Fein BOP6 Series, BOP10 Series, BOP13-2 Series, BOP10-2 Series Instruction Manual

© C. & E. Fein GmbH. Printed in Germany. Abbildungen unverbindlich. Technische Änderungen vorbehalten. 3 41 01 235 21 0 BY 2015.07 DE.

FEIN Service

USA

FEIN Power Tools Inc.

1000 Omega Drive

Suite 1180

Pittsburgh, PA 15205

Telephone: (412) 922-8886

Toll Free: 1-800-441-9878

www.feinus.com

Canada

FEIN Canadian Power Tool

Company

323 Traders Boulevard East

Mississauga, Ontario L4Z 2E5

Telephone.: (905) 8901390

Toll Free: 1-800-265-2581

FEIN Canadian Power Tool

Company

2810 De Miniac

St. Laurent, Quebec H4S 1K9

Telephone: (514) 331-7390

Toll Free: 1-800-789-8181

www.fein.com

Headquarter

C. & E. Fein GmbH

Hans-Fein-Straße 81

D-73529 Schwäbisch Gmünd-Bargau

www.fein.com

BOP6 (**) 7 205 ...

BOP10 (**) 7 205 ...

BOP10-2 (**) 7 205 ...

BOP13-2 (**) 7 205 ...

OBJ_DOKU-0000005362-001.fm Page 1 Tuesday, July 21, 2015 8:41 AM

2

Instruction Manual

Mode d'emploi

Instrucciones de uso

en

3

fr

19

es

36

OBJ_BUCH-0000000221-001.book Page 2 Tuesday, July 21, 2015 8:42 AM

3

en

en

For your safety.

Read all safety warnings and

all instructions. Failure to fol-

low the warnings and instructions may result

in electric shock, fire and/or serious injury.

Save all warnings and instructions for futurereference.

Do not use this power tool before you

have thoroughly read and completely

understood this Instruction Manual, including

the figures, specifications, safety regulations

and the signs indicating DANGER, WARNING and CAUTION.

Only carry out such operations with this

power tool as intended for by FEIN. Only use

application tools and accessories that have

been released by FEIN.

Please also observe the relevant national

industrial safety regulations.

Non-observance of the safety instructions in

the said documentation can lead to an electric

shock, burns and/or severe injuries.

This Instruction Manual should be kept for

later use and enclosed with the power tool,

should it be passed on or sold.

SAVE THESE INSTRUCTIONS.

The term “power tool” in the warnings refers

to your mains-operated (corded) power tool

or battery operated (cordless) power tool.

General safety rules.

1) Work area safety

a)Keep work area clean and well lit. Clut-

tered or dark areas invite accidents.

b)Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power

tools create sparks which may ignite the

dust or fumes.

c) Keep children and bystanders away

while operating a power tool. Distrac-

tion can cause you to lose control.

2) Electrical safety

a)Power tool plugs must match the outlet.

Never modify the plug in any way. Do not

use any adapter plugs with earthed

(grounded) power tools. Unmodified

plugs and matching outlets will reduce

risk of electric shock.

b)Avoid body contact with earthed or

grounded surfaces such as pipes, radiators, ranges and refrigerators. There is

an increased risk of electric shock if

your body is earthed or grounded.

c) Do not expose power tools to rain or wet

conditions. Water entering a power

tool will increase the risk of electric

shock.

d)Do not abuse the cord. Never use the

cord for carrying, pulling or unplugging

the power tool. Keep cord away from

heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase

the risk of electric shock.

e) When operating a power tool outdoors,

use an extension cord suitable for outdoor use. Use of a cord suitable for out-

door use reduces the risk of electric

shock.

f) If operating a power tool in a damp loca-

tion is unavoidable, use a ground fault

circuit interrupter (GFCI) protected supply. Use of an GFCI reduces the risk of

electric shock.

3) Personal safety

a)Stay alert, watch what you are doing

and use common sense when operating

a power tool. Do not use a power tool

while you are tired or under the influence of drugs, alcohol or medication. A

moment of inattention while operating

power tools may result in serious personal injury.

b)Use personal protective equipment.

Always wear eye protection. Protective

equipment such as dust mask, non-skid

safety shoes, hard hat, or hearing protection used for appropriate conditions

will reduce personal injuries.

c) Prevent unintentional starting. Ensure

the switch is in the off-position before

connecting to power source and/or battery pack, picking up or carrying the

tool. Carrying power tools with your

finger on the switch or energising

power tools that have the switch on

invites accidents.

WARNING

OBJ_BUCH-0000000221-001.book Page 3 Tuesday, July 21, 2015 8:42 AM

4

en

d)Remove any adjusting key or wrench

before turning the power tool on. A

wrench or a key left attached to a rotating part of the power tool may result in

personal injury.

e) Do not overreach. Keep proper footing

and balance at all times. This enables

better control of the power tool in

unexpected situations.

f) Dress properly. Do not wear loose cloth-

ing or jewelery. Keep your hair, clothing

and gloves away from moving parts.

Loose clothes, jewelry or long hair can

be caught in moving parts.

g)If devices are provided for the connec-

tion of dust extraction and collection

facilities, ensure these are connected

and properly used. Use of dust collec-

tion can reduce dust-related hazards.

4) Power tool use and care

a)Do not force the power tool. Use the cor-

rect power tool for your application. The

correct power tool will do the job better and safer at the rate for which it was

designed.

b)Do not use the power tool if the switch

does not turn it on and off. Any power

tool that cannot be controlled with the

switch is dangerous and must be

repaired.

c) Disconnect the plug from the power

source and/or the battery pack from the

power tool before making any adjustments, changing accessories, or storing

power tools. Such preventive safety

measures reduce the risk of starting the

power tool accidentally.

d) Store idle power tools out of the reach of

children and do not allow persons unfamiliar with the power tool or these

instructions to operate the power tool.

Power tools are dangerous in the hands

of untrained users.

e) Maintain power tools. Check for mis-

alignment or binding of moving parts,

breakage of parts and any other condition that may affect the power tool’s

operation. If damaged, have the power

tool repaired before use. Many accidents

are caused by poorly maintained power

tools.

f) Keep cutting tools sharp and clean.

Properly maintained cutting tools with

sharp cutting edges are less likely to

bind and are easier to control.

g) Use the power tool, accessories and tool

bits etc. in accordance with these

instructions, taking into account the

working conditions and the work to be

performed. Use of the power tool for

operations different from those

intended could result in a hazardous situation.

5) Service

a)Have your power tool serviced by a qual-

ified repair person using only identical

replacement parts. This will ensure that

the safety of the power tool is maintained.

Special safety instructions.

Use the auxiliary handle provided with the

power tool. Loss of control can lead to injury.

Hold the power tool by the insulated gripping

surfaces when performing operations where

the application tool could contact hidden wiring or its own power supply cable. Contact

with a “live” wire will also make exposed

metal parts of the power tool “live” and

shock the operator.

Beware of any concealed electric cables, gas

or water conduits. Check the working area

before commencing work, e. g. with a metal

detector.

Secure the work piece firmly. A work piece

that is gripped tightly in a clamping device or

vice, is more secure than if held by hand.

Hold the power tool firmly. High reaction

torque can briefly occur.

Do not direct the power tool against yourself,

other persons or animals. Danger of injury

from sharp or hot application tools.

OBJ_BUCH-0000000221-001.book Page 4 Tuesday, July 21, 2015 8:42 AM

5

en

Do not rivet or screw any name-plates or

signs onto the power tool. If the insulation is

damaged, protection against an electric shock

will be ineffective. Adhesive labels are recommended.

Do not use accessories which are not specifically designed and recommended by the

power tool manufacturer. Safe operation is

not ensured merely because an accessory fits

your power tool.

Clean the ventilation openings on the power

tool at regular intervals using non-metal

tools. The blower of the motor draws dust

into the housing. An excessive accumulation

of metallic dust can cause an electrical hazard.

Before putting into operation, check the

power connection and the power plug for

damage.

Recommendation: The tool should always be

supplied with power via a ground fault circuit

interrupter (GFCI) with a rated current of

30 mA or less.

Handling hazardous dusts.

When working with power

tools, such as when grinding,

sanding, polishing, sawing or for other work

procedures where material is removed, dusts

develop that are both hazardous to one’s

health and can spontaneously combust or be

explosive.

Contact with or inhaling some dust types can

trigger allergic reactions to the operator or

bystanders and/or lead to respiratory infections, cancer, birth defects or other reproductive harm.

Examples of such materials which contain

chemicals that can produce hazardous dusts,

are:

– Asbestos and materials containing asbes-

tos;

– Lead-containing coatings, some wood

types such as beech and oak;

– Minerals and metal;

– Silicate particles from bricks, concrete and

other materials containing stone;

– Solvent from solvent-containing paint/

varnish;

– Arsenic, chromium and other wood pre-

servatives;

– Materials for pesticide treatment on boat

and ship hulls;

– Stainless steel dust, metal dust and non-

ferrous metal dust;

To minimize the unwanted intake of these

materials:

– Use dust extraction matched appropriately

for the developing dust.

– Use personal protective equipment, such

as a P2 filter-class dust protection mask.

– Provide for good ventilation of the work-

place.

The risk from inhaling dusts depends on how

often these materials are worked. Materials

containing asbestos may only be worked on

by specialists.

Wood and light-metal dust can

cause spontaneous combustion or explosions.

Hot mixtures of sanding dust and paint/varnish remainders or other chemical materials

in the filter bag or the vac filter can self-ignite

under unfavorable conditions, such as sparking from sanding metal, continuous sunlight

or high ambient temperatures. To prevent

this:

– Avoid overheating the material being

sanded and the power tool.

– Empty the dust collector/container in time.

– Observe the material manufacturer’s

working instructions.

– Observe the relevant regulations in your

country for the materials being worked.

WARNING

CAUTION

OBJ_BUCH-0000000221-001.book Page 5 Tuesday, July 21, 2015 8:42 AM

6

en

Hand/arm vibrations.

While working with this power

tool, hand/arm vibrations

occur. These can lead to health impairments.

The vibration emission value

during actual use of the power

tool can differ from the declared value

depending on the ways in which the tool is

used.

It is necessary to identify safety

measures to protect the operator that are based on an estimation of exposure in the actual conditions of use.

The vibration emission level given in this

information sheet has been measured in

accordance with a standardised test given in

EN 60745 and may be used to compare one

tool with another. It may be used for a preliminary assessment of exposure.

The declared vibration emission level represents the main applications of the tool. However if the tool is used for different

applications, with different accessories or

poorly maintained, the vibration emission

may differ. This may significantly increase the

exposure level over the total working period.

An estimation of the level of exposure to

vibration should also take into account the

times when the tool is switched off or when

it is running but not actually doing the job.

This may significantly reduce the exposure

level over the total working period.

Identify additional safety measures to protect

the operator from the effects of vibration

such as: maintain the tool and the accessories,

keep the hands warm, organisation of work

patterns.

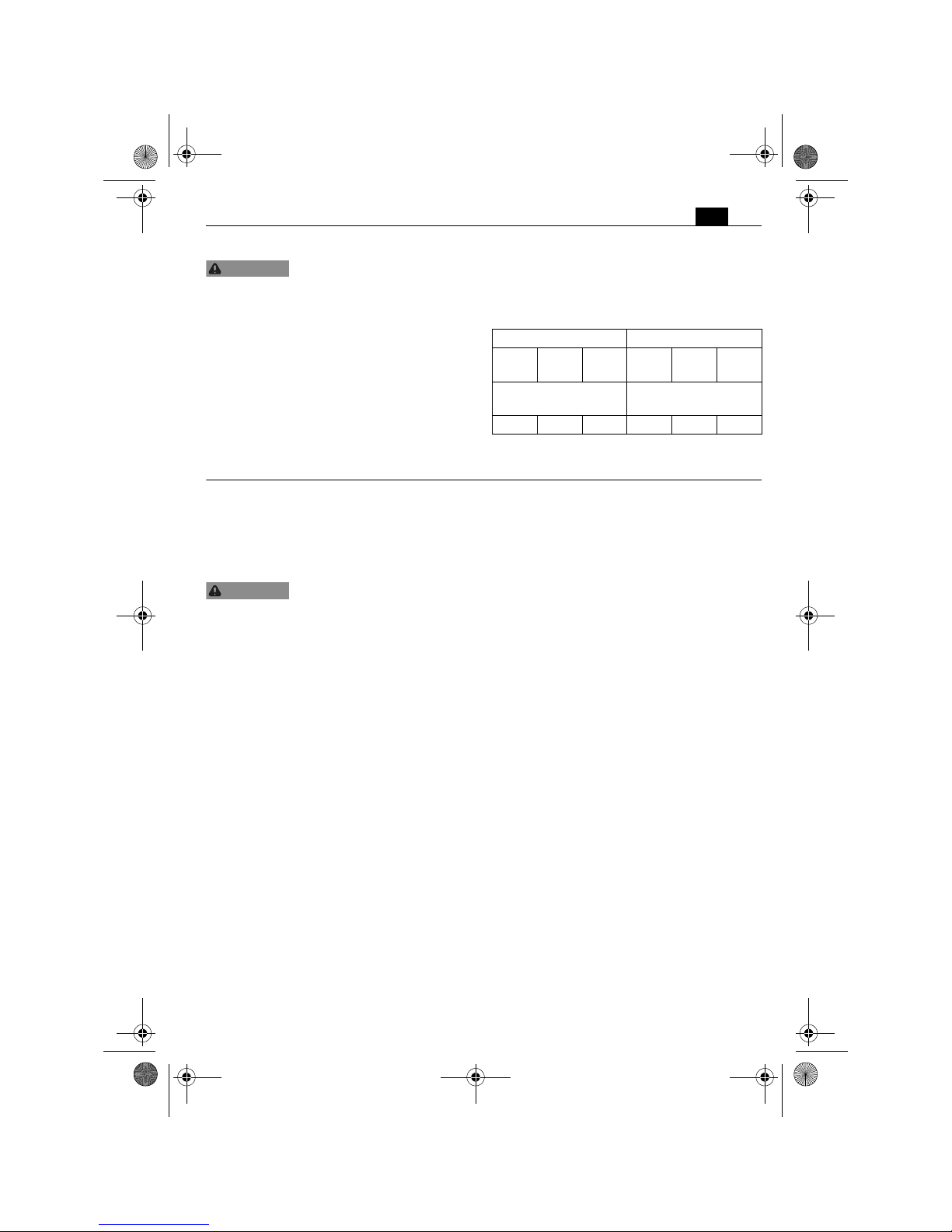

Emission values for sound and vibration (Two-figure – specifications as per ISO 4871)

WARNING

WARNING

WARNING

Sound emission BOP6 (**) BOP10 (**) BOP10-2 (**) BOP13-2 (**)

A-weighted emission pressure power

level measured at the workplace

L

pA

(re 20 μPa), in decibels 82 82 82 82

Measuring uncertainty

K

pA

, in decibels 3 3 3 3

Measured A-weighted sound power

level

L

wA

(re 1 pW), in decibels 93 93 93 93

Measuring uncertainty

K

wA

, in decibels 3 3 3 3

C-weighted peak sound pressure level

measured at the workplace

L

pCpeak

, in

decibels 96 96 96 96

Measuring uncertainty

K

pCpeak

, in deci-

bels 3 3 3 3

Vibrations

Weighted acceleration, in

– m/s

2

– ft/s

2

4

13

3

10

3

10

3

10

Measuring uncertainty

K

, in

– m/s

2

– ft/s

2

1.5

5

1.5

5

1.5

5

1.5

5

REMARK: The sum of the measured emission value and respective measuring inaccuracy

represents the upper limit of the values that can occur during measuring.

Wear hearing protection!

Measured values determined in accordance with the corresponding product standard.

OBJ_BUCH-0000000221-001.book Page 6 Tuesday, July 21, 2015 8:42 AM

7

en

Extension cable.

If the use of an extension cord

is required, its length and conductor cross-section must be adequate for the

application in order to prevent a voltage drop

in the extension cord, power loss and overheating of the power tool. Otherwise, the

extension cable and power tool are prone to

electrical danger, and the working efficiency is

decreased.

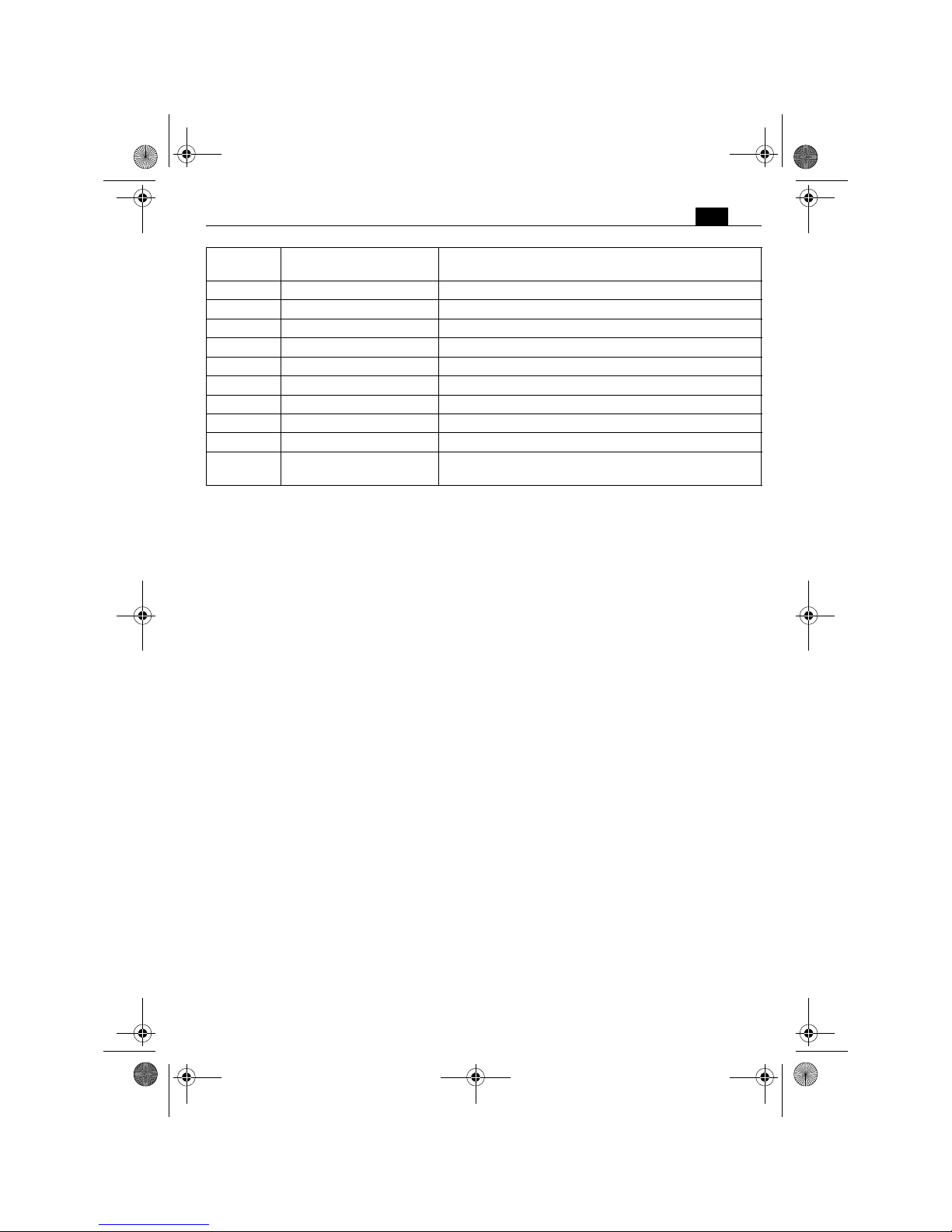

Recommended dimensions of extension cords

at an operating voltage of 120 V – singlephase a. c., with only BOP6 (**), BOP10 (**),

BOP10-2 (**), BOP13-2 (**) connected:

Intended use of the power tool:

hand-held drill for drilling in metal, wood,

plastic, ceramics, and for tapping in weatherprotected environments using the application

tools and accessories recommended by FEIN.

Operation of the power tool off power generators.

Operating the power tool off

power generators whose noload speed exceeds the voltage value on the

type plate of the power tool is prohibited.

WARNING

Max. cable length, ft Max. cable length, m

≤ 100 100

–200

200

–300

≤ 30 30

– 6060–100

Min. conductor size

A.W.G.

Min. conductorcrosssection, mm

2

16 16 14 1.5 1.5 2.5

WARNING

OBJ_BUCH-0000000221-001.book Page 7 Tuesday, July 21, 2015 8:42 AM

8

en

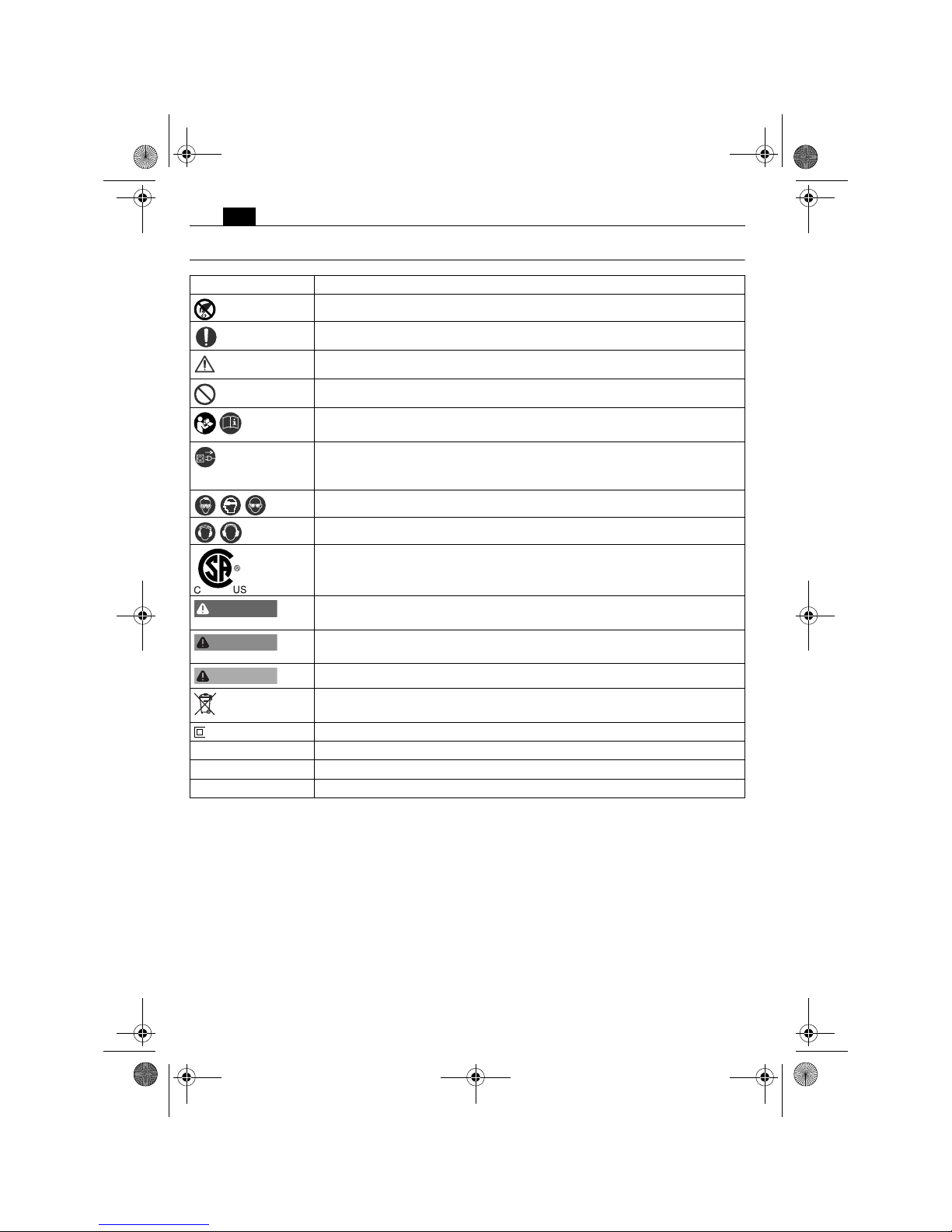

Symbols.

Symbol, character Explanation

Do not touch the rotating parts of the power tool.

Observe the instructions in the text or graphic opposite!

Observe the notes in the text aside!

General prohibition sign. This action is prohibited.

Make sure to read the enclosed documents such as the Instruction Manual and the General Safety Instructions.

Before commencing this working step, pull the power plug out of thesocket. Otherwise there will be danger of injury if the power tool

should start unintentionally.

Use eye protection during operation.

Use ear protection during operation.

This symbol confirms the certification of this product for the USA and

Canada.

This sign warns of a directly imminent, dangerous situation. A false reaction can cause a severe or fatal injury.

This sign indicates a possible dangerous situation that could cause severe

or fatal injury.

This sign warns of a possible dangerous situation that could cause injury.

Worn out power tools and other electrotechnical and electrical prod-

ucts should be sorted separately for environmentally-friendly recycling.

Product with double or reinforced insulation

~ or a. c. Alternating current

1 ~ Alternating current, single-phase

** may contain numbers and letters

DANGER

WARNING

CAUTION

OBJ_BUCH-0000000221-001.book Page 8 Tuesday, July 21, 2015 8:42 AM

9

en

Character Unit of measurement,

national

Explanation

n

/min, min-1, rpm, r/min Rated speed

P

W Electrical power

°Angle width

U V Electric voltage

f Hz Frequency

I

A Electric current intensity

m

kg, lbs Mass

l ft, in Length, width, height, depth, diameter or thread

Ø ft, in Diameter of a round part

m, s, kg, A, mm, V, W,

Hz, N, °C, dB, min, m/s

2

Basic and derived units of measurement from the

international system of units SI.

OBJ_BUCH-0000000221-001.book Page 9 Tuesday, July 21, 2015 8:42 AM

10

en

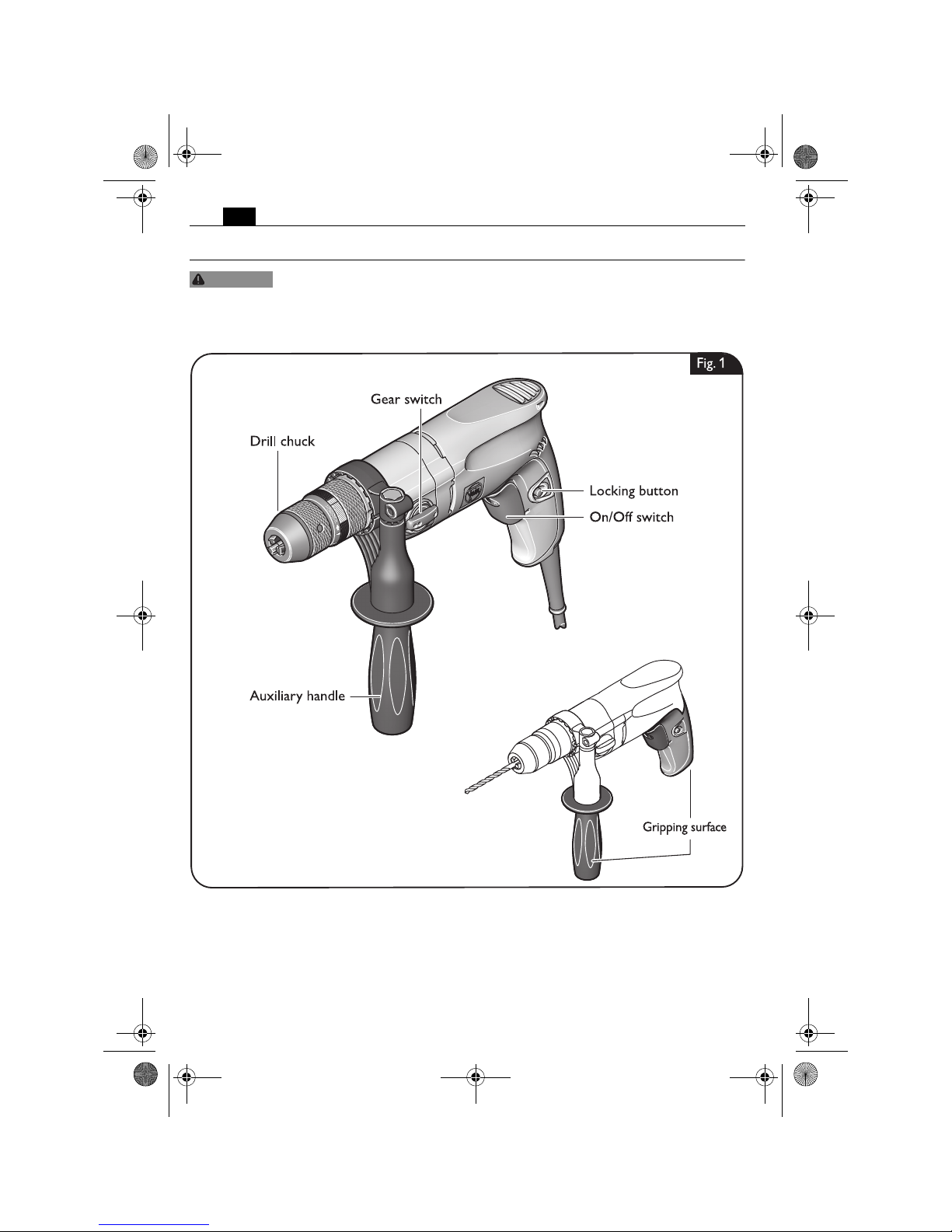

Technical description and specifications.

Before mounting or replacing cutting tool or accessories, pull the power plug.

This preventive safety measure rules out the danger of injuries through accidental starting of the power tool.

All accessories described or shown in this instruction manual will not be included with yourpower tool.

WARNING

OBJ_BUCH-0000000221-001.book Page 10 Tuesday, July 21, 2015 8:42 AM

11

en

Type BOP6 (**) BOP10 (**) BOP10-2 (**) BOP13-2 (**)

Order number 7 205 ... 7 205 ... 7 205 ... 7 205 ...

Current consump-

tion

4.4 A 4.4 A 4.4 A 4.8 A

No-load speed

– 1. Gear

– 2. Gear

0 – 4000/min–0–1500/min

–

0 – 700/min

0–2250/min

0 – 680/min

0–2200/min

On-load speed

– 1. Gear

– 2. Gear

0 – 2700/min

–

0 – 900/min

–

0 – 460/min

0–1350/min

0 – 440/min

0–1300/min

Drilling capacity in

steel

– 1. Gear

– 2. Gear

6 mm, 1/4 in–10 mm, 3/8 in–10 mm, 3/8 in

8 mm, 5/16 in

13 mm, 1/2 in

10 mm, 3/8 in

Drilling capacity in

aluminum

– 1. Gear

– 2. Gear

10 mm, 3/8 in–15 mm, 19/32 in–16 mm, 5/8 in

10 mm, 3/8 in

16 mm, 5/8 in

10 mm, 3/8 in

Drilling capacity in

wood

– 1. Gear

– 2. Gear

15 mm, 19/32 in

–

25 mm, 1 in–30 mm, 1 3/16 in

20 mm, 3/4 in

32 mm, 1 1/4 in

22 mm, 7/8 in

Tap size – M6, 1/4 in M10, 3/8 in M10, 3/8 in

Clamping range of

drill chuck

0.5–10mm

1/64–3/8 in

1.5 – 13 mm

1/16 – 1/2 in

1.5–13mm

1/16 – 1/2 in

1.5 – 13 mm

1/16 – 1/2 in

Thread size of drilling shaft 1/2" – 20UNF 1/2" – 20UNF 1/2" –20UNF 1/2" – 20UNF

Collar diameter 43 mm

15/8in

43 mm

15/8in

43 mm

15/8in

43 mm

15/8in

Weight according to

EPTA-Procedure 01

3.7 lbs (1.7 kg) 4 lbs (1.8 kg) 4.4 lbs (2.0 kg) 4.4 lbs (2.0 kg)

Class of protection /II /II /II /II

OBJ_BUCH-0000000221-001.book Page 11 Tuesday, July 21, 2015 8:42 AM

12

en

Assembly instructions.

Before mounting or replacing cutting tool or accessories, pull the power plug.

This preventive safety measure rules out the danger of injuries through accidental starting of the power tool.

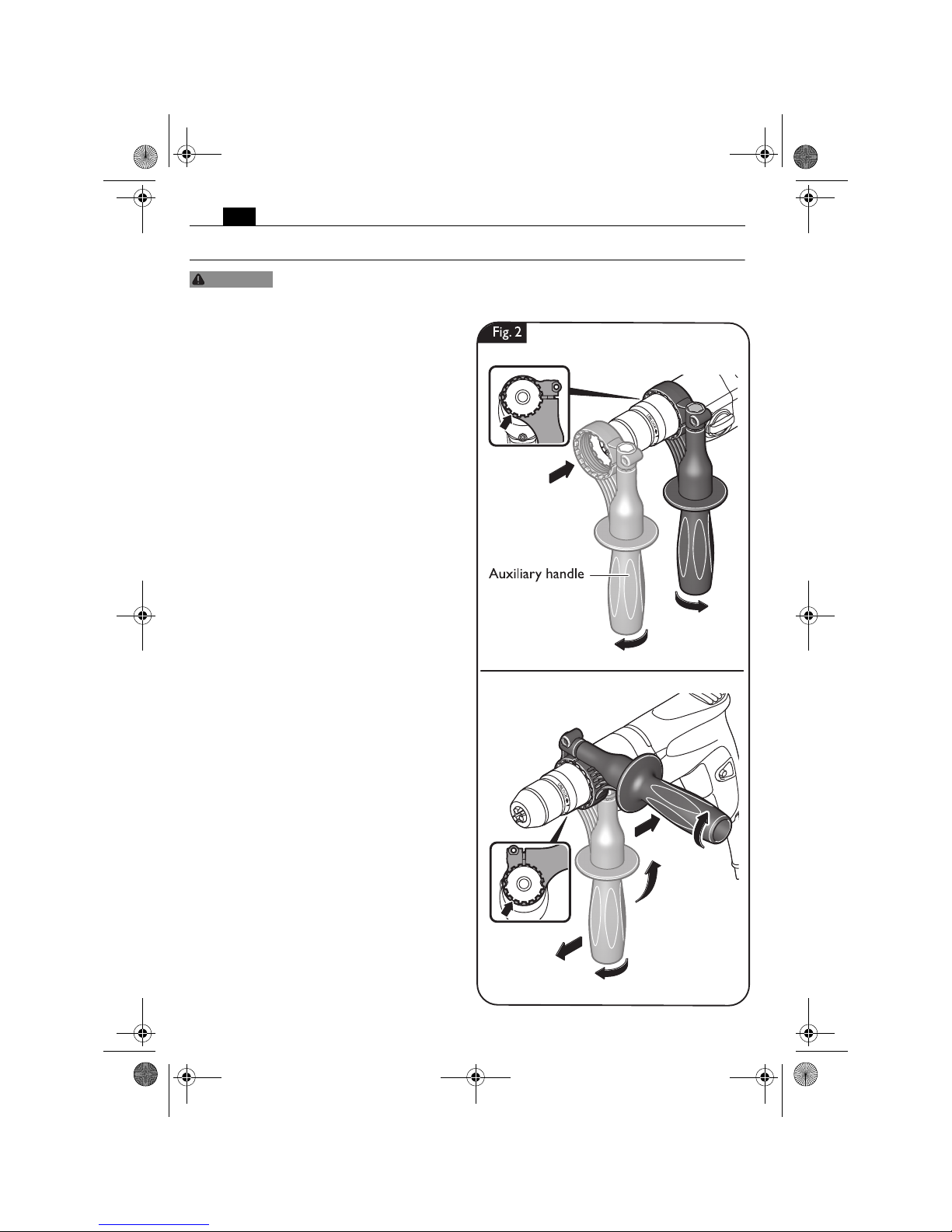

Mounting the auxiliary handle

(figure 2).

To loosen the clamping strap of the auxiliary

handle, turn the handle counterclockwise.

Slide the strap of the auxiliary handle in the

desired working position onto the collar until

the teeth engage into the recesses, and then

tighten.

WARNING

1.

2.

3.

1.

4.

3.

2.

5.

OBJ_BUCH-0000000221-001.book Page 12 Tuesday, July 21, 2015 8:42 AM

13

en

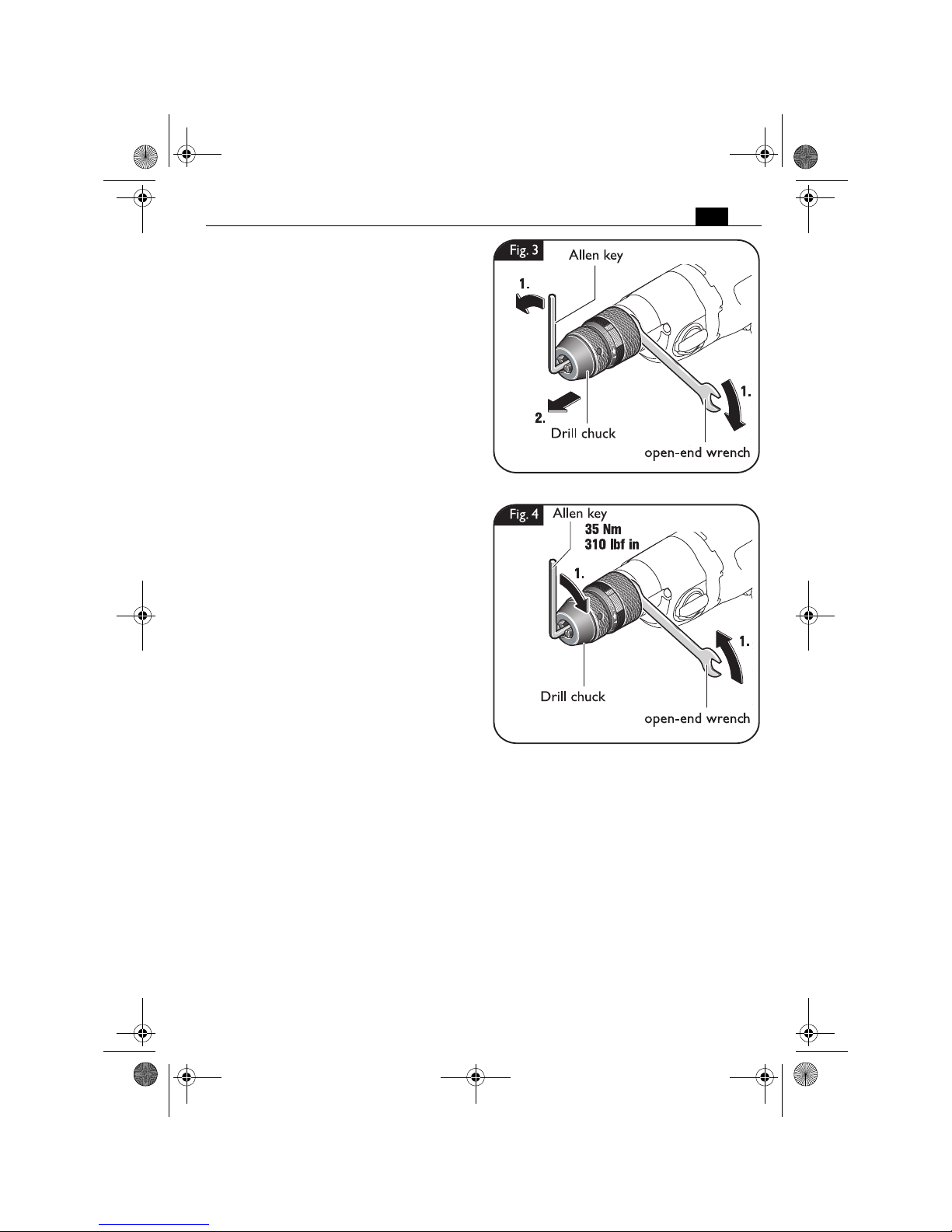

Removing the drill chuck (figure 3).

Insert a hex key into the drill chuck and

tighten the drill chuck.

Unscrew the drill chuck using the hex key and

the open-end wrench (size 17 mm).

Mounting the drill chuck (figure 4).

Mount the drill chuck in reverse order.

Tighten the drill chuck using a hex key and

the open-end wrench (size 17 mm) (tightening torque: 310 lbf in, 35 Nm).

OBJ_BUCH-0000000221-001.book Page 13 Tuesday, July 21, 2015 8:42 AM

14

en

Changing the tool.

Before mounting or replacing cutting tool or accessories, pull the power plug.

This preventive safety measure rules out the danger of injuries through accidental starting of the power tool.

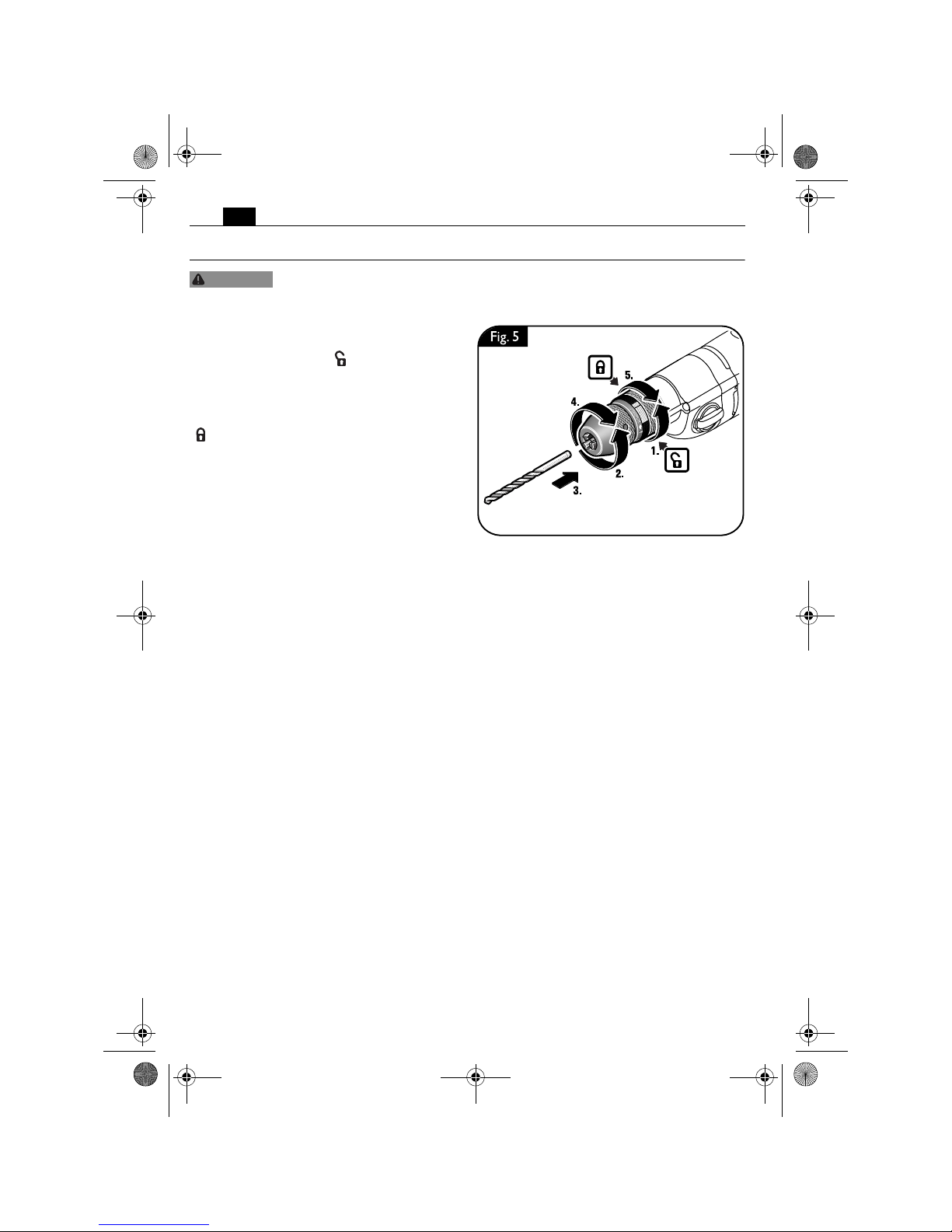

Mounting application tools (figure 5).

To loosen the lock of the drill chuck, turn the

rear sleeve toward the “ ” direction.

Unscrew the front sleeve to replace the application tool.

Tighten the front sleeve and lock the drill

chuck by turning the rear sleeve toward the

“ ” direction.

WARNING

OBJ_BUCH-0000000221-001.book Page 14 Tuesday, July 21, 2015 8:42 AM

15

en

Working instructions.

Before mounting or replacing cutting tool or accessories, pull the power plug.

This preventive safety measure rules out the danger of injuries through accidental starting of the power tool.

For each job, use only the FEIN application tool released and intended for the

respective application.

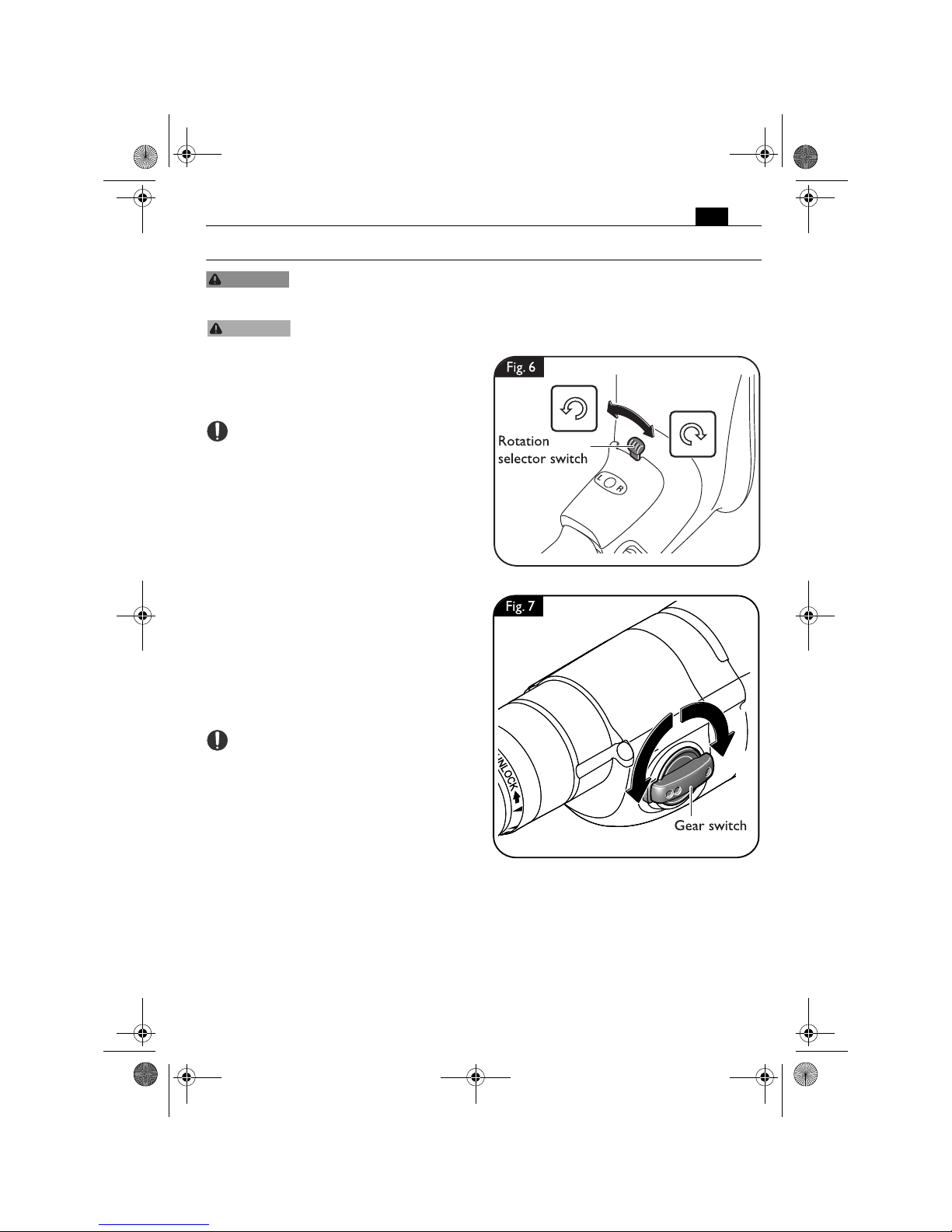

Selecting the rotation direction

(figure 6).

Set the rotation selector switch to right or left

rotation as required.

Adjust the rotation selector switch only

when the machine is at a complete stop.

Adjusting the gear setting (figure 7).

Adjust gear setting 1 to work with low speed

and high torque. This gear setting is suitable

for drilling with large drill bit diameters.

Adjust gear setting 2 to work with high speed

and a lower torque. This setting is suitable for

drilling with small drill bit diameters.

The material-dependent gear setting can be

determined by practical testing.

Adjust the rotation direction only when

the machine is at a complete stop.

WARNING

CAUTION

OBJ_BUCH-0000000221-001.book Page 15 Tuesday, July 21, 2015 8:42 AM

16

en

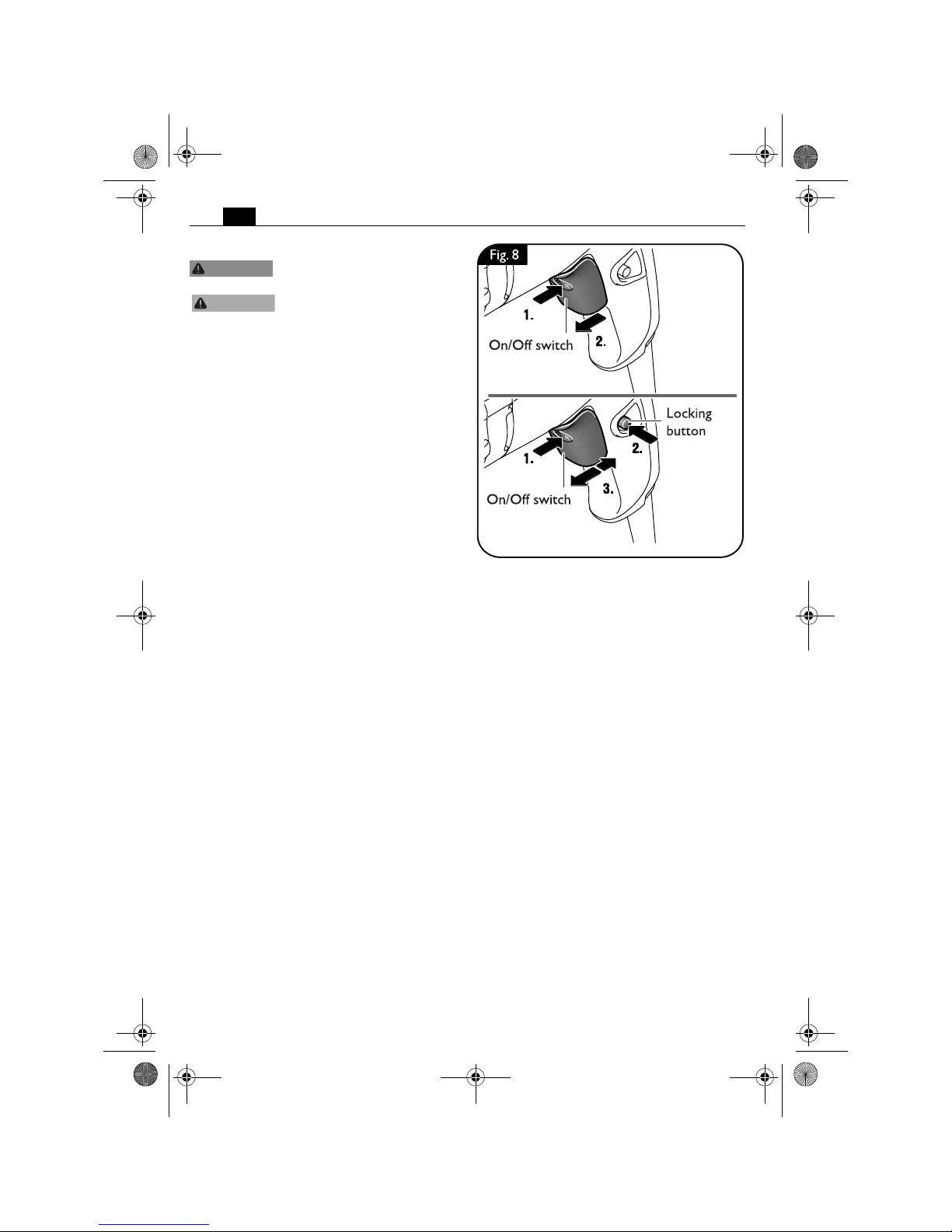

Switching on and off (figure 8).

Check the power supply cable

and the plug for damage.

Always hold the power tool

firmly. Otherwise, you could

lose control over the power tool.

For stationary use in a drill stand, remove the

switched off power tool from the drill stand

at operating temperature every 50 operating

hours and turn it by 180° to achieve uniform

lubrication.

Switching on:

Press the On/Off switch. The speed increases

the more you press the On/Off switch.

Switching off:

To switch off the power tool, release the

On/Off switch.

Locking on:

Press the On/Off switch to the stop and press

in the Locking button.

Release the On/Off switch.

For switching off, briefly press the On/Off

switch until the Locking button disengages.

Release the On/Off switch.

WARNING

CAUTION

OBJ_BUCH-0000000221-001.book Page 16 Tuesday, July 21, 2015 8:42 AM

Loading...

Loading...