Federal Signal Corporation ARJENT S2 SERIES Installation And Maintenance Instructions Manual

Page 1

2562366A

REV. A 1007

Printed in U.S.A.

INSTALLATION AND MAINTENANCE INSTRUCTIONS

FOR

ARJENT® S2 SERIES B LED/HALOGEN LIGHT ASSEMBLY

SAFETY MESSAGE TO INSTALLERS

OF

FEDERAL SIGNAL LIGHT SYSTEMS

People’s lives depend on your safe installation of our products. It is important to

read, understand and follow all instructions

shipped with the products. In addition, listed

below are some other important safety instructions and precautions you should follow:

• To properly install a light assembly: you must

have a good understanding of automotive

electrical procedures and systems, along with

proficiency in the installation and use of safety

warning equipment.

• When installing equipment or wiring inside air

bag equipped vehicles, the installer MUST en‑

sure that the equipment or wiring is installed

ONLY in areas recommended by the vehicle

manufacturer. Failure to observe this warn‑

ing will reduce the effectiveness of the air bag,

damage the air bag, or potentially damage or

dislodge the equipment, causing serious injury

or death to you or others.

• When drilling into a vehicle structure, be sure

that both sides of the surface are clear of any‑

thing that could be damaged.

• A light system is a high current device. In

order for it to function properly, a separate

ground connection must be made. If practical,

it should be connected to the negative battery

terminal. At a minimum, it may be attached

to a solid metal body or chassis part that will

provide an effective ground path as long as the

light system is to be used.

• Locate light system controls so the VEHICLE

and CONTROLS can be operated safely under

all driving conditions.

• This product contains high intensity LED de‑

vices. To prevent eye damage, DO NOT stare

into the light beam at close range.

• You should frequently inspect the light system

to ensure that it is operating properly and that

it is securely attached to the vehicle.

• File these instructions in a safe place and refer

to them when maintaining and/or reinstalling

the product.

Failure to follow all safety precautions and

instructions may result in property damage, serious

injury, or death to you or others.

I. UNPACKING.

After unpacking the Arjent S2 lightbar, inspect it for

damage that may have occurred in transit. If the unit has

been damaged, file a claim immediately with the carrier,

stating the extent of damage. Carefully check all envelopes,

shipping labels and tags before removing or destroying

them.

II. DESCRIPTION.

The Arjent S2 lightbar is available in either a 36”, 44”

or 53” length and operates on a nominal input of 13.6 volts

DC (11 volts DC minimum). Clear polycarbonate bases

along with clear or colored polycarbonate domes house a

multi‑channel programmable (via serial interface module)

circuit board assembly within the bar. The multi‑channel

PCB assembly is connected in turn to additional multiple

circuit board panels, each having the availability of 4 to 5

maximum factory‑installed options per panel. The lightbars

have an operating temperature range of ‑30°C to +65°C

(‑22°F to +149°F). They may be mounted with a hook,

permanent, or flat mounting kit to the vehicle. Available

built to order options on the Arjent S2 include:

Panelized Solaris LED Options:

XD1LC6‑A, ‑R, ‑B, ‑W, ‑G: 6‑button Solaris S2 LED

light head

XDALED‑A, ‑R, ‑B, ‑W, ‑G: 3‑button Solaris S2 LED

light head, alley light position (factory default at front

light cutoff)

• Flashing pattern selectability of the LED options

may be specified via programming of the lightbar.

See table 2.

• SignalMaster operation is accomplished via

programming of the lightbar.

4‑pos. SignalMaster available on the 36” bar;

6‑pos. SignalMaster available on the 44” bar;

8‑pos. SignalMaster available on the 53” bar

• Steady‑burn availability of 1 or 2 front LED

heads must be specified via the Arjent S2 initial

order entry.

Panelized Halogen Options (maximum of 6 per

lightbar):

XDAHAL Alley Light, 35 watts/head (MR 11)

adjustable

XDTD Takedown Light 50 watts/head

XDWL Work Light 50 watts/head

• Flashing of the halogen options is accomplished via

programming of the lightbar.

Mounting Options:

XAHKN‑SC, XAHK‑SC Hook Mount, Neutral or

Black

XAPKN‑SC, XAPK‑SC Permanent Mount, Neutral

or Black

XAFM Flat Mount

Page 2

III. INSTALLATION.

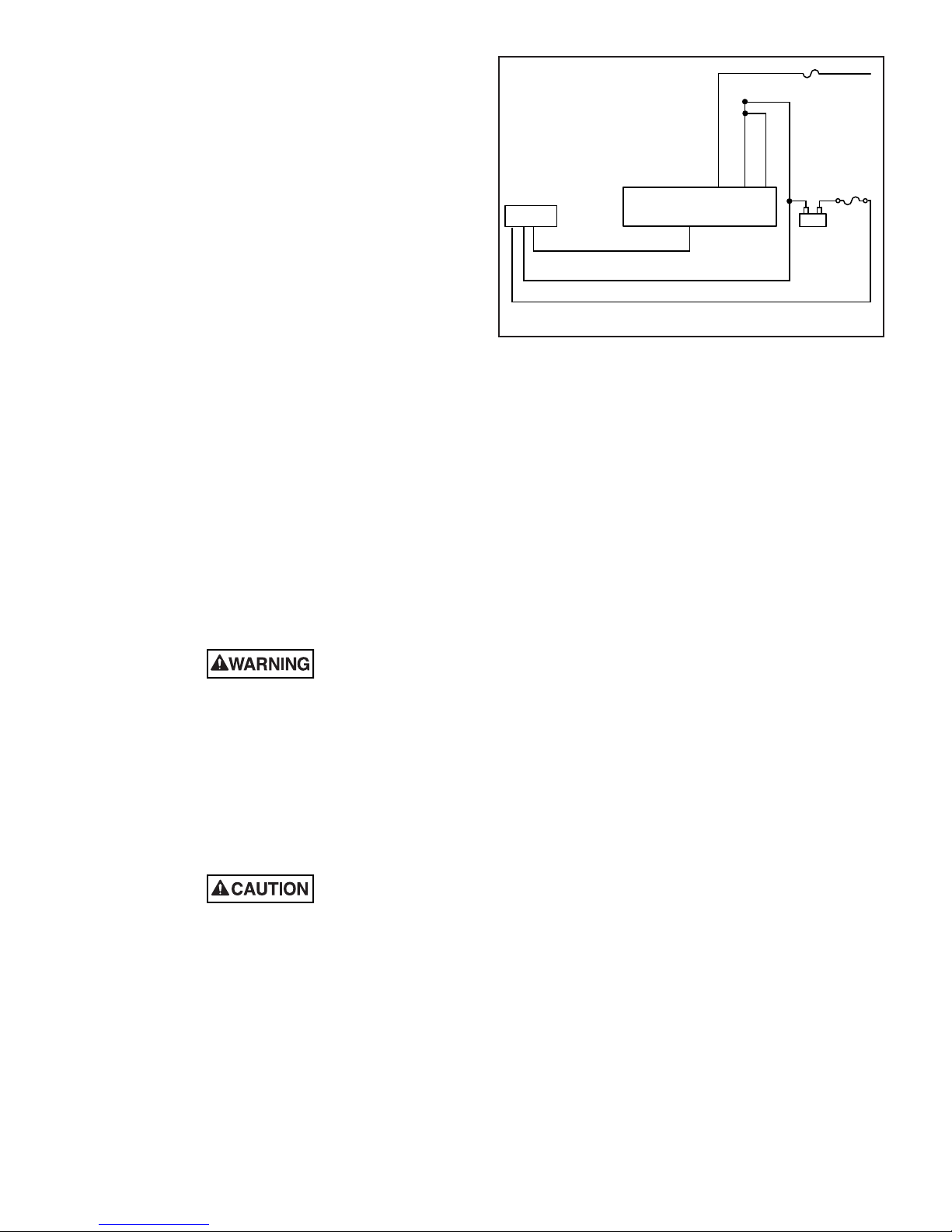

290A5859

LIGHTBAR

FSC SERIAL INTERFACE MODULE

PART #8583446 REFERENCE

INSTRUCTION SHEET 2562248

SERIAL, CAT5., CONTROL CABLE

-

+

BLACK 10AWG

RED 10AWG

FUSE

40AMP

BLACK

WHITE

BLACK / WHITE

16AWG

IGNITION

1A

BATTERY

NOTICE

Improper warning system and/or two‑way radio

system operation may result if a two‑way radio

antenna is installed on, or within 18‑inches of, the

lightbar. Before permanent installation of the light‑

bar or a two‑way radio antenna, test the warning

system and two‑way radio system. DO NOT install

a two‑way radio antenna on the lightbar.

Some installations may require relocation of the

two‑way radio antenna to a trunk or fender loca‑

tion.

Warning system failure may result if additional

holes are drilled in the lightbar, or if auxiliary

devices are installed on the lightbar. DO NOT drill

additional holes in the lightbar, or install auxiliary

devices on the lightbar.

The lightbar is completely wired at the factory and

does not require any additional internal wiring; two 10

AWG power conductors (red and black) and the CAT5

communication cable exit the lightbar. All the conductors

necessary for control of any and all basic and optional

functions are contained in the CAT5 cable.

The basic light functions of the unit are communicated

via the CAT5 cable. The cable connects to either a

compatible Federal Signal Serial control head, or, a Federal

Signal Serial Interface Module.

Before proceeding, ensure that the lightbar has

been installed on the vehicle roof in accordance with the

instructions packed with the mounting kit.

Figure 1. Block Wiring Diagram.

D. SignalMaster Option.

Each lightbar is equipped for SignalMaster

operation via an external control unit or control leads on

the Interface Module (refer to paragraph III.F.). When

SignalMaster operation is not initiated, the SignalMaster

heads will flash per the selected Mode for additional light

indication to the rear.

The SignalMaster function is completely

configured at the factory and does not require any

additional wiring inside the light bar. All conductors

necessary for control of the SignalMaster is via the

compatible Serial communication control head or the

FSC #8583446 Serial Interface Module. For wiring and

operation instructions, refer to the instruction sheet

packed with the applicable control head or the FSC

Serial Interface Module’s Instruction sheet (part number

2562248).

Light system controls must be located so that

VEHICLE and CONTROLS can be operated

safely under all driving conditions.

A. See figure 1. From the lightbar, route the CAT5

control cable into the vehicle’s cab or trunk near the

eventual location of the compatible Federal Signal Serial

control head or FSC #8583446 Interface Module. An input

cable is also provided with the FSC #8583446 Serial

Interface Module.

Reverse polarity may damage any power supply

and prevent operation. Ensure that correct polarity

is observed. Unit must be fused at the source.

B. Connect the separate 10 gauge black lead to the

vehicle battery ground (‑) terminal.

C. Route and connect the 10 gauge red lead through

the supplied 40A fuse, fused at the source, to the BAT+

terminal.

E. Light Bar Controls.

The Arjent S2 functions are communicated via

the serial cable. Both the Federal Signal control head

and the Serial Interface Module are capable of providing

the following controls to the lightbar. For programming

options, refer to the Installation Manual shipped with the

Interface Module or the Federal Signal Control Head.

1. MODE 1 ‑

2. MODE 2 – overrides MODE 1;

3. MODE 3 – Overides MODES 1&2;

4. STEADY BURN RED

5. FRONT CUTOFF

6. REAR CUTOFF

7. INTERSECTION

8. FLASH HALOGEN

9. LEFT ALLEY

10. RIGHT ALLEY

11. TAKEDOWN

12. LOW POWER

13. LIGHTBAR TEST

-2-

Page 3

F. Cutoff for LED Alley Light Option.

290A5860

TAKEDOWN 50W LAMP

BI-PIN, #GH-8, #GH-9.

INSURE BULB SURFACE

IS FREE OF SEDIMENT, OILS, ETC.

REMOVE SUNSCREEN FOLD ON

PASSENGER SIDE OF BAR FOR

15A FUSE REPLACEMENTACCESS

LOCATED ON MULTI-CHANNEL

CONTROLLER PCB ASSEMBLY

FIRMLY SEAT REPLACED

BULB HORIZONTALLY

WITHIN SOCKET

B

C

D

290A5861

LED ALLEY CUTOFF JUMPER (PANEL #2005395 DRIVER & PASSENGER SIDES)

B-C PINS JUMPERED = FRONT LIGHT CUTOFF FOR DRIVER’S SIDE 2005395

PANEL (FACTORY DEFAULT)

B-C PINS JUMPERED = REAR LIGHT CUTOFF FOR PASSENGER’S SIDE

2005395 PANEL

C-D PINS JUMPERED = REAR LIGHT CUTOFF FOR DRIVER’S SIDE 2005395 PANEL

C-D PINS JUMPERED = FRONT LIGHT CUTOFF FOR PASSENGER’S SIDE 2005395

PANEL (FACTORY DEFAULT)

L22

L21

0

0

0

0

L20

L19

U7

R7

0 0 0

L26 L27 L28

U9

R31

C11

R26

C

B D

J2

L37

Q1

1

C2

R9

C1

L25

R25

L9

0

0

0

L10

L11

L12

C7

R13

The XDALED‑A, ‑R, ‑B, ‑W, ‑G option installed in

the alley position is factory set for front light cutoff of both

the passenger and driver sides of the option. The cutoff may

be changed to the rear by means of an on‑board 2‑position

jumper found on the component side fo the 2005395 panel.

The jumper is factory set across the pair of pins justified

to the front side of the lightbar. (For example: B‑C for the

driver’s side 2005395 panel denoting front cutoff of the

LED alley, and C‑D for the passenger’s side 2005395 panel

denoting front cutoff ot that LED alley.) See figure 3. The

jumper may be reset for rear cutoff by placing it across the

pins that are justified to the rear of the bar. If the jumper

is removed completely from the pins the alley light will not

function.

IV. BASIC MAINTENANCE.

Be sure to disconnect all incoming power

wiring to the lightbar before servicing the

lighbar’s interior. Failure to do so may result

in property damage, serious injury, or death

to you and others.

Disconnect ALL power to the lightbar before any

maintenance is performed.

A. Cleaning the Plastic Domes.

Ordinary cleaning of the plastic domes can be

accomplished by using mild soap and a soft rag. Should

fine scratches or a haze appear on the domes, they can

ordinarily be removed with a non‑abrasive, high quality

automotive paste wax.

Crazing (cracking) of domes will cause reduced effectiveness of light system. Do not

use cleaning agents (which will cause crazing) such as strong detergents, solvents, or

petroleum products. If crazing of domes does

occur, reliability of light for emergency warning purposes may be reduced until domes are

replaced.

B. Halogen Lamp Replacement.

A serious injury may result if lamp is touched

when hot. Always allow lamp to cool before

removing. Halogen lamps are pressurized

and if broken can result in flying glass.

Always wear gloves and eye protection when

handling the lamps.

Service life of lamp will be shortened if glass por‑

tion is touched. If glass has been handled, clean

carefully with a grease solvent.

See figures 2 and 4. Refer to table 1 and replace

the defective lamp with an exact replacement only.

Figure 2. Takedown Halogen Lamp, Fuse Replacement.

Figure 3. Cutoff for LED Alley Light Option.

-3-

Page 4

Table 1.

290A5862

35W MR11 LAMP

DISCONNECT

ATTACHED

9-CONDUCTOR

CABLE

DISCONNECT

ATTACHED

GROUND STRAP

GROUND

STRAP

290A5863

LED REFLECTOR

(REMOVE REAR SCREW)

DISCONNECT ATTACHED

GROUND STRAP FROM

END PANEL

DISCONNECT ATTACHED

9-CONDUCTOR CABLE

FROM PANEL

GROUND

STRAP

Function Description

Takedown, Worklight 50W Halogen, GH‑8 (bi‑pin)

Part No. 8107169

Alley 35W Halogen MR11

Part No. 8107241

Reflector, 6 LED 6‑Button, S2 (Solaris)

Part No. 8653104

Reflector, 3 LED Part No. 8583462

(Alley Position Option)

Multi‑channel Part No. 2005382

circuit board

panel from the lightbar. Removal of the dome above the

panel, followed by removal of the screws restraining the

panel and disconnection of the 9‑wire cable harness (see

figure 5) will allow access to the reflector’s cleaning or

replacement. Refer to table 1 for replacement part number.

NOTE

Individual LED Modules cannot be serviced. The

entire LED panel is replaced.

2. LED Panel Replacement.

C. Cleaning Reflector Assemblies.

Use a soft tissue to clean the reflectors. Avoid

heavy pressure and the use of caustic or petroleum base

solvents which will scratch or dull the surface.

D. LED Panel Replacement.

A serious injury may result if the LED assembly is touched when hot. Always allow the

LED assembly to cool before removing.

1. LED Reflector Replacement.

Individual LED reflectors may be replaced if

needed by disassembly of the LED reflector’s parent LED

In the rare occurrence a LED module is found

not functioning properly, the parent circuit board panel to

which it belongs needs to be replaced with its equivalent.

A corresponding label may be found on the topside of each

of the LED panels with a 2005xxxx‑xxxxxxxx pc board part

number and the finished model number (58300x‑xxxxx)

for ordering its replacement. See figures 4 and 5 for board

removal/replacement.

3. 15A Fuse Replacement.

Four 15A fuses are present on the main

control circuit board located on the passenger side of the

lightbar. Access the fuses by removing the sunscreen fold

from the top side of the panel to expose the control board

(see figures 2 and 7).

Figure 4. Alley MR11 Halogen Lamp Replacement.

Figure 5. LED Reflector Replacement.

-4-

Page 5

4. Control Board Replacement.

290A5864

DISCONNECT ATTACHED

9-CONDUCTOR CABLE

FROM PANEL END

MULTI-CHANNEL

CONTROLLER PCB ASSY.

FOR CONTROL BOARD REMOVAL

DISCONNECT ALL ATTACHED:

> RS485 CABLE

> POWER CABLE (RED)

> GROUND CABLE (BLACK)

> 9-CONDUCTOR PANEL HARNESSES

(PASSENGER SIDE)

DISCONNECT ATTACHED

GROUND STRAP FROM PANEL

290A55865

ARJENT S2/LEGEND LIGHTBAR CONTROLLER PCB ASSEMBLY

15A FUSES

If it is determined that the main control

board (#2005382) needs to be replaced, the inboard LED

panel on the passenger’s side must be disconnected and

removed first to gain access to the main control board.

Next, disconnect the power and ground leads to the board.

The Serial input cable must then be disconnected along

with the associated wire harness leads to the board. Last,

the four screws restraining the control board must then be

removed for its replacement (see figure 6).

Copyright 2007 Federal Signal Corporation

Figure 7. Internal vs External SignalMaster Configuration.

Figure 6. Multi-channel Controller Replacement.

-5-

Page 6

Table 2. 44” Arjent S2 Flash Pattern Lighting Standard Compliance

Table (for software revision ARJM44B and higher).

Pattern Number SAE J845 Compliant Title 13 Compliant

1 Yes Yes

2 Yes Yes

3 Yes Yes

4 Yes Yes

5 Yes Yes

6 Yes Yes

7 Yes No

8 No No

9 Yes No

10 Default Mode 1 Yes Yes

11 Yes No

12 No No

13 Yes No

14 Yes No

15 Yes No

16 No No

17 Default Mode 2 Yes No

18 No No

19 Yes No

20 Yes No

21 No No

22 Intersection No No

23 No No

24 No No

25 No No

26 Default Mode 3 Yes No

27 For testing only No No

28 For testing only No No

NOTICE

The table above identifies the light bar’s flash pattern

compliance. (for software revision ARJM44B or higher).

Patterns listed as “Yes” comply with the flash requirements

and light output requirements for the identified lighting

standard. Patterns listed as “No” do not comply with either the

flash requirements or the light output requirements for the

standard. A non‑compliant pattern should only be used after

those you are trying to warn have been trained to recognize

the pattern as a warning signal. The end user is responsible

for choosing the light patterns that meet their jurisdiction’s

requirements.

NOTE

Pattern 27 ‑ all lights on.

Pattern 28 ‑ each light sequentially lights for 2 seconds with

the exception of designated steady burn heads.

-6-

Loading...

Loading...