Federal Signal Corporation Personnel Alerting System Installation And Operation Instructions Manual

Page 1

Federal Signal UltraVoicetm

Personnel Alerting System

Including Models:

UltraVoice Indoor Controller (UVIC)

UltraVoice Audio and Relay Module (UVARM)

UltraVoice Local Operation Console (UVLOC)

INSTALLATION and OPERATION

255364F

4/07 Copyright 2007 Federal Signal Corporation

INSTRUCTIONS

Page 2

Federal Signal UltraVoice

Installation and Operation Manual

SAFETY NOTICES

People’s lives depend on your selection of suitable equipment and installation sites and

your safe installation, service, and operation of our products. Federal Signal recommends the

following publications from the Federal Emergency Management Agency for assistance with

planning an outdoor warning system: 1. The “Outdoor Warning Guide (CPG 1-17), 2. “Civil

Preparedness, Principles of Warning” (CPG 1-14), 3. FEMA-REP-1, Appendix 3 (Nuclear Plant

Guideline), and 4. FEMA-REP-10 (Nuclear Plant Guideline). Contact Federal Warning System’s

Customer Care Center at:

further information about these publications.

It is important to read, understand and follow all instructions shipped with this product. In

addition, listed below are some other important safety instructions and precautions you should

follow.

• If suitable warning equipment is not selected, the installation site for the siren is not selected

properly or the siren is not installed properly, it may not produce the intended optimum

audible warning. Follow Federal Emergency Management Agency (FEMA)

recommendations.

• If sirens or speakers are not activated in a timely manner when an emergency condition

exists, they cannot provide the intended audible warning. It is imperative that

knowledgeable people, who are provided with the necessary information, are available at all

times to authorize the activation of the sirens or speakers.

• When sirens are used out of doors, people indoors may not be able to hear the warning

signals. Separate warning devices or procedures may be needed to effectively warn people

indoors.

• The sound output of sirens is capable of causing permanent hearing damage. To prevent

excessive exposure, carefully plan siren placement, post warnings, and restrict access to

areas near sirens.

• Activating the sirens or speakers may not result in people taking the desired actions if those

to be warned are not properly trained about the meaning of warning sounds. Siren users

should follow FEMA recommendations and instruct those to be warned of correct actions to

be taken.

• A siren or speaker that doesn’t work won’t provide any warning. After installation, service, or

maintenance, test the mass notification system to confirm that it is operating properly. Test

the system regularly to confirm that it will be operational in an emergency.

http://www.federalwarningsystems.com or 1-800-524-3021 for

PLANNING

SAFETY NOTICES

2

Page 3

Federal Signal UltraVoice

Installation and Operation Manual

• If future service and operating personnel do not have these instructions to refer to, the siren

system may not provide the intended audible warning and service personnel may be

exposed to death, permanent hearing loss, or other bodily injury. File these instructions in a

safe place and refer to them periodically. Give a copy of these instructions to new recruits

and trainees. Also give a copy to anyone who is going to service or repair the siren.

People’s lives depend on your safe installation, service and operation of our products. It is

important to read, understand and follow all instructions shipped with this product. In addition,

listed below are some other important safety instructions and precautions you should follow:

INSTALLATION & SERVICE

• Electrocution or severe personal injury can occur when performing various installation and

service functions such as making electrical connections, drilling holes, or lifting equipment.

Therefore experienced electricians in accordance with national, state and any other

electrical codes having jurisdiction should perform installation. All work should be performed

under the direction of the installation or service crew safety foreman.

• The sound output of sirens or speakers is capable of causing permanent hearing damage.

To prevent excessive exposure, carefully plan siren placement, post warnings and restrict

access to areas near the sirens. Sirens and distributed speakers may be operated from

remote control points. Whenever possible, disconnect all siren power including batteries

before working near the siren.

• After installation or service, test the siren system to confirm that it is operating properly.

Test the system regularly to confirm that it will be operational in an emergency.

• If future service personnel do not have these warnings and all other instructions shipped

with the equipment to refer to, the siren or distributed speaker system may not provide the

intended audible warning and service personnel may be exposed to death, permanent

hearing loss, or other bodily injury. File these instructions in a safe place and refer to them

periodically. Give a copy of these instructions to new recruits and trainees. Also, give a

copy to anyone who is going to service or repair the sirens. For additional copies, call the

Federal Warning Systems Customer Care Center at 800-524-3021 or write to them at 2645

Federal Signal Drive, University Park, IL 60466.

OPERATION

• Failure to understand the capabilities and limitations of your siren system could result in

permanent hearing loss, other serious injuries or death to persons too close to the sirens

when you activate them or to those you need to warn. Carefully read and thoroughly

understand all safety notices in this manual and all operations-related-items in all instruction

manuals shipped with equipment. Thoroughly discuss all contingency plans with those

responsible for warning people in your community, company, or jurisdiction.

SAFETY NOTICES

3

Page 4

Federal Signal UltraVoice

Installation and Operation Manual

WARNING

Read and understand the information contained

in this manual, before attempting to install or

service this product.

Pay careful attention to the following notices located on the equipment.

A. NOTICES - EXTERNALLY PLACED

B. NOTICES-INTERNALLY PLACED

SAFETY NOTICES

4

Page 5

Federal Signal UltraVoice

Installation and Operation Manual

Limited Warranty

The Federal Warning Systems Division of Federal Signal Corporation warrants each new product to

be free from defects in material and workmanship, under normal use and service, for a period of two

years on parts replacement and factory-performed labor (one year for Informer, EAS, and Federal

software products) from the date of delivery to the first user-purchaser. Federal Warning Systems

warrants every 2001 & Eclipse Siren (Top of pole only) to be free from defects in material, per our

standard warranty, under normal use and service for a period of five years on parts replacement.

During this warranty period, the obligation of Federal is limited to repairing or replacing, as Federal

may elect, any part or parts of such product which after examination by Federal discloses to be

defective in material and/or workmanship.

Federal will provide warranty for any unit which is delivered, transported prepaid, to the Federal factory

or designated authorized warranty service center for examination and such examination reveals a

defect in material and/or workmanship.

This warranty does not cover travel expenses, the cost of specialized equipment for gaining access to

the product, or labor changes for removal and re-installation of the product. The Federal Signal

Corporation warranty shall not apply to components or accessories that have a separate warranty by

the original manufacturer, such as, but not limited to, batteries.

Federal will provide on-site warranty service during the first 60-days after the completion of the

installation, when Federal has provided a turn-key installation including optimization and/or

commissioning services.

This warranty does not extend to any unit which has been subjected to abuse, misuse, improper

installation or which has been inadequately maintained, nor to units which have problems related to

service or modification at any facility other than Federal factory or authorized warranty service centers.

Moreover, Federal shall have no liability with respect to defects arising in Products through any cause

other than ordinary use (such as, for example, accident, fire, lightning, water damage, or other

remaining acts of god).

THERE ARE NO OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING BUT NOT

LIMITED TO, ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. IN NO EVENT SHALL FEDERAL BE LIABLE FOR ANY LOSS OF

PROFITS OR ANY INDIRECT OR CONSEQUENTIAL DAMAGES ARISING OUT OF ANY SUCH

DEFECT IN MATERIAL WORKMANSHIP.

2645 Federal Signal Drive, University Park, IL 60466

Phone: (800) 524-3021 Fax: (708) 534-4865

Website: http://www.federalwarningsystems.com

TABLE OF CONTENTS

5

Page 6

Federal Signal UltraVoice

Installation and Operation Manual

TABLE OF CONTENTS

Section Page

SAFETY NOTICES.................................................................................................................. 2

1.1 General Description................................................................................................. 10

1.2 Model Number Descriptions.................................................................................... 11

1.3 Standard Feature Descriptions:............................................................................... 11

1.4 Motherboard Description......................................................................................... 17

1.5 Configuration...........................................................................................................17

Unit Type........................................................................................................................18

Unit Address................................................................................................................... 18

RF Frequency................................................................................................................. 19

Single-Tone, Two-Tone Timing...................................................................................... 19

EAS Location Codes ......................................................................................................19

128-bit Encryption Key ...................................................................................................19

Security Key................................................................................................................... 20

User Programs............................................................................................................... 20

Available Functions: .......................................................................................................21

2. SPECIFICATIONS ......................................................................................................... 22

2.1 Electrical.................................................................................................................. 22

2.2 Charger................................................................................................................... 22

2.3 Battery..................................................................................................................... 23

2.4 Controller................................................................................................................. 23

Serial & I2C Ports........................................................................................................... 23

Signaling Formats .......................................................................................................... 23

Audio Output to Amplifiers .............................................................................................. 24

2.5 Motherboard............................................................................................................ 24

Relay Output .................................................................................................................. 24

600 Ohm Balanced Line Port ......................................................................................... 24

Remote Activation, Sensor and Direction Inputs............................................................ 24

Expansion Slot ............................................................................................................... 25

Amplifier Outputs............................................................................................................ 25

Motherboard Connectors ................................................................................................ 25

Indicators........................................................................................................................ 28

Fuses ............................................................................................................................. 28

2.6 UVIC25SD............................................................................................................... 28

2.7 Controller Front Panel Controls, Jacks, Switches and Indicators............................ 30

Controls:......................................................................................................................... 30

Jacks:............................................................................................................................. 30

Indicators:....................................................................................................................... 31

Control Unit Connector Configuration............................................................................. 32

2.8 Audio Power Amplifier Modules Model (UV400) ..................................................... 34

2.9 Audio and Relay Output Card Option (2005300)..................................................... 35

Connectors..................................................................................................................... 35

TABLE OF CONTENTS

6

Page 7

Federal Signal UltraVoice

Installation and Operation Manual

Indicators........................................................................................................................ 36

2.10 Model UVLOC......................................................................................................... 37

UVLOC Connectors........................................................................................................ 37

2.11 Alarm Panel Interface.............................................................................................. 37

Alarm Panel Interface Connectors.................................................................................. 38

2.12 Environmental ......................................................................................................... 39

2.13 Physical................................................................................................................... 39

3. UVIC OPERATION......................................................................................................... 40

3.1 Hardware General Description................................................................................ 40

3.2 Manual Activation.................................................................................................... 40

3.3 Local Public Address............................................................................................... 41

3.4 Relay Output........................................................................................................... 41

3.5 600 Ohm I/O............................................................................................................ 41

3.6 Remote-Landline Activation .................................................................................... 41

3.7 Sensor Inputs and Isolated Sensor Power.............................................................. 42

3.8 Spare Sensor Inputs................................................................................................ 43

3.9 Two-Way Status Monitoring.................................................................................... 43

3.10 Quiet Test................................................................................................................ 43

B. Finding Faults.......................................................................................................... 43

3.11 Battery Charger....................................................................................................... 44

3.12 UVLOC.................................................................................................................... 45

4. SYSTEM PLANNING ..................................................................................................... 46

4.1 Control Unit.............................................................................................................46

4.2 Speaker Placement................................................................................................. 46

4.3 UVLOC Placement.................................................................................................. 47

5. INSTALLATION.............................................................................................................. 48

5.1 UVIC Siren Controller Installation Reference Drawings .......................................... 48

5.2 General Mounting Guidelines For All Applications ..................................................52

5.3 UVIC Installation Material List and Installation Guidelines ...................................... 53

Concrete or Filled Cement Block Wall Mounting Guidelines: ......................................... 53

Hollow Block Wall Mounting Guidelines: ........................................................................ 53

Wood Stud Wall Mounting Guidelines:........................................................................... 54

Metal Stud Wall Mounting Guidelines:............................................................................ 55

5.4 Installer Supplied UVIC Electrical Installation Material List ..................................... 56

5.5 Electrical Connections............................................................................................. 57

Grounding Requirements ...............................................................................................57

AC Power Connections ..................................................................................................57

Wiring Guidelines for 120VAC Electrical Service ........................................................... 57

Wiring Guidelines for 240VAC Electrical Service ........................................................... 58

Battery Connections....................................................................................................... 58

5.6 Antenna Types........................................................................................................ 59

5.7 Cabinet Mounted Magnetic Base Antenna Installation............................................ 59

5.8 Remote Mounted Magnetic Base Antenna Installation............................................ 59

5.9 Yagi Antenna Installation......................................................................................... 59

TABLE OF CONTENTS

7

Page 8

Federal Signal UltraVoice

Installation and Operation Manual

Final VSWR Tuning........................................................................................................ 60

Yagi Antenna Mounting.................................................................................................. 61

5.10 Omni Antenna Installation .......................................................................................61

5.11 Speaker Connections.............................................................................................. 65

5.12 PA Audio Connections ............................................................................................ 65

5.13 Contact Closure Inputs............................................................................................ 65

5.14 Optional UVARM Connections................................................................................ 65

5.15 Optional UVLOC Connections and Wall Mounting.................................................. 66

5.16 External 24VDC Power Connections....................................................................... 66

5.17 600 Ohm I/O Connections....................................................................................... 66

Control Connections....................................................................................................... 66

Audio Connections.........................................................................................................66

5.18 Turning Power On...................................................................................................67

6. PRE-OPERATION CHECKOUT AND TEST.................................................................. 71

6.1 Visual Inspection..................................................................................................... 71

6.2 Amplifier and Speaker Pre-Operation Checkout ..................................................... 71

6.3 Radio Transceiver Adjustment Procedure............................................................... 72

6.4 600 Ohm Level Adjustment Procedure for Communications................................... 72

6.5 600 Ohm Adjustment Procedure for External Audio Source ................................... 73

6.6 Control and Status Monitoring................................................................................. 73

6.7 Optional UVLOC ..................................................................................................... 73

7. MAINTENANCE............................................................................................................. 76

7.1 Control Unit Preventive Maintenance...................................................................... 77

7.2 General Maintenance.............................................................................................. 77

Signal Operational Check............................................................................................... 77

Battery Check................................................................................................................. 77

7.3 Troubleshooting ...................................................................................................... 78

8. OPTIONS....................................................................................................................... 79

8.1 Radio Control.......................................................................................................... 79

8.2 Digital Voice Recording...........................................................................................79

8.3 UVIC25ST Option.................................................................................................... 79

8.4 UVIC25SD Option................................................................................................... 79

8.5 UVARM Option........................................................................................................ 79

8.6 UVLOC Option.......................................................................................................80

8.7 Installation of User Supplied Radio Receivers ........................................................ 80

9. Final Assembly Drawing and Parts List.......................................................................... 82

TABLE OF CONTENTS

8

Page 9

Federal Signal UltraVoice

Installation and Operation Manual

TABLE OF FIGURES

Figure 1.1 - UVIC Parts Layout.............................................................................................. 13

Figure 1.2 – Control and Amplifier Identification.................................................................... 14

Figure 1.3 – UVARM Identification ........................................................................................ 15

Figure 1.4 – UVLOC Identification......................................................................................... 16

Figure 2.1 - Motherboard Outline Drawing ............................................................................ 29

Figure 5.1 - Typical UVIC Installation Drawing...................................................................... 48

Figure 5.2 - UVIC Cabinet Dimensional Outline Drawing ......................................................49

Figure 5.3 – UVIC Wiring Diagram........................................................................................ 50

Figure 5.4 – UVIC Battery Connections................................................................................. 51

Figure 5.5 - Yagi Antenna Installation Example..................................................................... 62

Figure 5.6 - Omni Antenna Installation Example ...................................................................63

Figure 5.7 – Antenna Grounding Example ............................................................................ 64

Figure 5.8 – UVIC Strobe and Speaker Wiring...................................................................... 67

Figure 5.9 - UVLOC Interface Wiring Diagram ......................................................................68

Figure 5.10 - UVLOC Dimensional Outline............................................................................ 69

Figure 5.11 – UVIC25SD Wiring Diagram .............................................................................70

Field Test Data Sheet............................................................................................................ 75

Figure 9.1 – UVIC Final Assembly and Parts List (Page 1 of 2)............................................ 82

Figure 9.2 – UVIC25ST Wiring Detail.................................................................................... 84

TABLE OF CONTENTS

9

Page 10

Federal Signal UltraVoice

Installation and Operation Manual

SECTION I

1.1 General Description

The UltraVoice Indoor Controller (UVIC) is designed to fulfill the need for an indoor

electronic controller that is smaller and less expensive than the full size UltraVoice

outdoor warning siren controller. It shares the same control board and amplifiers as the

standard UltraVoice but is limited to 800 total Watts of amplifier power, and uses a

single, wall-mountable NEMA1 / UL Type 1 rated enclosure that has a built-in lock.

The use of smaller, sealed VRLA AGM type batteries minimizes battery out-gassing and

makes the controller better suited for indoor operation.

Model UVARM: The UVIC supports an optional Audio and Relay Output Module (model

UVARM) that provides three audio outputs and four relay outputs to enable the UVIC to

be connected to existing PA systems or other auxiliary devices.

Model UVLOC: An optional Local Operation Console (model UVLOC) enables users to

control the UVIC from an easy to use pushbutton control panel. The panel is connected

to the UVIC with a standard CAT5 network cable and may be located up to ½ mile away

from the UVIC controller. The UVLOC is remotely powered from the UVIC and requires

no local power source of it’s own. The panel measures only 10” x 4.75” x 3” (L x W x D)

and is easily wall mounted. The UVLOC provides control for 7 digital recordings: Live

P.A., P.A. Recording from an integrated microphone, Recorded P.A. Playback, and two

Auxiliary user programmable functions.

Model UVIC25ST: An optional 25 volt step-down transformer may be required to

convert 70 volts to 25 volts, depending on location and installation.

Model UVIC25SD:

convert 70 volts to 25 volts, depending on location and installation. The UVIC25SD

includes two step-down transformers in a NEMA 4X fiberglass enclosure.

Model UVIC: The amplifiers and optional equipment are all modularly constructed to

ease removal without disconnecting a large number of wires. In most instances, field

service is limited to replacement of a slide out module, which can be performed by nontechnical personal with only a screwdriver.

Activation codes, command sequences, and operating parameters are uploaded from

an IBM compatible computer through the RS232 port located on the front panel or over

the radio channel with the Federal Commander Digital System. All user information is

stored in non-volatile FLASH memory, immune to power and battery failure.

Refer to Figures 1.1, 1.2, 1.3 and 1.4 for reference.

An optional 25 volt step-down transformer may be required to

GENERAL DESCRIPTION

10

Page 11

Federal Signal UltraVoice

Installation and Operation Manual

1.2 Model Number Descriptions

All UVIC models are set up for 2-way control and status monitoring using the Federal

Commander Digital Control system including a 13.6V radio power supply and antenna

lightning protector. All models include 8 minutes of digital voice storage. Custom digital

voice recording requires a model DVR. All of the following models are available in a

240VAC version by adding a 240 to the model number i.e.: UVICH240.

CONTROLLER OPTIONS UVIC MODEL #

NO RADIO (RF) UVIC

UHF BAND Transceiver UVICU

HIGH BAND Transceiver UVICH

LOW BAND Transceiver UVICL (Special Order)

1.3 Standard Feature Descriptions:

• Seven standard warning signals

• Up to 16 digitally stored voice messages; 8 minutes total recording time

• Local push-button control

• Local microphone for PA with hanger mounted in cabinet

• 8 remote contact closure inputs for activation

• Single tone, 2-tone, DTMF, EAS and MSK decoders for remote siren control

• MSK modem with 128-bit encryption for remote status monitoring over radio or

wire

• 600 ohm I/O for wire-line control and status monitoring

• 15A relay output

• Quiet test - siren status monitoring

• Zoning - up to 8 zones per control cabinet for selective control of speaker outputs

• Power control ramps up siren or speaker volume for added safety, custom volume

settings, and low power testing

• Stackable siren or distributed speaker functions enable user pre-defined warning

scenarios

• Low band, VHF, or UHF radio transceiver options

• Modular design - no inter-board wiring, easy field service

• Windows

®

based siren programming software (optional)

• Cabinet:

- Single NEMA1/UL type 1, powder coated steel cabinet

- Single lockable door hasp that can be easily opened without tools

- Wall mountable

- 8 multi-size knockouts for conduit entrances

- Bulkhead mounted type N female antenna connection

GENERAL DESCRIPTION

11

Page 12

Federal Signal UltraVoice

Installation and Operation Manual

• Amplifiers (Model UV400):

- 2 amplifier slots for 400 Watt amplifiers, 70Vrms

- Optionally, one UV400 with a UVIC25ST (25Vrms step-down transformer)

- 12 speaker pair connections per amplifier

• Audio and Relay Output Module (UVARM) Option:

- Balanced 33 ohm output

- Balanced 600 ohm output

- Selectable balanced or single-ended 600 ohm line-level output

- Four SPDT relay outputs

• Local Operation Console (UVLOC and UVLOC-IM) Option:

- Operator interface panel for controlling 7 digital messages, Live P.A., Record

and Playback functions, plus two user programmable functions.

- Remotely powered from the UVIC controller

- LED status indicators

- Balanced 600 ohm output

- CAT5 wiring interface

• Batteries:

- 44 A/H (min), sealed VRLA AGM type

- Over 45 minutes full sounding battery backup without AC power

• Battery Charger:

- 24 VDC, 10A

- Temperature compensated

GENERAL DESCRIPTION

12

Page 13

Federal Signal UltraVoice

Installation and Operation Manual

MOUNTING HOLES

UV400 AMPLIFIERS

UVARM I/0 MODULE

(OPTIONAL)

(TOP & BOTTOM FLANGES)

CONTROL MODULE

INTRUSION SWITCH

BATTERY CHARGER

230/115VAC STEPDOWN

TRANSFORMER

(240 MODELS ONLY)

AC POWER

FIELD WIRING

TYPE N-FEMALE

ANTENNA CONNECTOR

TRANSCEIVER

DC POWER

CONNECTIONS,

FUSING & SPEAKER

FIELD WIRING.

(BEHIND COVER PLATE)

(2) 12VDC

BATTERIES

CONDUIT KNOCKOUTS

Figure 1.1 - UVIC Parts Layout

GENERAL DESCRIPTION

13

291327A

NOTE: CABINET DOOR

NOT SHOWN

Page 14

Federal Signal UltraVoice

Installation and Operation Manual

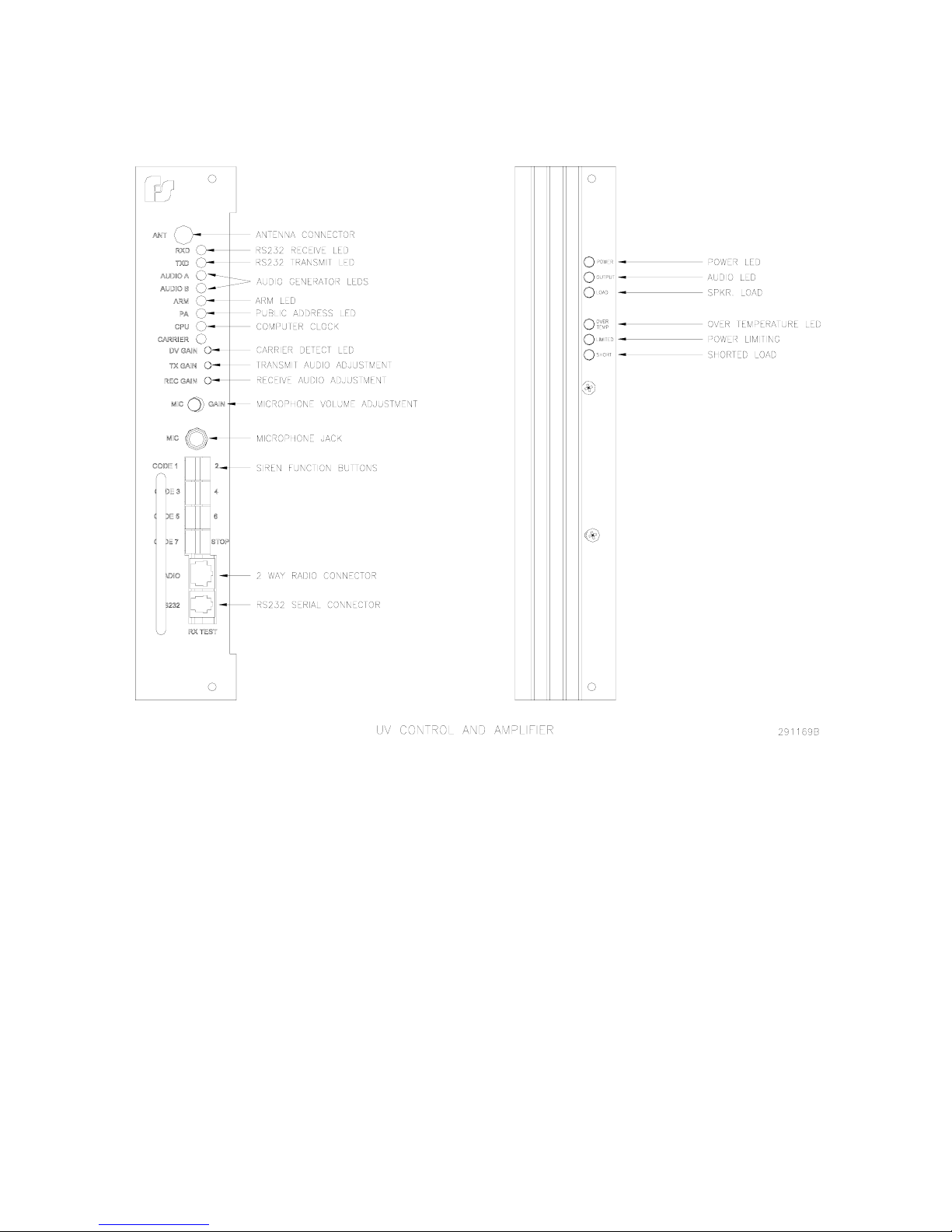

Control Amplifier

Figure 1.2 – Control and Amplifier Identification

GENERAL DESCRIPTION

14

Page 15

Federal Signal UltraVoice

Installation and Operation Manual

1.

Figure 1.3 – UVARM Identification

GENERAL DESCRIPTION

15

Page 16

Federal Signal UltraVoice

Installation and Operation Manual

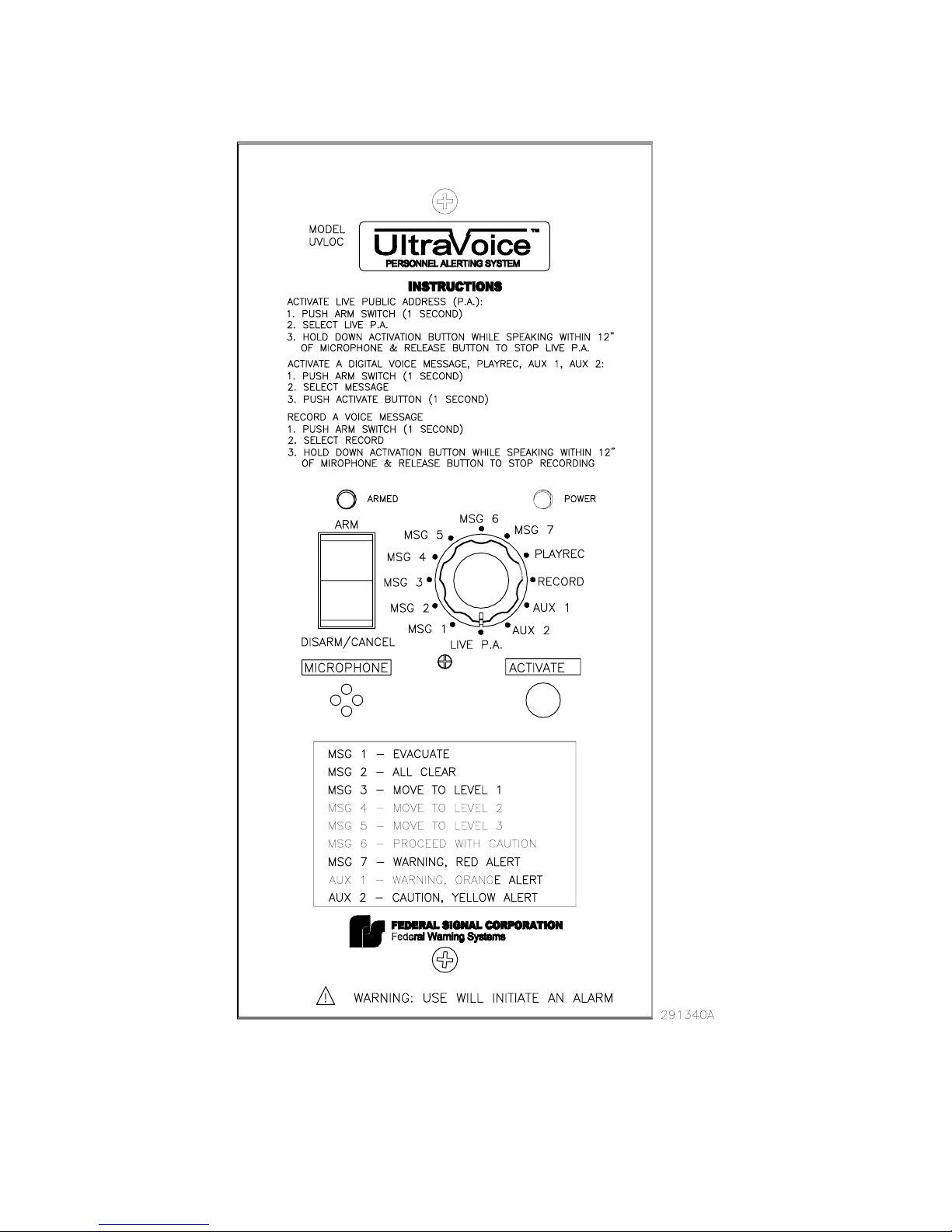

Figure 1.4 – UVLOC Identification

GENERAL DESCRIPTION

16

Page 17

Federal Signal UltraVoice

Installation and Operation Manual

1.4 Motherboard Description

The Motherboard for the UVIC is a scaled down 800 Watt version of the 3200 Watt

UltraVoice product. The board is primarily a passive back plane that provides the

electrical connections between the Microprocessor Control board, the Audio and Relay

output board, and the UV400 amplifiers. In addition, it provides connections for field

wiring and a relay output.

The UVIC Motherboard is limited to two amplifier slots. It uses the same style

connectors as the UltraVoice except for the removable fused 50A, 24VDC power input

and the 50A, 24VDC output connector.

The Motherboard has a fused normally open relay output. The relay is normally

programmed to close while a control function is active. An LED indicator turns on when

the relay is active.

Capacitor C1 and inductor T1 are used to filter the 24VDC power source. This filtered

power is fused by F2 and is routed to JP1, JP2, JP6 and JP7.

1.5 Configuration

Each modular UltraVoice siren contains the following configuration parameters, which

are configured by the user:

1. Unit Type

2. Unit Address (see below)

3. RF Frequency

4. Single-Tone or Two-Tone Timing (A-time, B-time, S-time)

5. EAS Location Codes

6. 128-bit Encryption Key

7. Security Key

GENERAL DESCRIPTION

17

Page 18

Federal Signal UltraVoice

Installation and Operation Manual

Unit Type

The Unit Type is set to the type of siren this unit is controlling, and is usually determined

by the number of cells in the speaker array. When setting up the unit type, the user

selects from a menu with the following choices:

UV1 1 - UV400 Amplifier, 400 Watts total power

UV2 2 - UV400 Amplifiers, 800 Watts total power

Unit Address

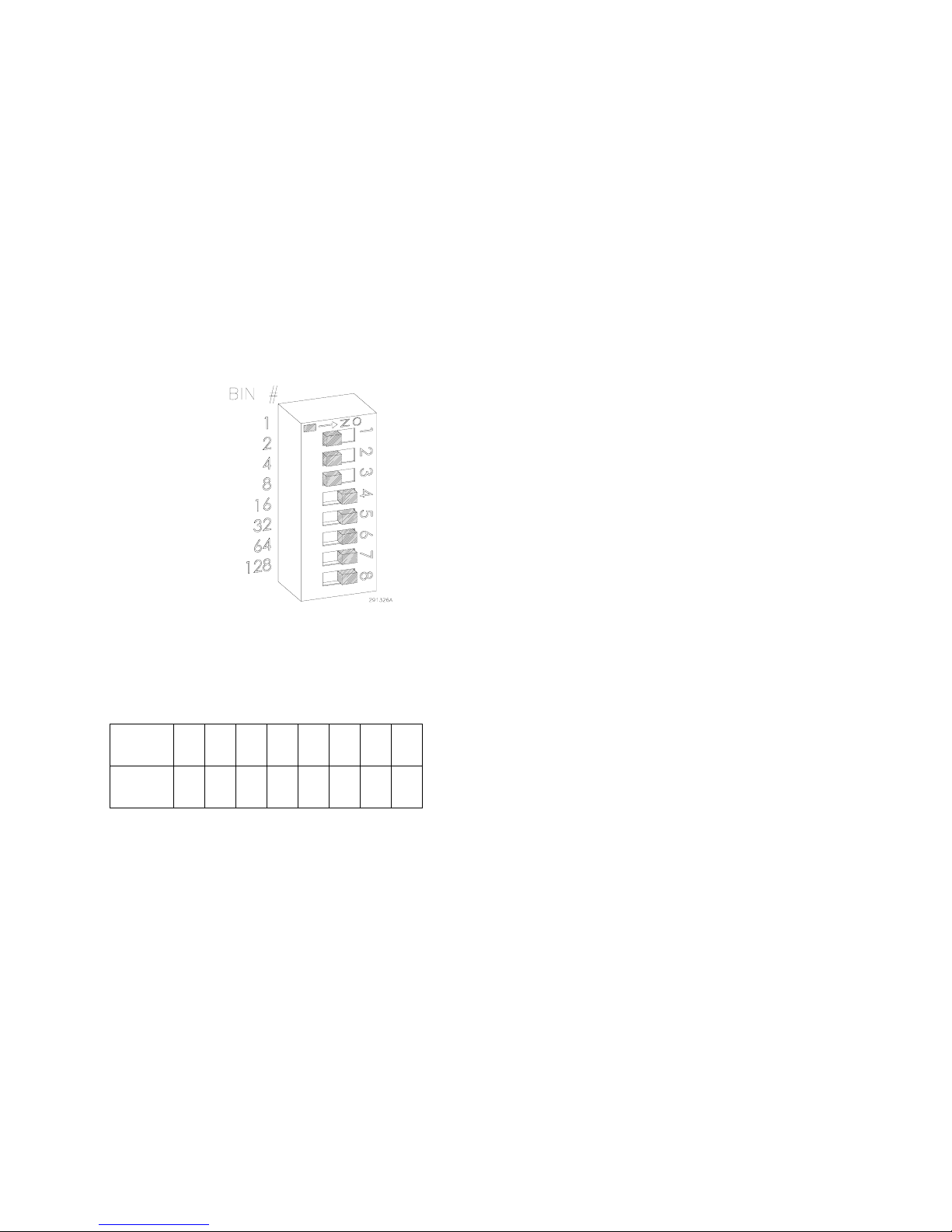

Address Switch

The Unit Address is a three-digit number with a range of 001-255. The unit address is

set via dipswitch S1. S1 Off position indicates active position. Add binary active switch

positions to get ID address.

Switch

number 1 2 3 4 5 6 7 8

Binary

number

1 2 4 8 16 32 64 128

Example: Switch number 1, 2 & 3 is binary number 1, 2 & 4, which when added, would

equal unit address 7.

Programming details are in the software manual. The ID address is stored at power up

of the controller. If the ID address is changed, the power (battery and AC) must be

turned off and then on.

GENERAL DESCRIPTION

18

Page 19

Federal Signal UltraVoice

Installation and Operation Manual

RF Frequency

For units equipped with the optional integral radio receiver, the RF Frequency

configuration parameter sets the frequency of the radio channel. Changing this

parameter from its factory setting may require re-alignment of the radio for maximum

performance. The value entered must fall within the range specified for the receiver

band equipped.

Single-Tone, Two-Tone Timing

For Two-Tone activated units, the Two-Tone Timing parameters set up the time

duration of the activation tone codes. The three parameters, A-Time, B-Time, and STime; sets the time duration for the A-tone, B-tone, and Single-Tone respectively. Note:

The Two-Tone timing parameters are minimum values only. The actual tone times may

be longer than the specified times.

EAS Location Codes

Up to three location codes may be assigned for EAS activation. For activation to occur,

the location code of the received EAS message must match one of the three assigned

codes.

Units cannot be programmed for both Tone and EAS activation at the same time.

Therefore, when using EAS decoding, the A-Time, B-Time, and S-Time parameters

above must be set to zero. The UVIC is capable of being programmed for EAS, DTMF

and Federal Digital decoding at the same time. Refer to www.fcc.gov for further

information about EAS messages.

128-bit Encryption Key

For MSK activated units, 128-bit data encryption provides security against malicious

operation or monitoring. The 128-bit key is programmed during the flashing of the

microprocessor and must match the encoder (SS2000D or SFCDWARE) being used to

activate the unit. A key value of zero disables 128-bit encryption and must be used if the

encoder does not support 128-bit encryption. All sites in the system must use the same

encryption key.

GENERAL DESCRIPTION

19

Page 20

Federal Signal UltraVoice

Installation and Operation Manual

Security Key

For MSK activated units, the Security Key is a unique number assigned to the system

that prevents nearby systems operating on the same RF frequency from interfering. Like

the 128-bit encryption key, the Security Key is programmed during the flashing of the

microprocessor and must match the encoder. The exception is a key value of 65535

(the default), defined as an “open” system and will communicate with all encoders

regardless of the encoder’s key setting.

User Programs

The UVIC has the capacity to store up to fifty (50) user programs. Each user program

contains the following elements:

1) Optional DTMF Activation Code

2) Optional Two-Tone Activation Code

3) Optional EAS Event Code

4) List of up to 20 functions

The ability to assign more than one function to each activation code or user program is

a new feature not previously found in electronic sirens. This allows the user to run a

sequence of functions without sending additional activation commands, greatly

enhancing flexibility while reducing operator involvement and communication channel

traffic.

GENERAL DESCRIPTION

20

Page 21

Federal Signal UltraVoice

Installation and Operation Manual

Available Functions:

Arm

Disarm

Report

Master Reset

Cancel

PA Output

Quiet Test

Low Power Mode

Hi Power Mode

Zone A (Rotating Sirens Only)

Zone B (Rotating Sirens Only)

Zone C (Rotating Sirens Only)

Zone D (Rotating Sirens Only)

Wail

Pulsed Wail

Alt Wail

Steady

Pulsed Steady

Alt Steady

Auxiliary (Chime)

Delay

Digital Voice (1-16)

Amp/Audio Zone Control

Power

Report

Record PA Message

Play Recorded PA Message

RelayN On (N = Relay#)

RelayN Off (N = Relay#)

The SFCDWARE program is required to configure the UVIC. Refer to the SFCDWARE

Reference Manual for a full description of all available functions.

GENERAL DESCRIPTION

21

Page 22

Federal Signal UltraVoice

Installation and Operation Manual

2. SPECIFICATIONS

2.1 Electrical

AC Input Voltage 120 or 240VAC 50-60Hz*

(*two separate models)

AC Input Current 5 amps maximum

Battery Input Voltage 20-28VDC, 24 volts (nominal)

Battery Current 120 mA standby current,

Battery Capacity >45 minutes continuous operation without AC

Stand By Time >72 hours (3 days) including 2-way radio

(with 5-minute full signal reserve min.)

SECTION II

+18 to 22 amps for each amplifier module

running, 50A maximum

power

2.2 Charger

Current Limit Protected with automatic recovery

EMI/RFI Filtering Meets FCC requirements

Input 115VAC (50-60Hz), 3.5A maximum

Output Voltage 26 – 30VDC (temperature compensated)

Output Current 0 -10 amps DC

SPECIFICATIONS

22

Page 23

Federal Signal UltraVoice

Installation and Operation Manual

2.3 Battery

Battery Voltage (72F) 27.2VDC nominal

Recommended Batteries: NorthStar model: NFB12-180

HAZE model: HZB12-44

Type VRLA

Rating 44A/H minimum

CAUTION: Substituting batteries may be hazardous and will void warranty.

Use specified batteries only.

2.4 Controller

Serial & I2C Ports

Serial Port Protocol RS232C 1200,N,8,1

I

2

C Port Protocol Philips Standard I2C

Signaling Formats

Number of codes Up to 50 activation codes max.

Two-Tone Sequential or Single Tone 282Hz - 3000Hz

0.5 sec (A) - .25 sec (B) minimum

to 8 sec maximum

DTMF 3 to 12 digits standard

50ms/50ms timing or greater

AFSK 1200,N,8,1 (MSK 2-way modem)

EAS AFSK, 520.83 baud

Modem Tones 2083.3Hz and 1562.5Hz

Number of functions allowed stacked

under each code Up to 20

SPECIFICATIONS

23

Page 24

Federal Signal UltraVoice

Installation and Operation Manual

Audio Output to Amplifiers

Output Voltage Swing >9V peak-to-peak (p-p)

Maximum Load 600 ohms

Total Harmonic Distortion < 10% w/1KHz sine-wave

2.5 Motherboard

Relay Output

Contact Rating 30VDC, 15A

600 Ohm Balanced Line Port

Audio Input Level 0.10 to 2 volts p-p to make

1 volt p-p TP10

Audio Output Level 0.25 to 2.0 volts p-p

Remote Activation, Sensor and Direction Inputs

Number of Remote Activation Inputs 8

Number of Remote Sensor Inputs 4

Number of Direction Sense Inputs 4

Input Type Optically isolated activated by

Dry contact closure < 2 k ohms

SPECIFICATIONS

24

Page 25

Federal Signal UltraVoice

Installation and Operation Manual

Expansion Slot

The expansion slot contains the same connector pin-out as the controller slot.

Signals available:

Two I2C Ports

600 Ohm Balanced Port

+5VDC

+24VDC

PTT

AUDIO-A and AUDIO-B

Open-Collector Output (for Rotator Relay)

Charger Indicator

4 Remote Sensor Inputs

8 Remote Activation Inputs

4 Direction Sensor Inputs

Amplifier Outputs

Number 12 speaker connection/amp

Rating 22-14 AWG

Battery Connection 50A at 30VDC

Remote Power Output 50A at 30VDC

Radio Power Output 20A at 30VDC

(To 12V DC-DC converter - radio fused at 15 amps)

Motherboard Connectors

CONNECTOR DESIGNATION PURPOSE

JP1 ULTRAVOICE Controller Interconnect

JP2 Expansion Port/Audio Relay Output Port

JP3 Amplifier 1 Interconnect

JP4 Amplifier 2 Interconnect

JP5 24VDC Battery Input, fused @ 50 amps

Pin 1 Ground

SPECIFICATIONS

25

Page 26

Federal Signal UltraVoice

Installation and Operation Manual

Pin 2 24VDC

JP6 Unfiltered 24VDC Output (for accessories)

Pin 1 Ground

Pin 2 24VDC

JP7 Filtered 24VDC Output (for radio power 12V

DC-DC converter)

Pin 1 Ground

Pin 2 +24VDC

JP8-JP10 Not Used

JP11 20A DC, Normally Open Relay Output:

JP12 600 ohm Transformer Balanced Audio I/O

-See controller JP8 jumper

- Requires PTT @ JP15-10

JP13 Filtered 24VDC Power Output

Pin 1 Ground

Pin 2 +24VDC

JP14 Remote Activation Input

Pins:

1,10 ISO Ground

2 Function 1

3 Function 2

4 Function 3

5 Function 4

6 Function 5

7 Function 6

8 Function 7

9 Function 8

JP15 Sensor Inputs

Pins:

1,3,5,7,9,11 ISO Ground

2 Spare #1

4 Intrusion

6 Solar

8 AC Power

10 600 Ohm PTT

12 Spare #2

JP16 Isolated Power Supply

SPECIFICATIONS

26

Page 27

Federal Signal UltraVoice

Installation and Operation Manual

Pins:

1 5 (-)

2 5 (+)

- 150mA max current

for external equipment

JP17 Spare Sensor Input

Pins:

1 ISO Ground

2 SPR3 -active low

3 SPR4 -active low

4 SPR5 -active low

5 SPR6 -active low

JP18 Expansion Port, Secondary Cabinet

Pins:

1 Ground

2 I2C VCC 5

3 Serial Clock 2

4 Serial Data 2

5 Amplifier Audio Signal 1

6 Amplifier Audio Signal 2

JP19 Test Speaker (listen to receive audio)

Pins:

1 Receive Audio (same as TP6 on control

board)

2 Ground

JP20 Charger Sensor Input

Pins:

1,3 Ground

2 Input from Charger

-See JP4 on controller board

JP21 Amplifier 1 Output

Pins:

1 - 12 SIG -

JP22 Amplifier 1 Output

Pins:

1 - 12 SIG +

JP23 Amplifier 2 Output

Pins:

1 - 12 SIG -

SPECIFICATIONS

27

Page 28

Federal Signal UltraVoice

Installation and Operation Manual

JP24 Amplifier 2 Output

Pins:

1 - 12 SIG +

JP29 Expansion Port, Primary Cabinet

Pins:

1 Ground

2 I2C VCC 5

3 Serial Clock 1

4 Serial Data 1

5 Amplifier Audio Signal A

6 Amplifier Audio Signal B

Indicators

D2 Relay Output LED

Fuses

(F1) Relay Fuse @JP11 AGC 20A, 40VDC

(F2) 24VDC Output @JP13 AGC 10A, 32VDC

(F3) 24VDC Input @JP5 JJN-50L, 50A, 160VDC

2.6 UVIC25SD

Input Voltage 70VAC rms

Output Voltage 25VAC rms

Power Rating 400 Watts

SPECIFICATIONS

28

Page 29

Federal Signal UltraVoice

Installation and Operation Manual

SPECIFICATIONS

29

Figure 2.1 - Motherboard Outline Drawing

Page 30

Federal Signal UltraVoice

Installation and Operation Manual

2.7 Controller Front Panel Controls, Jacks, Switches and Indicators

Controls:

DV GAIN Internal Digital Voice Level sufficient to drive

TP1 or TP2 into clipping

TX GAIN Transmitted Audio Adjustable from

50mv to 1 volt peak-to-peak (p-p)

REC GAIN Received Audio Level 150 mV to 3 volts p-p

MIC GAIN Local PA Level range sufficient to drive

amplifiers into clipping w/50 mV nominal input

level

Jacks:

MIC 10k ohms input impedance,

50mv nominal input level

XCVR External Receiver or Transceiver

Receive audio level required to 150 mV to 3 volts peak-to-peak

make 1 volt peak to peak at

TP10

Transmit Audio Output 50mv to 3 volt peak-to-peak

Carrier Detect Input Less than 1 volt DC to make active

PTT Output Active low, will sink 500 mA maximum

12Vdc +/- 0.2 volts, 1.0 amps maximum

Ground 1.5 amps max current capacity

2

I

C 5 volts peak-to-peak +/- 1 volt input

5 volts DC +/- .2 volts 250 mA

Ground 250mA maximum sink

RS232 Serial Port RS232 standard, 1200 baud,N,8,1

SPECIFICATIONS

30

Page 31

Federal Signal UltraVoice

Installation and Operation Manual

Manual Activation Switches: QTY 8, activate with a hold time >0.50 seconds

Indicators:

RXD Receive Serial Data & receipt of

radio channel modulation

TXD Transmit Serial Data & DTMF & Digital

AUDIO A Audio present on Channel A

AUDIO B Audio present on Channel B

ARM Unit Armed indicator

PA Public Address mode indicator

CPU Microprocessor Heartbeat

CARRIER RF Carrier indicator on w/carrier

present

SPECIFICATIONS

31

Page 32

Federal Signal UltraVoice

Installation and Operation Manual

Control Unit Connector Configuration

Refer to tables below for description of connectors in control assembly.

Connectors for 2005141 PCB

CONNECTOR DESIGNATION PURPOSE

JP1 On-Board Receiver Module Connector

Pins:

1 Ground

2 +8V

3 Clock

4 Data

5 Latch Enable

6 Carrier Detect Not

7 De-Emphasized Receive Audio

8 Flat Receive Audio

JP2 Inter Board Connections

JP3 SINAD

Pin 1: Ground

Pin 2: SINAD

JP4 Battery Charger Sense:

-Jumper out: used with battery charger

Pass on >3VDC@JP20-2

-Jumper in: Used with solar, Pass on 1

VDC less than battery voltage@JP20-2

JP5 Short to force Carrier Detect

JP6 External Radio Connector

Pins:

1 RX Audio In

2 TX Audio Out

3 Carrier Detect

4 PTT

5,7 12VDC for Radio

6,8 Ground

1 Carrier Detect

2 Ground

SPECIFICATIONS

32

Page 33

Federal Signal UltraVoice

Installation and Operation Manual

Connectors for 2005141 PCB – Continued

CONNECTOR DESIGNATION PURPOSE

JP7 CTCSS Connector

Pins:

1 RX Audio In

2 Ground

3 8VDC for CTCSS Board

4 Audio Switch

5 TX CTCSS Tone

JP8 600 Ohm Configuration Jumper

-See motherboard JP15 and JP12

Pins: Jumpered is active

2-3 Activation audio from JP12

1-2 PA mode

- External audio source at JP12

- Level adjusted by R111

JP9 Receiver Priority

Pins:

1-3 External Receiver Priority

2-4 Internal Receiver Priority

JP10 Digital Disable

Jumper Pins 1-2 to disable Digital

Decoder

JP11 SINAD

Jumper Pins 1-2 to enable SINAD Board

Note: JP9 Must have both 1-3 & 2-4

jumpered when SINAD is used

J1 Microphone Jack

Tip Audio In

Ring PTT

Sleeve Ground

SPECIFICATIONS

33

Page 34

Federal Signal UltraVoice

Installation and Operation Manual

2.8 Audio Pow er Amplifier Modules Model (UV400)

Input voltage 24VDC nominal

28VDC maximum

Input Current Siren mode @ 24VDC w/1KC square-wave

into 11 ohms: <20 amps

Input Current Voice Mode @ 24VDC w/1KHz tone set to 67VRMS

into 11 ohms: <24 amps

Standby current at amps turned off <10 milliamps

Efficiency >90% - siren mode

>80% - voice mode

Output voltage into 11 ohms @1KHz 67VRMS minimum - siren mode

and 24VDC nominal operating voltage 67VRMS minimum - voice mode

Input impedance 100K ohms

A to D sensor accuracy < +/- 10%

Duty Cycle, Continuous Signaling Times

Siren Mode 30 minutes

Digital Voice or PA 30 minutes(depending on signal source)

Audio distortion < 10% - voice mode – below clipping

Frequency response +/- 3dB, 300 – 3000Hz

Power Low Power mode < 5 Watts per amplifier

Ripple on power supply w/all amps

running at rated power in siren mode 0.5 volt peak-to-peak maximum

SPECIFICATIONS

34

Page 35

Federal Signal UltraVoice

Installation and Operation Manual

2.9 Audio and Relay Output Card Option (2005300)

Input voltage 13.5 - 30

Input current 200 mA maximum

Balanced 33 ohm output Adjustable from 0.2 – 1.9VRMS

Balanced 600 ohm output Adjustable from 0.2 – 3VRMS or

-12 to +11dB, surge protected

Single-ended or balanced Adjustable from 0.2 – 3VRMS

Line-level/600 ohm output

Relay outputs 4 SPDT

Contact rating 20A @ 30VDC with NO & NC contacts

Connectors

Wire Size All front panel connectors 22-14 AWG

P1, Back plane

48 pin EPT male card edge connector

JP1, 33 ohm audio output

1 & 2 balanced output

JP3, 600 ohm audio output

1 & 2 balanced output

JP7, 600 ohm/line level audio output

1 & 2 balanced output or

1 - signal

2 - ground

JP6, 2 pin shorting jumper

Shorted makes JP7 unbalanced output

Open makes JP7 balanced output

JP2, 3 pin shorting jumper

Short pins 1 & 2 to select channel A audio for JP1 output

Short pins 2 & 3 to select channel B audio for JP1 output

SPECIFICATIONS

35

Page 36

Federal Signal UltraVoice

Installation and Operation Manual

JP4, 3 pin shorting jumper

Short pins 1 & 2 to select channel A audio for JP3 output

Short pins 2 & 3 to select channel B audio for JP3 output

JP5, 3 pin shorting jumper

Short pins 1 & 2 to select channel A audio for JP7 output

Short pins 2 & 3 to select channel B audio for JP7 output

JP8, Relay Outputs

1 - Relay #1, N.O.

2 - Relay #1, COM

3 - Relay #1, N.C.

4 - Relay #2, N.O.

5 - Relay #2, COM

6 - Relay #2, N.C.

7 - Relay #3, N.O.

8 - Relay #3, COM

9 - Relay #3, N.C.

10 - Relay #4, N.O.

11 - Relay #4, COM

12 - Relay #4, N.C.

Indicators

LED D18, Power

LED D1, 33 ohm output active

LED D3, 600 ohm output active

LED D5, Line level output active

LED D11, Relay #1 energized

LED D10, Relay #2 energized

LED D9, Relay #3 energized

LED D8, Relay #4 energized

SPECIFICATIONS

36

Page 37

2.10 Model UVLOC

Operating Voltage: 20 - 32VDC

Operating Current: < 25 mA

Digital Outputs: Four BCD encoded, 1 amp current sink maximum

Audio Output: 600 ohm balanced, adjustable 700 mVpp to 5 Vpp

Maximum Distance between

Control Panel and UV: Approx 1/2 mile of cable, </= 200 ohms of cable

Maximum Number of

Control Panels per UV: 10 (external wire management required)

UV-Control Panel

Interface Cable: CAT5, 4 pairs

Size (L x W x D) 10” x 4.75” x 3” maximum

Federal Signal UltraVoice

Installation and Operation Manual

UVLOC Connectors

JP2 & JP1, RJ45 and 8 position terminal strip wired in parallel:

1 - 600 Ohm Audio

2 - 600 Ohm Audio

3 - Direction Input # 3

4 - Direction Input # 2

5 - Direction Input # 1

6 - Direction Input # 0

7 - Power

8 - Ground

2.11 Alarm Panel Interface

Operating Voltage: 20 - 32VDC

Operating Current: < 50 mA

Digital Outputs: Four BCD encoded, 10 mA current sink max.

ARM Input: 0 – 5VDC, 5VDC = ARMed

ARM Output: 7.4 – 8.0VDC Not ARMed, 20 – 32VDC ARMed

Environmental: Indoor Use, -30C to +65C, non-condensing humidity

SPECIFICATIONS

37

Page 38

Alarm Panel Interface Connectors

JP2, JP3, JP4, JP5, JP7, JP7 & JP8, six RJ45s and one 8 position terminal strip

wired in parallel;

1 – Ground

2 – Power

3 – Direction Input # 0

4 – Direction Input # 1

6 – Direction Input # 3

7 – 600 Ohm Audio

8 – 600 Ohm Audio

JP1, 10 position connections to UV back-plane;

1 – Ground

2 – Power

3 – ISO Ground

4 – Direction Input # 3

5 – Direction Input # 2

7 – Direction Input # 0

8 – ARM

9 – 600 Ohm Audio

10 – 600 Ohm Audio

Federal Signal UltraVoice

Installation and Operation Manual

5 – Direction Input # 2

6 – Direction Input # 1

SPECIFICATIONS

38

Page 39

Federal Signal UltraVoice

Installation and Operation Manual

2.12 Environmental

Operating Temperature -30°C - +65°C

Humidity 0-98% non-condensing

Notes:

1. The UVIC can operate throughout this temperature range provided the

battery temperature is maintained at -18°C or higher.

2. The UVIC housing carries a NEMA 1 rating

2.13 Physical

UV400 amplifiers 10.5” height, 2.0” width, 8.5” depth,

weight 4.12 lbs, 1.9 kg

Control cabinet 31” height, 17.36” width, 13.62” depth

78.73 cm x 44.09 cm x 35.59 cm

Weight 130 lbs/ 58.97 kg (including batteries)

Net Shipping Weight 200 lbs/ 90.72 kg (including batteries)

SPECIFICATIONS

39

Page 40

3. UVIC OPERATION

3.1 Hardware General Description

The UVIC contains a card cage with four

plug-in boards consisting of; one

controller slot, one optional accessory

slot and two amplifier slots. The UVIC

uses one amplifier card for a 400 Watt

system and two amplifiers for an 800

Watt system. All siren control, audio

generation and remote communication

functions are handled by a single

SECTION III

microcomputer controlled control board.

The back-plane (motherboard) contains

connectors and terminal blocks for

wireless interconnection of the other

system components. To facilitate field

service, no active circuitry is located on

the back-plane. Power for the siren is

supplied by two 12 volt batteries.

3.2 Manual Activation

The manual activation switches located

on the face of the controller are used to

manually activate siren functions.

Function Switch Function

FUNC1 Activates Functions under code 1

FUNC2 Activates Functions under code 2

FUNC3 Activates Functions under code 3

FUNC4 Activates Functions under code 4

FUNC5 Activates Functions under code 5

FUNC6 Activates Functions under code 6

FUNC7 Activates Functions under code 7

FUNC8 Reset

FUNC1 & FUNC6 Load default speaker calibration values & send a DTMF

calibration tone

FUNC2 & FUNC3 Calibrate speaker load

FUNC5 & FUNC7 Digital Transmit Deviation tone

NOTE: At any time during a sounding function the "RESET" button may be pushed to

cause the unit to halt all output immediately.

UVIC OPERATION

40

Page 41

3.3 Local Public Address

The operator has the ability to give local

Public Address (PA) messages using

the model MNC-MC microphone

provided. PA mode can be entered

simply by pressing the press-to-talk

(PTT) button on the MIC while the MIC

is plugged into the 1/4” receptacle on

the front panel. The PA LED will be lit

anytime the PTT button on the

microphone is pressed. The local PA

volume level is set by adjusting the MIC

GAIN knob located directly above the

MIC jack.

NOTE: Local PA overrides ALL siren

functions activated either remotely or

locally.

3.4 Relay Output

Terminal block JP11 at the bottom of the

system motherboard is the relay output.

This relay closes whenever a siren

function is running. In PA mode, the

relay closes for approximately 30

seconds when the PTT button is

released. The relay is open while the

MIC PTT button is pushed.

3.5 600 Ohm I/O

Terminal block JP12 at the bottom of the

system motherboard is the 600 ohm

input/output connector. This port can be

used to make connections for activation

and status monitoring of the unit over

wire-lines. It can also be used to

connect external audio sources to the

amplification system.

3.6 Remote-Landline Activation

Terminal block JP14 at the bottom of the

system motherboard is the Remote

Activation input. There are eight inputs

available on JP14. The electronic siren

controller can optionally be operated by

separate remote dry contact closures

provided across this input.

Any of the codes, which means all of the

functions programmed for that code, can

be activated by providing a momentary,

dry contact closure between “COM” and

the desired JP14 terminal. For example,

shorting “F1” to “COM” will activate

whatever is programmed for code #1,

and shorting “F2” to “COM” will activate

whatever is programmed for code #2

and so on.

Provide a momentary contact closure

between JP14 “COM” and “F8” (RESET)

if desired to terminate an activated

signal before it runs for the full duration.

Remote Activation Connections

JP14 Terminal Function

1 “Common”

2 “F1”

3 “F2”

4 “F3”

5 “F4”

6 “F5”

7 “F6”

8 “F7”

9 “F8”

10 “Common”

UVIC OPERATION

41

Page 42

3.7 Sensor Inputs and Isolated

Terminal block JP15 at the bottom of the

system motherboard is the Sensor

Inputs. These are activated by a short to

“Common”.

Sensor Connections:

JP15

Function

Terminal

1 “Common”

2 “Spare #1”

3 “Common”

4 “Intrusion”

5 “Common”

6 “Solar”

7 “Common”

8 “AC Power”

9 “Common”

10 “600 PTT”

11 “Common”

12 “Spare #2”

Isolated Supply used to power

External Sensors

JP16

Function

Terminal

1 “Isolated Supply (Ground)”

2 “Isolated Supply (+5V)”

Sensor Power

Intrusion: Alerts the controller when one

of the unit’s doors has been

opened. Low is intrusion pass

Solar: Used to sense operation of

solar power system.

Jumper JP15: pins 5 to 6 and

to enable solar sensing. Solar

mode latches power sense to

prevent low light conditions

from causing failures. For

solar panel test, initiate a

reset, and then a poll.

Immediate good power input

required after a reset to pass.

Jumper JP15 pins 7 to 8 AC

sense is required if solar only

unit.

Spare

1 & 2: Unused inputs for special

functions.

AC

Power: Alerts the controller when the

AC Power has failed. Open is

fail. Closed is

pass.

600 Ohm

PTT: Puts the unit in Local PA

mode for input of external

audio. Closed is active.

UVIC OPERATION

42

Page 43

3.8 Spare Sensor Inputs

The inputs at JP17 are not used in

typical applications with the UVIC

controller.

3.9 Tw o-Way Status Monitoring

The UVIC uses a variety of sensors in

the UVIC Series Controller, which when

equipped with a two-way radio, allows

the remote unit to communicate its

status back to the base station. This

reduces station downtime by quickly

alerting operating personnel to potential

problems at remote units.

The package itself consist of sensors to

provide information on the following

conditions:

1. AC Power

2. Battery Voltage (built in)

3. Charger Operation (built in)

4. Activation Current (built in)

5. Signal A (built in)

6. Signal B (built in)

7. Quiet Test (amplifiers and

drivers built in)

8. Intrusion

All sensors are optically coupled to

provide protection in electrical interface

conditions. Consult the Two-Way

System supplement or Federal Warning

Systems Engineering for further

information.

3.10 Quiet Test

This option enables acoustically quiet

tests to be performed on the siren

control and siren speaker array. Quiet

Test uses a 20 kHz tone to quietly test

the tone generators, amplifiers, and

speaker drivers. To perform this test the

Quiet Test must be programmed under

one of the activation codes. If it is one of

the first 7 codes then it can be activated

manually through the switches on the

front panel or with the remote activation

inputs. Normally once the Quiet Test is

programmed under one of the activation

codes, the code is activated over the

radio channel, the panel switches, or

with a local laptop computer running

SFCDWARE.

A. Operation

The results of a Quiet Test can be

obtained remotely using the SS2000

printout or the SFCDWARE control and

status monitoring software. The status

can also be obtained locally at the siren

site with a portable computer running

SFCDWARE. The actual amplifier

voltage and current are monitored with

Quiet Test providing a true indication of

each amplifier and load performance.

B. Finding Faults

When using SFCDWARE, the controller

will automatically update the Quiet Test

status each time a new Quiet Test is

run. The status can be obtained from

the status detail screen and from the

Reports menu.

UVIC OPERATION

43

Page 44

3.11 Battery Charger

The battery charger is a smart charger

that monitors battery conditions,

temperature, and varies charge rate. It

is a two-stage charger, charging each

12VDC stage separately. Each stage

can consist of more than one battery in

parallel. See “Specifications Section,”

“Battery,” for required quantity of

batteries. The two stages of batteries

add up in series to give the 24VDC

required for controller operation.

Charger Description Connection

Black wire Ground To 1st battery (-)

Red wire 12VDC 12VDC charge 1st battery To 1st battery (+)

Red wire 24VDC 24VDC charge 2nd battery To 2nd battery (+)

Side terminal

back- white wire

Side terminal

front- red wire

Charger sense output- switched voltage

driven from charger voltage input

Charger voltage input-voltage to drive

Charger sense output

To JP20-2

To JP13, 24VDC

Battery Charger Status – Charger Status is indicated by the LED’s on the front of the

chargers. The left, 1st pair of LED’s are for battery 1 and the 2nd pair of LEDs are for

battery 2.

Battery Status is as follows:

Red OFF, Green OFF = Charger OFF

Red ON, Green OFF = Charging, below 13VDC

Red ON, Green ON = Charging, above 13VDC

Red OFF, Green ON = Float charging, battery >90% charged or battery is

disconnected from charger.

Note: Battery voltage will be slightly higher when the temperature is below 72°F and

voltage will be slightly lower when the temperature is above 72°F.

UVIC OPERATION

44

Page 45

3.12 UVLOC

All potential users should be properly

trained on the use of the control panel.

When the UVLOC is properly connected

to the UVIC, the green power LED will

be lit. To use the panel, the UVLOC

must first be “ARMED” by pressing the

ARM button for 1 second. When the

UVIC detects that the ARM button has

been pressed, the red ARM LED on the

panel will light indicating the panel is

ready to be operated. When the UVLOC

Arm button is pressed, an alarm will be

automatically sent to the control system

indicating use of the control panel. If no

function is activated, the panel will be

automatically Disarmed after 30

seconds. If a function is activated, the

panel will remain Armed for the duration

of the function or until Disarmed. The

panel will also be Armed when any other

control point Arms the UVIC.

Once Armed, the user must then select

the desired function to operate by

turning the rotary function selection

switch to the desired position. The user

must then press the ACTIVATE button

for 1 second to operate the function

selected.

If LIVE P.A. or RECORD is selected, the

user must hold down the ACTIVATE

button for the duration of the live

message or for the duration of the

recording while speaking in a clear voice

and talking slowly within 12” of the

microphone on the control panel. When

the ACTIVATE button is released, the

microphone will be disconnected and

the function will stop until the ACTIVATE

button is pressed again. RECORD will

re-record the previous message each

time the ACTIVATE button is pressed.

Up to 2 minutes of recording time is

available for the record function. The

PLAYREC function will play-back the

digitally recorded message.

The CANCEL/DISARM button will stop

any function in progress and disarm the

control panel(s) which will also turn off

the Arm LED on the control panel(s).

A function description area is reserved

on the bottom of the UVLOC panel to

place a label describing each of the

functions available with a meaningful

description.

UVIC OPERATION

45

Page 46

SECTION IV

4. SYSTEM PLANNING

4.1 Control Unit

The information in this section provides

the user with guidelines necessary for

installation.

Control Unit mounting location must first

be considered. The Control Unit NEMA

Type 1 cabinet must be mounted indoors

away from moisture and heavy dust or

contaminants. The controller contains

batteries, therefore the selected area

must have adequate ventilation to prevent

accumulation of explosive gas from the

batteries.

A light duty lockable hasp secures entry

to the cabinet. If additional security is

desired, the cabinet should be placed

behind a locked door.

The cabinet is suitable for wall mounting

with mounting slots on 12” to 16” centers.

The total weights of the Control

assembly, including user provided

batteries, are listed in the specification

section. Insure that the mounting surface

and fasteners can safely sustain the

weight of the assembly.

The Control system requires a 120VAC or

240VAC 50-60 Hz power source (model

dependent).

Several methods can be used to activate

the Control Unit. The Manual activation

switches and a handheld microphone can

be used to activate the Control Unit

locally. Landline control can be used

through normally open contact switches.

Connections should be made directly to

the motherboard terminal blocks. The

control can also be remotely activated via

the optional radio receiver or an external

600 ohm audio source.

If radio control is going to be used,

consider RF coverage and antenna

placement when selecting a suitable

location.

4.2 Speaker Placement

WARNING

The sound output of speakers is capable

of causing permanent hearing damage.

Ensure people are not exposed to sounds

exceeding 120 dB. Post warnings where

applicable.

As a general rule, the warning signal SPL

should be at least 10dB above the

ambient sound level to ensure it will be

heard. Speaker fidelity and placement will

also affect voice intelligibility.

Many factors affect the propagation of

sound through barriers, over various

types of materials, terrain, and changing

weather conditions. Consult FEMA

CPG1-17, CPG1-14 and your local

Federal Signal representative for

SYSTEM PLANNING

46

Page 47

assistance to properly place your warning

equipment.

The speakers connected to the UVIC may

be selectively turned on using amplifier

zones. Up to two zones may be

programmed into the UVIC to allow Zone

1, Zone 2 or all amp zones to be

activated. Amp Zones are programmed

using the AZ commands in SFCDWARE.

4.3 UVLOC Placement

The UVLOC should be mounted in an

area that is readily accessible by all

potential operators. The console should

be clearly marked to identify its location.

Up to 10 Local Operation Consoles may

connect to each UVIC. The consoles may

be placed up to ½ mile away from the

UVIC. The console should be wall

mounted approximately 5’ above the

ground. The UVLOC should also be

mounted as far as possible from the

speaker locations to reduce the potential

for audio feedback during a live P.A.

announcement.

The UVLOC requires a CAT5 cable run

between the UVIC and the UVLOC. An

electrical back box is provided for

mounting the UVLOC either on or

recessed within a wall. Six RJ45

connectors are provided on the UVLOC

interface board for making connections.

A terminal strip is also provided that

accepts bare wire.

SYSTEM PLANNING

47

Page 48

5. INSTALLATION

SECTION V

WARNING

Read all Safety Notices at the beginning

of this manual before installation.

This section contains reference

drawings to assist with installation. A list

of typical installation materials required

may be obtained by reviewing the

Distributed Speakers

Type N RF Connector

cabinet mounting details in section 5.3

and the electrical installation material list

in section 5.4.

5.1 UVIC Siren Controller

Installation Reference Drawings

Refer to Figures 5.1, 5.2, 5.3,5.4 and

5.5 below for reference.

Radio Antenna

Antenna Ground Required

For Outdoor Antenna Masts

UVIC

Fused AC

Service

Disconnect

(22-14 AWG COPPER, 4mm

Figure 5.1 - Typical UVIC Installation Drawing

Audio Wire Pairs

2

max)

Field Ground

INSTALLATION

48

14-12AWG COPPER

AC Power Wires

3/8" Ground Stud

Field Ground

120 or 240 VAC Service

(Depending on UVIC Model)

Page 49

Figure 5.2 - UVIC Cabinet Dimensional Outline Drawing

INSTALLATION

49

Page 50

INSTALLATION

50

Figure 5.3 – UVIC Wiring Diagram

Page 51

Figure 5.4 – UVIC Battery Connections

INSTALLATION

51

Page 52

5.2 General Mounting Guidelines For All Applications

These general installation instructions

are pertinent to all installations. Specific

mounting methods and required

installation materials are described in

the next section.

1. There are three pre-drilled holes in

each of the cabinet mounting

flanges, (see Figure 5.2). Depending

on the mounting surface, the cabinet

may be mounted using either of the

following sets of holes:

(2) Centered 0.41” mounting holes

(4) Mounting slots 0.41” x 2” with

12” to 16” centers.

2. The total weight of the UVIC Cabinet

with batteries is listed in the

specifications section. It is imperative

that the mounting surface and

mounting method selected can

safely sustain the weight of the

assembly. To reduce the weight of

the cabinet during installation, do not

install the batteries before mounting

the cabinet.

3. Prepare the mounting surface for

hanging the cabinet by

predetermining the location of the

mounting holes. The cabinet should

be attached to a wall or other

substantial vertical surface using the

four 0.41” mounting slots.

Alternatively, the two-center

mounting holes may be utilized

alone, if securely lagging directly into

a wood stud or other vertical surface

capable of handling the weight load.

If the mounting surface is not flat, the

cabinet may require shimming to

keep the cabinet square.

4. Guidelines for various attachment

methods to accommodate different

wall types are described in the

following section. Provisions should

be made for spacing behind the

cabinet when mounting to an exterior

wall that is susceptible to

condensation or other surface

moisture.

5. With the two batteries removed, use

two people to lift the cabinet to the

desired mounting height and lag to

the wall using the prepared holes

and anchors.

6. After the cabinet is securely

mounted, remove any debris that