(

DSk

658

To be handed to the workshop!

Operating instructions

for the Two

Speed Electric Drill type DSk

658

and for DSk

758

(42

Volts)

and for DSke

658

(with electronic

sp~ed

control)

1.

Technical

data

Type

of

current: ~ AC

single

phase

Internal

fuses

for

220

Volts:

10 A (slow)

or

15

A (fast)

Capacity

in

steel

Speed

R.

P.M

.

Morse

Taper

Net

Type

Input

I

Output

Socket

of

weight

in

.

I

mm

full

load I no

load

Watts

Watts

spindle

lbs

I

kg

DSk

658 l

'/,/3/4

13/19 420/200 720/340

540 320

2

13,42 6,1

DSk

758

{42

V)

DSke

658

1

/2fl/4

13/19

240-420/

330-720/

540 320

2

14,1

6,4

I

110-200

:l.

Construction

The

two

speed

hand

drill

DSk

658

is

an

electric

tool

of

Class

II

with

protective

insulation

according

to

VDE

regulations

0740.

The

protective

insulation

is

additional

to

the

normal

insulation

and

separates

all

accessible

parts

of

the

metal

casing

from

all

internal

parts

liable

to

become

live

.

The

machine

must

not

be

earthed

and

must

be

connected

with

a

two-core

cable

without

earth

wire.

The

drill

is

tested

with

the

prescribed

test

voltage

of

4000 V.

The

machin

e is

radio

suppressed

according

to

radio

interference

VDE 0875.

Type

DSk

758,

for

low

tension

(42 V)

is

of

the

same

design,

but

without

double

insulation.

To

prevent

the

overbridging

of

the

insulation

no

additional

marking

plates

and

signs

must

be

riveted

or

screwed

on

the

housing.

We

recommend

the

use

of

transfers

only.

BE 209/e X

1.

73

Printed

in

Germany

150-340

3.

Connection

and

operation

Main

voltage

must

correspond

to

the

operating

voltage

marked

on

the

rating

plate.

The

tool

can

be

plugged

into

plain

or

safet

y

sockets.

Switch

must

be

in

the

"Off"

position

when

connecting.

The

speed

of

the

machine

must

only

be

changed

at

stand-still

or

at

slowing

down

without

load. Release

switch

handle

(47)

of

its

longitudinal

position,

put

it

across

by

turning

it

out,

then

push

it

into

the

wanted

switch

direction

and

reset

the

switch

handle

in

opposite

direction

again

into

its

longitudinal

position.

The

type

DSke

658

has

an

electronic

speed

control.

The

speed

will

be

changed

by

turning

the

button

situated

on

the

handle,

when

the

machine

is

running

or

not.

The

speed

will

be

increased

by

turning

the

button

clockwise

and

reduced

by

turning

it

anticlockwise

.

·,-

0@

T

I

r - ; 1

~ar~~

a

52-~~

7

50

~

310 '[

~

--r'?"'--

32 33

34

36

37

~

•lli+B

a m ·1. - 8

1-110

I I I - I

40

38

39

41

61

I 0

el)

0

8

e) 0

e)

........,

0

I I

________________________________

,.

___

62_

_______ §.;i

______________________________________

,.

______________________________________________

.._

___________

_

1:

t

l

____

g

II

~

,

--

59

5857

15

~

I I I

6 2 - 3

--

ic---i--

----------------)>-------------------------------------------------------------)>-------------------------------------------)>------------

-,

' -------

~

-

~~

•

1111

77

I

I~

74

-

!JJJ

~

llll

J

J

JJJJJJJ

60

- [

__

•

__

/

~=

==

::

-----~

-

10

78 i

, I

@=C

llllill

llllill:ll

llll

--

~

-------

~~····,

~

,,

~

!

64

-T

,,

r

......_.,

!

:

I

'

- ' -

EZ

1-7~

220V~

Wiring

diagram

-

only

for

DSke

658

b

a

b

b

b

b

.

0

z

Order

;;..

....,

....

Reference

5

r;j

P-<

I

1-13

MK

3-101-2

1

)

1

1-14

MK

3-101-8

1

)

1

1

MK

3-101

1

2, 3

MK

13-17-1

1

2

MK

13-17

1

3

EZ

12-50

2

4

SR

2-M5x15

2

5

PT

5d-M5

2

6

state type

1

and volta

ge

7

SR 1-M4x60

2

8

PT

37-13

2

10

EZ 11-70

I

2

11'

12

PT

27-3'i'-1

2

13

SR

2-M4x12

4

15-20

sta

te

type

1

and

voltage

20

FL 4-2-1

1

21-52

LA

8-116-2

1

21

LA

6-169

1

22-52

LA

8-116

-1

1

22

LA

8-1 16

1

25

BF 1-4x15

1

26

WB

2-38

1

27

RJ

12-50

1

28

LK 13-9

1

29

PT

8-164

1

29a

PT

8-175

1

30

DJ

1-61

1

31

PT

8-173 1

32

DJ

1-60

1

32a

PT

11-67 1

33

LK 16-16

1

34

PT

8-168 1

35

BF

21-5x5x10 1

36

ZR

15-12x1,25

1

37

MR

3-M1

4xl,5

1

38

ZR 16-

9x

1 1

39

ZR

15-32x0,

75

1

40 LK 1-3 2

41

LK 1-3 2

42

ZR

16-5x1,25

1

43 BF 21-6x6x36

1

44

ZR

15-27x1 1

45

RJ

16-9 1

46

BF17-

186 1

47-51

SA

5-52-1 1

47

SA

5-52

1

48

FD

1-202 1

49 BF 16-86 1

50

BF 17-191

1

51 BF 38-2x12 1

52

BF

38-3x

16

1

56

LK 1-3

1

57

LK 16-30

1

58

RJ

12-57

1

59

JS

6-28

1

60

SR

33-M5x25

4

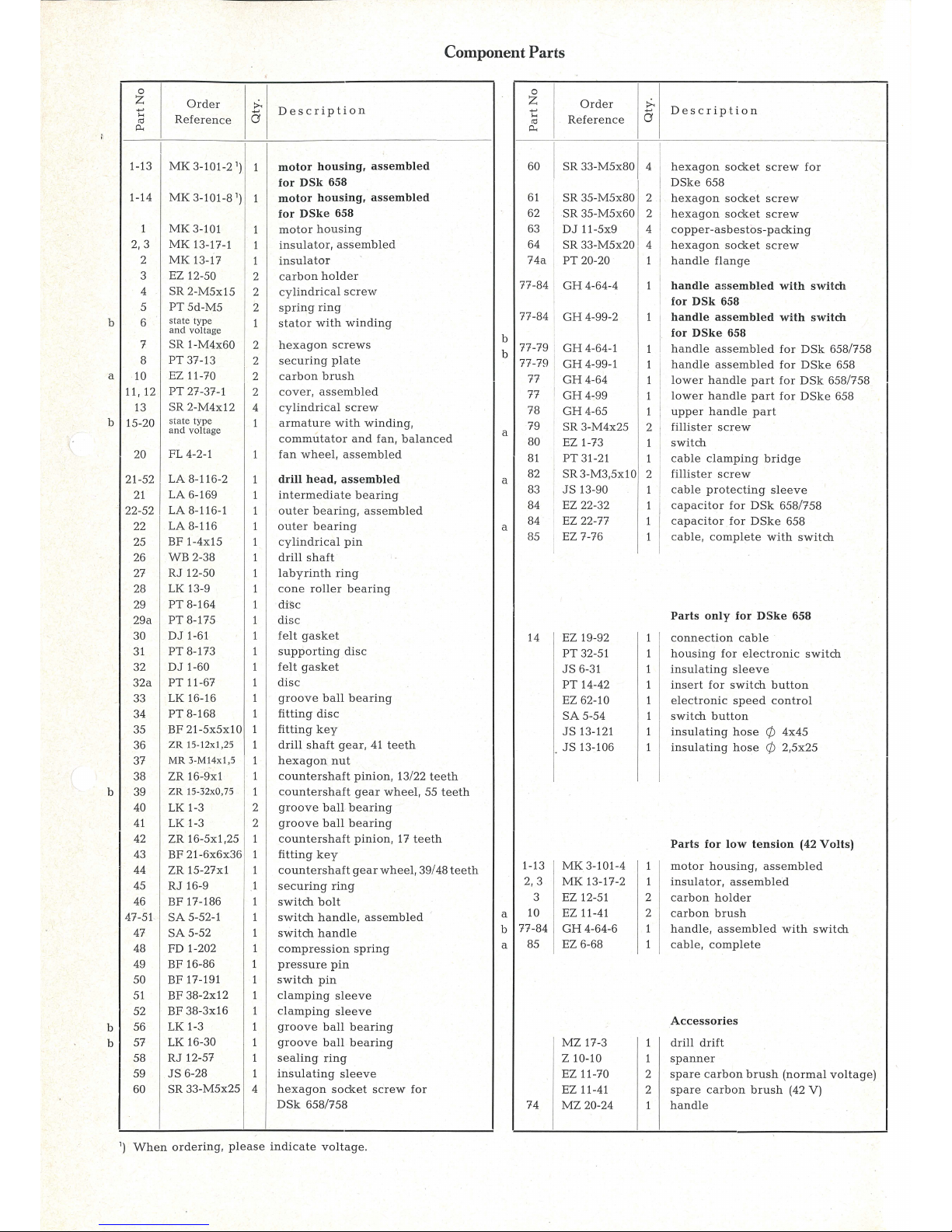

Component Parts

Description

motor

housing,

assembled

for

DSk

658

motor

housing,

assembled

for

DSke

658

motor

housing

insulator,

assembled

insulator

carbon

holder

cy

lindrical

screw

spring

ring

stator

with

winding

hexagon

screws

securing

plate

carbon

brush

cover,

assembled

cy

lindrical

screw

armature

with winding,

commutator

and

fan,

balanced

fan

wheel,

assembled

drill

head,

assembled

intermediate

bearing

outer bear

ing,

assembled

outer

bearing

cylindrical

pin

drill

shaft

labyrinth

ring

cone

roller

bearing

di:sc

dis

c

felt

gasket

supporting

disc

felt

gasket

disc

groove

ball

bearing

fitting

disc

fitting

key

drill

shaft

gear,

41

teeth

h

exa

gon

nut

countershaft

pinion,

13/22

teeth

countershaft

gear

wheel,

55

teeth

groove

ball

bearing

groove

ball

bearing

countershaft

pinion,

17

teeth

fitting

key

countershaft gear

wheel,

39/48

teeth

sec

uring

ring

switch

bolt

switch

handle,

assembled

switch

handle

compression

spring

pressure pin

switch

pin

clamping

sleeve

clamping slee

ve

groove

ball

bearing

groove

ball

bearing

sealing

ring

insulating

sleeve

h

exag

on

socket

screw

for

DSk

658/758

b

b

a

a

a

a

b

a

0

z

Order

;;..

....,

5

....

Reference

co

P-<

60

I

SR 33-M5x80 1 4 1

61

, SR 35-M5x80

2

62

SR 35-M5x60 2

63

DJ 11-5x9 4

64

SR 33-M5x20 4

74a

PT

20-20

1

77-84

GH4

-64-4

1

77-84

GH

4-99-2

1

77-79

GH

4-64-1

1

77-79

GH

4-99-1

1

77

GH

4-64

1

77

GH4-99

1

78

GH

4-65

1

79

SR

3-M4x25

2

80

EZ 1-73

1

81

PT

31-21

1

82

SR3

-M3,5x 10

2

83

JS

13-90

1

84 EZ 22-32

1

84

EZ

22-77

1

85

EZ

7-76

1

I

14 EZ 19-92

1

PT

32-51

1

JS

6-31

1

PT

14-42

1

EZ

62- 10

1

SA

5-54

1

JS

13-121

1

JS

13-106

1

1-13

MK

3-101-4

1

2,3

MK

13-17-2

1

3 EZ 12-5 1

2

10

EZ 11-41

2

77-84

GH

4-64-6

1

85 EZ 6-68

1

MZ

17-3

1

z 10-10

1

EZ11-70

2

EZ 11-41

2

74

MZ

20-24 1

1

)

When

ordering,

please

indicate

voltage.

Description

hex

agon

socket

screw

for

DSke

658

h

exagon

socket

screw

hexa

gon

socket

screw

coppe

r-asbesto

s-packing

hexa

gon

socket

screw

hand

le

flange

handle

assembled

with

switch

for

DSk

658

handle

assembled

with

switch

for

DSke

658

ha

ndle

assembled

for

DSk

658/758

handle

assembled

for

DSke

658

low

er

handle

part

for

DSk

658/758

lower

handle

part

for DSke

658

upper

handle

part

fillister

screw

switch

cable

clamping

bridge

fillist

er

screw

cable

protecting

sleeve

capa

citor

for

DSk

658/758

c

apacitor

for

DSk

e 658

cable,

complete

with

switch

Parts

only

for

DSke

658

connection

cable

housing

for

electronic

switch

insu

lating

sleeve

insert

for

switch

button

electronic

speed

control

swi

tch

button

insulating

hose

q;

4x45

insu

lating

hose

q;

2,

5x25

Parts

for

low

tension

(42

Volts)

motor

housing,

assembled

insulator,

assembl

ed

carbon

holder

carbon

brush

handle,

assembled

with

switch

cable,

complete

Accessories

drill

drift

spanner

spare

carbon

brush

(normal

voltage)

spare

carbon

brush

(42 V)

ha

ndle

4.

Maintenance

and

lubrication

Before

carrying

out

any

maintenance

work

always

remember

to

pul~

out

the

plug.

After

300

working

hours

clean

air

openings

of

the

motor

housing.

Blow

out

motor

with

dry

pneumatic

air.

Renew

the

gear

grease.

Only

use

the

Fein

special

grease

Sst

1.

Worn

carbon

brushes

automatically

switch

off

the

machine

after

reaching

their

minimum

length.

After

checking

the

carbon

brushes

make

sure

to

refit

them

in

their

original

position

and

check

that

they

move

easily

in

their

holder.

After

fitting

new

brushes,

run

tool

unloaded

for

about

15

minutes

to

allow

brushes

to

bed

in.

Please,

only

use

original

Fein

carbon

brushes.

In

order

to

prevent

accidents

check

cable

and

connections

at

both

sides

at

regular

intervals.

Use

only

Fein

special

grease

Sst

1.

Quantity of

grease

120 g.

The

order

reference

for a tube

of

approx.

180

giis

MZ 60-4/Sst 1.

After

900

duty

hours

the

machine

should

be

completely

dis

-

mantled

as

described

under

paragraph 6 and

all

parts

should

be

thoroughly

cleaned.

Rinse

ball

bearings

and

gears

in

clean

solvent

and

pack

with

grease

Sst

1.

The

space· between

inner

and

outer

ring

is

to

be

one

third

filled

with

grease

in

order

that

the

bearings

do

not

overheat.

Please

be

sure

that

all

electric

and

plastic

parts

are

only

cleaned

dry.

For

good

and

adequa

te

lubrication

and

to

avoid

overheating,

it

is

important

to

pack

gearing

and

bearings

with

the

grades

and

quantities

of

grease

indicated.

No

claims

can

be

entertained

for

damage

due

to

negligent

main-

tenance

and

inadequate

lubrication.

5.

Dismantling

The

tool

should

only

be

taken

apart

by

an

expert.

1.

Pull

plug

from

socket.

2.

Take

off

motor

housing

cover

(11),

take

out

carbon

brushes

(10).

3.

Take

off

handle

cover

(78),

loosen

supply cable

and

interior

connection

cable

from

switch

(80). Take out

switch

and

clamp

off

cab

le

(85)

together

with

protecting

sleeve

(83)

from

clamping

bridge

(81).

4.

Remove

lower

handle

section

(77),

draw

out

insulation

sleeve

(59).

For

the

type

DSke

658:

take

off

the

lower

part

of

the

handle

.

Loose

the

soldering

part

between

the

black

connecting

cable

of

the

electronic

speed

control and

the

cable

of

the

pole

housing

and

between

the

protection cab

le

(b)

of

the

capacitor

and

the

connection

cable.

Take

off

the

housing with

the

electronic

speed

control.

5.

Unscrew

two

screws

from

61

and

from

62,

take out

bear

ing

(2

2),

intermedia

te

bearing (21) with

armature

(15)

of mot

or

housing

(1),

push

out

armature

(15)

togeth

er

with wheel

and

ball

bearing

(20

and

57)

out

of

intermediate

bearing

(21).

6.

Push

out

the

clam

ping

sleeve

(52)

of

shift-bolt

(46) by

means

of

a 3

mm

pin

in

direction

of

boring

shaft,

pull

out

sw itch

handle

(47) with

switch

pin

(50)

at

the

side.

Remo

ve switch

bolt

(46)

and pay

attention

to the

easily

accessib

le

clamping

slee

ves

(52).

7.

Draw

countershafts

(38)

and

(42) out

of

outer

bearing

(22).

8.

Unscrew hex

agon

nut

(37), dr

aw

off

drill

shaft

gear wheel

(36),

take

out

fitting

key

(35), push out

drill

shaft

(26)

.

Pay

attention

to

washers!

9.

Only

in

case

of

damage,

take

out insulator

(2) with stat

or

(6)

after

pulling supply cable through

the lateral bor

ing

into

the

housing

and

unscrewi

ng

fillister

head

screws with

slots

(4).

Re-assemble

in

reverse

sequence.

We

supply

special keys

ZSo 29-2-1

for

the

assemb

ly

of the

contact

spring

tools

of the

car

bon

brushes.

6.

Stationary

use

in

the

bench

drill stand:

If

the

machine

remains

in

the

bench

drill

stand,

the

gear

grease

is

not

sufficiently changed,

that

is

why

it

must

be

regreas-

ed

once a week

with

the

grease

gun.

The

grease

pins

el

lies

in

the

intermediate

bearing

(21).

After

operation

do

not

keep the

magnetic

bench

drill

stand with

the

fixed

machines

in a ve

rtical

position,

but

in a horizon

tal

one

so

that

the

gear

grease

is

distrib

uted equally.

7.

Repair

and

Spare

Parts

We

recommend

our Fe

in Servic

e S

tations to

carry out

all

over-

haul

and

repair work

quickly

and

expertly

.

Please

quote

Order

Reference

when

ordering

spare

parts or

send

in

sample

part, stating

the

type

of

the

machine.

We

draw

your

attention

to

the

need

to

carry out

a h i

gh

volta

ge

test

in

accordance with

your

loc

al

regulations

(or

VDE

regu-

la

tion

0740) b

efore taking a tool into

service

after any repair

ca

rri

ed

out

by your

own

staff.

(

Loading...

Loading...