Page 1

SelecToneTM Models 304X and 314X

Explosion-Proof Amplied Speakers

Installation and

Maintenance Instructions

2562113A

Rev. A1 114

Printed in U.S.A.

français...............page 23

español...............página 45

Page 2

Warranty – Seller warrants all goods for ve years on parts and 2-1/2 years on

labor, under the following conditions and exceptions: Seller warrants that all

goods of Seller's manufacture will conform to any descriptions thereof for specications which are expressly made a part of this sales contract and at the time of

sale by Seller such goods shall be commercially free from defects in material or

workmanship. Seller reserves the right at the Seller’s discretion to “Repair and

Return” or “Replace” any item deemed defective during the warranty period.

This warranty does not cover travel expenses, the cost of specialized equipment

for gaining access to the product, or labor charges for removal and reinstallation of the product. This warranty shall be ineffective and shall not apply to

goods that have been subjected to misuse, neglect, accident, damage, improper

maintenance, or to goods altered or repaired by anyone other than Seller or its

authorized representative, or if ve years have elapsed from the date of shipment

of the goods by Seller with the following exceptions: lamps and strobe tubes are

not covered under this warranty. Outdoor warning sirens and controllers manufactured by Federal Warning Systems are warranteed for two years on parts and

one year on labor. No agent, employee, representative or distributor of Seller has

any authority to bind the Seller to any representation, afrmation, or warranty

concerning the goods and any such representation, afrmation or warranty shall

not be deemed to have become a part of the basics of the sales contract and

shall be unenforceable. THE FOREGOING WARRANTIES ARE EXCLUSIVE

AND IN LIEU OF ALL OTHER WARRANTIES OR MERCHANTABILITY,

FITNESS FOR PURPOSE AND OF ANY OTHER TYPE, WHETHER EXPRESS OR IMPLIED. These warranties shall not apply unless Seller shall be

given reasonable opportunity to investigate all claims for allegedly defective

goods. Upon Seller's instruction a sample only of allegedly defective goods shall

be returned to Seller for its inspection and approval. The basis of all claims for

alleged defects in the goods not discoverable upon reasonable inspection thereof

pursuant to paragraph 8 hereof must be fully explained in writing and received

by Seller within thirty days after Buyer learns of the defect or such claim shall be

deemed waived.

Industrial Systems

2645 Federal Signal Drive • University Park, IL 60484-3167

Tel: 708-534-4756 • Fax: 708-534-4852

Email: elp@federalsignal.com • www.federalsignal-indust.com

Page 3

Models 304X and 314X Explosion-Proof Amplied Speakers

Contents

Safety Message to Installers and Users ............................................... 5

An Overview of the Speakers

Unpacking the Speaker

Mounting the Speaker

Installing the UTM Universal Tone Module

Installing the Speaker Connector Card

Safety Message to Operators

Testing and Operating the Speaker

Safety Message to Maintenance Personnel

Maintaining the Speaker

Ordering Replacement Parts

Returning the Product for Credit

............................................................................ 8

................................................................ 6

.......................................................................... 7

........................................ 11

.............................................. 13

.............................................................. 17

.................................................... 17

....................................... 18

...................................................................... 19

............................................................... 19

........................................................ 20

Tables

Table 1 Model 304X specications .......................................................... 7

Table 2 Model 314X specications .......................................................... 8

Table 3 Tone and Connector Card UL Audibility Ratings ........................8

Table 4 Model 304X replacement parts ................................................20

Table 5 Model 314X replacement parts ................................................20

Figures

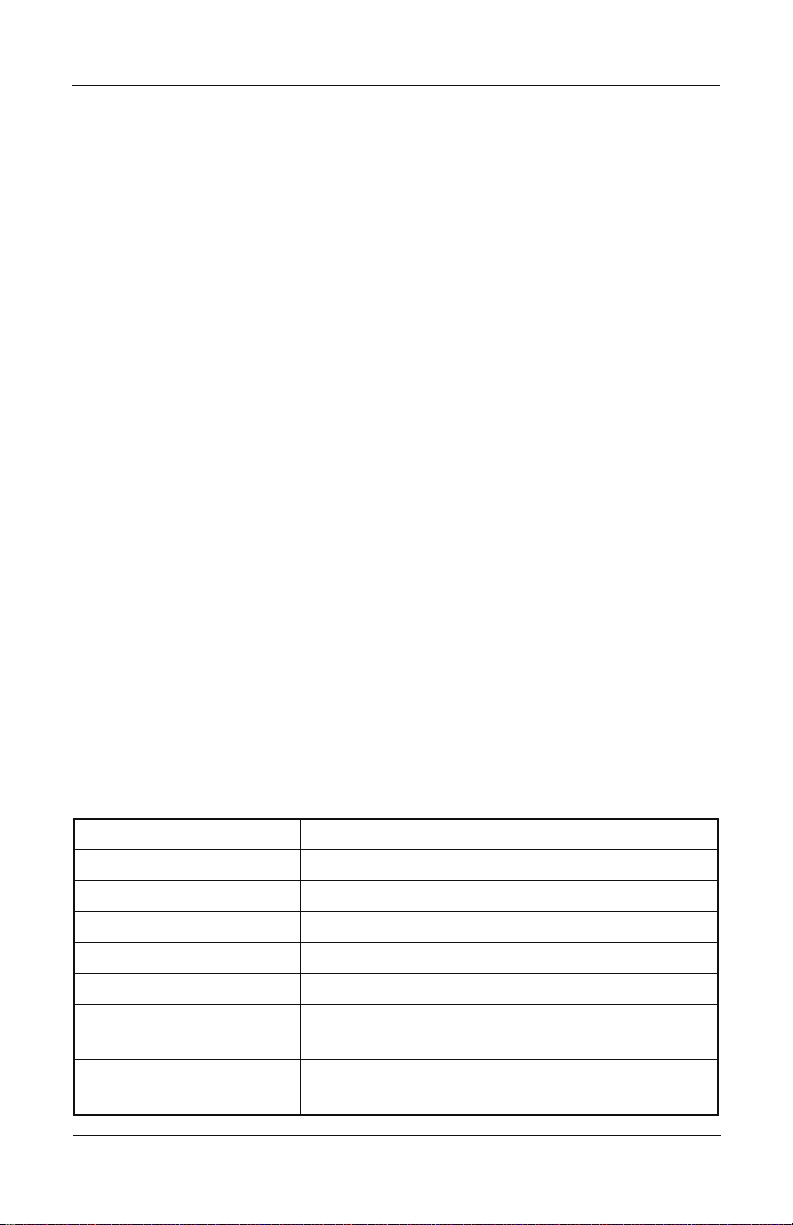

Figure 1 Mounting hole locations and dimensions.................................. 9

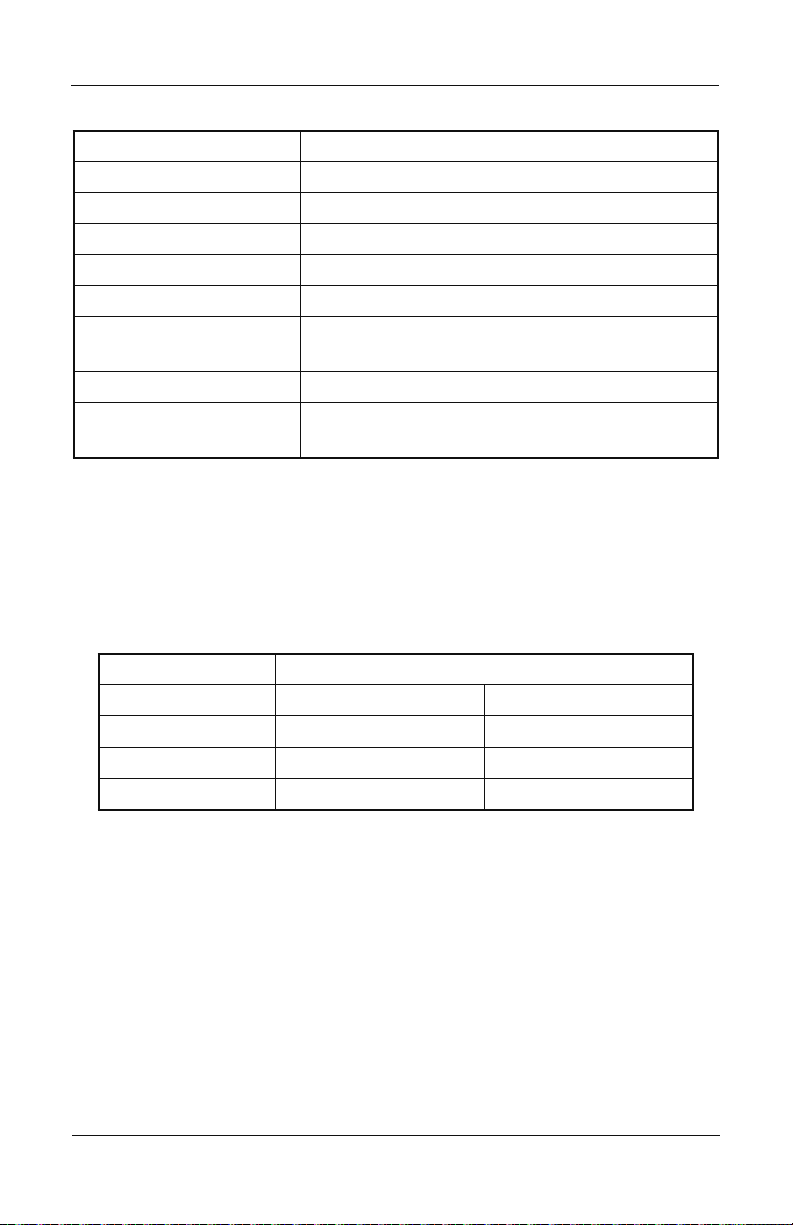

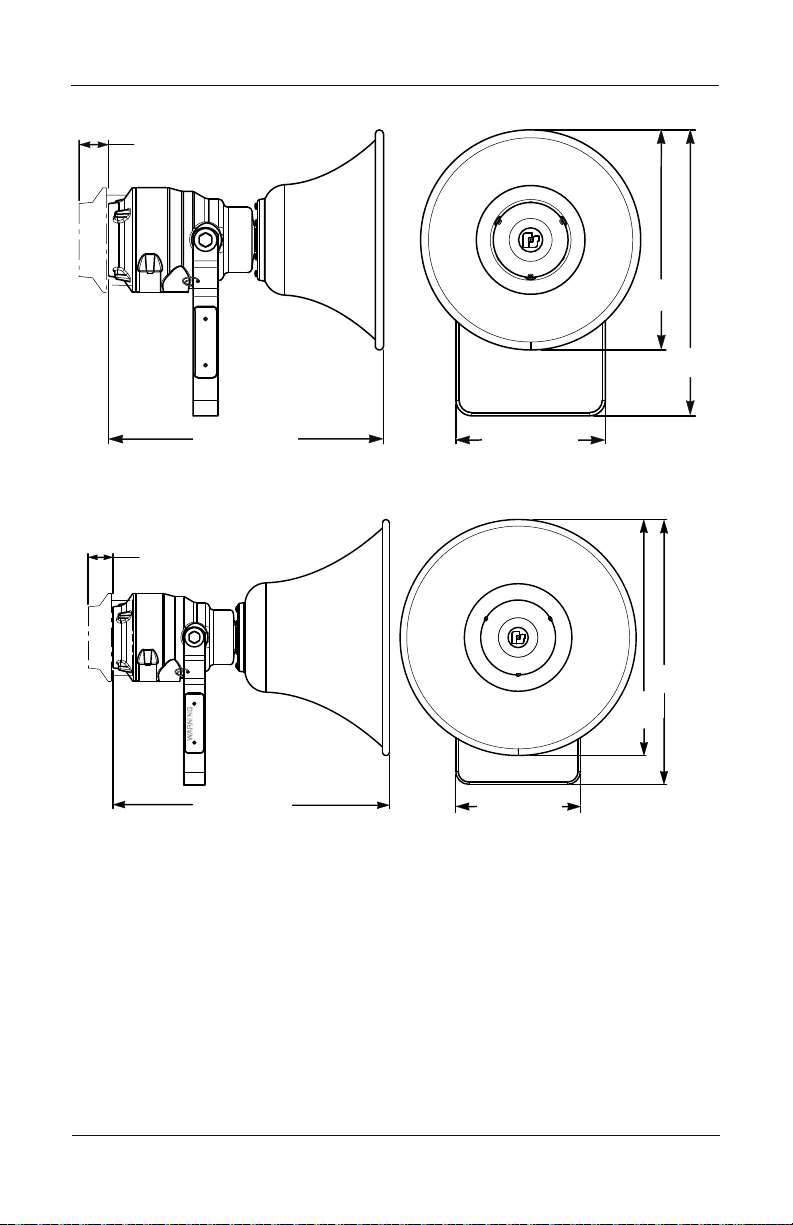

Figure 2 Dimensions of the Model 304X............................................... 10

Figure 3 Dimensions of the Model 314X............................................... 10

Figure 4 Speaker with cover removed .................................................. 12

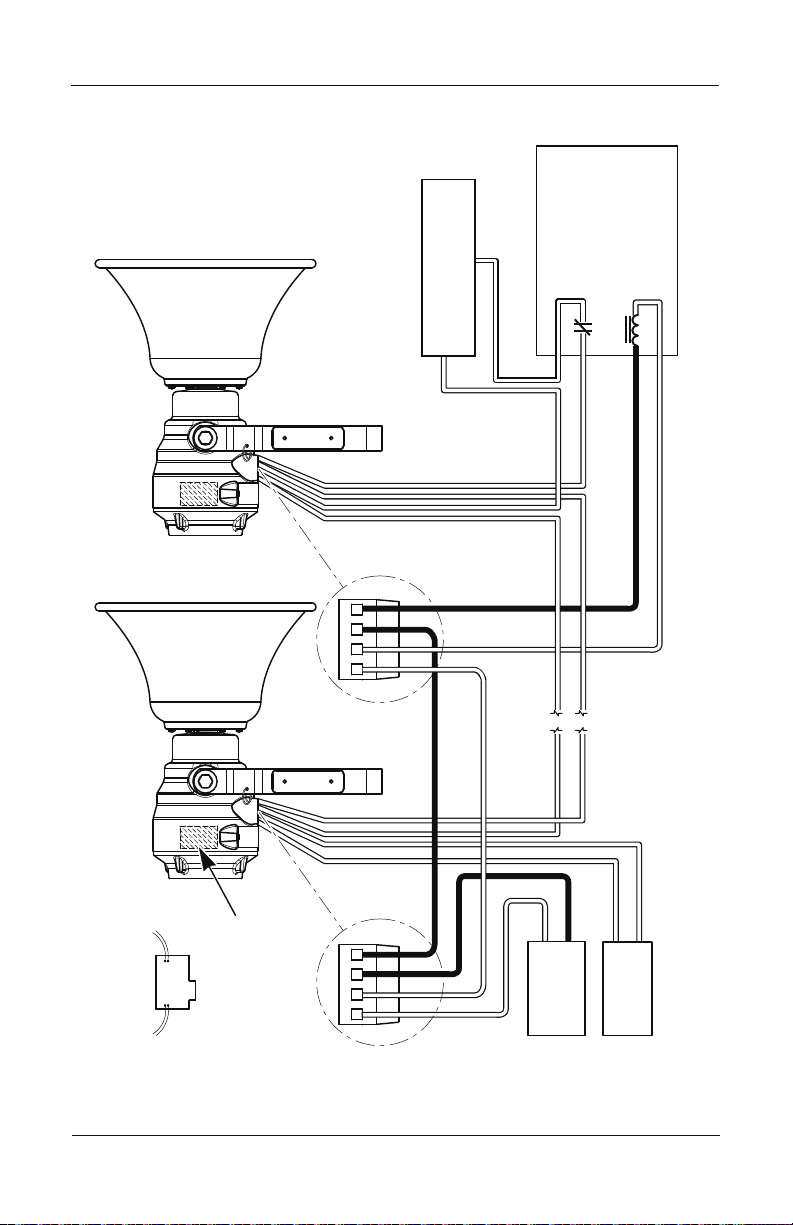

Figure 5 Speakers connected to EOL device ....................................... 15

Figure 6 Speakers with supervision relay and connector card ............. 16

3

Page 4

© 2013 Federal Signal Corporation. All rights reserved.

Page 5

Installation and Maintenance Instructions

Safety Message to Installers and Users

People’s lives depend on your safe installation of our products. It is

important to follow all instructions shipped with this product. This

device is to be installed by a trained electrician who is thoroughly

familiar with the National Electrical Code and/or Canadian Electrical

Code and will follow the NEC and/or CEC Guidelines as well as all

local codes. This horn should be considered a part of the warning

system and not the entire warning system.

The selection of the mounting location for this horn, its controls and

the routing of the wiring are to be accomplished under the direction

of the Facilities Engineer and the Safety Engineer. In addition, listed

below are some other important safety instructions and precautions

you should follow:

• Read and understand all instructions before installing, operating,

or maintaining this equipment.

•

Warning–Explosion Hazard – Do not disconnect equipment

unless power has been switched off or the area in known to be

non-hazardous.

• Do not connect this unit to the system when power is on.

• Optimum sound distribution will be severely reduced if any

objects are in front of the horn. You should ensure that the front

of the horn is clear of any obstructions.

• All effective warning horns produce loud sounds which may

cause, in certain situations, permanent hearing loss. The device

should be installed far enough away from potential listeners to

limit their exposure while still maintaining its effectiveness. The

OSHA Code of Federal Regulations 1910.95 Noise Standard

provides guidelines which may be used regarding permissible

noise exposure levels.

• After installation, ensure that all mounting screws, bolts, and

threaded joints are tightened.

Models 304X and 314X Explosion-Proof Amplied Speakers

5

Page 6

Installation and Maintenance Instructions

• Establish a procedure to routinely check the signal system for

proper activation and operation.

• Any maintenance to the unit MUST be performed by a trained

electrician in accordance with NEC Guidelines and local codes.

• Never alter the unit in any manner.

• The nameplate should NOT be obscured, as it contains cautionary

and/or other information of importance to maintenance personnel.

• After installation and completion of initial system test, a program

for periodic testing of this device must be established. Refer to

NFPA 72G, local Fire Codes and the authority having jurisdiction

for this information.

• Provide a copy of these instructions to the Safety Engineer,

operator(s) and maintenance personnel.

• File these instructions in a safe place and refer to them when

maintaining and/or reinstalling the device.

Failure to follow all safety precautions and instructions may result in

property damage, serious injury, or death.

An Overview of the Speakers

The Federal Signal Model 304X and 314X Explosion-Proof

Amplied Speakers are designed to produce crisp, clear tones in

supervised alarm notication systems. Both models are compatible

with re alarm, voice evacuation, suppression supervised control

panels, and power boosters.

These amplied speakers can broadcast tones generated by a Tone

Card installed into the speaker (the plug-in 32-tone UTM) or by a

central tone source in a voice evacuation or paging system. When live

public address or voice messages are required, plug-in Federal Signal

Connector Cards (AM25CK or AM70CK) interface with the Vrms of

the EVAC panel.

6

Models 304X and 314X Explosion-Proof Amplied Speakers

Page 7

Installation and Maintenance Instructions

The speaker cone and projector are constructed of rugged spun

aluminum. The solid-state amplier circuit is protected in a diecast aluminum housing. Dust- and moisture-proof gaskets provide

protection from the elements. All external surfaces are sealed with

gray powder-coat paint. A heavy-duty swivel mount bracket allows

the installer to direct the output effectively.

The rugged construction and high output of the Model 304X and

314X make them ideal for use in harsh environments with high

ambient noise levels. Both models feature an internal gain control for

adjustment to suit the area.

This equipment is suitable for use in Class 1, Division 1, Groups B, C,

D; Class I, Division 2, Groups A, B, C, D or non-hazardous locations

only.

Unpacking the Speaker

After unpacking the horn, examine it for damage that may have

occurred in transit. If the horn has been damaged, do not attempt to

install or operate it. File a claim immediately with the carrier, stating

the extent of the damage. Carefully check all envelopes, shipping

labels, and tags before removing or discarding them. Disposal of all

shipping materials must be carried out in accordance with national

and local codes and standards. If any parts are missing, please call

Federal Signal Customer Support at 708-534-4756 or 877-289-3246.

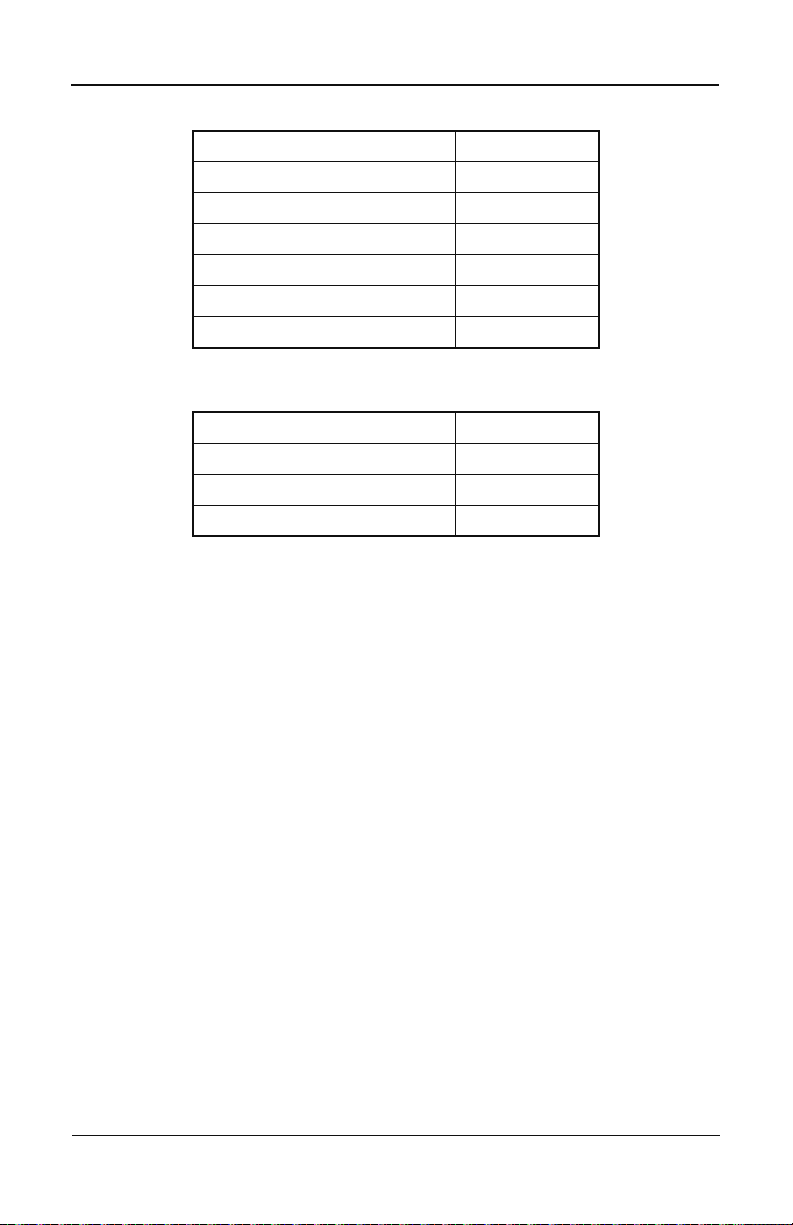

Table 1 Model 304X specications

Operating Voltage: Regulated 24 Vdc (16 Vdc to 33 Vdc)

Maximum Current: 0.83 A

Standby Current: 0.13 A

Operating Temperature: -40 ºF to 150 ºF (-40 ºC to 66 ºC)

Net Weight: 15.4 lb (7.0 kg)

Shipping Weight: 22.8 lb (10.4 kg)

Dimensions:

Construction:

Models 304X and 314X Explosion-Proof Amplied Speakers

16.3 in D x 17.0 in H x 13.1 in W

414.02 mm D x 431.80 mm H x 332.73 mm W

Aluminum enclosure and adjustable steel

mounting bracket with a powder-coat nish

7

Page 8

Installation and Maintenance Instructions

Table 2 Model 314X specications

Operating Voltage: Regulated 24 Vdc (16 Vdc to 33 Vdc)

Maximum Current: 0.90 A

Standby Current: 0.13 A

Operating Temperature: -40 ºF to 150 ºF (-40 ºC to 66 ºC)

Net Weight: 16.4 lb (7.4 kg)

Shipping Weight: 32.4 lb (14.7 kg)

Dimensions: 19.5 in D x 18.8 in H x 16.7 in W

495.30 mm D x 477.52 mm H x 424.17 mm W

Ingress Protection: IP65 and NEMA 4X Approved

Construction: Aluminum enclosure and adjustable steel

mounting bracket with a powder-coat nish.

Compatible Tone Modules: TM2 or UTM

Compatible Speaker Connector Cards: AM25CK*, AM70CK*,

or 300CKS

*Series A versions of these connector cards are not compatible.

Table 3 Tone and Connector Card UL Audibility Ratings

Rating: UL dB (A) Sound Pressure per UL1480

Speaker: 304X 314X

Audibility Rating*: 91 97

AM25CK: 101 99

AM70CK: 101 99

*Based on TM6, HORN

Mounting the Speaker

The speaker can be mounted on any relatively at surface capable

of supporting the weight of the speaker. Conduit connections can be

made to the 1/2" NPT threaded openings at bottom of the housing

(see Figure 4 on page 12).

To mount the speaker:

Remove the two 1/2"-13 hex-head bolts, at washers, and

1.

lockwashers that secure the mounting bracket to the speaker.

8

Models 304X and 314X Explosion-Proof Amplied Speakers

Page 9

Installation and Maintenance Instructions

5.0" (127 mm)

0.53" (13.5 mm)

290A5198

2. Disconnect the lanyard from the mounting bracket at the cotter ring.

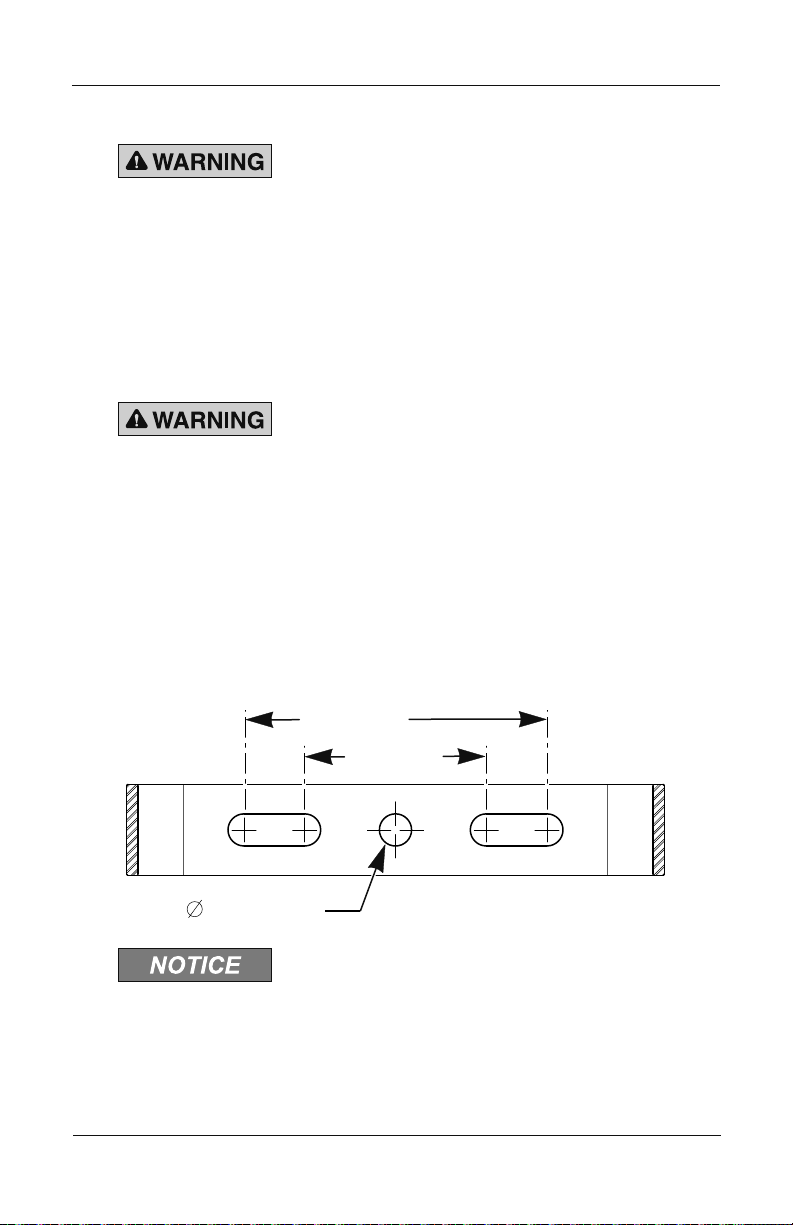

MOUNTING PRECAUTION — Property damage, serious

injury, or death could occur if an accumulation of water,

snow, dust, etc. resides in the speaker projector, severely

reducing or preventing the operation of this device. Mount

the speaker so the speaker projector is pointed horizontally

or slightly downward.

3. Select the mounting location.

MOUNTING PRECAUTION — Property damage, serious

injury, or death could occur if any objects are in front of

speaker, severely reducing optimum sound distribution. For

maximum effectiveness, ensure that the front of the speaker

is clear of obstructions.

4. See Figure 1. Using the mounting bracket as a template, scribe

drill position marks on the mounting surface.

Figure 1 Mounting hole locations and dimensions

3.0" (76 mm)

+

DRILLING PRECAUTION — Before drilling holes in any

surface, be sure both sides of surface are clear of anything

that could be damaged.

Models 304X and 314X Explosion-Proof Amplied Speakers

9

Page 10

Installation and Maintenance Instructions

290A5201

Figure 2 Dimensions of the Model 304X

1.8" (46 mm)

TO REMOVE COVER

13.1"

(333 mm)

WARNING

16.3" (414 mm)

8.9" (226 mm)

17.0"

(432 mm)

290A5200

Figure 3 Dimensions of the Model 314X

1.8" (46 mm)

TO REMOVE COVER

18.8"

(478 mm)

16.7"

WARNING

19.5" (496 mm)

8.9" (226 mm)

(425 mm)

5. Drill holes at the scribed drill-position marks to accommodate the

1/2" diameter bolts.

Secure the bracket to the mounting surface with the 1/2" diameter

6.

hex-head bolts, lockwashers, and hex nuts.

Reattach the speaker to the mounting bracket with the two

7.

1/2"-13 hex-head bolts, at washers, and lockwashers.

Position the speaker to obtain the required sound coverage, then

8.

tighten the bolts securely.

10

Models 304X and 314X Explosion-Proof Amplied Speakers

Page 11

Installation and Maintenance Instructions

9. Reattach the lanyard to the cotter ring and mounting bracket.

Verify that it is securely attached to both the cover and the

mounting bracket.

Route wires through the 1/2" NPT threaded openings into the

10.

SelecTone unit in accordance with national and local electrical

and re codes. Wire size depends upon the operating current

and the distance from the power source.

See the next sections for instructions on installing the speaker

connector card and UTM module, and wiring the speaker.

Installing the UTM Universal Tone Module

MISWIRING/ELECTRICAL SUPERVISION — Property damage,

serious injury, or death could occur if independent conductors

are terminated together; both wires of the same polarity must

be used as two separate connections. NFPA 72 requires that

the wires be terminated independently to provide electrical

supervision of the connection.

SHOCK HAZARD — To avoid electrical shock hazards, do not

connect wires when power is applied. Failure to heed this

warning may cause serious injury or death.

For details, refer to the instructions for the Model UTM Universal

Tone Module, doc. No. 2561101.

To install the UTM module in the speaker:

DO NOT DAMAGE SEALING SURFACES — Property damage,

serious injury, or death could occur if the machined sealing

surfaces are damaged on this product. To maintain the

effectiveness of the explosion-proof enclosure, be careful

to avoid damaging the machined sealing surfaces of cover

and housing.

Models 304X and 314X Explosion-Proof Amplied Speakers

11

Page 12

Installation and Maintenance Instructions

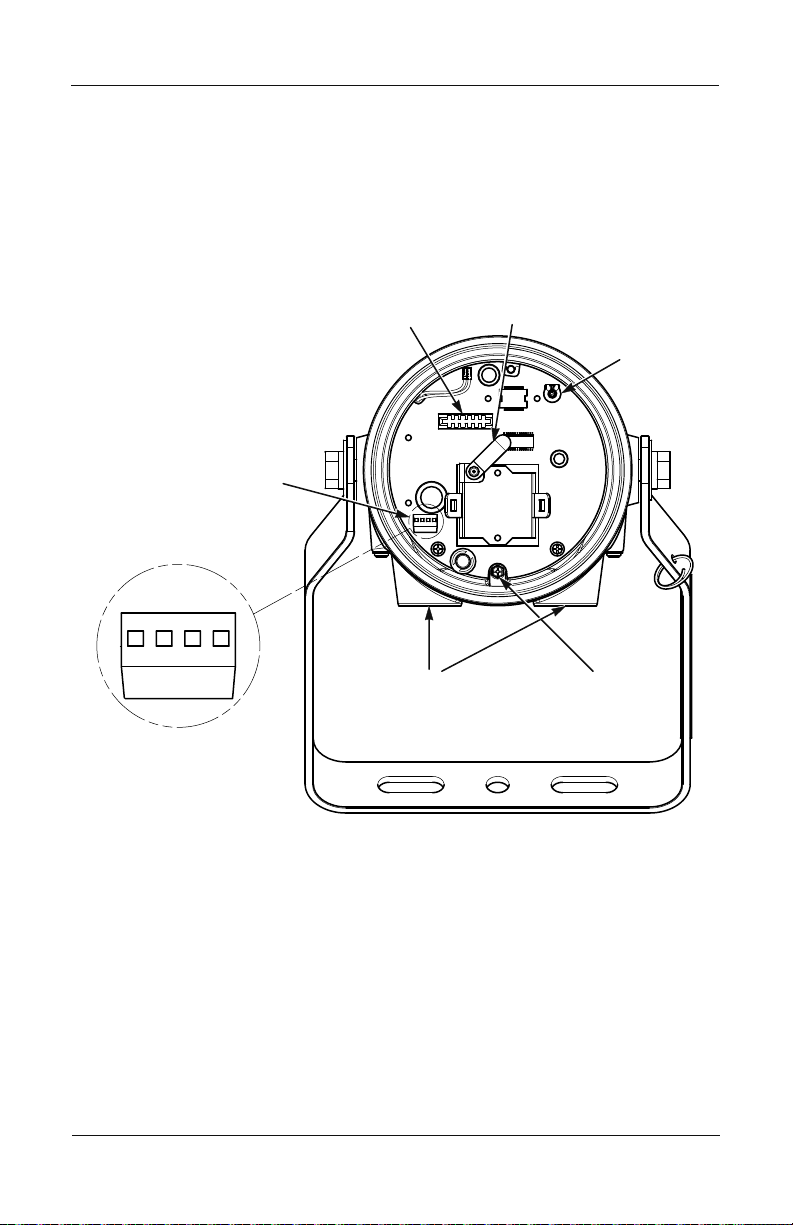

POWER CONNECTOR

DETAIL

1/2" NPT

CONDUIT

ENTRANCES

EARTH

GROUND

POWER

CONNECTOR

SOCKET FOR TONE OR

CONNECTOR CARD

TONE/CONNECTOR

CARD RETAINER

VOLUME

CONTROL

L

(+)

L

(+)N(-)N(-)

1. Loosen and remove the threaded cover by turning it counterclockwise. Allow the cover to hang by the attached lanyard.

Plug the tone card (purchased separately) into the socket as

2.

shown in Figure 4.

Figure 4 Speaker with cover removed

3. Rotate the card retainer into position over the tone card so that it

holds the card in place (Figure 4).

See Figure 5 on page 15 and Figure 6 on page 16. Connect the

4.

positive (+) power-source lead to the terminal block labeled L+.

Connect the negative (–) power-source lead to the terminal block

5.

labeled N–.

Connect the additional positive (L+) and negative (N–) terminal

6.

leads to the next speaker or to an end-of-line device.

12

Models 304X and 314X Explosion-Proof Amplied Speakers

Page 13

Installation and Maintenance Instructions

EXPLOSION HAZARD — Property damage, serious injury, or

death could occur if the housing is not closed properly. To

reduce possibility of explosion, the housing cover must be

kept tight while circuits are energized.

7. Carefully reinstall the housing cover and tighten it until the cover

ange makes contact with the housing.

8.

To secure the cover, tighten the set screw on the cover. Verify that

the mounting bolts are securely tightened.

Installing the Speaker Connector Card

For more details, refer to the instructions for the SelecTone AM25CK

and AM70CK Connector Cards, doc. No. 2561183.

MISWIRING/ELECTRICAL SUPERVISION FAILURE — Property

damage, serious injury, or death could occur if independent

conductors are terminated together; both wires of the same

polarity must be used as two separate connections. NFPA 72

requires that the wires be terminated independently to provide

electrical supervision of the power supply connection and

audio lines.

SHOCK HAZARD — To avoid electrical shock, do not connect

wires when circuits are energized. Failure to heed this warning

may cause serious injury or death.

To install the connector card:

1.

Plug the connector card (purchased separately) into the socket as

shown in Figure 4 on page 12.

2.

Rotate the card retainer into position over the tone card so that it

holds the card in place (Figure 4).

3.

See Figure 5 on page 15 or Figure 6 on page 16. Connect the

positive power-source (+) lead to the terminal labeled L+.

Models 304X and 314X Explosion-Proof Amplied Speakers

13

Page 14

Installation and Maintenance Instructions

4. Connect the negative (–) power-source lead to the negative

terminal labeled

Connect the additional positive (L+) and negative (N –) terminal-

5.

N –.

block leads to the next speaker or to a power supervision relay.

Connect one pair of white leads from the connector card to the

6.

audio output of the re alarm panel.

Connect the other pair of white leads to the connector card in the

7.

next speaker or to a contact on the power supervision relay and

an end of line device.

NOTE: Check with the authority having jurisdiction for the proper

application of the required EOL resistor and power supervision

relay (see Figure 6 on 16).

EXPLOSION HAZARD — Property damage, serious injury, or

death could occur if the housing is not closed properly. To

reduce possibility of explosion, the housing cover must be

kept tight while circuits are energized.

8. Carefully reinstall the housing cover and tighten it until the cover

ange makes contact with the housing.

To secure the cover, tighten the set screw on the cover. Verify that

9.

the mounting bolts are securely tightened.

14

Models 304X and 314X Explosion-Proof Amplied Speakers

Page 15

Installation and Maintenance Instructions

290A5202

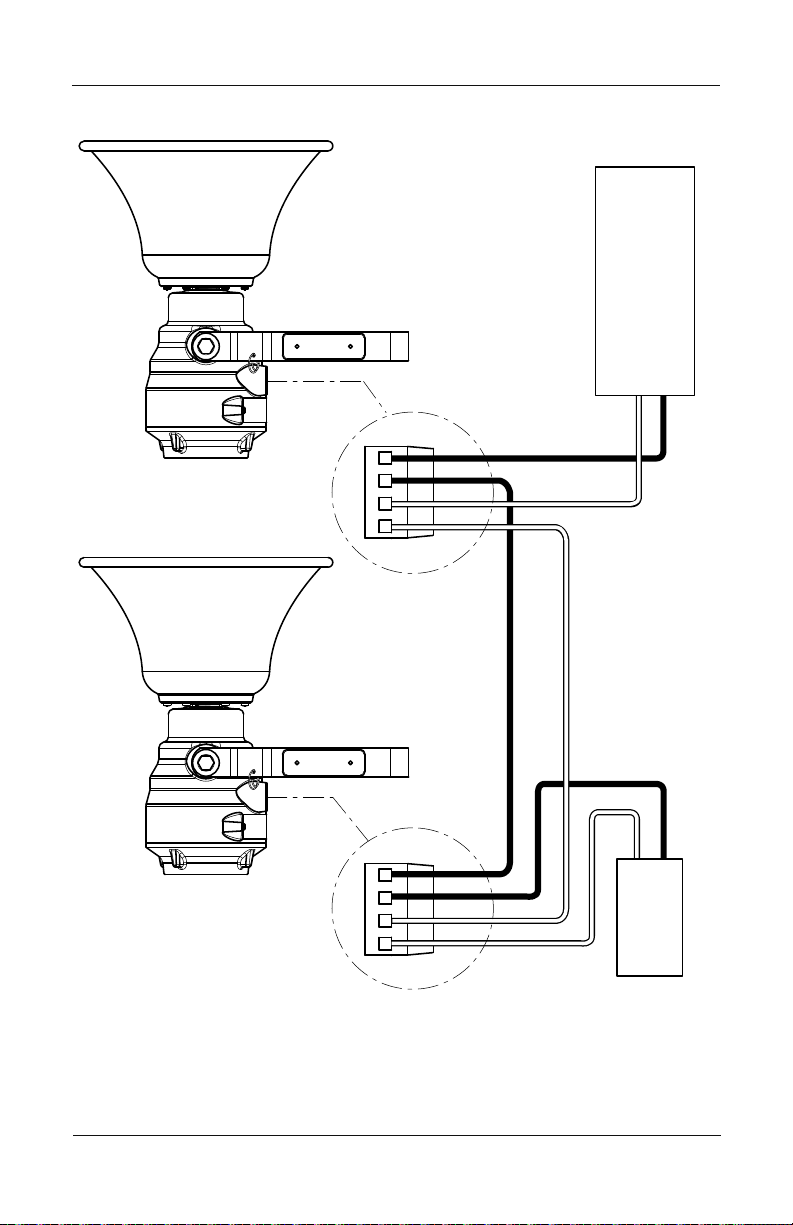

Figure 5 Speakers connected to EOL device

WARNING

WARNING

POR EL PROVEEDOR

DISPOSITIVOS DE FINAL DE

DE LA UNIDAD DE CONTROL

LÍNEA (DFL) RECOMENDADO

–

+

–

N

–

N

L

+

L

+

–

N

–

N

L

+

L

+

–

+

ALIMENTACIÓN

24 VCC

Models 304X and 314X Explosion-Proof Amplied Speakers

15

Page 16

Installation and Maintenance Instructions

290A5203

Figure 6 Speakers with supervision relay and connector card

WARNING

WARNING

RECOMMENDED BY

END OF LINE DEVICE

CONTROL UNIT SUPPLIER

–

N

–

N

L

+

+

L

A77-716-02

RELAY MODEL

FOR 24 VDC USE:

POWER SUPERVISION

OR MODEL R64 BY

BY SYSTEM SENSOR,

–

WHT

WHT

WHT

WHT

PRODUCTS

UNITED SECURITY

+

16

–

+

–

N

–

N

L

+

L

+

CARD (25 OR 70 VMRS

INTERNAL CONNECTOR

(SUPPLIED SEPARATELY)

Models 304X and 314X Explosion-Proof Amplied Speakers

POWER

SPEAKER

WHT

WHT

25 OR 70

VRMS AUDIO

Page 17

Installation and Maintenance Instructions

Safety Message to Operators

TESTING/TRAINING PRECAUTIONS — Even if your warning

system is operating properly, it may not be completely effective.

People may not hear or heed your warning signal. You must

recognize this fact and ensure that your warning signal achieves

its intended effect through proper test/training sequences within

your specic application(s).

Testing and Operating the Speaker

SOUND HAZARD — Under certain conditions these devices are

capable of producing sounds loud enough to cause hearing

damage. Adequate hearing protection should be worn if standing

within close proximity to device while testing. Recommendations

in the OSHA Sound Level Standard (29 CFR 1910) should not be

exceeded.

EXPLOSION HAZARD — Property damage, serious injury, or

death could occur if the housing is not closed properly. To

reduce possibility of explosion, the housing cover must be kept

tight while circuits are energized.

After the installation is completed, be sure to test the system to verify

that each amplied speaker operates satisfactorily. If the speaker is too

loud for the location, adjust the volume as described in these steps:

1.

Remove the housing cover and insert a slotted electrician-type

screwdriver into the volume control shown in Figure 4 on page 12.

2. Gently turn the control counter-clockwise to decrease the sound

output to the desired loudness.

3.

Reinstall the housing cover.

After completion of the initial system test, establish a program for

periodic testing of this device. Refer to NFPA 72G, local Fire Codes

and the authority having jurisdiction for this information.

Models 304X and 314X Explosion-Proof Amplied Speakers

17

Page 18

Installation and Maintenance Instructions

Provide a copy of these instructions for the Safety Engineer, system

operator(s) and maintenance personnel.

Safety Message to Maintenance Personnel

Failure to follow all safety precautions and instructions may result in

property damage, serious injury, or death to you or others.

• Read and understand all instructions before performing

maintenance on this unit.

• Do not perform maintenance on this unit when circuits are

energized.

• Do not disconnect the speaker from the system wiring when

circuits are energized.

• Periodic checks should be made to ensure that effectiveness of this

device has not been reduced because speaker has become clogged

with a foreign substance or because objects have been placed in

front of the speaker.

• Any maintenance to this unit MUST be performed by a trained

electrician in accordance with the National Electrical Code,

National Fire Codes, and the local codes.

• Never alter this unit in any manner. Safety in hazardous locations

may be jeopardized if additional openings or alterations are made

to this device.

• The nameplates, which contain cautionary or other information of

importance to maintenance personnel, should not be obscured if

exterior of device is painted.

• WARNING: Explosion Hazard — Substitution of components

may impair suitability for Class I, Division 2 and Class I,

Zone 2.

Failure to follow all safety precautions and instructions may result in

property damage, serious injury, or death.

18

Models 304X and 314X Explosion-Proof Amplied Speakers

Page 19

Installation and Maintenance Instructions

Maintaining the Speaker

UNAUTHORIZED REPAIR/SERVICING — Unauthorized

repair/servicing of the speaker may result in degradation of

performance and/or property damage, serious injury, or death

to you or others. If a malfunctioning unit is encountered, do not

attempt any eld repair/retrot of parts.

EXPLOSION HAZARD — Property damage, serious injury or

death could occur if this product’s machined sealing surfaces

are damaged. To maintain the effectiveness of the explosionproof enclosure, use caution to avoid damaging the machined

surfaces.

Periodically check this device to verify that there are no foreign

substances in, or in front of, the speaker which will reduce its

effectiveness.

Testing should be periodically performed. Refer to NFPA 72G, local

Fire Codes and the authority having jurisdiction for information.

If a volume adjustment or other repair is needed, be sure to refer to

the “Safety Message For Maintenance Personnel” on page 18 before

proceeding.

Ordering Replacement Parts

Typical spare parts are listed in Tables 4 and 5 on page 20. Due

to certication, certain component parts are not available for eld

replacement. Units with this type of damage must be either replaced

entirely or returned to Federal Signal for service.

To order accessories and replacement parts, call Federal Signal

Customer Support at 708-534-4756 or 877-289-3246

Models 304X and 314X Explosion-Proof Amplied Speakers

19

Page 20

Installation and Maintenance Instructions

Models 304X and 314X Explosion-Proof Amplied Speakers

Table 4 Model 304X replacement parts

Description Part Number

Amplier Assembly K2005355-01

Horn Assembly K8593100

Driver Assembly K8593097

Cover Assembly K8593098

Mounting Bracket Assembly K8593071

4-Position Connector K140340

Table 5 Model 314X replacement parts

Description Part Number

Amplier Assembly K2005355-01

Horn Assembly K8593101

4-Position Connector K140340

Returning the Product for Credit

Product returns for credit require a return authorization from your

local distributor prior to returning the product to Federal Signal.

Please contact your distributor for assistance.

A product is qualied to be returned for credit when the following

conditions are met:

• Product is resalable and in the original cartons

• Product has not been previously installed

• Product is the current revision

• Product has not been previously repaired

• Product is a standard product

• Product is not a service part

All returns are subject to a re-stock fee.

20

Page 21

Installation and Maintenance Instructions

Models 304X and 314X Explosion-Proof Amplied Speakers

Defective products that are returned within the warranty period will

be repaired or replaced at Federal Signal’s sole discretion. Defective

products do not include those products with lamp failure.

Circumstances other than those listed above will be addressed on a

case-by-case basis.

21

Page 22

Industrial Systems

2645 Federal Signal Drive • University Park, IL 60484-3167

Tel: 708-534-4756 • Fax: 708-534-4852

Email: elp@federalsignal.com • www.federalsignal-indust.com

22

Page 23

Modèles SelecTone

MD

304X et 314X

antidéagrant haut-parleurs ampliés

Instructions d’installation

et d’entretien

2562113A

Rev. A1 114

Imprimé aux Etats-Unis

23

Page 24

ans

G

A

E

I

T

R

N

A

Garantie – Tous les produits du vendeur sont couverts par une garantie de cinq ans pour

les pièces et de deux ans et demi pour la main-d’œuvre selon les conditions et exceptions

suivantes : Le vendeur garantit que tous les produits qu’il fabrique seront conformes

aux descriptions correspondant aux spécications qui font expressément partie de ce

contrat de vente et qu’au moment de la vente par le vendeur, de tels produits devront

être exempts de défauts de matériel ou de fabrication. Le vendeur se réserve le droit, à sa

discrétion, de « Réparer et retourner » ou de « Remplacer » tout article jugé défectueux

durant la période de garantie. Cette garantie ne couvre pas les frais de voyage, le coût

de l’équipement spécialisé pour avoir accès au produit ou les frais de main-d’œuvre

liés à l’enlèvement et à la réinstallation du produit. Cette garantie sera inopérante et

ne s’appliquera pas aux produits qui ont subi un mauvais usage, une négligence, un

accident, des dommages ou un entretien inapproprié, ou aux produits modiés ou réparés

par quelqu’un d’autre que le vendeur ou son représentant autorisé, ou si cinq ans se

sont écoulés depuis la date de l’envoi des produits par le vendeur avec les exceptions

suivantes : les lampes et les tubes stroboscopiques ne sont pas couverts par cette garantie.

Les sirènes d’avertissement extérieures et les appareils de contrôle fabriqués par Federal

Warning Systems sont couverts par une garantie deux ans sur les pièces et d’un an sur la

main-d’œuvre. Aucun agent, employé, représentant ou distributeur du vendeur n’a autorité pour lier celui-ci à une représentation, afrmation, ou garantie relative aux produits

et une telle représentation, afrmation, ou garantie ne pourra pas être considérée comme

faisant partie des généralités du contrat de vente et sera inexécutable. LES GARANTIES

CI-DESSUS SONT EXCLUSIVES ET REMPLACENT TOUTES LES AUTRES

GARANTIES DE QUALITÉ MARCHANDE, DE COMPATIBILITÉ À UN USAGE

PARTICULIER OU D’UN AUTRE TYPE, QU’ELLES SOIENT EXPRESSES OU

IMPLICITES. Ces garanties ne s’appliqueront pas si le vendeur ne se voit pas aménager

la possibilité raisonnable d’enquêter sur toutes les réclamations de produits présumés défectueux. À la demande du vendeur, un seul échantillon des produits présumés défectueux

lui sera renvoyé pour inspection et approbation. Le fondement de toutes les réclamations

liées à des défauts présumés dans les produits qui ne peuvent être découverts sans une

inspection raisonnable en vertu du paragraphe 8 des présentes, doit être entièrement

expliqué par écrit et reçu par le vendeur dans les trente jours suivant la découverte du

défaut par l’acheteur. À défaut, une telle réclamation sera considérée comme nulle.

Industrial Systems

2645 Federal Signal Drive • University Park, IL 60484-3167

Téléphone: 708-534-4756 • Fax: 708-534-4852

Email: elp@federalsignal.com • www.federalsignal-indust.com • www.fs-isys.com

24

Page 25

Modèles 304X et 314X antidéagrant haut-parleurs ampliés

Contenu

Messages de sécurité destinés aux installateurs ............................. 27

Présentation des haut-parleurs........................................................... 28

Déballage de le haut-parleur amplié

Fixation du haut-parleur ...................................................................... 31

Installation du module de tonalité UTM Universal ............................ 34

Installation de carte de connecteurs .................................................. 36

Message de sécurité destiné aux opérateurs .................................... 40

Tester et utiliser le haut-parleur .......................................................... 40

Message de sécurité destiné aux personnel d’entretien .................. 41

Maintenir le haut-parleur amplié ....................................................... 42

Commande de pièces de rechange .................................................... 43

Réparation et assistance technique ................................................... 43

Retour du produit et avoir ................................................................... 44

................................................. 29

Tables

Tableau 1 Caractéristiques techniques du modèle 304X ...................... 30

Tableau 2 Caractéristiques techniques du modèle 314X ...................... 30

Tableau 3 Classement d’audibilité UL des AM25CK et AM70CK.......... 31

Tableau 4 Pièces de rechange pour le modèle 304X ........................... 43

Tableau 5 Pièces de rechange pour le modèle 314X ........................... 43

Figures

Illustration 1 Dimensions et les trous de montage ............................... 32

Illustration 2 Dimensions du modèle 304X .......................................... 33

Illustration 3 Dimensions du modèle 314X .......................................... 33

Illustration 4 Haut-parleur amplié avec couvercle retiré..................... 35

Illustration 5 Parleurs connectés à un dispositif de n de ligne ........... 38

Illustration 6 Connexions à relais et la carte de deconnecteurs .......... 39

25

Page 26

© 2013 Federal Signal Corporation. Tous droits réservés.

Page 27

IInstructions d’installation et d’entretien

AVERTISSEMENT

Messages de sécurité destinés aux installateurs

L’installation sécurisée de nos produits permet d’éviter de mettre

en danger des vies humaines. Il est important de respecter toutes les

consignes jointes à ce produit au moment de l’expédition. Cet appareil

doit être installé par un électricien qualié qui maîtrise parfaitement

le Code national d’électricité et/ou le Code d’électricité canadien et

qui respectera les directives CNE et/ou CCE ainsi que tous les codes

locaux. Ce haut-parleur amplié doit être considéré comme une partie

du système d’avertissement et non comme l’intégralité de celui-ci.

Le choix du lieu de montage de cet avertisseur sonore, de ses

commandes et du passage des câbles doit être effectué sous la

direction de l’ingénieur responsable des installations et de l’ingénieur

responsable de la sécurité. Voici par ailleurs une liste complémentaire

d’instructions et de précautions de sécurité importantes à respecter :

• Lire et comprendre toutes les instructions avant d’installer,

d’utiliser ou d’assurer la maintenance de cet appareil.

•

Avertissement : -- Risque d’explosion ‒ Ne débrancher le haut-

parleur amplié que si le circuit est hors tension, ou qu’il n’y a

pas de concentrations de produits inammables dans la zone.

• Ne pas connecter ce dispositif au système lorsque ce dernier est

sous tension.

• Pour une diffusion optimale du son, veiller à installer l’appareil à

un endroit où la trajectoire du son ne rencontre aucun obstacle.

• Tous les haut-parleurs d’avertissement efcaces produisent

des sons puissants qui, dans certains cas, peuvent entraîner une

perte auditive irréversible. Prendre les précautions appropriées,

comme l’utilisation d’une protection acoustique. Respecter les

recommandations de la norme OSHA sur le niveau sonore (29

CFR 1910).

• Après l’installation, s’assurer que tous les boulons et joints letés

sont bien serrés.

Modèles 304X et 314X antidéagrant haut-parleurs ampliés

27

Page 28

Instructions d’installation et d’entretien

• Dénir une procédure de vérication régulière de l’activation et

du bon fonctionnement du système de signalisation.

• Tout entretien de cet appareil DOIT être effectué par un électricien

formé conformément aux directives du CNE, ainsi qu’aux codes

locaux.

• Ne jamais modier cet appareil de quelque façon que ce soit.

• La plaque signalétique, qui comprend des informations de

mise en garde et/ou d’autres informations importantes pour le

personnel de maintenance, ne doit PAS être masquée. .

• Après l’installation et la réalisation du test initial du système,

un programme de tests périodiques de l’appareil doit être établi.

Se reporter au guide NFPA 72G, aux codes de prévention des

incendies locaux et à l’autorité compétente concernant ces

informations.

• Fournir une copie de ce manuel d’instructions à l’ingénieur

responsable de la sécurité, à l’(aux) opérateur(s) et au personnel

d’entretien.

• Conserver ces instructions dans un endroit sûr et s’y reporter

pour l’entretien et/ou la réinstallation du dispositif.

Le non-respect de l’ensemble des mesures et consignes de sécurité

peut entraîner des dommages matériels, ou des blessures graves voire

mortelles.

Présentation des haut-parleurs

Les modèles 304X et 314X de haut-parleurs ampliés antidéagrants

de Federal Signal sont conçus pour produire des tonalités claires dans

les systèmes supervisés de notication d’alarmes. Les deux modèles

sont compatibles avec les panneaux de contrôle supervisés d’alarme

incendie, d’instructions vocales d’évacuation et de suppression, ainsi

qu’avec les amplicateurs de puissance.

Ces haut-parleurs ampliés permettent de diffuser des tonalités

générées par une carte de tonalité installée dans le haut-parleur

Modèles 304X et 314X antidéagrant haut-parleurs ampliés

28

Page 29

IInstructions d’installation et d’entretien

(le module enchable 32 tonalités UTM) ou par une source de tonalité

centrale dans un système d’instructions vocales d’évacuation ou de

téléavertissement. S’il est nécessaire de s’adresser directement au

public ou de diffuser des messages vocaux, les cartes de connecteurs

enchables (AM25CK ou AM70CK) s’interfacent avec la valeur

efcace de la tension du panneau EVAC.

Le cône diffuseur et le cornet du projecteur sont en aluminium

repoussé robuste. Le circuit de l’amplicateur à semi-conducteurs est

protégé par un boîtier en aluminium coulé sous pression. Des joints

d’étanchéité à la poussière et à l’humidité protègent des éléments.

Toutes les surfaces externes sont étanchéiées avec de la peinture

grise en poudre. Un support de xation pivotant robuste permet à

l’installateur d’orienter efcacement la sortie.

La conception renforcée et la sortie puissante des modèles 304X et

314X en font un appareil idéal dans les environnements difciles où

le niveau sonore ambiant est élevé. Les deux modèles permettent un

contrôle du gain interne an de régler l’appareil en fonction de la

zone.

Cet appareil convient pour une utilisation de classe I, division 1,

groupes B, C, D ; classe I, division 2, groupes A, B, C, D, ou dans les

zones non dangereuses uniquement.

Déballage de le haut-parleur amplié

Après avoir déballé le haut-parleur amplié, soigneusement vérier

s’il a été endommagé lors du transport. S’il a été endommagé, ne pas

tenter de l’installer ou de le faire fonctionner. Déposer immédiatement

une réclamation auprès du transporteur, déclarant l’étendue des

dommages. Examiner soigneusement toutes les enveloppes, étiquettes

d’expédition et autres étiquettes avant de les retirer ou de les détruire.

La mise au rebut de tout matériel d’expédition doit être effectuée

conformément aux normes et codes locaux et nationaux. S’il manque

des pièces, appeler l’assistance clientèle de Federal Signal au

708 534 4756 ou au 877 289 3246.

Modèles 304X et 314X antidéagrant haut-parleurs ampliés

29

Page 30

Instructions d’installation et d’entretien

Tableau 1 Caractéristiques techniques du modèle 304X

Tension de

fonctionnement :

Intensité : 0,83 A max.

Courant de veille : 0,13 A

Température de

fonctionnement :

Poids net : 7,0 kg (15,4 livres)

Poids à l’expédition : 10,4 kg (22,8 livres)

Dimensions : 414 mm (16,3 pouces) de long x 432 mm

Tableau 2 Caractéristiques techniques du modèle 314X

Tension de

fonctionnement :

Intensité : 0,90 A max.

Courant de veille : 0,13 A

Température de

fonctionnement :

Poids net : 7,4 kg (16,4 livres)

Poids à l’expédition : 14,7 kg (32,41 livres)

Dimensions : 496 mm (19,5 pouces) de long x 478 mm

Indice de protection : IP65 et NEMA 4X approuvé

24 V c.c. régulée (de 16 V c.c. à 33 V c.c.)

-40 ºC à 66 ºC

(17,0 pouces) de haut x 333 mm

(13,1 pouces) de diamètre.

24 V c.c. régulée (de 16 V c.c. à 33 V c.c.)

-40 ºC à 66 ºC

(18,8 pouces) de haut x 425 mm

(16,7 pouces) de diamètre.

Modules de tonalité compatibles : TM2 ou UTM

Cartes compatibles de connecteurs pour haut-parleurs : AM25CK*,

AM70CK*, ou 300CKS

* - les versions de la série A de ces cartes de connecteurs ne sont pas

compatibles

Modèles 304X et 314X antidéagrant haut-parleurs ampliés

30

Page 31

IInstructions d’installation et d’entretien

Tableau 3 Classement d’audibilité UL des AM25CK et AM70CK

Classement :

Haut-parleur :

Classement

d’audibilité* :

AM25CK : 101 99

AM70CK : 101 99

*

- Basée sur TM6, HORN (klaxon)

Pression acoustique en dB (A)

conformément au classement UL1480

304X 314X

91 97

Fixation du haut-parleur

Le haut-parleur peut être xé sur toute surface relativement plane

capable de supporter son poids. Les conduits de câbles peuvent être

raccordés aux ouvertures taraudées NPT de 1/2 po à la base du boîtier

(voir illustration 4, page 35).

Pour xer le haut-parleur :

Retirer les deux boulons à tête hexagonale de 1/2"-13, les

1.

rondelles plates et les rondelles de blocage qui xent le support

à l’unité.

Débrancher le cordon du support de xation au niveau de l’anneau

2.

à goupille.

AVERTISSEMENT

PRÉCAUTION DE FIXATION — Des dommages matériels

et des blessures graves voire mortelles peuvent être

occasionnés par l’accumulation d’eau, de neige, de

poussière etc. à l’intérieur du cornet du haut-parleur, ce

qui risque de sérieusement compromettre, voire empêcher,

l’utilisation de l’appareil. Fixer le dispositif de sorte que le

cornet du haut-parleur soit à l’horizontale ou légèrement

orienté vers le bas.

3. Choisir l’emplacement du montage.

Modèles 304X et 314X antidéagrant haut-parleurs ampliés

31

Page 32

Instructions d’installation et d’entretien

127 mm (5,0 pouce)

AVERTISSEMENT

PRÉCAUTION DE FIXATION — Des dommages matériels

et des blessures graves voire mortelles peuvent être

occasionnés par la présence d’objets devant le haut-parleur,

ce qui risque sérieusement de compromettre une diffusion

optimale du son. Pour une efcacité maximale, s’assurer de

l’absence d’obstacles devant le haut-parleur.

4. Voir illustration 1. À l’aide du support de xation en guise de

gabarit, marquer la position des trous à percer sur la surface de

montage.

Illustration 1 Dimensions et les trous de montage

76 mm

(3,0 pouce)

+

13,5 mm

(0,53 pouce)

290A7676

32

PRÉCAUTION DE FORAGE — Avant de percer des trous

sur toute surface, s’assurer que les deux côtés de la

surface sont dégagés et de l’absence d’objet pouvant être

endommagé.

Modèles 304X et 314X antidéagrant haut-parleurs ampliés

Page 33

Illustration 2 Dimensions du modèle 304X

290A7677

8,9 pouce

18,8 pouce

46mm (1,8pouce)

POUR RETIRER

LE COUVERCLE

IInstructions d’installation et d’entretien

333 mm

13,1

WARNING

414 mm (16.3 pouce)

226 mm

(8,9 pouce)

432 mm

17,0 pouce

Illustration 3 Dimensions du modèle 314X

46 mm (1,8 pouce)

POUR RETIRER

LE COUVERCLE

478 mm

425 mm

WARNING

496 mm (19,5")

226 mm

(16,7 pouce)

290A7678

5. Percer des trous aux emplacements marqués précédemment. Ils

doivent pouvoir accueillir des boulons de ½ pouce de diamètre.

6. Fixer le support à la surface de montage avec des boulons à tête

hexagonale de 1/2 pouce de diamètre, des rondelles de blocage

et des écrous hexagonaux.

Rexer le haut-parleur sur son support avec les deux boulons à

7.

tête hexagonale de 1/2"-13, les rondelles plates et les rondelles

de blocage retirés auparavant.

Modèles 304X et 314X antidéagrant haut-parleurs ampliés

33

Page 34

Instructions d’installation et d’entretien

AVERTISSEMENT

AVERTISSEMENT

8. Placer le haut-parleur de façon à obtenir la couverture sonore

voulue, puis serrer fermement ces boulons.

Rexer le cordon sur l’anneau à goupille et le support de xation.

9.

Vérier qu’il est bien xé à la fois au couvercle et au support de

xation.

Passer les ls par les ouvertures taraudées NPT 1/2 po dans

10.

l’unité SelecTone conformément aux codes électriques et de

prévention des incendies nationaux et locaux. La section du

l dépend du courant de fonctionnement et de la distance par

rapport à la source d’alimentation.

Voir les sections suivantes pour obtenir des instructions pour

l’installation de la carte connecteur haut-parleur et le module de

l’UTM et câblage de l’orateur.

Installation du module de tonalité UTM Universal

CÂBLAGE INCORRECT/SURVEILLANCE ÉLECTRIQUE — Il

existe un risque de dommages matériels et de blessures

graves voire mortelles si des conducteurs indépendants ont

les mêmes terminaisons ; les ls de même polarité doivent

être utilisés comme deux branchements distincts. Le guide

NFPA 72 impose que les ls aient une terminaison indépendante

an de permettre la surveillance électrique de la connexion

d’alimentation et des lignes audio.

RISQUE D’ÉLECTROCUTION — An d’éviter les chocs

électriques, ne pas brancher de ls tant que les circuits sont sous

tension. Le non-respect de cet avertissement peut entraîner des

blessures graves ou la mort.

Pour plus de détails, reportez-vous aux instructions pour le modèle

UTM universal module de sons, doc. N ° 2561101.

Modèles 304X et 314X antidéagrant haut-parleurs ampliés

34

Page 35

IInstructions d’installation et d’entretien

DÉTAIL DU CONNECTEUR

D'ALIMENTATION

ENTRÉES DE

CONDUIT 1/2" NPT

MISE À LA TERRE

CONNECTEUR

D'ALIMENTATION

DISPOSITIF DE RETENUE

DE CARTE DE TONALITÉ/

DE CONNECTEURS

PRISE DE CARTE DE TONALITÉ

OU CARTE DE CONNECTEURS

CONTRÔLE

DU VOLUME

L

(+)

L

(+)N(-)N(-)

Pour installer le module UTM dans le haut-parleur :

AVERTISSEMENT

RISQUE D’EXPLOSION — Des dommages matériels et des

blessures graves voire mortelles peuvent survenir si les

surfaces d’étanchéité usinées sont endommagées sur ce

produit. Pour conserver l’efcacité du coffret antidéagrant,

veiller à ne pas endommager les surfaces d’étanchéité usinées

du couvercle et du boîtier.

1. Dévisser le couvercle leté dans le sens inverse des aiguilles d’une

montre et le retirer. Laisser pendre le couvercle par le cordon.

2.

Insérer la carte de tonalité (achetée séparément) dans la prise

comme indiqué dans l’illustration 4.

3. Pivoter le dispositif de retenue de sorte à maintenir la carte en place.

Illustration 4 Haut-parleur amplié avec couvercle retiré

Modèles 304X et 314X antidéagrant haut-parleurs ampliés

35

Page 36

Instructions d’installation et d’entretien

4. Voir l’illustration 5, page 38 et l’illustration 6, page 39. Raccorder

le l positif (+) de la source d’alimentation à la borne “L+.”

Raccorder le l négatif (–) de la source d’alimentation à la borne

5.

“N –.”

Raccorder les bornes (L+) et (N–) supplémentaires à l’unité

6.

suivante ou à un dispositif de n de ligne (DFL).

AVERTISSEMENT

RISQUE D’EXPLOSION — Des dommages matériels et des

blessures graves voire mortelles peuvent survenir si le

boîtier n’est pas correctement fermé. Pour limiter le risque

d’explosion, le couvercle du boîtier doit rester parfaitement

fermé lorsque les circuits sont mis sous tension.

7. Réinstaller soigneusement le couvercle du boîtier et serrer

jusqu’à ce que la bride du couvercle entre en contact avec le

boîtier.

Serrer la vis sans tête sur le couvercle pour le sécuriser. Vérier

8.

que les boulons de xation ont été serrés fermement.

Installation de carte de connecteurs

Pour plus de détails, reportez-vous aux instructions de la SelecTone

AM25CK et AM70CK cartes connecteur, doc. N ° 2561183.

AVERTISSEMENT

CÂBLAGE INCORRECT/SURVEILLANCE ÉLECTRIQUE — Il

existe un risque de dommages matériels et de blessures

graves voire mortelles si des conducteurs indépendants ont

les mêmes terminaisons ; les ls de même polarité doivent

être utilisés comme deux branchements distincts. Le guide

NFPA 72 impose que les ls aient une terminaison indépendante

an de permettre la surveillance électrique de la connexion

d’alimentation et des lignes audio.

Modèles 304X et 314X antidéagrant haut-parleurs ampliés

36

Page 37

IInstructions d’installation et d’entretien

AVERTISSEMENT

RISQUE D’ÉLECTROCUTION — An d’éviter les chocs

électriques, ne pas brancher de ls tant que les circuits sont sous

tension. Le non-respect de cet avertissement peut entraîner des

blessures graves ou la mort.

Pour installer la carte de connecteurs :

Insérer la carte de connecteurs (achetée séparément) dans la prise

1.

comme indiqué dans l’illustration 4, page 35.

Pivoter le dispositif de retenue de sorte à maintenir la carte en

2.

place (illustration 4).

Voir l’illustration 5, page 38 ou l’illustration 6, page 39. Raccorder

3.

le l positif (+) de la source d’alimentation à la borne “L+.”

Raccorder le l négatif (–) de la source d’alimentation à la borne

4.

“N –.”

Raccorder les bornes (L+) et (N –) supplémentaires à l’unité

5.

suivante ou à un relais de surveillance de l’alimentation.

Connecter une paire de ls blancs de la carte de connecteurs à la

6.

sortie audio du panneau d’alarme incendie.

Connecter l’autre paire de ls blancs à la carte de connecteurs

7.

de l’unité suivante ou à un contact du relais de surveillance de

l’alimentation et à un appareil de n de ligne.

NOTE: Vérier auprès de l’autorité compétente que la résistance

de n de ligne et le relais de surveillance de l’alimentation requis

sont correctement utilisés (voir illustration 6, page 39).

AVERTISSEMENT

RISQUE D’EXPLOSION — Des dommages matériels et des

blessures graves voire mortelles peuvent survenir si le

boîtier n’est pas correctement fermé. Pour limiter le risque

d’explosion, le couvercle du boîtier doit rester parfaitement

fermé lorsque les circuits sont mis sous tension.

Modèles 304X et 314X antidéagrant haut-parleurs ampliés

37

Page 38

Instructions d’installation et d’entretien

290A7680

8. Réinstaller soigneusement le couvercle du boîtier et serrer

jusqu’à ce que la bride du couvercle entre en contact avec le

boîtier.

Serrer la vis sans tête sur le couvercle pour le sécuriser. Vérier

9.

que les boulons de xation ont été serrés fermement.

Illustration 5 Parleurs connectés à un dispositif de n de ligne

WARNING

–

N

–

N

L

+

L

+

FOURNISSEUR DE

APPAREIL DE FIN DE LIGNE

(DFL) RECOMMANDÉ PAR LE

–

+

L'UNITÉ DE CONTRÔLE

38

WARNING

–

N

–

N

L

+

L

+

Modèles 304X et 314X antidéagrant haut-parleurs ampliés

+

–

24 V c.c.

ALIMENTATION

Page 39

IInstructions d’installation et d’entretien

290A7681

Illustration 6 Connexions à relais et la carte de deconnecteurs

POUR 24 V c.c :

SUPERVISION DE

PUISSANCE RELAIS

BLANC

BLANC

BLANC

BLANC

MODÈLE A77-716-02

FOURNISSEUR DE

L'UNITÉ DE CONTRÔLE

APPAREIL DE FIN DE LIGNE

(DFL) RECOMMANDÉ PAR LE

WARNING

–

N

–

N

L

+

+

L

WARNING

PRODUCTS

UNITED SECURITY

OU MODÈLE R64 DE

DE SYSTEM SENSOR,

+

–

–

CONNECTEURS

CARTE INTERNE DE

FOURNI SÉPARÉMENT

(VMRS 25 OU 70 VMRS)

+

–

N

–

N

L

+

L

+

ALIMENTATION

POUR HAUT-

BLANC

PARLEUR

BLANC

AUDIO

25 OU 70 VRMS

Modèles 304X et 314X antidéagrant haut-parleurs ampliés

39

Page 40

Instructions d’installation et d’entretien

Message de sécurité destiné aux opérateurs

AVERTISSEMENT

PRÉCAUTIONS D’ESSAI / FORMATION — Même si votre système

de signalisation fonctionne correctement, son efcacité n’est

peut-être pas optimale. Les personnes concernées peuvent ne

pas entendre ou prêter attention à votre signal d’avertissement.

Vous devez en tenir compte et vous assurer que votre signal

d’avertissement produise l’effet escompté par le biais de

tests/sessions de formation appropriés dans le cadre de vos

applications spéciques.

Tester et utiliser le haut-parleur

AVERTISSEMENT

RISQUE DE BRUIT FORT — Tous les haut-parleurs

d’avertissement efcaces produisent des sons puissants

qui, dans certains cas, peuvent entraîner une perte auditive

irréversible. Prendre les précautions appropriées, comme

l’utilisation d’une protection acoustique. Respecter les

recommandations de la norme OSHA sur le niveau sonore

(29 CFR 1910).

AVERTISSEMENT

RISQUE D’EXPLOSION — Des dommages matériels et des

blessures graves voire mortelles peuvent survenir si le boîtier

n’est pas correctement fermé. Pour limiter le risque d’explosion,

le couvercle du boîtier doit rester parfaitement fermé lorsque les

circuits sont mis sous tension

Une fois l’installation terminée, tester le système pour vérier que

chaque haut-parleur amplié fonctionne correctement. Si l’unité

est trop bruyante pour son emplacement, de régler le volume en

procédant comme suit :

1. Retirer le couvercle du boîtier et insérer un tournevis plat de

type électricien dans la commande de volume présentée dans

l’illustration 4, page 35.

Modèles 304X et 314X antidéagrant haut-parleurs ampliés

40

Page 41

IInstructions d’installation et d’entretien

AVERTISSEMENT

2. Tourner doucement la commande dans le sens inverse des

aiguilles d’une montre pour baisser la sortie du son à la puissance

souhaitée.

Remettre le couvercle du boîtier en place.

3.

Après la réalisation du test initial du système, dénir un programme

de tests périodiques de l’appareil. Se reporter au guide NFPA 72G, aux

codes de prévention des incendies locaux et à l’autorité compétente

concernant ces informations

Fournir une copie de ce manuel d’instructions à l’ingénieur

responsable de la sécurité, aux opérateurs du système et au personnel

de maintenance.

Message de sécurité destiné aux personnel

d’entretien

Le non-respect de l’ensemble des mesures et consignes de sécurité

peut entraîner des dommages matériels, ou des blessures graves voire

mortelles des personnes concernées ou d’autres personnes.

• Lire et comprendre toutes les instructions avant de procéder à une

opération de maintenance sur cet appareil.

• Ne pas effectuer d’opération de maintenance sur cet appareil

lorsque les circuits sont sous tension.

• Ne pas débrancher le haut-parleur du câblage du système lorsque

les circuits sont sous tension.

• Des contrôles périodiques doivent être effectués pour vérier que

l’appareil n’a pas perdu de son efcacité du fait d’une obstruction

du haut-parleur par des substances étrangères ou de la présence

d’objets placés devant le haut-parleur.

• Toute opération de maintenance menée sur cet appareil DOIT être

réalisée par un électricien qualié conformément à tous les codes

d’électricité et de prévention des incendies locaux et nationaux.

Modèles 304X et 314X antidéagrant haut-parleurs ampliés

41

Page 42

Instructions d’installation et d’entretien

AVERTISSEMENT

AVERTISSEMENT

• Ne jamais modier cette unité d’aucune façon. La sécurité dans les

zones dangereuses peut être compromise si d’autres ouvertures sont

ajoutées ou si d’autres modications sont apportées à cet appareil.

• Si l’extérieur de l’appareil est peint, veiller à ne pas recouvrir les

plaques signalétiques qui comportent des avertissements et autres

renseignements importants pour le personnel de maintenance.

• Avertissement -- Risque d’explosion—la substitution de

composants pourrait réduire la compatibilité avec la classe 1,

division 2 et classe 1, zone 2.

Le non-respect de toutes les précautions et instructions de sécurité

peut provoquer des dommages à la propriété, des blessures graves

voire la mort.

Maintenir le haut-parleur amplié

RÉPARATION/DÉPANNAGE NON AUTORISÉS — Une réparation

ou un dépannage non autorisés du haut-parleur pourraient altérer

les performances et/ou entraîner des dommages matériels ou des

blessures graves voire mortelles. En cas de dysfonctionnement

du haut-parleur, ne pas tenter de réparer sur place ou d’adapter

des pièces.

RISQUE D’EXPLOSION — Des dommages matériels et des

blessures graves voire mortelles peuvent survenir si les

surfaces d’étanchéité usinées sont endommagées sur ce

produit. Pour conserver l’efcacité du coffret antidéagrant,

veiller à ne pas endommager les surfaces d’étanchéité usinées

du couvercle et du boîtier.

Effectuer des contrôles périodiques pour vérier l’absence de

substances étrangères à l’intérieur ou devant le haut-parleur qui

pourraient réduire son efcacité.

Des tests doivent être réalisés de manière périodique. Consulter le

guide NFPA 72G, les codes locaux de prévention des incendies et

l’autorité compétente pour plus d’informations.

Modèles 304X et 314X antidéagrant haut-parleurs ampliés

42

Page 43

IInstructions d’installation et d’entretien

Modèles 304X et 314X antidéagrant haut-parleurs ampliés

Si un réglage du volume ou toute autre réparation est nécessaire, se

référer au “Message de sécurité destiné au personnel d’entretien”

(page 41) avant de continuer.

Commande de pièces de rechange

Les pièces de rechange courantes sont énumérées au tableaux 4 et 5.

Pour des raisons de certication, les pièces de certains composants

ne peuvent pas être remplacées sur place. Dans ce cas, l’appareil au

complet doit être remplacé ou renvoyé à Federal Signal pour y être

réparé. Pour commander des accessoires ou des pièces manquantes,

communiquer avec le Service à la clientèle de Federal Signal au

708 534 4756 ou au 877 289 3246.

Tableau 4 Pièces de rechange pour le modèle 304X

Description Référence

Ensemble amplicateur K2005355-01

Ensemble avertisseur sonore K8593100

Ensemble moteur K8593097

Ensemble couvercle K8593098

Ensemble support de xation K8593071

Connecteur 4 positions K140340

Tableau 5 Pièces de rechange pour le modèle 314X

Description Référence

Ensemble amplicateur K2005355-01

Ensemble avertisseur sonore K8593101

Connecteur 4 positions K140340

Réparation et assistance technique

Les produits retournés pour réparation doivent être accompagnés

d’un formulaire d’autorisation de retour, disponible auprès de

votre distributeur local ou de Federal Signal. Pour toute demande

de réparation ou d’assistance technique à Federal Signal, appelez

le 708 534 4756 ou le 877 289 3246. Pour accéder aux manuels

d’instructions et informations supplémentaires sur les produits

43

Page 44

Instructions d’installation et d’entretien

Modèles 304X et 314X antidéagrant haut-parleurs ampliés

connexes, consulter la page à l’adresse suivante :

http://www.federalsignal-indust.com

Retour du produit et avoir

Avant de retourner un produit à Federal Signal en vue d’obtenir un

avoir, vous devez obtenir une autorisation de retour auprès de votre

distributeur local. Veuillez contacter votre distributeur pour obtenir de

l’aide.

Un produit peut être renvoyé en vue d’obtenir un avoir s’il remplit les

conditions suivantes :

• Le produit peut être revendu et est restitué dans son emballage

d’origine.

• Le produit n’a pas encore été installé.

• Le produit est le modèle le plus récent.

• Le produit n’a jamais été réparé.

• Le produit est un produit normalisé.

• Le produit n’est pas une pièce détachée.

Tous les renvois de produits font l’objet de frais de restockage.

Les produits défectueux retournés au cours de la période de garantie

seront réparés ou remplacés à la discrétion de Federal Signal. Les

produits dont la lampe est défectueuse ne sont pas considérés comme

des produits défectueux.

Les cas autres que ceux cités ci-dessus seront examinés au cas par cas.

Industrial Systems

2645 Federal Signal Drive • University Park, IL 60484-3167

Téléphone: 708-534-4756 • Fax: 708-534-4852

Email: elp@federalsignal.com • www.federalsignal-indust.com • www.fs-isys.com

44

Page 45

Altavoces amplicados a prueba

de explosiones SelecToneMR

Modelos 304X y 314X

Instrucciones de instalación

2562113

Rev. A0 114

Impreso en los EE. UU.

y mantenimiento

45

Page 46

años

G

A

R

Garantía: El vendedor garantiza todos los productos por cinco años para las piezas

y por 2-1/2 años para la mano de obra, con las siguientes condiciones y excepciones:

El Vendedor garantiza que todos los productos fabricados por el Vendedor se

ajustarán a las descripciones de los mismos para especicaciones que expresamente

forman parte de este contrato de venta y en el momento de la venta por parte del

Vendedor tales productos estarán comercialmente libres de defectos en material

o mano de obra. El Vendedor se reserva el derecho, a criterio del Vendedor, de

“Reparar y devolver” o de “Reemplazar” cualquier elemento considerado defectuoso

durante el período de garantía. Esta garantía no cubre gastos de viaje, el costo de

equipos especializados para obtener acceso al producto ni los cargos de mano de

obra por la extracción y la nueva instalación del producto. Esta garantía no tendrá

validez y no será de aplicación a productos que hayan sido sometidos a uso incorrecto, descuido, accidente, daño, mantenimiento incorrecto o productos alterados

o reparados por otra persona que no sea el Vendedor o su representante autorizado,

o si han transcurrido cinco años desde la fecha de envío del producto por parte del

Vendedor, con las excepciones siguientes: las lámparas y los tubos estroboscópicos

no están cubiertos por esta garantía. Las sirenas de advertencia y los controladores

externos fabricados por Federal Warning Systems cuentan con garantía de dos años

sobre las piezas y de un año sobre la mano de obra. Ningún agente, empleado,

representante o distribuidor del Vendedor tiene autorización de obligar al Vendedor

frente a ninguna declaración, armación o garantía relacionada con los productos

y tal declaración, armación o garantía no se considerará parte de los elementos

básicos del contrato de venta y no será exigible. LAS GARANTÍAS ANTERIORES

SON EXCLUSIVAS Y REEMPLAZAN TODA OTRA GARANTÍA DE COMERCIABILIDAD, DE IDONEIDAD PARA UN PROPÓSITO Y DE CUALQUIER

TIPO, YA SEA EXPRESA O IMPLÍCITA. Estas garantías no serán de aplicación

a menos que el Vendedor reciba una oportunidad razonable de investigar todos

los reclamos por mercaderías supuestamente defectuosas. Ante la indicación del Vendedor, se devolverá una sola muestra de los productos defectuosos al Vendedor para

su inspección y aprobación. La base de todos los reclamos por supuestos defectos

en los productos que no se descubra ante la inspección razonable de los mismos en

virtud del párrafo 8 del presente debe explicarse totalmente por escrito y debe ser

recibida por el Vendedor dentro de los treinta días posteriores a que el Comprador

tome conocimiento del defecto o tal reclamo se considerará caducado.

A

I

T

A

N

Industrial Systems

2645 Federal Signal Drive • University Park, IL 60484-3167

Teléfono: 708-534-4756 • Fax: 708-534-4852

Email: elp@federalsignal.com • www.federalsignal-indust.com • www.isys.com

46

Page 47

SelecTone

MR

Modelos 304X y 314X

Contents

Mensaje de seguridad para los instaladores los usuarios ............... 49

Descripción de los altavoces

Desembalaje del altavoz

Montaje del altavoz............................................................................... 53

Instalación del módulo de tono universal UTM

Instalación de la tarjeta de conexión del altavoz

Mensaje de seguridad a los operadores

Probando y operar el altavoz

Mensaje de seguridad para el personal mantenimiento

Mantener el altavoz

Pedido de piezas de repuesto

Servicio de reparación o asistencia técnica

Devolución del producto para obtener crédito

.............................................................................. 64

.............................................................. 51

...................................................................... 51

................................. 56

.............................. 58

............................................ 62

.............................................................. 62

................... 63

............................................................. 65

.................................... 65

.................................. 66

Tables

Tabla 1 Especicaciones del modelo 304X ........................................... 52

Tabla 2 Especicaciones del modelo 314X ........................................... 52

Tabla 3 Clasicaciones UL audibilidad del AM25CK y AM70CK .......... 53

Tabla 4 Piezas de repuesto del modelo 304X ....................................... 65

Tabla 5 Piezas de repuesto del modelo 304X ....................................... 65

Figures

Figura 1 Ubicaciones y las dimensiones de los oricios de xation ..... 54

Figura 2 Dimensiones del Modelo 304 ................................................. 55

Figura 3 Dimensiones del Modelo 304X y 314X................................... 55

Figura 4 Altavoz sin la cubierta ............................................................. 57

Figura 5 Altavoces conectados a un dispositivo de nal de línea ........60

Figura 6 Altavoces con relé de supervisión y la tarjeta de conecto ...... 61

47

Page 48

© 2013 Federal Signal Corporation. Todos los derechos reservados.

Page 49

Instrucciones de instalación y mantenimiento

ADVERTENCIA

Mensaje de seguridad para los instaladores

y los usuarios

Las vidas de las personas dependen de su instalación segura de

nuestros productos. Es importante seguir todas las instrucciones

enviadas con este producto. Este dispositivo debe ser instalado por

un técnico electricista que conozca en detalle el Código Eléctrico

Nacional (NEC, por su sigla en inglés) o el Código Eléctrico

Canadiense (CEC, por su sigla en inglés) y que siga los lineamientos

del NEC o del CEC y todos los códigos locales. Este altavoz

amplicado debe considerarse parte del sistema de advertencia y no el

sistema de advertencia completo.

La selección del lugar de montaje del altavoz, sus controles y la

colocación del cableado deben realizarse bajo la dirección del

ingeniero de la planta y del ingeniero de seguridad. Asimismo,

a continuación se incluyen algunas instrucciones y precauciones

importantes de seguridad que debe seguir:

• Lea y comprenda todas las instrucciones antes de instalar, poner

en funcionamiento o mantener este equipo.

•

Advertencia de peligro de explosión — No desconecte el

equipo, excepto que se haya desconectado la alimentación

eléctrica o que sepa el área no representa ningún riesgo.

• No conecte esta unidad al sistema cuando esté encendido.

• La distribución óptima del sonido se verá seriamente reducida si

hay objetos delante del altavoz. Debe asegurarse de que el frente

de altavoz esté libre de obstrucciones.

• Todas los altavoces de advertencia efectiva producen sonidos

fuertes que pueden ocasionar, en ciertas situaciones, la pérdida

permanente de la audición. El dispositivo debe ser instalado

a una distancia suciente de las personas que potencialmente

puedan escucharlo para limitar su exposición y al mismo tiempo

mantener su efectividad. La Norma sobre Ruidos del Código

SelecTone

Modelos 304X y 314X

MR

49

Page 50

Instrucciones de instalación y mantenimiento

de Reglamentaciones Federales 1910.95 de la Administración

de Seguridad y Salud Ocupacional proporciona lineamientos

que pueden usarse con respecto a los niveles permitidos de

exposición al ruido.

• Después de la instalación, asegúrese de que todos los pernos y de

que todas las uniones roscadas estén rmes.

• Establezca un procedimiento para vericar periódicamente el

sistema de señalización a n de comprobar la activación y el

funcionamiento apropiados.

• Todo mantenimiento de la unidad DEBE ser realizado por un

electricista capacitado de acuerdo con los lineamientos NEC y con

los códigos locales.

• No altere nunca la unidad de ninguna forma.

• La placa de identicación NO debe quedar oculta, ya que

contiene precauciones u otra información de importancia para el

personal de mantenimiento.

• Después de la instalación y la nalización de la prueba inicial

del sistema, debe establecerse un programa para realizar pruebas

periódicas de este dispositivo. Consulte NFPA 72G, los códigos

locales de protección contra incendios y a la autoridad con

jurisdicción para obtener esta información.

• Entregue una copia de estas instrucciones al ingeniero de

seguridad, al (los) operador(es) y al personal de mantenimiento.

• Conserve estas instrucciones en un lugar seguro y consúltelas al

realizar tareas de mantenimiento o volver a instalar el dispositivo.

Si no se siguen todas estas precauciones e instrucciones de seguridad,

pueden producirse daños materiales, lesiones graves o incluso la

muerte.

50

SelecTone

MR

Modelos 304X y 314X

Page 51

Instrucciones de instalación y mantenimiento

Descripción de los altavoces

Los altavoces amplicados a prueba de explosiones Federal Signal

Modelos 304X y 314X están diseñados para producir tonos nítidos

y claros en sistemas supervisados de noticación de alarmas. Ambos

modelos son compatibles con la alarma para incendios, la evacuación

por voz, los paneles de control supervisado de supresión y los

reforzadores de energía.

Estos altavoces amplicados pueden transmitir tonos generados por

una tarjeta de tonos instalada en el altavoz (la UTM complementaria

de 32 tonos) o a través de una fuente central de tonos en un sistema

de evacuación por voz o de buscapersonas. Cuando se deben

realizar anuncios públicos o mensajes de voz en vivo, las tarjetas

complementarias de conexión (AM25CK o AM70CK) interactúan con

el Vrms del panel EVAC.

El cono del altavoz y el proyector están construidos con aluminio

resistente entallado. El circuito del amplicador de estado sólido está

protegido por una carcasa de aluminio fundido a presión. Las juntas

a prueba de polvo y de humedad proporcionan protección contra los

elementos. Todas las supercies externas están selladas con pintura de

revestimiento en polvo gris. Un soporte de montaje giratorio de alta

resistencia permite al instalador dirigir la salida de manera efectiva.

La sólida construcción y la alta salida de los Modelos 304X y 314X

los hacen ideales para usar en ambientes difíciles con altos niveles de

ruido. Ambos modelos presentan un control de ganancia interna para

ajustarse a un área en particular.

Este equipo es adecuado para usar solamente en ubicaciones de

Clase I, División 1, grupos B, C y D; Clase I, División 2, Grupos A,

B, C, D o ubicaciones no peligrosas.

Desembalaje del altavoz

Después de desembalar el altavoz, examínela para detectar daños

que puedan haber ocurrido durante el tránsito. Si el altavoz se ha

dañado, no intente instalarla ni ponerla en funcionamiento. Presente

un reclamo de inmediato al transportista que indique el alcance de

SelecTone

Modelos 304X y 314X

MR

51

Page 52

Instrucciones de instalación y mantenimiento

los daños. Con cuidado, inspeccione todos los sobres, las etiquetas

de envío y los rótulos antes de retirarlos o descartarlos. El desecho

de todos los materiales de envío debe realizarse de acuerdo con los

códigos y las normas nacionales y locales. Si falta alguna pieza,

contacte al Servicio de Asistencia al Cliente de Federal Signal al

708-534-4756 o 877-289-3246.

Tabla 1 Especicaciones del modelo 304X

Voltaje de

funcionamiento:

Corriente máxima: 0,83 A

Corriente de espera: 0,13 A

Temperatura de

funcionamiento:

Peso neto: 7,0 kg (15,4 lb)

Peso del envío: 10,4 kg (22,8 lb)

Dimensiones:

Construcción:

Tabla 2 Especicaciones del modelo 314X

Voltaje de

funcionamiento:

Corriente máxima 0,90 A

Corriente de espera: 0,13 A

Temperatura de

funcionamiento:

Peso neto: 7,4 kg (16,4 lb)

Peso del envío: 14,7 kg (32,4 lb)

Dimensiones: Modelo 314X: 496 mm (19,5 in) largo x 478

Construcción: Unidad de aluminio y soporte de montaje de

Grado de protección: IP65 y NEMA 4X aprobado

24 VCC regulados (16 VCC a 33 VCC)

-40 ºC a 66 ºC (-40 ºF a 150 ºF)

414 mm (16,3 in) largo x 432 mm (17,0 in)

alto x 333 mm (13,1 in) ancho.

Unidad de aluminio y soporte de montaje de

acero ajustable pintada con un acabado de

recubrimiento en polvo.

24 VCC regulados (16 VCC a 33 VCC)

-40 ºC a 66 ºC (-40 ºF a 150 ºF)

mm (18,8 in) alto x 425 mm (16,7 in) ancho.

acero ajustable pintada con un acabado de

recubrimiento en polvo.

52

SelecTone

MR

Modelos 304X y 314X

Page 53