Fei Bao SU-27 Assembly Manual

FB Su-27

DISCLAIMER:

THIS IS NOT A TOY. This is a high-performance

miniature aircraft, capable of high speeds and damage to

life, limb, and property. The manufacturer and its

distributors cannot control how you assemble this model,

what equipment you use to fit it out, or how you fly it, and

can assume no liability whatsoever for any damages that

may occur when you fly your aircraft. By assembling this

model, you are agreeing to indemnify and hold blameless

the manufacturer and/or his agents from any and all torts

and liability associated with the use of this product.

Please inspect all parts before beginning assembly. If

any parts appear to be suspect, contact your dealer or the

manufacturer for repair or replacement BEFORE you

begin. Once you have assembled the aircraft, you are

the pilot in command and assume any and all

responsibility for the use of the model and any damages

that might occur by flying or attempting to fly this aircraft.

R/C model jets require a high level of skill in both their

assembly and their flying. If you do not feel confident in

either your building or flying skills, PLEASE seek

assistance from more experienced modelers. It is a wise

idea, no matter what level of skills you possess, to have a

second experienced modeler go over your installation

after assembly. A second set of eyes may spot a problem

you have missed. If you have not flown a model like this

before, it is HIGHLY recommended that you get an

experienced turbine pilot to do your maiden flight. Very

often, the first few seconds of a maiden flight are critical

until the aircraft is trimmed out, and having an

experienced pilot at the controls can make the difference

between a wrecked aircraft and once that enjoys many

hundreds of flights. Be sure to select a suitable field for

flying...take the time to find a large paved runway if at all

possible, especially for test flights, until you feel

comfortable getting the aircraft in and out of smaller grass

fields.

BEFORE YOU BEGIN:

Keep this in mind as you proceed:

Look at EVERY assembly step you finish, and ask

yourself:

"Is this going to crash my airplane?"

A chain is only as strong as its weakest link, and this is a

high-performance aircraft that will be very intolerant of

sloppy assembly techniques. Even the smallest

component is important and can cause the loss of your

Page 1

FB Su-27

airplane, so take the time to do things right. Or REdo

them if they are wrong. Careful work will result in a longlasting plane that gives you years of pleasure, one loose

component could result in the complete loss of the aircraft

and all the components inside it, and someone can even

get hurt. So pause every once in a while when building it

and double-check your workmanship.

A. Introduction:

You have chosen a model that represents the pinnacle of

ARF technology. While there is not a lot of building to do,

there is enough to keep you busy for a few evenings.

Even if you have assembled maybe other ARF jets, we

highly recommend following our assembly sequence and

procedures anyway.

Chances are it will save you a lot of time, prevent you

from running down dead ends, and perhaps remind you

of a few small things that might end up saving your

aircraft.

We have tried to arrange a construction sequence that

will allow you to keep moving forward, rather than

standing around waiting for glue to dry before you can

proceed to the next step.

Just because the model is almost completely built does

not mean you can rush through the final assembly.

You need to employ fine craftsmanship every step of the

way, turbine models are critical. Keep this in mind with

everything you do, every part you install...look at the work

you just did, evaluate it critically, and ask yourself "is this

going to potentially crash my airplane?" If there is any

doubt about the work you have done, back up, and re-do

it properly.

B. Adhesives:

The correct adhesive to use for all procedures is Loctite

Hysol 9462. This is a very strong white epoxy that is

thixotropic. "Thixotropic" means it does not run at all, but

stays only where you put it. It is infinitely superior to

regular epoxy, even slow-setting epoxy, for our purposes,

because of this characteristic.

Regular epoxy will run downhill with gravity as it dries,

taking it away from where it is supposed to be.

A good example is in the hinges...using regular epoxy, a

good portion of the glue will migrate down away from the

hinge into the inside of the wing as it dries, and you won't

even know it is happening. Hysol stays where you put it.

The downside of Hysol is it takes overnight to dry

properly, but we have tried to arrange things to keep you

busy while waiting for glue to dry.

We also highly recommend that you only use a proper

Hysol dispensing gun, and only the long-type mixing

nozzles.

The short nozzles do not mix this glue enough, and only a

thin nozzle and gun will let you fill the hinge and control

horn holes properly with glue, you can't do it mixing your

Hysol on a flat surface and trying to get the glue in the

proper place by a brush or stick.

You can buy a complete Hysol setup with a gun, nozzles,

and two cartridges of glue from your dealer for

approximately $60.

Page 2

FB Su-27

Consider it a great investment, the glue is the best you

will use. One cartridge is plenty to assemble your aircraft.

C. WORKING WITH PNEUMATIC SYSTEMS:

The T45 uses pneumatic brakes and retracts. If you

follow a few tips, you should have very reliable, leak-free

operation. Neatness counts.

All airlines should be secured to the airframe to keep

them from flopping around or getting kinked. Use tie

wraps for this.

The other very important thing is to cut off the end of each

airline dead square before installing it on the nipple.

This is VITAL. You can either purchase a professional

tubing cutter from your dealer (they are approximately

$10), or you can make up a little jig to hold the airline and

keep a sharp, new razor blade perfectly upright as you

cut.

Either one works, just ensure that all ends of all airlines

are cut off dead square. Make sure all airlines are

pushed ALL THE WAY onto their nipples.

They should not need to be secured otherwise, but you

can add fine wire safety wraps if you like. Make sure all

left and right matching airlines are the same length,

particularly the brake lines, or you will get uneven

retraction or braking action.

It's worth taking the time to get everything pneumatic right

the first time, as having your landing gear fail to retract is

not THAT bad, but having it fail to deploy can really ruin

you day and the paint on the bottom of your model.

Sample Servo List:

Rudder: JR 3301 (2)

Flaps: JR 8611A (2)

Elevators: JR 8711 or equivalent (Use highest torque

servos available)

Nose Gear Steering: JR 8411 or JR 2721

Air and Brake Systems: As necessary

Parts List:

Forward Fuse with Component Boards and Nose Gear

•

Pitot Tubes (2)

•

Aft Fuse, Main Landing Gear

•

Parachute Stinger

•

Canopy

•

Cockpit Tub and Glare Shield

•

Main Upper Hatch with Speed Brake

•

Left Intake

•

Right Intake

•

Wings, Flaps

•

Vertical Stabs (2), Rudders (2)

•

Ventral Strakes (2)

•

Fuel Tanks

•

Pipes (2)

•

Air Kit

•

Hardware Kit

•

Page 3

FB Su-27

Notes

These instructions were written based upon the

prototype kit from the Fei Bao factory. Please

note that the kit and components may have

undergone changes through the production

process. Center of Gravity and control surface

throws were confirmed as a good starting point

through limited flight testing, but it is important

that you contact your Fei Bao representative prior

to your first flight to obtain the most current

information on these important parameters.

Begin construction by prepping the airframe

Insert the stabs, wings and vertical stabs into

their respective mounts. Check each mount for

security, tightening bolts and nuts if necessary.

it is recommended that you run a bead of

Aeropoxy around the mounts to secure them

firmly in position on their formers.

Check all accessible areas for the integrity of

glue joints and add Aeropoxy if necessary. Pay

special attention to the formers that secure the

horizontal stab bearings, adding glue to make

sure they are firmly affixed to the fuselage.

Take care not to get any glue into the bearing

components.

Join fuselage halves and bolt securely in five

places.

If already assembled, remove the bypass

modules from the airframe (see photo). They

are attached by two bolts accessed through the

hatch on each side.

Remove the engine hatch covers, marking

them for side and orientation as you do so.

Using a hand pump and a short piece of tubing,

check each of the gear door air cylinders for

leaks. If they hold air under pressure, secure

the nuts and bolts attaching the cylinders to

the fuselage and doors with a small drop of

thin CA.

Page 4

FB Su-27

Air systems

Remove the nose gear from the aircraft.

Using a Matchmaker or a receiver and your

transmitter, center the nose steering servo and

attach a heavy duty steering arm.

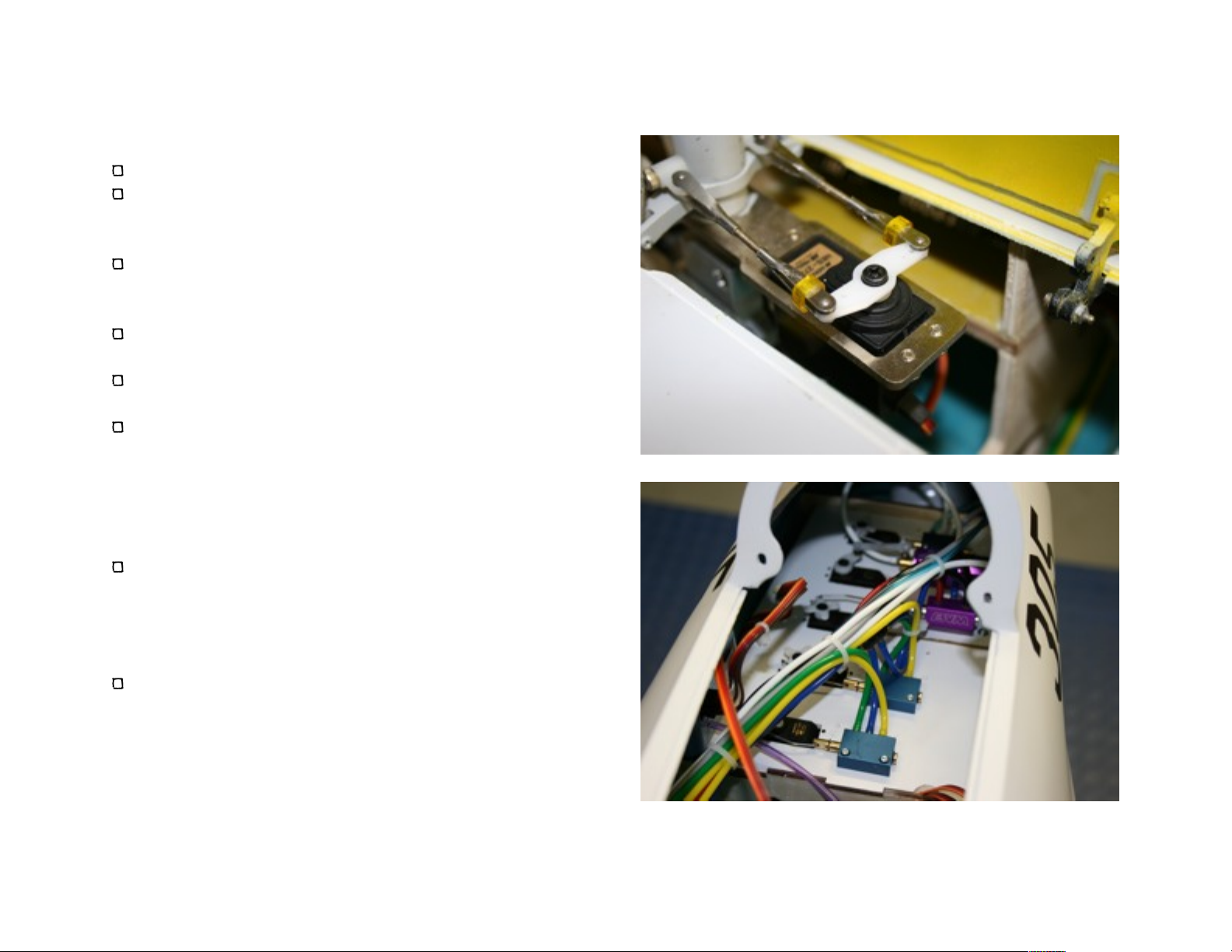

Bolt in the nose gear steering servo as shown

in the photo. Do not use the rubber mounts

and brass eyelets. Loctite the bolts.

While the nose gear is out, make sure there are

no kinks or bends in the air lines.

Check the security of all screws and C clamps

on the struts and retract units.

Option: If your nose and main gear were

attached to their mounting plates by wood

screws, you may opt to reattach them with cap

head bolts and blind nuts. If so, remove the

mains, drill and install blind nuts for all three

landing gear, and reinstall.

Once the nose gear is reinstalled, operate the

strut by hand and insure that the nose gear

door will close completely over the nose wheel

mud guard. If not, shim the retract unit with

washers or ply until the door closes.

It is recommended that you install your air

systems for doors, retracts, brakes and speed

brake on the removable board in the nose of

the aircraft. Remove the board, paint if

desired, and install servos and valves. Make

sure to allow clearance to the sides of the

board for the curvature of the nose section.

Page 5

FB Su-27

The receiver may also be installed on this

board.

As the three main gear all retract forward, you

may wish to provide more air to each unit. To

accomplish this, set up the nose gear on one

air valve designed for large scale aircraft and

supply air to the mains from a second,

separate valve. Use separate air supplies for

each. Run separate lines to each main from

the valve ... do not “T” from a single supply.

Make sure to pull up the landing gear before

the aircraft picks up speed after liftoff.

As you position these components, make sure

to leave room for the cockpit installation.

You will need to supply sequencing for the

doors. On the full scale aircraft, all doors

remain open with the gear extended.

Run air lines to all the door cylinders, the

retracts, the brakes and the speed brake.

Hook up fill valves, air meters if used and

supply tanks.

Test the system for operation and leaks.

Adjust as necessary.

Page 6

FB Su-27

Horizontal Stabilizers

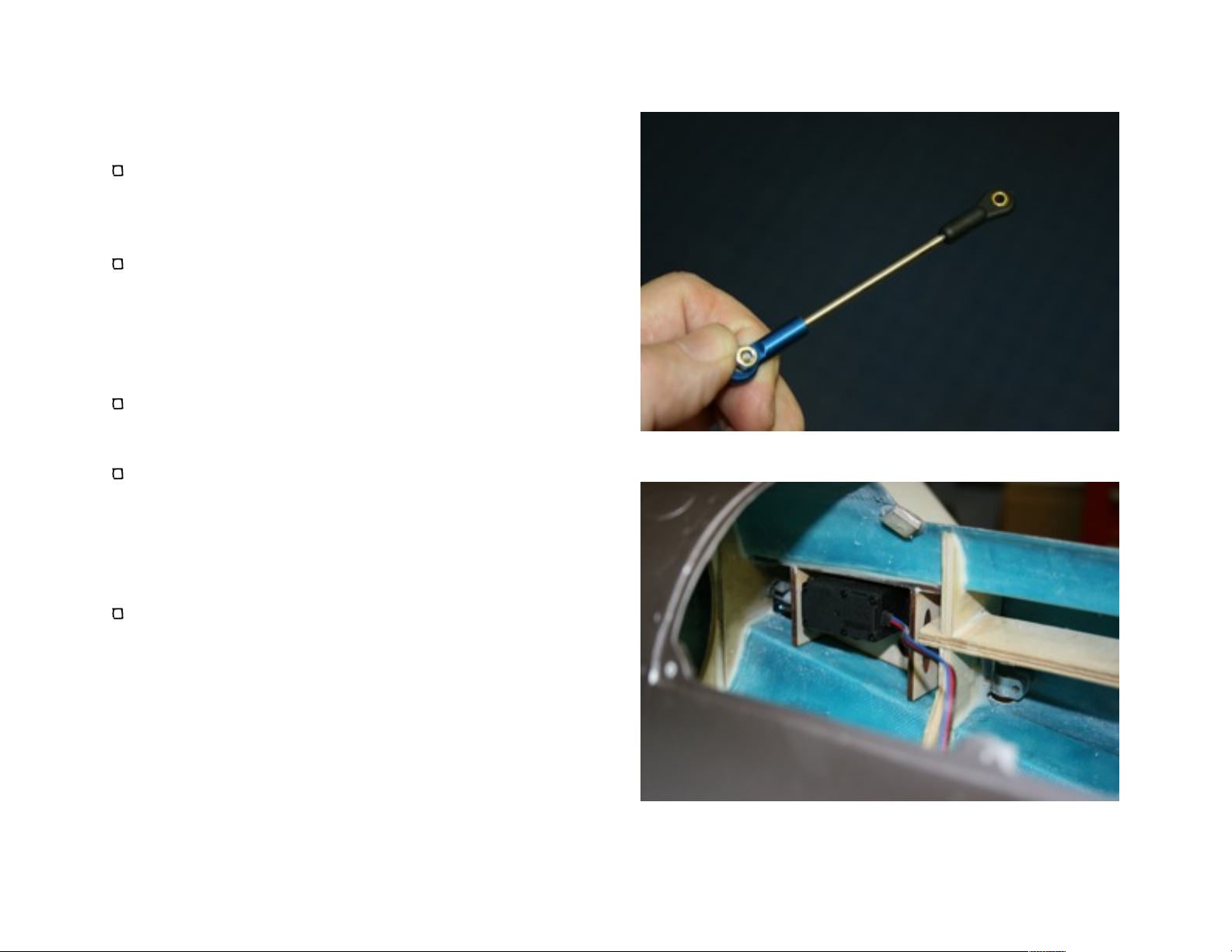

Using a Matchmaker or receiver and

transmitter, center both horizontal stab servos.

Install the servo arms such that they are

matched as closely as possible for both servos.

Option: for added security, use metal servo

arms for this application. If you use a tapped

metal servo arm, you will need to replace the

clevis supplied with the kit with an appropriate

ball link. You can secure with a small amount

of CA for extra security. See photo.

Install servo into its mount, securing with four

screws. Do not use rubber mounts and brass

eyelets.

To keep the heat away from the servo during

engine operation, make a small shield that can

be bolted to the formers. In the prototype,

BVM heat insulation covered by aluminum tape

was used. Leave some space for air

circulation. See photo on following page.

Insert stab spars into control arms, using large

Delrin washer for spacing from fuselage. Hold

pressure against fuselage and tighten allen

bolts securely. Check for smooth operation and

minimal play.

Page 7

Loading...

Loading...