Fein ASt 636, ASt 736 Operating Instructions Manual

ASt

636

To

be

handed

to

the

workshop

Operating

instructions

for

the

double

in~ulated

und

radio

suppressed

Electric

Power

Hack

Saw

type

ASt

636

and

ASt

736

(42

Volts)

I.

Technical

Data

Type

of

current:

single

(-)

phase

A. C.

Incisions

Stroke

.

Input

Output

We1gm

Type

per

minute

in.

I

ASt

636

3

1600

-

ASt

736

(42V)

4

I

2.

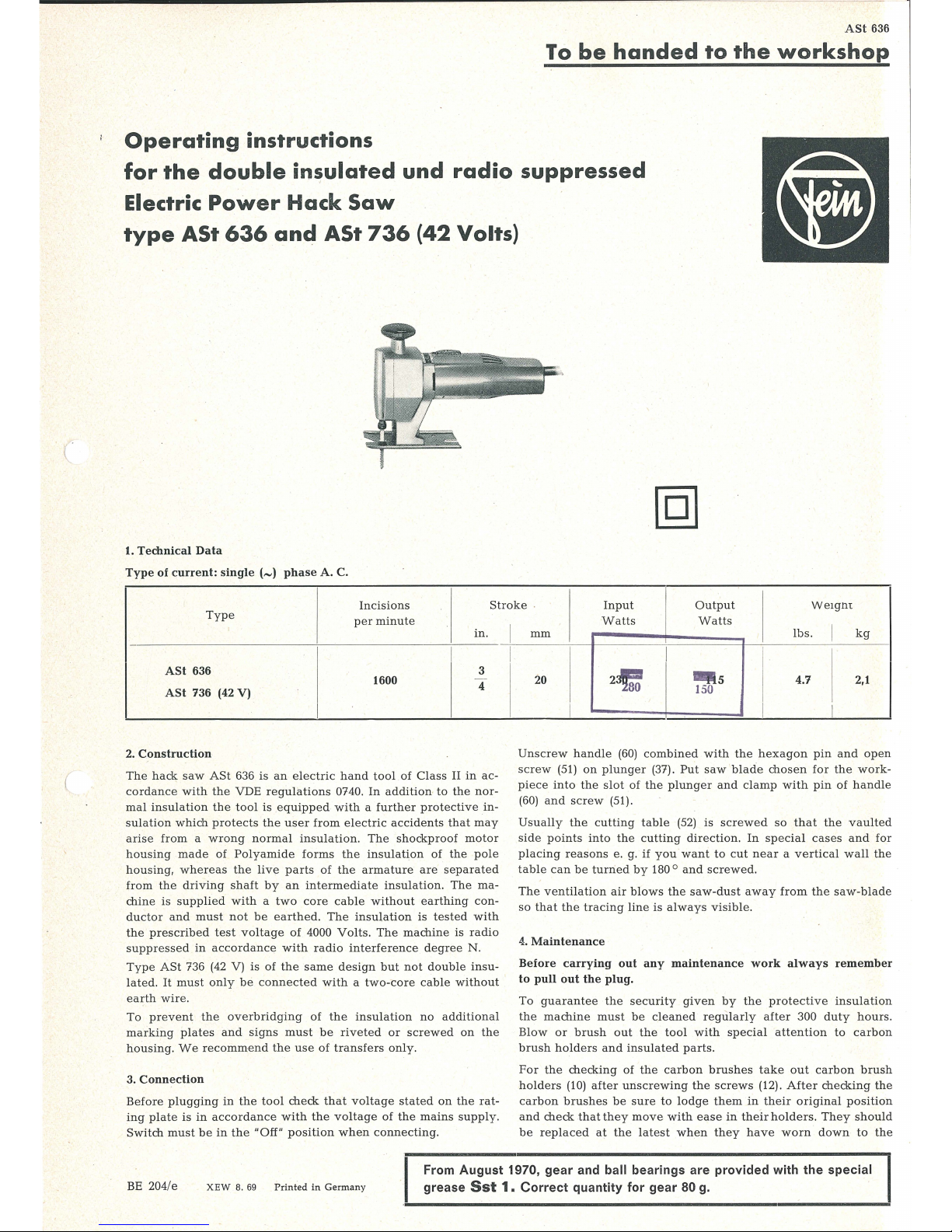

Construction

The

hack

saw

ASt

636 is

an

electric

hand

tool

of

Class

II

in

ac-

cordance

with

the

VDE

regulations

0740.

In

addition

to

the

nor-

mal

insulation

the

tool

is

equipped

with a further

protective

in-

sulation

which

protects

the

user

from

electric

accidents

that

may

arise

from a wrong

normal

insulation. The

shockproof

motor

housing

made

of

Polyamide

forms

the

insulation

of

the

pole

housing,

whereas

the

live

parts

of

the

armature

are

separated

from

the

driving

shaft

by

an

intermediate

insulation. The

ma-

chine is

supplied

with a two

core

cable

without

earthing

con-

ductor

and

must

not

be

earthed.

The

insulation

is

tested

with

the

prescribed

test

voltage

of

4000

Volts.

The

machine

is

radio

suppressed

in

accordance

with

radio

interference

degree

N.

Type

ASt

736

(42

V) is of

the

same

design

but

not

double

insu-

lated.

It

must

only

be

connected

with a two-core

cable

without

earth

wire.

To

prevent

the

overbridging

of

the

insulation

no

additional

marking

plates

and

signs

must

be

riveted

or

screwed

on

the

housing.

We

recommend

the

use

of

transfers

only.

3.

Connection

Before

plugging

in

the

tool

check

that

voltage

stated

on

the

rat-

ing

plate

is

in

accordance

with

the

voltage

of

the

mains

supply.

Switch

must

be

in

the

"Off"

position

when

connecting

.

I

Watts

Watts

mm

lbs.

I

kg

I

2e

20

5

4.7

2,1

150

I

I

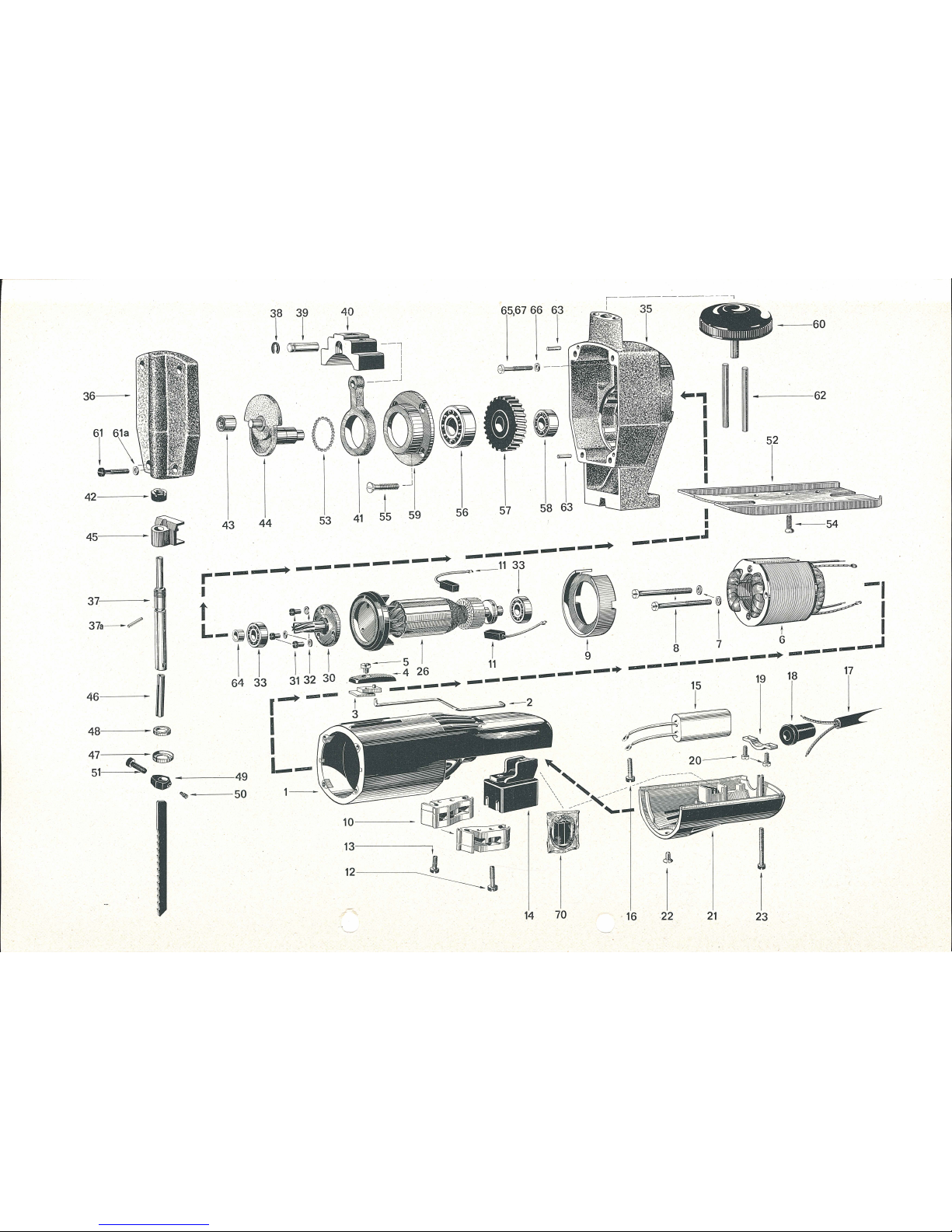

Unscrew

handle

(60)

combined

with

the

hexagon

pin

and

open

screw

(51)

on

plunger

(37).

Put

saw

blade

chosen

for

the

work-

piece

into

the

slot

of

the

plunger

and

clamp

with

pin

of

handle

(60)

and

screw

(51).

Usually

the

cutting

table

(52)

is

screwed

so

that

the

vaulted

side

points

into

the

cutting

direction.

In

special

cases

and

for

placing

reasons

e. g. if

you

want

to

cut

near a vertical

wall

the

table

can

be

turned

by

180 °

and

screwed.

The

ventilation

air

blows

the

saw-dust

away

from

the

saw-blade

so

that

the

tracing

line

is

always

visible.

4.

Maintenance

Before

carrying

out

any

maintenance

work

always

remember

to

pull

out

the

plug.

To

guarantee

the

security

given

by

the

protective

insulation

the

machine

must

be

cleaned

regularly

after

300

duty

hours.

Blow

or

brush

out

the

tool

with

special

attention

to

carbon

brush

holders

and

insulated

parts.

For

the

checking of

the

carbon

brushes

take

out

carbon

brush

holders

(10)

after

unscrewing

the

screws

(12).

After

checking

the

carbon

brushes

be

sure

to

lodge

them

in

their

original

position

and

check

that

they

move

with

ease

in

their

holders.

They

should

be

replaced

at

the

latest

when

they

have

worn

down

to

the

BE

204/e

XEW

8.

69

Printed

in

Germany

I

From

August

1970,

gear

and ball bearings are

provided

with

the

special

grease

Sst

1.

Correct

quantity

for

gear

80

g.

42 •

45---

37

fl

37a

- - /

;I[

I,,

I

46

I

48

~

47

@

51

~

~

~

G

I

43

38 39

40

l l I

~~~Q-l

I

44

53

____

J

I

~

-

_j

I

41

55 59

--,

65.67

66

6r

,_

60

~@--

sl~

~~I

I

62

I

52

I

I

I

"'

56

57

58

63

I

I

____

..

r----

--------

--------

__

_

1133

• j

lJ'

"" ,

·-

&:c

·a

@)

, ·' -

1

~

0 I 1

::

;.

...

_,

I

•

:=:::..

aP

®

=

~

f ...__

'ilf-

5 1 I I I

.

~

4

26

11

9 B 7 6 I

~

----

--------·

---------

_____

J

1~~~

1

-~~

.~~~~-

"'

---2

15 19 18

7

..

·~'¥!~

j

-

>£20.~--~

~

~

~j

l

l

~~

·Y

\

~'

" .. . --··-

-·

20

~

'--A

,

"'"

A

---

, '

--

\,

//_,----

'-

I

t

o-

®

I I

L -

~

.IJii

---::._

=-

1 )

JJ

do

64

33

--

,

....

I

I

1--

49

50

10--13

----

ct

14

70

·

16

22

21

23

Loading...

Loading...