QSz

663

To be handed to the workshop!

Operating instructions

for the

double insulated and radio suppressed

Sheet Metal Shear QSz

663

and type QSz

63

K

(42

Volts)

1. Technical

Data

Current: ~ (AC

single phase)

for sheet

metal

up

to

Radius of

Cutting

Incisions

Capacit

y

Net

Type

Steel

1

)

Stainless steel

2

)

smallest

curve

capacity

per

input I output

weight

mm

I

m.

mm

I

m.

mm

m.

m/

min

I Ft!min

minute

Watts Watts

kg

I

lbs

QS:z:

663

4,5

11

/64

3,0

1

/s

50

13

1

/a2

1,5 4,9

1700 750 520 9,9

21,8

QSz 63 K (42 V)

1

)

up

to

max. material thickness

of

28,4 sh.

ton

/sq. in. (40

kp/mm

2

)

2

)

up

to

max. material thickness of 49,8 sh. ton/sq. in. (70 kp/

mm'

)

2. Construction

The

sheet

metal

shear

QSz

663 is

an

electric

hand

tool fitted

with

protective insul

ation

according

to Cla

ss

II

of

the

VDE

Specifications

0740.

In addition

to

the

norm

al i

nsulation the tool is equipped

with

a

further

protective

insu,lation.

Thereby

the

touchable

external

metal

housing is

separated

from

all

internal

parts,

which

can

become live

in

case

of

failure.

The

dustproof

switch

is

built

into

the

plastic handle.

The

tool

is

not

to

be

earthed

and

must be connected

with a two

-core

cable

:

without

earth

wire.

The

r~dio

suppression

of

the

machine

is

in accordance with radio

suppression degree

N.

Type

QSz

63 K

for

low

tension

(voltage

42 V) is

of

the same design,

but

without

double insulation.

To

prevent

the

overbridging

of

the ins

ulation

no

additional

marking

plates

and

signs must be

riveted

or

screwed

on

the

housing. We re-

commend

the

use

of

transfers

only.

3. Connection and Operation

Main

voltage must correspond

to

the

operating

voltage

marked

on

the

rating

plate.

The

tool

can

be

plugged

into

plain

or

safety

sockets.

Switch must be in

the

"Off"

position

when

connecting.

The

machine

performs

quick

and

clean cuts

when

blades are inserted

and

adjusted in accordance

with the instructions . Stops

or jams

only

occur w

hen shear

is

worked

in

the wrong position a

nd

will be

eliminated as soon as

the

shear is

brought

by the rig

ht

touch in

the

right

position. Use

no

force!

If

necessary switch off

motor

and

restart

cutting operation.

Attention.

Do

not

cut welding seams.

BE 125/e X 10.70

Printed

in

German

y

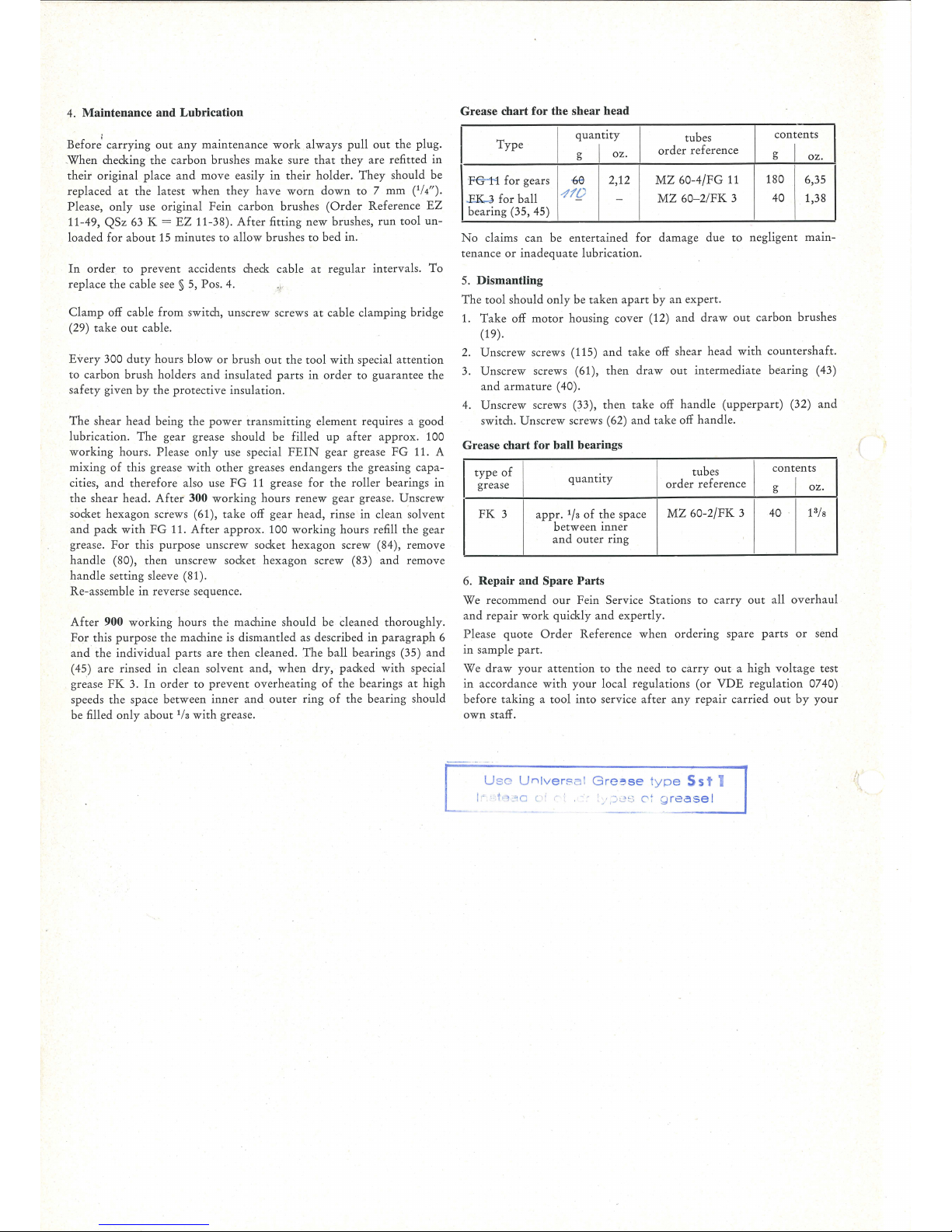

Fitting and adjusting

of

the blades

Insert

fixed blade

and

plunger blade (116)

and

secure sli

ghtly

with

screws (117).

Turn

set screw (101)

until

the

corners

of

the

blades

at

highest

plunger

position overcross

at

about

0.5

mm

(0.2 in)

(Dim

en-

sion F). Screw

and

plunger

blade sho

uld

then

be tightened.

Hereafter

the

fixed bl ade should finally be

adjusted

by

set screw

(108) so

that

the

gap

"L"

is

1/10

of

the

sheet thickn

ess

to

be cut.

(e.g. sheet metal

of 2 mm

thickness-

0,2 mm).

highest

position

l

owes

t

p

os

ition

Attention!

Never

work

with

blunt

blades!

For

resharpening, the

blades

ca

n be removed

after

unscrew

ing

the two screws (117). When

sharpening

use

plenty of

coolant a

nd

strictly obse

rve the prescrib ed

cutting

angle.

If

blades are resha

rpened

in

time,

breaking

out

is

avo

ided

. The fixed blade

and

the

plunger

bla

de

are

interchangeable.

No

claims can be

entertained

for

damage

due

to

work with

materia

l

of

too much strength

or

sheet too thick

or

work

with blunt

blades.

81

- -------,_

96

106

105

104

103

102

Q1

~

~

...

I I

'!Al.W~

\

'11:11

Jl

)..

KJO

I

~~ i ~· I ~~ I~~ I ~·

I

97

t:f)

CD

l:C

1:/

""

""

101

108

109

~91,5

QSz 663

3'

35

l l

lllllllllllllilillllllllll

iiiiiiiiiliililiiii

iiillliilil

iiiiiii

l

/N

~I

liif1<'l

~

~~

""t'

I

\

I

( {

·~

1- i

~

·

I

- I .

I

-

-

--

•v

-~

25

26

27

/C

N

/1"1

D

~

35

64

63a

63

32

32b

32c

QSz

63K

"$-

g

......

II

I I

--·

-

--·---

::.

14

62

1C»'

I

28

34

114

115

29

31

I

110 I 111

112 113

I

r

I

+

-·

I

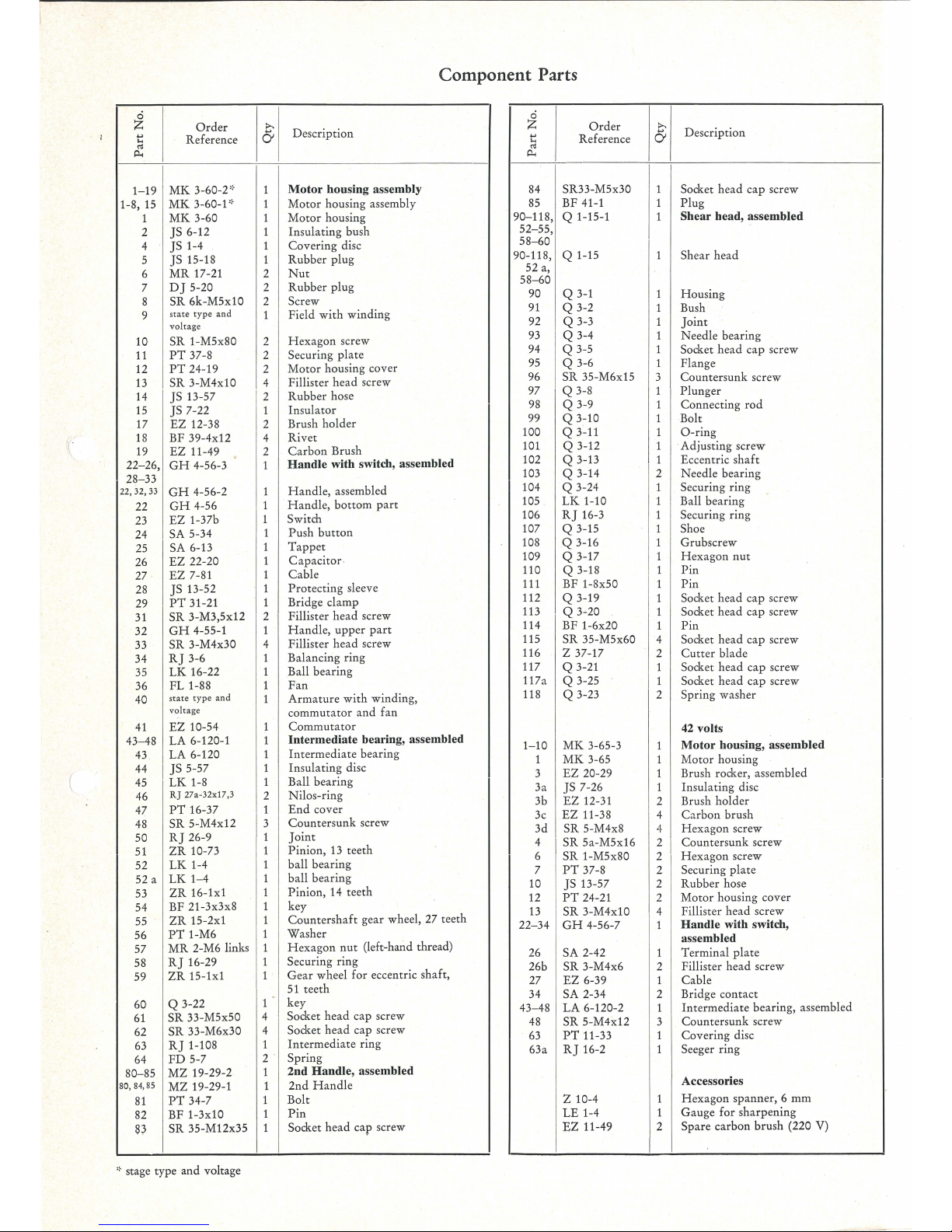

Component Parts

0

z

Order

>.

Description

...,

Reference

6

....

"'

0

z

Order

>.

Description

...,

Reference 6

....

"'

p..

p..

1-19

MK

3-60-2''·

Motor housing assembly

84

SR33-M5x30

1 Socket

head

cap screw

1-8,

15

MK

3-60-P

Motor

housing assembly

85

BF 41-1

1

Plug

1

MK

3-60

Motor

housing

90-118, Q 1-15-1 1

Shear head, assembled

2

JS

6-12

Insulating bush

4

]S 1-4

Covering

disc

5

]S 15-18

Rubber

plug

6

MR

17-21

2

Nut

7

D]

5-20 2

Rubber

plug

8

SR

6k-M5x10 2

Screw

9

state

type

and

1

Field

with

winding

voltage

10

SR

1-M5x80 2

Hexagon

screw

11

PT

37-8 2

Securing

plate

12

PT

24-19 2

Motor

housing cover

13

SR

3-M4x10

4

Fillister

head

screw

14

]S 13-57 2

Rubber

hose

15

JS 7-22

1

Insulator

17

EZ

12-38

2

Brush holder

18

BF 39-4x12 4

Rivet

19

EZ

11-49 2

Carbon

Brush

22- 26,

GH

4-56-3

Handle with switch, assembled

28-33

Handle,

assembled

22, 32,

33

GH

4-56-2

1

22

GH

4-56

1

Handle,

bottom

part

23

EZ

1-37b

1

Switch

24

SA

5-34

1

Push

button

25

SA

6-13

Tappet

26

EZ

22-20

Capacitor

·

27

EZ

7-81

Cable

28

JS 13-52

Protecting

sleeve

29

PT

31-21

1

Bridge clamp

31

SR

3-M3,5x12

2

Fillister

head

screw

32

GH

4-55-1

1

Handle,

upper

part

33

SR 3-M4x30

4

Fillister

head

screw

34

R]

3-6

1

Balancing ring

35

LK

16-22 1

Ball bearing

36

FL

1-88 1

Fan

40

state type and

1

Armature

with

winding,

52-55,

58-60

90-118,

Q 1-15 1 Shear

head

52 a,

58-60

90

Q 3-1 1 Housing

91

Q 3-2 1 Bush

92

Q 3-3 1

Joint

93

Q 3-4 1

Needle

bearing

94

Q 3-5

1

Socket head cap screw

95

Q 3-6 1 Flange

96

SR

35-M6x15

3

Countersunk

screw

97

Q 3-8 1

Plunger

98

Q 3-9 1 Connecting

rod

99

Q 3-10 1 Bolt

100

Q 3-11

1

0-ring

101

Q 3-12

1 Adjusting screw

102

Q 3-13 1

Eccentric

shaft

103

Q 3-14 2

Needle bearing

104

Q 3-24

1 Securing ring

105

LK

1-10 1 Ball bearing

106

RJ

16-3 1

Securing ring

107

Q 3-15

1 Shoe

108

Q 3-16

1 Grubscrew

109

Q 3-17

1

Hexagon

nut

110 Q 3-18 1

Pin

111

BF 1-8x50

1

Pin

112

Q 3-19 1

Socket head cap screw

113

Q 3-20

1

Socket head cap screw

114 BF

1-6x20

1

Pin

115

SR

35-M5x60

4 Socket

head

cap screw

116

z 37-17

2

Cutter

blade

117

Q 3-21 1 Socket head

cap

screw

117a

Q 3-25

1

Socket head

cap

screw

118

Q 3-23 2 Spring washer

voltage

commutator

and

fan

41

EZ

10-54

Commutator

42 volts

43-48

LA

6-120-1

Intermediate bearing, assembled

43

LA 6-120

Intermediate

bearing

44

I JS 5-57

Insulating

disc

45

LK

1-8 1

Ball bearing

46

RJ

27a-32xl7,3

2

Nilos-ring

47

PT

16-37 1

End

cover

48

SR

5-M4x12

I

~

Countersunk

screw

50

R]

26-9

Joint

51

ZR

10-73

Pinion,

13

teeth

52

LK

1-4

ball bearing

52 a

LK

1-4

ball

bearing

53

ZR

16-1x1

Pinion, 14 teeth

54

BF 21-3x3x8

key

55

ZR

15-2x1

Countershaft

gear wheel, 27 teeth

56

PT

1-M6

Washer

57

MR

2-M6 links 1

Hexagon

nut

(left-hand thread)

58

R]

16-29

1

Securing ring

59

ZR

15-1x1

1

Gear

wheel for eccentric shaft,

11 -

51

teeth

60

Q 3-22

key

61

SR 33-M5x50

4

Socket

head

cap screw

62

SR

33-M6x30

4

Socket

head

cap screw

63

R]

1-108

1

Intermediate

ring

64

FD

5-7

2 .

Spring

1-10

MK

3-65-3

1

Motor housing, assembled

1

MK

3-65

1

Motor

housing

3

EZ

20-29 1

Brush rocker, assembled

3a

JS

7-26 1

Insulating disc

3b

EZ

12-31

2 Brush holder

3c

EZ

11-38

4

Carbon

brush

3d

SR

5-M4x8 4

He

xagon screw

4

I

SR

5a-M5x16

2

I

Countersunk

screw

6

SR

1-M5x80

2

Hexagon

screw

7

PT

37-8 2 Securing

plate

10

JS 13-57

2

Rubber

hose

12

PT

24-21

2

Motor

housing cover

13

SR

3-M4x10 4

Fillister

head

screw

22-34

GH

4-56-7 1

Handle with switch,

assembled

26

SA

2-42

1

Terminal

plate

26b

SR

3-M4x6

2

Fillister head screw

27

EZ

6-39 1 Cable

34 SA

2-34

2

Bridge contact

43-48 LA

6-120-2

1

Intermediate

bearing, assembled

48

SR 5-M4x12 3

Countersunk

screw

63

PT

11-33 1

Covering

disc

63a

R]

16-2 1

Seeger ring

80-85

MZ

19-29-2

1

2nd Handle, assembled

80,

84,

85

MZ

19-29-1

1

2nd

Handle

Accessories

81

PT

34-7

1

Bolt

z 10-4

1

Hexagon

spanner, 6

mm

82

BF 1-3x10

1

Pin

LE

1-4 1

Gauge for sharpening

S3

SR 35-M12x35

Socket

head

cap screw

EZ

11-49 2

Spare carbon brush

(220

V)

,,.

stage type and voltage

4. Maintenance and Lubrication Grease chart

for

the shear head

Before1 carrying

out

any

maintenance

work

always

pull

out

the

plug.

.

When

checking

the

carbon

brushes

make

sure

that

they

are

refitted

in

their

original

place

and

move

easily

in

their

holder.

They

should

be

replaced

at

the

latest

when

they

have

worn

down

to 7 mm

(1

/4").

Please,

only

use

original

Fein

carbon

brushes

(Order

Reference

EZ

11-49,

QSz

63 K =

EZ

11-38).

After

fitting

new

brushes,

run

tool

un-

I

Type

I

·FG-1- 1

for

gears

.EK..J

for

ball

bearing

(35, 45)

quantity

g

I

oz.

{,6

2,12

-1

1[)

-

I

tubes

contents

ord

er

reference

I

g

oz

.

MZ

60-4/FG

11

180

6,35

MZ

60-2/FK

3

40

1,38

loaded

for

about

15

minutes

to

allow

brushes

to

bed

in.

No

claims

can

be

entertained

for

damage

due

to

negligent

mam-

tenance

or

inadequate

lubrication.

In

order

to

prevent

accidents check cable

at

regular

intervals.

To

replace

the

cable see § 5, Pos. 4.

.,

5. Dismantling

Clamp

off cable

from

switch, unscrew screws

at

cable

clamping

bridge

(29)

take

out

cable.

Every

300

duty

hours

blow

or

brush

out

the

tool

with

special

attention

to

carbon

brush

holders

and

insulated

parts

in

order

to

guarantee

the

safety

given

by

the

protective

insulation.

The

shear

head

being

the

power

transmitting

element requires a

good

lubrication.

The

gear

grease should

be

filled

up

after

approx.

100

working

hours. Please

only

use special

FEIN

gear

grease

FG

11. A

mixing

of

this grease

with

other

greases

endangers

the

greasing

capa-

cities,

and

therefore

also use

FG

11

grease

for

the

roller

bearings

in

the

shear

head.

After

300

working

hours

renew

gear

grease,

Unscrew

socket

hexagon

screws (61),

take

off gea r

head,

rinse

in

clean solvent

and

pack

with

FG

11.

After

appro

x. 100

working

hours

refill

the

gear

grease.

For

this

purpose

unscrew

socket

hexagon

screw (84),

remove

handle

(80),

then

unscrew

socket

hexagon

screw

(83)

and

remove

handle

setting

sleeve (81).

Re-assemble in reverse sequence.

After

900 w

orking

hours

the

machine

should

be

cleaned

thoroughl

y.

For

this

purpo

se

the

machine is

dismantled

as described

in

paragraph

6

and

the

individu

al

parts

are

then

cleaned.

The

ball

bearin

gs (35)

and

(45)

are

rinsed

in

clean

solvent

and,

when

dry,

packed

with

special

grease

FK

3.

In

order

to

prevent

overheating

of

the

bearings

at

high

speeds

the

space

between

inner

and

outer

ring

of

the

bearing

should

be

filled

only

about 1/s

with

grease.

The

tool

should

only be

taken

apart

by

an

expert.

1.

Take

off

motor

housing

cover

(12)

and

draw

out

carbon

brushes

(19).

2.

Unscrew

screws (115)

and

take

off shear

head

with

countershaft.

3.

Unscrew

screws (61),

then

draw out

intermediate

bearing

(43)

and

armature

( 40 ).

4.

Unscre

w screws (33),

then

take

off

handle

(upperpart)

(32) a

nd

switch.

Unscrew

screws (62)

and

take

off

handle.

Grease chart for ball bearings

I

type

of

I

I

tubes

I

contents

quantity

order reference

I

grease

g

oz.

FK

3

appr

. 1/a

of

the

space

bet

ween

inner

MZ

60-2/FK

3

40 !3/s

and

outer

ring

6. Repair and Spare Parts

We

recommend

our

Fein

Service

Statio

ns

to

carry

out

all over

haul

and

repair

work quickly

and

expertl

y.

Please

quote Order

Reference when

ordering

spare

parts

or

send

in

sample part.

We

draw

your

attention

to

the

need

to

carry

out a high

voltage

test

in

accordance

with your

local

regulat

ions (

or

VDE

regulation

0740)

before

taking

a tool

into

service

after any

repair

carried

out

by

your

own

staff.

U

sc Univer

sa l

G

re::~se

typ

e

Ss

t 1

1·

h:1a

c ·

:_,

)-5S

o: g

rease

I

Loading...

Loading...