Fein ASsd 636-1, ASsd 736-1 Operating Instructions Manual

ASsd

636-1

To be handed to the workshop

Operating instructions

for the

Electric Screw-Driver type ASsd 636-1

and for type

ASsd 736-1

(42

Volts)

1.

Technical

data

Current: ~ (single

phase

AC)

for

iron

screws

Tool

holder

Input

Type

up

to

Speed

R.P.M.

Watts

mm

Net

weight

in.

I

mm

full

load

ASsd

636-1

ASsd

736-1

,,4

6

450

2.

Construction

This

screwdriver

is

an

electric

tool

of

class

II

with

protective

insulation

without

earth

wire

and

is

in

accordance

with

the

VDE

regulations

0740.

The

protective

insulation

is

attained

by

the

shockproof

motor

housing

made

of

Polyamide-and

by

insulat-

ing

the

armature

against

the

pinion.

The

protective

insulation

is tested

with

the

prescribed

test

voltage

of

4000 V.

The

machine

is

radio

suppressed

in

accordance

with

radio

interference

VDE

0875.

It

is

supplied

with a two-core

cable

without

earth

wire

and

must

not

be

earthed.

Type

ASsd

736-1

for

low

tension

(42

Volts)

is

of

the

same

design,

but

without

protective insulation.

The machine

is

provided

with a reversing

switch

for

clockwise

and

anticlockwise

rotation.

It

must

not

be

operated

when

the

machine

is

running

.

To

prevent

the

overbridging

of

the

insulation

no

additional

marking

plates

and

signs

must

be

riveted

or

screwed

on

the

housing.

We

recommend

the

use

of

transfers

only

.

3.

Connection

Main volt

age

must

correspond

to

the

operating

voltage

marked

I

no

load

lbs

I

kg

70

800 230

with

round

5.1 2.3

receiver

table

below)

by

simply

exchanging

the

pressure

spring

(70).

For

exchanging

the

pressure

spring

only

unscrew

the

three

screws

(71)

and

draw

off

guide

bushing.

First

relieve

the

stress ·of

the

adjusting

ring

(68)!

By

turning

the

adjusting

ring

(68)

the

required torque

is

adjusted

by

means

of

the

pressure

spring

(70)

infinitely

variable

within a range

of

torque.

I

Torque

I

I

Wire

dia.

I

Spring

I

kpm

ft.

lbs

mm

in

.

0.30-0.70

2.2 -5.0 FD 1-186

(stand.)

4

5

h2

0.15-0.30

1.1

-2.2 FD 1-187

3.2

1

/a

0.10-0.20 0.75-1.5 FD 1-190 2.5

3

h2

The screwdriver

is

provided

with

an

instant

release

clutch,

so

that

the

tool

shaft

is

separated

from

the

motor

when

reaching

the

torque.

When

removing

the

machine

from

the

tigh

tened

screw

the

clutch

engages

automatically.

Tightened

screws

can

be un-

screwed

without

adjusting the

reversing

ring

(68).

on

the

rating

plate. The

tool

can

be

plugged

into

plain

or

safety

5.

Maintenance

sockets.

Switch

must

be

in

the

"Off"

position

when

connecting

.

4.

Adjustment

of

the• torque

The

screwdriver

can

be

adjusted

for three

ranges

of

torq

ue

(see

BE 223/e X 1.73

Printed

in

Germany

Before

carrying

out

any

maintenance

work

always

remember

to

pull

out

the

plug.

Every

300

duty

hours

blow

or

brush

out

the

tool

with

special

attention

to

carbon

brush

holders and

insulated

parts

in

order

to

guarantee

the

safety

given

by

the

protective

insulation

.

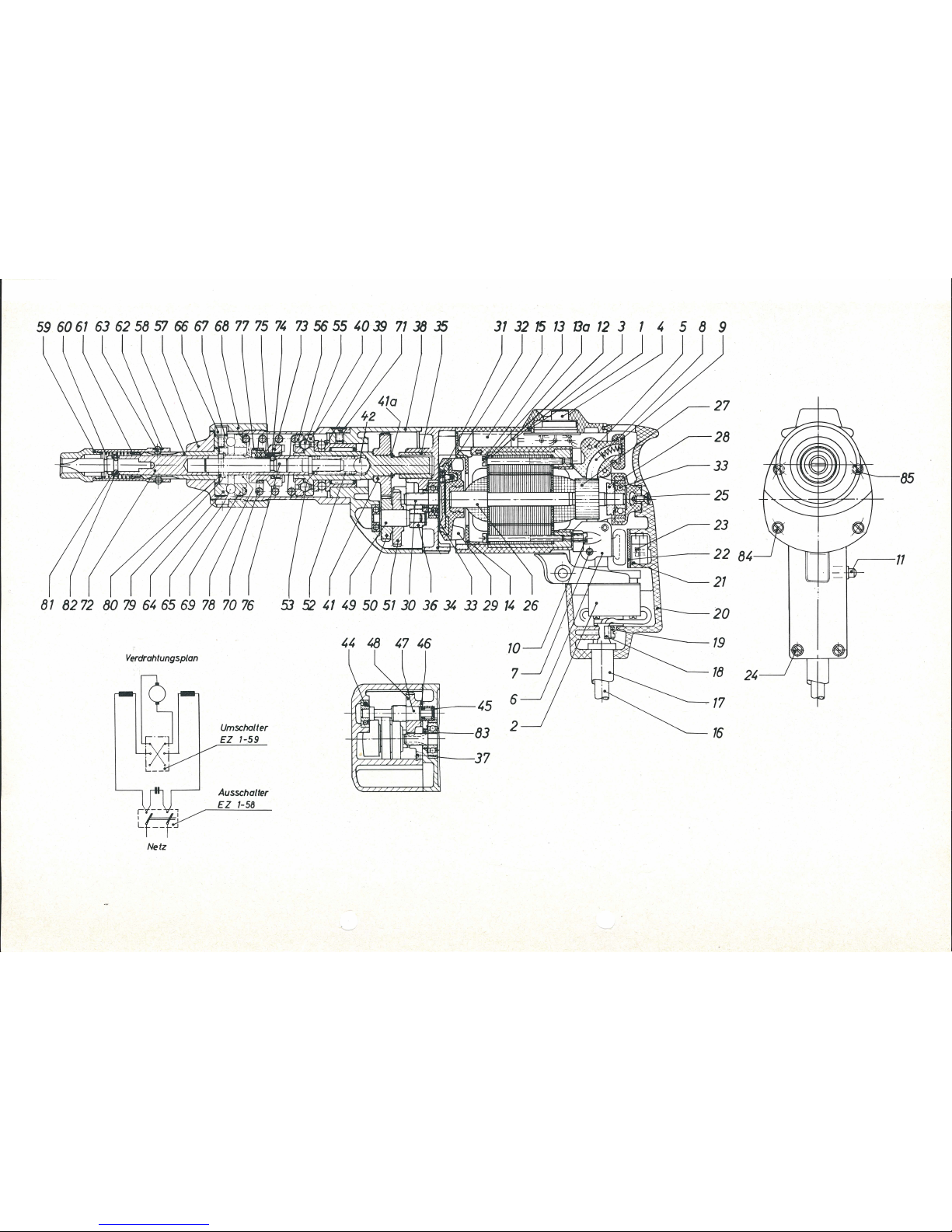

59

6061

63

62

58

57

66

67 68

77

75

74

73

56 55

4039

7138

35

31

32

15

13

13a

12

3 1 4 5 8 9

81

82

72

80

79

64

65

69

78

70

76

53

52

41

49

50

51

30

36

.34

33

29

14

26

Verdrahtungsptan

Netz

Umschalter

EZ

1-59

Ausscha/ter

EZ

1-58

44

48

47 46

A""""""~~t

··;~~..JI

45

~1~

~~

2

16

85

,.-------11

24

Loading...

Loading...