Page 1

2561079C

REV. C 805

Printed in U.S.A.

INSTALLATION AND MAINTENANCE INSTRUCTIONS

FOR

SENTRY™ WARNING LIGHTS

SAFETY MESSAGE TO INSTALLERS AND USERS

People’s lives depend on your safe installation of our

products. It is important to read, understand and follow

all instructions shipped with the products. In addition,

listed below are some other important safety instructions and precautions you should follow:

• To properly install this kit: you must have a

good understanding of automotive electrical

procedures and systems, along with proficiency in the installation and use of safety

warning equipment.

• DO NOT install equipment or route wiring

in the deployment path of an air bag.

• When drilling into a vehicle structure, be

sure that both sides of the surface are clear

of anything that could be damaged.

• In order for the light to function properly, a

separate ground connection must be made.

If practical, it should be connected to the

negative battery terminal. At a minimum, it

may be attached to a solid metal body or

chassis part that will provide an effective

ground path as long as the light system is to

be used.

stating the extent of damage. Carefully check all

envelopes, shipping labels, and tags before removing or

destroying them. Ensure that the parts listed in the

appropriate KIT CONTENTS LIST are contained in the

package.

II. KIT CONTENTS LIST.

SURFACE MOUNT MODELS

Qty. Description Part Number

1 Cable Tie 150A109

1 Terminal, Female 224A216-04L

1 Terminal, Male 224A217-02L

3 Screw, #10 Thd. Frm. 7011A122-12

3 Flat Washer, #10 7072A119

1 Gasket, Mounting 8433011

1 Grommet 8108A002

PIPE MOUNT MODELS

Qty. Description Part Number

1 Cable Tie 150A109

1 Terminal, Female 224A216-04L

1 Terminal, Male 224A217-02L

MAGNETIC MOUNT MODELS

Qty. Description Part Number

1 Cover, Magnet, Mylar 16111464-01

1 Label, Caution, Magnetic Mnt. 200389

• Locate light control so the VEHICLE and

CONTROL can be operated safely under all

driving conditions.

• Do not attempt to activate or deactivate

light control while driving in a hazardous

situation.

• You should frequently inspect the light to

ensure that it is operating properly and that

it is securely attached to the vehicle.

• File these instructions in a safe place and

refer to them when maintaining and/or

reinstalling the product.

Failure to follow all safety precautions and instructions may result in property damage, serious injury, or

death to you or others.

I. UNPACKING.

After unpacking the unit, inspect it for damage that

may have occurred in transit. If the unit has been

damaged, file a claim immediately with the carrier,

III. INSTALLATION.

A. Surface Mount Models.

To install the light, proceed as follows:

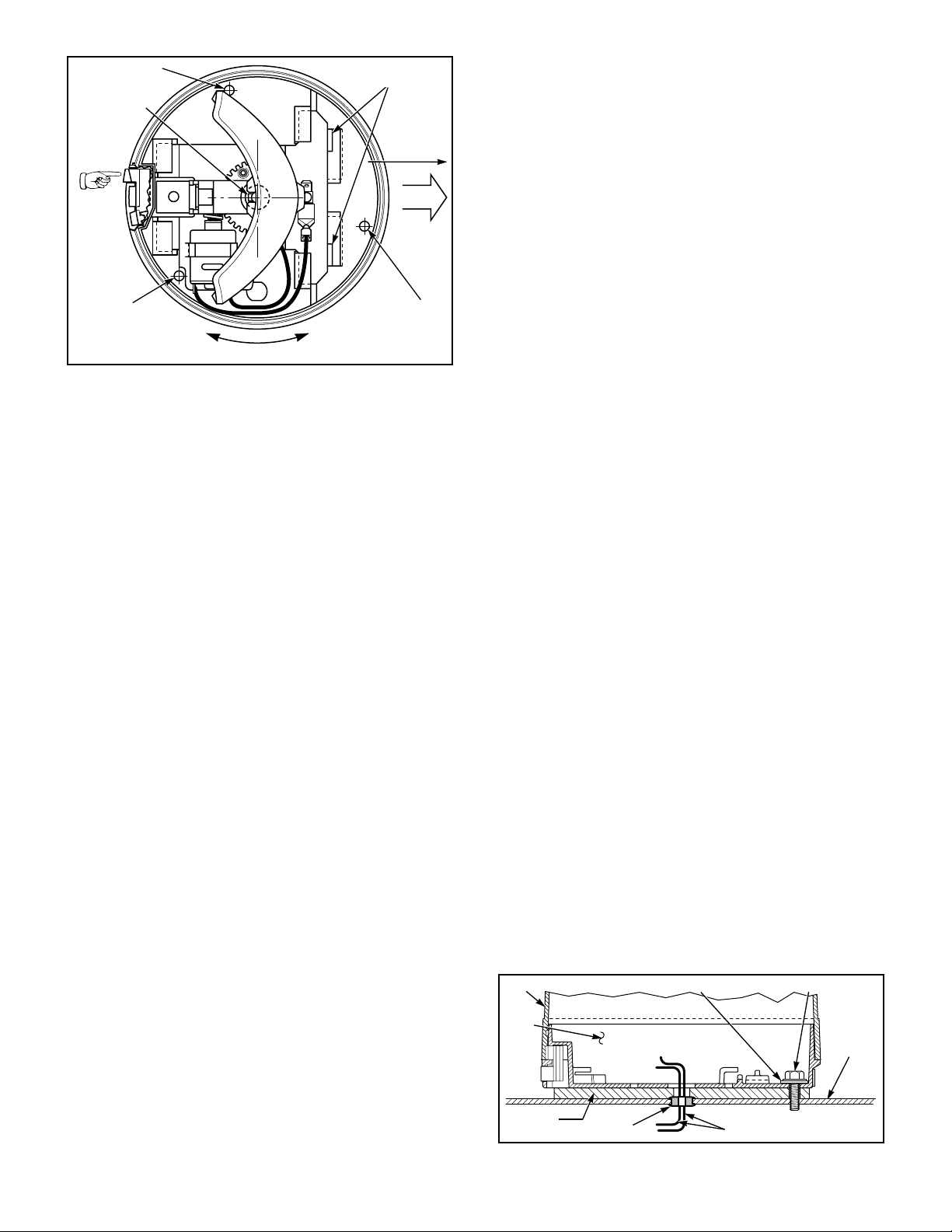

1. Push and hold the dome release button

(located in the plastic base). Turn the dome counterclockwise and lift the dome off the base (see figure 1).

2. Position the vehicle on a level surface.

Select a relatively flat mounting position which provides

sufficient rigidity to support the light and prevent

vibrations caused by the light when the vehicle is in

motion.

CAUTION

Turning reflector by hand may damage motor or

worm gear. To rotate the reflector, connect to an

appropriate power source.

3. Position the light with the dome release

button toward the rear at the selected mounting location.

Page 2

MOUNTING HOLE

DOME

BASE

MOUNTING

SURFACE

MOUNTING

GASKET

#10 FLAT WASHERS (3) #10-32 x 3/4" SCREWS (3)

290A2669-02B

WIRE LEADS

GROMMET

WIRING HOLE

PUSH

TO

RELEASE

DOME

MOUNTING

HOLE

INST ALL REMOVE

TWIST DOME

MECHANISM RELEASE TABS

(PUSH DOWN HERE)

SLIDE TO

REMOVE

FRONT

MOUNTING

HOLE

290A2669-01

Figure 1.

4. Use the base of the light as a template and

scribe three mounting hole drill position marks on the

mounting surface. Also, srcibe one wire routing hole

drill position mark at the center.

mounting surface and leave about 6" of excess wire

above the mounting surface. Also, route a user-supplied

16AWG black wire from a known good vehicle ground

through the grommet in the mounting surface and leave

about 6" of excess wire above the mounting surface.

9. Apply a silicone sealing compound around

the wires and grommet where they pass through the

mounting surface to prevent leakage.

10. Align the holes in the mounting gasket with

the appropriate holes in the base and apply the mounting gasket to the base of the light . Route the wires

through the gasket’s wire routing hole and into the base

of the light.

11. See figure 2. Secure the base to the mounting surface with the three thread-forming screws and

flat washers.

12. Strip approximately 1/4" of insulation from

the end of the red and black wires previously routed into

the base of the light.

CAUTION

To avoid damage when drilling, ensure that

both sides of mounting surface are clear of any

parts or wires.

Also, when drilling any holes, ensure that holes

are drilled only through sheet metal and not

through upholstery.

5. Drill one 1/2" (0.50) hole (wire routing hole)

at the previously scribed center drill position mark.

Drill three 9/64" (0.140) holes (mounting holes) at the

previously scribed outer drill position marks.

6. Install the grommet in the 1/2" wire routing

hole.

WARNING

When installing equipment inside air bag

equipped vehicles, the installer MUST ensure

that the equipment is installed ONLY in areas

recommended by the vehicle manufacturer.

Failure to observe this warning will reduce the

effectiveness of the air bag, damage the air bag,

or potentially damage or dislodge the equipment, causing serious injury or death to you or

others.

13. Crimp the female terminal on the black

wire and attach it to the short black wire with the male

terminal.

14. Crimp the male terminal on the red wire

and attach it to the short red wire with the female

terminal in the light.

CAUTION

Interference with a rotating reflector can

damage the reflector or wires. Ensure that wires

are dressed to prevent any interference.

15. Use the cable tie to dress the wires.

16. Connect the unused terminal of the previously installed switch to one side of a user-supplied

fuseholder. Connect the other side of the fuseholder to

the positive (+) terminal of the vehicle’s battery. Install

an eight (8) ampere fuse in the fuseholder.

17. Replace the dome.

B. Pipe Mount Models.

1. Push and hold the dome release button

(located in the plastic base). Turn the dome counterclockwise and lift the dome off the base (see figure 1).

7. Install a user-supplied switch (current

capacity of at least 8-amperes) at a location which

allows the vehicle and all controls to be operated safely

under all driving conditions.

8. Route a user-supplied 16AWG red wire

from one side of the switch through the grommet in the

Figure 2.

-2-

Page 3

WARNING

When installing equipment inside air bag

equipped vehicles, the installer MUST ensure

that the equipment is installed ONLY in areas

recommended by the vehicle manufacturer.

Failure to observe this warning will reduce the

effectiveness of the air bag, damage the air bag,

or potentially damage or dislodge the equipment, causing serious injury or death to you or

others.

2. Install a user-supplied switch (current

capacity of at least 8-amperes) at a location which

allows the vehicle and all controls to be operated safely

under all driving conditions.

3. Route a user-supplied 16AWG red wire

from one side of the switch through the pipe flange and

into the light. Leave about 6" of excess wire above the

pipe flange. Also, route a user-supplied 16AWG black

wire from a known good vehicle ground through the pipe

flange and into the light. Leave about 6" of excess wire

above the pipe flange.

4. Screw the flange mount light onto the pipe.

Position the light with the dome release button toward

the rear.

it is not intended for use on the exterior of a moving

vehicle.

WARNING

Because vehicle roof construction and driving

conditions vary, Federal does not recommend

driving a vehicle with a magnetically mounted

warning light installed. The light could fly off

the vehicle causing injury or damage. Repair of

damage incurred because of ignoring this

warning shall be the sole responsibility of the

user.

Holding power of magnetic mounting systems is

dependent upon surface finish, surface flatness,

and thickness of the steel mounting surface.

Therefore, to promote proper magnetic mounting:

• Mounting surface and magnets must be

kept clean, dry, and free of foreign particles

that prevent good surface contact.

• Ensure that mounting surface is flat.

• Magnet mounting system should not be

used on vehicles with vinyl tops.

5. Strip approximately 1/4" of insulation from

the end of the red and black wires previously routed into

the base of the light.

6. Crimp the female terminal on the black

wire and attach it to the short black wire with the male

terminal.

7. Crimp the male terminal on the red wire

and attach it to the short red wire with the female

terminal in the light.

CAUTION

Interference with a rotating reflector can

damage the reflector or wires. Ensure that wires

are dressed to prevent any interference.

8. Use the cable tie to dress the wires.

9. Connect the unused terminal of the previously installed switch to one side of a user-supplied

fuseholder. Connect the other side of the fuseholder to

the positive (+) terminal of the vehicle’s battery. Install

an eight (8) ampere fuse in the fuseholder.

10. Replace the dome.

C. Magnetic Mount Models.

Magnetic mounting provides a secure, tempo-

rary mounting method for most installations. However,

• To prevent sliding of light assembly on

mounting surface, quick acceleration and

hard stops should be avoided.

• If the light is to be held directly to the roof

by the magnet, ensure that the power cable

is not under the magnet.

1. Place the light assembly on a level steel

surface. Ensure that the light is placed to promote

maximum coverage and range of the light’s warning

signal.

2. Insert the plug on the end of the power cord

into the cigar lighter socket.

NOTE

When using the vehicle’s cigar lighter socket as

the light’s power source, Federal recommends

replacing the original lighter circuit fuse with

an eight-ampere fuse. After the original fuse has

been replaced, devices requiring more than

eight amperes will cause failure of the lighter

circuit fuse and therefore should not be plugged

into the cigar lighter socket.

If direct connection to the power source (not

utilizing the cigar lighter plug) is desired, a

user-supplied in-line fuseholder and eightampere fuse must be installed in the power

cord’s ribbed (positive) lead.

-3-

Page 4

D. DIN Mount Models.

These models utilize a DIN mounting/connection installation. They are designed for installation on a

24mm tube/female DIN connector.

NOTE

If a user-supplied switch is used, it must have a

current capacity of at least 8-amperes.

1. Loosen the wing nut on the base of the light

assembly.

2. Slide the light assembly onto the 24mm

tube/female DIN connector. Ensure that the connector is

seated in the base of the light.

3. Finger-tighten the wing nut until the base

is snug on the DIN connector.

4. Install a user-supplied fuseholder in the

light’s positive lead and install a 8-ampere fuse in the

fuseholder.

IV. MAINTENANCE.

A. General.

WARNING

Crazing (cracking) of domes will cause reduced

effectiveness of the light. Do not use cleaning

agents (which will cause crazing) such as strong

detergents, solvents, or petroleum products. If

crazing of dome does occur, reliability of light for

emergency signalling purposes may be reduced

until dome is replaced.

CAUTION

Service life of lamp will be shortened if glass

portion is touched. If glass has been handled,

clean carefully with a grease solvent.

1. Rotate the reflector until the C-clip (located

at the base of the lamp) can be removed, and remove the

C-clip by sliding it away from the reflector.

2. See figure 3. Note the lamp’s orientation

and replace the lamp with the straight edge of the

lamp’s base toward the reflector. Replace the 12V lamp

with Part No. 8440A265 and the 24V lamp with Part

No. 8444A151.

C. Mechanism Removal (for servicing).

1. Push and hold the dome release button

(located in the plastic base). Turn the dome counterclockwise and lift the dome off the base (see figure 1).

2. Disconnect power to the light. Disconnect

the red and black leads in the light.

3. See figure 1. Push and hold the mechanism

release tabs.

4. Slide the mechanism over the release tabs

and lift the mechanism out of the base.

5. After servicing, replace the mechanism by

performing the above steps in reverse order.

1. The dome can be cleaned using a nonabrasive, high quality, automotive paste wax and a soft

cloth.

2. On magnetic mount lights, periodically

inspect the magnet for dirt and metal shavings. Clean

the magnet as necessary. Keep the area around the

magnetic mount light free of dirt and metal shavings.

3. Apply a film of light grease to the gears

when necessary.

B. Lamp Replacement.

WARNING

A serious injury may result if lamp is touched

when hot. Always allow lamp to cool before

removing. Halogen lamps are pressurized and if

broken can result in flying glass. Always wear

gloves and eye protection when handling the

lamps.

H-I HALOGEN LAMP

LAMP BASE

ORIENTED PARALLEL

TO GROVES IN

LAMP SOCKET

CONNECTOR

LAMP SOCKET

GROOVES(2)

GEAR AND REFLECTOR

ASSEMBLY

Figure 3.

DO NOT TOUCH

GLASS PORTION

OF LAMP

SLIDE CLIP OVER

LAMP BASE INTO

GROOVES ON

LAMP SOCKET

290A2600-01

-4-

Loading...

Loading...