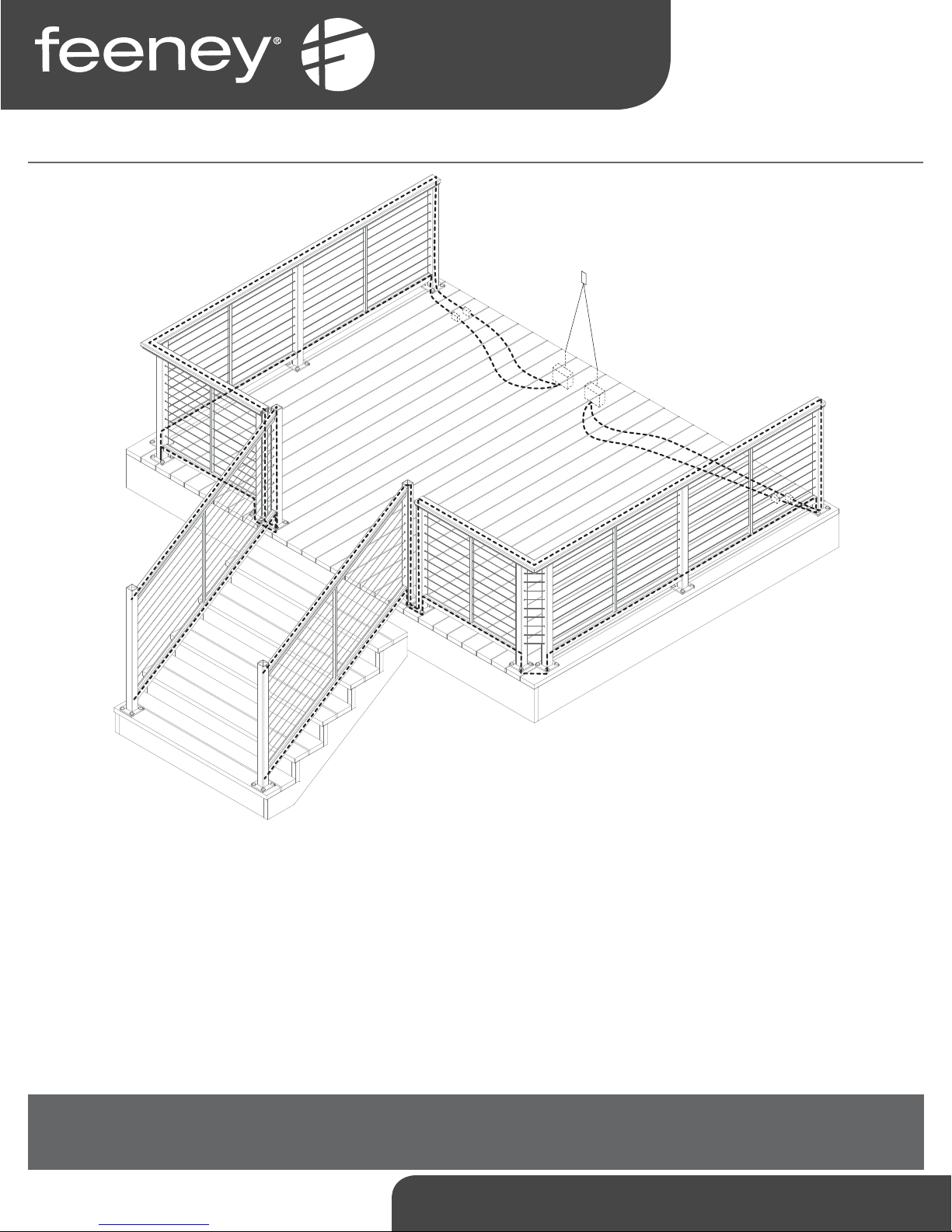

Feeney DesignRail Installation Instructions Manual

Installa on Instruc ons

for DesignRail® 24VDC LED Ligh ng

Drivers are available in a variety of wa ages. In general a driver should not exceed more than 80% of its rated wa age.

(Example: 60W Driver = 60 x 0.8 = 48W Max).

Strip Lights require 1.44 wa s per foot. A er determining the necessary length of strip ligh ng, calculate the wa age and ensure the

driver being used has adequate capacity. (Example: 10’ = 10 x 1.44 = 14.4W)

The maximum length of strip ligh ng that can be connected in one run is 25 feet. If one sec on of ligh ng is longer than 25 feet, it

must be broken into mul ple smaller sec ons and run on separate circuits.

Building codes vary by loca on and jurisdic on. Consult all applicable codes before installing DesignRail® LED Ligh ng.DesignRail®

LED Ligh ng may not be suitable for every applica on and it is the sole responsibility of the installer to ensure that DesignRail® LED

Ligh ng is used for its intended purpose.

WARNING: ELECTRIC SHOCK IS ALWAYS POSSIBLE WHEN WORKING WITH ELECTRICITY. THIS CAN CAUSE SERIOUS PERSONAL

INJURIES OR DEATH. ELECTRICAL SHORTS CAN ALSO CAUSE FIRES AND PROPERTY DAMAGE. ALWAYS MAKE SURE THE

ELECTRICAL OUTLET YOU ARE PLUGGING INTO IS GROUNDED.

1-800-888-2418 | www.feeneyinc.com 1

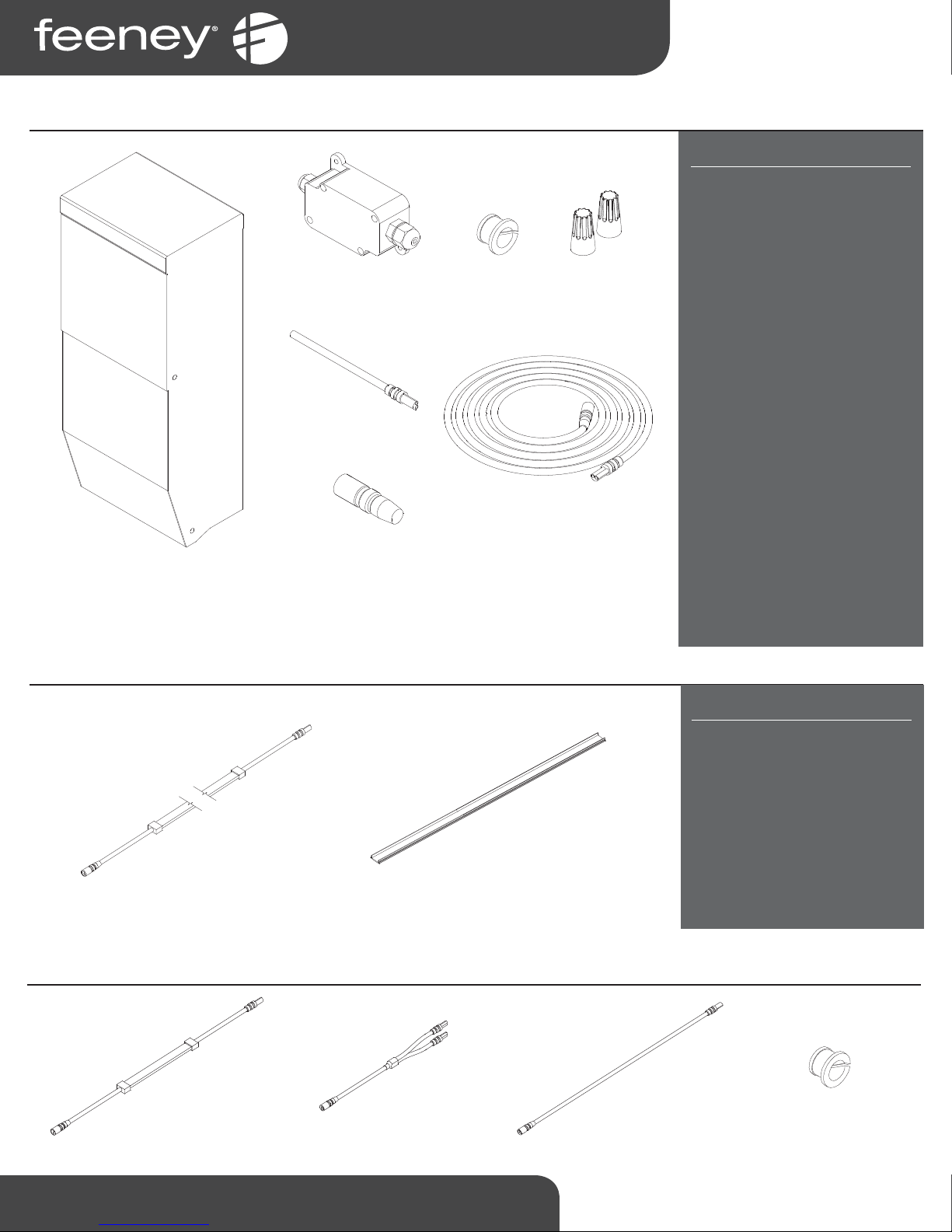

Power Kits - Package Contents

COMMERCIAL GRADE

WET LOCATION

MINI JUNCTION BOX

(SKU #7680)

SOLDER CONNECTOR (UL)

(MALE ONLY)

(SKU #7673)

ISOLATION

BUSHING

(SKU #1114)

WIRE NUTS

(PAIR)

(SKU #7670)

POWER KIT OPTIONS

SKU #7683 - 96w Power Kit

1x 96w Dimmable Driver

2x Mini Junc on Box

2x 11' Extension Cable

2x Wire Nuts

2x Solder Connector

2x Isola on Bushing

2x Terminator Cap

SKU #7682 - 60w Power Kit

1x 60w Dimmable Driver

2x Mini Junc on Box

2x 11' Extension Cable

2x Wire Nuts

2x Solder Connector

2x Isola on Bushing

2x Terminator Cap

(Pair)

(1114)

(Pair)

(1114)

TERMINATOR CAP

(FEMALE ONLY)

24V MAGNETIC DIMMABLE DRIVER

(SKU # VARIES BY WATTAGE)

(SKU #7671)

Light Kits - Package Contents

LED LIGHT STRIP (UL)

(SKU # VARIES BY LEGNTH)

11' EXTENSION CABLE (UL)

(SKU #7650)

48" FROSTED

DIFFUSER LENS

(SKU #7662)

SKU #7681 - 40w Power Kit

1x 40w Dimmable Driver

1x Mini Junc on Box

1x 11' Extension Cable

1x Wire Nuts

(Pair)

1x Solder Connector

1x Isola on Bushing

(1114)

1x Terminator Cap

LIGHT KIT OPTIONS

SKU #7653 - 32" LED Kit

1x 32" LED Light Strip*

1x 48" Frosted Diff user Lens

SKU #7652 - 20" LED Kit

1x 20" LED Light Strip*

1x 48" Frosted Diff user Lens

*All Light Strips are 3000K/24V

Addi onal Items

4" LED LIGHT STRIP (UL)

(SKU #7684)

1-800-888-2418 | www.feeneyinc.com2

2 WAY WATERPROOF

SPLITTER (UL)

(SKU #7668)

12" EXTENSION CABLE (UL)

(SKU #7719)

40" EXTENSION CABLE (UL)

(SKU #7669)

ISOLATION BUSHING FOR

BOTTOM RAIL/100 SERIES

LIGHTING

(SKU #1114)

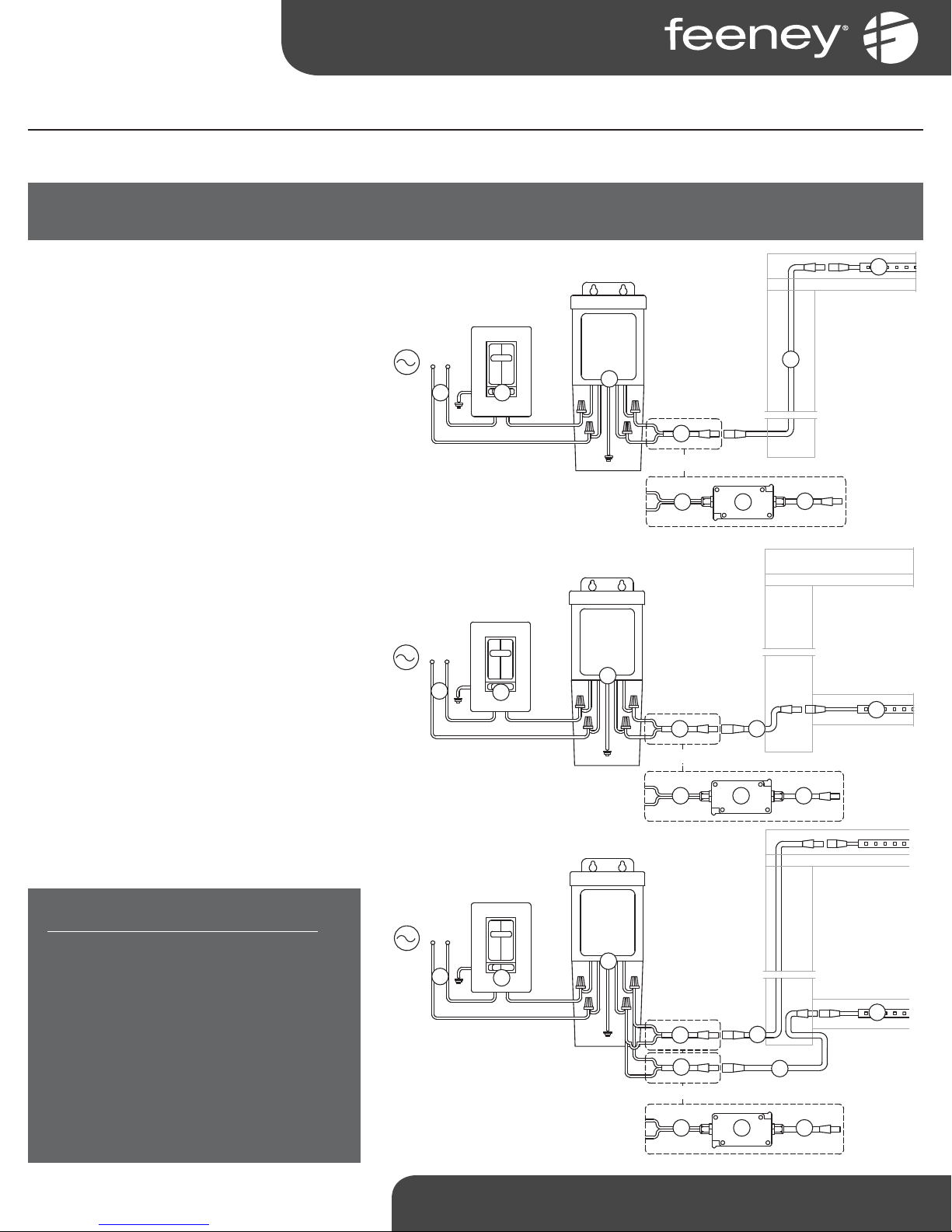

Power Kits - Installa on

Step 1 – Connect Source Power to Driver

IMPORTANT SAFETY NOTE: TO REDUCE RISK OF ELECTRICAL SHOCK, TURN OFF AC CIRCUIT BREAKER PRIOR TO COMMENCING ANY ELECTRICAL WORK AND

CONNECTING DRIVER(S) TO AC POWER SOURCE. VERIFY THAT LIVE POWER IS NOT PRESENT AT JUNCTION BOX WHEN MAKING CONNECTIONS.

Determine loca on of driver.

Note: It is best to locate the drivers as close as

possible to the lighࢼ ng to reduce the possibility

of voltage drop occuring. If possible, the driver

enclosure should be within 5 feet of the post that

will accept the 11' extension cable, acࢼ ng as the

lead wire to the fi rst strip light. If necessary, up

to 30 feet of 14 AWG wire can be used between

the driver and the 11' extension cable.

Route exterior rated wiring from compa ble

dimmer switch/AC power source to loca on of

driver.

Connect drivers to dimmer switch/AC power

source using wire nuts.

Connect 11' extension cable(s) and route outside

of driver to post.

If necessary, run up to 30 feet of 14 AWG wire

to a wet-loca on mini junc on box and transi -

on to solder connector.

TOP RAIL LIGHTING - WIRING DIAGRAM

3

1 2

BOTTOM RAIL LIGHTING - WIRING DIAGRAM

3

1

2

6

OR

4

6

8

7

5

6

8

7

LIGHTING COMPONENTS

1. Power (by customer)

2. Light Switch (by customer)

3. 24v Dimmable Driver

1

2

4. 14 Gauge Wire (by customer)

5. Mini Junc on Box

6. Solder Connector

7. 11' Extension Cable

8. LED Light Strip

1. Mount ver cally only. See Switch Compatabilty Spec Sheet at

www.feeneyinc.com

2. See Driver Spec Sheet at www.feeneyinc.com

OR

4 6

TOP & BOTTOM RAIL LIGHTING - WIRING DIAGRAM

5

3

1

2

6

6

OR

4 6

Note: If using both top and bo om rail lighࢼ ng, run each on their own circuit.

7

7

5

1-800-888-2418 | www.feeneyinc.com 3

8

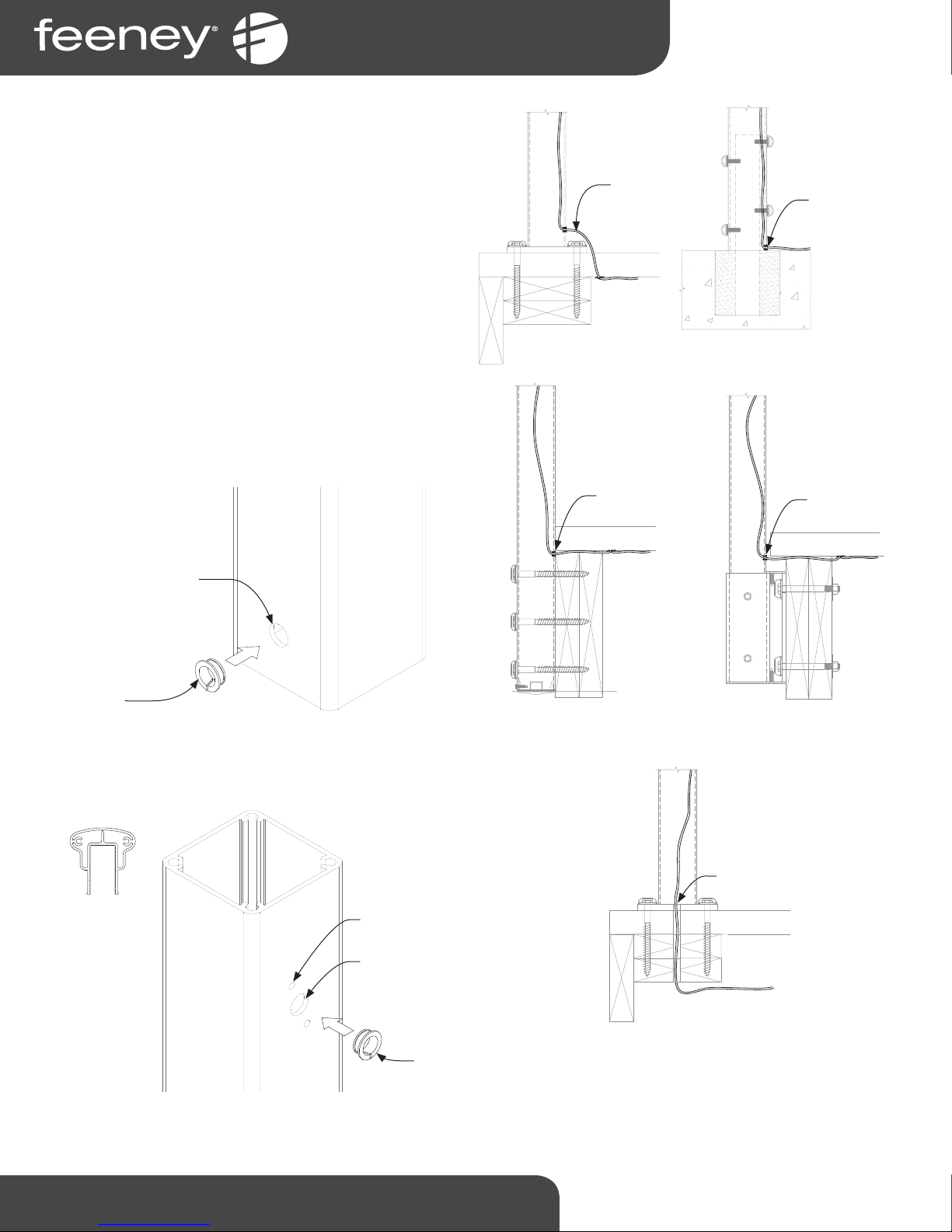

STEP 2 - DRILL POSTS AND ROUTE LEAD WIRE

Note: Running the lead wire through the post is easier when done

prior to mounࢼ ng post.

Determine loca on that lead wire will enter post.

Note: Depending on the post mounࢼ ng method, and enclosure

locaࢼ on relaࢼ ve to the post, the lead wire entrance point may

vary. (See Figure 1.2 for typical recommendaࢼ ons)

Drill 1/2” diameter hole in post at desired lead wire entrance

loca on and insert supplied grommet, part #1114. (See Figure 1.1)

For Series 150: drill a 1/2” diameter hole ver cally centered

between the top RCB holes and insert supplied grommet (See

Figure 1.3).

the RCB hollow. Repeat this step for each post which will have

light strips running through it.

This will allow the light strip wiring to pass through

WIRE COMES

UP THROUGH

DECKING AND

INTO POST.

WIRE RUNS UNDER

DECK THROUGH

FASCIA BOARDS

AND ENTERS POST

BELOW DECKING

DURFACE BETWEEN

FACSIA AND POST

FACE.

WIRE CAN BE RUN

IN CONDUIT BURIED

IN CONCRETE, OR

RUN DIRECTLY

FROM ENCLOSURE

TO POST. WIRE

INSIDE POST RUNS

BETWEEN INSIDE

POST WALL AND

STANCHION.

WIRE RUNS

UNDER DECK AND

ENTERS POST

ABOVE FASICA

BRACKET BELOW

DECKING.

GROMMET

PAR T # 1114

SERIES 150

1/2" DIA.

HOLE

Figure 1.1

SERIES 150 TOP RAIL

RCB SCREW HOLES

1/2" DIA. HOLE (CENTER

BETWEEN RCB HOLES)

WIRE RUNS UNDER

DECK THROUGH 3/4"

HOLE IN BASEPLATE

AND BLOCKING.

(3/4" HOLE DRILLED BY

CUSTOMER)

Figure 1.3

1-800-888-2418 | www.feeneyinc.com4

GROMMET

PAR T # 1114

Figure 1.2

Loading...

Loading...