Federal Signal Corporation PVS220W-24, PVS220W-48, PVS240W-24, PVS240W-48 Installation Manual

Page 1

Solar Power Systems

Models: PVS220W-24, PVS220W-48,

PVS240W-24, and PVS240W-48

255379

Rev. E3 0917

Printed in U.S.A.

© Copyright 2017 Federal Signal Corporation

Installation Manual

Page 2

Limited Warranty

This product is subject to and covered by a limited warranty,

a copy of which can be found at www.fedsig.com/SSG-Warranty.

A copy of this limited warranty can also be obtained by written

request to Federal Signal Corporation, 2645 Federal Signal Drive,

University Park, IL 60484, email to info@fedsig.com or

call +1 708-534-3400.

This limited warranty is in lieu of all other warranties, express or

implied, contractual or statutory, including, but not limited to the

warranty of merchantability, warranty of tness for a particular

purpose and any warranty against failure of its essential purpose.

2645 Federal Signal Drive

University Park, Illinois 60484-3617

www.fedsig.com

Customer Support 800-548-7229 • +1 708 534-3400

Technical Support 800-524-3021 • +1 708 534-3400

Page 3

Contents

Safety Messages..................................................................................................................................... 5

General Description ............................................................................................................................... 8

Required Equipment ........................................................................................................................... 8

Weight................................................................................................................................................. 8

Installation Instructions ......................................................................................................................... 9

Installing the Solar Panel Bracket ....................................................................................................... 9

Side Pole Installation ................................................................................................................... 9

Top-of-Pole Installation ............................................................................................................. 14

Power Supply and Wiring .................................................................................................................... 16

Power Supply ................................................................................................................................... 16

Wiring the 48 V Junction Box ........................................................................................................... 16

Wiring the 24 V Junction Box (55 W Modules) ................................................................................. 17

Wiring the 24 V Junction Box (110 W Modules, three conductors) .................................................. 20

Wiring the Junction Box for 24 V (110 W Modules, four-wire) .......................................................... 21

Getting Service ..................................................................................................................................... 24

Tables

Table 1 Required Tools .......................................................................................................................... 8

Table 2 Side Pole Mount ........................................................................................................................ 8

Table 3 Top-of-Pole Mount ..................................................................................................................... 9

Installation Manual

3

Page 4

Figures

Figure 1 Placement of 55 W Module (Top View) .................................................................................11

Figure 2 Placement of 60 W Module (Top View) ................................................................................ 12

Figure 3 Side Pole Mount (55 W or 60 W Modules) ........................................................................... 13

Figure 4 Side Pole Mount (110 W Modules) ....................................................................................... 14

Figure 5 Top-of-Pole Mount ................................................................................................................. 15

Figure 6 Module Wiring (back view) ................................................................................................... 18

Figure 7 Wiring PVS220W Systems .................................................................................................... 19

Figure 8 Wiring PVS240W Systems .................................................................................................... 20

Figure 9 Module Wiring 110 W Panels ................................................................................................ 22

Figure 10 Wiring PVS220W Systems .................................................................................................. 23

Figure 11 Module 110 W Placement .................................................................................................... 24

Figure 12 Final Assembly Solar Bracket 55 W or 60 W (4 Panel) ..................................................... 25

Figure 13 Final Assembly Solar Bracket Side Mount 110 W ............................................................ 26

Figure 14 Final Assembly Solar Bracket Top-of-Pole Mount 110 W (2 Panel) ................................ 27

Figure 15 DCB and DCFCB Solar Wiring ............................................................................................ 28

Figure 16 DCFCTB Solar Wiring .......................................................................................................... 29

Figure 17 One-Way Solar UltraVoice Wiring Diagram ...................................................................... 30

Figure 18 Two-Way Solar UltraVoice Wiring Diagram ...................................................................... 31

Figure 19 Hawaii UltraVoice Wiring Diagram ..................................................................................... 32

Figure 20 Solar Assembly for the UltraVoice ..................................................................................... 33

Figure 21 Solar Assembly for the DC Series Siren Control System ................................................ 34

4

Solar Power Systems

Page 5

Safety Messages

It is important to follow all instructions shipped with this product. This device

is to be installed by trained personnel who are thoroughly familiar with the

country electric codes and will follow these guidelines as well as local codes.

Listed below are important safety instructions and precautions you should follow.

Important Notice

Federal Signal reserves the right to make changes to devices and specications detailed in

the manual at any time in order to improve reliability, function or design. The information

in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for any inaccuracies.

Publications

Federal Signal recommends the following publications from the Federal Emergency

Management Agency for assistance with planning an outdoor warning system:

• The “Outdoor Warning Guide” (CPG 1-17)

Safety Messages

• “Civil Preparedness, Principles of Warning” (CPG 1-14)

• FEMA-REP-1, Appendix 3 (Nuclear Plant Guideline)

• FEMA-REP-10 (Nuclear Plant Guideline).

Planning

• If suitable warning equipment is not selected, the installation site for the siren

is not selected properly or the siren is not installed properly, it may not produce

the intended optimum audible warning. Follow Federal Emergency Management

Agency (FEMA) recommendations.

• If sirens are not activated in a timely manner when an emergency condition

exists, they cannot provide the intended audible warning. It is imperative that

knowledgeable people, who are provided with the necessary information, are

available at all times to authorize the activation of the sirens.

• When sirens are used out of doors, people indoors may not be able to hear the

warning signals. Separate warning devices or procedures may be needed to

effectively warn people indoors.

• The sound output of sirens is capable of causing permanent hearing damage. To

prevent excessive exposure, carefully plan siren placement, post warnings, and

restrict access to areas near sirens.

• Activating the sirens may not result in people taking the desired actions if those to

be warned are not properly trained about the meaning of siren sounds. Siren users

should follow FEMA recommendations and instruct those to be warned of correct

actions to be taken.

Installation Manual

5

Page 6

Safety Messages

• After installation, service, or maintenance, test the siren system to conrm

• If future service and operating personnel do not have these instructions to refer

Installation and Service

• Electrocution or severe personal injury can occur when performing various

that it is operating properly. Test the system regularly to conrm that it will be

operational in an emergency.

to, the siren system may not provide the intended audible warning and service

personnel may be exposed to death, permanent hearing loss, or other bodily

injury. File these instructions in a safe place and refer to them periodically. Give a

copy of these instructions to new recruits and trainees. Also give a copy to anyone

who is going to service or repair the siren.

installation and service functions such as making electrical connections, drilling

holes, or lifting equipment. Therefore only experienced electricians should install

this product in accordance with national, state and any other electrical codes

having jurisdiction. Perform all work under the direction of the installation or

service crew safety foreman.

• The sound output of sirens is capable of causing permanent hearing damage.

To prevent excessive exposure, carefully plan siren placement, post warnings

and restrict access to areas near the sirens. Sirens may be operated from remote

control points. Whenever possible, disconnect all siren power including batteries

before working near the siren.

• After installation or service, test the siren system to conrm that it is operating

properly. Test the system regularly to conrm that it will be operational in an

emergency.

• If future service personnel do not have these warnings and all other instructions

shipped with the equipment to refer to, the siren system may not provide the

intended audible warning and service personnel may be exposed to death,

permanent hearing loss, or other bodily injury. File these instructions in a safe

place and refer to them periodically. Give a copy of these instructions to new

recruits and trainees. Also, give a copy to anyone who is going to service or repair

the sirens.

Operation

Failure to understand the capabilities and limitations of your siren system could result in

permanent hearing loss, other serious injuries or death to persons too close to the sirens

when you activate them or to those you need to warn. Carefully read and thoroughly

understand all safety notices in this manual and all operations-related-items in all

instruction manuals shipped with equipment. Thoroughly discuss all contingency plans

with those responsible for warning people in your community, company, or jurisdiction.

6

Solar Power Systems

Page 7

Safety Messages

Read and understand the information contained in this manual before

attempting to install or service the siren.

Solar modules generate DC electricity when exposed to light. Exposure

to this voltage can result in serious injury or even death. Follow all safety

precautions.

To stop production of electricity, cover panel surfaces with opaque material

while working on system. Avoid touching terminals and/or wire ends until

connections are made.

Pay careful attention to the notices located on the equipment.

Installation Manual

7

Page 8

General Description

General Description

This manual describes how to install the Solar Power Systems.

The Solar Power Systems provide an all inclusive solar powering options for all outdoor

sirens. Solar powering of batteries is an efcient and economical method of powering

remote sirens, alerting, or control equipment. Applications include, but are not limited to,

remote tsunami sirens, muster stations, and tornado sirens.

The PVS220W-24 and PVS220W-48 provide 220 W of power for charging of batteries in

24 or 48 Vdc applications. The PVS240W-24 and PVS240W-48 provide 240 W of power

for charging of batteries in 24 or 48 Vdc applications. These systems are equipped with

solar regulators for accurate control, protection, and monitoring of the solar panels. These

kits use four 55 W highly efcient solar panels, each with junction boxes to allow ease of

wiring.

The mounting hardware is aluminum for light weight and high strength, able to withstand

wind loads up to 170 mph. The kit includes thirty feet of cable to allow wiring from the

panels to the Battery Cabinet. The solar regulators support gel, sealed or ooded batteries

with temperature compensation to extend battery life and improve system performance.

Federal Signal determines the proper direction and tilt for each solar application based on

location. Federal Signal recommends gel batteries for solar applications.

Required Equipment

You need the following equipment.

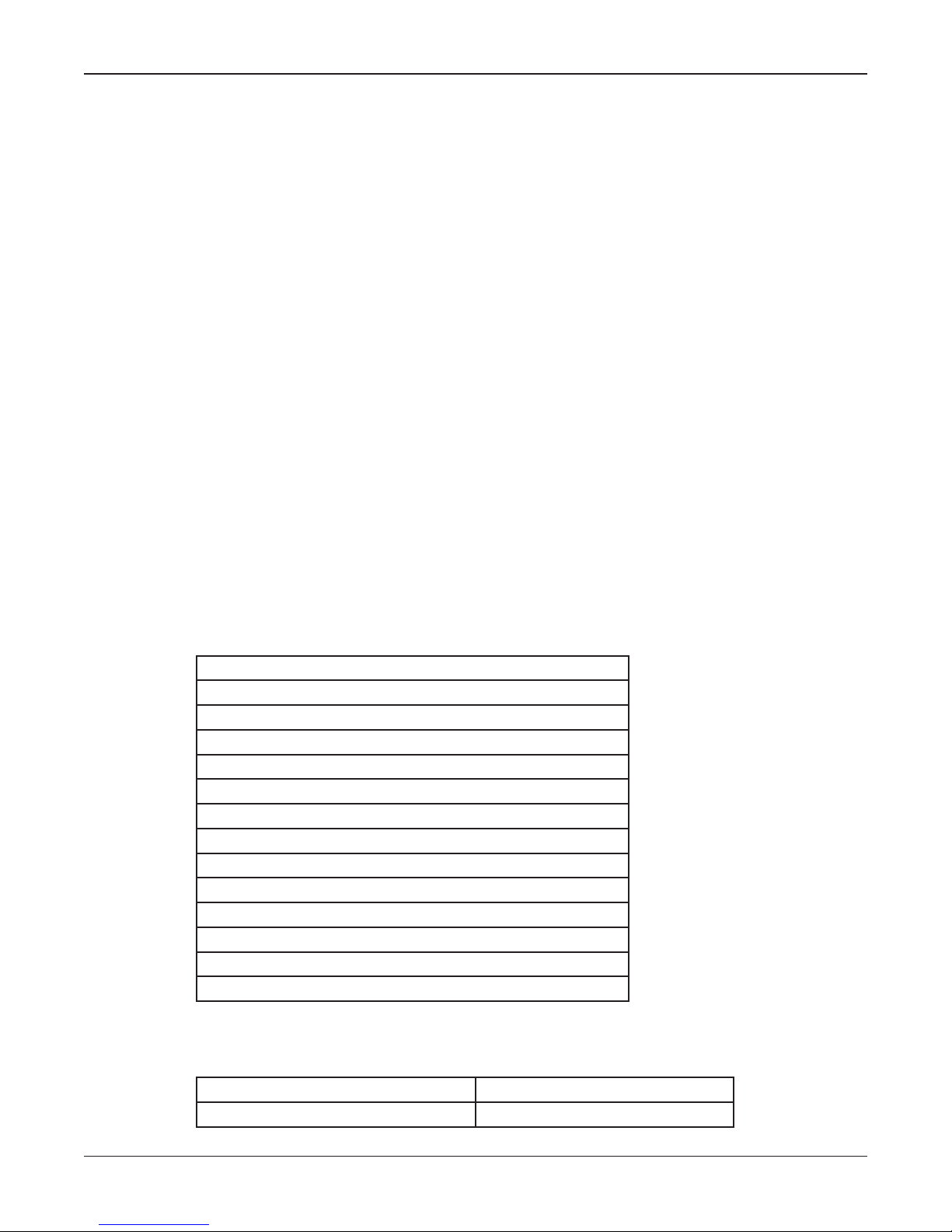

Table 1 Required Tools

Large at head screwdriver

Medium at head screwdriver

Narrow (3/16-in) at head screwdriver

Medium cross head screwdriver

Socket driver set with 7/16-in, 9/16-in and 3/4-in sockets

7/16-in open end wrench

9/16-in open end wrench

Adjustable wrench

Wire cutters

Needle nose pliers

Wire strip and crimp tool

Electric drill with 1/4-in drill bit

Utility knife

Measuring tape

Weight

Table 2 Side Pole Mount

Net Weight 115 pounds (52 kg)

Shipping Weight 153 pounds (69 kg)

8

Solar Power Systems

Page 9

Table 3 Top-of-Pole Mount

Net Weight 112 pounds (51 kg)

Shipping Weight 150 pounds (68 kg)

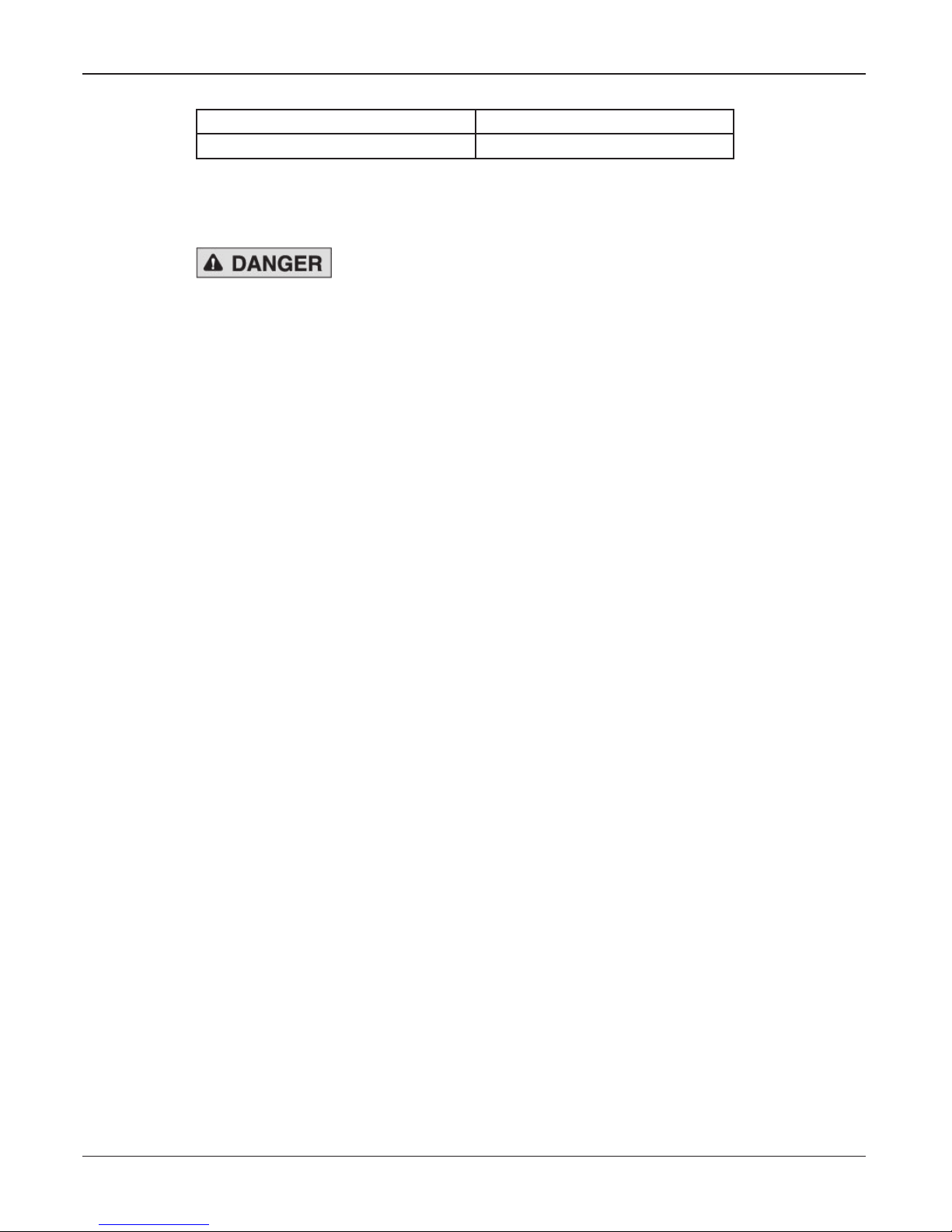

Installation Instructions

Installing the Solar Panel Bracket

Electrocution or severe personal injury can occur when making electrical

connections, drilling holes, or lifting equipment. Therefore, installation should

be performed by experienced electricians in accordance with national and

local codes.

Most bracket installations are one of two types: Side Pole Mount or Top Pole Mount.

These two congurations make it possible to provide solar power in almost any situation.

If the installations in this manual are not suitable, it may be practical to modify one of the

congurations.

For best results, the solar modules must face true south. Consult FEMA CPG 1-17 and

CPG 1-14 and your local Federal Signal representative to properly place your outdoor

warning equipment.

Installation Instructions

Side Pole Installation

The bracket is typically mounted on a Class 2 utility pole (ANSI type wooden pole or

equivalent) with a minimum horizontal ground stress rating of 3,700 pounds (1678 kg).

Insure that soil loads will conform to this size utility pole.

NOTE: Certain soil conditions may require guying for the pole. Check with proper

building authorities.

To install a side pole mount solar bracket onto a wooden utility pole, do the following:

1. Uncrate and identify the various parts. You can use an empty box as a platform to

protect assembly and modules from damage.

2. Place the solar modules face down with their junction boxes toward center for the

55 W and 60 W modules or toward top for the 110 W panels.

NOTE: 55 W modules come in two alternate sizes (See 55 W Module

Placement).

3. Assemble the solar bracket onto the solar modules per nal assembly drawing.

Apply thread locking compound to all fastening hardware to ensure secure

assembly.

4. Find the desired elevation on the pole. For best results, the solar modules must

face true south. Mark the eight mounting holes on the pole for the bracket.

5. Drill a 3/8-inch pilot hole at each of the locations. Drill each hole at least

3-1/2 inch deep.

Installation Manual

9

Page 10

Installation Instructions

6. Using eight 1/2-inch stainless steel lag screws (minimum of 5 inches in length)

or two sections of ¾-inch wide stainless steel strapping, secure the solar bracket

onto the pole.

7. Locate your site and nd the latitude of your location. For the Northern

Hemisphere, add or set the tilt angle at the value specied in the following table.

Latitude Range Tilt Angle

90° to 60° 60°

60° to 25° +15°

25° to 20° +5°

20° to 0° 25°

Tilt angles are limited to a minimum of 25° and maximum of 60° degrees.

8. Find the vertical distance Y for your setup from the tilt angle charts.

For any other type of pole, such as a galvanized steel pole, install the side mount solar

bracket as follows:

1. Uncrate and identify the various parts. Use an empty box as a platform to protect

assembly and modules from damage.

2. Start by placing the solar modules face down with their junction boxes toward

center for the 55 W and 60 W modules or toward top for the 110 W panels.

NOTE: 55 W modules come in two alternate sizes (see Placement of 55 W

Module).

3. Assemble the solar bracket onto the solar modules per nal assembly drawing.

Apply thread locking compound to all fastening hardware to ensure secure

assembly.

4. Find the desired elevation on the pole. For best results, the solar modules must

face true south. Mark the two placement locations on the pole for the bracket.

5. Secure the solar bracket by clamping it onto the pole by using two sections of

¾-inch wide stainless steel strapping and the tilt angle charts.

6. Locate your site and nd the latitude of your location. For the Northern

Hemisphere, add or set the tilt angle at the following table.

Latitude Range Tilt Angle

90° to 60° 60°

60° to 25° +15°

25° to 20° +5°

20° to 0° 25°

Tilt angles are limited to a minimum of 25° and maximum of 60° degrees.

10

Solar Power Systems

Page 11

Installation Instructions

7. Find the vertical distance Y for your setup from the tilt angle charts.

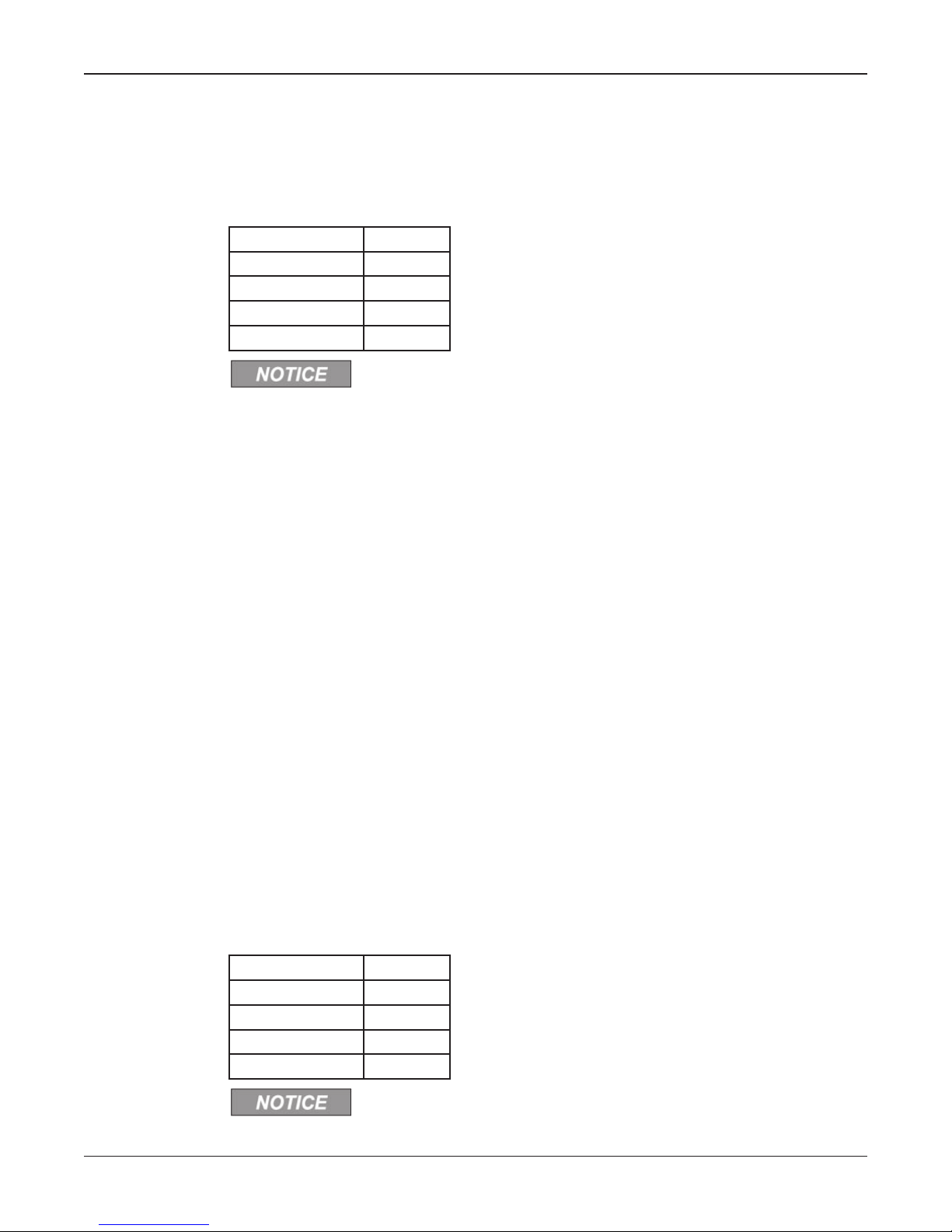

Figure 1 Placement of 55 W Module (Top View)

Installation Manual

11

Page 12

Installation Instructions

Figure 2 Placement of 60 W Module (Top View)

24.75

LOCATOR

HOLE

12

Solar Power Systems

Page 13

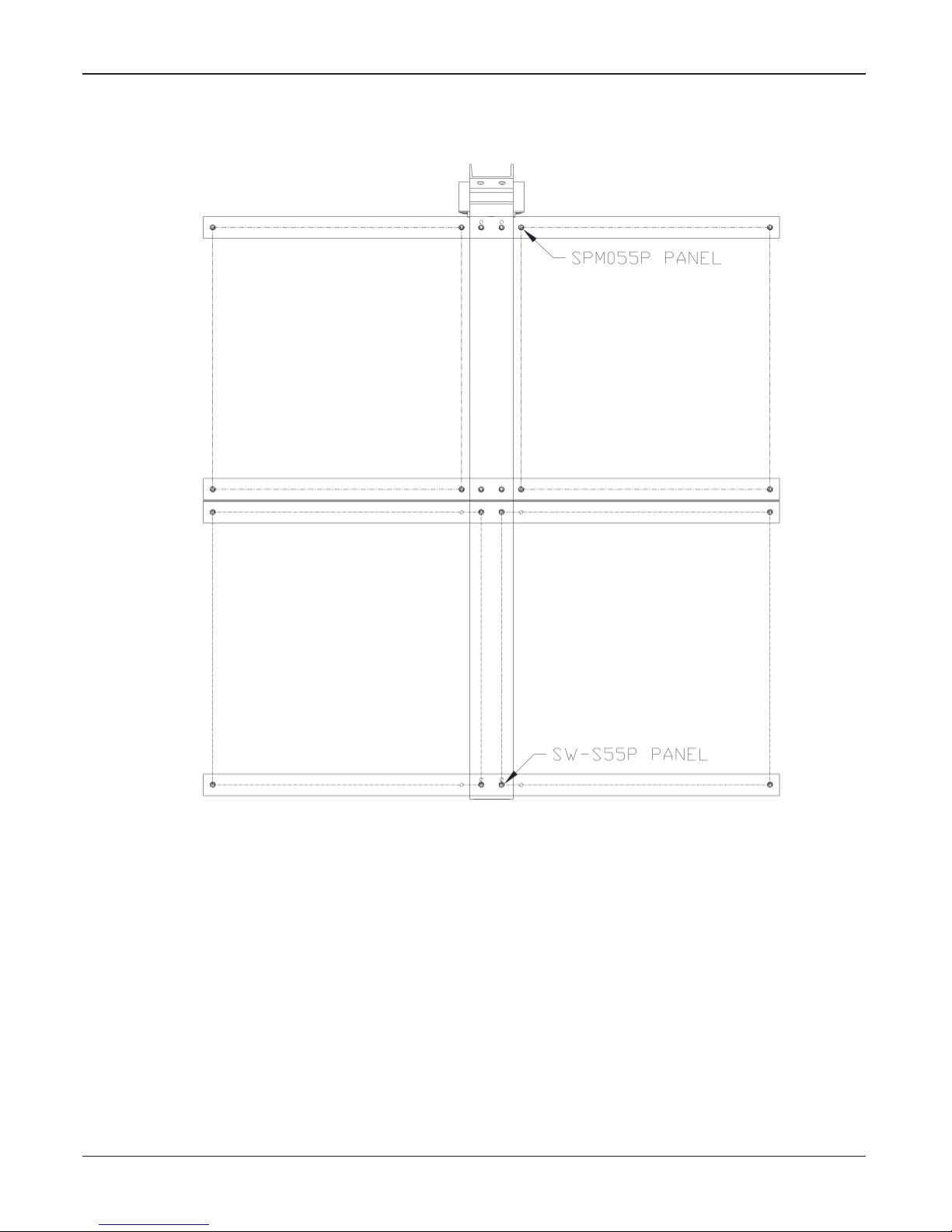

Figure 3 Side Pole Mount (55 W or 60 W Modules)

Y

TILT ANGLE°

Installation Instructions

Tilt Angle

Vertical Distance Y Hole Number

from horizontal

25° 15.00 in (38.10 cm) 1

30° 20.50 in (52.07 cm) 1

35° 26.00 in (66.04 cm) 1

40° 26.00 in (66.04 cm) 2

45° 31.50 in (80.01 cm) 2

50° 33.50 in (85.09 cm) 3

55° 42.50 in (107.95 cm) 3

60° 48.00 in (121.92 cm) 3

291355C

Installation Manual

13

Page 14

Installation Instructions

Figure 4 Side Pole Mount (110 W Modules)

Y

TILT ANGLE°

Tilt Angle

from horizontal

30° 23.00 in (58.42 cm) 1

35° 30.00 in (76.20 cm) 1

40° 28.75 in (73.03 cm) 2

45° 37.50 in (95.25 cm) 2

55° 48.00 in (121.92 cm) 1

60° 51.25 in (130.18 cm) 1

Top-of-Pole Installation

To install a top-of-pole solar bracket, do the following:

1. Uncrate and identify the various parts. Use an empty box as a platform to protect

assembly and modules from damage.

2. Start by placing the solar modules face down with their junction boxes toward

center for the 55 W and 60 W modules or toward top for the 110 W panels.

3. Assemble the solar bracket onto the solar modules per nal assembly drawing.

Apply thread locking compound to all fastening hardware to ensure secure

assembly.

Vertical Distance Y Hole Number

14

Solar Power Systems

Page 15

Installation Instructions

4. Locate your site and nd the latitude of your location. For the Northern

Hemisphere, add or set the tilt angle at the value specied in the following table.

Latitude Range Tilt Angle

90° to 60° 50°

60° to 25° +15°

25° to 20° +5°

20° to 0° 25°

Tilt angles are limited to a minimum of 25° and maximum of 50° degrees.

5. Find the vertical distance Y for your setup from the tilt angle chart. For best

results, the solar modules must face true south.

6. Using the stainless steel u-bolt provided, secure the solar bracket onto the pole.

Figure 5 Top-of-Pole Mount

Y

TILT

ANGLE°

291356B

Installation Manual

15

Page 16

Power Supply and Wiring

Tilt Angle

from horizontal

25° 5.00 in (12.70 cm)

30° 5.50 in (13.97 cm)

35° 6.25 in (15.88 cm)

40° 7.00 in (17.78 cm)

45° 7.50 in (19.05 cm)

50° 7.75 in (19.69 cm)

Power Supply and Wiring

Power Supply

Connect four 55 W or 60 W, 12 V solar modules in series to supply a 48 Vdc power

supply for the 2001-130, Equinox, 508-128, and Eclipse8 electro-mechanical siren

controls.

Connect four 55 W or 60 W, 12 V solar modules in series/parallel to supply a 24 Vdc

power supply for the UV electronic siren controls.

Connect two 110 W, 12V solar modules in series/parallel to supply a 24 Vdc power

supply for the UV electronic siren controls.

Vertical Distance Y

Wiring the 48 V Junction Box

To wire the junction box for the 48 V (55 W or 60 W Modules), do the following:

1. Open the module junction box covers.

2. Knock out the appropriate junction box holes in the modules to allow addition of

cable clamps. An additional knockout will be required for the array output wires

leading from the array to the Control Cabinet.

3. Coat module terminals with NO-OX or an equivalent corrosion inhibitor to

prevent corrosion.

4. Cut the three-conductor cable 8-foot length (2.44 m) into three 32-inch

(81.28 cm) sections.

5. Connect the black wires from the three-conductor cable sections as follows:

• Negative (-) terminal of module A to positive (+) terminal of module B

• Negative (-) terminal of module B to positive (+) terminal of module C

• Negative (-) terminal of module C to positive (+) terminal of module D

6. Run one side of the two-conductor PV output cable 30-foot length (9.144 m)

through the cable clamp, to module D junction box. Connect the black wire to the

negative (-) terminal and butt splice the red wire to the red wire from the threeconductor cable within the junction box. Use wire tie wraps provided to secure

the output cable to the bracket.

16

Solar Power Systems

Page 17

7. Measure the voltage between red (+) and black (-) wires at the end of the PV

output cable with the modules exposed to sunlight. If the wiring is correct, the

voltage measures between 60 and 92 Volts. If the voltage is not in this range,

check the wire connections to ensure all steps were followed.

8. Close junction box covers.

9. Run the other side of the two-conductor PV output cable (30-foot length) down

the pole to the Control Cabinet. Use wire tie wraps provided to secure the output

cable. Form a drip loop where the cable enters the Control Cabinet. Run the

cable through the ½-inch NPT aluminum cord grip provided and connect to solar

regulator using the spade terminals.

10. Installation is now complete.

Wiring the 24 V Junction Box (55 W Modules)

To wire the junction box for the 24 V (55 W or 60 W Modules), do the following:

1. Open the module junction box covers.

2. Knock out the appropriate junction box holes in the modules to allow addition of

cable clamps. An additional knockout will be required for the array output wires

leading from the array to the Control Cabinet.

Power Supply and Wiring

3. Coat module terminals with NO-OX or an equivalent corrosion inhibitor to

prevent corrosion.

4. Cut a 32-inch (81.28 cm) section from the three-conductor cable 8-foot length

(2.44 m).

5. Connect the white wire from the three-conductor section as follows:

• Negative (-) terminal of module A to positive (+) terminal of module B

• Negative (-) terminal of module C to positive (+) terminal of module D

6. Run the two-conductor PV output cable 30-foot length (9.144 m) through the

cable clamp, to module D junction box. Connect the black wire to the negative

(-) terminal and butt splice the red wire to the red wire from the three-conductor

cable within the junction box. Use wire tie wraps provided to secure the output

cable to the bracket.

7. Measure the voltage between red (+) and black (-) wires at the end of the PV

output cable with the modules exposed to sunlight. If the wiring is correct, the

voltage measures between 30 and 46 Volts. If the voltage is not in this range,

check the wire connections to ensure all steps were followed.

8. Close junction box covers.

Installation Manual

17

Page 18

Power Supply and Wiring

9. Run the two-conductor PV output cable (30-foot length) down the pole to the

Control Cabinet. Use wire tie wraps provided to secure the output cable. Form

a drip loop where the cable enters the Control Cabinet. Run cable through the

½-inch NPT aluminum cord grip provided and connect to solar regulator using

the spade terminals.

10. Installation is now complete.

Figure 6 Module Wiring (back view)

3-CONDUCTOR CABLE (QTY. 3)

CABLE CLAMP (QTY. 7)

18

(BACK VIEW)

MODULE WIRING

Solar Power Systems

2-CONDUCTOR CABLE

TO SOLAR REGULATOR IN

CONTROL CABINET

291357B

Page 19

Figure 7 Wiring PVS220W Systems

(PVS220W-24)

Power Supply and Wiring

-

+

55W,12V 55W,12V 55W,12V 55W,12V

+ +

3-COND CABLE

+

+ +

-

RED

WHT

3-COND CABLE 3-COND CABLE

-

55W,12V 55W,12V 55W,12V 55W,12V

-

-

+

+- + -

-

+

+-

+ -

WHT

+ -

-- + + -

BLK

BUTT SPLICE

(PVS220W-48)

+ -

-- + + -

WHTRED

+ -

+ + - -

WHT

2-COND CABLE

RED (+)

BLK (-)

+ -

+ + - -

3-COND CABLE 3-COND CABLE 3-COND CABLE

BUTT SPLICE

2-COND CABLE

RED (+)

BLK (-)

291358B

Installation Manual

19

Page 20

Power Supply and Wiring

Figure 8 Wiring PVS240W Systems

A B C D

-

24 VOLT SYSTEM (PVS240W-24)

+

60W,12V 60W,12V 60W,12V 60W,12V

-

+

-

+

-

+

A B C D

-

BLK

TO SOLAR REGULATOR PV-

WHT

RED

BLK

TO SOLAR REGULATOR PV-

48 VOLT SYSTEM (PVS240W-48)

+

60W,12V 60W,12V 60W,12V 60W,12V

-

WHT

+

WHT

-

+

BLK

WHT

TO SOLAR REGULATOR PV+

-

WHT

TO SOLAR REGULATOR PV+

Wiring the 24 V Junction Box (110 W Modules, three conductors)

To wire the 24 V junction box (110 W modules, three conductors), do the following:

RED

+

RED

1. Open the module junction box covers.

2. Knock out the appropriate junction box holes in the modules to allow addition of

cable clamps. An additional knockout will be required for the array output wires

leading from the array to the Control Cabinet.

3. Coat module terminals with NO-OX or an equivalent corrosion inhibitor to

prevent corrosion.

4. Connect the white wire from the short three-conductor cable 3-foot length

(91.44 cm) as follows:

• Negative (-) terminal of module A to positive (+) terminal of module B

5. Run the long three-conductor PV output cable 60-foot length (18.288 m) through

the cable clamp, to module B junction box. Connect the black wire to the negative

(-) terminal and butt splice the red wire to the red wire from the three-conductor

cable within the junction box. Use wire tie wraps provided to secure the output

cable to the bracket.

20

Solar Power Systems

Page 21

Power Supply and Wiring

6. Measure the voltage between red (+) and black (-) wires at the end of the PV

output cable with the modules exposed to sunlight. If the wiring is correct, the

voltage measures between 30 and 46 Volts. If the voltage is not in this range,

check the wire connections to ensure all steps were followed.

7. Close junction box covers.

8. Run the three-conductor PV output cable (60-foot length) down the pole to the

Control Cabinet. Use wire tie wraps provided to secure the output cable. Form

a drip loop where the cable enters the Control Cabinet. Run cable through the

½-inch NPT aluminum cord grip provided and connect to solar regulator using

the spade terminals. Check the wire connections are made per diagram “Figure 19

Hawaii UltraVoice Wiring Diagram” on page 32.

9. Installation is now complete.

Wiring the Junction Box for 24 V (110 W Modules, four-wire)

To wire the junction box for the 24 V (110 W modules, four-wire Hawaii), do the

following:

1. Open the module junction box covers.

2. Knock out the appropriate junction box holes in the modules to allow addition of

cable clamps. An additional knockout will be required for the array output wires

leading from the array to the Control Cabinet.

3. Coat module terminals with NO-OX or an equivalent corrosion inhibitor to

prevent corrosion.

4. Run the wires 60-foot length (18.288 m) for top mount or 30-foot (9.144 m)

for side mount, with an additional 3-foot length (91.44 cm) through the cable

clamp, to module B junction box. Connect the shorter wires to the positive (+)

and negative (-) terminals of module B. Run the longer wires out and connect to

terminals of module A. Use wire tie wraps provided to secure the output cable to

the bracket.

5. Measure the voltage between the two sets of red (+) and black (-) wires at the

end of the PV output wires with the modules exposed to sunlight. If the wiring

is correct, the voltage on each set of wires measures between 15 and 23 Volts.

With a jumper installed on terminal blocks in the UV Control Cabinet, the series

combination of the two modules measures between 30 and 46 Vdc. If either of

these voltage values is not obtained, check the wire connections are made per

diagram “Figure 19 Hawaii UltraVoice Wiring Diagram” on page 32.

6. Close junction box covers.

7. Run the wires down the pole to the Control Cabinet. Use wire tie wraps provided

to secure the output cable. Form a drip loop where the cable enters the Control

Cabinet. Run cable through the ½-inch NPT aluminum cord grip provided and

connect to solar regulator using the spade terminals.

Installation Manual

21

Page 22

Power Supply and Wiring

8. Installation is now complete.

Figure 9 Module Wiring 110 W Panels

22

Solar Power Systems

Page 23

Figure 10 Wiring PVS220W Systems

Power Supply and Wiring

Installation Manual

23

Page 24

Getting Service

Figure 11 Module 110 W Placement

Getting Service

If you are experiencing any difculties, contact Federal Signal Customer Care at:

800-548-7229 or 708-534-3400 extension 5822 or Technical Support at: 800-524-3021

or 708-534-3400 extension 7329 or through e-mail at: techsupport@fedsig.com. For

instruction manuals and information on related products, visit: http://www.fedsig.com/

24

Solar Power Systems

Page 25

25

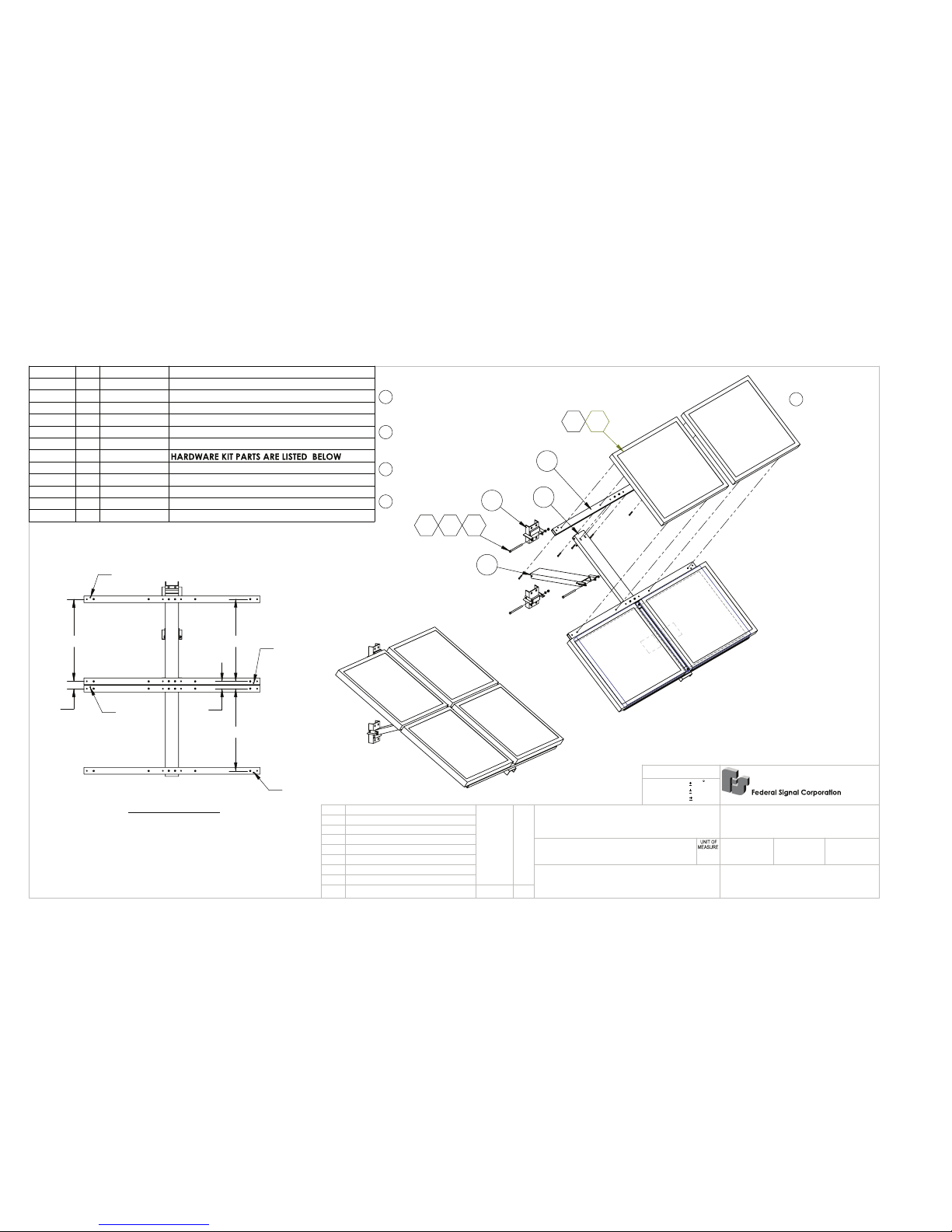

Figure 12 Final Assembly Solar Bracket 55 W or 60 W (4 Panel)

3

1

4

60W SOLAR PANEL

103102101

105104

2

ITEM NO.

QTY.

PART NO.

DESCRIPTION

1 1

2881278C

CHANNEL, BASE, SOLAR 55W (4 PANEL)

2 4

2881279B

TUBING, RECTANGULAR, SOLAR 55W/60W (2

3 1

2881284A

ASSEMBLY, WELD, SUPPORT, CHANNEL

4 2

2881286A

CHANNEL, BRACKET, WELD

5 1 2881333

HARDWARE KIT

101 3

7002080A-80

SCREW,HEX,SS,3/8-16 X 5,FULL THRD

102 3

7058A013

NUT,EL STOP,HEX,LT SS,3/8-16

103 3

7074A046

LKWSHR, SPLT, SS, 3/8

104 24

7000A311-30

SCREW, MACH, 1/4-20, HEX HD, , SS,

105 24

7058A010

NUT, EL STOP, 1/4-20, , SS,

24.75

24.75

2.19

24.69

2.25

LOCATOR

HOLE

LOCATOR

HOLE

LOCATOR

HOLE

LOCATOR

HOLE

BRACKET ASSEMBLY

D0

D0

D0

D0

D0

MATERIAL DESCRIBED AND INFORMATION CONVEYED IS

PROPRIETARY TO FEDERAL SIGNAL CORPORATION, IS OR

MAY BE THE SUBJECT OF PATENT APPLICATIONS, AND

MAY NOT BE COPIED, DIVULGED TO OTHERS, OR USED

FOR MANUFACTURING WITHOUT CONSENT.

DRAWN BY:

DATE:

CHKD. BY:

DATE:

SCALE AT B SIZE:

DRAWING NUMBER:

FINISH:

MATERIAL:

NAME:

CHANGE

DATE

BY

DIVISION

SIGNAL

2645 FEDERAL SIGNAL DRIVE - UNIVERSITY PARK,IL 60466

SC

NONE

2881287

NONE

AS SPECIFIED

FINAL ASSEMBLY, SOLAR BRACKET

55W/60W (4 PANEL)

PC

SEE ECO# 09-4542

3/10/09

VT

Tolerances Unless

Otherwise Specified

Angles -------

0.5

X.XX ----------

0.015

X.XXX ----------

0.005

REV

REMOVE BURRS, SHARP CORNERS AND EDGES

B

2/2/09

VT

1/30/09

B1

MAF

1/8/10

SEE ECR #09-5802

VT

SEE ECR# 10-7179

12/6/10

C

D0

MAF

5/23/16

SEE ECR# 5602

Page 26

26

Figure 13 Final Assembly Solar Bracket Side Mount 110 W

14

110W SOLAR PANEL

102105103

104106

3

2

ITEM NO.

QTY.

PART NO.

DESCRIPTION

1 1

861000124A

CHANNEL, BASE, SOLAR SIDE MT 110W

2 2

861000053A

TUBING, RECTANGULAR, SOLAR 110W

3 1

861000126A

ASSY., WELD, SUPPORT, CHANNEL SIDE MT 110W

4 2

2881286A

CHANNEL, BRACKET, WELD

5 1

2881333B

HARDWARE KIT

HARDWARE KIT PARTS ARE LISTED BELOW

101 12

7000A311-30

SCR,HEX HD,SS,1/4-20X1-7/8

102 3

7002080A-80

SCREW,HEX,SS,3/8-16 X 5,FULL THRD

103 3

7058A013

NUT, EL STOP, 3/8-16, 0.468/0.438" THK, SS,

104 12

7058050A

NUT,MACH SCR,KEPS,1/4-20

105 3

7074A046

LKWSHR, SPLT, SS, 3/8

106 12

7000A311-30

SCREW, MACH, 1/4-20, HEX HD, , SS,

MATERIAL DESCRIBED AND INFORMATION CONVEYED IS

PROPRIETARY TO FEDERAL SIGNAL CORPORATION, IS OR

MAY BE THE SUBJECT OF PATENT APPLICATIONS, AND

MAY NOT BE COPIED, DIVULGED TO OTHERS, OR USED

FOR MANUFACTURING WITHOUT CONSENT.

DRAWN BY:

DATE:

CHKD. BY:

DATE:

SCALE AT B SIZE:

DRAWING NUMBER:

FINISH:

MATERIAL:

NAME:

CHANGE

DATE

BY

DIVISION

SIGNAL

2645 FEDERAL SIGNAL DRIVE - UNIVERSITY PARK,IL 60466

Federal Signal Corporation

SAC

NONE

861000127A

NONE

AS SPECIFIED

FINAL ASSEMBLY, SOLAR BRACKET

SIDE MOUNT 110W

PC

SEE ECR# 841

6/24/13

VT

Tolerances Unless

Otherwise Specified

Angles -------

0.5

X.XX ----------

0.015

X.XXX ----------

0.005

REV

REMOVE BURRS, SHARP CORNERS AND EDGES

A0

6/14/13

VT

6/12/13

Page 27

27

Figure 14 Final Assembly Solar Bracket Top-of-Pole Mount 110 W (2 Panel)

5

2

3

110W SOLAR PANEL

4103108

104

1101107105

NOTE: SOLAR PANEL OMMITED FOR DETAIL

102107105

106100

7109

A1

ITEM NO.

QTY.

PART NO.

DESCRIPTION

1 1

2881295A

ASSY, WELD, CHANNEL SUPPORT, TOP-OF-PO

2 1

2881298A

WELD ASSY, BRACKET, TOP-OF-POLE MOUNT

3 1

861000052A

CHANNEL, BASE, SOLAR 110W

4 1

2881294A

ASSEMBLY, WELD, BASE BRACKET

5 2

861000053A

TUBING, RECTANGULAR, SOLAR 110W

6 1 2881335

HARDWARE KIT

7 1

8570073A

WELDMENT ASSY, PIPE SLEEVE, SOLAR, PVS22

HARDWARE KIT PARTS LISTED BELOW

100 12

7000A311-28

SCR,HEX HD,SS,1/4-20X1-7/8

101 2

7002080A-88

SCREW,HEX,SS,3/8-16 X 6-1/2

102 1

7002080A-96

SCREW,HEX,SS,3/8-16 X 6

103 1

7002A014-24

SCREW,CAP,HEX HD,SS,1/2-13 X 1-1/2

104 1

7003018A

BOLT, U, 1/2-13, , SS, FOR 4" PIPE

105 3

7058A013

NUT, EL STOP, 3/8-16, 0.468/0.438" THK, SS,

106 12

7058A010

NUT, EL STOP, 1/4-20, , SS,

107 3

7074A046

LKWSHR, SPLT, SS, 3/8

108 1

7074A059

WASHER, SPLT, 1/2, .873 OD, 0.135/0.125"

109 2

7000A338-104

SCREW HEX HD 1/2-13 SS

A2

A2

A2

MATERIAL DESCRIBED AND INFORMATION CONVEYED IS

PROPRIETARY TO FEDERAL SIGNAL CORPORATION, IS OR

MAY BE THE SUBJECT OF PATENT APPLICATIONS, AND

MAY NOT BE COPIED, DIVULGED TO OTHERS, OR USED

FOR MANUFACTURING WITHOUT CONSENT.

DRAWN BY:

DATE:

CHKD. BY:

DATE:

SCALE AT B SIZE:

DRAWING NUMBER:

FINISH:

MATERIAL:

NAME:

CHANGE

DATE

BY

DIVISION

SIGNAL

2645 FEDERAL SIGNAL DRIVE - UNIVERSITY PARK,IL 60466

Federal Signal Corporation

SAC

NONE

861000039A

NONE

AS SPECIFED

FINAL ASSEMBLY, SOLAR BRACKET

TOP-OF-POLE MOUNT 110W (2 PANEL)

REL. TO ECR # 113

10/30/12

VT

Tolerances Unless

Otherwise Specified

Angles -------

0.5

X.XX ----------

0.015

X.XXX ----------

0.005

REV

REMOVE BURRS, SHARP CORNERS AND EDGES

A0

10/30/12

VT

10/29/12

PC

SEE ECR # 768

5/21/13

VT

A1

A2

SEE ECR # 2268

8/5/14

VT

Page 28

28

Figure 15 DCB and DCFCB Solar Wiring

Page 29

29

Figure 16 DCFCTB Solar Wiring

Page 30

30

Figure 17 One-Way Solar UltraVoice Wiring Diagram

T300104-02-014

1 FUSE 2

1461309A

1461503A

20 AMP

200A

RED 4 GA

PRIMARY CABINET

SECONDARY CABINET

COM

REMOTE ACTIVATION INPUTS

SLOWBLO

RELAY

JP11

F1

JP14

600 OHM

20A

JP12

C4

CHARGER

JP20

RELAY

D2

AMP 5

COM

JP15

JP18

F5F2F1F3F4

F8F6F7

COM

SENSOR INPUTS

COM#1COM

SPR

COM

INTR

COMACSOL

PTT

600

COM

TEST

SPEAKER

JP29

JP19

JP17

JP16

DIR

-

SPR

#2

+

VISO

SOU

COM

NOR

EAS

WES

- +

24VDC

JP13

T1

C1

10A

F2

SIG-

SIG-

SIG+

SIG+

SIG-

SIG+

SIG+

SIG-

JP23

AMP 3AMP 1

JP21

AMP 2

JP22

AMP 4

JP24

SIG-

SIG+

BATTERY

(+)

JP25

SIG-

SIG+

BATTERY

(-)

AMP 6

JP26

SIG-

2005147

SIG+

JP27

AMP 7

(-)

SIG-

SIG+

AMP 8

JP28

T300422-03-059 ORN

RADIO

RS232

RX TEST

3

+

4

+

-

2

1

+

-

+

-

T300104-09-004

WHT 4 GA.

T300104-09-001

WHT 4 GA.

T300112-05-005 GRN 12 GA

T300104-10-011 BLK 4GA

T300112-02-056 RED 12 GA

T300420-05-011 GRN

T300422-03-060 ORN

BATTERY BOX CONNECTIONS

T300104-02-010

RED 4AWG

T300104-09-004

WHT 4 GA.

(1 REQUIRED

WITH 2 BATTERIES)

SW1

2

1

RED 4 GA

T300104-02-016

COMMON

OPEN

OPEN

COMMON

1461504A

C300422-09-143

WHT

2-WAY

MODELS

ONLY

122378A

2-WAY

MODELS

ONLY

122378A

NOTES:

1. BATTERY CONNECTIONS ARE MADE DURING SIREN INSTALLATION.

2. WHEN USING ONLY TWO BAT TERIES, DO NOT USE (3) WHITE 4 AWG WIRES (T300104-09-004).

3. ORANGE INTRUSION SWITCH WIRES INCLUDED FOR POSSIBLE FUTURE USE.

4. LENGTH OF WIRES IN BATTERY CABINET (MEASURED FROM CONDUIT END TO TERMINAL START ā0.5").

T300422-03-060 & T300422-03-061, ORANGE, 36"

T300104-02-016, RED, 13"

T300104-10-011, BLACK, 10.5"

1461503A, 6.5"

A7

A7

RED

BLK

BLK

RED

BLK

BLK

PV

+

+

LOAD

+

- ++- +

+

BATTERY

-

SOLAR REGULATOR

RED

+ - +

-

TO SOLAR REGULATOR PV+

BLK

BLK

-

288996 (PVS220W-24-DSA, PVS220W-24-MOD, PVS220W-24-H-S)

288995D (PVS220W-24)

-+ + ++ - - ++ - - ++ - -

RED

WHT

CONTROL CABINET

INTRUSION SWITCH

CONTROL CABINET

INTRUSION SWITCH

SEE NOTE 3

55W,12V

110W, 12V 110W, 12V

SOLAR WIRING CONFIGURATIONS

A2

WHT

A3

A4

A5

A6

55W,12V 55W,12V 55W,12V

WHT

BLK

RED

RED

+

-

WHT

BLK

+

-

+

-

+

-

288995 (PVS240W-24)

60W,12V 60W,12V 60W,12V 60W,12V

TO SOLAR REGULATOR PV-

RED

TO SOLAR REGULATOR PV+

TO SOLAR REGULATOR PV-

A1

+ - + -

+ +- -+ - + -

A REL. TO ECO# 06-4033 3/6/06 VT

N/A

AS SPECIFIED

RF

259185A

VT

3/10/06

SC

6/8/06

NONE

WIRING DIAGRAM

1-WAY, SOLAR, ULTRAVOICE

A1 SEE ECO #07-4009 1/25/07 MAF

A2 SEE ECO #07-4054 4/12/07 MAF

A3 SEE ECR #10-7179 12/6/10 VT

A4 SEE ECR #443 2/13/13 BWH

A5 SEE ECR# 2268 8/22/14 VT

A6 SEE ECR# 4142 9/8/15 MAF

A7 SEE ECR #5602 5/31/16 MAF

Otherwise Specied

------

-------

Angles

x.xx

x.xxx

-----

Tolerances Unless

±0.5°

±.015

±.005

Page 31

31

Figure 18 Two-Way Solar UltraVoice Wiring Diagram

T300104-02-014

1 FUSE 2

1461309A

1461503A

20 AMP

200A

RED 4 GA

DC CONVERTER

PRIMARY CABINET

SECONDARY CABINET

COM

REMOTE ACTIVATION INPUTS

SLOWBLO

RELAY

JP11

F1

JP14

600 OHM

20A

JP12

C4

CHARGER

JP20

RELAY

D2

AMP 5

COM

JP15

JP18

F5F2F1F3F4

F8F6F7

COM

SENSOR INPUTS

COM

#1

COM

SPR

COM

INTR

COMACSOL

PTT

600

COM

TEST

SPEAKER

JP29

JP19

JP17

JP16

DIR

-

SPR

#2

+

VISO

SOU

COM

NOR

EAS

WES

- +

24VDC

JP13

T1

C1

10A

F2

SIG-

SIG-

SIG+

SIG+

SIG-

SIG+

SIG+

SIG-

JP23

AMP 3AMP 1

JP21

AMP 2

JP22

AMP 4

JP24

SIG-

SIG+

BATTERY

(+)

JP25

SIG-

SIG+

BATTERY

(-)

AMP 6

JP26

SIG-

2005147

SIG+

JP27

AMP 7

(-)

SIG-

SIG+

AMP 8

JP28

T300422-03-059 ORN

RADIO

RS232

RX TEST

17500919

3

+

4

+

-

2

1

+

-

+

-

T300104-09-004

WHT 4 GA.

T300104-09-001

WHT 4 GA.

T300112-05-005 GRN 12 GA

T300104-10-011 BLK 4 GA

T300112-02-056 RED 12 GA

T300420-05-011 GRN

T300422-03-060 ORN

17500861

RED

BLK

BLK

RED

Federal Signal Corporation

15 AMP

148A107 (REF)

BATTERY BOX CONNECTIONS

RADIO WIRING

T300104-02-010

RED 4AWG

175902A-10

ANTENNA

EQUIPMENT

POLYPHASER

T300104-09-004

WHT 4 GA.

(1 REQUIRED

WITH 2 BATTERIES)

SW1

2

1

RED 4 GAT300104-02-016

122378A

COMMON

OPEN

OPEN

COMMON

122378A

1461504A

C300422-09-143

WHT

VX-4500

NOTES:

1. BATTERY CONNECTIONS ARE MADE DURING SIREN INSTALLATION.

2. WHEN USING ONLY TWO BAT TERIES, DO NOT USE (3) WHITE 4 AWG WIRES (T300104-09-004).

3. LENGTH OF WIRES IN BATTERY CABINET (MEASURED FROM CONDUIT END TO TERMINAL START ±0.5").

T300422-03-060 & T300422-03-061, ORANGE, 36"

T300104-02-016, RED, 13"

T300104-10-011, BLACK, 10.5"

1461503A, 6.5"

A7

BATTERY CABINET

INTRUSION SWITCH

INTRUSION SWITCH

CONTROL CABINET

AND SCREWS AROUND COILED ANTENNA CABLE.

NOTE: TAPE SACK WITH ANTENNA GASKET

+

+ -

PV++BATTERY

+ -

+

LOAD

+ -

SOLAR REGULATOR

RED

++ -- +

WHT

BLK

+ - - + +

RED

BLK

- - + + - -

288995D (PVS220W-24)

RED

BLK

RED

-

+

BLK

RED

BLK

+

-

BLK

55W,12V

110W, 12V 110W, 12V

SOLAR WIRING CONFIGURATIONS

A2

A3

WHT

A4

A5

A6

A6

A6

55W,12V 55W,12V 55W,12V

WHT

BLK

RED

RED

+

-

WHT

BLK

+

-

+

-

+

-

288995 (PVS240W-24)

60W,12V 60W,12V 60W,12V 60W,12V

288996 (PVS220W-24-DSA, PVS220W-24-MOD, PVS220W-24-H-S)

TO SOLAR REGULATOR PV+

TO SOLAR REGULATOR PV-

TO SOLAR REGULATOR PV+

TO SOLAR REGULATOR PV-

A1

+-+ -- + - +

-+ + -

A REL. TO ECO# 06-4033 3/6/06 VT

N/A

AS SPECIFIED

RF

259186A

VT

3/10/06

SC

6/8/06

NONE

WIRING DIAGRAM

2-WAY, SOLAR, ULTRAVOICE

A1 SEE ECO #07-4009 1/25/07 MAF

A2 SEE ECO #07-4054 4/12/07 MAF

A3 SEE ECR #10-7179 12/6/10 VT

A4 SEE ECR #443 2/13/13 BWH

A5 SEE ECR# 2268 8/22/14 VT

A6 SEE ECR# 4142 9/8/15 MAF

A7 SEE ECR #5602 5/31/16 MAF

Otherwise Specied

------

-------

Angles

x.xx

x.xxx

-----

Tolerances Unless

±0.5°

±.015

±.005

Page 32

32

Figure 19 Hawaii UltraVoice Wiring Diagram

1 FUSE 2

200A

SECONDARY CABINET

PRIMARY CABINET

COM

REMOTE ACTIVATION INPUTS

SLOWBLO

RELAY

JP11

F1

JP14

600 OHM

20A

JP12

C4

CHARGER

JP20

RELAY

D2

AMP 5

COM

JP15

JP18

F5

F2

F1F3F4

F8F6F7

COM

SENSOR INPUTS

COM

#1

COM

SPR

COM

INTR

COM

AC

SOL

PTT

600

COM

TEST

SPEAKER

JP29

JP19

JP17

JP16

DIR

-

SPR

#2

+

VISO

SOU

COM

NOR

EAS

WES

24VDC

JP13

T1

C1

10A

F2

SIG-

SIG-

SIG+

SIG+

SIG-

SIG+

SIG+

SIG-

JP23

AMP 3AMP 1

JP21

AMP 2

JP22

AMP 4

JP24

SIG-

SIG+

BATTERY

(+)

JP25

SIG-

SIG+

BATTERY

(-)

AMP 6

JP26

SIG-

2005147

SIG+

JP27

AMP 7

(-)

SIG-

SIG+

AMP 8

JP28

3

+

4

-

+

-

2

1

+

-

+

-

BATTERY BOX CONNECTIONS

SW1

2

1

COMMON

OPEN

OPEN

COMMON

- +

NOTES:

1. OPTIONS SHOWN IN ITALICIZED TEXT FOR REFERENCE.

2. BATTERY, SATELLITE RECEIVER & ANTENNA CONNECTIONS MADE DURING SIREN INSTALLATION.

3. WHEN USING ONLY TWO BATTERIES, DO NOT USE (3) WHITE 4 AWG WIRES (T300104-09-004).

4. LENGTH OF WIRES IN BATTERY CABINET (MEASURED FROM CONDUIT END TO TERMINAL START ±0.5").

T300420-05-011, GREEN, 36"

T300104-02-016, RED, 13"

T300104-10-011, BLACK, 10.5"

1461309A

T300104-02-014 RED 4 GA

BATTERY CABINET

INTRUSION SWITCH

INTRUSION SWITCH

CONTROL CABINET

T300422-03-059 ORN

T300104-09-004

WHT 4 GA.

T300104-09-001

WHT 4 GA.

T300112-05-005 GRN 12 GA

T300104-10-011 BLK 4 GA

T300112-02-056 RED 12 GA

T300420-05-011 GRN

T300422-03-060 ORN

T300104-02-010

RED 4AWG

T300104-09-004

WHT 4 GA.

(1 REQUIRED

WITH 2 BATTERIES)

T300104-02-016 RED 4 GA

122378A

122378A

1751620A

MODEM

1461916A

SHIELD/GND

BLU

GRN

WHT

BLK

ORG

RED

RED/BLK

CELLULAR

ANTENNA

288232A

175902A-26

Q-UV-ISAT or Q-UV-SATCELL1

2881411

1461503A

20 AMP

17500033A

C1

-

BATT

+ -

SOLAR

CONTROLLER

REMOTE

TEMP.

C300422-09-143

C300218-10-266 BLK

T300218-02-235 RED

C300218-10-266 BLK

T300218-02-235 RED

Q-UV-SATCELL1

1751186B

1751186B

1751618A

SATELLITE

RECEIVER

2881412A

RS232 1

CELL

RS232 2

SAT

71400089A-02

71400089A-01

C1

+

SOLAR

TB

1 2

+ + -

110W, 12V

- -

110W, 12V

++ -

RED

A B

24 VOLT SYSTEM: 288996 (PVS220W-24)

288455A

BUSS BAR JUMPER

BLK

RED

RED

BLK

RED

BLK BLK

3 4

RED

BLK

C3

C4

T300214-10-102 BLK

1461309A

Q-UV-SATCELL1

C4

C5

(+)

GND

+23.3V

(-)

CELLULAR SERIAL PORT

JP6

2005762

1 AMP

SATELLITE

SERIAL PORT

CELLULAR

SERIAL PORT

POWER

2 AMP

CELLULAR

POWER

I/O4

I/O2 (+)

RXD

TXD

I/O3

GND

I/O1

SATELLITE

+ - + -

TP2

R7

R4R5R2R3

D3

D2

Q3

D5

R6

TP1

F2

C2

R1

JP5

JP2

F1

D1

C1

D4

Q1

Q2

JP1

JP3

JP4

C REL. TO ECR# 12-8998 5/29/12 VT

N/A

AS SPECIFIED

RF

259298C

VT

5/25/12

RW

12/14/12

NONE

WIRING DIAGRAM, HAWAII

SOLAR IN UV

C1 SEE ECR# 12-9359 8/7/12 VT

C2 SEE ECR# 113 10/12/12 VT

C3 SEE ECR# 768 5/21/13 VT

C4 SEE ECR# 1605 2/12/14 VT

C5 SEE ECR# 2268 8/22/14 VT

Page 33

33

Figure 20 Solar Assembly for the UltraVoice

3

1

2

B2

B3B4

B4

B4

B4

B4

B4

B4

B4

# ONLY QTY 2 ON 1-WAY

## ONLY 1-WAY MODELS

### ONLY 2-WAY MODELS

B2

ITEM NO.

QTY.

PART NUMBER

DESCRIPTION

1 1

288964A-24

SOLAR REGULATOR, MORNING STAR, PROSTAR

2

4

7000A070-12

SCREW, MACH, 10-32, RND HD, PHIL, SS, 3/4

3

1

8600148A-01

BRKT ASSY, SOLAR, PROSTAR, UV

1

1461503A

1

1461504A

WIRE LEAD,SOLAR GND TO MOTHERBOARD

3

C300422-09-143

NT SHWN

1 255379

MANUAL

1 288995

1 2881287

SOLAR BRACKET

1 2881336

KIT, CABLE AND CLAMP, SOLAR

2

7000A427-10

SCREWS,6-32,SS

REF

0

259185

WIRING DIA,UV 1-WAY,SOLAR

REF

0

259186

WIRING DIA,UV 2-WAY,SOLAR

REF

0

8600109

FINAL ASSY,UV 1-WAY

REF

0

8600111

FINAL ASSY, UV 2-WAY

DELETIONS (CONT.)

QTY.

PART NUMBER

DESCRIPTION

1

1751064A-04

CABLE,AC TERMINATED

2###

C300218-09-119

WIRE,CUT,WHT,5"

2###

C300218-10-258

WIRE,CUT,BLK,5"

1###

T300422-02-094

T-WIRE,RED,28"

1###

T300422-06-060

T-WIRE,BLUE,28"

1###

T300422-10-099

T-WIRE,BLACK,28"

1

8549A193A

LIGHTNING PROTECTOR

1

1461243A

WIRE

LEAD,FUSED,POWER

SUPPLY

1

81461875B

LABEL,NAMEPLATE,UL

1

1612875A-05

LABEL, ELECTRICAL

RATINGS

DELETIONS FOR SOLAR OPTION (1-WAY & 2-WAY)

QTY.

PART

NUMBER

DESCRIPTION

1 120816

CHARGER,24V,10A

1

1612393B

LABEL,DIN RAIL,UV

2

229218A

BRKT,T-BLOCK,END

4#

229282A

TERM. BLOCK,1-POLE,35MM

DIN

1##

229283A

CAP,END,TERM BLOCK,1

POLE

1

229288A

GROUND TERM BLOCK,3

POS

1

288810A-04

DIN

RAIL,ALUM,UNCOATED,4.00"

1###

288454B

INPUT MODULE,120V

2

7011A152-06

#8 SHT METAL SCREW,SS

6

7058050A

NUT,MACH SCREW,KEPS 1/420

1

8600112A-01

BRKT ASSY,PWR SUPPLY

MATERIAL DESCRIBED AND INFORMATION CONVEYED IS

PROPRIETARY TO FEDERAL SIGNAL CORPORATION, IS OR

MAYNOT BE COPIED, DIVULGED TO OTHERS, OR USED

FOR MANUFACTURING WITHOUT CONSENT.

CHANGE

DATE

BY

DIVISION

SIGNAL

2645 FEDERAL SIGNAL DRIVE - UNIVERSITY PARK,IL 60466

Federal Signal Corporation

NONE

8600124B

N/A

N/A

SOLAR ASSY,UV

RF

REL TO PROD ECO #05-4142

9/21/05

MAF

0.5

0.015

0.005

REV

REMOVE BURRS, SHARP CORNERS AND EDGES

B1

9/21/05

MAF

7/8/05

B3

SEE ECO #08-2746

2/26/08

VT

MAF

11/22/05

SEE ECO #05-4180

B2

B4

MAF

5/31/16

SEE ECO #5602

Page 34

34

Figure 21 Solar Assembly for the DC Series Siren Control System

UNITS: INCHES

D

A

A

1

B

C

B

2

1

C

D

2

SHEET: 1 OF 1

THIRD ANGLE

PROJECTION

DATE:

DATE:

REMOVE BURRS, SHARP CORNERS AND EDGES

UNIT OF

MEASURE

DRAWN BY:

CHKD. BY:

DRAWING NUMBER

SCALE AT B SIZE:

MATERIAL

FINISH

NAME

S

AFETY &

S

ECURITY

G

ROUP

FEDERAL SIGNAL

2645 FEDERAL SIGNAL DRIVE

UNIVERSITY PARK, IL 60484

ā

0.5

Ā

ā

0.015[ā0.4]

ā

0.005[ā0.12]

------

-----

---

IN[mm]

Angles

x.xx[x.x]

x.xxx[x.xx]

Tolerances Unless Otherwise Specified

BYDATE

CHANGE

REV.

MATERIAL DESCRIBED AND INFORMATION CONVEYED IS PROPRIETARY TO FEDERAL SIGNAL CORPORATION, IS OR

MAY BE THE SUBJECT OF PATENT APPLICATIONS, AND MAY NOT BE COPIED, DIVULGED TO OTHERS, OR USED

FOR MANUFACTURING WITHOUT CONSENT.

7/8/05

MAF

9/21/05

MJF

EA

SOLAR ASSY, DC, 48V

N/A

N/A

8402166C

NONE

ITEM #

QTY. PART NO. DESCRIPTION

1 1 2881240A TS DIGITAL METER

2 1 288812A SOLAR REGULATOR, TS-45

3 4 7000A070-12

SCREW, MACH, 10-32, RND HD, PHIL, SS, 3/4

4 1 7058050A

NUT,MACH SCR,KEPS,1/4-20

* 1 C300214-02-132 CUT WIRE,RED,35"

* 1 C300214-10-092 CUT WIRE,BLACK,35"

** 1 288995 SOLAR KIT,SUNWIZE

REF 0 259187

WIRING DIA,DCB/DCFCB, SOLAR

REF 0 259188 WIRING DIA,DCFCTB, SOLAR

REF 0 8402147 FINAL ASSY,DCFCTB

REF 0 8402148 FINAL ASSY,DCFCB

NOT SHOWN 1 17500033A REMOTE SENSOR

NOT SHOWN 1 255379 MANUAL

NOT SHOWN 1 2881287

SOLAR BRKT ASSY, 55W/60W (4 PANEL)

NOT SHOWN 1 2881336A KIT, CABLE AND CLAMP, SOLAR

5 1 840200308A BRKT ASSY, SOLAR REG MOUNT

* SHOWN ON

WIRING DIAGRAM

** NOT SHOWN, SHIPPED

DIRECT TO CUSTOMER

C1

C2

9/21/05

SEE ECR #6821

12/28/16

MAFC0

VTB2

112/3/07

SEE ECO #07-4186

MAF

11/22/05

SEE ECO #05-4180

B1

B

MAF

REL TO PROD. ECO #05-4143

AEO

5/17/2017

REL FOR ECR #7436

C1

C2

REL FOR ECR #8128

8/8/2017

AEO

DELETIONS FOR SOLAR OPTION (1-WAY & 2-WAY)

QTY PART NO. DESCRIPTION

2 143139A FUSE LEVER

2 143140A FUSE COVER

1 1461361A WIRE LEAD,110V PWR

2 148154A FUSE,10A

1 1461389A WIRE ASSY,BAT CHRGR

1 1612400A LABEL, FC CONTROL

1 1612875A-03 LABEL, UL ELECT. RATING

1 1751064A-04 CABLE,AC FOR BATT CAB.

2 229218A BRKT,BLOCK END

4 229282A TERM BLOCK

1 229288A GROUND TERM BLOCK

2 288782A JUMPER

1 288810A-04 DIN RAIL

2 7011A069-08 SCREW

4 7058050A

KEPS NUT,1/4-20

1 81461875B LABEL, NAMEPLATE

1 840200205 BATTERY CHARGER

1 8549A193A LIGHTNING PROTECT.

1 C300218-09-119 CUT WIRE

1 C300218-10-258 CUT WIRE

C1

3

5

4

1

2

Loading...

Loading...