Federal Signal Corporation VISIBEAM II Installation, Operation And Maintenance Instructions

2561083A

REV. A 801

Printed in U.S.A.

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

FOR

VISIBEAM® II REMOTE CONTROLLED SPOTLIGHT

SAFETY MESSAGE TO INSTALLERS AND USERS

People’s lives depend on your safe installation of our

products. It is important to read, understand and follow all

instructions shipped with the products. In addition, listed

below are some other important safety instructions and

precautions you should follow:

• To properly install this kit: you must have a

good understanding of automotive electrical

procedures and systems, along with proficiency

in the installation and use of safety warning

equipment.

• DO NOT install equipment or route wiring or

cord in the deployment path of an air bag.

• When drilling into a vehicle structure, be sure

that both sides of the surface are clear of anything that could be damaged.

• In order for the light to function properly, a

separate ground connection must be made. If

practical, it should be connected to the negative

battery terminal. At a minimum, it may be

attached to a solid metal body or chassis part

that will provide an effective ground path as

long as the light system is to be used.

• Locate light control so the VEHICLE and CONTROL can be operated safely under all driving

conditions.

• Do not attempt to activate or deactivate light

control while driving in a hazardous situation.

• You should frequently inspect the light to ensure that it is operating properly and that it is

securely attached to the vehicle.

• File these instructions in a safe place and refer

to them when maintaining and/or reinstalling

the product.

Failure to follow all safety precautions and instructions may result in property damage, serious injury, or

death to you or others.

I. UNPACKING.

After unpacking the unit, inspect it for damage that

may have occurred in transit. If the unit has been damaged, file a claim immediately with the carrier, stating the

extent of damage. Carefully check all envelopes, shipping

labels, and tags before removing or destroying them.

Ensure that the parts listed in the appropriate KIT

CONTENTS LIST are contained in the package.

II. KIT CONTENTS LIST.

ALL SURFACE MOUNT MODELS

Qty. Description

4 Screw, #6

3 Screw, #10, Hex

3 Flat Washer, #10

1 Gasket, Mounting

1 Plate, Mounting

1 Velcro Loop

1 Velcro Hook

ALL PIPE MOUNT MODELS

Qty. Description

4 Screw, #6

1 Plate, Mounting

1 Velcro Loop

1 Velcro Hook

ALL MAGNETIC MOUNT MODELS

Qty. Description

1 Cover, Magnet

1 Label, Caution

4 Screw, #6

1 Plate, Mounting

1 Velcro Loop

1 Velcro Hook

III. CONTROL INSTALLATION.

WARNING

When installing equipment inside air bag equipped

vehicles, the installer MUST ensure that the equipment is installed ONLY in areas recommended by

the vehicle manufacturer.

Failure to observe this warning will reduce the

effectiveness of the air bag, damage the air bag, or

potentially damage or dislodge the equipment,

causing serious injury or death to you or others.

A. Hook-and-Loop Mounting.

NOTE

The hook-and-loop mounting method is intended for

storing the control unit when it is not in use. The

hook-and-loop material may not provide sufficient

rigidity for proper control unit operation.

1. Locate a suitable mounting location for the

control unit.

NOTE

The hook-and-loop pads’ mounting surfaces must be

clean and dry for proper adhesion. If necessary, use

isopropyl alcohol and water to clean the mounting

surfaces.

4. Secure the mounting plate to the mounting

surface using the #6 thread-forming phillips screws.

5. To attach the control unit to the mounting

plate, align the mounting studs with the stud retainers and

press the control unit until it snaps in position.

2. Remove the paper backing from the hook pad

and affix it to the back of the control unit.

3. Remove the paper backing from the loop pad

and affix it to the mounting surface.

4. Place the control unit in position by mating

the hook and loop surfaces.

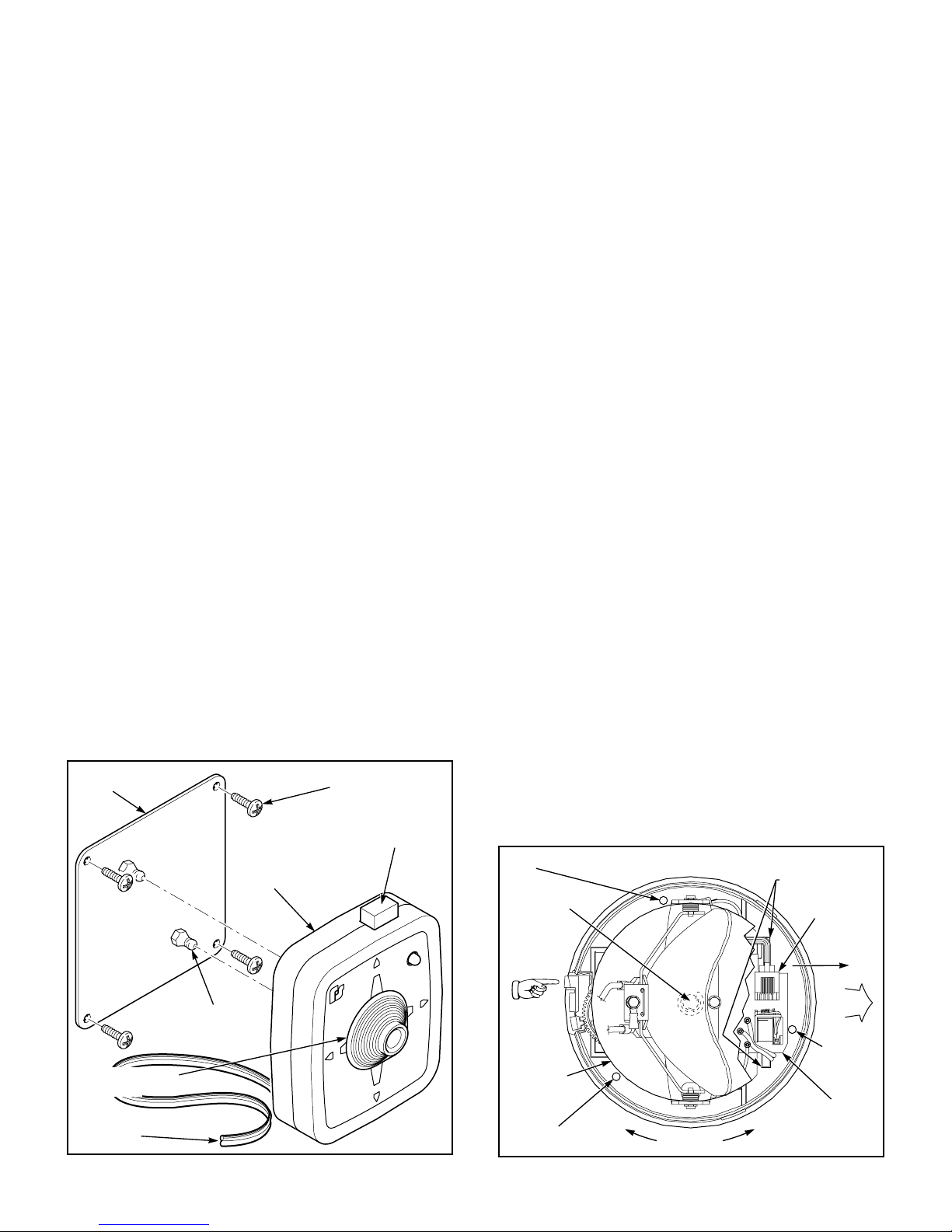

B. Snap Mounting (see figure 1).

1. Locate a suitable mounting location for the

control unit.

NOTE

Before marking the drill position marks, ensure that

the mounting plate’s orientation will allow the control

to snap on the mounting plate in the desired position.

2. Using the control mounting plate as a template, scribe four drill position marks on the mounting

surface.

CAUTION

To avoid damage when drilling, ensure that both

sides of mounting surface are clear of any parts or

wires.

Also, when drilling any holes, ensure that holes are

drilled only through sheet metal and not through

upholstery.

3. Drill four 7/64" holes at the previously scribed

drill position marks.

IV. LIGHT INSTALLATION.

A. Surface Mount Models.

To install the light, proceed as follows:

1. Push and hold the dome release button

(located in the plastic base). Turn the dome counterclockwise and lift the dome off the base (see figure 2).

2. Position the vehicle on a level surface. Select a

relatively flat mounting position which provides sufficient

rigidity to support the light and prevent vibrations caused

by the light when the vehicle is in motion.

CAUTION

Turning reflector by hand may damage motor or

worm gear. To rotate the reflector, connect to an

appropriate power source.

3. Position the light with the dome release

button toward the rear at the selected mounting location.

4. Use the base of the light as a template and

scribe three mounting hole drill position marks on the

mounting surface. Also, scribe one wire routing hole drill

position mark at the center.

CAUTION

To avoid damage when drilling, ensure that both

sides of mounting surface are clear of any parts or

wires.

Also, when drilling any holes, ensure that holes are

drilled only through sheet metal and not through

upholstery.

CONTROL

MOUNTING

PLATE

SLIDE KNOB TO MOVE

REFLECTOR POSITION

GRAY CABLE

FROM LIGHT

MOUNTING

STUDS (2)

SCREWS, #6 x 5/8", TYPE A THD. FRM.,

CONTROL

Figure 1.

PHILLIPS PAN HEAD (4)

PRESS BUTTON TO TURN

LAMP ON OR OFF

P

U

R

I

G

H

T

L

E

F

T

N

W

O

D

290A2669-03B

5. Drill one 5/8" (0.625) hole (wire routing hole)

at the previously scribed center drill position mark. Drill

three 9/64" (0.140) holes (mounting holes) at the previously

scribed outer drill position marks.

MOUNTING

-2-

HOLE

WIRING HOLE

PUSH TO

RELEASE

DOME

MECHANISM

COVER

MOUNTING

HOLE

TWIST DOME

Figure 2.

REMOVEINSTALL

RELEASE T ABS

(PUSH DOWN HERE)

CONTROL CABLE

CIRCUIT BOARD

MECHANISM

CONNECTOR

SLIDE TO

REMOVE

FRONT

MOUNTING

HOLE

PRINTED

290A2669-04B

Loading...

Loading...