Page 1

2561007E

REV. E 1002

Printed in U.S.A.

INSTRUCTION SHEET

SIGNALMASTER™ MODEL 331102

SAFETY MESSAGE TO INSTALLERS

People’s lives depend on your safe installation of our products.

It is important to read, understand and follow all instructions

shipped with the products. In addition, listed below are some other

important safety instructions and precautions you should follow:

• To properly install this light: you must have a good

understanding of automotive electrical procedures

and systems, along with proficiency in the installation and use of safety warning equipment.

• DO NOT install equipment or route wiring in the

deployment path of an air bag.

• When drilling into a vehicle structure, be sure that

both sides of the surface are clear of anything that

could be damaged.

• In order for the light to function properly, a good

ground connection must be made. At a minimum, it

must be attached to a solid metal body or chassis

part that will provide an effective ground path as

long as the light system is to be used.

• Locate light control so the VEHICLE and CONTROL can be operated safely under all driving

conditions.

• Do not attempt to activate or deactivate light control

while driving in a hazardous situation.

• This product controls high intensity LED devices. To

prevent eye damage, DO NOT stare into the light

beam at close range.

• You should frequently inspect the light to ensure

that it is operating properly and that it is securely

attached to the vehicle.

• File these instructions in a safe place and refer to

them when maintaining and/or reinstalling the

product.

Failure to follow all safety precautions and instructions may

result in property damage, serious injury, or death to you or

others.

I. GENERAL.

The Federal Signal SignalMaster Model 331102 is an

economical, low profile, solid state, directional light control that is

designed to operate with any of Federal Signal’s SignalMaster

series eight-lamp directional lights. This control will also operate

two sets of external lamps (Federal Signal Models 320102,

SMLED1, 320112, and 320721, or other 50 watt lamps). The unit

is reversed polarity protected to avoid damage if the positive and

negative power connections are connected incorrectly.

This model provides three distinctive directional signals, left

arrow, right arrow, and center out. An alternating flash pattern

produces a warning signal for use when a directional signal may

not be appropriate. In addition, an auxiliary flash pattern

alternately flashes the external lamps. The directional and

alternating flash patterns can also be selected to operate faster, or

with decreased current draw. The slide switch overrides the

WARN and AUX functions.

When normal directional signal operation is selected, the

lamps individually activate sequentially in a sweeping motion

until all eight are illuminated. When LOW (current) operation is

selected, the lamps turn on/off in sequence until a pattern is

completed. When FAST is selected, the chosen pattern sequences

at an increased rate.

FOR

An auxiliary input and output are provided for integrating

external controls and lights into the SignalMaster system. When

properly connected, a positive (+) 12 volts applied to the AUX IN

terminal will activate the alternating flash pattern. The AUX OUT

terminal can activate a ground-activated relay (user-supplied)

when the AUX switch is operated.

WARNING

These lights are intended for secondary warning only.

They are not intended for use as a primary warning

system.

II. SPECIFICATIONS.

Input Voltage 11VDC to 16VDC.

Polarity Negative ground only.

Operating Temperature -30° C to +65° C.

Range

Standby Current Zero amperes.

+BAT Fuse 25 amperes.

+IGNITION Fuse 1 ampere.

AUX OUT Fuse 1 ampere.

Output Drive

Capability (Total)

Directional 8, 27 watt lamps.

Auxiliary 4, 27 watt lamps (2 per output) or

2, 50 watt lamps (1 per output).

Normal Flash Rate:

Directional 35 patterns/min.

Warn 60 patterns/min.

Auxiliary 95 patterns/min.

Fast Flash Rate:

Directional 60 patterns/min.

Warn 95 patterns/min.

Auxiliary 95 patterns/min.

Dimensions:

Height 1-1/2"

Width 6-1/8"

Depth 5"

Shipping Weight 2.5 lbs.

III. INSTALLATION.

A. SignalMaster Light Assembly.

Install the light assembly as described in the instructions packed with the 320340 universal mounting kit. Route the

cable near the eventual location of the control unit.

B. Control Unit.

WARNING

When installing equipment inside air bag equipped vehicles, the installer MUST ensure that the equipment is

installed ONLY in areas recommended by the vehicle

manufacturer.

Failure to observe this warning will reduce the effectiveness of the air bag, damage the air bag, or potentially

damage or dislodge the equipment, causing serious injury

or death to you or others.

Page 2

control unit to be mounted in a variety of positions. To install the

B

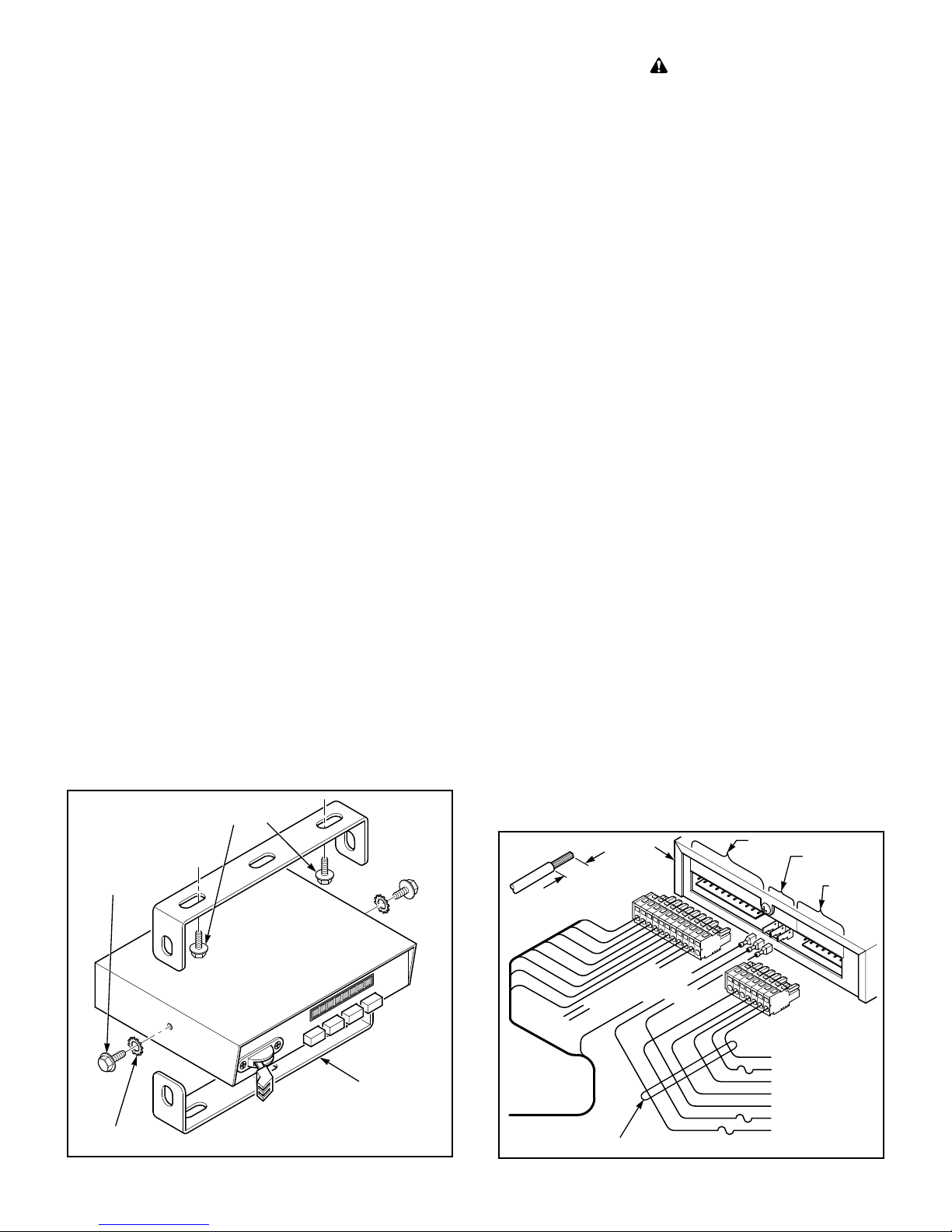

See figure 1. The supplied mounting bracket allows the

control unit, proceed as follows:

CAUTION

Install the control unit in an adequately ventilated area.

Never install near heater ducts.

NOTE

When selecting a mounting location for the control unit,

it is necessary to keep in mind the SignalMaster cable

length. Plan wiring and cable routing before installation.

1. Select a mounting location for the control unit that

allows the vehicle and controls to be operated safely at all times.

2. Use the mounting bracket as a template and scribe

two drill position marks at the selected mounting location.

CAUTION

Before drilling holes in ANY part of a vehicle, be sure that

both sides of the mounting surface are clear of parts that

could be damaged; such as brake lines, fuel lines, electrical

wiring or other vital parts.

3. Drill two holes at the previously scribed position

marks.

4. Secure the mounting bracket to the mounting

surface with two user-supplied, thread-forming, 1/4-20 screws.

C. Electrical Connections.

WARNING

Failure to observe this WARNING may result in fire,

burns or blindness.

If shorted to vehicle frame, high current conductors can

cause hazardous sparks resulting in electrical fires or

molten metal.

DO NOT connect this system to vehicle battery until ALL

other electrical connections are made and mounting of all

components is complete.

Verify that no short circuits exist, before connecting to the

Positive (+) battery terminal.

SCREWS,THREAD FORM.,

USER SUPPLIED

1/4-20 x 3/8" SCREW,

HEX WASH. HD .(2)

WARN

AUX

1/4" LOCKWASHER,

EXT . T OOTH(2)

FAST

LOW

REVERSED AS SHOWN HERE,

IF IT BETTER SUITS YOUR SPECIFIC

NOTE: ONLY ONE BRACKET IS SUPPLIED.

MOUNTING REQUIREMENTS.

BRACKET MAY BE

Figure 1.

331102

290A2542-48

WARNING

Do not connect more than one, 6 or 8 head, halogen

SignalMaster assembly to a SignalMaster controller or the SignalMaster outputs of a SmartSiren.

Electrical fire or damage to the controller or siren

will result.

The control unit is supplied with a seven-position

connector, an eleven-position connector, and insulated spade

connectors (0.250" (1) and 0.187" (2)) to perform the electrical

installation. User-supplied, 14-gauge red and black wires are

required for the (+) BAT and (-) GND connections. User-supplied,

18-gauge red and green wires are required for the (+) IGNITION

and (-) CASE GROUND connections on the seven-position

connector. In addition, user-supplied 18-gauge wire is used for the

AUX IN, AUX OUT, and DASH LIGHTS connections. Using figure

2 as a guide, complete this portion of the installation as follows:

1. Power Connections.

CAUTION

To avoid damage and ensure proper operation, the red

and black wires MUST be installed as shown in figure 2.

a. Strip 1/4" of insulation off of each 14AWG red

and black wire. See figure 2. Crimp a 0.187" wide spade receptacle

on the red wire. Crimp the 0.250" wide spade receptacle on the

black wire.

b. Connect the red and black 14-gauge terminated

wires to the +BAT and GND positions as shown in figure 2.

c. Route the red and black 14-gauge wires

through the firewall and toward the battery. Connect the black

wire to a good frame ground near the battery. In most vehicles, a

wire from the negative terminal of the battery is routed and

attached to the body/frame at the fender. This is a convenient

point to connect the 14-gauge black wire. Do not connect the red

wire to the (+) positive terminal at this time.

d. Connect the 18-gauge red (IGNITION) and

green (CASE GROUND) wires to the connector as shown in figures

2 and 3.

IMPORTANT

The (+) IGNITION (18-gauge red) wire’s termination

point determines when the directional signal can be

activated. When the wire is attached to a vehicle fuse

that is powered when the ignition switch is in the run or

start position, the vehicle’s ignition switch must be in the

run or start position to operate the directional signal.

When the wire is attached to the vehicle battery, the

directional signal can be operated at any time. Note that

the unit draws no current when in the “off” position.

GREEN

ORANGE

VIOLET

GRAY

LIGHT OUTPUTS

YELLOW

BLUE

WHT/BLU

WHT/GRN

WHT/RED

WHT/ORN

RED

18 AWG DASH LIGHTS

1A

18 AWG AUX OUT

18 AWG AUX IN

18 AWG CASE GND.

14 AWG (-)GND

1A

18 AWG IGNITION

25A

14 AWG +BAT

POWER AND

+BAT

24 AMP.

+BAT/IGN

-2-

WIRE STRIPPING

TYPICAL

9 CONDUCTOR

CABLE FROM

SIGNALMASTER

320172

GRAY

YEL

BLUE

PRP

+BAT

1/4"

ORN

GRN

CUSTOMER SUPPLIED

331102

W

HT

BRN

EXTERNAL LAMP

CONNECTIONS

RED

+BAT

LAMP COM

GND.

Figure 2.

WHITE

BROWN

GROUND

CONTROL

LEADS

(-) GND

(-) CASE

GROUNG

AUX IN

AUX OUT

DASH

LIGHTS

290A2542-54B

Page 3

WIRE STRIPPING

TYPICAL

1/4"

STRIPPED

WIRES

TIP OF SMALL

SCREWDRIVER

Figure 3.

1. INSERT SCREWDRIVER

TIP INTO RECTANGULAR

HOLE.

2. INSERT STRIPPED WIRE

END IN ROUND HOLE.

3. REMOVE SCREWDRIVER.

290A4458

e. Select the desired termination point. As

applicable, route the 18-gauge red wire toward the vehicle fuse

block or through the firewall toward the battery. Install a usersupplied, 1-ampere, in-line fuse in the 18-gauge red wire as close

to the power source as possible and terminate as required.

f. Route the 18-gauge green wire to a known good

chassis ground near the 331102 control. To provide a good ground

connection, scrape any painted surface to bare metal.

2. AUX IN and AUX OUT Connections.

When a positive (+)12 volts is applied to the AUX IN

connection, the alternating flash pattern is activated.

The AUX OUT connection will provide a ground to

activate a ground-activated relay (user-supplied) when the AUX

switch is operated. To perform the wiring for these connections,

proceed as follows (see figures 2 and 3):

CAUTION

To avoid damage and ensure proper operation, the wires

MUST be installed in the seven- position connector as

shown in figure 3.

a. Connect a user-supplied 18-gauge wire to the

seven-position connector’s AUX IN connection. Route the wire to a

user-supplied external switch which will provide a positive (+) 12volts (such as Federal Signal Model SW400SS) when activated.

b. Connect a user-supplied 18-gauge wire to the

seven-position connector’s AUX OUT connection. Route the wire to

a user-supplied ground-activated relay for activation of an external

device. Install an in-line, user-supplied, 1 ampere fuse between the

control and the relay.

the eleven-position connector as shown in figures 2 and 3.

d. Connect the remaining SignalMaster wires to

e. If applicable, connect the external lamp ground

cables to the connector (positions 9 and 10) as shown in figures 2

and 3. Each of these two positions provides an alternating ground

signal to activate external lamps.

D. Inspection and Final Installation.

1. Ensure that there are no loose wire strands or other

bare wires which may cause a short circuit. Also, all wires must be

protected from any sharp edges which could eventually cut

through the insulation.

2. Plug the seven-position connector into the mating

connector on the control unit, and apply pressure until it locks into

place.

3. Plug the eleven-position connector into the mating

connector on the control unit, and apply pressure until it locks into

place.

4. Connect the remaining end of the 14-gauge red wire

from the +BAT spade connector to the (+) positive terminal of the

battery using an in-line, user-supplied fuseholder and 25A fuse.

Locate the fuse as near the battery as possible to protect the entire

length of wire.

5. Read and understand paragraph IV OPERATION,

and test for proper operation of all functions.

6. Secure the mounting bracket to the control unit

with the 1/4-20 hex head, thread forming screws and 1/4" external

tooth lock washers (see figure 1).

IV. OPERATION.

SAFETY MESSAGE TO OPERATORS

Peoples’ lives depend on your safe use of our products. Listed

below are some important safety instructions and precautions you

should follow:

• Although your warning system is operating

properly, it may not be completely effective. People

may not see or heed your warning signal. You must

recognize this fact and continue driving cautiously.

• Also, situations may occur which obstruct your

warning signal when natural or man-made objects

are between your vehicle and others, such as: raising

your hood or trunk lid. If these situations occur, be

especially careful.

• This product controls high intensity LED devices. To

prevent eye damage, DO NOT stare into the light

beam at close range.

3. DASH LIGHTS Connection.

See figures 2 and 3. Connect a user-supplied 18-

gauge wire to the seven-position connector’s DASH LIGHTS

connection. Route the wire to the vehicle instrument light circuit

(if backlight dimming is required) or the accessory terminal of the

ignition switch and terminate as required.

4. SignalMaster Cable Connections.

a. Route the SignalMaster cable towards the

control unit, while being careful not to scrape the wires on any

sharp edges.

b. If necessary, cut the cable to the appropriate

length.

c. Crimp a 0.187" wide spade receptacle on the

SignalMaster cable red (lamp common) wire and connect it to the

controller's LAMP COM (red) input.

• At the start of your shift, you should ensure that the

light is securely attached and all lamps are operating properly. The LED display on the control only

simulates the operation of the lamps.

• If a selected function does not perform properly or if

any of the lamps remain illuminated when the

control is off, disconnect the power connector from

the control unit and contact the nearest service

center.

Failure to follow these safety precautions may result in

property damage, serious injury, or death to you, to passengers, or

to others.

RETAIN AND REFER TO THIS MESSAGE

See figure 4. All controls utilized during normal operation of

the SignalMaster directional light are located on the front panel of

-3-

Page 4

E. LOW switch.

B

OFF

FEDERAL SIGNAL CORPORATION

331102

Figure 4.

WARNAUXFASTLOW

SignalMaster

290A2542-40

TM

the control unit. The LED display simulates the light pattern

being executed by the directional light.

A. Slide Switch.

1. LEFT (Position 1).

In this position, the light produces a left arrow

flashing pattern, instructing traffic to move left.

2. CENTER OUT (Position 2).

In this position, a center out flashing pattern is

produced, instructing traffic to move around either side of the

vehicle.

3. RIGHT (Position 3).

In this position, the light produces a right arrow

flashing pattern, instructing traffic to move right.

B. WARN switch.

When this switch is pressed, an alternating pattern is

produced. The four middle lights activate alternately with the two

outside lights on each side. The slide switch will override this

pattern.

C. AUX switch.

1. When this switch is pressed, external lamps

alternately flash at a constant rate. The wiring configuration

determines the flash combination of the external lamps. The slide

switch will override the external lamp pattern when the AUX

switch is depressed, but will not override the AUX OUT terminal

output.

2. If connected, the seven-position connector’s AUX

OUT connection provides a ground to activate a user-supplied

relay to control an external device.

D. FAST switch.

When this switch is pressed, the flash rate of the selected

directional or WARN pattern will increase. The rate of the AUX

switch function is not affected.

changed to turn lamps on/off in sequence until a pattern is

When this switch is pressed, all directional patterns are

completed. The last lamp activated in the pattern will flash three

times. If this switch is operated while the WARN pattern is

activated, the first and eighth lamp activate alternately with the

third and sixth lamp. The selection of this function reduces the

current draw for the directional light assembly’s patterns. The

AUX switch function is not affected by the LOW switch.

F. Auxiliary Input.

If connected, application of a positive (+) 12-volts to the

AUX IN connection on the seven-position connector produces the

WARN pattern described above. When the positive (+) 12-volts is

removed from the AUX IN connection, the WARN pattern will

stop. Slide switch activation will override the WARN pattern.

V. SERVICE.

A. General.

Servicing, other than cosmetic features, should be

performed by a qualified Federal Signal service center. If the

control unit is not working properly, disconnect all electrical

connections starting with the power leads. Remove the control unit

from the mounting bracket. Send the unit to the nearest authorized service center or the Federal Signal service department.

Communication and shipments should be addressed to:

Service Department

Federal Signal Corporation

2645 Federal Signal Drive

University Park, IL 60466

1-800-433-9132

After servicing is complete, perform a test of all

functions to ensure the control unit is operating properly.

B. Replacement Parts List.

Description Part Number

Printed Circuit Board Assembly 2001142-02

Knob, Pushbutton 8573065

Knob, Slide Switch 8536C1041

Bezel, Slide Switch 8573060

Connector, Female, 7-position 140325-05

Connector, Female, 11-position 140325-09

Bracket, Mounting 8573070

Screw, Hex Head, Mounting 7011164-08

Lockwasher, 1/4" 7075078

Chassis 8573247

Cover 8573066

-4-

Loading...

Loading...