Federal Signal Corporation Commander 371LED-120 Installation And Maintenance Manual

Commander® Rotating Light

Model 371LED-120

2562671A

REV. A1 0714

Printed in U.S.A.

Installation and

Maintenance Manual

français...............page 17

español...............página 33

Warranty – Seller warrants all goods for ve years on parts and 2-1/2 years

on labor, under the following conditions and exceptions: Seller warrants that

all goods of Seller's manufacture will conform to any descriptions thereof

for specications which are expressly made a part of this sales contract and

at the time of sale by Seller such goods shall be commercially free from

defects in material or workmanship. Seller reserves the right at the Seller’s

discretion to “Repair and Return” or “Replace” any item deemed defective

during the warranty period. This warranty does not cover travel expenses,

the cost of specialized equipment for gaining access to the product, or labor

charges for removal and reinstallation of the product. This warranty shall be

ineffective and shall not apply to goods that have been subjected to misuse,

neglect, accident, damage, improper maintenance, or to goods altered or

repaired by anyone other than Seller or its authorized representative, or if

ve years have elapsed from the date of shipment of the goods by Seller with

the following exceptions: lamps and strobe tubes are not covered under this

warranty. Outdoor warning sirens and controllers manufactured by Federal

Warning Systems are warranteed for two years on parts and one year on labor.

No agent, employee, representative or distributor of Seller has any authority

to bind the Seller to any representation, afrmation, or warranty concerning

the goods and any such representation, afrmation or warranty shall not be

deemed to have become a part of the basics of the sales contract and shall

be unenforceable. THE FOREGOING WARRANTIES ARE EXCLUSIVE

AND IN LIEU OF ALL OTHER WARRANTIES OR MERCHANTABILITY,

FITNESS FOR PURPOSE AND OF ANY OTHER TYPE, WHETHER

EXPRESS OR IMPLIED. These warranties shall not apply unless Seller

shall be given reasonable opportunity to investigate all claims for allegedly

defective goods. Upon Seller's instruction a sample only of allegedly defective

goods shall be returned to Seller for its inspection and approval. The basis of

all claims for alleged defects in the goods not discoverable upon reasonable

inspection thereof pursuant to paragraph 8 hereof must be fully explained

in writing and received by Seller within thirty days after Buyer learns of the

defect or such claim shall be deemed waived.

Industrial Systems

2645 Federal Signal Drive • University Park, IL 60484-3167

Tel: 708-534-4756 • Fax: 708-534-4852

Email: elp@federalsignal.com • www.federalsignal-indust.com

Model 371LED-120 Rotating Light

Contents

Safety Messages to Installers ..........................................................5

An Overview of the Model 371LED-120 ........................................... 6

Unpacking the Light .......................................................................... 6

Mounting the Light ............................................................................8

Pipe Mounting the Light .......................................................... 8

Surface Mounting the Light

Installing the Optional 22.5-Degree Reector ................................. 9

Wiring the Light ............................................................................... 11

Safety Messages to Maintenance Personnel ................................ 13

Maintaining the Model 371LED-120 ...............................................13

Getting Service, Assistance, and Parts ......................................... 14

.....................................................9

Repair Service ....................................................................... 14

Technical Assistance

Accessories and Replacement Parts

Returning the Product for Credit ...................................................16

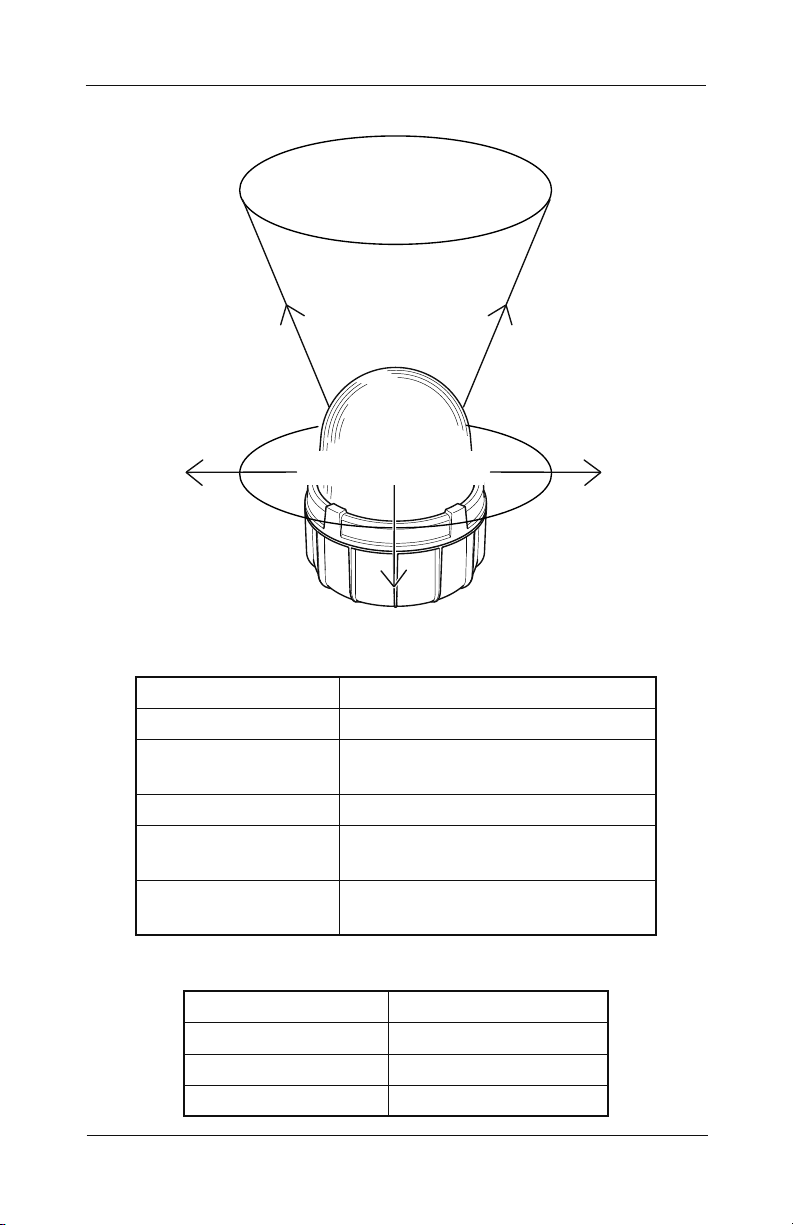

Figure 1 Beam with 22.5- and 90-degree reectors .........................7

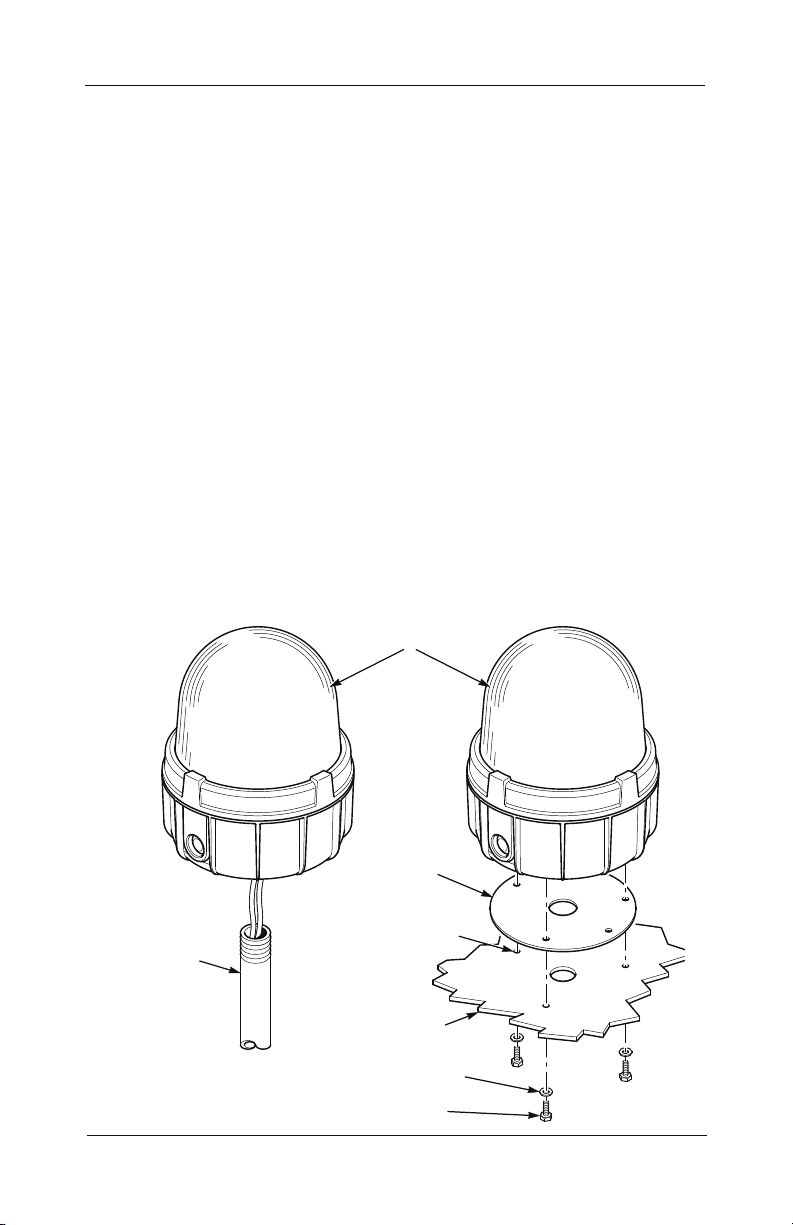

Figure 2 Mounting options ................................................................8

............................................................... 14

....................................... 14

Figures

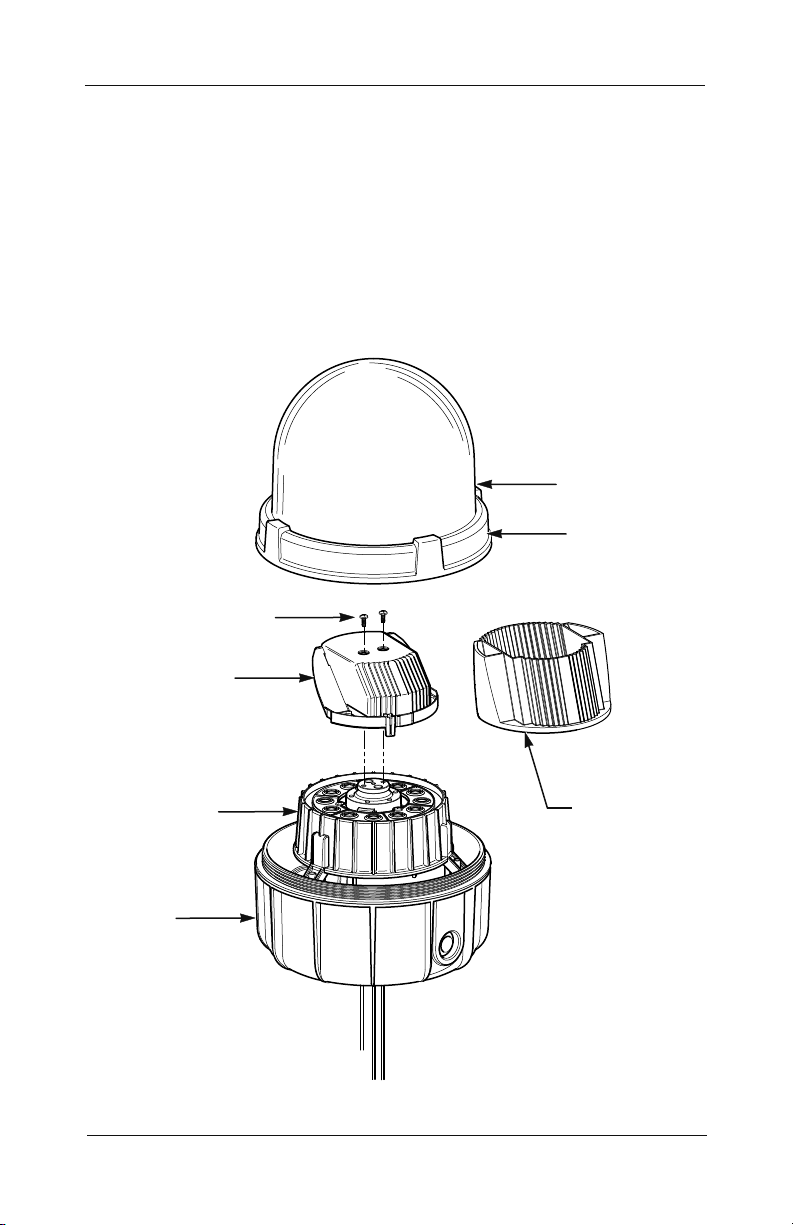

Figure 3 Installing the 22.5-degree reector ....................................10

Figure 4 Connecting leads to the terminal block ............................. 12

3

Model 371LED-120 Rotating Light

Contents

Tables

Table 1 Electrical and environmental ratings .....................................7

Table 2 Dimensions ............................................................................ 7

Table 4 Replacement parts .............................................................. 15

Table 5 Accessories ......................................................................... 15

4

Installation and Maintenance Instructions

Safety Messages to Installers

It is important to follow all instructions shipped with this product.

This device is to be installed by a trained electrician who is

thoroughly familiar with the National Electrical Code and/or

Canadian Electrical Code and will follow the NEC and/or CEC

Guidelines as well as all local codes. This light should be considered

a part of the warning system and not the entire warning system.

The selection of the mounting location for the light, its controls

and the routing of the wiring are to be accomplished under the

direction of the facilities engineer and the safety engineer. In

addition, listed below are some other important safety instructions

and precautions you should follow:

• Read and understand all instructions before installing or

operating this light.

• Do not connect this light to the system when power is on.

• After installation, make sure that all set screws and threaded

joints are properly tightened.

• To be an effective warning device, this product produces bright

light that can be hazardous to your eyesight when viewed at a

close range. Do not stare directly into this lighting product at a

close range or permanent damage to your eyesight may occur.

• After installation, test the light to make sure that it is

operating properly.

• After testing is complete; provide a copy of this instruction

booklet to all personnel.

• Establish a procedure to routinely check the light for proper

activation and operation.

Failure to follow all safety precautions and instructions may result

in property damage, serious injury, or death.

Model 371LED-120 Rotating Light

5

Installation and Maintenance Instructions

An Overview of the Model 371LED-120

Federal Signal Model 371LED-120 warning light incorporates

an array of high power LEDs, a custom optic, and a rotating

reector to focus a beam of light that rotates 360 degrees within

|a plastic dome.

The Model 371LED-120 features a impact-resistant plastic dome.

The Model 371LED is available in ve colors: amber, blue, clear,

green, and red. The dome-and-ring assembly screws on, providing

access to the interior of the light. The base features textured black

powder paint for greater corrosion-resistance. Wiring can be routed

through the pipe-mount opening in the bottom of the light or the

two side knockouts can be used for side entry wiring. Installation

can be surface or 1-inch NPT pipe mount.

An optional reector is available that reects the light beam at

22.5 degrees from the vertical orientation for overhead mounting

and other applications. See Figure 1 on page 7.

Also available is an optional wall-mount bracket. The LHWB

wall-mount bracket can be used to mount the Model 371LED. For

surface mounting on solid substrates, the separately purchased

Model 371BRCKT three-point surface-mount bracket is available.

Unpacking the Light

After unpacking the light, examine it for damage that may

have occurred in transit. If the light has been damaged, do not

attempt to install or operate it. File a claim immediately with

the carrier, stating the extent of the damage. Carefully check all

envelopes, shipping labels, and tags before removing or discarding

them. Disposal of all shipping materials must be carried out in

accordance with national and local codes and standards. If any

parts are missing, please call Federal Signal Customer Support at

708-534-4756.

6

Model 371LED-120 Rotating Light

Installation and Maintenance Instructions

Figure 1 Beam with 22.5- and 90-degree reectors

BEAM FROM OPTIONAL

22.5-DEGREE REFLECTOR

BEAM FROM STANDARD

90-DEGREE REFLECTOR

290A6862

Table 1 Electrical and environmental ratings

Operating Voltage: 120 Vac 50 Hz/60 Hz

Flash Rate: 60 FPM

Maximum Operating

320 mA

Current, mA:

In-rush Current: 25.1 A for 0.63 ms

Operating

-31 °F to 104 °F (-35 °C to 40 °C)

Temperature:

Environmental

Type 4X, IP66

Ratings:

Table 2 Dimensions

Height: 11.38 in (288.9 mm)

Diameter: 9.12 in (231.6 mm)

Net Weight: 7.1 lb (3.2 kg)

Shipping Weight: 8.1 lb (3.7 kg)

Model 371LED-120 Rotating Light

7

Installation and Maintenance Instructions

PIPE MOUNT

SURFACE MOUNT

1/4" SCREWS

290A6859

Mounting the Light

The Model 371LED-120 light is designed for mounting on a at

horizontal surface or on a 1-inch NPT pipe. For surface mounting on

solid substrates, the separately purchased Model 371BRCKT surface

mounting bracket can be used. If conduit side-entries are to be used,

disassemble the light as described in “Wiring the Light” on page 11

and remove one or more knockouts with a blunt tool before mounting

the light. Use a le to remove excess ash around the knockout.

INSTALLATION NOTE: To avoid moisture buildup within the

light enclosure in highly humid areas where condensation is present

in the conduit system, duct sealant or other suitable materials are

recommended for sealing the wires/conduit entrances.

Pipe Mounting the Light

Attach the light to the 1-inch NPT pipe by threading the light

clockwise on the pipe (Figure 2). For information on making the

electrical connections, see “Wiring the Light” on page 11.

Figure 2 Mounting options

371LED-120 LIGHT

ASSEMBLY

8

1" NPT

PIPE

GASKET

DRILL THREE 9/32"

(7.143 mm) HOLES

MOUNTING

SURFACE

1/4" FLATWASHERS

Model 371LED-120 Rotating Light

Installation and Maintenance Instructions

Surface Mounting the Light

To mount the light on a at surface:

1. Using the gasket as a template, scribe four drill-position

marks on the mounting surface (Figure 2).

Drill a 9/32-inch (7.1 mm) diameter hole at each of the

2.

outside drill-position marks for mounting.

Drill or punch a 1-3/8 inch (34.9 mm) diameter hole at the

3.

center drill-position mark for the wire entry.

Attach a suitable 1-inch NPT hub or connector to conduit

4.

entrance in bottom of light. For Type 4X/IP66 applications,

the hub or connector must be suitably rated (Myers®

STTTB-2 or T&B® H100-TB hubs are recommended.)

Set the light on the gasket and attach it to the mounting

5.

surface with the provided 1/4-inch screws and washers.

For information on making the electrical connections, see

6.

page 11.

Installing the Optional 22.5-Degree Reector

The light is shipped from the factory with the standard reector

that creates a horizontal lightbeam that is 90 degrees from the

vertical orientation. An optional reector is available that reects

the light beam at 22.5 degrees from the vertical orientation (see

Figure 1 on page 7 and “Table 4 Accessories” on page 15).

To replace the standard reector with the 22.5-degree reector:

1. Disconnect power to the light.

See Figure 3 on page 10. Remove the dome assembly by

2.

grasping the die-cast ring attached to the dome and turning it

counter-clockwise.

Loosen the two Phillips screws that retain the reector.

3.

Model 371LED-120 Rotating Light

9

Installation and Maintenance Instructions

4. Gently lift the reector from the assembly while being careful

to not drop the two screws.

5.

Position the new reector onto the assembly and secure it with

the two screws.

6.

Reinstall the dome assembly.

7. Reinstall power and test the light for proper operation.

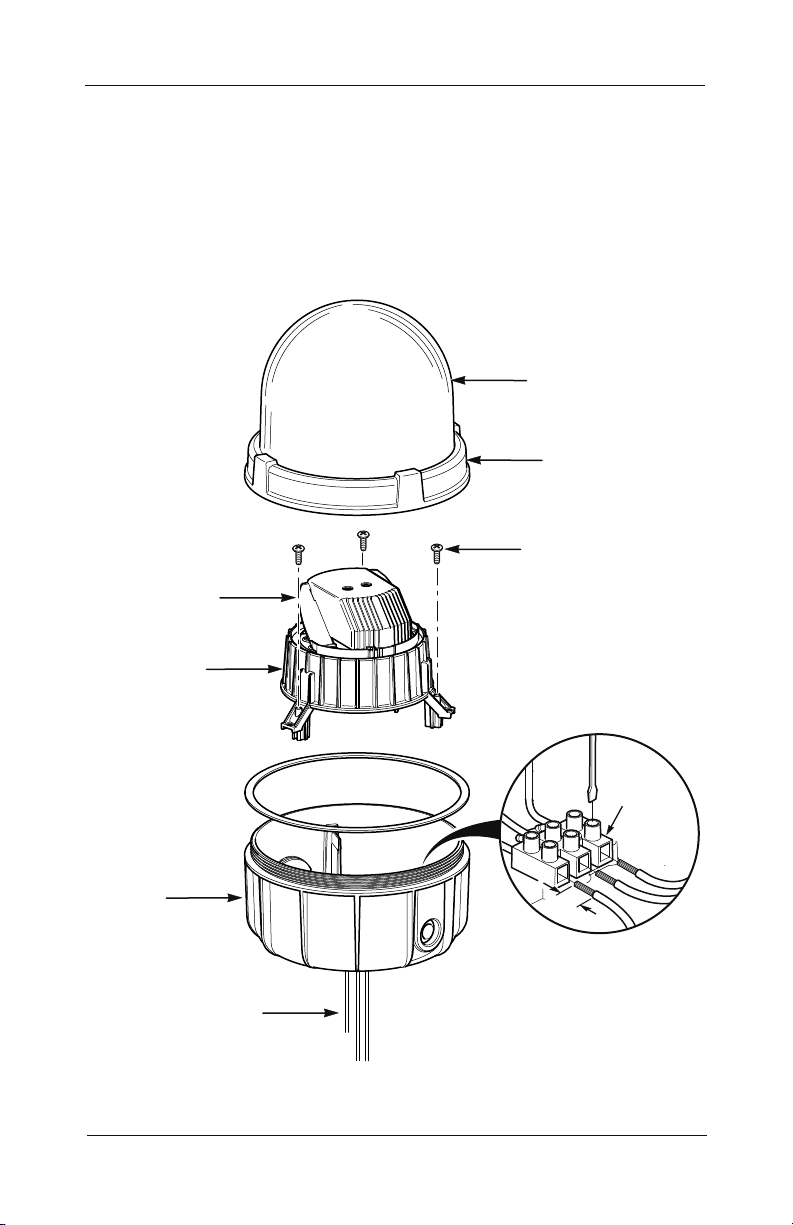

Figure 3 Installing the 22.5-degree reector

PLASTIC DOME

DIECAST RING

PHILLIPS SCREWS (2)

10

REFLECTOR

/

LED

MODULE

DIECAST

BASE

MOTOR

22.5-DEGREE

REFLECTOR

290A6855

Model 371LED-120 Rotating Light

Installation and Maintenance Instructions

Wiring the Light

SHOCK HAZARD

To avoid electrical shock hazards, do not connect wires while

power is applied.

The Model 371LED comes assembled from the factory with two

color-coded leads for wiring to a junction box. If desired, the

factory leads can be removed and the supply connections can be

directly made to the terminal block located on the bottom of the

light base as described below

Disassemble the light (Figure 4 on page 12):

1.

a) Remove the dome assembly by grasping the die-cast ring

attached to the dome and turning it counter-clockwise.

Remove three #10 Phillips screws that secure the LED /

b)

motor module to the housing.

Remove the LED / motor module.

c)

If preferred, remove the factory-supplied leads from the

d)

terminal block.

If you are using conduit side-entries, attach a Myers®

2.

STTTB-2 or a T&B® H075TBH 3/4-inch NPT conduit hub

with a 3/4-inch NPT close nipple (both installer-supplied)

to the housing and securely tighten the hub. When side

entries are used, the bottom 1-inch NPT conduit entry must

be plugged with a threaded plug (installer-supplied). (See

“Table 4 Accessories” on page 15.)

Route the supply wires (10 AWG to 16 AWG) into the light

3.

housing.

Strip a maximum of 0.28 inch (7 mm) of insulation from

4.

the ends of the power leads. Connect the wires to the

terminal block by inserting the stripped ends of the wires

into the connectors as far as they can travel.

Model 371LED-120 Rotating Light

11

Installation and Maintenance Instructions

5. Tighten the clamping screw. The maximum tightening

torque is 7.0 in-lb (0.8 N • m).

Connect the earth ground to the terminal block.

6.

7. Reassemble the light and test it for proper operation.

Figure 4 Connecting leads to the terminal block

PLASTIC DOME

DIECAST RING

#10 PHILLIPS

SCREW (3)

REFLECTOR

LED / MOTOR

MODULE

DIECAST

BASE

FACTORY-SUPPLIED

TERMINAL BLOCK

12

LEADS FROM

Model 371LED-120 Rotating Light

(7mm)

0.28"

TERMINAL

BLOCK

Installation and Maintenance Instructions

Safety Messages to Maintenance Personnel

Listed below are some important safety instructions and

precautions you should follow:

• Read and understand all instructions before operating this

system.

• Any maintenance to the light system must be done with the

power turned off.

• Any maintenance to the light system must be performed by a

trained electrician in accordance with NEC/CEC Guidelines

and local codes.

• Never alter the unit in any manner. Safety may be endangered

if additional openings or other alterations are made to units.

• The nameplate, which contains cautionary or other information

of importance to maintenance personnel, should not be

obscured.

• If the dome is damaged in any way, the complete dome

assembly MUST be replaced.

• After performing any maintenance, test the light system to

ensure that it is operating properly.

Failure to follow all safety precautions and instructions may result

in property damage, serious injury, or death.

Maintaining the Model 371LED-120

Establishing a regular maintenance schedule for the Model

371LED-120 extends the life of the light and ensures safety.

Periodically check that the light operates properly. Also, inspect

the dome for cracks, crazing (hairline cracks), discoloration, and

other defects.

The threaded dome ring joint should be well lubricated with

petroleum or a soap-thickened mineral oil. If corrosive products

have accumulated on joints and cannot readily be removed with

solvents, the parts should be discarded and replaced.

Model 371LED-120 Rotating Light

13

Installation and Maintenance Instructions

Cleaning the Dome

NOTE: Maintenance procedures sometimes require xtures to be

hosed down for good housekeeping. The electrical circuit should

be turned off prior to hosing down the light.

Clean the dome periodically to maintain maximum light output.

Use only mild, non-abrasive cleaning agents.

Getting Service, Assistance, and Parts

Federal Signal will service your product and provide technical

assistance and support. Please call the phone numbers listed below.

For instruction manuals and information about related products,

please go to http://www.federalsignal-indust.com.

Repair Service

Products returned for repair require a Return Authorization

form. To obtain service for the product, please contact the

Federal Signal Service Department at 708-534-4858.

Technical Assistance

For technical assistance, please call Technical Support at

708-534-3424, extension 5823.

14

Accessories and Replacement Parts

Typical replacement parts are listed on page 15. Due to

certication, certain component parts are not available for eld

replacement. Units with this type of damage must be either

replaced entirely or returned to Federal Signal for service.

The LED / Motor Modules in Table 4 on page 15 include the

following parts: motor bracket, LED PCBA, power supply

PCBA, thermal pads, standard reector, and dome gasket.

To order accessories and replacement parts, please call Federal

Signal Customer Support at 708-534-4756.

Model 371LED-120 Rotating Light

Installation and Maintenance Instructions

Table 4 Replacement parts

Description Part Number

Plastic Dome Assembly, Amber K8459125

Plastic Dome Assembly, Blue K8459125-01

Plastic Dome Assembly, Clear K8459125-02

Plastic Dome Assembly, Green K8459125-03

Plastic Dome Assembly, Red K8459125-04

Gasket, Surface Mount K8459127

LED / Motor Module, Amber K8459159-A

LED / Motor Module, Blue K8459159-B

LED / Motor Module, White K8459159-W

LED / Motor Module, Green K8459159-G

LED / Motor Module, Red K8459159-R

Table 5 Accessories

Description Part Number

Wall-Mount Bracket LWMB2

Corner-Mount Bracket LCMB2

Mounting Bracket, Surface 371BRCKT

Conduit Hub Kit, 3/4" NPT K8459138

Close-Up Plug, 1" NPT K8459130

22.5 Degree Reector K8459154

Model 371LED-120 Rotating Light

15

Loading...

Loading...