Fein ASs 636, ASs 736, ASs 636 b, ASs 736 b Operating Instructions Manual

r

ASs

636

To be handed to the workshop

Operating instructions

for the

double insulated and radio suppressed

Electric Screw-Driver type

ASs

636,

ASs

636

b

and for type

ASs

736,

ASs

736 b (42

Volts)

1.

Technical

data

Current:

""'

(single

phase

AC)

I

for

screws

Speed R.P.M.

Net weight

Type

Input

Output

up

to

I

m.

I

mm

full load

I

A

Ss

636

ASs

736 (42 V)

1/4

6

450

ASs

636b

self

drilling

screws

up

to

1900

ASs

736 b (42 V)

3

ft6

I

4,8

2.

Construction

This scr

ew-driver

is

an

electric

tool

of

Class

II with

protective

insulat-

ion

without

earthing conductor

and

is

in

accordance

with

the

VDE

regulations 0740. The

protective

insulation

is

attained

by

the

shoc

k-

proof

motor

hou

sing

made

of

Polyamide and

by

insulating the arm

a-

tur

e against the

pinion.

The

protecti

ve

insulation is tested

with the

prescribed

test volt

age

of

4000 V. The machine is radio suppressed

in

accordance w

ith

radio

int

erfe

rence degree

N.

It

is supplied with

a

t

wo

-cor

e cable w

ithout

eart

hing conductor

and

must

not

be

eart

hed.

Ty

pe

ASs 736

for

low

tension (42 V) is

of

the

same design,

but

with

~

out

double insulation

and

not

radio suppr

essed.

The

machine is provi

ded

with a reversin

g switch

for

clockwi

se and

anticlockwise

rot

ation.

It

must

not

be

operated

when

the

machine

is

running.

To prevent

the

overbridgi

ng

of

the insulation

no

additional marking

plates

and

signs

must

be rive

ted

or

screwed

on

the

hou

sin

g.

We

recommend

the

use

of

transfers

only.

3.

Connection

Before

pluggin

g m the tool check

that volt

age st

ated on

the

rating

plate

is

in

acco

rdance

with

the voltage of t

he

mains

supp

ly.

Switch

must

be

in

the

"Off"

position

when

connecting.

BE

173/e

XEW

11.69

Printed

in

Germany

no

load

Watts

Watts

lb

s

I

kg

800

-

..

3.5 1.6

.230

115

3000

3.5 1.6

.230

11

5

4.

Adjustment

of

the

torque

The

machine is

provided with

a positive clutch.

The

torque

is adju

sted

by

changi

ng

the

positi

on

of

the

clut

ch claws;

the

deeper

the

gripping

of

the

claws,

the

higher

the

torque

.

In

order

to adju

st

the

claws loosen securing screw (56),

then

turn

screw

(55).

Moreover, the

torqu

e is depende

nt

on the pressure

of the

driver

agai

nst

the scre

w.

5.

Maintenance

Before carrying

out

any maintenance

work always rem

ember

to

pull

out

the

plu

g.

Eve

ry 300

dut

y hours

blow

or

brush

out the

tool

with

special atten

tion

to

car

bon brush holders

and

ins

ulate

d p arts

in

order to

guarantee

the

safety given

by

the

protective

insulation.

After

checking

the

carbon

bru

shes m

ake

sure

to refit

them

in

their

original

position

and

check th

at they

move

easily

in

their

holde

r.

They shou

ld

be

repla

ced

at

the

latest when they have worn down

to

7

mm

(1

/4"). Please,

on

ly use original

Fein

carbon

brushes.

Aft

er fitting

new brushes,

run

tool unl

oaded

for about

15

minute

s to

allow

bru

shes

to

bed

in.

One

pai r

of

spare carbon brush

es will

be found

in the

cover

of the

hand

le; please, do

not

forget

to

reorder

them

in time.

From

August 1970, gear and ball bearin

gs

are provided with

the

special gre

ase

Sst 1. Correct quantity for gear 20 g.

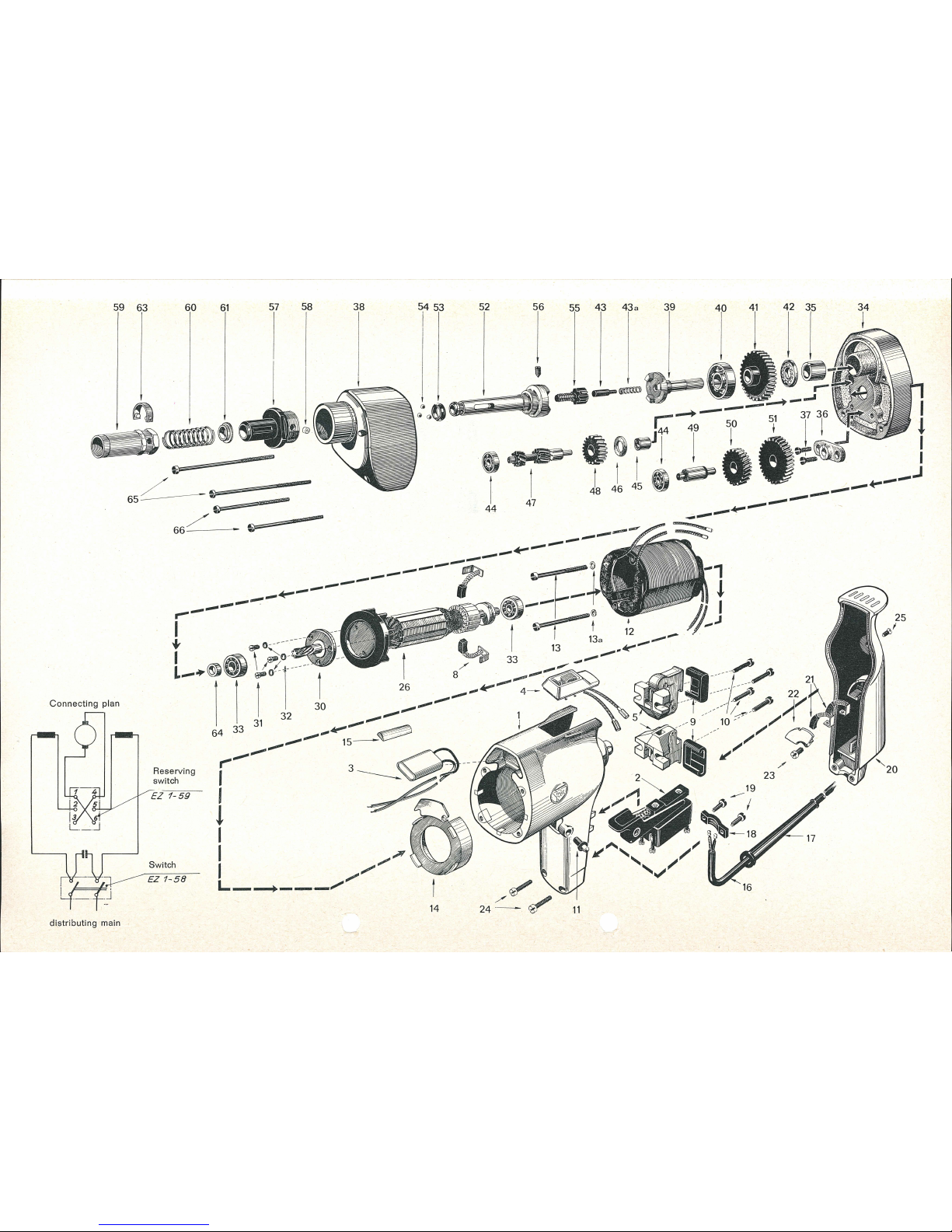

59

63

Connecting

plan

60

61

57

58

38

54

53

52

I I

56

55

43

43a

39

40

41

42

35

S)

~

i

(j(j

(jo

'

..-...--.~

lr-

':.-+-..A

----

,_......

51

37

36

--

J44

49

50

I I I

•

0•

! l j

.~~

-~

I I . - I

=;.,.

1 I l

46

45

I

.-.

___

...

__

J

M

~

~~~

-

_ __._.

....

~

~--------""'

---------"""'

~--------------

~

I I

"'

I

e-

..

___

____

_

26

L-~®)~

\I,

w

"'"T

--

1 L

64

33

31

32

,.,.----

,.,.,.,...

,.,.,.,.

....

~

~

,.,.,.,.,.,.

15

-~

Reserving

,..

switch I

3

I

------------.:_

Switch

!

I

I

I

13a

1

2

-----

----

..

4t!"'

......

-----

------

~

/

--

----

1~.

~

3~

--f~

'

~

'I

/

,/?'

,/'

Q

-

~/

~

~

/

23

I

.,.

L-~

A,..,

____

,,

I v'

-·

--"f/

·

L{f

~

14

24/c#'

~

11

distributing

main

Loading...

Loading...