Federal Signal Corporation Global G-SPA-D Series, Global G-SPA-E Series, Global G-SPA-T Series, Global G-SPA Series, Global Series Installation And Maintenance Instructions Manual

Page 1

Global Series

Model G-SPA Amplied Speaker

For Use in Hazardous Locations

Installation and

Maintenance Instructions

To view this manual in Portuguese, go to www.federalsignal-indust.com.

To view this manual in Mandarin, go to www.federalsignal-indust.com.

To view this manual in Russian, go to www.federalsignal-indust.com.

25500188

Rev. A0 0815

Printed in U.S.A.

Page 2

Warranty – Seller warrants all goods for ve years on parts and 2-1/2 years

on labor, under the following conditions and exceptions: Seller warrants that

all goods of Seller's manufacture will conform to any descriptions thereof

for specications which are expressly made a part of this sales contract and

at the time of sale by Seller such goods shall be commercially free from

defects in material or workmanship. Seller reserves the right at the Seller’s

discretion to “Repair and Return” or “Replace” any item deemed defective

during the warranty period. This warranty does not cover travel expenses,

the cost of specialized equipment for gaining access to the product, or labor

charges for removal and reinstallation of the product. This warranty shall be

ineffective and shall not apply to goods that have been subjected to misuse,

neglect, accident, damage, improper maintenance, or to goods altered or

repaired by anyone other than Seller or its authorized representative, or if

ve years have elapsed from the date of shipment of the goods by Seller with

the following exceptions: lamps and strobe tubes are not covered under this

warranty. Outdoor warning sirens and controllers manufactured by Federal

Warning Systems are warranteed for two years on parts and one year on labor.

No agent, employee, representative or distributor of Seller has any authority

to bind the Seller to any representation, afrmation, or warranty concerning

the goods and any such representation, afrmation or warranty shall not be

deemed to have become a part of the basics of the sales contract and shall

be unenforceable. THE FOREGOING WARRANTIES ARE EXCLUSIVE

AND IN LIEU OF ALL OTHER WARRANTIES OR MERCHANTABILITY,

FITNESS FOR PURPOSE AND OF ANY OTHER TYPE, WHETHER

EXPRESS OR IMPLIED. These warranties shall not apply unless Seller

shall be given reasonable opportunity to investigate all claims for allegedly

defective goods. Upon Seller's instruction a sample only of allegedly defective

goods shall be returned to Seller for its inspection and approval. The basis of

all claims for alleged defects in the goods not discoverable upon reasonable

inspection thereof pursuant to paragraph 8 hereof must be fully explained

in writing and received by Seller within thirty days after Buyer learns of the

defect or such claim shall be deemed waived.

Industrial Systems

2645 Federal Signal Drive • University Park, IL 60484-3167

Tel: 708-534-4756 • 877-289-3246 • Fax: 708-534-4852

Email: elp@federalsignal.com • www.federalsignal-indust.com

Page 3

Contents

Safety Messages to Installers and Users ...................................5

Certication ...................................................................................6

Unpacking the Amplied Speaker ..............................................7

Creating Combination Fixtures in the Field ...............................7

Mounting the Amplied Speaker .................................................8

Mounting the Trunnion-Mount Amplied speaker ............................ 8

Mounting the Surface-Mount Ex d Amplied Speaker ................... 10

Mounting the Ex de Surface-Mount Amplied Speaker ...................11

Safety Messages for Wiring .......................................................13

Connecting to the Terminal Block ............................................14

Preparing to Wire the Ex d Flameproof Models .......................14

Wiring the Ex d Models ................................................................... 15

Adjusting the Sound Pressure and Audio Input (Ex d) .................... 17

Preparing to Wire the Ex de Increased Safety Models ............19

Wiring the Ex de Models ................................................................. 20

Adjusting the Sound Pressure and Audio Input (Ex de) .................. 22

Safety Messages to Maintenance Personnel ...........................23

Maintaining the Amplied Speaker ...........................................24

Cleaning the Enclosure .................................................................... 24

Lubricating the Threaded Joints ....................................................... 24

Ordering Replacement Parts and Accessories .......................24

Getting Repair Service or Technical Assistance .....................25

Returning the Product for Credit ..............................................27

Model G-SPA Global Series Amplied Speaker

3

Page 4

Contents

Tables

Table 1 Replacement part ..................................................................... 25

Table 2 Accessories .............................................................................. 25

Table 3 Choosing cable-entry devices for Equipment

in Potentially Explosive Atmospheres .....................................................26

Figures

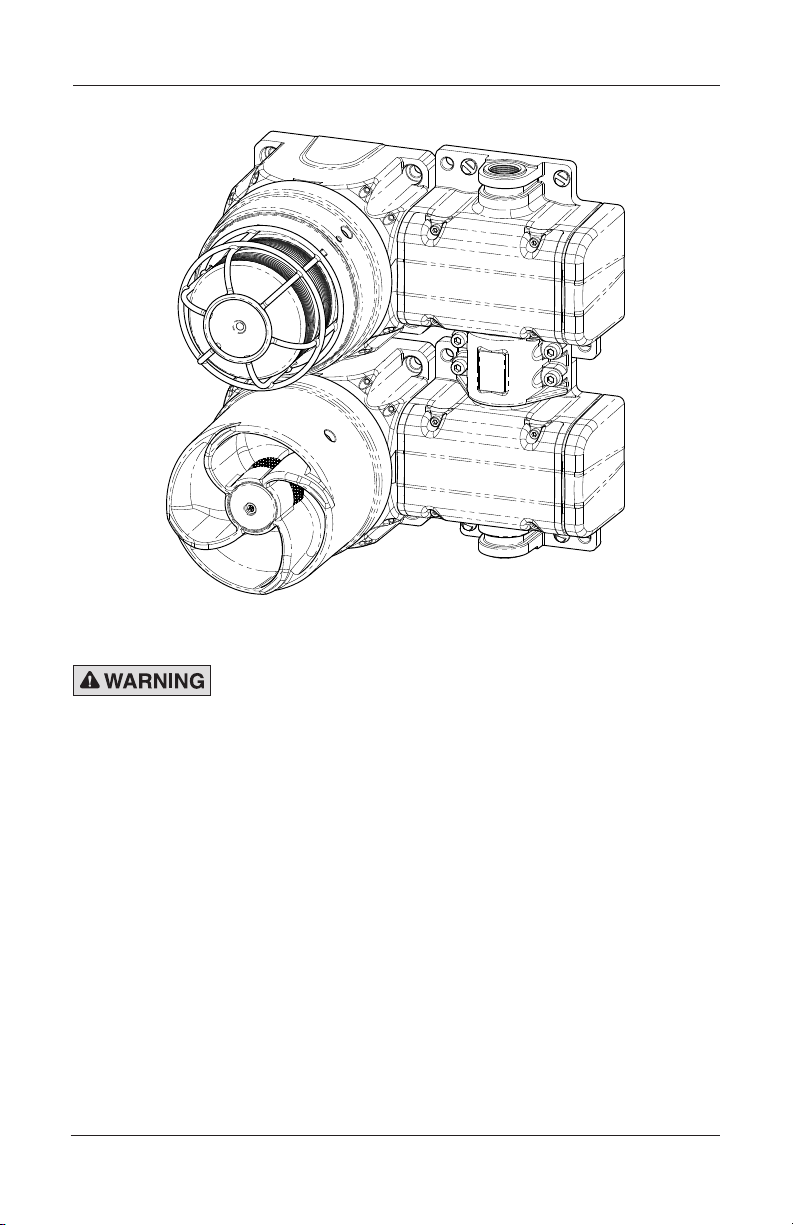

Figure 1 Beacon and amplied speaker combination xture .................. 8

Figure 2 Bracket dimensions .................................................................. 9

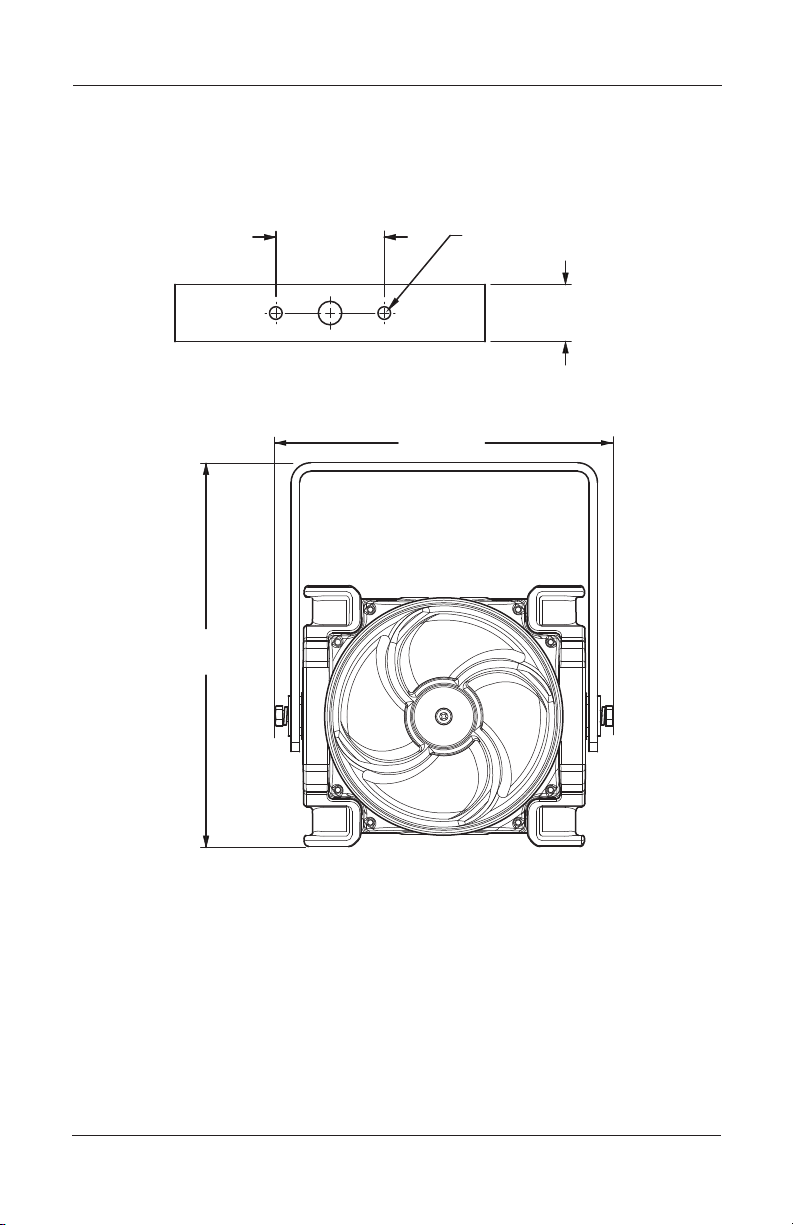

Figure 3 Front view of trunnion-mount amplied speaker....................... 9

Figure 4 Side view of trunnion mount amplied speaker ...................... 10

Figure 5 Front view of Ex d amplied speaker...................................... 10

Figure 7 Front view of Ex de surface mount ......................................... 11

Figure 8 Side view of Ex de surface mount .......................................... 12

Figure 9 Disengaging a terminal block spring clamp ............................ 14

Figure 10 Ex d in/out PCB connections ................................................ 15

Figure 11 Location of VR1 potentiometer (sound pressure) ................. 17

Figure 12 Location of jumper JP3 (audio input) .................................. 18

Figure 13 Connections for DC or AC Ex de amplied speaker ............. 20

© 2015 Federal Signal Corporation. All rights reserved.

4

Model G-SPA Global Series Amplied Speaker

Page 5

Installation and Maintenance Instructions

Safety Messages to Installers and Users

It is important to follow all instructions shipped with this product.

This amplied speaker is to be installed by a trained electrician who

is thoroughly familiar with and will follow all applicable national and

local codes in the country of use.

This amplied speaker should be considered a part of the warning

system and not the entire warning system.

The selection of the mounting location for the amplied speaker, its

controls and the routing of the wiring are to be accomplished under

the direction of the facilities engineer and the safety engineer. In

addition, listed below are some other important safety instructions and

precautions you should follow:

• Read and understand all instructions before installing or operating

this equipment.

• To avoid electrical shock hazards, do not connect wires when

power is applied. Failure to observe this warning may lead to

serious injury or death.

• Never alter the unit in any manner. Safety in hazardous locations

may be endangered if additional openings or other alterations are

made in units specically designed for use in these locations.

• Do not connect this amplied speaker to the system when power

is on.

• All effective warning speakers produce loud sounds, which

may cause, in certain situations, permanent hearing loss. Take

appropriate precautions such as hearing protection. The device

should be installed far enough away from potential listeners to

limit their exposure while still maintaining its effectiveness.

• After installation, ensure that all threaded joints are properly

tightened.

Model G-SPA Global Series Amplied Speaker

5

Page 6

Installation and Maintenance Instructions

• After installation, test the amplied speaker system to ensure that

it is operating properly

• Keep the unit tightly closed when in operation.

• After testing is complete, provide a copy of this instruction sheet

to all personnel.

• Brass inserts have the potential to store charge when they are not

plugged. Consideration should be taken to prevent these from

becoming a sparking hazard.

• Establish a procedure to routinely check the amplied speaker

system for proper activation and operation.

Failure to follow all safety precautions and instructions may result in

property damage, serious injury, or death.

Certication

Certicate Nos.: ATEX Cert No.: Baseefa15ATEX0155X

IECEx Cert No.: IECEx BAS 15.0104X

ATEX coding: II 2 G D

Protection: Ex db IIB T5 Gb or Ex db e IIB T5 Gb

Ex tb IIIC T100°C Db IP66 (Tamb = -50°C to + 49°C)

Ex db IIC T4 Gb or Ex db e IIC T4 Gb

Ex tb IIIC T135°C Db IP66 (Tamb = -50°C to + 60°C)

Standards: EN60079-0: 2012 +A11:2013, EN60079-1: 2014,

EN60079-7: 2007, EN60079-31: 2014, IEC60079-0: 6th Ed.,

IEC 60079-1: 7th Ed., IEC 60079-7: 4th Ed.,

IEC 60079-31:2nd Ed

Specic Conditions of Use:

1. The Modular Audible Device enclosure incorporates a sinter and

the volume is greater than 100 cm3, therefore use of the Modular

Audible Device in carbon disulphide gas atmospheres is not

permitted.

2. The Modular Audible Device has external non-metallic surfaces

which may provide electrostatic charging hazard. See the

manufacturer's instructions for further information.

6

Model G-SPA Global Series Amplied Speaker

Page 7

Installation and Maintenance Instructions

3. The Modular Audible Device has metallic components in the non-

metallic walls of the enclosure which can store electrical charge

and therefore may provide a potential electrostatic discharge.

The metallic brass inserts have a capacitance of 24 pF. See the

manufacturer's instructions for further information.

Unpacking the Amplied Speaker

After unpacking the amplied speaker, examine it for damage that

may have occurred in transit. If it has been damaged, do not attempt to

install or operate it. File a claim immediately with the carrier, stating the

extent of the damage. Carefully check all envelopes, shipping labels,

and tags before removing or discarding them. Disposal of all shipping

materials must be carried out in accordance with national and local

codes and standards. If any parts are missing, please call Federal Signal

Customer Support at +1 708-534-4756 or +1 877-289-3246.

Creating Combination Fixtures in the Field

The Federal Signal Global Series Ex de products can be connected

together in the eld using interchangeable E-box end caps and a

proprietary coupling system.

The proprietary coupling system allows for simple and cost effective,

wiring from product to product often eliminating the need for

expensive Ex wiring practices and Ex rated glands. The E-box is

available only when factory installed on an Ex d unit or when used

as a E-box spacer adjoining an existing E-box. Please refer to the

accessories listed on page 25 for available options. When creating

certain xture combinations, it is necessary to replace E-box end caps

before mounting the product. If you are creating combination xtures,

refer to instruction manual 25500259 for specic instructions and

details.

A note about combination xtures: If the product is Ex db marked

only, it is for use in gas atmospheres. If the product is Ex db e marked,

it uses the increased-safety terminal enclosures and is only for gas

atmospheres. If the product is Ex tb marked, it is for installation in

dust atmospheres.

Model G-SPA Global Series Amplied Speaker

7

Page 8

Installation and Maintenance Instructions

Figure 1 Beacon and amplied speaker combination xture

Mounting the Amplied Speaker

ATTACH THE AMPLIFIED SPEAKER SECURELY: To prevent injury,

this apparatus must be securely attached to the mounting surface

in accordance with the installation instructions. Use installersupplied fasteners suitable for the mounting surface.

The mounting method and the installer-supplied mounting hardware

depend on which of the three G-SPA models you are installing:

Mounting the Trunnion-Mount Amplied speaker

For the amplied speaker dimensions, see Figures 3 on page 9 and

4 on page 10. Mount the trunnion bracket to a at surface using

the two 7.0 mm mounting holes (Figure 2). Use installer-supplied

fasteners suitable for the surface to which the device will be

mounted.

8

Model G-SPA Global Series Amplied Speaker

Page 9

Installation and Maintenance Instructions

60.0 mm

2X M6 SCREW HOLE

189.2 mm

To adjust the vertical angle of the amplied speaker, loosen

the fasteners on the mounting bracket to disengage the ratchet.

Vertically aim the amplied speaker, and tighten the fasteners.

Figure 2 Bracket dimensions

(2.36 in)

31.8 mm

(1.25 in)

Figure 3 Front view of trunnion-mount amplied speaker

(7.45 in)

215.2 mm

(8.47 in)

Model G-SPA Global Series Amplied Speaker

9

Page 10

Installation and Maintenance Instructions

Ø133.8 mm (5.27 in)

4X COUNTER-BORED

Figure 4 Side view of trunnion mount amplied speaker

190.6 mm

(7.50 in)

Mounting the Surface-Mount Ex d Amplied Speaker

Mount the amplied speaker to a at surface using the four 8.5 mm

mounting holes. Use installer-supplied fasteners suitable for the

surface to which the device will be mounted.

10

Figure 5 Front view of Ex d amplied speaker

105.9 mm

(4.17 in

105.9 mm

)

(4.17 in

Model G-SPA Global Series Amplied Speaker

HOLES TO FIT M8

SOCKET-HEAD

CAP SCREWS

Page 11

Installation and Maintenance Instructions

(4.83 in)

4X COUNTER-BORED

Mounting the Ex de Surface-Mount Amplied Speaker

Mount the amplied speaker to a at surface using the six 8.5 mm

mounting holes. Use installer-supplied fasteners suitable for the

surface to which the device will be mounted.

Figure 7 Front view of Ex de surface mount

HOLES TO FIT M8

SOCKET-HEAD

CAP SCREWS

105.9 mm

(4.17 in)

23.2 mm

(0.91 in)

2X Ø8.5 mm

3X M20

GLAND

ENTRIES

103.2 mm

(4.06 in)

122.6 mm

Model G-SPA Global Series Amplied Speaker

11

Page 12

Installation and Maintenance Instructions

272.0 mm

Figure 8 Side view of Ex de surface mount

190.6 mm

(7.50 in)

(10.71 in)

3X M20 GLAND ENTRIES

REPLACEABLE E-BOX END CAPS

12

SEE ACCESSORIES FOR

Model G-SPA Global Series Amplied Speaker

Page 13

Installation and Maintenance Instructions

Safety Messages for Wiring

When installing and operating ame-proof electrical equipment,

the relevant national regulations for installation and operation (e.g.,

EN60079-14, IEC Wiring Regulations and NEC/CEC) must be

observed.

• To avoid electrical shock hazards, do not connect wires when

power is applied. Failure to observe this warning may lead to

serious injury or death.

• To maintain the ame-proof integrity of the enclosure, DO NOT

damage the cover or threads while disassembling or reassembling

the unit.

• Painting and surface nishes, other than those applied by Federal

Signal Corporation, are not permitted.

• Cable termination should be in accordance with specications

applying to the application. Federal Signal recommends that all

cables and cores should be fully identied.

• Ensure that only the correct equipment-certied glands are used

and that the assembly is shrouded and correctly earthed. Gland

entries are M20-1.5 6H with an option for the M25 entry on the

end of the increased safety box models. See Table 3 on page 30

for choosing correct cable entry devices for Equipment in

Potentially Explosive Atmospheres.

• Because of space limitations, ensure the cable cores within the

unit are not too slack.

• In all countries, the wiring must comply with all national and local

codes and standards.

• Ensure that all nuts, bolts, and xings are secure.

Model G-SPA Global Series Amplied Speaker

13

Page 14

Installation and Maintenance Instructions

Connecting to the Terminal Block

The terminal block for all models uses a spring clamp connection

to engage the wire. To disengage the clamp, insert the tip of the

screwdriver into the small openings near the top and press down. Insert

the stripped wire into the larger opening and remove the screwdriver to

engage the wire clamp.

Figure 9 Disengaging a terminal block spring clamp

Preparing to Wire the Ex d Flameproof Models

SHOCK HAZARD: To avoid electrical shock hazards, do not

connect wires when power is applied. Failure to observe this

warning may lead to serious injury or death.

CIRCUIT BOARD DAMAGE: The DC amplied speakers are

polarity sensitive, and MAY BE DAMAGED by incorrect electrical

hookup. When connecting the DC amplied speaker to the voltage

supply lines, POLARITY MUST BE OBSERVED. In addition,

damage will result if the voltage rating of the particular model is

exceeded by more than 10 percent.

This section has wiring instructions for the ameproof models

G-SPA 24 Vdc, 120 Vac, 220-240 Vac.

The maximum wire gauge is 2.5 mm2 (12 AWG). The wire must

be rated 85 °C or higher. Use only stranded cable to terminate the

amplied speaker.

The cross-sectional area of the primary earth

(ground) must equal the cross-sectional area of the phase conductor.

14

Model G-SPA Global Series Amplied Speaker

Page 15

Installation and Maintenance Instructions

Cable termination for these models should be in accordance with

specications applying to the application. It is recommended that all

cables and cores should be fully identied. Use the appropriate cable

gland for the application. Gland entry threads are M20-1.5 x 6H.

Tools needed:

• 1.5 mm A/F hexagon key

• No. 1 Phillips screwdriver

• Wire stripper

Figure 10 Ex d in/out PCB connections

VOLTAGE

SELECTOR

SWITCH

Wiring the Ex d Models

To wire the Ex d ameproof amplied speaker:

1. Unscrew the M3 hex set screw on the side of the housing one

full turn.

2. Remove the cover from the housing by turning the cover

counter-clockwise. Three 120 degree spaced reliefs are

provided for a 3/8 inch spanner wrench if needed. If the cover

will not unscrew, back out the set screw a few additional turns.

Model G-SPA Global Series Amplied Speaker

15

Page 16

Installation and Maintenance Instructions

3. Loosen the captive Phillips screw retaining the driver/printed

circuit board (PCB).

4. Slide out the PCB until the terminals clear the housing. Strip

the wire insulation 5 mm to 6 mm (0.22 in).

5. Follow the instructions below for your line voltage and

continue to Step 6 on page 18. Refer to Figure 10 on page 15

for the voltage selector switch.

120 Vac operation

a. Set the voltage selector switch to 120.

b. Connect the line (hot) power source wire to the terminal

block position marked L1 on the PCB.

c. Connect the neutral (common) power source wire to the

terminal block position marked L2 on the PCB.

d. Connect ground wire to the terminal block position

marked EARTH.

e. Connect the positive (+) audio source wire to the terminal

block position marked AUD+.

16

f. Connect the negative (–) audio source to the terminal

block position marked AUD-.

220-240 Vac operation

a. Set the voltage selector switch to 240.

b. Connect the line (hot) power source wire to the terminal

block position marked L1 on the PCB.

c. Connect the neutral (common) power source wire to the

terminal block position marked L2 on the PCB.

d. Connect ground wire to the terminal block position

marked EARTH.

e. Connect the positive (+) audio source wire to the terminal

block position marked AUD+.

f. Connect the negative (–) audio source to the terminal

block position marked AUD-.

Model G-SPA Global Series Amplied Speaker

Page 17

Installation and Maintenance Instructions

= MAX. VOLUME

24 Vdc operation

a. Connect the positive (+) power-source wire to the

terminal block position marked + on the PCB.

b. Connect the negative (–) power-source wire to the

terminal block position marked – on the PCB.

c. Connect ground wire to the terminal block position

marked EARTH.

f. Connect the positive (+) audio source wire to the terminal

block position marked AUD+.

g. Connect the negative (–) audio source to the terminal

block position marked AUD-.

Adjusting the Sound Pressure and Audio Input (Ex d)

Sound Pressure: See Figure 11. The 3/4-turn VR1

potentiometer on the PCB is factory-set to the maximum

sound pressure level (MAX). To reduce the level, turn VR1

counter-clockwise to the desired setting.

Figure 11 Location of VR1 potentiometer (sound pressure)

VR1 POTENTIOMETER:

FULL CLOCKWISE

Model G-SPA Global Series Amplied Speaker

17

Page 18

Installation and Maintenance Instructions

AUDIO INPUT LEVEL

Audio Input: See Figure 12. Two audio input levels are

available to match the audio level provided by the peripheral

system. To change the level from the factory-set 2.8 Vrms,

move jumper JP3 to 0.8 Vrms.

Figure 12 Location of jumper JP3 (audio input)

JP3 JUMPER FOR

6. Insert the PCB into the enclosure and fully tighten the PCB

captive screw.

7. Place the cover on the housing and tighten it by turning it

clockwise.

8. To ensure O-ring compression, the cover must be fully seated

against the housing when the threads are tightened. Turn

the M3 set screw on the side of the housing until the screw

contacts the housing.

9. Ensure that the unused wire entry is sealed with the provided

brass M20-1.5 x 6 g stopping plug (equipment-certied).

18

Model G-SPA Global Series Amplied Speaker

Page 19

Installation and Maintenance Instructions

Preparing to Wire the Ex de Increased Safety Models

SHOCK HAZARD: To avoid electrical shock hazards, do not

connect wires when power is applied. Failure to observe this

warning may lead to serious injury or death.

This section has wiring instructions for the three increased safety models:

G-SPA 120 Vac, G-SPA 220-240 Vac, and G-SPA 24 Vdc.

The maximum wire gauge is 4.0 mm2 (12 AWG). The wire must

be rated 85 °C or higher. Use only stranded cable to terminate the

amplied speaker.

(ground) must equal the cross-sectional area of the phase conductor.

Cable termination should be in accordance with specications

applying to the application. It is recommended that all cables and

cores should be fully identied. Use the appropriate cable gland for

the application. Gland entry threads are M20-1.5 6H.

Conductive metalwork, including cable glands, must be a minimum

of 5 mm away from the terminals.

The cross-sectional area of the primary earth

Leads connected to the terminals shall be insulated for the appropriate

voltage and this insulation shall extend to within 1 mm of the metal of

the terminal throat.

The G-SPA terminal block is supplied with three poles and two

conductors per pole. The terminal block allows for easy supply-in and

loop-out wiring to connect amplied speakers in series.

Tools needed:

• 3.0 mm A/F hexagon key

• No. 1 Phillips screwdriver

• Wire stripper

Model G-SPA Global Series Amplied Speaker

19

Page 20

Installation and Maintenance Instructions

Wiring the Ex de Models

CIRCUIT BOARD DAMAGE: The DC amplied speakers

are polarity sensitive, and MAY BE DAMAGED by incorrect

electrical hookup. When connecting the DC amplied speaker

to the voltage supply lines, POLARITY MUST BE OBSERVED.

In addition, damage will result if the voltage rating of the

particular model is exceeded by more than 10 percent.

To wire the Ex de models:

1. Unscrew the four M4 socket-head cap screws and remove the

terminal box cover.

2. Strip the wire insulation 8 mm to 9 mm (0.33 in).

NOTE: When using more than one single or multiple strand

lead, the connection into either side of any terminal must be

joined in a suitable manner, e.g. two conductors into a single

insulated crimped bootlace ferrule.

3. Follow the instructions starting below for your line voltage

and continue to Step 4 on page 22. Refer to Figure 10 on page

15 for the voltage selector switch.

20

Figure 13 Connections for DC or AC Ex de amplied speaker

Aud+L1/+ L2/-

L3/Alt+

A A

Model G-SPA Global Series Amplied Speaker

Aud-

Aud+L1/+ L2/- L3/Alt+ Aud-

Page 21

Installation and Maintenance Instructions

220-240 Vac operation

a. Connect the line (hot) power source wire to the position

marked L1/+ on the terminal block.

b. Connect the neutral (common) power source wire to the

position marked L2/- on the terminal block.

c. Connect the ground wire to the position marked on the

terminal block.

d. Connect the positive (+) audio source wire to the position

marked Aud + on the terminal block.

e. Connect the negative (-) audio source wire to the position

marked Aud - on the terminal block.

120 Vac operation

a. Connect the line (hot) power source wire to the position

marked L1/+ on the terminal block.

b. Connect the neutral (common) power source wire to the

position marked L2/- on the terminal block.

c. Connect the ground wire to the position marked on the

terminal block.

d. Connect the positive (+) audio source wire to the position

marked Aud + on the terminal block.

e. Connect the negative (-) audio source wire to the position

marked Aud - on the terminal block.

24 Vdc Operation

a. Connect the positive (+) power source wire to the position

marked L1/+ on the terminal block.

b. Connect the negative (-) power source wire to the position

marked L2/- on the terminal block.

c. Connect the ground wire to the position marked on the

terminal block.

Model G-SPA Global Series Amplied Speaker

21

Page 22

Installation and Maintenance Instructions

d. Connect the positive (+) audio source wire to the position

marked Aud + on the terminal block.

e. Connect the negative (-) audio source wire to the position

marked Aud - on the terminal block.

4. Secure the cover on the terminal box with the four M4

screws. Ensure that the gasket is properly seated to maintain

IP rating. Do not overtighten the screws.

Adjusting the Sound Pressure and Audio Input (Ex de)

To set levels for the Ex de models:

1. Unscrew the M3 hex set screw on the side of the housing one

full turn.

2. Remove the cover from the housing by turning the cover

counter-clockwise. Three 120 degree spaced reliefs are

provided for a 3/8 inch spanner wrench if needed. If the cover

will not unscrew, back out the set screw a few additional turns.

3. Loosen the captive Phillips screw retaining the driver/printed

circuit board (PCB).

4. Slide out the PCB.

Sound Pressure: See Figure 11 on page 17. The 3/4-turn

VR1 potentiometer on the PCB is factory-set to the maximum

sound pressure level (MAX). To reduce the level, turn VR1

counter-clockwise to the desired setting.

Audio Input: See Figure 12 on page 18. Two audio input

levels are available to match the audio level provided by the

peripheral system. To change the level from the factory-set

2.8 Vrms, move jumper JP3 to 0.8 Vrms.

5. Insert the PCB into the enclosure and fully tighten the PCB

captive screw.

6. Place the cover on the housing and tighten it by turning it

clockwise.

22

Model G-SPA Global Series Amplied Speaker

Page 23

Installation and Maintenance Instructions

7. To ensure O-ring compression, the cover must be fully seated

against the housing when the threads are tightened. Turn

the M3 set screw on the side of the housing until the screw

contacts the housing.

Safety Messages to Maintenance Personnel

Listed below are some important safety instructions and precautions

you should follow:

• Read and understand all instructions before operating this system.

• Repair of amepaths is not recommended.

• If you acquired a signicant quantity of units, it is recommended

that spares are also made available.

• To avoid electrical shock hazards, do not connect wires when

power is applied. Failure to observe this warning may lead to

serious injury or death.

• Any maintenance to the amplied speaker system must be

performed by a trained electrician who is thoroughly familiar with

all applicable national and local codes in the country of use.

• Any maintenance to the amplied speaker system must be done

with power turned off.

• Check the amplied speaker periodically to ensure that the

effectiveness of the device has not been reduced because it has

been clogged with a foreign substance or because objects have

been placed in front of it.

• Never alter the unit in any manner. Safety of the unit may be

affected if additional openings or other alterations are made to the

internal components or housing.

• The nameplate, which may contain cautionary or other information

of importance to maintenance personnel, should NOT be obscured

in any way. Ensure that the nameplate remains readable.

Model G-SPA Global Series Amplied Speaker

23

Page 24

Installation and Maintenance Instructions

• After performing any maintenance, test the amplied speaker

system to ensure that it is operating properly.

Failure to follow all safety precautions and instructions may result in

property damage, serious injury, or death.

Maintaining the Amplied Speaker

EXPLOSION HAZARD: To prevent ignition of hazardous

atmosphere, disconnect the amplied speaker from the supply

circuit before opening it. Do not open the amplied speaker in the

presence of explosive gases in the atmosphere. Failure to follow

this warning may result in serious injury or death.

During the working life of the amplied speaker, it should require

little or no maintenance. The non-metallic housing will resist

attack by most acids, alkalis, and chemicals and is as resistant to

concentrated acids and alkalis as most metal products. However,

if abnormal or unusual environment conditions occur due to plant

damage or accident, etc., visual inspection of the amplied speaker is

recommended.

Cleaning the Enclosure

The enclosure should be cleaned periodically with a damp cloth to

maintain maximum sound output. Periodic checks should be made

to ensure the effectiveness of this device has not been reduced

because the amplied speaker has become clogged with a foreign

substance or because objects have been placed in front of the

amplied speaker.

Lubricating the Threaded Joints

A silicone based, non-hardening, chemically compatible grease can

be applied if required.

Ordering Replacement Parts and Accessories

Replacement parts and accessories are listed in Tables 1 and 2. Due

to certication, certain component parts are not available for eld

replacement. Amplied speakers with this type of damage must be

24

Model G-SPA Global Series Amplied Speaker

Page 25

Installation and Maintenance Instructions

either replaced entirely or returned to Federal Signal for service.

To order, call Federal Signal Customer Support at 708-534-4756 or

877-289-3246.

Table 1 Replacement part

Description Part Number

Driver/PCB Assembly K859501403

Table 2 Accessories

Description Part Number

Indicator Ring/Legend Kit, Black G-KIT-RP-BK

Indicator Ring/Legend Kit, Blue G-KIT-RP-B

Indicator Ring/Legend Kit, Green G-KIT-RP-G

Indicator Ring/Legend Kit, Magenta G-KIT-RP-M

Indicator Ring/Legend Kit, Red G-KIT-RP-R

Indicator Ring/Legend Kit, Yellow G-KIT-RP-Y

E-Box Coupler Kit K859501228

E-Box End Cap, M20 K859500805-02

E-Box End Cap, M20 with Flange K859500805-03

In-Line E-Box Coupler Kit G-KIT-EC180

90-Degree E-Box Coupler Kit G-KIT-EC90

Extension Box Spacer Kit G-KIT-EXTB

Single Trunnion Kit G-KIT-ST

Dual Trunnion Kit G-KIT-DT

Getting Repair Service or Technical Assistance

Products returned for repair require a Return Authorization form from

your local distributor or from Federal Signal. To obtain repair service

or technical assistance from Federal Signal, call 708-534-4756 or

877-289-3246. For instruction manuals and information on related

products, visit: http://www.federalsignal-indust.com.

Model G-SPA Global Series Amplied Speaker

25

Page 26

Installation and Maintenance Instructions

Table 3 Choosing cable-entry devices for Equipment

in Potentially Explosive Atmospheres

Models Ex Atmospheres

G-SPA-XXX-D

Gas Cable entry devices shall

(Ex db surface

mount)

G-SPA-XXX-T

(Ex db trunnion

mount)

G-SPA-XXX-E

Gas For the ameproof amplied

(Ex db e surface

mount)

G-SPA-XXX-D

Dust Cable entry devices for the

(Ex db surface

mount)

G-SPA-XXX-T

(Ex db trunnion

mount)

G-SPA-XXX-E

(Ex db e surface

mount)

Cable Entry Devices (cable

glands, stopping plugs, etc.

be equipment certied as

ameproof. To maintain

the ingress protection of

the ameproof amplied

loudspeaker enclosure, we

recommend the cable entry

device be IP66 certied.

loudspeaker enclosure,

cable entry devices shall

be equipment certied as

ameproof. To maintain

the ingress protection of

the ameproof amplied

loudspeaker enclosure we

recommend the cable entry

device be IP66 certied. For

the increased safety terminal

enclosures (terminal boxes),

cable entry devices shall

be equipment certied as

increased safety and shall

maintain an IP rating of IP54.

and terminal enclosures shall

be equipment certied as

dust protected. To maintain

the ingress protection of the

amplied loudspeaker and

terminal enclosures the cable

entry devices shall be IP6X

certied.

26

Model G-SPA Global Series Amplied Speaker

Page 27

Installation and Maintenance Instructions

Returning the Product for Credit

Product returns for credit require a return authorization from your

local distributor prior to returning the product to Federal Signal.

Please contact your distributor for assistance.

A product is qualied to be returned for credit when the following

conditions are met:

• The product is resalable and in the original cartons.

• The product has not been previously installed.

• The product is the current revision.

• The product has not been previously repaired.

• The product is a standard product.

• The product is not a service part.

All returns are subject to a re-stock fee.

Defective products that are returned within the warranty period will

be repaired or replaced at Federal Signal’s sole discretion. Defective

products do not include those products with lamp failure.

Circumstances other than those listed above will be addressed on a

case-by-case basis

Model G-SPA Global Series Amplied Speaker

27

Page 28

Industrial Systems

2645 Federal Signal Drive • University Park, IL 60484-3167

Tel: 708-534-4756 • Fax: 708-534-4852

Email: elp@federalsignal.com

www.federalsignal-indust.com

Loading...

Loading...