Fein ASg 636, ASg 736 Operating Instructions Manual

ASg

636

To

be

handed

to

the

workshop!

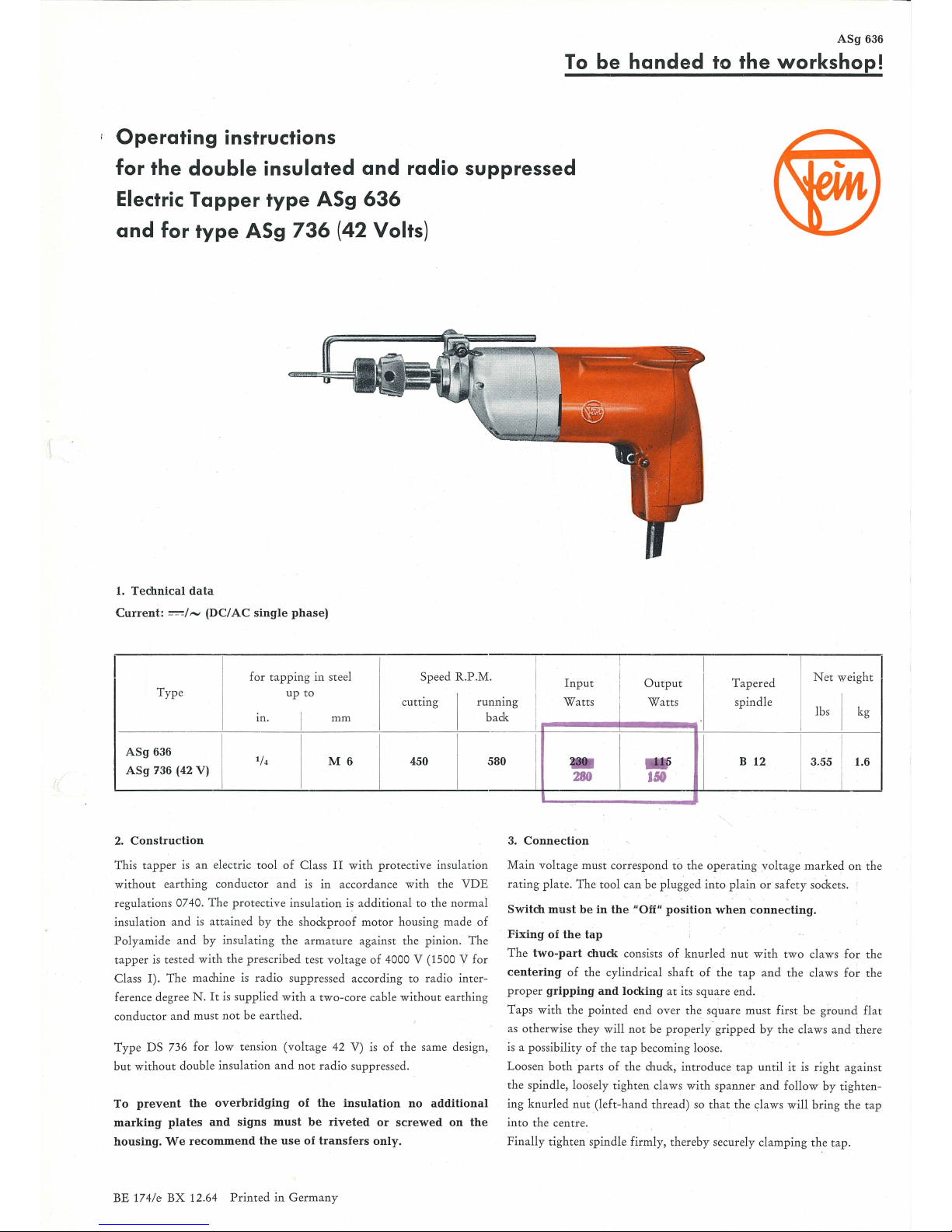

Operating

instructions

for

the

double

insulated

and

radio

suppressed

Electric

Tapper

type

ASg

636

and

for

type

ASg

736

(42 Volts)

1. Te

chnical

data

Current: ==1-

(DC/AC

single

phase)

for ta

pping in

steel Spe

ed

R.P

.M.

I

Input

O

utput

Tap

ered

Net weight

I

Type

I

up

to

c

uttin

g

I

runnin

g I

Watts

I

Watts s

pindl

e

I

I

I

I

lbs kg

I I

back

I

I

m. mm

I

I

A

Sg

636

1

/4

M6

450 580

ASg 736 (42

V)

I

2.

Construction

Th

is

tappe

r is an elec

tric tool of

Class

II

with protective

insula

tion

witho

ut

eart

hing conductor and is

in

accordance with the

VDE

re

gulations 074 0. T he

protecti

ve insula

tion

is

additional

to

the normal

in

sulation a

nd

is attained by

the

shockpr

oof

motor

hou

sing made of

Pol

yamide a

nd

by insula

ting th

e ar

mature

against the pinion. The

ta

pp

er is tested wi

th the prescribed test volt

age of 4000 V (1500 V

for

Class I). The machine is radio supp ressed accor

din

g to r

adio

inter-

feren

ce

degree N .

It

is supplied with a

two

-core cable

without

eart

hing

co

ndu

ctor a

nd must not be

eart

hed.

Type

DS 736 for l

ow

tension (v

olta

ge 42

V)

is of

the

same design,

but without

double insula

tion and

not

rad

io su

ppr

essed.

To

prevent

the

overbridging

of the

insulation

no

additional

marking

plates

and

signs must

be

rivet

ed

or

screwed

on

the

housing.

We

recommend

the

use

of

transfers

only.

BE 174/e

BX

12.64 P

rint

ed

in Ger

man

y

I

I

I

I

B 12 3.55

1.6

I

280

uo

I

I

3.

Connection

Ma

in

voltage must corresp

ond

to

the op

erating voltage mark

ed

on

the

rating plat

e.

The tool can be

plugged

in"

to pla

in

or

safety sockets.

Switch

must

be

in

the

"Off"

position

when

connecting.

Fixing

of the

tap

Th

e t w

o-part

chuck

consists

of

knurled

nut

with

two

claws for the

centering

of

the cyli

ndrical

shaft

of the t

ap

and

the claws

for

the

p

roper gripping

and

locking

at its square end.

Taps with

the poin

ted

end over the square

must

first

be

gro

und

flat

as

oth

erwise th

ey

will

not

be properly-g

ripped

by the

claws and there

is a

possibili

ty

of the

tap

becoming loose.

Loosen both ·parts of the chuck, i

ntroduce

tap until it is rig

ht

against

the spindl

e,

loosely tighten claws wi

th

spann

er

and

follow

by

tigh

ten

-

ing

knurled nut (left

-hand thread) so that the claws w

ill bring the

tap

in

to

the

centre.

Finall

y tighten s

pindl

e firml y, thereby securely clamping the tap.

-

--

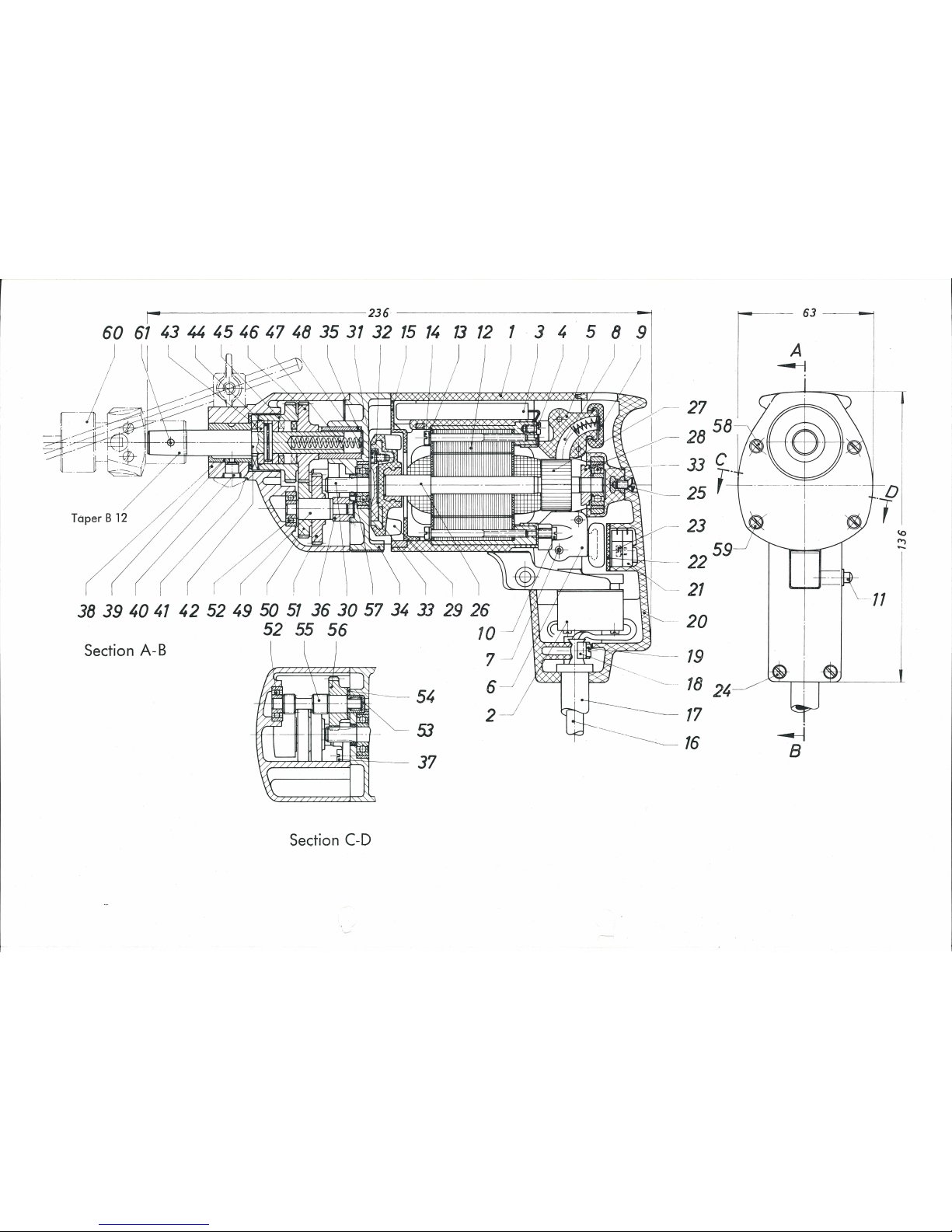

236

_____,

60

61

43

'"

45

46 47 48 35

31

32

15

11,

13

12

1 3 4

8 9

I

Taper B 12

~

23

- i 59

7

-=f=L.=.,~

-- 22

-

21

~

--

::

----

-

38

39

1,0

41

42

52

1,9

50

51

36 30 57

34

33

29 26

52

55

56

10

Section A-B

-).

..

~~~----~

-

54

-~

----

18

24

17

16

2

---

~

53

>' ' ' ' '

.l

'\

,',

"q'

~

37

Section C-D

r-

_;3

1

. I

Lv

ll

~

B

I

---

11

~

f")

-

Loading...

Loading...