Page 1

25500463

B0 0818

Printed in U.S.A.

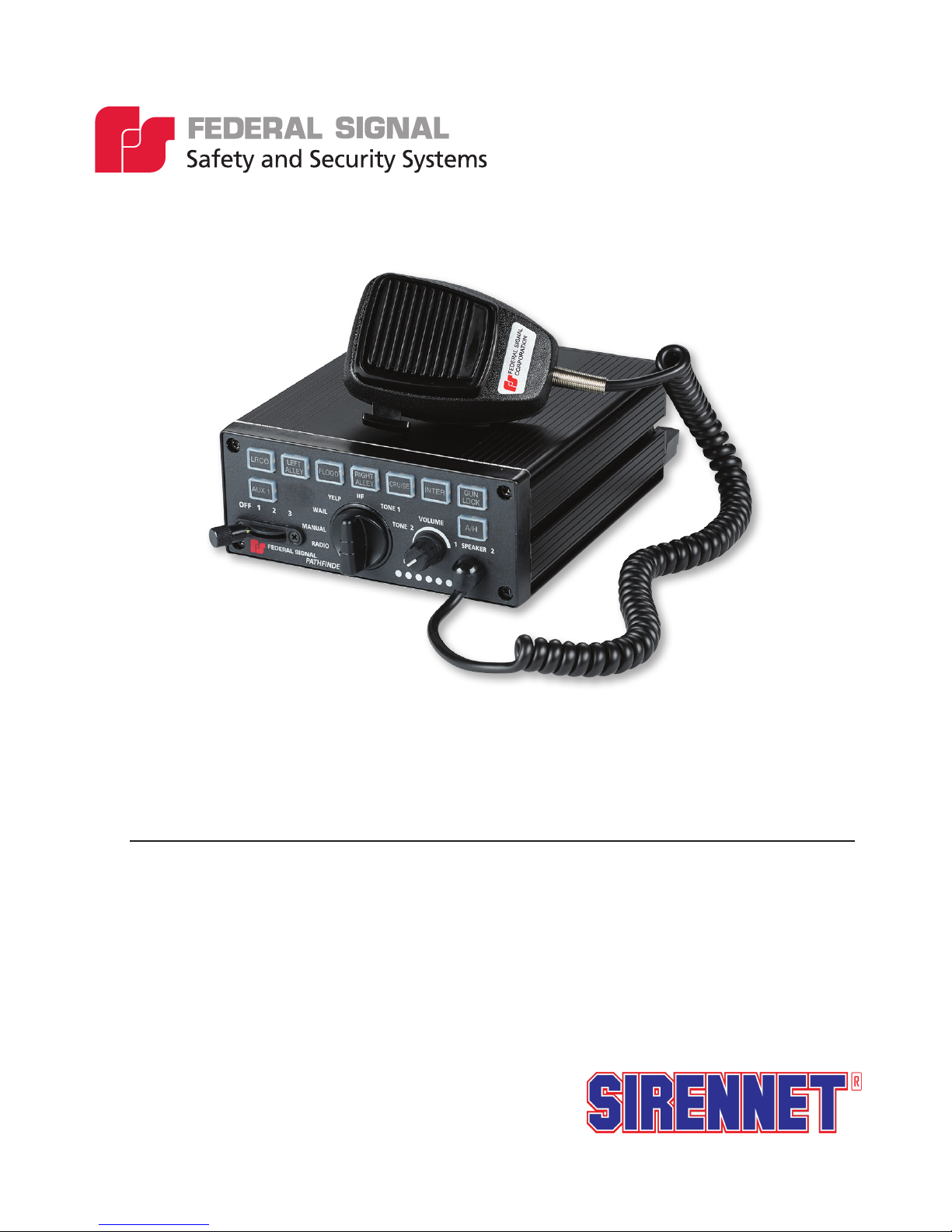

PathnderTM

Installation and

Maintenance Instructions

Distributed By:

Page 2

Limited Warranty

This product is subject to and covered by a limited warranty,

a copy of which can be found at www.fedsig.com/SSG-Warranty.

A copy of this limited warranty can also be obtained by written

request to Federal Signal Corporation, 2645 Federal Signal Drive,

University Park, IL 60484, email to info@fedsig.com or

call +1 708-534-3400.

This limited warranty is in lieu of all other warranties, express or

implied, contractual or statutory, including, but not limited to the

warranty of merchantability, warranty of tness for a particular

purpose and any warranty against failure of its essential purpose.

2645 Federal Signal Drive

University Park, Illinois 60484

www.fedsig.com

Customer Support

Police/Fire-EMS: 800-264-3578 • +1 708 534-3400

Work Truck: 800-824-0254 • +1 708 534-3400

Technical Support 800-433-9132 • +1 708 534-3400

Allegiant, Integrity, Navigator, Rumbler, SignalMaster, SpectraLux, and Valor are registered trademarks of Federal Signal Corporation

Page 3

Contents

Chapter 1 Safety Messages for Installers and Operators ......................................................5

Safety Messages to Installers of Sound/Light Systems .....................................................................5

Safety Messages to Operators of Sound/Light Systems ....................................................................8

Chapter 2 An Overview of the Pathnder .............................................................................. 10

Siren, PA, and Speakers ...................................................................................................................10

Lightbars and SignalMasterTM Control .............................................................................................10

FS Vehicle Integration ...................................................................................................................... 11

Programmable Solid-State Auxiliary Relays ...................................................................................11

Programmable Input Circuits ........................................................................................................... 11

LED Indicators and Visual Diagnostics ........................................................................................... 11

System Specications ......................................................................................................................12

Siren Specications ..........................................................................................................................12

Relay Specications .........................................................................................................................12

Pathnder Kit Contents ....................................................................................................................13

Chapter 3 Wiring the Pathnder .............................................................................................15

General Guidelines for Wiring the Pathnder on a Vehicle .............................................................15

Overview of the Pathnder Connections .........................................................................................17

Convergence Network Ports .......................................................................................................17

Relay Outputs .............................................................................................................................17

General Purpose Inputs ...............................................................................................................17

Park Input ...................................................................................................................................17

Horn Ring Transfer .....................................................................................................................18

Speaker Connections ..................................................................................................................18

Speaker Diagnostics ...................................................................................................................19

Radio Re-Broadcast ....................................................................................................................19

FS Vehicle Integration ................................................................................................................19

Ignition Input ..............................................................................................................................19

System Power .............................................................................................................................19

Chapter 4 Mounting the Pathnder ........................................................................................ 21

Mounting the Siren ..........................................................................................................................23

Mounting the Control Head (PF200R) ............................................................................................23

Chapter 5 Testing the Pathnder Installation ........................................................................25

Pathnder

TM

3

Page 4

Contents

Chapter 6 Control Head Legends and Safety Messages .....................................................28

Applying the Replaceable Control Head Legends ...........................................................................28

Distributing the Safety Message Card .............................................................................................29

Applying the Siren Safety Labels in the Vehicle .............................................................................29

Chapter 7 Safety Messages to Personnel Servicing Federal Electronic Sirens ................30

Chapter 8 Servicing the Pathnder ........................................................................................ 31

Replacing the Slide Switch ..............................................................................................................31

Getting Technical Support and Service ............................................................................................34

Returning a Product to Federal Signal .............................................................................................35

Tables

Table 2.1 PF200 Kit Contents .............................................................................................................13

Table 2.2 PF200R Kit Contents ...........................................................................................................14

Table 5.1 Pathnder Switch Default Programming .............................................................................26

Table 5.2 Pathnder Button Default Programming .................................................................................... 26

Table 5.3 Pathnder Input Default Programming ....................................................................................... 27

Table 8.1 Service Parts ........................................................................................................................33

Figures

Figure 3.1 100W Single Tone and 200W Dual Tone Siren Connections ............................................ 16

Figure 3.2 100W Siren with Integrated Rumbler ................................................................................16

Figure 3.3 Battery Connections...........................................................................................................20

Figure 4.1 Pathnder Dimensions .......................................................................................................22

Figure 4.2 Mounting Hardward Dimensions ......................................................................................22

Figure 4.3 Bail Bracket Assembly ........................................................................................................ 23

Figure 4.4 Bracket Attached to Back of Control Head ........................................................................24

Figure 4.5 Brackets Attached to Control Head and Mounting Surface ............................................... 24

Figure 5.1 Pathnder Default Programming .......................................................................................25

Figure 6.1 Installing the Control Head Labels ....................................................................................28

Figure 6.2 Safety Message Card (left) and Siren Safety Labels (right) ..............................................29

Figure 8.1 Keypad Removal ................................................................................................................31

Figure 8.2 Slide Switch Replacement .................................................................................................32

4

Pathnder

TM

Page 5

CHAPTER 1

Safety Messages for Installers and Operators

For your safety, read and understand this manual thoroughly before installing, operating, and

servicing the Pathnder siren amplier/relay module. The safety messages presented in this chapter

and throughout the manual are reminders to exercise extreme care at all times. In addition, read and

understand the safety instructions to installers (doc. no. 256A692), and keep it close at hand for

reference.

To download copies of this manual, go to www.fedsig.com or call the Federal Signal Service

Department at 1-800-433-9132 (708-534-3400) 7 a.m. to 5 p.m., Monday through Friday (CT).

Safety Messages to Installers of Sound/Light Systems

People’s lives depend on your proper installation and servicing of Federal Signal products. It is

important to read and follow all instructions shipped with this product. In addition, listed below are

some other important safety instructions and precautions you should follow:

Before Installation

Qualications

• To properly install an electronic siren, you must have a good understanding of automotive

electrical procedures and systems, along with prociency in the installation and service of safety

warning equipment. Always refer to the vehicle’s service manuals when performing equipment

installations on a vehicle.

Sound Hazards

• Your hearing and the hearing of others, in or close to your emergency vehicle, could be damaged

by loud sounds. This can occur from short exposures to very loud sounds, or from longer

exposures to moderately loud sounds. For hearing conservation guidance, refer to federal, state,

or local recommendations. OSHA Standard 1910.95 offers guidance on “Permissible Noise

Exposure.”

• All effective sirens and horns produce loud sounds (120 dB) that may cause permanent hearing

loss. Always minimize your exposure to siren sound and wear hearing protection. Do not sound

the siren indoors or in enclosed areas where you and others will be exposed to the sound.

Pathnder

TM

5

Page 6

Chapter 1: Safety Messages for Installers and Operators

• Federal Signal siren amplier/relay modules and speakers are designed to work together as a

system. Combining a siren and speaker from different manufacturers may reduce the warning

effectiveness of the siren system and may damage the components. You should verify or test your

combination to make sure the system works together properly and meets federal, state and local

standards or guidelines.

During Installation

• Do NOT get metal shavings inside the product. Metal shavings in the product can cause the

system to fail. If drilling must be done near the unit, place an ESD approved cover over the unit to

prevent metal shavings from entering the unit. Inspect the unit after mounting to be sure there are

no shavings present in or near the unit.

• Do NOT connect this system to the vehicle battery until ALL other electrical connections are

made, mounting of all components is complete, and you have veried that no shorts exist. If

wiring is shorted to vehicle frame, high current conductors can cause hazardous sparks resulting in

electrical res or ying molten metal.

• Be sure the siren amplier/relay module and speaker(s) in your installation have compatible

wattage ratings.

• In order for the electronic siren to function properly, the ground connection must be made to the

NEGATIVE battery terminal.

• Sound output will be severely reduced if any objects are in front of the speaker. If maximum

sound output is required for your application, you should ensure that the front of the speaker is

clear of any obstructions.

• Install the speaker(s) as far forward on the vehicle as possible, in a location which provides

maximum signaling effectiveness and minimizes the sound reaching the vehicle’s occupants.

Refer to the National Institute of Justice guide 500-00 for further information.

• Mounting the speakers behind the grille will reduce the sound output and warning effectiveness of

the siren system. Before mounting speakers behind the grille, make sure the vehicle operators are

trained and understand that this type of installation is less effective for warning others.

• Sound propagation and warning effectiveness will be severely reduced if the speaker is not facing

forward. Carefully follow the installation instructions and always install the speaker with the

projector facing forward.

• Do NOT install the speaker(s) or route the speaker wires where they may interfere with the

operation of airbag sensors.

• Installation of two speakers requires wiring speakers in phase.

• Never attempt to install aftermarket equipment, which connects to the vehicle wiring, without

reviewing a vehicle wiring diagram available from the vehicle manufacturer. Insure that your

installation will not affect vehicle operation and safety functions or circuits. Always check vehicle

for proper operation after installation.

6

Pathnder

TM

Page 7

Chapter 1: Safety Messages for Installers and Operators

• Do NOT install equipment or route wiring or cord in the deployment path of an airbag.

• If a vehicle seat is temporarily removed, verify with the vehicle manufacturer if the seat needs to

be recalibrated for proper airbag deployment.

• Locate the control head so the vehicle, controls, and microphone can be operated safely.

• When drilling into a vehicle structure, be sure that both sides of the surface are clear of anything

that could be damaged. All drilled holes should be deburred and all sharp edges should be

smoothed. All wires going through drilled holes should be protected by a grommet or convolute/

split-loom tubing. Additionally, all exterior drilled holes must be sealed with Motorcraft seam

sealer T-A-2-B or equivalent to prevent the potential exposure to carbon monoxide or other

potentially harmful fumes. Failure to observe this warning could cause serious injury or death.

After Installation

• After installation, test the siren and light system to ensure that it is operating properly.

• Test all vehicle functions, including horn operation, vehicle safety functions and vehicle light

systems, to ensure proper operation. Ensure that installation has not affected vehicle operation or

changed any vehicle safety function or circuit.

• After testing is complete, provide a copy of these instructions to the instructional staff and all

operating personnel.

• File these instructions in a safe place and refer to them when maintaining or reinstalling the

product.

Failure to follow all safety precautions and instructions may result in property damage, serious injury,

or death.

RETAIN AND REFER TO THESE MESSAGES

Pathnder

TM

7

Page 8

Chapter 1: Safety Messages for Installers and Operators

Safety Messages to Operators of Sound/Light Systems

People’s lives depend on your safe operation of Federal Signal products. It is important to read and

follow all instructions shipped with the products. In addition, listed below are some other important

safety instructions and precautions you should follow:

• Do not attempt to activate or de-activate the light system control while driving in a hazardous

situation.

• Although your warning system is operating properly, it may not be completely effective. People

may not see or heed your warning signal. You must recognize this fact and continue driving

cautiously.

• Also, situations may occur which obstruct your warning signal when natural and man-made

objects are between your vehicle and others, such as raising your hood or trunk lid. If these

situations occur, be especially careful.

• All effective sirens and horns produce loud sounds that may cause, in certain situations, permanent

hearing loss. You and your passengers should consider taking appropriate safety precautions, such

as wearing hearing protection.

• In order to be an effective warning device, this product produces bright light that can be hazardous

to your eyesight when viewed at a close range. Do not stare directly into this lighting product at a

close range or permanent damage to your eyesight may occur.

• It is important that you fully understand how to safely operate this warning system before use.

• You should only operate your vehicle and its light/sound system in accordance with your

department’s Standard Operating Procedures.

• If a selected function does not perform properly or if any of the lamps remain illuminated when

the control is off, disconnect the power connector from the control unit and contact the nearest

service center.

• At the start of your shift, you should ensure that the entire warning light system and the siren

system is securely attached and operating properly.

• The effectiveness of an interior mounted warning light depends on the clarity, the tinting, and the

angle of the glass it is being placed behind. Tinting, dirt, defects, and steeply angled glass reduce

the light output of the warning light. This may reduce the effectiveness of the light as a warning

signal. If your vehicle has dirty, tinted, or steeply angled glass, use extra caution when driving

your vehicle or blocking the right of way with your vehicle.

• Suction cup mounting is for temporary applications only. The unit should be removed from the

window and stored securely when not in use. Temperature changes and sunlight can cause suction

cups to lose holding power. Periodically check the unit to be sure the suction cups have a rm grip

on the mounting surface. An improperly secured light could fall off of the vehicle causing injury

and damage.

8

Pathnder

TM

Page 9

Chapter 1: Safety Messages for Installers and Operators

• The holding power of magnetic mounting systems is dependent upon surface nish, surface

atness, and thickness of the steel mounting surface.

Therefore, to promote proper magnetic mounting:

✓

The mounting surface and magnets must be kept clean, dry, and free of foreign particles that

prevent good surface contact.

✓

Ensure that the mounting surface is at.

✓

A magnet mounting system should not be used on vehicles with vinyl tops.

✓

To prevent the light assembly from sliding on mounting surface, avoid quick acceleration and

hard stops.

Failure to follow these precautions may result in property damage, serious injury, or death.

RETAIN AND REFER TO THESE MESSAGES

Pathnder

TM

9

Page 10

CHAPTER 2

An Overview of the Pathnder

The Pathnder siren is a full-featured, programmable electronic siren and light control system. State-

of-the-art microprocessor technology is used to create a system with a small, compact siren system

that can be installed under the dashboard (PF200, Self -Contained), in the trunk or under the seat

(PF200R, Remote) of any vehicle with a 12 V or 24 V negative ground system. The Pathnder siren

uses class D amplier technology to provide two independent 100W channels of audio, for a total

of 200W, without the need for a large and heavy transformer. The module provides the automatic,

simultaneous light and siren activation required by some jurisdictions. A security gun timer is also

provided to minimize the possibility of unauthorized shotgun release. The module has two easily

accessible Convergence Network serial ports that can connect a remote mounted control head and/

or any serially-controlled Federal Signal product. The siren also has FS Vehicle Integration to allow

for various events a vehicle to integrate with siren/lighting control. A variety of system features

can be programmed with the Convergence Network Conguration Software from a computer via a

USB cable that connects the siren amplier. System features include ash patterns, siren tones, and

momentary, push-on/push-off, timed relay operation, as well as vehicle events. Programming does

not require disassembling or removing any hardware from the vehicle.

Siren, PA, and Speakers

The Pathnder produces wail, yelp, priority, and as well as an air horn sound by default. The horn-

ring transfer feature enables the driver to control siren tones by pressing the horn button. Public

address is available with the Federal Signal microphone, which is included with the system. Radio

rebroadcast is also available. The Pathnder can drive one or two 11-ohm impedance, 100 W

speakers. The two 11-ohm impedance, 100 W speakers have separate wires that allow the Pathnder

to provide dual siren tones. Alternatively, the Pathnder can drive one 11-ohm impedance, 100

W speaker on one channel, and two Rumbler speakers on the second channel to provide Rumbler

integration, without the need for a secondary external amplier.

Lightbars and SignalMasterTM Control

Compatible lightbars include full featured, serially-controlled Federal Signal Legend®, Valor®,

TM

Allegiant

lightbars. In addition, ash rates and patterns, lightbar dimming, external SignalMaster control and

other options can be programmed with the Convergence Network Conguration Software.

, Navigator®, and Integrity® as well as the SpectraLux ILS Series of interior-mounted

10

Pathnder

TM

Page 11

Chapter 2: An Overview of the Pathnder

FS Vehicle Integration

The Pathnder siren includes the capability to integrate with the existing vehicle CAN bus. The

FS Vehicle Integration uses a vehicle specic cable (not included) to seamlessly integrate with the

vehicle. Vehicle events can be programmed with the Convergence Network Conguration Software to

interface with the lighting/siren control. The Convergence Network Conguration Software contains

the latest list of events supported based on model, make and year of the vehicle.

Programmable Solid-State Auxiliary Relays

The Pathnder has 12 solid-state relays: ve 10A active high solid-state relays: one 10 A high-low and

six 5 A high. The maximum output current for each relay can be set with the Convergence Network

Conguration Software.

Programmable Input Circuits

The Pathnder has connections for four general purpose input circuits, plus dedicated inputs for

park, horn and ign. Ignition is an active-high only input, while all other inputs are programmable for

active-high or active-low. The inputs are most commonly used for switches that send a signal to the

siren when a condition in the vehicle changes.

LED Indicators and Visual Diagnostics

All buttons on the control head glow when the system is on. Pressed buttons turn bright to indicate

that the function they control is active. The buttons are programmable for red or blue backlighting.

LEDs on the keypad mimic these active SignalMaster patterns: Left, Right, Center-Out, and Warn

patterns. An LED glows over the position in which the slide switch is placed. Diagnostic LEDs for

speaker fault detection are also available and are programmable.

Pathnder

TM

11

Page 12

Chapter 2: An Overview of the Pathnder

System Specications

Input Voltage 11 Vdc to 28 Vdc

Polarity Negative ground only

Operating Temperature Range -40 °C to +80 °C (all relays at 50 percent power)

Standby Current Less than 0.1 A

Max Input Current 75 A (siren and relays)

Dimensions:

PF200 (Self Contained Siren)

Height 2.5 in (6.4 cm)

Width 6.0 in (15.2 cm)

Length 8.4 in (21.3 cm)

Net Weight 3.9 lb (1.77 kg)

Siren Specications

Speakers One or two 100 W, 11-ohm speakers or

One 100 W, 11-ohm speaker and two Rumbler speakers

Operating Current 100 W - One 11-ohm speaker – 8 A

200 W - Two 11-ohm speakers – 16 A

(13.6 V battery, No Relays active)

Frequency Range 182 to 1600 Hz

Nominal Cycle Rate Wail: 12 cycles per minute

Yelp: 180 cycles per minute

Priority: 370 cycles per minute

High-Low: 60 cycles per minute

Nominal Voltage Output 64 V peak-to-peak (siren tones)

Audio Response 300 Hz to 3,000 Hz ± 3 dB

Siren Tone Compliances SAE J1849 JUL89

Relay Specications

Relays 1-5 10 A (active high)

Relays 6 10 A (active high or active low)

Relays 7-12 5 A (active high)

12

Pathnder

TM

Page 13

Chapter 2: An Overview of the Pathnder

Pathnder Kit Contents

Table 2.1 and Table 2.2 list the parts included with the kit. After unpacking the kit, examine it for

damage that may have occurred in transit. If the product has been damaged, le a claim immediately

with the carrier stating the extent of damage. Carefully check all envelopes, shipping labels, and tags

before removing or destroying them. Ensure all parts in the packing list are included in the shipment.

If any parts are missing, call Federal Signal Customer Support at 1-800-264-3578, 7 a.m. to 5 p.m.,

Monday through Friday, Central Time.

Table 2.1 PF200 Kit Contents

Qty. Description Part Number

1 100/200-Watt Siren/Light Controller, Self-Cont 862302144

1 Keypad Legend Stickers 8572294

1 Bracket, Bail, Pathnder 862302132

1 Cable Assy, RS485, 25ft 1751357-02

1 Wire Assy, Relay, Pathnder 17501359

1 Wire Assy, I/O, Pathnder 17501360

1 Cable, USB 2.0, A male to Mini-B 17501813

1 Term, #8, 6 Awg 19001363

1 Kit, Hardware, Pathnder 77700765

Siren Mount Kit Contains:

2 Bolt, Carriage, 1/4-20, SS 7004A020-12

2 Nut, Ext Keps, 1/4-20, Stl 7058A005

2 Washer, Flat, 1/4 7072A028

2 Screw, Pan, Sems, M4 70000451-06

2 Lockwasher, Int Tth, 1/4 7075A016

Pathnder

TM

13

Page 14

Chapter 2: An Overview of the Pathnder

Table 2.2 PF200R Kit Contents

Qty. Description Part Number

1 100/200-Watt Amplier, Pathnder 862302662

1 Control Head, Remote, PF200R, Pathnder 862302151

1 Keypad Legend Stickers 8572294

1 Dynamic Microphone with Mod 258B577-03

1 Bracket, Bail, Pathnder 862302132

2 Bracket, Mtg. Control, Smart 85361065

1 Cable Assy, RS485, 25ft 1751357-02

1 Wire Assy, Relay, Pathnder 17501359

1 Wire Assy, I/O, Pathnder 17501360

1 Cable, USB 2.0, A male to Mini-B 17501813

1 Term, #8, 6 Awg 19001363

1 Kit, Hardware, Pathnder 77700765

Siren Mount Kit Contains:

2 Bolt, Carriage, 1/4-20, SS 7004A020-12

2 Nut, Ext Keps, 1/4-20, Stl 7058A005

2 Washer, Flat, 1/4 7072A028

2 Screw, Pan, Sems, M4 70000451-06

2 Lockwasher, Int Tth, 1/4 7075A016

1 Kit, Hardware, Control Head, Pathnder 77700992

Control Head Kit Contains:

2 Screw, 6-32, Pan HD, Phil 7000A404-05

2 Bolt, Carriage, 1/4-20, SS 7004A020-12

2 Screw, #10 TYP B, Pan Torx, Stl, Blk Zn 7011246-08

2 Washer, Flat, 1/4 7072A028

2 Lockwasher, Split Stl #6 Screw 7074A001

2 Lockwasher, Ext Tth, 1/4 7075A007

14

Pathnder

TM

Page 15

CHAPTER 3

Wiring the Pathnder

General Guidelines for Wiring the Pathnder on a Vehicle

HIGH CURRENT ARCING: Do not connect this system to the vehicle battery until

ALL other electrical connections are made and you have veried that no shorts

exist. High current conductors can cause hazardous sparks or burning wire

resulting in electrical res.

DRILLING PRECAUTIONS: When drilling into a vehicle structure, be sure that

both sides of the surface are clear of anything that could be damaged. All drilled

holes should be deburred and all sharp edges should be smoothed. All wires

going through drilled holes should be protected by a grommet or convolute/

split-loom tubing. Additionally, all exterior drilled holes must be sealed with

Motorcraft seam sealer T-A-2-B or equivalent to prevent the potential exposure

to carbon monoxide or other potentially harmful fumes. Failure to observe this

warning could cause serious injury or death.

Before permanently installing the Pathnder system, plan all wire routings and select the mounting

locations for the siren amplier/relay module. Read and understand all instructions included with

related equipment before installing it. Ensure that all wiring is protected from damage during normal

operation of the vehicle and away from any sharp edges and screws. Splice joints should be soldered

or crimped with butt-connectors, and properly insulated. Splice joints that will be exposed to the

elements should be adequately sealed and insulated. All wires that are extended should not be a lesser

gauge than its original mating wire. Make sure that connections are easily accessible for assembly

and service.

Pathnder

TM

15

Page 16

Chapter 3: Wiring the Pathnder

Figure 3.1 100W Single Tone and 200W Dual Tone Siren Connections

GREEN 20AWG

RADIO

SPEAKER

VEHICLE HORNS

11 OHM, 100 WATT SPEAKER

11 OHM, 100 WATT SPEAKER

OMIT IF ONLY

USING 1

SPEAKER

TWOWAY

RADIO

GREEN/WHITE 20AWG

STEERING COLUMN

SPST RELAY

(INSTALLER-SUPPLIED)

SW

TO BATTERY

CUT

WIRE

TO HORN RING SIDE OF CUT WIRE

BLUE 20AWG

BROWN 20AWG

BLUE/WHITE 20AWG

BROWN/WHITE 20AWG

Figure 3.2 100W Siren with Integrated Rumbler

TO HORN RING

WHITE/YELLOW 20AWG

WHITE 20AWG

TO HORN OR HORN RELAY

BATTERY +

GROUND -

®

FS VEHICLE

INTEGRATION*

RADIO

SPEAKER

VEHICLE HORNS

11 OHM, 100 WATT SPEAKER

2 RUMBLER SPEAKERS

GREEN 20AWG

TWOWAY

RADIO

GREEN/WHITE 20AWG

STEERING COLUMN

SPST RELAY

(INSTALLER-SUPPLIED)

SW

TO BATTERY

CUT

WIRE

TO HORN RING SIDE OF CUT WIRE

BLUE 20AWG

BROWN 20AWG

BLUE/WHITE 20AWG

BROWN/WHITE 20AWG

TO HORN RING

WHITE/YELLOW 20AWG

WHITE 20AWG

TO HORN OR HORN RELAY

GROUND -

BATTERY +

FS VEHICLE

INTEGRATION*

16

Pathnder

TM

Page 17

Chapter 3: Wiring the Pathnder

Overview of the Pathnder Connections

To prepare the vehicle for connecting the Convergence Network system:

1. After planning where to route the wires and cables for the system components — such as Federal

Signal warning lights, directional lights, and speakers — drill the holes for the wiring. Smooth,

deburr, and insert a grommet in the holes.

2. Mount the system components according to the instructions included with each product.

The next sections describe how to connect and wire each system component to the siren amplier/

relay module.

Convergence Network Ports

There are two “plug and play” serial ports that communicate on the Federal Signal Convergence

Network. Federal Signal Network devices include exterior mount lightbar, interior mount

ILS systems and remote keypads. For instructions on mounting network devices, refer to

the instructions included with the products. For instructions on conguring the operation

of the devices connected through the Convergence Network ports, see the help menu in the

Convergence Network Conguration Software.

Relay Outputs

The Pathnder has a total of twelve solid-state relay output available. Relays 1-6 can each

provide up to 10 A switched from the battery terminal on the Pathnder. Relay 6 can switch

both battery (active-high) and ground (active-low). Relays 7-12 can each provide up to 5A

switched from the battery terminal on the Pathnder. Each relay has a software programmable

current limit set that can be set. By default, the current limit setting is disabled. Each relay also

can also be programmed to ash various patterns and dim levels. See the Convergence Network

Conguration Software for all available programming options available for the Pathnder

relay outputs.

General Purpose Inputs

The Pathnder has a total of four general purpose inputs available. These inputs are by default

set to detect active-high (battery). Each input can individually be programmed to detect an

active-high (battery) or active-low (ground). All inputs are software-congurable options

include siren activation or siren mute, timer settings, and switch operation. See the Convergence

Network Conguration Software for all available programming options available for the

Pathnder inputs.

Park Input

The park input circuit sends a signal to the siren amplier/relay module to mute all siren

functions except Air Horn and Manual and shut off any ashing white light in the lightbar when

the vehicle transmission is shifted into park. This input is by default set to detect active-low

(ground). The park input can be programmed to detect an active-high (battery) or active-low

(ground). The functionality of the park wire (as well as the input polarity) can be congured

with the Convergence Network Conguration Software. If using FS Vehicle Integration to detect

the park event, this wire is not used. Fold and seal.

Pathnder

TM

17

Page 18

Chapter 3: Wiring the Pathnder

Horn Ring Transfer

DETERMINE CURRENT FOR HORN — The horn ring transfer circuit of the

siren can switch a maximum of 5 A. Some vehicles do not have a horn relay

and consequently will draw more than 5 A when the vehicle horn is activated.

Consult your vehicle service manual or a qualied mechanic to determine the

current required to activate the horn. If it is less than 5 A, perform step 3. If it is

greater than 5 A, perform steps 4 through 9.

The horn input circuit is designed to allow siren and lighting control from the vehicle horn.

This input is by default set to detect active-low (ground). The horn input can be programmed to

detect an active-high (battery) or active-low (ground). The horn signal event may be available

using FS Vehicle Integration, if so fold and seal the unused leads.

NOTE: To enable horn-ring control of siren tones, obtain a SPST relay of enough contactcurrent capacity to activate the vehicle horn:

1. Cut the wire that connects the switch for the vehicle horn ring to the horn or horn relay

(Figure 3.3).

2. Splice the white/yellow wire from the power cable to the horn ring side of the wire

that you cut in step 1.

3. Splice the white wire from the power cable to the horn side of the cut wire.

4. Mount the SPST relay in a suitable location.

5. Connect the horn side of the wire cut in step 1 to the relay-contact terminal.

6. Determine the “sense” of the vehicle’s horn ring activation circuit. Does the horn

circuit require a switched positive (active-low) voltage or switched ground (active-high)

for activation?

7. Connect the switched relay-contact terminal to the positive or negative potential you

determined in step 6.

8. Connect the white wire from the power cable to one end of the relay coil.

9. Connect the other end of the relay coil to the opposite potential of that connected to

the switched relay contact terminal in step 7.

Speaker Connections

The Pathnder is designed to operate with a few different speaker congurations. It can operate

one or two 11-ohm impedance, 100 W speakers. If using two 11-ohm impedance, 100 W

speakers, they must be wired on separate channels of the amplier and in phase for proper

operation (see Figure 3.1). Alternatively, it can operate one 11-ohm impedance, 100 W speaker

and two Rumbler speakers, without the need for a separate amplier (see Figure 3.2). By

default, the siren is set for two 11-ohm impedance, 100 W speakers. See the Convergence

Network Conguration Software for all available programming options available for the

Pathnder tones.

18

Pathnder

TM

Page 19

Chapter 3: Wiring the Pathnder

Speaker Diagnostics

The Pathnder siren is designed to detect speaker faults. Diagnostic LEDs available on the

front of the keypad that can provide operating status of each of the amplier outputs. The LEDs

are fully programmable and can be set to steady burn or ash when the siren detects a fault or

normal operation for each individual speaker. By default, the diagnostic LEDs are disabled, but

can be programmed with the Convergence Network Conguration Software.

Radio Re-Broadcast

The Radio Re-Broadcast inputs allow incoming two-way radio messages to be amplied by the

siren amplier/relay module and rebroadcast over the siren speakers. The Radio Re-Broadcast

gain is set in the Convergence Network Conguration Software.

FS Vehicle Integration

The Pathnder can interface with the vehicle’s OBDII port or up-tter CAN bus, using a

separately available cable harness. Common signals that can be obtained are transmission,

door, headlight, brake and speed statues. Many other signals may available depending on

the make and model of vehicle. See the Convergence Network Conguration Software for

programming options. If using FS Vehicle Integration, discrete wiring inputs may not be

required for park, horn ring and/or ignition. By default, the PathFinder has the FS Vehicle

Integration port disabled.

Ignition Input

The ignition input a programmable active high input that can be used to turn on and off the

Pathnder system. This input can be programmed to keep the system alive for a set time

after ignition is removed. This input is by default set to turn off the system immediately

when ignition is removed. The functionality of the ignition wire can be congured with the

Convergence Network Conguration Software. If using FS Vehicle Integration to detect the

ignition event or key position, this wire is not used. Fold and seal.

System Power

The Pathnder system includes ring terminals for connecting the battery. The installer-supplied

red (positive) and black (negative ground) power leads from the siren to the vehicle battery

should be as short and direct as possible. Crimp the supplied ring terminal on the red lead

and connect it through an in-line fuse to the positive battery terminal. The fuse must be of an

amperage capacity sufcient to handle the total vehicle electrical loads plus siren. Crimp the

supplied ring terminal on the black lead and connect it to the negative battery terminal. See

Figure 3.3 for proper ring terminal orientation.

Pathnder

TM

19

Page 20

Chapter 3: Wiring the Pathnder

Figure 3.3 Battery Connections

20

Pathnder

TM

Page 21

CHAPTER 4

Mounting the Pathnder

The next step in the installation after wiring and connecting the system is to permanently mount the

siren in the vehicle. Verify that the mounting locations you selected earlier are safe for installing these

components. Before proceeding, review the following precautions before mounting the equipment.

AIRBAG DEPLOYMENT: Do not install equipment or route wiring in the

deployment path of an airbag. Failure to observe this warning will reduce the

effectiveness of the airbag or potentially dislodge the equipment, causing

serious injury or death.

SEAT REMOVAL PRECAUTION: If a vehicle seat is temporarily removed, verify

with the vehicle manufacturer if the seat needs to be recalibrated for proper

airbag deployment.

UNIT REQUIRES AIR FLOW: Do not install the siren in areas where the air ow is

restricted. Do not mount the unit near a heater duct or under the hood.

MODULE IS NOT WATERPROOF: The housing of the siren is NOT waterproof.

Select a mounting location that allows the vehicle, controls, and microphone to be operated safely

under all driving conditions. To identify safe mounting areas for equipment inside the vehicle, consult

the vehicle manufacturer’s guidelines. To avoid driver distraction and unreliable switch activation, the

mounting location must not allow any movement of the unit. Installer-supplied mounting hardware is

required to mount the siren.

Pathnder

TM

21

Page 22

Chapter 4: Mounting the Pathnder

7.0 in (17.78 cm)

1.4 in (3.55 cm)

Figure 4.1 Pathnder Dimensions

6.0 in (15.24 cm)

2.5 in (6.35 cm)

Figure 4.2 Mounting Hardware Dimensions

.47 in (1.19 cm) .28 in (.71 cm)

4.37 in (11.09 cm)

22

Pathnder

TM

Page 23

Chapter 4: Mounting the Pathnder

Figure 4.3 Bail Bracket Assembly

Mounting the Siren

1. Use the bracket as a template or the dimensions shown in Figure 4.2 to mark the centers of the

two mounting holes.

2. Choose a bit appropriate for the installer-supplied mounting hardware and drill the center of the

two mounting holes.

3. Mount the bracket with the installer-supplied mounting hardware.

4. Insert the ¼-20 carriage bolts into the bracket and loosely install the ¼" washers and Keps nuts.

5. Slide the siren onto the bracket assembly and tighten the ¼" nuts. Do not overtighten.

Mounting the Control Head (PF200R)

The control head comes with two mounting brackets and mounting hardware.

To mount the control head:

1. Secure a bracket to the control head with the 6-32 x ¼ Phillips screws and #6 lock washers

(Figure 4.4 on page 23).

2. Using a 7/16" nut driver, secure the other bracket to the control head/bracket assembly with the

¼-20 x 3/4 hex head screws and ¼" lock washers (Figure 4.5).

3. Use the mounting bracket as a template and scribe two drill position marks at the selected

mounting location.

Pathnder

TM

23

Page 24

Chapter 4: Mounting the Pathnder

Figure 4.4 Bracket Attached to Back of Control Head

Figure 4.5 Brackets Attached to Control Head and Mounting Surface

4. With an 11/64 bit, drill two mounting holes at the drill position marks.

5. Secure the mounting bracket to the mounting surface with the #10 thread-forming screws

(Figure 5.3).

6. To adjust the angle of the control head, loosen the hinge screws, tilt the control head forward or

backward, then securely tighten the screws

24

Pathnder

TM

Page 25

CHAPTER 5

Testing the Pathnder Installation

The Pathnder is programmed with a default conguration that you can use to quickly check your

initial installation system before you congure the system. Test all vehicle functions, including horn

operation, vehicle safety functions, and vehicle lighting systems for proper operation. Ensure that

the installation has not affected the vehicle operation or changed any vehicle safety functions or

circuits. Do not test the sound and light system of the vehicle while driving. Operating the vehicle

warning system may pose a hazard to the operator and other drivers if the system does not function as

expected. Test the vehicle only in a controlled environment. After testing is complete, provide a copy

of this manual to the instructional staff and all operating personnel.

Figure 5.1 Pathnder Default Programming

BTN 1

BTN 8

Volume ControlPush Buttons

BTN 2 BTN 3 BTN 4 BTN 5 BTN 6 BTN 7

Speaker Diagnostics

BTN 9

SignalMaster DisplayRotary KnobSlide Switch

Microphone

Self-Contained Model

Pathnder

TM

25

Page 26

Chapter 5: Testing the Pathnder Installation

Table 5.1 Pathnder Switch Default Programming

Switch Default Function

Slide Switch 1 Relay 1 ON, Relay 7, 8 – 90 FPM Alternate Flash,

Lightbar – Pattern 10, Front Cuto

Slide Switch 2 Relay 1 ON, Relay 2 ON, Relay 7, 8 – Double 120 FPM Alternate

Flash, Horn Ring Transfer, Lightbar – Pattern 17

Slide Switch 3 Relay 1 ON, Relay 2 ON, Relay 3 ON, Relay 4 ON, Relay 7,

8 – Common Quad 95 FPM Alternate Flash, Horn Ring Transfer,

Siren Enabled, Lightbar – Pattern 26, Flash White Enable

Rotary – Radio Radio Re-Broadcast

Rotary – Manual Standby

Rotary – Wail* Wail Horn Ring Transfer

Rotary – Yelp* Yelp Horn Ring Transfer

Rotary – HF* Horn Siren Control, Horn Ring Transfer

Rotary – Tone 1* Priority

Rotary – Tone 2* Dual Tone (Wail/Yelp)

Volume Switch Turns O Keypad Backlighting

*Siren Tones Dependent on Slide Switch 3

Table 5.2 Pathnder Button Default Programming

Button Default Function

BTN 1 Air Horn

BTN 2 Lightbar Left Alley

BTN 3 Step 1 – Lightbar Takedown

Step 2 – Lightbar Scene, Relay 5 ON

BTN 4 Lightbar Right Alley

BTN 5 Lightbar Cruise Pattern 2

BTN 6 Lightbar Dim

BTN 7 Relay 6 ON (12V) (8 Second Timer)

BTN 8 Manual Siren

BTN 9 Lightbar SM LRCO

26

Pathnder

TM

Page 27

Table 5.3 Pathnder Input Default Programming

Button Default Function

Ignition System Enable

Park Siren Mute, Relay 4 Cuto

Lightbar White Light Cuto

Horn Ring Siren Tone Override/Control

Input 1 Relay 9 ON

Input 2 Relay 10 ON

Input 3 Relay 11 ON

Input 4 Relay 12 ON

Chapter 5: Testing the Pathnder Installation

Pathnder

TM

27

Page 28

CHAPTER 6

AU

Y

E

Control Head Legends and Safety Messages

To complete the installation, the kit includes:

◆ A scored sheet of replaceable keypad legends that identify the functions of the control head

buttons). Before installing the legends, congure the operation of the control head with the

Convergence Conguration Software (see the Convergence Network Software Conguration

Manual, part no. 2562418).

◆ A scored sheet of two labels with precautions to guard against hearing loss when operating the

siren (part no. 1612339).

◆ A safety message card for operators of Federal Signal Sound and Light System

(part no. 256B691).

Applying the Replaceable Control Head Legends

To apply the legends:

1. Peel the appropriate legends from the sheet and apply them to the control head buttons.

2. Verify that the label is properly tucked under the retaining ridge on the button.

Figure 6.1 Installing the Control Head Labels

LEGEND STICKER

MAN

RIGHT

ALLEY

28

REMOVED FROM

ADHESIVE SHEET

BLANK PUSHBUTTONS

INSERTED LEGENDS

CONTROL PAD

Pathnder

ADHESIVE SHEET

WAIL

TM

AUX 1

A / H

P

AREA

DOOR

DOM

AUX 2

WAIL

290A6323

Page 29

Chapter 6: Control Head Legends and Safety Messages

Distributing the Safety Message Card

Give the operator of the system the card entitled “Safety Message to Operators of Federal Signal

Light/Sound Systems” (part no. 256B691) (Figure 6.2). The operator must read and understand the

safety instructions and keep the card in the vehicle for reference.

Applying the Siren Safety Labels in the Vehicle

The kit includes a sheet of two labels with siren safety messages (part no. 1612339) (Figure 6.2).

These labels must be installed in the vehicle in which the system is installed. Install these labels in

areas that are clearly visible to operators and passengers. Do not install the labels in locations that

would impair the operators’ abilities to operate the vehicle. Never install the labels in areas where

airbags may deploy.

Figure 6.2 Safety Message Card (left) and Siren Safety Labels (right)

Pathnder

TM

29

Page 30

CHAPTER 7

Safety Messages to Personnel Servicing Federal

Electronic Sirens

The people’s lives depend on your proper servicing of Federal Signal products. It is important to read

and follow all instructions shipped with the products. In addition, listed below are some other safety

instructions and precautions you should follow:

◆ Read and understand all instructions in this manual before servicing the electronic siren or control

head.

◆ To properly service an electronic siren or control head, you must have a good understanding

of automotive electrical procedures and systems, along with prociency in the installation

and service of safety warning equipment. Always refer to the vehicle service manuals when

performing service on a vehicle.

◆ Electronic repairs must be performed by a qualied and competent electronics technician. Your

hearing and the hearing of others, in or close to your emergency vehicle, could be damaged by

loud sounds. This can occur from short exposures to very loud sounds or from longer exposures

to moderately loud sounds. For hearing conservation guidance, refer to federal, state, or local

recommendations. OSHA Standard 1910.95 offers guidance on “Permissible Noise Exposure.”

◆ All effective sirens and horns produce loud sounds (120 dB) that may cause permanent hearing

loss. Always minimize your exposure to siren sound and wear hearing protection. Do not sound

the siren indoors or in enclosed areas where you and others will be exposed to the sound.

◆ Do NOT connect this system to the positive terminal of the battery until servicing is complete and

you have veried that there are no short circuits to ground.

◆ For the electronic siren to function properly, the ground connection must be made to the

NEGATIVE battery terminal.

◆ After repair, test the electronic siren and speaker system to ensure that it is operating properly.

◆ Federal Signal siren ampliers and speakers are designed to work together as a system.

Combining a siren and speaker from different manufacturers may reduce the warning

effectiveness of the siren system and may damage the components. You should verify or test your

combination to make sure the system works together properly and meets both federal, state and

local standards or guidelines. Failure to follow all safety precautions and instructions may result

in property damage, serious injury, or death.

30

Pathnder

TM

Page 31

CHAPTER 8

Servicing the Pathnder

Federal Signal recommends that the siren be returned to your local distributor or Federal Signal for

service. External components such as cabling are available as replacement parts (see Table 8.1).

Except for the slide switch in the siren, there are no other user-serviceable parts within the unit. After

servicing the system, test it to ensure that it is operating properly.

Replacing the Slide Switch

The slide switch can be removed from the siren without removing the siren from the vehicle in most

installations.

STATIC SENSITIVE DEVICE — The circuitry of the control head can be damaged

by electrostatic discharge. Follow anti-static procedures removing the slide

switch.

Figure 8.1 Keypad Removal

Pathnder

TM

31

Page 32

Chapter 8: Servicing the Pathnder

To replace the slide switch:

1. Use a T20 Torx driver to remove the four 8-32 shoulder screws securing the keypad to the

extrusion. (Figure 8.1).

2. Disconnect the ribbon cable and microphone lead from amp PCBA.

3. Gently unsnap the siren bezel from the keypad (Figure 8.2).

4. Note the orientation of the slide switch knob. Use a 1/64" hex key wrench to loosen the set screw

securing the knob to the shaft.

5. Remove the two #4-40 x 5/16" Phillips head screws securing the slide switch bezel to the control

head assembly. Unplug and remove old switch.

6. Place the new switch assembly in position with the knob in the same orientation as the old

switch.

7. Secure the switch bezel to the control head assembly with the two #4-40 x 5/16" Phillips head

screws.

8. Reinstall the knob and tighten set screw. Do not over-tighten screws.

9. Plug the slide switch connector into the four-pin connector on the control head assembly.

10. Snap the siren bezel to the keypad, connect the ribbon cable and microphone lead to the amp

PCBA, and secure the assembly with the four 8-32 shoulder screws. Do not over-tighten screws.

Figure 8.2 Slide Switch Replacement

32

Pathnder

TM

Page 33

Chapter 8: Servicing the Pathnder

Table 8.1 Service Parts

Description Part Number

Keypad Legends 8572294

Cable Assy, RS485, 25ft 1751357-02

Wire Assy, Relay, Pathnder 17501359

Wire Assy, I/O, Pathnder 17501360

Term, #8, 6AWG 19001363

Slide Switch Assy 122290

Bezel, Slide Switch 8573060

Knob, Aluminum, Slide Switch 85361185

Screw, #4-40 Flat Head, Phillips 7000259-06

Knob, Volume 141134

Keypad Assy 862302143

Screw, 8-32 Shoulder, Fillister HD, 6 Lobe 70000738-10

Pathnder

TM

33

Page 34

Chapter 8: Servicing the Pathnder

Getting Technical Support and Service

Federal Signal Corporation will service your equipment or provide technical assistance with any

problems that cannot be handled locally. Any product returned to Federal Signal for service, inspection,

or repair must be accompanied by a Return Material Authorization number. The RMA number can be

obtained from your local distributor or Federal Signal. Please provide a brief explanation of the service

requested or the nature of the malfunction. Contact your local dealer/distributor for replacement parts

availability or contact the Federal Signal Service Department (7 a.m. to 5 p.m., Monday through Friday,

Central Time) at:

Service Department

Federal Signal Corporation

2645 Federal Signal Drive

University Park, IL 60484-3167

800-433-9132

www.fedsig.com

34

Pathnder

TM

Page 35

Chapter 8: Servicing the Pathnder

Returning a Product to Federal Signal

Before returning a product to Federal Signal, call 800-264-3578, 800-433-9132, or 800-824-0254

to obtain a Returned Merchandise Authorization number (RMA number). To expedite the process,

please be prepared with the following information:

• Your Federal Signal customer or account number.

• The purchase order number under which the items were purchased.

• The shipping method.

• The model or part number of the product being returned.

• The quantity of products being returned.

• Drop ship information as needed.

• Any estimate required.

When you receive your RMA Number:

• Write the RMA number on the outside of the box of returned items.

• Reference the RMA number on your paperwork inside of the box.

• Write the RMA number down, so that you can easily check on status of the returned equipment.

Send all material with the issued RMA Number to:

Federal Signal Corporation

2645 Federal Signal Drive

University Park, IL 60484-3167

Attn: Service Department

RMA: #__________

Pathnder

TM

35

Page 36

2645 Federal Signal Drive, University Park, IL 60484-3167

Tel.: (800) 264-3578 • 708-534-3400 • Fax: (800) 682-8022

www.fedsig.com

© 2018 Federal Signal Corporation

36

Pathnder

TM

Loading...

Loading...