas

e,

do

not

forget

to reord

er them in time.

In

order to preve

nt

accidents che

ck

cable

at

regular interval

s.

To

replace the cable un

sc

rew the screws (22) a

nd

(23

) a

nd

rem

ove

the

c

over

(21). Cla

mp

off cable from switch (14), unscr

ew screws (20)

at cable clamping bridge (19) and take

out

cabl

e.

66-

- --

-.

65-~

•

IIIJr-

=

I

64

1lLl.illlr

69

u

73

67~

111111-..

I

70--

71

..

68

--

76-~,

72

74

45

49 46

=\ \

n;;&

\

I

75

42

44

I

52

53 54 52

57

56

r

____

___..

-----

t I I L I

~

~

47

48

50

51

=

eo,

I

_____

_.

______

..

41

40

I

L

..

® _

«P

•

'f>}rt-r

~@\-

~@

.----,

..

I

r----

--------

-------- --------

-----J

1

,_-

__

11

33

•

,....

I

0

,

---

L~

•

..__a

·

-.

~

~

-ill"'

. =

§~8

..

-.

I J I I J - 5 I 1 I I I t . 1

55

33

31

32

30

.J..--4

26

11

9 8

7

6 J

r---

....

--

•

t

I

._

____

_

~

----

---------·

---------

------

1

b~"'-

·-

19

18

17

3

"-----

-~ - 2

10•~~~

13

1M

10

13

I

14

,,

~-~

---

----

''-

11

CJ'

~

A /

::

~o

---=-

~

./

--

------

--

....

~

16

22

I

21

I

23

0

z

Order

:>-

'-'

Reference

cY

...

"'

P-.

1-16,

MK

1-17-1

1

)

1

19-23

b 1

MK

1-17

1

2 SA 16-25 1

3

SA 16-28 1

4

SA 5-48 1

5

SR

3-M4x6

1

b 6

state

type

1

and

voltage

7

PT 6-M

3,5 2

8

.

SR

2-M3,5x50

2

9

JS

28-7

1

10

EZ

12-55-1

1

lOa

EZ 12-56-1

1

a

11

EZ

11-62 2

13

SR

3-M3,5x18 I

2

14

EZ

1-60

I

'

1

a

15

EZ

22-37

1

16

SR

3-M3,5x6 1

a

17

EZ

7-101 1

a 18

JS 13-7

1

19

PT

31-21 1

20

SR

3-M3,5x10

2

b

21

PT

27-28

1

22 SR6k-M3,5x8 1

23

SR

3-M3,5x32 1

b

26-32

state type

1

an

d v

olta

ge

b 30

ZR

4-42

1

31

SR

2-M3,5x6

3

32

PT

5d-M3,5 3

b

33

LK 16-35 2

40-54

GH 7-4-3

1

62-76

GH

7-5-3

' 1

40

LA 6-160

1

41

BF 1-4x18 1

42

PT

5d-M5

2

43

SR

33-M5x

35

I 2

44-54 LA 8-111-1

1

44

LA

8-111

1

1

)

state type and voltage

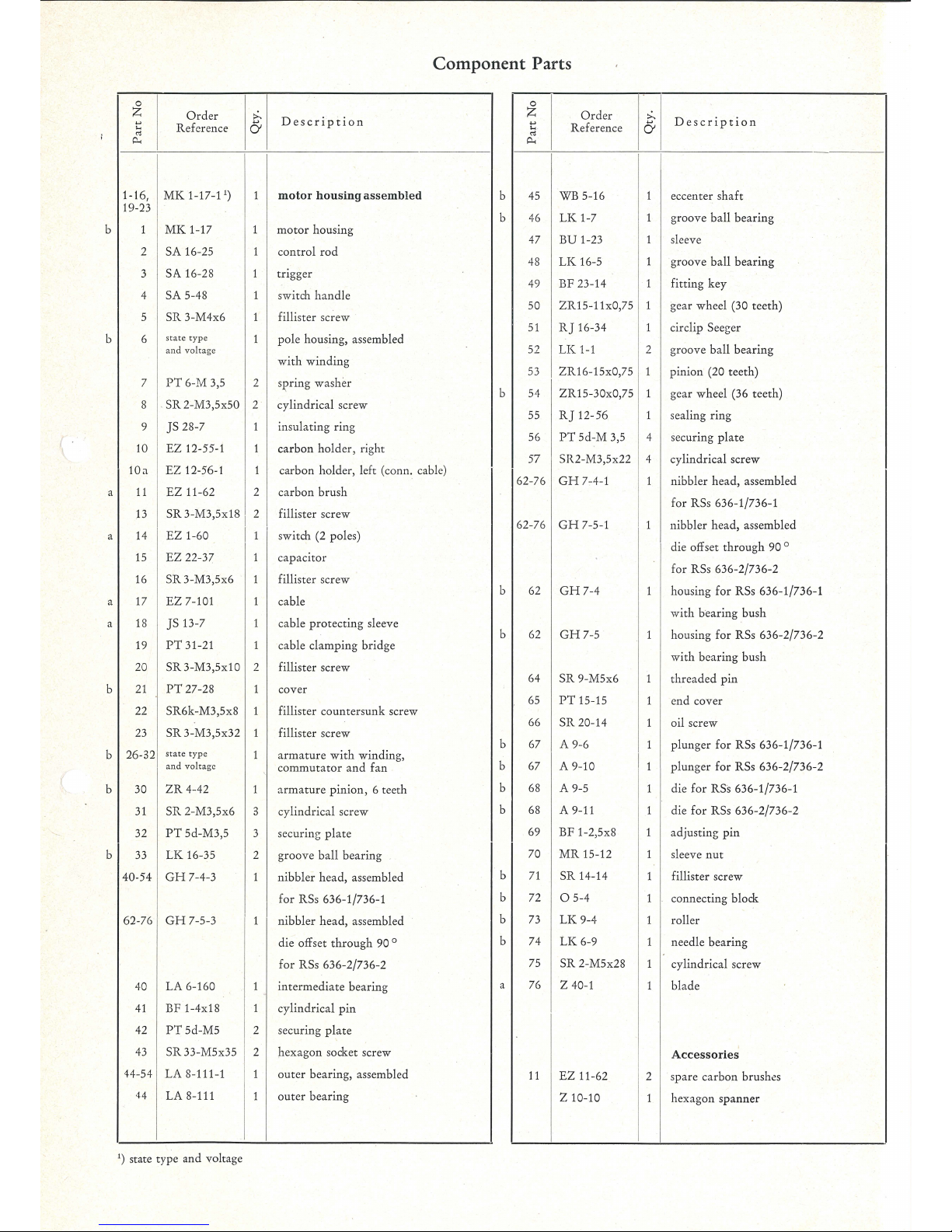

Component Parts

Description

motor

housing

assembled

motor

housing

control

rod

trigger

switch

handle

fillister screw

pole

housing, assembled

with

winding

SJ.?ring was

her

cy

lindrical

screw

insulating ring

carbon

holder,

right

carbon holder, left (conn. cable)

carbon

brush

fillister screw

switch (2 poles)

capacitor

fillister s

crew

cable

cable

protecting

sleeve

ca

ble clamping

brid

ge

fillister screw

cover

fillister countersunk screw

fillister screw

armature with windin

g,

c

ommutator

and

fan

armature

pinion,

6 teeth

cylindric

al screw

securing pl

ate

groove ball

bea

rin

g

nibbl

er hea

d,

asse

mbl

ed

for

RSs 636-1/736-1

nibbler

head,

assembled

die offset

through

90 °

for RSs 636-2/736-2

intermediate

bea

ring

cy

lindrical

pin

securing

plate

hexagon

socket screw

out

er bearing, assembled

out

er bea

ring

b

b

b

b

b

b

b

b

b

b

b

b

b

a

0

z

Order

..,

Reference

...

"'

P-.

45

WB 5-16

46

LK

1-7

47

BU

1-23

48

LK

16-5

49 BF 23-14

50

ZR

15-11x0,75

51

R]

16-34

52

LK

1-1

53

ZR16-15x0,75

54

ZR 15-30x0,75

55

RJ12-56

56

PT

5d-M

3,5

57 SR2-M3,5x22

62-76

GH

7-4-1

62-76

GH

7-5-1

62

GH7-4

62

GH

7-5

64

SR

9-M5x6

65

PT

15-15

66

SR

20-14

67 A 9-6

67 A

9-

10

68 A 9-5

68 A 9-11

69

BF 1-2,5x8

70 MR 15-12

71

SR

14-14

72

0 5-4

73

LK

9-4

74 LK 6-9

75

SR 2-M5x28

76

z 40-1

11

EZ 11-62

z 10-10

:>-

6

Description

I

1

eccenter

shaft

1 groove ball

bearing

1

sl

ee

ve

1

gr

oove

ball

bearing

1 fitti

ng

key

1

ge

ar

wheel (30 teeth)

1 circlip Seeger

2

groove ball

bearing

1 pini

on

(20 teeth)

1 gear wheel (36 teeth)

1 sealing

ring

4 securing

plate

4

cylin

drical

screw

1 nibbl

er

head,

assembled

I

for RSs 636-1/736-1

I

1

nibbler

head,

assembled

die offset

through

90 °

for RSs 636-2/736-2

1

housi

ng

for

RSs 636-1/736-1

with bearing

bush

1 housing

for

RSs 636-2/736-2

w

it

h be

aring

bush

1 threa

ded

pin

1 end

cover

1 oil s

crew

1

plung

er

for

RSs 636-1/736-1

I

1

plu

nger

for RSs 636-2/736-2

1 die f

or

RSs 636-1/736-1

1 die f

or

RSs 636-2/736-2

1 ad

just

ing

pin

1

sleeve

nut

1 fillister scr

ew

1

connecting block

1 roller

1

n

ee

dle

bearing

1 cyli

ndrical

screw

1

b

la

de

Accessories

2

spare

carbon

brush

~s

1

hexag

on

spanner

Blades

and

inserts should be sharpened

with

a fine honing stone. When

the

bright

cylindrical

part

of

the blade has been

ground

away, a new

blade

must

be fitted.

The

edge

of

the

cutter

insert must also be

sharp

at

all rimes; resharpen

only

the

top

face.

From

time to

tim

e,

apply

a few drops

of

oil

to

the

slot

in

the

anvil

to

lubricate the blade guides. Also lubricate

the

cutting edge

by

apply-

ing a

little

oil

with

a brush along the scribed line

on

the ·sheet. Slacken

screw (66), every day,

and

apply

a few drops

of

oil here, to lubricate

the slides

of

plunger (67), connecting linkage (72)

with

roller (73),

needle bearing (74)

and

ball bearing (46).

The

nibbler head being the

power

transmitting

element requires good

lubrication. The gear grease should be renewed

after

approx. 300

working

hours. Please,

only

use

our

special

FEIN

gear grease

Sst

1.

A mixing

of

this grease

with

other

greases endangers the greasing

capacities,

and

therefore also

usc

Sst 1 grease for rhe roller bearings in

the gear head.

quantity

order

reference

I

contents

·rype

I

I

oz

g oz

g

I Sst 1 for gears

1 0.53 1

15

MZ

60-3/Sst

1 I 3.2 I 90

No

claims can be

entertained

for

damage

due

to

negligent maintenance

or

inadequate

lubrication.

After

900

working

hours

the machine s

hould

be cleaned thoroughly.

For

this purpose the machine

is

dismantled as described in

paragraph

5

and

the

individual

parts

are

then cleaned.

The

ball

be~rings

(33)

are rinsed

in

clean solvent

and,

when

dry,

packed

with

our

special

grease Sst 1.

In

orda

to

prevent

overheating

of

the

bearings

at

high

speeds

the

space between

inner

and

outer ring

of

the bearing should

be filled

only

about

1

/a

with

grease.

5.

Dismantling

The

tool should only

be

taken

apart

by

an

expert, working m the

following sequence:

1. Unscrew screws (22, 23), then rake off handle cover (21 ).

2.

Loosen connection cable from switch (14)

and

draw

out

switch.

Clamp

off

motor

cable.

Unscrew screws (12),

take

out

carbon

holder

(10), remove screw

(16)

and draw

out

interference capacitor (15).

3.

Unscrew

two

hexagon socket screws ( 43)

and

remove

outer

bear-

ing ( 44 ), unscrew

four

cylindrical screws (57)

and

take

off

inter-

mediate bearing (40).

4.

Draw

out

armature

(26), unscrew three screws (31)

and

remove

armature

pinion (30).

5.

Draw

insulating ring (9)

out

of

motor housing (1), unscrew cylin-

drical screws (8)

and

take out

pole housing (6).

6.

Repair

and

Spare

Parts

We recommend

our

Fein Service Stations

to

carry

out

all

overh

aul

and

repair

work

quickly

and

expertly.

When

ordering

spare

parts,

please,

quote

model

and

serial

No

in

addition

to

order

reference

or

send

in

sample

part.

We

draw

your

attention

to

the need to

carry

out a high

voltage test

in accordance

with

your

local regulations (or

VDE

regulation 0740)

before

taking

a tool

into

service

after

any

repair

carried

out

by your

own

staff.

(

Loading...

Loading...