Fein ASg 658, ASg 758 Operating Instructions Manual

ASg

658

To be handed to your workshop

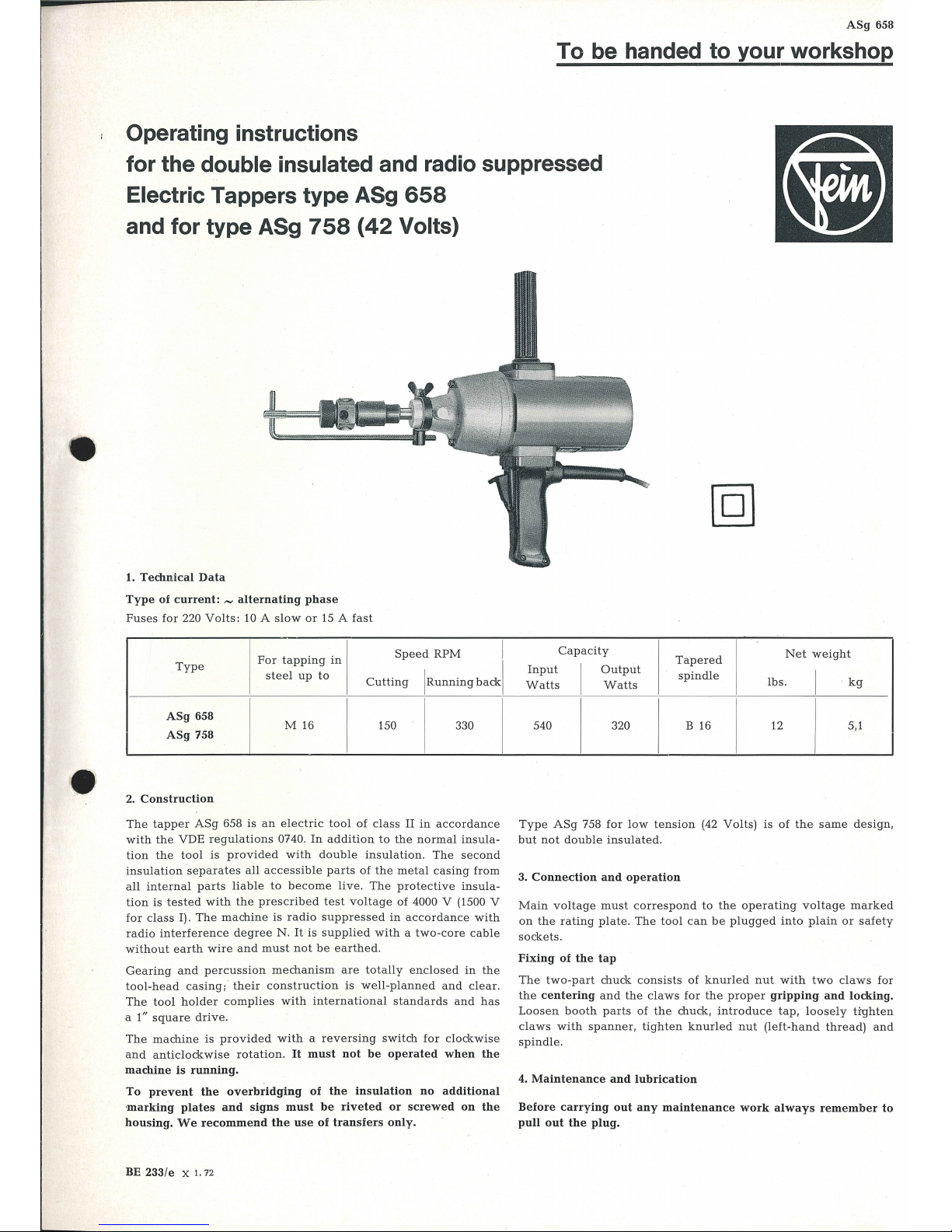

Operating instructions

for the

double insulated and radio suppressed

Electric Tappers type

ASg

658

and for type ASg

758

{42

Volts)

1.

Technical

Data

Type

of

current: -alternating

phase

Fuses

for

220

Volts:

10 A slow

or

15 A

fast

I

Type

For

tapping

in

Speed

RPM

[

Running

back

l

steel

up

to

Cutting

ASg

658

ASg

758

2.

Construction

M 16 150

330

The

tapper

ASg

658

is

an

electric

tool

of

class

II

in

accordance

with

the

VDE

regulations

0740.

In

addition

to

the

normal

insula-

tion

the

tool

is

provided

with double

insulation.

The

second

insulation

separates

all

accessib

le

parts

ofthe

metal

casing

from

all

internal

parts

liable

to

become

liv

e.

The

protective

insula-

tion

is

tested

with

the

prescribed

test

voltage

of

4000 V (1500 V

for

class

I).

The

machine

is

radio

suppressed

in

accordance

with

radio

interference

degree

N.

It

is

supplied

with a two-core cable

without

earth

wire

and

must

not

be earthed.

Gearing

and

percussion mecha

nism

are

totally enclosed

in

the

tool-head

casing; the

ir

construction

is

well-planned

and

clear.

The

tool

holder

complies

with

int

ernational standards

and

has

a 1"

square

drive

.

The

machine

is

provided

with a reversing

switch

for

clockwise

and

anticlockwise

rotation.

It

must

not

be

operated

when

the

machine

is

running.

To

prevent

the

overbridging

of

the

insulation

no

additional

•

marking

plates

and

signs

must

be

riveted

or

screwed

on

the

housing.

We

recommend

the

use

of

transfers

only.

BE 233/e x 1. 12

Capacity

Tapered

Net weig

ht

Input

Output

Watts Watts

spindle

lbs.

kg

540 320 B 16

12

5,1

Type

ASg

758

for

low

tens

ion

(42

Volts)

is

of the

same

design

,

but not

double

insulated

.

3.

Connection

and

operation

Main

voltage

must

correspond

to

the

operating

voltage

marked

on

the

rating

plate.

The

tool

can

be

plugged

into

plain

or

safe

ty

sockets.

Fixing

of

the tap

The

two-part

chuck

consists

of

knurled

nut

with two

claws

for

the

centering

and

the

claws

for

the proper

gripping

and

locking.

Loos

en

booth

parts

of the

chuck,

introduce

tap,

loosely Uyht

en

claws

with

spanner,

tighten

knurled

nut

(left-hand

thread)

and

spindle.

4.

Maintenance

and

lubrication

Before

carrying

out

any

maintenance

work

always

remember

to

pull

out

the

plug.

34

35

r-

~~

I

~

66

51a

I

46

45

44

42

51

~1

11111

74

79---

78

--

77

r-

84

JJJJ

±

II

I •

6

.

85

50

B

ohrkopf

um

90°

ver.selzf

geze

ichnet.

Loading...

Loading...