Page 1

VEK S4 Manual

2009-03-31

S4_Handbuch_GB_090331.doc

Traffic Detector - VEK S4

Page 2

Manual VEK S4

2 03/09 FEIG ELECTRONIC GmbH

Note

© Copyright 2009 by FEIG ELECTRONIC GmbH

Lange Straße 4

D - 35781 Weilburg

http://

www.feig.de

The specifications contained in this document may be changed without prior notice.

This edition replaces all earlier editions of the document.

The information in this guide has been compiled to the best of our knowledge and in good faith. FEIG

ELECTRONIC assumes no liability for the accuracy of the specifications in this guide. In particular FEIG

ELECTRONIC cannot be held liable for consequential damages resulting from improper installation.

Since errors can never be completely precluded in spite of all our efforts, we are always grateful for

corrections and suggestions.

The installation recommendations contained in this guide assume the most favorable circumstances. FEIG

ELECTRONIC assumes no liability for perfect function of the traffic detector in a foreign system environment.

Photocopying and reproduction of this guide in whole or in part as well as translation into other languages is

not permitted without prior written permission from FEIG ELECTRONIC. Also prohibited is storage of this

guide in whole or in part on modern storage devices for the purposes of further processing in data

processing systems.

Please read the user’s guide and safety advisories carefully and in full before starting up the traffic

detector!

Page 3

Manual VEK S4

FEIG ELECTRONIC GmbH 03/09 3

Contents

1 Functional Description ............................................................................................................................ 4

1.1 Vehicle detection................................................................................................................................. 5

1.2 Compensation..................................................................................................................................... 5

1.3 Classification of vehicles..................................................................................................................... 5

1.4 Possible outputs.................................................................................................................................. 6

1.5 Multiplexing methods .......................................................................................................................... 6

1.6 Synchronisation................................................................................................................................... 6

2 Settings ..................................................................................................................................................... 8

2.1 Frequency selection............................................................................................................................ 8

2.2 Multiplexing sequence......................................................................................................................... 8

2.3 Classification....................................................................................................................................... 8

2.4 Output modes.................................................................................................................................... 10

2.5 Time response of the output signals................................................................................................. 10

2.6 RS485 interface ................................................................................................................................ 11

2.7 CANopen interface............................................................................................................................ 11

3 Starting up............................................................................................................................................... 12

4 Display and Operation...........................................................................................................................14

4.1 Display elements............................................................................................................................... 14

4.2 (M)ode button.................................................................................................................................... 14

4.3 Factory settings................................................................................................................................. 15

4.4 Synchronisation display .................................................................................................................... 16

4.5 DIP switches ..................................................................................................................................... 16

5 Case......................................................................................................................................................... 18

5.1 Dimensions ....................................................................................................................................... 18

5.2 Opening the case.............................................................................................................................. 19

6 Technical data......................................................................................................................................... 20

7 Connector and pin assignment ............................................................................................................ 21

7.1 Power supply and interface screwless terminals.............................................................................. 21

7.2 Loop connections.............................................................................................................................. 22

7.3 2x5-pole pin connector for ribbon cables.......................................................................................... 22

7.4 Outputs.............................................................................................................................................. 22

7.5 PE connection................................................................................................................................... 22

8 Standard equipment, accessories........................................................................................................ 23

8.1 VEK M4D – connection kit ................................................................................................................ 23

8.2 VEK M4D accessories, 10 screwless terminals................................................................................ 23

8.3 Service software................................................................................................................................ 23

9 Safety instructions and warnings......................................................................................................... 24

10 4-channel functions ............................................................................................................................... 25

10.1 Scanning speed (4Ch) ...................................................................................................................... 25

10.2 Response sensitivity (4Ch)...............................................................................................................25

10.3 Hysteresis drop (4Ch)....................................................................................................................... 26

10.4 Holding time (4Ch)............................................................................................................................27

10.5 Direction recognition (4Ch)...............................................................................................................28

11 Notes........................................................................................................................................................ 36

Page 4

Manual VEK S4

4 03/09 FEIG ELECTRONIC GmbH

1 Functional Description

The VEK S4 traffic detector is a dual system for the inductive detection of vehicles. Information about the

speed, length and class of a vehicle can be provided using the measuring system (two loop principle) and its

evaluation. The data determined in this way are compiled in a report and provided to a higher level system

(host computer) for further evaluation.

Features:

• 4-channel induction loop detector

• two classification modules (for vehicle classification of, e.g. two lanes)

• automatic speed and length measurement

• vehicle classification in 8+1 classes according to TLS guidelines 2002

• vehicle detection and classification in both directions

• recording of the net time gap (time distance between two vehicles)

• loop dimensions according to TLS guidelines

1

• signal output can be adjusted using Open Drain in the case of excessive speed

• automatic adjustment of the system after switching on

• continuous readjustment of frequency drifts for largely eliminating environmental influences

• sensitivity independent from the loop inductance

• frequency band adjustment

• long loop supply lines possible (up to 300 m)

• simple installation using ribbon cable connection

• RS485 interface

• 4 Open Drain outputs

Other features:

• compact plastic case, mounting on DIN rail

• avoidance of reciprocal influencing of the channels using multiplexing methods

• avoidance of reciprocal influencing of several detectors using synchronisation

• LED display of the loop conditions

• insulation between loop and electronics

• gas surge arrester for improved surge resistance

• CANopen Interface

Setting options:

• five fixed frequency bands independent from the loop inductance

• head gap of the loops per classification module

• sensitivity adjustment of the loop pair per classification module

• adjustment of the vehicle length per classification module

• classification modules can be disconnected by deactivating the detector channels

• output can be set as presence signal, direction signal or general fault indicator, signal for excessive

speed, class-selective signal output

• hardware addresses 2 x (0-15) can be set using DIP switch and address offset via RS485 interface

• other setting options (4-channel functions) actuation threshold per channel in 256 stages

• hysteresis drop of 20-80% per channel

• holding time 1-255 minutes and indefinite per channel

• scanning speed

• direction logic

Compatibility

• downwards compatible to the TLS and FEIG protocol of the VEK S3-1

1

The publisher of the TLS (Technical delivery conditions for route stations) is the Federal Highway Research Institute

(BASt), Bergisch Gladbach

Page 5

Manual VEK S4

FEIG ELECTRONIC GmbH 03/09 5

1.1 Vehicle detection

It is established using an LC oscillator whether a metallic vehicle is in the loop area. The output of the

channel is switched depending on the selected output function.

Loop head gap and loop length are freely selectable and adjustable (see 6 Technical data ). The optimum

loop position must be determined with appropriate measuring methods for laying the loops over reinforced

roadbeds. The laying recommendations must be observed. It is recommended to use the widespread loop

geometry according to TLS II.

1.2 Compensation

A calibration is performed each time the detector is powered up or by pressing the button for longer than 1 s.

After a power interruption, automatic calibration is performed only if the supply voltage was absent for at

least 0.5 s. The calibration time is approx. 1 s if during this time no vehicles have passed through the loop.

Longer calibration times are caused by frequency instabilities; their causes must be determined and

remedied.

1.3 Classification of vehicles

The VEK S4 detector has two classification modules for the vehicle recording. These can be parameterised

independently from each other.

1.3.1 Vehicle data

The typical frequency change for vehicles and its time course on two induction loops with known geometric

dimensions are used for deriving the following factors:

• vehicle class

• vehicle speed

• vehicle length

• net time gap between the vehicles

• occupied time of the loops

• travel direction

The vehicles are classified in 8+1 classes according to TLS guidelines 2002:

• car

• car with trailer

• truck

• truck with trailer

• van

• bus

• motorcycle

• articulated vehicle

• non-classifiable vehicles, e.g. lane changers

1.3.2 Traffic Jam Detection

The detector signals a traffic jam if the traffic is flowing too slowly <10km/h. In this state, a dummy vehicle

with (Other, l = 4.0 m, v = 5 km/h) is reported. Every individual vehicle is also recognised and reported for

traffic queues if the gap between the vehicles enables both loops. The jam signal will be reset when both

loops become free.

Note: A correct detection of driving direction is not guaranteed for all traffic jam situations.

1.3.3 Recording in the case of loop fault

Speed and length measurement and classification is not possible in the case of a defective loop. A dummy

vehicle (Other, l = 4.0 m, v = 0 km/h) is reported for every vehicle which crosses the intact loop in the case of

loop malfunction.

Note: A loop fault is not reported if one or both loops have been intentionally deactivated as the classification

module concerned in this case is completely switched off.

Page 6

Manual VEK S4

6 03/09 FEIG ELECTRONIC GmbH

1.3.4 Tailgating

If a vehicle is driving to close to the car in front a dummy vehicle (Other, l = 4.5 m, v= last vehicle) is reported

with the vehicle speed of the car in front.

Note: A correct detection of driving direction is not guaranteed for all tailgating situations.

1.4 Possible outputs

Two Open Drain outputs each are assigned to every classification module. One of the functions listed below

can also be assigned to each output:

- no function (output deactivated)

- presence of a vehicle on the loops

- direction pulse signal

- pulse for vehicle crossing with vehicle class selection

- exceeding speed limit with vehicle class selection

- speed limit compliance with vehicle class selection

The function setting is made via the serial port using PC / Laptop with service program or host computer.

1.5 Multiplexing methods

The connected induction loops are switched on and off in rapid sequence, so that current flows only through

one loop at a time. This prevents mutual interference between the loops of a detector. All loops connected to

a detector can thus operate at the same loop frequency.

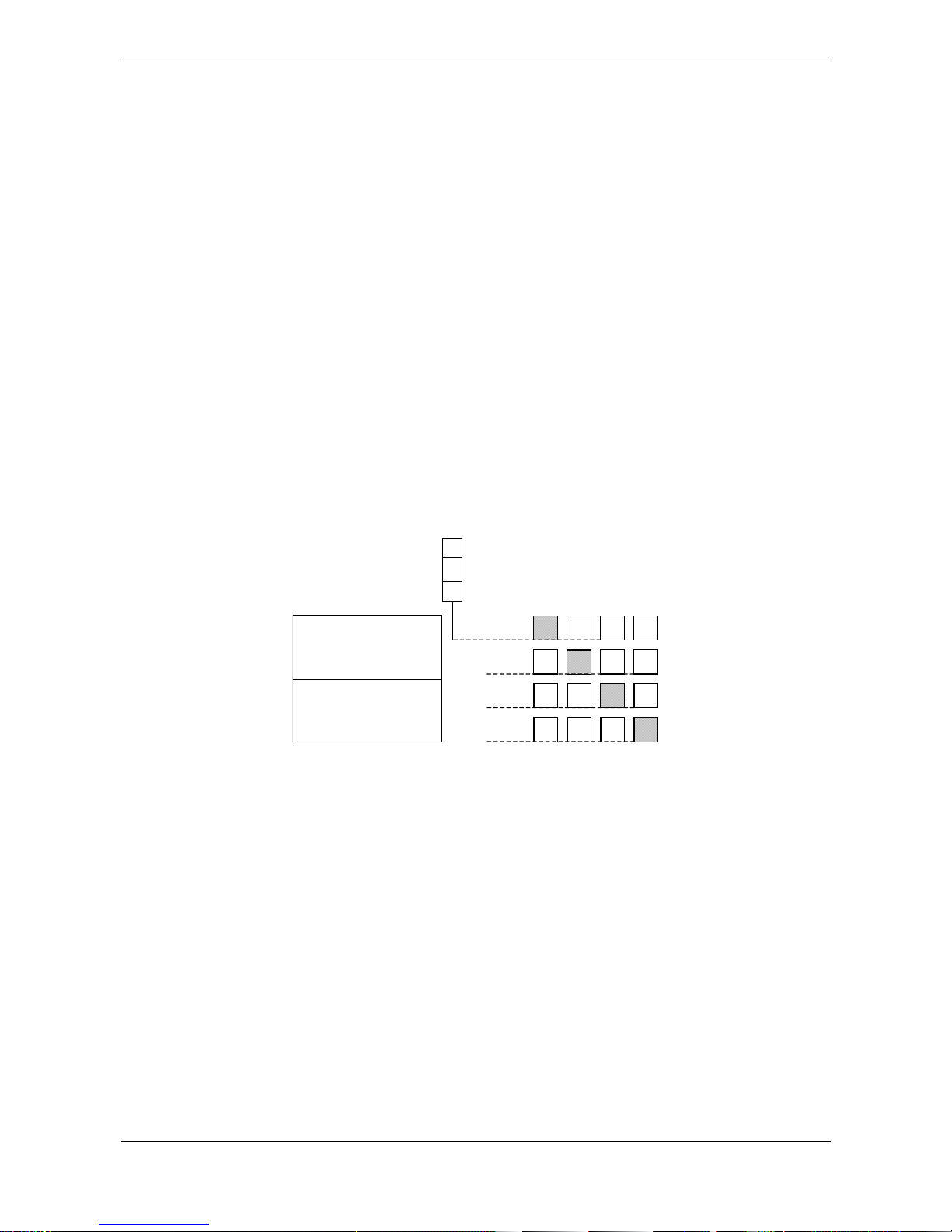

Kls-

modul 2

Kls-

modul 1

VEK S4

Time window 1

1 2 3 4

Inductance loops at a detector

1

2

3 4

1 2 3 4

1 2 3 4

Time window 2

T

ime window 3

Time window 4

1.6 Synchronisation

To prevent mutual interference between induction loops of multiple detectors, the latter can be synchronized

with each other using a connection in the front-side ribbon cable. All detectors connected via the

synchronous line process the multiplexing sequence synchronously. Only loops which are active in the same

time window can affect each other. Assigning the loops to the time windows is done by setting the multiplex

sequence.

Note:

• Adjacent loops should be assigned to different time windows.

• Loops in the same time window should be located physically as far away from each other as possible.

Page 7

Manual VEK S4

FEIG ELECTRONIC GmbH 03/09 7

1 2 3 4

1 2 3 4

1 2 3 4

1 2 3 4

1 2 3 4

VEK M4D

Induction loops on

multiple detectors

a) Example without synchronization:

Loop 2 of Detector Nr. 3 can in the

worst case affect all the loops of

Detectors 1,2,4 and themselves be

affected by these loops.

1 2 3 4

1 2 3 4

1 2 3 4

1 2 3 4

1 2 3 4

VEK M4D

Induction loops on

multiple detectors

b) Example with synchronization:

Loop 2 of Detector No. 3 can in the

worst case only affect loops in the same

time window of detectors 1,2,4 or be

affected by these loops.

Page 8

Manual VEK S4

8 03/09 FEIG ELECTRONIC GmbH

2 Settings

The settings described in the following are performed either on the RS485 interface or the CAN interface. It

is recommended that the system be equipped with an operating unit for setting the detectors. The settings

can also be made from a laptop. Setup programs are available from FEIG ELECTRONIC. An appropriate

interface converter is also required.

2.1 Frequency selection

The working frequency is set in order to prevent cross-coupling.

Cross-coupling may occur with adjacent loops or loop lines on other detectors. It is therefore important that

two or more detectors do not operate on the same frequency. A frequency separation of at least 10 kHz

should be maintained for neighboring loops which are not connected to the same detector.

The detector operates in five frequency bands:

Band Frequency range

0 automatic frequency setting (Factory default setting)

1 30 - 40 kHz

2 45 - 55 kHz

3 60 - 75 kHz

4 80 - 100 kHz

5 105 - 140 kHz

It is recommended that all four loops of one detector be set to the same frequency band. Multiplexing

prevents cross-coupling between the 4 loops of a detector.

Note:

For loops whose inductance lies outside the recommended range (see Section 6 Technical data), the

frequency band setting can be restricted. The detector may calibrate to a different frequency than shown in

the above table. This is not a problem as long as there is no cross-coupling with other loops. The currently

set frequencies should therefore be checked.

For long loop supply lines it is recommended to use band 2..4 for frequency setting.

If automatic frequency setting is activated, the VEK S4 uses the device address to choose one of the

frequency range above. Please check the real frequency, because it can differ from the nominal frequency.

For additional notes on preventing cross-coupling Æ see Section 1.6 Synchronisation

2.2 Multiplexing sequence

The default multiplexing sequence is 1-2-3-4. To prevent cross-coupling with neighboring loops of another

detector in exceptional cases, you may change the sequence (e.g. 1-4-2-3). Æ see also Section 1.6

Synchronisation

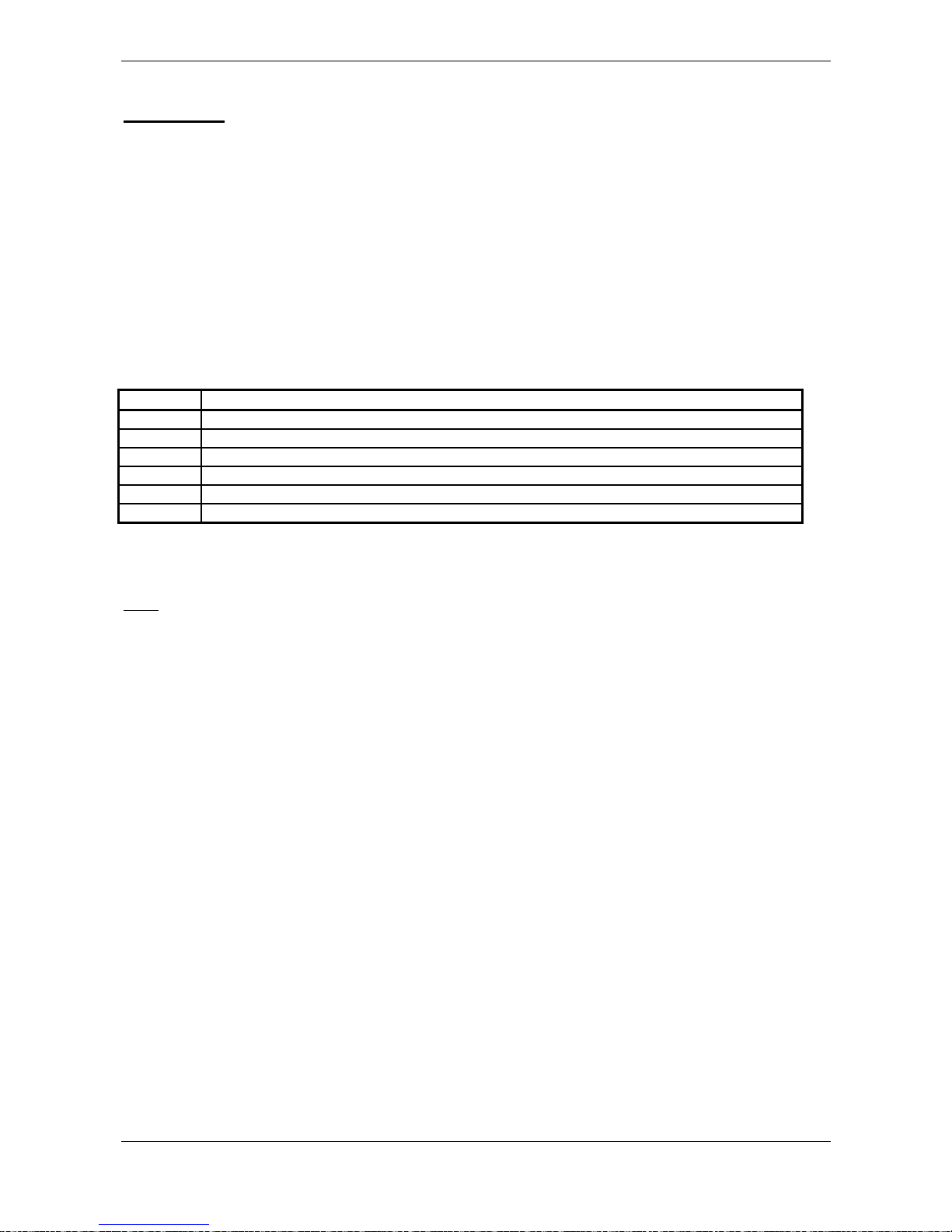

2.3 Classification

Both classification modules of the VEK S4 detector have separate loop parameters so that relevant

parameters per classification module can be set for the vehicle recording. The loop parameters include the

head gap, the amplitude factor for the sensitivity, the constant for the length adjustment and the loop length.

• Head gap

The correct setting of the head gap is relevant for the accuracy of the speed measurement and the vehicle

length.

Page 9

Manual VEK S4

FEIG ELECTRONIC GmbH 03/09 9

• Amplitude factor

The loss of sensitivity due to abnormal loop dimensions, long loop lines or road surface reinforcements is

largely compensated for using the amplitude factor. Automatic evaluation of this factor is also available.

• Length adjustment

The measured vehicle length is corrected with the length adjustment. No vehicle length adjustment is usually

required for normal loops according to TLS with loop lines up to 100 metres.

• Loop length

The loop type of the connected loops is adjusted using the loop length. Currently only the loop types TLS I

and TLS II according to the TLS 2002 guidelines are supported. The loop type TLS II is assumed for a length

up to 125 cm. The loop type TLS I is set for lengths of more than 125 cm.

loop

llenght

Kopfabstand

loop 3

loop 4

loop 1

loop 2

Classifaction-

modul 1

Classifaction-

modul 2

Signals

OpenCollector 3

Counter ever class

and directoin

OpenCollector 4

OpenCollector 1

OpenCollector 2

Loop allocation

is firm

Counter ever class

ans direction

Augangszuordnung

is firm

• Output signals

As already described in 1.4 Possible outputs, each classification module can control two outputs. Refer to

the diagram above for their assignment. One of the five available functions can be set for each output.

Outputs can also be deactivated.

• Vehicle counter

Each classification module has a 16-bit counter per vehicle class and travel direction which can be invoked

via the RS485 interface. It must be noted that the counters roll over at 65535 (2

16

) and restart from 0. It is not

recommended to reset the counters otherwise vehicles can be lost at the time of the reset. The counters in

the detector are not protected against power failure. The detectors must either be buffered with a UPS

system or the counter readings must be regularly read and stored in the higher level system for long-term

counting.

Page 10

Manual VEK S4

10 03/09 FEIG ELECTRONIC GmbH

2.4 Output modes

The following output modes can be set for the four open collector outputs:

Output mode Description

Standard output Normal output mode for presence or direction detection

Group fault message Output indicates loop faults from all loops

always off Output always turned off

always on Output always turned on

Simulation Output switches constantly, e.g. for testing purposes

Inverted or non-inverted signal output can be selected for all output modes.

In the case of standard output the loop faults of the respective channel can be output together with the

logical signal. Which fault is additionally indicated can be set to loop fault (break/short), loop frequency

outside frequency band and calibration procedure.

Factory default setting: Standard output,

Signals not inverted,

Respond to loop fault

The interface can be used to temporarily turn the outputs on or off. This allows you to implement control

tasks such as controlling traffic lights or variable message signs.

In simulation mode the output is constantly repeated according to the following scheme:

- The signal duration corresponds to the set minimum on duration

- The pause time corresponds to the set on delay. If no on-delay is set (0 ms), an idle time of 20s is

assumed.

For the factory set time behavior of the output signals this means a pulse signal of 200 ms duration and an

idle time of 20 s.

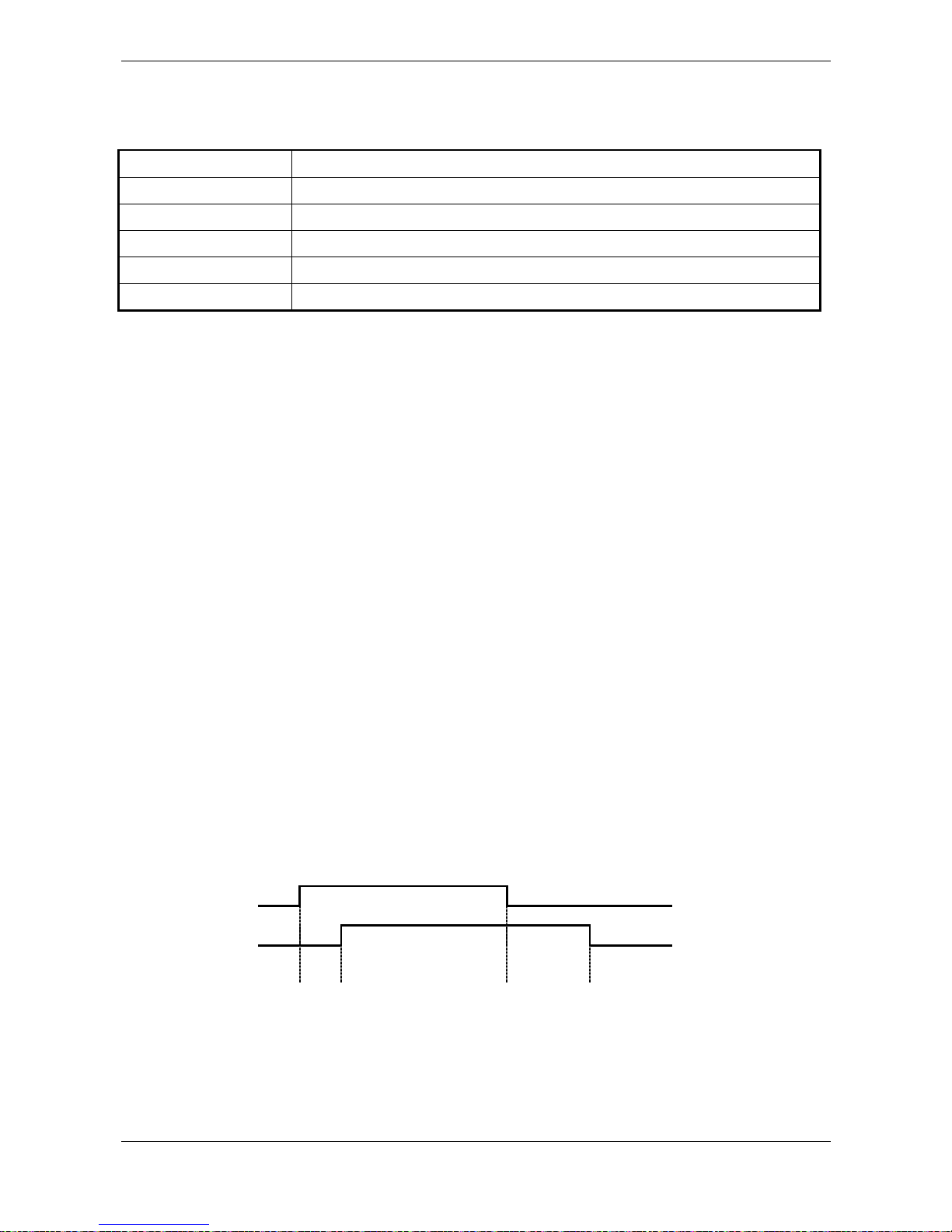

2.5 Time response of the output signals

On-delay, minimum on duration and off-delay for the hardware output signals can be set in 100 ms

increments over a range of 0...25500ms.

Factory default setting: On-delay 0 ms

Off-delay 0 ms

Minimum on duration 200 ms

Loop busy

Output signal

t

on

td ≥ t

dmin

t

off

ton: On delay

t

off

: Off delay

t

dmin

: Minimum on duration

t

d

: Signal duration

Page 11

Manual VEK S4

FEIG ELECTRONIC GmbH 03/09 11

2.6 RS485 interface

Baud rates: 9.6, 19.2, 38.4 kbaud

Parity: no, even, odd parity

Factory default setting: 9.6 kbaud, even parity

Refer to the RS485 documentation for the VEK S4 for the specification of the interface protocols.

The VEK S4 is downwards compatible with the interface protocols defined for the VEK S3. The

protocols based on the TLS defined in the VEK S3 are also supported. In these cases, one VEK S4

behaves like two separately addressable VEK S3 units. Mixed operation of VEK S3 and VEK S4 on

a common bus is not recommended.

Default or factory setting: 100 kBit/s

2.7 CANopen interface

The CANopen standard 301 according to CiA is supported

Baud rates: 100, 125, 250, 500, 800, 1000 kbps

Refer to the CANopen documentation for the VEK S4 for the specification of the CANopen protocols.

Please look for CANopen basics in the specifications from the CiA (CAN in Automation)

organisation.

Default or factory setting: 250 kbps

Page 12

Manual VEK S4

12 03/09 FEIG ELECTRONIC GmbH

3 Starting up

1. Installation – The installation rail must be grounded. Æ 5 Case and 7.5 PE connection

2. Address – The detector address is set to 48 at the factory using the address offset. All detectors which

will be operated on a common interface must be set to different addresses before the commissioning.

Æ

4.5.1 Device address

3. RS485 bus terminator – The RS485 interface must be terminated at the beginning and end in

accordance with the respective specification.

Æ

4.5.2RS485 interface bus termination

4. RS485 baud rate – Select the correct baud rate for the host computer / laptop port. When delivered, the

baud rate for the RS485 interface is set to 9600 bps. If the baud rate of a detector is not known, this can

be reset to 9600 bps by restoring the factory settings.

Attention: All other parameters are also reset when the factory settings are restored.

5. Loop assignment – assign loops to the classification modules. The loops on the connections Loop1 /

Loop2 and Loop3 / Loop4 are assigned to the classification module 1 or the classification module 2

respectively.

6. Loop scanning – Adjacent loop should not operate in the same time window. It must already be

ensured during the planning that neighbouring loops not connected to the same detector are preferably

assigned to different channel numbers. Otherwise the multiplexing sequence must be changed over

during the commissioning.

Æ

1.5 Multiplexing methods

Æ

1.6 Synchronisation

Æ

2.2 Multiplexing sequence

7. Frequency selection – The loops of a detector are usually set to the same frequency band.

Neighbouring loops or loops from neighbouring detectors must be set to different frequency bands.

Æ

2.1 Frequency selection.

8. Head gap – The head gap must be set individually for each classification module. It is usually 400 cm for

TLS I loops and 250 cm for TLS II loops.

9. Amplitude factor – The amplitude factor must be set individually for each classification module. The

displayed out of tune maximum must be checked and corrected using the amplitude factor.

If the S4 protocol is used, the out of tune maximum for TLS I loops for vans should be between 480 and

800 and between 275 and 420 for TLS II loops.

1

Factory settings of the amplitude factor:

Loop TLS type I 60

Loop TLS type II 100

Note: The amplitude factor must be set and checked for every measuring cross section. It is crucial

for the quality of the vehicle classification.

10. Loop length – The loop length of the connected loops must be set for each classification module. The

loop length is usually 250 cm for TLS I loops and 100 cm for TLS II loops.

1

When using the downwards compatible VEK S3 protocol, the maximum for vans should be approx. 20

(+/-5) for TLS I loops and approx. 11 (+/-3) for TLS II loops.

Page 13

Manual VEK S4

FEIG ELECTRONIC GmbH 03/09 13

11. Length adjustment – The displayed and actual lengths of a known vehicle must be compared and

adjusted using the length adjustment. The adjustment of the speed and length measurements should be

made with reference to average values obtained from several measuring cycles.

12. Speed – The speeds of the vehicles must be measured with a sufficiently accurate measuring method

and compared with the detector measured values. The measured speed can be adjusted to the actual

speed using corrections of the head gap for each classification module.

Page 14

Manual VEK S4

14 03/09 FEIG ELECTRONIC GmbH

4 Display and Operation

4.1 Display elements

The front panel of the detector contains 4 green LEDs for indicating the respective loop state.

LED behavior in normal operation:

LED Description

off Loop free

on Loop busy or direction pulse

flashes slowly Frequency calibration running

flashes rapidly Loop fault (break or short)

flashes in pairs automatic evaluation of amplitude factor in process

Chain Synchronization indicator in 8s rhythm

4.2 (M)ode button

The following functions can be activated by pressing the M-key on the front panel.

M-key LED display in

binary code

Function

1x short

Uses LEDs 1-4 to display the hardware address set with DIP

switches 1-4.

1x long

Generates a hardware reset

and before that displays the set hardware address

1x short, 1x long Generates a hardware reset

2x short, 1x long Polls the Master ( ) / Slave ( )

...

6x short, 1x long Resets to factory default settings

The number of short presses of the button is indicated on the LEDs in binary code – left 23, right 2

0

For hardware address ‚0’ the flashing sequence / is output.

The transition between long and short button depression is indicated after 1s by rapid flashing of all LEDs.

After an additional second the LED indicators go out to indicate the function is activated. If the button is

released sooner, during the flashing phase, the function is cancelled!

Page 15

Manual VEK S4

FEIG ELECTRONIC GmbH 03/09 15

4.3 Factory settings

To restore the factory default parameters, proceed as follows:

1) Press button 6x briefly until

shows on the LEDs.

2) Hold button down Æ After one second all LEDs flash rapidly.

After two seconds the LEDs go out.

3) Release button. Æ The essential detector parameters are now set as follows :

Parameter Value Description Comments

Frequency 0 automatic frequency setting depending on device address

Hardware output

Output mode

Inversion

Error output

3

0

0

normal output

not inverting

no loop errors

Standard hardware output for loop

assignment

Loop parameters

Classification module 1

and 2

Head gap 250 cm TLS II loop

Length adjustment 0

Amplitude factor 100 TLS II loop

Loop length 100 cm TLS II loop

Output parameters

Classification module 1

Outputs 1 and 2

Loop assignment

1

2

Output 1: loop 1

Output 2: loop 2

Outputs 1 and 2

Output function

1 Presence

Output parameters

Classification module 2

Outputs 3 and 4

Loop assignment

1

2

Output 3: loop 4

Output 4: loop 4

Outputs 3 and 4 Output function

1 Presence

Address offset 48 Offset

version dependent if necessary !

RS485 port

Baud rate

Parity

Parity detection

4

0

1

9600 Baud

even

active

Refer to the RS485 protocol specification for the basic setting of other parameters !

Page 16

Manual VEK S4

16 03/09 FEIG ELECTRONIC GmbH

4.4 Synchronisation display

Correct function of the synchronization of multiple detectors is indicated by the scrolling effect of the LEDs in

an 8s rhythm. As the device address increases from left to right, the scrolling LEDs also run from left to right

for all synchronized detectors.

Polling of the Master detector is also possible, as described in 4.2 (M)ode button. The Master sends the

synchronization signals over the ribbon cable to the other detectors (Slaves). Selection is random.

4.5 DIP switches

The 8-pole DIP switch is used for selecting the device address and for enabling termination for the CAN bus

and RS485 interface. The DIP switches are located inside the enclosure. As shipped all DIP switches are in

the OFF position.

1

2 3 4 5 6 7 81

ON

Address

0-15

RS485

Pullup / Pulldown

Bus termination

CAN

Bus termination

Note! Before startup check all DIP switches for the correct position! Improper setting can damage

the interfaces.

4.5.1 Device address

The device address results from the hardware device address set using the DIP switches and the software

settable address offset.

DIP switch

1234

Hardware

device address

0000 0

1000 2

0100 4

1100 6

0010 8

1010 10

0110 12

1110 14

0001 16

1001 18

0101 20

1101 22

0011 24

1011 26

0111 28

1111 30

Device address = Hardware device address + Address offset

For downward compatibility to VEK S3 the step size for address offset is 2

Page 17

Manual VEK S4

FEIG ELECTRONIC GmbH 03/09 17

4.5.2 RS485 interface bus termination

+5V

GND

470Ω

470Ω

120Ω 120Ω

. . . . . .

Station

Typical wiring of the RS485 interface

The shown resistors are mounted inside the detector and switch able by the help of the DIP-switches

DIP switch Description

5

470Ω-Pull-up resistor on RS485 B+

6

470Ω-Pull down resistor on RS485 A-

7

Bus termination 120Ω between RS485 B+ and A-

The RS485 bus must be terminated on the front end (control device or repeater) and back end (last detector)

with a 120Ω resistor. Set DIP switch 7 to ON in the last detector.

In addition the two RS485 signal lines B+ and A- must be connected once to 5V resp. to GND with a 470Ω

resistor each. If this has not been done on the control device or repeater, the circuit can be activated on the

last detector using DIP switches 5 and 6.

As shipped the DIP switches are in the ‚OFF‘ position.

4.5.3 CANopen bus termination

CAN High

120

Ω

120

Ω

. . . . . .

CANopen devices

CAN Low

DIP switch Description

8

Bus termination 120Ω between CAN-High and CAN-Low

The CAN bus must be terminated on the front end (control device or repeater) and back end (last detector)

with a 120Ω resistor. Set DIP switch 8 to ON in the last detector.

Page 18

Manual VEK S4

18 03/09 FEIG ELECTRONIC GmbH

5 Case

5.1 Dimensions

Page 19

Manual VEK S4

FEIG ELECTRONIC GmbH 03/09 19

5.2 Opening the case

Opening :

- Loosen upper section A by gently pressing with a screwdriver on the side springs at B.

- Remove upper section.

Closing:

- Check orientation, note contact surface C and PE contact D

- Guide circuit board into rear slot

- Latch upper and lower sections into place

E

C

D

A

B

Page 20

Manual VEK S4

20 03/09 FEIG ELECTRONIC GmbH

6 Technical data

Supply voltage: 12 to 24 V DC +/- 20 %

SELV, limited power sources according to EN 60950-1

Power consumption: typ. 900 mW, max. 1,2 W

Ambient temperature: -20 °C to +70 °C

Storage temperature: -40 °C to +85 °C

Humidity: max. 95% non-condensing

Loop inductance range: 25 – 1200 µH

recommended loop inductance 80 – 300 µH

Working frequency 30 – 140 kHz

Sensitivity

max. loop cable length 300 m

max. loop internal resistance

30 Ω (incl. cable)

Loop inputs galv. isolated (1kV),

90V gas tube arresters to PE contact

Cycle time 8 ms

Loop geometry Head gap: 250 cm and 400 cm

Length: 100 cm and 250 cm

Both loops must have an identical design.

Speed measurement Measuring range 10 km/h to 255 km/h

Tolerance under 100 km/h, +/-3 km/h

Tolerance over 100 km/h, +/-3%

Resolution 1 km/h

Length measurement 10 dm to 250 dm for constant vehicle speed

Tolerance +/- 3 dm

Vehicle classification 8+1 classes Car, car with trailer, truck, truck with trailer, van, bus,

motorcycle, articulated vehicle and unclassifiable vehicle

Outputs Low-Side Switch

Open Drain, short-circuit protected

max. 45 V / 350 mA, R

on

= 1,7 Ω

Enclosure Plastic housing, IP 30 for DIN rail mounting

Polyamide PA 6.6, blue

22.5 x 99 x 114.5 mm (W x H x D, excl. connector)

Integrated function ground contact via DIN rail

Weight 125 g (260 g with packaging)

Connections

Loops 1-4,

altern. CAN-/RS485- Bus and

supply voltage

Open Drain outputs 1-4 (Option)

4-pole plug terminals, 0.2 – 2.5 mm² (AWG 24-14)

Phoenix Combicon MSTBT 2.5, blue

Supply voltage, RS485,

Synchronisation

10-pole IDC plug with flat cable on frontside

Interface

RS 485 2400, 4800, 9600 Baud, 19200, 38400, 57600 Baud, 8E1

Termination 120 Ω, Pull-up / Pull down 470 Ω switchable

CAN 100, 125, 250 kBit/s, 500, 800 kBit/s, 1 MBit/s,

Termination 120 Ω switchable

Page 21

Manual VEK S4

FEIG ELECTRONIC GmbH 03/09 21

7 Connector and pin assignment

Loop 1

OC1 OC2 OC3 OC4

GND 24V

Low

High

1 234

M

B

us

Interface

VEK M4D

Loop 3 Loop 4

Loop 2

Interface

Bus connection

via ribbon cable

Plug terminal

Loops 1 and 2

Plug terminal

GND, 12..24V, Interface Low / High

Plug terminal

Loops 3 and 4

Plug terminal

Outputs 1 to 4

7.1 Power supply and interface screwless terminals

GND 24V

HighLow

Interface

The plug terminal contacts are also connected to contacts of the front-side ribbon cable terminal. This means

the supply and interface connections can also be made either using the plug terminal or ribbon cable. When

multiple detectors are involved, it is practical to combine the plug terminal and ribbon cable, i.e., connection

is made via the plug terminal of one detector, and the additional detectors are connected using ribbon cable

(see also section 8).

Two jumpers are used to connect the RS485 or CAN bus to the plug terminal. The jumpers are located

inside the enclosure. Both jumpers may be inserted only together for CAN or for RS485 !

Interface Low / High verbinden mit

CAN RS485-Bus

Page 22

Manual VEK S4

22 03/09 FEIG ELECTRONIC GmbH

7.2 Loop connections

Loop 1 Loop 2

Loop 3 Loop 4

7.3 2x5-pole pin connector for ribbon cables

Front view

RS485 A- 10

zz

9 RS485 B+

CAN Low 8

zz

7CAN High

Synchronization 6

zz

5GND

GND 4

zz

3GND

24 V 2

zz

1 24 V

The ribbon cable connection is used to synchronize the detectors with each other and to provide the supply

voltage and interface connection. The supply and interface connection to the control device can be made

either using the ribbon cable or a plug terminal (see 7.1 Power supply and interface screwless terminals).

7.4 Outputs

OC1 OC2 OC3 OC4

The Open-Collector outputs are short-circuit protected. When a signal is output the outputs switch on (Low

active).

Vbb U45V

Last

OC1...4

7.5 PE connection

Overvoltages on the loop inputs are diverted to PE using the integrated gas tube arrester. For this there is a

function ground contact on the enclosure bottom (see also 5.2 Opening the case– Part D), which connects

the inserted circuit board with the DIN rail. When the circuit board is inserted, be sure that contact surface C

fits in the PE contact spring D of the enclosure! The DIN rail must be connected to PE in the system with low

impedance !

Noise immunity of the VEK S4 cannot be guaranteed without a PE connection to the DIN rail !

Page 23

Manual VEK S4

FEIG ELECTRONIC GmbH 03/09 23

8 Standard equipment, accessories

The single unit includes four 4-pole plug terminals. This allows you to make all the connections including

the serial interface.

For larger systems the connection between the detectors is generally made using a ribbon cable. Therefore

the 10-pack includes only the terminals for the loop connections. Additional connection parts must be

ordered depending on which connection option is selected.

What you need:

• For connecting multiple detectors together a 10-pole ribbon cable with a corresponding number of spring

action contacts

• For the supply voltage and communications interface either a plug terminal or a longer ribbon cable per

system

• If using the open collector outputs an additional plug terminal per detector

The following accessory sets are available:

8.1 VEK M4D – connection kit

Contents: 4 plug terminals, configured 1m ribbon cable with 16 spring action contacts and an additional

spring action contact

The ribbon cable is trimmed to length by the user for the number of detectors. If the power is provided

through the plug terminals this set allows you to equip e.g. 4 systems with 4 detectors each. Using the

additional spring action contact you can alternatively provide power directly through the ribbon cable.

Additional plug terminals are required if using the detector outputs!

8.2 VEK M4D accessories, 10 screwless terminals

For additional connections or as a spare part for the loop connections

8.3 Service software

The traffic detector can be parameterised using the S4Com service program. As the VEK S4 is downwards

compatible and supports the interface protocols of the VEK S3, the S3ComWin service program can also be

used. Please pay attention here to the special features of the addressing. Æ 4.5.1 Device address

Note:

In order to avoid bus conflicts, the host computer must be disconnected from the RS485 bus while the

service program is being used.

Page 24

Manual VEK S4

24 03/09 FEIG ELECTRONIC GmbH

9 Safety instructions and warnings

• The device may be used only for the purpose intended by the manufacturer.

• This manual must be kept in an accessible place and handed out to each user.

• Improper modifications and use of replacement parts and add-on equipment not purchased or

recommended by the manufacturer may cause fire, electrical shock and injury. Such measures will

therefore result in liability exclusion and the manufacturer will assume no warranty.

• The warranty terms of the manufacturer in place at the time of purchase are considered valid. No liability

is assumed for improper, incorrect manual or automatic setting of parameters for a device or for improper

use of a device.

• Repairs are to be performed by the manufacturer only.

• The power supply must be fulfill the requirements for SELV and limited power sources according to

EN 60950-1.

• Wiring, startup, maintenance, measurement and setting work on the traffic detector are to be performed

only by trained electrical specialists with relevant accident protection instruction.

• All work on the device and its installation must be performed in accordance with the national electrical

regulations and local code.

• The user is responsible for installing and connecting the device according to the recognized technical

regulations in the country of installation as well as other regional accepted codes. Of particular

importance are cable dimensioning, safeguarding, grounding, shut-down, isolation, isolation monitoring

and overcurrent protection.

• The unit is not approved for use as a safety component in accordance with Machine Directive 98/37/EC,

Construction Products Directive 89/106/EEC or other safety regulations. Additional safety devices are

required in systems having the potential for hazard.

Page 25

Manual VEK S4

FEIG ELECTRONIC GmbH 03/09 25

10 4-channel functions

The VEK S4 detector can also be used for presence detection with flexible direction recognition due to its

integrated 4-channel functions (4Ch). The parameters for use as a presence detector are explained in this

chapter.

Please note that changing the following parameters can influence the classification results or deactivate

classification modules.

10.1 Scanning speed (4Ch)

The response time of the detector is dependent on the number of active loop channels and the adjustable

interference filter. The scanning speed is doubled respectively by changing the multiplexer to two loop or

single loop operation. The scanning speed can be further increased by deactivating the interference filter

whereby the response time can be reduced from to normal 16 ms to 2 ms.

Attention: The interference resistance of the system is also reduced for fast response times.

Activating the interference filter adversely affects the classification behaviour of the

classification modules.

Scanning mode Interf. filter Response time

4 loops on 16 ms

2 loops on 8 ms

1 loops on 4 ms

4 loops off 8 ms (Default or factory setting)

2 loops off 4 ms

1 loop off 2 ms

It is also possible to deactivate individual loops without changing the reaction time. It must be noted that the

time window of the deactivated loop is assigned to another active loop. Distances between loops must also

be complied with here to avoid couplings which operate in the same time window.

Attention: When a loop is deactivated, the classification module concerned is also deactivated.

10.2 Response sensitivity (4Ch)

The sensitivity for every channel in the range from 0.02% - 10.63% ∆f/f can be selected in 256 steps. In

order to minimise interference, the sensitivity should be set as high as is necessary, i.e. the response

sensitivity should be set as high as possible.

The sensitivity setting is usually adjusted in large steps and the response threshold values are nor selected

higher than 120. Settings above 120 and fine adjustments are used for applications where vehicle

differentiations are required. For example, buses can be selectively detected with a large loop with the

dimensions 10.0 m x 2.5 m.

Page 26

Manual VEK S4

26 03/09 FEIG ELECTRONIC GmbH

Parameter

value

Response

threshold

value

Sensitivity (∆ f/f)

0 4 0.02 % maximum sensitivity

1 10 0.04 %

2 20 0.08 %

3 30 0.13 %

4 40 0.17 %

5 50 0.20 %

::

11 110 0.46 %

12 120 0.5 % (Factory setting)

13 130 0.54 %

::

41 410 1.71 %

42 420 1.75 %

43 430 1.79 %

::

100 1000 4.17%

::

255 2550 10.63 % lowest sensitivity

Note: The response thresholds of the VEK S4 are different from the response threshold of the VEK M4D for

the same sensitivity (∆ f/f).

10.3 Hysteresis drop (4Ch)

In order to avoid an intermediate loss of the occupied signal for vehicles with a high undercarriage such as

articulated buses, trams, trucks with trailers etc, it is possible to modify the switching hystereses. An

interruption-free detection of critical vehicles is then also possible with low closure resistance setting. The

drop value threshold factory setting is 75%.

Page 27

Manual VEK S4

FEIG ELECTRONIC GmbH 03/09 27

Output signal for

25% drop value threshold

Drop value

threshold at 25%

Drop value threshold at 75%

Cut-in threshold

Output signal for 75% drop value

threshold

Detuning by vehicle

Output signal

10.4 Holding time (4Ch)

Separate holding times between 1 and 255 minutes can be set for each channel on the detector. A zero

setting means infinite waiting time. If the loop of a detector channel is occupied longer than the set holding

time, the detector channel tunes again.

Factory setting: 20 minutes

Page 28

Manual VEK S4

28 03/09 FEIG ELECTRONIC GmbH

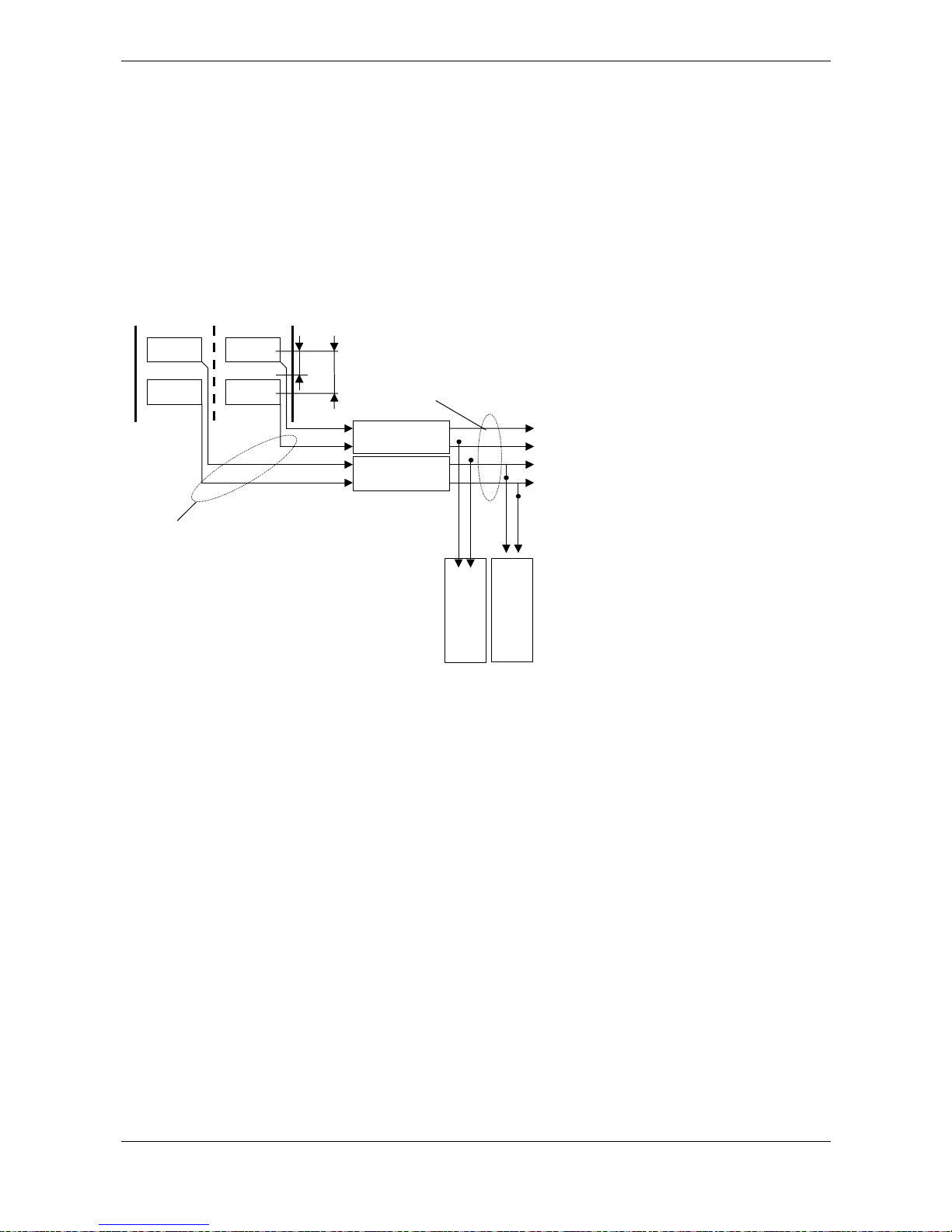

Logic module 1

Logic module 2

Parallel counting

Signals

Direction A

4+2 Count er

Direction logic

Direction B

Direction A

Direction B

4 Counter

allocation

Loop allocation

adjustable

10.5 Direction recognition (4Ch)

In addition to the simple direction recognition present in the classification modules, the VEK S4 detector has

two parameterisable logic modules for the direction-dependent recording of vehicles. Complex evaluation

algorithms using double loops are integrated in the detector. The direction logic generates logical output

signals which can be output via a hardware output or via an interface depending on the setting. The logic

signals are also counted in parallel in the detector independently.

Two direction logic modules each with 2 inputs (double loops) and 2 outputs (directions A and B) are

integrated in the detector. The assignment of the loops to the logical inputs and the assignment of the logical

outputs to the Open Drain outputs can be adjusted.

The assignment meters can be invoked via the interface. For counting in time intervals, the counting result

must be determined from the meter readings at the start and at the end of the time interval. It must be noted

that the counters roll over at 65535 (2

16

) and restart from 0. It is not recommended to reset the counters

otherwise vehicles can be lost at the time of the reset. The counters in the detector are not protected against

power failure. The detectors must either be buffered with a UPS system or the counter readings must be

regularly read and stored in the higher level system for long-term counting.

In addition to the double loop counting, a four loop counting which counts parallel passages is integrated. If

needed, the total count can be corrected by the assumed lane-changers in the superordinate system using

these count values.

Depending on the application, several different evaluation logics can be set for each of the four logical

outputs. The different logics for the direction recognition are shown briefly below. The detailed method of

working for different traffic situations follows afterwards.

Page 29

Manual VEK S4

FEIG ELECTRONIC GmbH 03/09 29

Direction logic Signal output Signal waste Remark

D1 - Continuous signal 1 left 1. loop

DB - Continuous signal

both loops

Allocation 1. loop

D2 – Continuous signal 2 Allocation 2. loop

left 2. loop

Signal output in opposite direction takes place only

again if both loops were free before-

F1 – Wrong driver 1

(Factory setting)

F2 – Wrong driver 2

Correct behavior with column traffic and Rangierer.

Different behavior with wrong driver situations (see

appendix).

BS - both loops

Allocation 2. loop

Correct behavior with column traffic should not seem to

Rangierer.

FE – Feig left 1. loop Correct behavior with column traffic and Rangierer

SF – loop freely left 2. loop

Collection of single vehicles and Rangierer. Columns

should not occur

PB – Park bay related to the direction

Expenditure for

impulse with adjusted

minimum signal

period

(Standard 200ms)

For short in and exits (see appendix)

With all logics the loop occupied first determines the counting and/or expenditure direction. I.e. for example

loop 1 is occupied first, takes place expenditure and counting for direction A.

Page 30

Manual VEK S4

30 03/09 FEIG ELECTRONIC GmbH

10.5.1 Direction detection in various traffic situations

Various traffic situations are shown in the following for Loops 1 and 2. The evaluation of the direction signal

is performed in the same manner in the reverse direction of travel as well for Loops 3 and 4 or other loop

combinations.

Explanations for the table:

xx

Direction logic, gray = logic with incorrect count in this traffic situation.

___

Imp Æ Direction pulse Imp Æ Direction pulse in the opposite direction

on Æ Continuous signal on off Æ Continuous signal off

The direction signal is output on the channel of the first loop to be traversed.

10.5.1.1 Single vehicle

PB

D2 D1 DB F1 F2 FE SF BS

Ri1 Ri2

12

1 2

on on

12

on||

|

|

||Imp Imp Imp

1 2

|

||off||

|

Imp Imp

12

off off Imp Imp

Page 31

Manual VEK S4

FEIG ELECTRONIC GmbH 03/09 31

10.5.1.2 Traffic line

PB

D2 D1 DB F1 F2 FE SF BS

Ri1 Ri2

1 2

on on

12

on||

|

|

||Imp Imp Imp

1 2

|

||off||

|

Imp Imp

1 2

|

||on||

|

1 2

off||

|

|

|

|

___

Imp

12

on||

|

|

||Imp Imp Imp

1 2

|

||off||

|

Imp Imp

12

off off Imp Imp

10.5.1.3 Wrong-way driver 1

PB

D2 D1 DB F1 F2 FE SF BS

Ri1 Ri2

1 2

on on

12

on||

|

|

||Imp Imp Imp

1 2

off||

|

|

|

|

12

off off

___

Imp

___

Imp

Page 32

Manual VEK S4

32 03/09 FEIG ELECTRONIC GmbH

10.5.1.4 Wrong-way driver 2

PB

D2 D1 DB F1 F2 FE SF BS

Ri1 Ri2

1 2

on on

12

on||

|

|

||Imp Imp Imp

1 2

|

||off||

|

Imp Imp

12

|

||on||

|

1 2

off||

|

|

|

|

___

Imp

12

off off

___

Imp

10.5.1.5 Maneuverer 1

PB

D2 D1 DB F1 F2 FE SF BS

Ri1 Ri2

1 2

on on

12

on||

|

|

||Imp Imp Imp

1 2

off||

|

|

|

|

12

on||

|

|

|

|

1 2

|

||off||

|

Imp Imp

12

off off

Imp Imp

Page 33

Manual VEK S4

FEIG ELECTRONIC GmbH 03/09 33

10.5.1.6 Maneuverer 2

PB

D2 D1 DB F1 F2 FE SF BS

Ri1 Ri2

1 2

on on

12

on||

|

|

||Imp Imp Imp

1 2

|

||off||

|

Imp Imp

12

|

||on||

|

1 2

off||

|

|

|

|

Imp

12

on||

|

|

||Imp Imp Imp

1 2

|

||off||

|

Imp Imp

12

off off Imp Imp

Page 34

Manual VEK S4

34 03/09 FEIG ELECTRONIC GmbH

10.5.1.7 Wrong-way driver in traffic line

PB

D2 D1 DB F1 F2 FE SF BS

Ri1 Ri2

1 2

on on

12

on||

|

|

||Imp Imp Imp

1 2

|

||off||

|

Imp Imp

1 2

|

||on||

|

1 2

off||

|

|

|

|

___

Imp

12

off off

___

Imp

10.5.1.8 Cross-traffic

PB

D2 D1 DB F1 F2 FE SF BS

Ri1 Ri2

1 2

on on

12

on||

|

|

||Imp Imp Imp

1 2

|

||off||

|

Imp Imp

12

|

||on||

|

1 2

off||

|

|

|

|

___

Imp

12

off off

___

Imp

All logics except for PB in Direction 1 will result in incorrect counts in this traffic situation, since they

count in instead of out.

Page 35

Manual VEK S4

FEIG ELECTRONIC GmbH 03/09 35

10.5.2 Direction logic „Parking Bay“

This direction logic is used for short entrances and exits. This logic suppresses compromising of the count

by cross-traffic on Loop 1. This means it is non-critical whether Loop 1 is placed in the passing lane or in the

maneuvering area.

1 2 Parking

Lane

1 2

Parking

Lane

Parking

The placing of the loops depends on which travel direction backups are anticipated in. In travel direction 1 →

2 no backups are permitted! In travel direction 2 → 1 even vehicles in traffic line situations are correctly

counted, whereby the vehicle gap must always enable a loop.

Logic for travel direction 1 → 2

• The counter pulse arrives when both loops have been fully traversed

• Correct count for individual vehicles

• Correct count for maneuvering as well

• Traffic jam situation and traffic lines may not occur for travel direction 1 -> 2!

Logic for travel direction 2 → 1

• The counter pulse arrives as soon as Loop 2 is left in the direction of Loop 1

• Correct count for cross-traffic as well

• Correct count for traffic lines

• Correct count even for maneuvering of a single vehicle

• No maneuverers are allowed within a traffic line!

Page 36

Manual VEK S4

36 03/09 FEIG ELECTRONIC GmbH

11 Notes

Loading...

Loading...