Page 1

FeelChip-D Manual

Maurice Op de Beek

version 1 , 20190607

Page 2

Table of Contents

Introduction 3

Programming 4

Tag-Connect PCB Pads 4

Board Overview TOP 5

TOP Parts 6

TOP Pads 7

Board overview BOTTOM 8

BOTTOM Parts 9

BOTTOM Pads 9

USB Battery Charger 10

LDO Power 10

Battery power 10

DC motor 10

FCC information 11

Page 3

Introduction

The FeelChip D is PCBA board designed for the haptic industry. It has 3 motor channels and

5 touch channels. The FeelChip D is equipped with:

1. a LIPO charging unit

a. 5 volt

2. RGB LED light

a. Charging (red)

b. Almost empty (blinking red)

c. Bluetooth (blue)

d. Charged (green)

3. Press Button

a. Turn the device on/off

b. Switch through patterns

4. Programmer

a. Pin to program the ESP32

5. MPR121

a. ReceiPintove up to 5 capacitive touch inputs

6. Bluetooth and Main processor (Espressif ESP32)

a. Get firmware version

b. Get hardware version

c. Get battery level

d. Control up to 1 to 3 motors

e. Read up to 5 touch sensors

Page 4

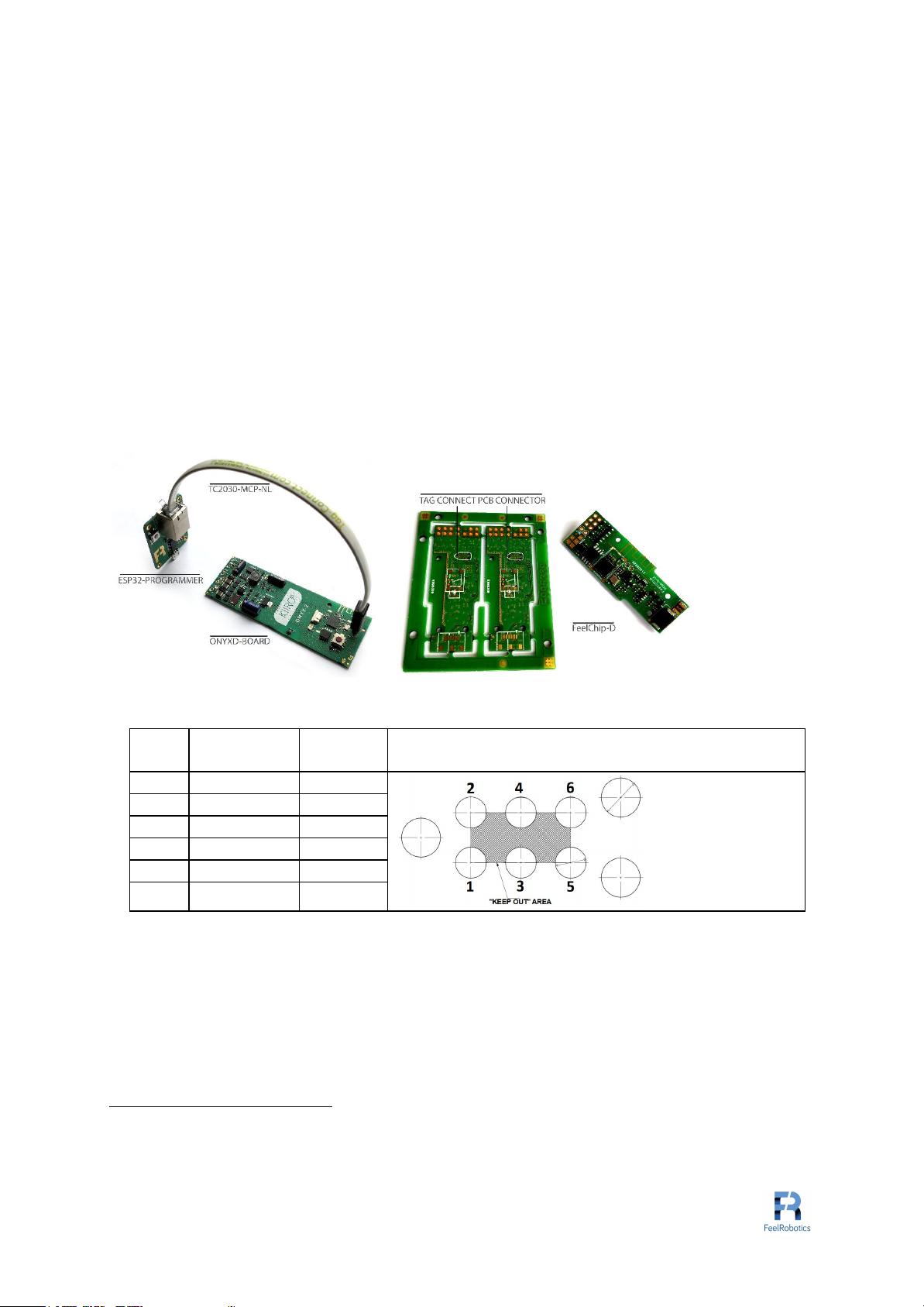

Programming

The FeelChip-D-2p can be programmed with a Tag connect TC2030-IDC-NL or a

1

TC2030-MCP-NL on the small footprint PCB Tag-Connect PAD. Alternatively it can be

2

programmed using the test pads with the aid of a Pogo Pin test setup.

There are two methods to programming the FeelChipD:

,

1) Via Tag-Connect PCB pads

2) Via Pogo-Pin Test pads

Tag-Connect PCB Pads

For manual programming, the Feel Robotics ESP32 programmer is used which is only

compatible with the TC2030-MCP-NL cable. The programmer features an FT232RL USB

3

to UART.

Figure 1 - ESP32 Programmer

Pad

#

Net Name

Test

PAD

Layout

4

1

GND

TP2

2

EN

TP7

3

2V8

TP1

4

ESP_RX

TP10

5

EPS_TX

TP11

6

IO0/PwrOn

TP8

Table 1 – Tag Connect Pinout

ESP_RX and EPS_TX are used for serial communication from the FT232RL to the ESP32.

EN and IO0 are used to toggle the ESP32 during boot go into bootloader modus so the

FT232RL can upload to code to the flash memory. For programming either the ESP32

Flash-Tool or the python script from Espressif. 2V8 and GND are used to power up the

ESP32 during programming.

1

http://www.tag-connect.com/TC2030-IDC-NL

2

http://www.tag-connect.com/TC2030-MCP-NL

3

https://nl.mouser.com/datasheet/2/163/DS_FT232R-11534.pdf

4

http://www.tag-connect.com/Materials/TC2030-IDC-NL.pdf

Page 5

Board Overview TOP

Page 6

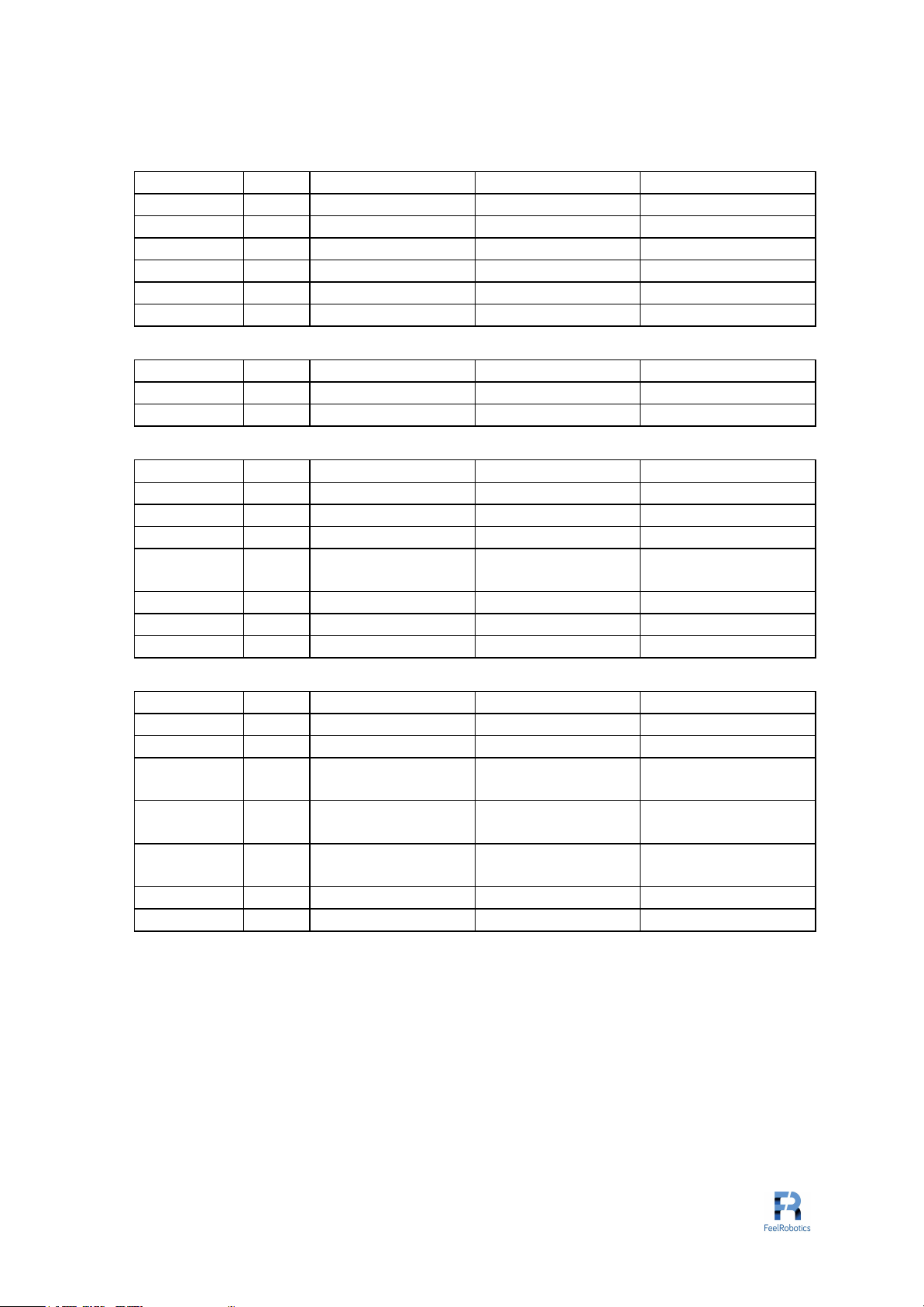

TOP Parts

PART

UNIT

PART NUMBER

FUNCTION

DESCRIPTION

PART

U1

ESP32-D0WDQ6

MCU

Main processor

PART

U2

WS25Q32JVSSIQ

FLASH

Flash memory

PART

U3

AP7361

LDO

Voltage regulator

PART

U4

Removed

Removed

PART

U5

MPC7382

Lipo Charger

PART

U6

MPR121QR2

TOUCH

Touch sensor

Table 2 - Main units

PART

UNIT

PART NUMBER

FUNCTION

DESCRIPTION

PART

RT1

MSMF050

PTC Reset Fuse

PART

Y1

CLOCK

CLOCK

Table 3 - Miscellaneous

PART

UNIT

PART NUMBER

FUNCTION

DESCRIPTION

PART

Q1

BSS806N

N-Channel Mosfet

Drives Motor 1

PART

Q2

BSS806N

N-Channel Mosfet

Drives Motor 2

PART

Q3

BSS806N

N-Channel Mosfet

Drives Motor 3

PART

Q4

NX3008NBKS

(Dual)

N-Channel Mosfet

On/Off Control

PART

Q5

BSS84LT1G

P-Channel Mosfet

Voltage divider

PART

Q6

DMP2104V

P-Channel Mosfet

Powers LDO

PART

Q7

FDN335N

N-Channel Mosfet

ESD Protector

Table 4 - Switches

PART

UNIT

PART NUMBER

FUNCTION

DESCRIPTION

PART

D1

SMCJ5.0CA-TR

ESD Suppressor

ESD Suppressor

PART

D2

BZX88-B2V7

Zener diode

PART

D3

NSR1020MW

Flyback diode

MTR1

For Motor 1

PART

D4

NSR1020MW

Flyback diode

MTR3

For Motor 3

PART

D5

NSR1020MW

Flyback diode

MTR2

For Motor 2

PART

D6

BAT54WS

Skotty Diode

PART

D7

CD0603-B00340

Skotty Diode

Table 5 - Diodes

Page 7

TOP Pads

PAD

PAD

PART NUMBER

NET

DESCRIPTION

PAD

J1(1)

Touch PAD 1

Touch 4

MPR121 Electrode 6

PAD

J1(2)

Touch PAD 2

Touch 5

MPR121 Electrode 7

PAD

J1(3)

Touch PAD 3

Touch 2

MPR121 Electrode 4

PAD

J1(4)

Touch PAD 4

Touch 3

MPR121 Electrode 5

PAD

J1(5)

Touch PAD 5

Touch 1

MPR121 Electrode 3

Table 6 - Touch Pads

PAD

PAD

PART NUMBER

NET

DESCRIPTION

PAD

J2(1)

Motor PAD 1

VBATT

PAD

J2(2)

Motor PAD 2

MTR 1

For Motor 1

PAD

J2(3)

Motor PAD 3

VBATT

PAD

J2(4)

Motor PAD 4

MTR 2

For Motor 2

PAD

J2(5)

Motor PAD 5

VBATT

PAD

J2(6)

Motor PAD 6

MTR 3

For Motor 3

Table 7 - Motor Pads

TPAD

PAD

PART NUMBER

NET

DESCRIPTION

PAD

W1

Button PAD 1

Short button

PAD

W2

Button PAD 1

Short button

Table 8 - Switch Pads

PAD

PAD

PART NUMBER

NET

DESCRIPTION

PAD

+

Battery PAD

VBATT

PAD

-

Battery PAD

GND

Table 9 - Battery Pads

Page 8

Board overview BOTTOM

Page 9

BOTTOM Parts

PART

UNIT

PART NUMBER

FUNCTION

DESCRIPTION

PART

S1

B3FS-1010

Tactile Switch

Tactile Switch

PART

DS1

AAA3528LSEEZGK

QBKS

RGB LED

RGB LED

PART

J4

SM02B-SRSS-TB

Shrouded Header

USB 5V

Table 10 - Switches

BOTTOM Pads

Testpoint

Net Name

Function

Function

TP1

2V8

LDO Voltage source

2.8V

Programming, Power

Test

TP2

GND

Ground

Programming

TP3

5Vin

USB Voltage source

5.0V

Power Test

TP4

RED 2

Rgb led red

RGB2 Test

TP5

BLUE 2

Rgb led blue

RGB2 Test

TP6

GREEN 2

Rgb led green

RGB2 Test

TP7

EN

ESP32 Enable

Programming

TP8

IO0/PwrOn

ESP32 IO0

Programming

TP9

2V8

LDO Voltage source

2.8V

Programming, Power

Test

TP10

ESP_RX

ESP32 RX programming

Programming

TP11

ESP_TX

ESP32 TX programming

Programming

Table 11 – Pinout

PAD

PAD

PART NUMBER

NET

DESCRIPTION

PAD

J1(1)

TouchPAD1

Touch 4

MPR121 Electrode 6

PAD

J1(2)

TouchPAD 2

Touch 5

MPR121 Electrode 7

PAD

J1(3)

TouchPAD 3

Touch 2

MPR121 Electrode 4

PAD

J1(4)

TouchPAD 4

Touch 3

MPR121 Electrode 5

PAD

J1(5)

TouchPAD 5

Touch 1

MPR121 Electrode 3

Table 12 - TTouchPads

PAD

PAD

PART NUMBER

NET

DESCRIPTION

PAD

J2(1)

Motor PAD 1

VBATT

PAD

J2(2)

Motor PAD 2

MTR 1

For Motor 1

PAD

J2(3)

Motor PAD 3

VBATT

PAD

J2(4)

Motor PAD 4

MTR 2

For Motor 2

PAD

J2(5)

Motor PAD 5

VBATT

PAD

J2(6)

Motor PAD 6

MTR 3

For Motor 3

Table 13 - Motor Pads

Alternative to Tag-Connect PCB Pads the test pads can be used for programming and basic

power testing as described in 5.

Page 10

USB Battery Charger

To test if the battery charger is working 5V is applied over TP3(5V) and TP2(GND). If pads

5

+(VBATT) and –(GND) will have approx. 4.2V across the battery charger is functioning

properly.

LDO Power

To test if the battery charger is working 5V is applied over with POGO pins connected to

6

TP3(5V) and TP2(GND). If POGO pins connected to TP(1) or TP9(2V8) will have 2.8V

across it to TP2(GND) the LDO is functioning properly.

Battery power

To test if the battery power is functioning 4,2V is applied over pads +(VBATT) and –(GND). If

TP(1) or TP9(2V8) will have 2.8V across it to TP2(GND) battery power is functioning

properly.

DC motor

Up to three small brushed DC motors can be controlled by the FeelChip D board. The motors

are driven by three N-channel MOSFETs with designators Q1, Q2, Q3 (MPN: BSS806N) with

a maximum voltage of 3.3V and a maximum current of 3A. PWM can be applied to each of

these channels.

5

Designator in schematic = U5 and part number is MPC7382

6

Designator in schematic = U5 and part number is MPC7382

Page 11

FCC information

The OEM integrator is still responsible for testing their end-product for any additional

compliance requirements required with this module installed.

Host manufacturer (OEM) is responsible for ensuring that the host continues to be compliant

with the Part 15 subpart B unintentional radiator requirements after the module is installed

and operational.

The grantee's FCC ID can be used only when all FCC compliance requirements are met.

End Product Labeling

This transmitter module is authorized only for use in a portable configuration where the

antenna may be installed such that 0 cm may be maintained between the antenna and users.

The final end product must be labeled in a visible area with the following: “Contains FCC ID:

2AO5N -FCHD18”.

Manual Information To the End User

The OEM integrator has to be aware not to provide information to the end user regarding

how to install or remove this RF module in the user’s manual of the end product which

integrates this module.

The end user manual shall include all required regulatory information/warning as shown in

this manual.

Loading...

Loading...