Page 1

Model 151XST Series Strobe Light

for Use in Hazardous Conditions

Installation and

Maintenance Manual

256822J

Rev. J0 913

Printed in U.S.A.

français...............page 21

español...............página 43

Page 2

Warranty – Seller warrants all goods for ve years on parts and 2-1/2 years on labor,

under the following conditions and exceptions: Seller warrants that all goods of

Seller's manufacture will conform to any descriptions thereof for specications which

are expressly made a part of this sales contract and at the time of sale by Seller such

goods shall be commercially free from defects in material or workmanship. Seller

reserves the right at the Seller’s discretion to “Repair and Return” or “Replace” any

item deemed defective during the warranty period. This warranty does not cover

travel expenses, the cost of specialized equipment for gaining access to the product,

or labor charges for removal and reinstallation of the product. This warranty shall be

ineffective and shall not apply to goods that have been subjected to misuse, neglect,

accident, damage, improper maintenance, or to goods altered or repaired by anyone

other than Seller or its authorized representative, or if ve years have elapsed from

the date of shipment of the goods by Seller with the following exceptions: lamps

and strobe tubes are not covered under this warranty. Outdoor warning sirens and

controllers manufactured by Federal Warning Systems are warranteed for two years

on parts and one year on labor. No agent, employee, representative or distributor

of Seller has any authority to bind the Seller to any representation, afrmation, or

warranty concerning the goods and any such representation, afrmation or warranty

shall not be deemed to have become a part of the basics of the sales contract and shall

be unenforceable. THE FOREGOING WARRANTIES ARE EXCLUSIVE AND IN

LIEU OF ALL OTHER WARRANTIES OR MERCHANTABILITY, FITNESS FOR

PURPOSE AND OF ANY OTHER TYPE, WHETHER EXPRESS OR IMPLIED.

These warranties shall not apply unless Seller shall be given reasonable opportunity

to investigate all claims for allegedly defective goods. Upon Seller's instruction a

sample only of allegedly defective goods shall be returned to Seller for its inspection

and approval. The basis of all claims for alleged defects in the goods not discoverable

upon reasonable inspection thereof pursuant to paragraph 8 hereof must be fully

explained in writing and received by Seller within thirty days after Buyer learns of

the defect or such claim shall be deemed waived.

Industrial Systems

2645 Federal Signal Drive • University Park, IL 60484-3167

Tel: 708-534-4756 • Fax: 708-534-4852

Email: elp@federalsignal.com • www.federalsignal-indust.com

© 2013 Federal Signal Corporation. All rights reserved.

Page 3

Models 151XST and 151XST-S

Contents

Safety Messages to Installers ..........................................................5

An Overview of the 151XST Series .................................................. 6

Unpacking the Light .......................................................................... 7

Pipe-Mounting the Beacon (151XST) ............................................... 9

Surface-Mounting the Beacon (151XST-S) ....................................10

Wiring the Beacon ........................................................................... 11

Wiring the AC Models............................................................ 12

Wiring the DC Models

Safety Message to Maintenance Personnel .................................. 14

...........................................................14

Replacing the Flash Tube ....................................................... 16

Replacing the Printed Circuit Board (PCB)

Cleaning the Fixture

Lubricating the Threaded Joint

Getting Repair Service or Technical Assistance .........................19

Ordering Accessories and Replacement Parts ............................19

Returning the Product for Credit ...................................................20

Table 1 Specications ........................................................................7

Table 2 Voltage and operating current ............................................... 7

Table 3 Flash rate and candelas ........................................................ 8

Table 4 Hazardous Location Rating ................................................... 8

............................................................... 18

............................................... 18

Tables

........................... 17

Table 5 Replacement parts ..............................................................19

Table 6 Accessory ............................................................................20

3

Page 4

Models 151XST and 151XST-S

Contents

Figures

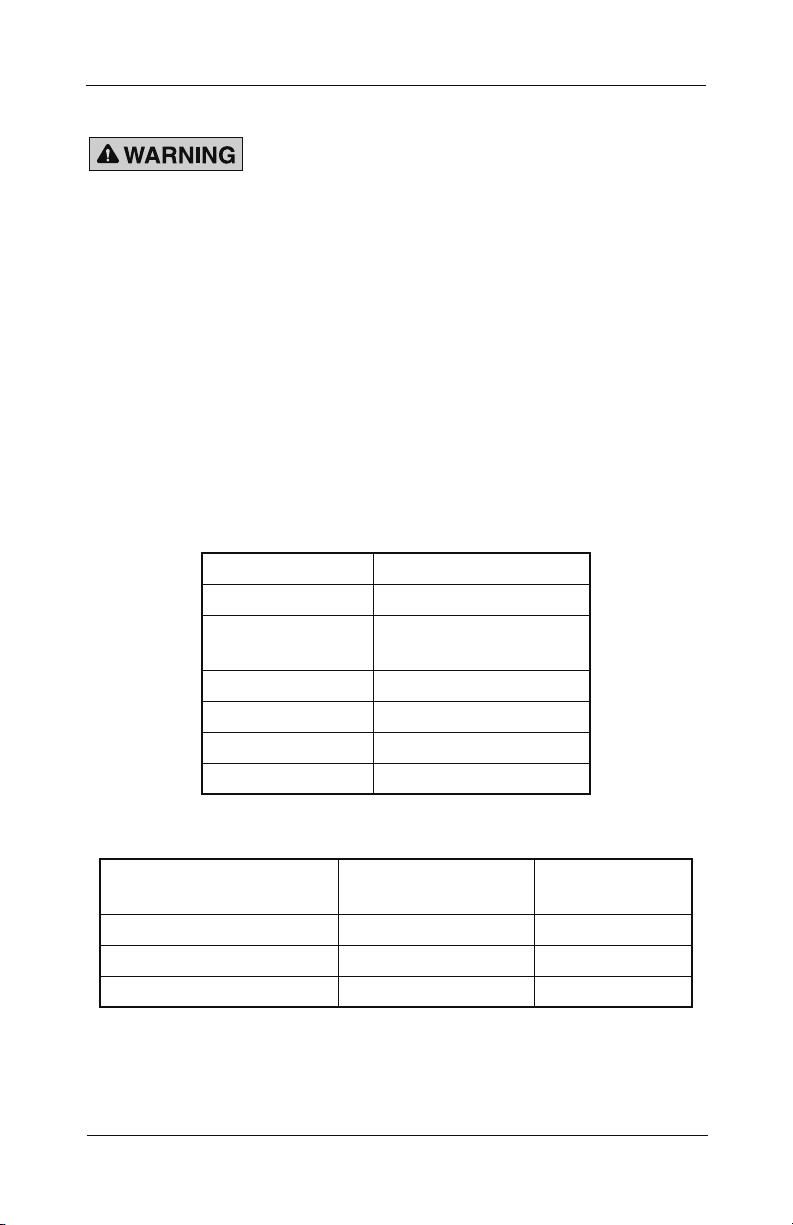

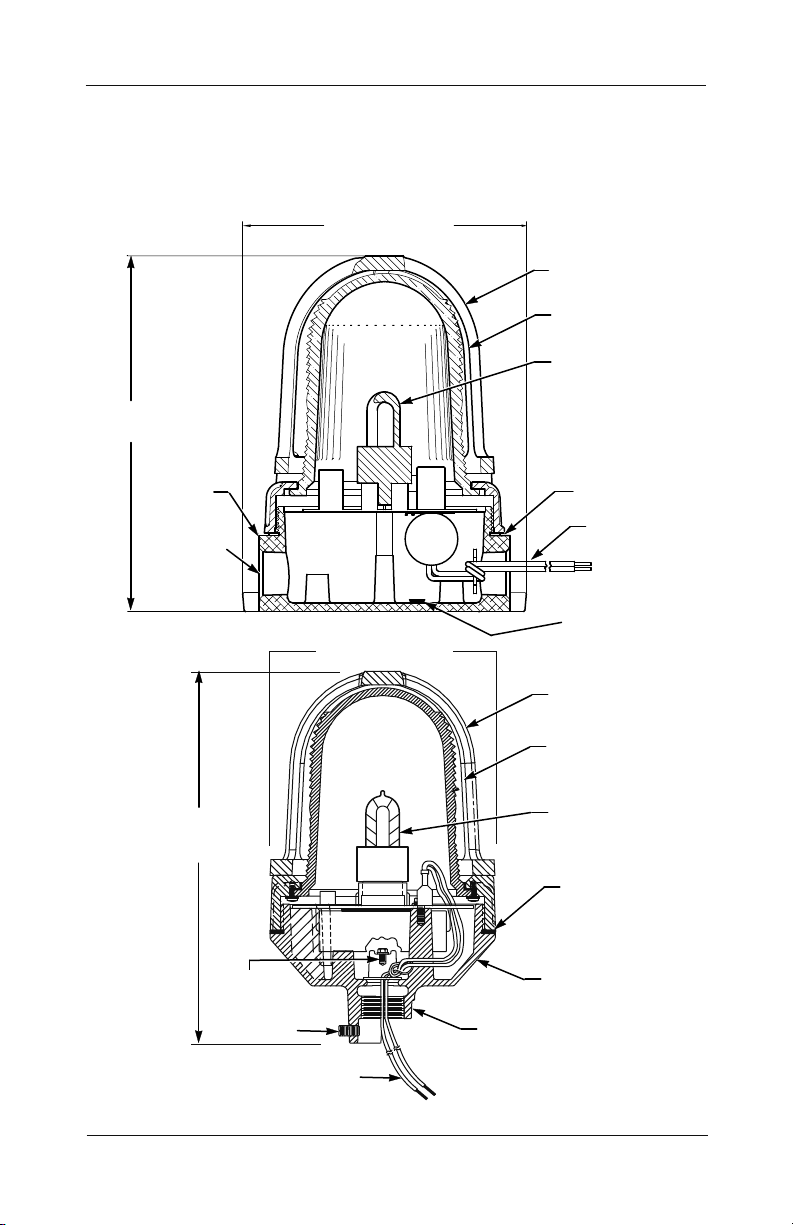

Figure 1 Pipe-mounted beacon .......................................................10

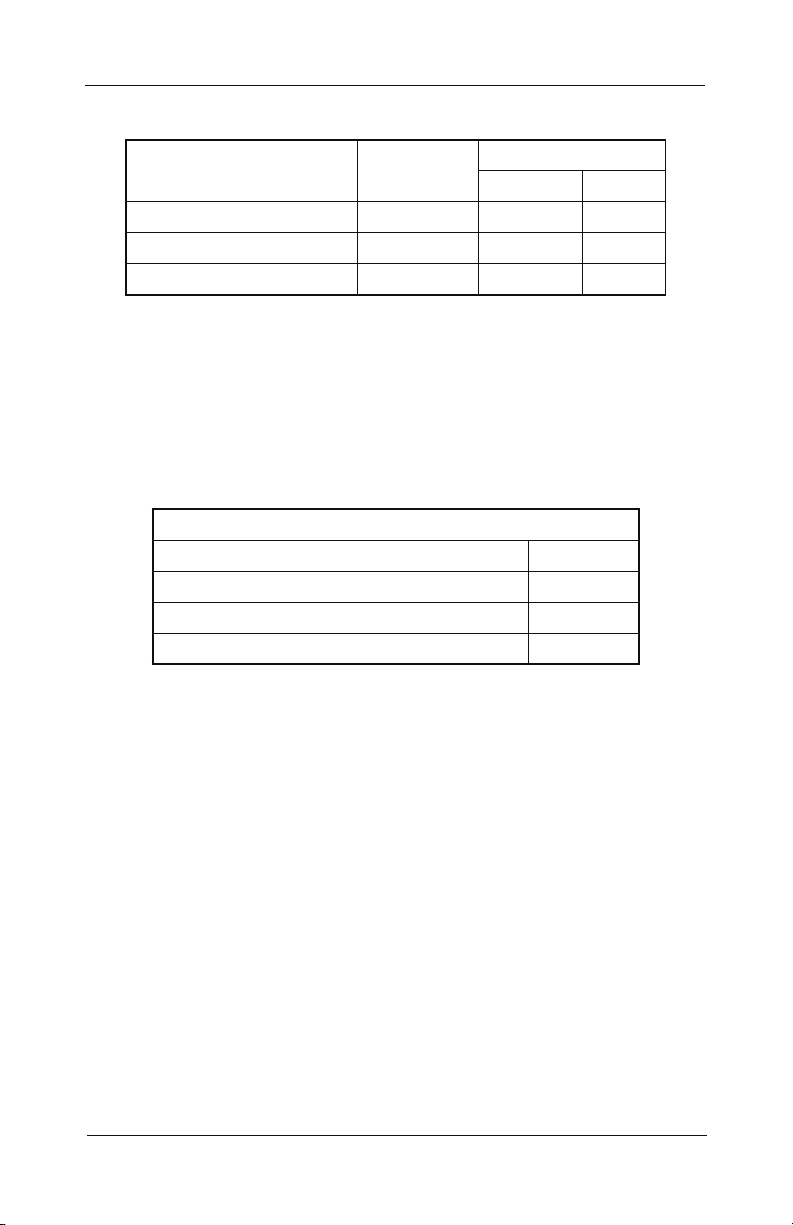

Figure 2 Surface-mounted beacon .................................................. 11

Figure 3 Cross section of beacons .................................................. 13

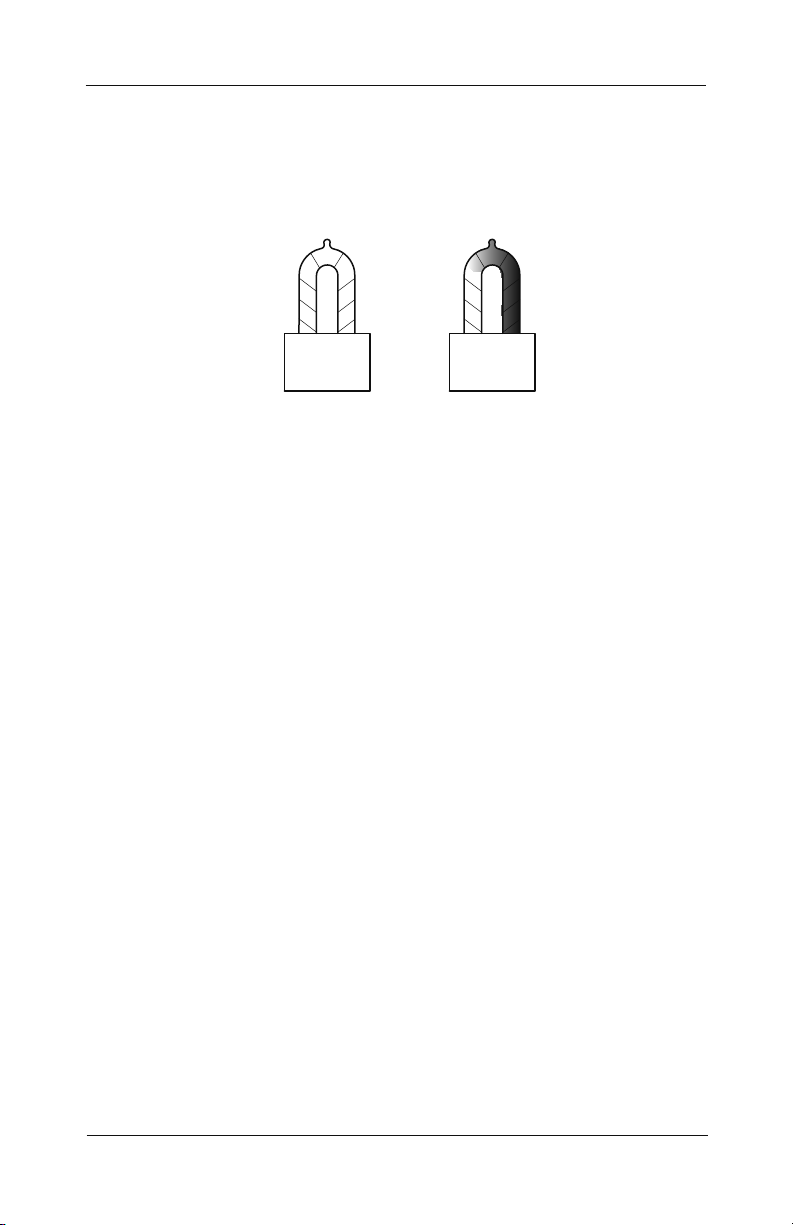

Figure 4 Normal (A) and darkened (B) ash tube ............................17

4

Page 5

Installation and Maintenance Instructions

Safety Messages to Installers

It is important to follow all instructions shipped with this product.

This device is to be installed by a trained electrician who is

thoroughly familiar with the National Electrical Code and/or

Canadian Electrical Code and will follow the NEC and/or CEC

Guidelines as well as all local codes. This beacon should be

considered a part of the warning system and not the entire warning

system.

The selection of the mounting location for the beacon, its controls

and the routing of the wiring are to be accomplished under the

direction of the facilities engineer and the safety engineer. In

addition, listed below are some other important safety instructions

and precautions you should follow:

• Read and understand all instructions before installing or

operating this beacon.

• Never alter the beacon in any manner. Safety in hazardous

locations may be endangered if additional openings or other

alterations are made to units specically designed for use in

these locations.

• Do not connect this beacon to the system when power is on.

• After installation, ensure that the set screw is properly

tightened and that threaded joints are fully engaged.

• After installation, test the beacon to ensure that it is operating

properly.

• After testing is complete, provide a copy of this instruction

booklet to all operating personnel.

• Establish a procedure to routinely check the light installation

for integrity and proper operation.

Models 151XST and 151XST-S

5

Page 6

Installation and Maintenance Instructions

Failure to follow all safety precautions and instructions may result

in property damage, serious injury, or death.

An Overview of the 151XST Series

Federal Signal’s Model 151XST hazardous location strobe light

provides 80 high-intensity ashes per minute. This warning light is

available in 12-24 Vdc, 120 Vac and 240 Vac, 50/60 Hz.

The Model 151XST strobe light is UL Listed and CSA Certied

for Class I, Division 2, Groups A, B, C and D; Class II, Division 1,

Groups E, F and G; and Class III.

The 151XST meets Type 4X water-tight, dust-tight, and corrosionresistant requirements; constructed to IP66. This hazardous

location warning light has an aluminum base, coated for corrosion

resistance that is ready for mounting on a 3/4-inch NPT pipe.

The included dome guard ts over the glass dome to protect it

against accidental collision with moving equipment, such as

forklifts. An optional wall bracket is also available.

The 151XST has an effective candela (ECP) of 165 and a 520,000

peak candela. It is available in six dome colors, including amber,

blue, clear, green and red (magenta upon request).

Federal Signal’s rugged 151XST strobe warning light is

specically designed for hazardous locations or corrosive

environments where a very bright visual signal is required.

This warning light can be used for plant evacuation or other

communication needs.

Models are available for pipe mounting (151XST) or surface

mounting (151XST-S).

NOTE: The Model 151XST can be mounted to a Federal

Signal Model LHWB bracket. If installed in this way, the entire

assembled device is suitable only for Class I, Div. 2, Groups A, B,

C, and D; Class II, Div. 2, Groups F and G; Class III locations.

6

Models 151XST and 151XST-S

Page 7

Installation and Maintenance Instructions

Unpacking the Light

EXPLOSION HAZARD—Damaged domes can lead to

explosions that could result in serious injury or death.

After unpacking the beacon, examine it for damage that may

have occurred in transit. If the beacon has been damaged, do not

attempt to install or operate it. File a claim immediately with

the carrier, stating the extent of the damage. Carefully check all

envelopes, shipping labels, and tags before removing or discarding

them. Disposal of all shipping materials must be carried out in

accordance with national and local codes and standards. If any

parts are missing, please call Federal Signal Customer Support at

708-534-4756 or 877-289-3246.

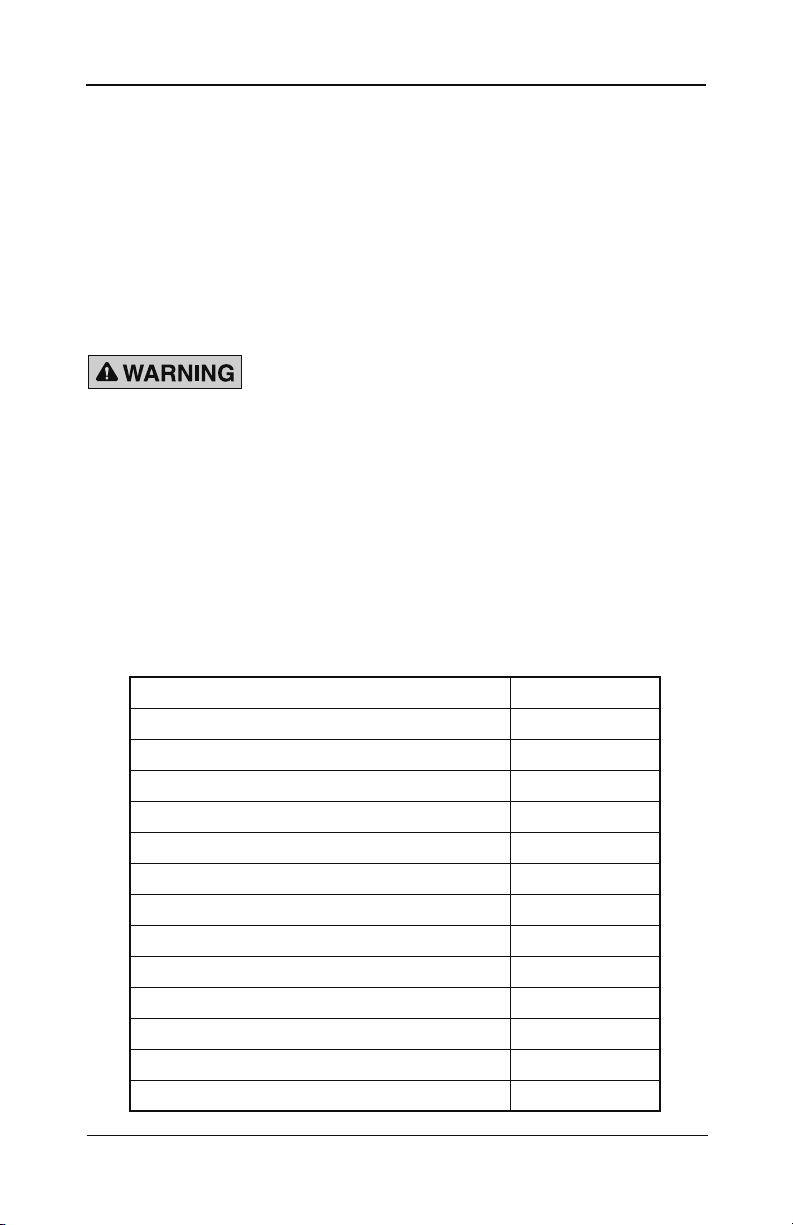

Table 1 Specications

Lamp Life: 10,000 hours

Light Source: Strobe tube

Operating

Temperature:

Net Weight: 3.8 lb (1.7 kg)

Shipping Weight: 4.5 lb (2.0 kg)

Height: 9.25 in (234.95 mm)

Diameter: 5.5 in (139.7 mm)

-67 °F to 150 °F

(-55 °C to 65.6 °C)

Table 2 Voltage and operating current

Model Voltage Operating

Current

151XST(-S) 012-024__ 12-24 Vdc 1.3 A to 0.60 A

151XST(-S)-120__ 120 Vac, 50/60 Hz 0.35 A

151XST(-S)-240__ 240 Vac, 50/60 Hz 0.16 A

__ Indicates color: (A) amber, (B) blue, (C) clear, (G) green, (M) magenta

or (R) red.

Models 151XST and 151XST-S

7

Page 8

Installation and Maintenance Instructions

Table 3 Flash rate and candelas

Model Flash Rate

per Minute

Candela

Peak

1

ECP

2

151XST(-S) 012-024__ 80 520,000 165

151XST(-S)-120__ 80 520,000 165

151XST(-S)-240__ 80 520,000 165

__ Indicates color: (A) amber, (B) blue, (C) clear, (G) green,

(M) magenta or (R) red.

1

Peak candela is the maximum light intensity generated

by a ashing light during its light phase.

2

ECP (Effective Candela) is the intensity that would appear

to an observer if the light were burning steadily.

Table 4 Hazardous Location Rating

Temperature Code at Maximum Temperature, °C

Hazardous Location 66 ºC

Class I, Div 2, Groups A, B, C & D T1/301º

Class II, Div 1, Groups E, F & G T5/100º

Class III T5/100º

To reduce the risk of re or explosion, do not install the beacon

in a hazardous location if the operating temperature exceeds the

ignition temperature of hazardous atmosphere.

Before proceeding, use Table 4 above as a guide and determine

that the unit’s operating temperature DOES NOT exceed the

hazardous atmosphere’s ignition temperature.

For marine applications, all wiring including supply wire must be

stranded wire and meet the USCG (CFR46) Sections (110-113).

NOTE: In high-humidity environments when units are mounted

dome down, condensation may occur in the conduit system. Use

properly rated conduit seals/drains to prevent moisture from

entering the xture.

8

Models 151XST and 151XST-S

Page 9

Installation and Maintenance Instructions

Pipe-Mounting the Beacon (151XST)

EXPLOSION HAZARD—To reduce the risk of re or explosion,

do not install the beacon in a hazardous location if the

operating temperature exceeds the hazardous atmosphere’s

ignition temperature. Before proceeding, consult the product

nameplate and determine the operating temperature of the

beacon.

NOTE: To comply with NEC Section 300-14, which requires a

minimum of 6 inches (15.25 cm) of free conductor at a junction,

when mounting the Model 151XST, the mounting pipe used to join

the unit to a splice box should be no longer than 10 in (25.4 cm).

The Model 151XST has provisions for mounting a 3/4" pipe and

can be mounted in any position.

Before mounting the beacon, ensure that the mating threads

1.

are clean.

2.

To prevent the ingress of water and dust, apply conductive

sealant to the conduit threads prior to mounting. If nonconductive sealant is used, the enclosure must be earthed

via the provided internal grounding wire/grounding screw to

ensure proper grounding continuity (Figure 3 on page 13).

3.

See Figure 1 on page 10. Thread the xture onto the 3/4-inch

pipe and secure it with the set screw.

Models 151XST and 151XST-S

9

Page 10

Installation and Maintenance Instructions

Figure 1 Pipe-mounted beacon

3/4" NPT PIPE

151XST LIGHT

ASSEMBLY

SET SCREW

290A6904

Surface-Mounting the Beacon (151XST-S)

To surface mount the beacon:

See Figure 2. Use the mounting base as a template to mark the

1.

location of the two mounting holes.

2.

Drill a 9/32-inch (7.143 mm) hole at each mark.

3. Secure the beacon to the mounting surface with installer

supplied hardware.

10

Models 151XST and 151XST-S

Page 11

Figure 2 Surface-mounted beacon

290A6905

151XST-S LIGHT

ASSEMBLY

INSTALLER-SUPPLIED

MOUNTING HARDWARE

DRILL TWO 9/32 in

(7.143 mm) HOLES

Installation and Maintenance Instructions

MOUNTING SURFACE

Wiring the Beacon

The Model 151XST Series Beacon should be installed per the

NEC or CEC, STATE and LOCAL CODES. Alternate installation

locations and/or orientations should only be performed with the

approval of the authority having jurisdiction. In addition, the unit

can be mounted using an optional ceiling mount or optional wall

mount.

NOTE: The 120 Vac or 230-240 Vac strobe units are designed

to operate on both 50 Hz and 60 Hz electrical power. Special

modications are NOT required for the two different AC line

frequencies.

Models 151XST and 151XST-S

11

Page 12

Installation and Maintenance Instructions

SHOCK HAZARD—To avoid electrical shock hazards, do not

connect wires while power is applied.

EXPLOSION HAZARD—Do not disconnect the beacon while

the circuit is live or unless the area is known to be free of

ignitable concentrations. Keep the beacon tightly closed

when in operation.

REVERSE POLARITY/MISWIRING—Although the 151XST

is not polarity sensitive, it MAY BE DAMAGED by incorrect

electrical hookup. Damage will result if the voltage rating of

the particular model is exceeded.

NOTE: Wiring must comply with the National Electrical Code

or Canadian Electrical Code and the local authority having

jurisdiction.

12

Wiring the AC Models

The AC models have two 24-inch leads, one black and one

white. To wire the AC beacon:

Ensure that power is off.

1.

2. Remove the threaded dome assembly by twisting it

counterclockwise.

Connect the black lead to the phase (hot) side of the power

3.

source and the white lead to the common (neutral) side of

the AC power source.

If required, the green screw in the housing is provided

4.

for connection to an earth ground (Figure 3 on page 13).

To gain access to the screw, remove the power supply

assembly.

Secure the dome to the base of the beacon.

5.

Models 151XST and 151XST-S

Page 13

Installation and Maintenance Instructions

207.8 mm

165.6 mm (6.52 in)

POWER WIRES

6. Connect power to the beacon and test it for proper

operation.

Figure 3 Cross section of beacons

MODEL 151XST-S

DOME GUARD

(INCLUDED)

GLASS DOME ASSY.

(8.18 in)

FLASH TUBE

ALUMINUM

BASE

2 x 3/4" NPT

ENTRY

MODEL 151XST

234.95 mm

(9.25 in)

SET SCREW

GROUND

SCREW

139.7 mm (5.5 in)

GASKET

GROUND SCREW

DOME GUARD

(INCLUDED)

GLASS DOME ASSY.

FLASH TUBE

GASKET

ALUNIMUM BASE

3/4" NPT PIPE MOUNT

POWER WIRES

Models 151XST and 151XST-S

290A7397

13

Page 14

Installation and Maintenance Instructions

Wiring the DC Models

The DC units have two 24-inch leads, one black and one red.

To wire the DC beacon:

Ensure that power is off.

1.

2. Remove the threaded dome assembly by twisting it

counterclockwise.

Connect the red (+) lead to the positive side of the power

3.

source and the black (–) lead to the negative side of power

source.

If required, the green screw in the housing is provided for

4.

connection to an earth ground. To gain access to the screw,

remove the power supply assembly.

Secure the dome to the base of the beacon.

5.

6. Connect power to the beacon and test it for proper operation.

Safety Message to Maintenance Personnel

Listed below are some important safety instructions and

precautions you should follow:

• Read and understand all instructions before operating this

system.

• Any maintenance to the light system must be done with power

turned off.

• Any maintenance to the light system must be performed

by a trained electrician who is thoroughly familiar with all

applicable national and local codes in the country of use.

• Do not connect this beacon to the system when power is on.

• Do not disconnect the beacon while the circuit is live or unless

the area is known to be free of ignitable concentrations. Keep

the beacon tightly closed when in operation.

14

Models 151XST and 151XST-S

Page 15

Installation and Maintenance Instructions

• Never alter the unit in any manner. Safety of the unit may be

affected if additional openings or other alterations are made to

the internal components or housing.

• The nameplate should NOT be obscured, as it contains

cautionary and/or other information of importance to

maintenance personnel. Ensure the nameplate remains readable

if the housing exterior is painted.

• If the dome is damaged in any way, it MUST be replaced.

• After performing any maintenance, test the light system to

ensure that it is operating properly.

Failure to follow all safety precautions and instructions may result

in property damage, serious injury, or death.

Servicing the Beacon

EXPLOSION HAZARD—To prevent ignition of hazardous

atmospheres, disconnect the xture from the supply circuit

before opening it.

EXPLOSION HAZARD—Do not disconnect the beacon while

the circuit is live or unless the area is known to be free of

ignitable concentrations. Keep the beacon tightly closed

when in operation.

EXPLOSION HAZARD—To maintain the vapor-tight enclosure,

do not damage the globe or threads while disassembling or

reassembling the unit. Lubricated threaded joints exposed

for long periods of time may attract small particles of dirt or

other foreign materials. Housing and cover joints should be

reassembled immediately, with all the threads fully engaged.

Models 151XST and 151XST-S

15

Page 16

Installation and Maintenance Instructions

SHOCK HAZARD—High voltages are present inside the light

assembly. Wait at least 5 minutes after shutting off the power

before servicing this unit.

Establishing a regular maintenance and inspection schedule

extends the life of the Model 151XST and ensures safety. For

service, support, or replacement parts, see pages 19 and 20.

Replacing the Flash Tube

As strobe lights are used, the ash tubes begin to darken,

causing the light output to decrease. This darkening is

characteristic of ash tubes. Darkening will begin near the base

of the tube and progress upward. Also, as ash tubes age, they

may have a tendency to misre (not re periodically).

After extended operation, occasionally check for ash tube

degradation. Should the ash tube misre, have a noticeable

decrease in light output, glow continuously or darken to a

point beyond that shown in Figure 4 on page 17, it should be

replaced.

16

To replace the ash tube:

Disconnect power to the beacon and wait at least 5 minutes

1.

to allow all capacitors to discharge.

Remove the threaded dome assembly by twisting it

2.

counterclockwise.

With the dome removed, gently pull the ash tube from its

3.

socket. A rocking motion is most helpful when installing or

removing the tube.

Replace the ash tube. Ensure that the replacement tube is

4.

fully seated in the socket.

Replace the globe assembly. Ensure that the globe

5.

assembly is seated securely against the gasket.

Models 151XST and 151XST-S

Page 17

Installation and Maintenance Instructions

6. Test the beacon for proper operation.

Figure 4 Normal (A) and darkened (B) ash tube

A B

Replacing the Printed Circuit Board (PCB)

To replace the PCB:

Disconnect the power to the beacon and wait at least 5

1.

minutes to allow all capacitors to discharge.

Remove the threaded dome assembly by twisting it

2.

counterclockwise.

Remove and retain the screw that secures the circuit board

3.

to the housing.

Disconnect power to the PCB:

4.

a) To replace a Series A1 PCB, disconnect the two supply

wires from the old circuit board and connect them

to the mating side of the supplied adapter assembly.

Connect the other side of the adapter assembly to the

new circuit board.

To replace a Series A2 circuit board, disconnect the

b)

power connector from the old circuit board and connect

it to the connector on the new circuit board.

NOTE: Ensure that the connector is fully seated on the

circuit board connectors.

Models 151XST and 151XST-S

17

Page 18

Installation and Maintenance Instructions

5. Secure the new circuit board to the housing with the screw

removed in step 2.

Install the new ash tube in the socket. Ensure that the ash

6.

tube is fully seated in the socket.

Replace the globe assembly. Ensure that the globe

7.

assembly is seated securely against the gasket.

8. Test the light for proper operation.

Cleaning the Fixture

EXPLOSION HAZARD—Never use an abrasive material

or le to remove corrosive materials from threaded

surfaces. In extremely corrosive locations, equipment

should be periodically inspected to guard against unusual

deterioration and possible porosity, since this may weaken

the enclosure structurally.

Maintenance procedures sometimes require xtures to be hosed

down for good housekeeping. The circuit should be turned off

prior to hosing down the xture.

18

The xture should be cleaned periodically to maintain

maximum light output. Only mild, non-abrasive cleaning agents

should be used. The glass globe should be regularly inspected

for scratches and chips, and if damaged, MUST be replaced.

Lubricating the Threaded Joint

The threaded joint on the cover should be kept well lubricated

with a corrosion inhibiting grease such a petrolatum or soapthickened mineral oil. If corrosive materials have accumulated

on the threaded joints and cannot be removed with solvents, the

parts should be discarded and replaced.

Models 151XST and 151XST-S

Page 19

Installation and Maintenance Instructions

Models 151XST and 151XST-S

Getting Repair Service or Technical Assistance

Products returned for repair require a Return Authorization form

from your local distributor or from Federal Signal. To obtain

repair service or technical assistance from Federal Signal, call

708-534-4756 or 877-289-3246. For instruction manuals and

information on related products, visit:

http://www.federalsignal-indust.com

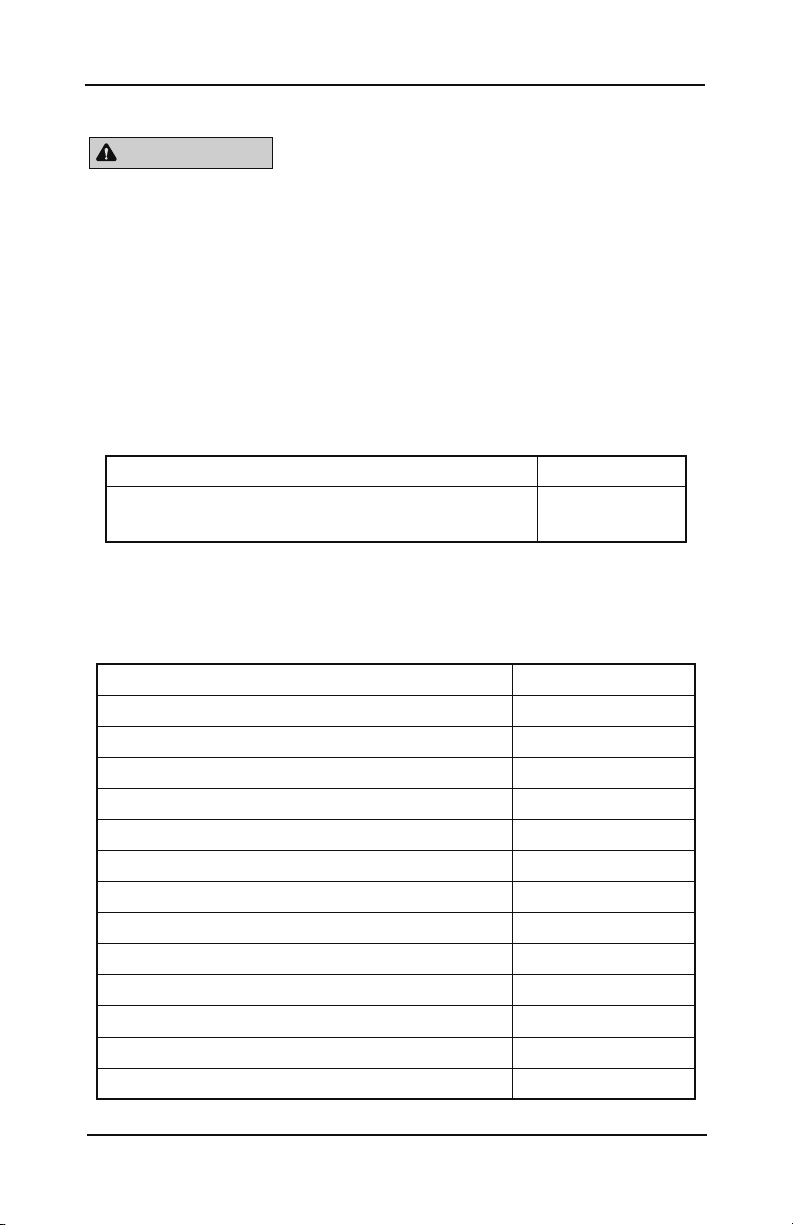

Ordering Accessories and Replacement Parts

EXPLOSION HAZARD—Substitution of components may

impair suitability for Class I, Division 2.

Typical spare parts are listed in Table 4. Due to certication,

certain component parts are not available for eld replacement.

Units with this type of damage must be either replaced entirely or

returned to Federal Signal for service. To order accessories and

replacement parts, please call Federal Signal Customer Support at

708-534-4756 or 877-289-3246.

Table 5 Replacement parts

Description Part Number

Dome Assy., Red K8449078

Dome Assy., Amber K8449078-01

Dome Assy., Clear K8449078-04

Dome Assy., Blue K8449078-06

Dome Assy., Green K8449078-07

Dome Assy., Magenta K8449078-05

Gasket K8449080

Grease, 8 oz Tube KR81-05-01

Dome Guard K8449090

Power Supply Assy., 12-24 Vdc K2001173

Power Supply Assy., 120 Vac K2001071

Power Supply Assy., 240 Vac K2001071-01

Flash Tube K149122

19

Page 20

Installation and Maintenance Instructions

Models 151XST and 151XST-S

Description Model

Hazardous Location Wall-Mount Bracket LHWB*

* Cannot be used in Class II, Division 1 applications. NEMA 4X and IP66

rated when used with the appropriate conduit ttings.

Table 6 Accessory

Returning the Product for Credit

Product returns for credit require a return authorization from your

local distributor prior to returning the product to Federal Signal.

Please contact your distributor for assistance.

A product is qualied to be returned for credit when the following

conditions are met:

• Product is resalable and in the original cartons

• Product has not been previously installed

• Product is the current revision

• Product has not been previously repaired

• Product is a standard product

• Product is not a service part

All returns are subject to a re-stock fee.

Defective products that are returned within the warranty period

will be repaired or replaced at Federal Signal’s sole discretion.

Defective products do not include those products with lamp

failure.

Circumstances other than those listed above will be addressed on a

case-by-case basis.

Industrial Systems

2645 Federal Signal Drive • University Park, IL 60484-3167

Tel: 708-534-4756 • Fax: 708-534-4852

Email: elp@federalsignal.com • www.federalsignal-indust.com

20

Page 21

Lumière stroboscopique 151XST

pour endroits dangereux

Instructions d’installation

et d’entretien

256822J

Rev. J0 913

Imprimé aux États-Unis

21

Page 22

ans

G

A

E

I

T

R

N

A

Garantie – Le vendeur offre pour tous les produits une garantie de cinq ans sur

les pièces et de 2,5 ans sur la main-d’œuvre, selon les conditions et exceptions

suivantes : le vendeur garantit que tous les produits qu’il fabrique seront conformes

aux descriptions correspondant aux spécications qui font expressément partie de ce

contrat de vente et qu’au moment de la vente par le vendeur, de tels produits devront

être exempts de défauts de matériel et de fabrication. Le vendeur se réserve le droit, à

sa discrétion, de « Réparer et retourner » ou «Remplacer » tout article jugé défectueux

durant la période de garantie. Cette garantie ne couvre pas les frais de voyage, le coût

de l’équipement spécialisé pour avoir accès au produit ou les frais de main-d’œuvre

liés à l’enlèvement et à la réinstallation du produit. Cette garantie sera inopérante

et ne s’appliquera pas aux produits qui ont subi un mauvais usage, une négligence,

un accident, des dommages ou un entretien inapproprié, ou aux produits modiés

ou réparés par quelqu’un d’autre que le vendeur ou son représentant autorisé, ou si

cinq ans se sont écoulés depuis la date de l’envoi des produits par le vendeur avec les

exceptions suivantes : les lampes et les tubes stroboscopiques ne sont pas couverts par

cette garantie. Les sirènes d’alarme extérieures et les appareils de contrôle fabriqués

par Federal Warning Systems sont couverts par une garantie deux ans sur les pièces

et de un an sur la main-d’œuvre. Aucun agent, employé, représentant ou distributeur

du vendeur n’a autorité pour lier celui-ci à une représentation, afrmation, ou garantie

relative au produit et une telle représentation, afrmation, ou garantie ne pourra

pas être considérée comme faisant partie des généralités du contrat de vent et sera

inexécutable. LES GARANTIES CI-DESSUS SONT EXCLUSIVES ET TIENNENT

LIEU DE TOUTES LES AUTRES GARANTIES DE LA QUALITÉ MARCHANDE,

DE COMPATIBILITÉ À UN USAGE PARTICULIER OU D’UN AUTRE TYPE,

QU’ELLES SOIENT EXPRESSES OU IMPLICITES. Ces garanties ne s’appliqueront

pas si le vendeur n’a pas la possibilité raisonnable d’enquêter sur toutes les réclamations

de produits soi-disant défectueux. À la demande du vendeur, un échantillon seulement

des produits soi-disant défectueux lui sera retourné pour inspection et approbation. La

raison de toute réclamation pour de soi-disant défauts dans les produits ne pouvant être

découverts après une inspection raisonnable en vertu du paragraphe 8 ci-contre doit

être entièrement expliquée par écrit et reçue par le vendeur dans les trente jours après

que l’acheteur ait pris connaissance du défaut ou une telle réclamation sera considérée

comme nulle.

Industrial Systems

2645 Federal Signal Drive • University Park, IL 60484-3167

Tel: 1-708-534-4756 • 1-877-289-3246 • Fax: 1-708-534-4852

www.federalsignal-indust.com • www.fs-isys.com

© 2013 Federal Signal Corporation. Tous droits réservés.

22

Page 23

Modèles 151XST et 151XST-S

Contenu

Messages de sécurité destinés aux installateurs ........................25

Aperçu de la gamme 151XST .........................................................26

Déballage de la lumière...................................................................27

Installation de la lumière sur un tuyau (151XST)..........................29

Installation de la balise lumineuse sur une surface (151XST-S) ...30

Câblage de la lumière......................................................................31

Câblage des modèles en CA ................................................... 32

Câblage des modèles en CC

Message de sécurité destiné au personnel d’entretien ............... 34

................................................... 34

Remplacement du tube à éclats .............................................. 36

Remplacement de la carte de circuits imprimés

Nettoyage de l’appareil

Lubrication du joint leté

Service de réparation ou assistance technique .......................... 39

Accessoires et pièces de rechange ............................................... 39

Renvoi du produit pour obtention d’un crédit .............................. 40

Tableau 1 Caractéristiques techniques ............................................27

Tableau 2 Tension et courant de fonctionnement ............................27

Tableau 3 Fréquence des éclats et intensité lumineuse .................. 28

Tableau 4 Classication des endroits dangereux ............................28

Tableau 5 Accessoire .......................................................................40

..........................................................38

.....................................................39

Tableaux

..................... 37

Tableau 6 Pièces de rechange ........................................................40

23

Page 24

Modèles 151XST et 151XST-S

Contenu

Figures

Figure 1 Lumière 151XST installée sur un tuyau ............................. 30

Figure 2 Lumière 151XST-S installée sur une surface ....................31

Figure 3 Coupe transversale des lumières ......................................33

Figure 4 Tube à éclats normale (A) et foncé (B) .............................. 37

24

Page 25

Instructions d’installation et d’entretien

Messages de sécurité destinés aux installateurs

AVERTISSEMENT

Bien suivre toutes les instructions fournies avec ce produit. Cet

appareil doit être installé par un électricien qualié qui connaît

parfaitement le Code national de l’électricité et/ou le Code

canadien de l’électricité, et suivra les directives du CNE et/

ou du CCE, ainsi que des codes locaux. Cette lumière doit être

considérée comme faisant partie du système d’avertissement et

non comme le système lui-même.

Le choix du lieu d’installation de la lumière, les commandes et

le passage des câbles doivent s’effectuer sous la direction de

l’ingénieur des installations et de l’ingénieur de la sécurité. De

plus, d’autres précautions et instructions importantes relatives à la

sécurité et à observer gurent dans la liste ci-dessous :

• Bien lire et comprendre toutes les instructions avant d’installer

ou d’utiliser cette lumière.

• Ne jamais modier cet appareil de quelque façon que ce soit.

Le fait de ménager d’autres ouvertures ou d’apporter d’autres

modications à des appareils spécialement conçus pour des

emplacements dangereux peut compromettre la sécurité.

• Ne pas connecter ce dispositif au système lorsque ce dernier est

sous tension.

• Après l’installation, vérier que les vis sont bien serrées et que

les joints letés sont vissés jusqu’au bout.

• Après l’installation, tester la lumière pour vérier son bon

fonctionnement.

• Une fois le test terminé, distribuer un exemplaire de cette che

d’instructions à l’ensemble du personnel d’exécution.

• Mettre en place une procédure visant à vérier régulièrement

l’intégrité et le bon fonctionnement de la lumière installée.

Modèles 151XST et 151XST-S

25

Page 26

Instructions d’installation et d’entretien

Le non-respect de toutes les précautions et instructions de sécurité

peut provoquer des dommages à la propriété, des blessures graves

voire la mort.

Aperçu de la gamme 151XST

La lumière stroboscopique pour endroits dangereux 151XST

de Federal Signal émet 80 éclats lumineux à haute intensité par

minute. Cet avertisseur lumineux est proposé en 12 à 24 Vcc, 120

Vca et 240 Vca, à 50/60 Hz.

Homologué UL, le modèle 151XST possède également la

certication CSA de classe I, division 2, groupes A, B, C et D;

classe II, division 1, groupes E, F et G et classe III.

Sa protection répondant aux normes IP66 est de type 4X en

ce qui concerne l’étanchéité à l’eau et à la poussière, ainsi que

la résistance à la corrosion. Cet avertisseur lumineux pour

emplacement dangereux est fait d’une base en aluminium avec

revêtement anticorrosion, prête à être xée sur un tuyau de 19 mm

NPT (0,75 po).

L’intensité lumineuse efcace par seconde du modèle 151XST

s’élève à 165, avec une capacité limite de 520 000. Le dôme se

décline en six couleurs : ambre, bleu, transparent, vert, rouge, et

magenta sur demande.

Robuste, l’avertisseur lumineux stroboscopique 151XST est

spécialement conçu pour les endroits dangereux ou les milieux

corrosifs nécessitant la présence d’un signal visuel brillant. Il

peut être utilisé pour l’évacuation d’une usine ou pour d’autres

besoins de communication. Certains modèles se xent sur un

tuyau (151XST), tandis que d’autres se montent sur une surface

(151XST-S).

REMARQUE : Le modèle 151XST peut être xé sur un support

LHWB de Federal Signal. Dans ce cas, l’installation nale n’est

destinée qu’à des emplacements de la classe I, division 2, groupes

A, B, C et D; de la classe II, division 2, groupes F et G ainsi que de

la classe III.

26

Modèles 151XST et 151XST-S

Page 27

Instructions d’installation et d’entretien

Déballage de la lumière

AVERTISSEMENT

RISQUE D’EXPLOSION—S’ils sont abîmés, les dômes

peuvent provoquer des explosions susceptibles d’entraîner

des blessures graves, voire la mort.

Après avoir déballé la lumière, l’inspecter pour vérier qu’aucun

dommage n’est survenu lors du transport. Si la lumière a été

endommagée, ne pas essayer de l’installer ou de l’utiliser. Déposer

immédiatement une réclamation auprès du transporteur en précisant

l’étendue des dégâts. Vérier avec soin toutes les enveloppes,

étiquettes d’expédition et autres étiquettes avant de les retirer ou de

les détruire. La mise au rébus de tout matériel de transport doit être

effectuée conformément aux normes et codes locaux et nationaux.

En cas de pièces manquantes, communiquer avec le Service à la

clientèle de Federal Signal au 708-534-4756 ou 877-289-3246.

Tableau 1 Caractéristiques techniques

Durée de vie de l’ampoule : 10 000 heures

Source lumineuse : Tube stroboscopique

Température de fonctionnement :

Poids net : 1,7 kg (3,8 lb)

Poids d’expédition : 2,0 kg (4,5 lb)

Longueur : 234,95 mm (9,25 po)

Diamètre : 139,7 mm (5,5 po)

-55 °C à 65.6 °C

(-67 °F à 150 °F)

Tableau 2 Tension et courant de fonctionnement

Modèle Tension Courant de

fonctionnement

151XST(-S) 012-024__ 12-24 Vcc 1,3 A to 0,60 A

151XST(-S)-120__ 120 Vca, 50/60 Hz 0,35 A

151XST(-S)-240__ 240 Vca, 50/60 Hz 0,16 A

__ correspond à la couleur : (A) ambre, (B) bleu, (C) transparent, (G) vert,

(M) magenta ou (R) rouge.

Modèles 151XST et 151XST-S

27

Page 28

Instructions d’installation et d’entretien

Tableau 3 Fréquence des éclats et intensité lumineuse

Modèle Nombre

d’éclats

par minute

Intensité lumineuse

Limite

1

ILE

2

luminosité

efcace

151XST(-S) 012-024__ 80 520 000 165

151XST(-S)-120__ 80 520 000 165

151XST(-S)-240__ 80 520 000 165

__ correspond à la couleur : (A) ambre, (B) bleu, (C) transparent, (G) vert,

(M) magenta ou (R) rouge.

1

L’intensité lumineuse limite est l’intensité maximale générée par

un éclat au cours de sa phase lumineuse.

2

L’intensité lumineuse efcace (ILE) est l’intensité qui serait

observée si la lumière était constante.

Tableau 4 Classication des endroits dangereux

Code de température à la température maximale, en °C

Milieu dangereux 66 ºC

Classe I, div. 2, groupes A, B, C et D T1/301º

Classe II, div 1, groupes E, F et G T5/100º

Classe III T5/100º

Pour réduire les risques d’incendie ou d’explosion, ne pas

installer la lumière dans un endroit dangereux si la température de

fonctionnement dépasse le point d’inammation de l’atmosphère

dangereuse.

Avant l’installation, consulter le tableau 4 ci-dessus pour vérier

que la température de fonctionnement de la balise lumineuse

NE DÉPASSE PAS le point d’inammation de l’atmosphère

dangereuse.

En cas d’utilisation en milieu marin, tous les ls, y compris les

ls d’alimentation, doivent être des ls multibrins conformes aux

sections 110 à 113 de la norme USCG CFR46.

28

Modèles 151XST et 151XST-S

Page 29

Instructions d’installation et d’entretien

REMARQUE : En cas d’installation du dôme vers le bas dans

des milieux très humides, de la condensation peut apparaître dans

les conduits. Utiliser des évacuations ou des joints pour conduits

adaptés an que l’humidité ne puisse pas pénétrer dans l’appareil.

Installation de la lumière sur un tuyau (151XST)

AVERTISSEMENT

RISQUES D’EXPLOSION—Pour réduire les risques d’incendie

ou d’explosion, ne pas installer la lumière dans un endroit

dangereux si la température de fonctionnement dépasse le

point d’inammation de l’atmosphère dangereuse. Avant

toute chose, consulter la plaque signalétique du produit pour

connaître la température de fonctionnement de la lumière

REMARQUE : Conformément à la section 300-14 du NEC, qui

exige une longueur minimale de 15,25 cm (6 po) de conducteur

libre au raccordement, le tuyau utilisé pour brancher l’appareil à la

boîte de branchement lors de l’installation du modèle 151XST ne

doit pas dépasser 25,4 cm (10 po).

Le modèle 151XST est conçu pour être installé sur un tuyau de

19 mm (0,75 po), dans n’importe quelle position.

Avant l’installation, vérier que les lets correspondants sont

1.

propres.

Pour empêcher l’eau et la poussière d’entrer dans l’appareil,

2.

appliquer du produit d’étanchéité aux lets du conduit avant

l’installation. Si le produit d’étanchéité n’est pas conducteur,

le boîtier doit être mis à la terre grâce au l ou au câble interne

prévu à cet effet, an d’assurer la continuité de la mise à la

terre (gure 3, page 33).

Voir la gure 1, page 30. Visser la lumière sur le tuyau de

3.

19 mm (0,75 po) et la xer à l’aide de la vis de serrage.

Modèles 151XST et 151XST-S

29

Page 30

Instructions d’installation et d’entretien

Figure 1 Lumière 151XST installée sur un tuyau

CORPS DE LA

LUMIÈRE 151XST

VIS DE SERRAGE

19 mm NPT (0,75 PO)

TUYAU DE

290A7391

Installation de la balise lumineuse sur une

surface (151XST-S)

Pour xer la lumière sur une surface :

Voir la gure 2. Utiliser la base de xation comme modèle

1.

pour marquer l’emplacement des deux trous de xation.

Percer un trou de 7,1 mm (9/32 po) à chaque emplacement

2.

marqué.

Fixer la lumière sur la surface à l’aide du matériel fourni.

3.

30

Modèles 151XST et 151XST-S

Page 31

Instructions d’installation et d’entretien

Figure 2 Lumière 151XST-S installée sur une surface

LUMIÈRE 151XST

MATÉRIEL DE FIXATION

FOURNI PAR L'INSTALLATEUR

PERCER DEUX TROUS

DE 7,143 mm (9/32 PO)

SURFACE DE MONTAGE

290A7392

Câblage de la lumière

Le modèle 151XST(-S) doit être installée conformément au

Code national de l’électricité, au Code canadien de l’électricité,

aux CODES PROVINCIAUX et aux CODES LOCAUX. Pour

procéder à l’installation à un autre endroit ou dans un autre sens,

il vous faut l’approbation de l’autorité compétente. En outre, il est

possible de xer l’appareil à l’aide d’un montant pour plafond ou

pour mur, offert en option.

REMARQUE :

230-240 Vca sont conçues pour une alimentation de 50 Hz et

60 Hz. AUCUNE modication n’est nécessaire pour les deux

lignes à courant CA.

Les lumières stroboscopiques de 120 Vca ou

Modèles 151XST et 151XST-S

31

Page 32

Instructions d’installation et d’entretien

AVERTISSEMENT

RISQUE DE CHOC ÉLECTRIQUE — Pour éviter les chocs

électriques, ne pas brancher les ls lorsque l’appareil est

sous tension.

AVERTISSEMENT

RISQUES D’EXPLOSION—Ne débrancher la lumière que si le

circuit est sous tension, ou si vous avez vérié qu’il n’y a pas

de concentrations de produits inammables dans la zone.

Lors du fonctionnement, la lumière doit être hermétiquement

fermée.

POLARITÉ INVERSÉE/MAUVAIS BRANCHEMENT—Bien qu’il

ne soit pas polarisé, l’appareil 151XST(-S) peut s’abîmer s’il

est mal branché. En particulier, il peut subir des dégâts en

cas de dépassement de la tension nominale prévue.

REMARQUE : Le câblage doit être conforme aux dispositions du

Code national de l’électricité, du Code canadien de l’électricité et

des dispositions des autorités compétentes.

32

Câblage des modèles en CA

Les modèles en CA comportent deux ls de 61 cm (24 po), un

noir et un blanc. Pour brancher la balise lumineuse en CA :

Vérier que l’alimentation électrique est coupée.

1.

2. Retirer le dôme leté en le tournant dans le sens inverse des

aiguilles d’une montre.

Brancher le l noir sur le côté phase (sous tension)

3.

et le blanc sur le côté commun (neutre) de la source

d’alimentation en CA.

Au besoin, la vis verte du boîtier sert à la mise à la

4.

terre (gure 3, page 33). Pour y accéder, retirer le bloc

d’alimentation.

Modèles 151XST et 151XST-S

Page 33

Instructions d’installation et d’entretien

165,6 mm (6,52 PO)

ÉLECTRIQUES

5. Fixer le dôme à la base de la lumière.

6. Vérier si la lumière fonctionne normalement.

Figure 3 Coupe transversale des lumières

MODÈLE 151XST-S

207,8 mm

(8,18 PO)

PROTECTEUR

DE DÔME (INCLUS)

DÔME DE VERRE

TUBE À ÉCLATS

BASE EN

ALUMINIUM

ENTRÉE DE

2x 3/4 PO NPT

MODÈLE 151XST

234,95 mm

(9,25 PO)

VIS DE MISE

À LA TERRE

SERRAGE

VIS DE

139,7 mm (5,5 PO)

CÂBLES

JOINT STATIQUE

CÂBLES

ÉLECTRIQUES

VIS DE MISE

À LA TERRE

PROTECTEUR

DE DÔME (INCLUS)

DÔME DE VERRE

TUBE À ÉCLATS

JOINT STATIQUE

BASE EN

ALUMINIUM

MONTAGE DE TUYAU

3/4 PO NPT

290A7393

Modèles 151XST et 151XST-S

33

Page 34

Instructions d’installation et d’entretien

Câblage des modèles en CC

Les modèles en CC comportent deux ls de 61 cm (24 po), un

noir et un rouge. Pour brancher la balise lumineuse en CC :

Vérier que l’alimentation électrique est coupée.

1.

2. Retirer le dôme leté en le tournant dans le sens inverse des

aiguilles d’une montre.

Brancher le l rouge (+) sur le côté positif de la source

3.

d’alimentation et le l noir (–) sur le côté négatif de la

source d’alimentation.

Au besoin, la vis verte se trouvant à l’intérieur du boîtier

4.

est prévue pour la mise à la terre. Pour y accéder, retirer le

bloc d’alimentation.

Fixer le dôme à la base de la lumière.

5.

6. Brancher l’alimentation et vérier si la lumière fonctionne

normalement.

Message de sécurité destiné au personnel

d’entretien

Les précautions et instructions de sécurité à suivre sont listées cidessous :

• Bien lire et comprendre toutes les instructions avant d’utiliser

ce système.

• L’entretien du système lumineux doit s’effectuer lorsque

l’alimentation est coupée.

• L’entretien doit être exécuté par un électricien formé qui

connaît bien les codes nationaux et locaux du pays d’utilisation.

• Ne pas connecter cette lumière au système lorsque ce dernier

est sous tension.

34

Modèles 151XST et 151XST-S

Page 35

Instructions d’installation et d’entretien

• Ne débrancher la lumière que si le circuit est sous tension, ou si

vous avez vérié qu’il n’y a pas de concentrations de produits

inammables dans la zone. Lors du fonctionnement, la lumière

doit être hermétiquement fermée.

• Ne jamais modier cet appareil de quelque façon que ce soit.

La sûreté de l’appareil peut être compromise si des composants

internes ou le boîtier sont percés ou modiés.

• La plaque signalétique NE DOIT PAS être masquée, car elle

comporte des avertissements et d’autres données importantes

pour le personnel d’entretien. Si le boîtier extérieur est peint,

veiller à ce que la plaque signalétique reste lisible.

• Si le dôme est abîmé d’une manière ou d’une autre, IL FAUT le

remplacer.

• Après avoir effectué l’entretien, tester le système lumineux

pour s’assurer du bon fonctionnement de la lumière.

Le non-respect de toutes les précautions et instructions de sécurité

peut provoquer des dommages à la propriété, des blessures graves

voire la mort.

Dépannage de la lumière

AVERTISSEMENT

RISQUES D’EXPLOSION — Pour éviter l’inammation en cas

d’atmosphère dangereuse, débrancher l’appareil du circuit

d’alimentation avant de l’ouvrir.

AVERTISSEMENT

RISQUES D’EXPLOSION — Ne débrancher la lumière que si le

circuit est sous tension, ou si vous avez vérié qu’il n’y a pas

de concentrations de produits inammables dans la zone.

Lors du fonctionnement, la lumière doit être hermétiquement

fermée.

Modèles 151XST et 151XST-S

35

Page 36

Instructions d’installation et d’entretien

AVERTISSEMENT

RISQUES D’EXPLOSION — Pour que le boîtier reste étanche

à la vapeur, éviter d’abîmer le dôme ou les lets lors du

démontage ou de l’assemblage de l’appareil. Lorsque

les joints letés lubriés restent longtemps exposés, ils

peuvent attirer de petites particules de poussière ou d’autres

matières. Les joints du boîtier et du couvercle doivent être

remontés immédiatement, et les lets vissés jusqu’au bout.

AVERTISSEMENT

RISQUE DE CHOC ÉLECTRIQUE— Des tensions élevées

traversent l’appareil. Attendre au moins 5 minutes après avoir

coupé le courant avant de dépanner l’appareil.

Un entretien et une inspection réguliers prolongent la vie du

modèle 151XST et favorisent la sécurité. Pour obtenir du service

de dépannage, du soutien ou des pièces de rechange, consulter les

pages 39 et 40.

Remplacement du tube à éclats

Au l de l’utilisation de la lumière stroboscopique, le tube

à éclats commence à foncer, ce qui affaiblit l’émission

lumineuse. Ce noircissement est caractéristique des tubes à

éclats. Il débute près de la base du tube pour se poursuivre vers

le haut. Parallèlement, lorsque le tube vieillit, son allumage

devient défectueux (il ne s’allume pas toujours).

36

Après une longue utilisation, vérier l’état du tube. Si

l’allumage montre des ratés, si la puissance lumineuse est

nettement plus faible, si la lumière luit de manière continue

ou devient plus sombre que l’illustration à la gure 4 de la

page 37, il faut remplacer le tube.

Pour remplacer le tube à éclats :

. Couper l’alimentation de la balise lumineuse et attendre au

1

moins 5 minutes que tous les condensateurs se déchargent.

Modèles 151XST et 151XST-S

Page 37

Instructions d’installation et d’entretien

A B

2. Retirer le dôme leté en le tournant dans le sens inverse des

aiguilles d’une montre.

Une fois le dôme déposé, tirer doucement sur le tube à

3.

éclats pour le déloger du socle. Il sera plus facile d’installer

ou de retirer le tube si vous faites un mouvement oscillant.

Remplacer le tube à éclats. Vérier que le tube de rechange

4.

est bien rentré dans le socle.

Remettre le dôme à sa place. Vérier qu’il est bien appuyé

5.

sur le joint statique.

Vérier si la lumière fonctionne bien.

6.

Figure 4 Tube à éclats normale (A) et foncé (B)

Remplacement de la carte de circuits imprimés

Pour remplacer la carte de circuits imprimés :

Couper l’alimentation de la lumière et attendre au moins 5

1.

minutes que tous les condensateurs se déchargent.

Retirer le dôme leté en le tournant dans le sens inverse des

2.

aiguilles d’une montre.

Retirer et conserver la vis qui xe la carte au boîtier.

3.

4. Débrancher la carte de circuits imprimés :

a) Pour remplacer une carte A1, débrancher les deux ls

d’alimentation de l’ancienne carte et les brancher sur

Modèles 151XST et 151XST-S

37

Page 38

Instructions d’installation et d’entretien

le côté correspondant de l’adaptateur fourni. Connecter

l’autre côté de l’adaptateur à la nouvelle carte.

Pour remplacer une carte A2, débrancher le connecteur

b)

d’alimentation de l’ancienne carte et le brancher au

connecteur de la nouvelle carte.

REMARQUE : Vérier que le connecteur est bien

installé sur les connecteurs de la carte de circuits

imprimés.

Fixer la nouvelle carte au boîtier à l’aide de la vis démontée

5.

à l’étape 2.

Installer le nouveau tube à éclats dans le socle. Vérier

6.

qu’il est bien enfoncé.

. Remettre le dôme à sa place. Vérier qu’il est bien appuyé

7

sur le joint d’étanchéité.

Faire un essai pour vérier que la lampe fonctionne

8.

normalement.

38

Nettoyage de l’appareil

AVERTISSEMENT

RISQUES D’EXPLOSION—Ne jamais utiliser une matière

ou une lime abrasive pour éliminer des substances

corrosives sur les surfaces letées. En cas de très forte

corrosion, il faut inspecter régulièrement l’équipement

pour le protéger d’une détérioration anormale et éviter

qu’il devienne poreux, ce qui pourrait affaiblir la structure

du boîtier.

Il est parfois nécessaire de laver les appareils d’éclairage au

jet d’eau pour bien les nettoyer. Dans ce cas, il faut couper le

circuit d’alimentation électrique avant de procéder.

Pour conserver une émission lumineuse maximale, il faut

nettoyer l’appareil périodiquement. Seuls les produits de

Modèles 151XST et 151XST-S

Page 39

Instructions d’installation et d’entretien

nettoyage doux et non abrasifs sont autorisés. Il faut inspecter

régulièrement le dôme de verre à la recherche d’éraures et

d’éclats. S’il est abîmé, IL FAUT le remplacer.

Lubrication du joint leté

Le joint leté du couvercle doit toujours rester bien lubrié à

l’aide d’une graisse anticorrosion, comme de la gelée de pétrole

ou de l’huile minérale épaissie par un savon. Si le solvant ne

suft pas à retirer la corrosion accumulée sur les joints letés, il

faut jeter les pièces et les remplacer.

Service de réparation ou assistance technique

Les produits renvoyés pour réparation doivent être accompagnés

d’un formulaire d’autorisation de renvoi par le distributeur local

ou par Federal Signal. Pour l’entretien du produit ou assistance

technique par Federal Signal, communiquer avec nous au

708-534-4858 ou 877-289-3246. Pour les manuels d’instructions

et d’informations sur les produits connexes, aller à:

http://www.federalsignal-indust.com

Accessoires et pièces de rechange

AVERTISSEMENT

RISQUES D’EXPLOSION — Il se peut qu’un appareil dont

les composants ont été remplacés ne convienne plus à

l’utilisation de classe I, division 2

Les pièces de rechange courantes sont énumérées au tableau 6,

page 40. Pour des raisons de certication, les pièces de certains

composants ne peuvent pas être remplacées sur place. Dans ce

cas, l’appareil au complet doit être remplacé ou renvoyé à Federal

Signal pour y être réparé. Pour commander des accessoires et

pièces de rechange, communiquer avec Federal Signal au

708-534-4756 ou 877-289-3246.

Modèles 151XST et 151XST-S

39

Page 40

Instructions d’installation et d’entretien

Modèles 151XST et 151XST-S

Description Modèle

Support mural pour endroit dangereux LHWB*

*Non destiné aux utilisations de classe II, division 1. Répond

aux normes NEMA 4X et IP66 lorsqu’utilisé avec les raccords de

conduits adaptés.

Tableau 5 Accessoire

Tableau 6 Pièces de rechange

Description

Dôme, Rouge

Dôme, ambre

Dôme, transparent

Dôme, bleu

Dôme, vert

Dôme, Mag enta

Gasket K8449080

Joint statique

Protecteur de dôme

Bloc d’alimentation, 12-24 Vcc

Bloc d’alimentation, 120 Vca

Bloc d’alimentation, 240 Vca

Tube à éclats

Numéro de pièce

K8449078

K8449078-01

K8449078-04

K8449078-06

K8449078-07

K8449078-05

KR81-05-01

K8449090

K2001173

K2001071

K2001071-01

K149122

Renvoi du produit pour obtention d’un crédit

Les produits renvoyés doivent être accompagnés d’une autorisation

de renvoi accordée par le distributeur local avant l’envoi chez

Federal Signal. Communiquer avec le distributeur pour obtenir de

l’aide.

Un produit peut être renvoyé avec obtention d’un crédit si les

conditions suivantes sont remplies :

• Le produit est revendable puis est renvoyé dans son emballage

d’origine

40

Page 41

Instructions d’installation et d’entretien

Modèles 151XST et 151XST-S

• Le produit n’a pas encore été installé

• Le produit est le modèle le plus récent

• Le produit n’a jamais été réparé

• Le produit est un produit standard

• Le produit n’est pas une pièce détachée

Tous les renvois de produits font l’objet de frais de restockage.

Les produits défectueux renvoyés au cours de la période de

garantie seront réparés ou remplacés à la seule discrétion de

Federal Signal. Les produits dont la lampe est défectueuse ne sont

pas considérés comme des produits défectueux.

Toute demande autre que celles citées ci-dessus sera examinée au

cas par cas.

41

Page 42

Industrial Systems

2645 Federal Signal Drive • University Park, IL 60484-3167

Tel: 708-534-4756 • Fax: 708-534-4852

Email: elp@federalsignal.com • www.federalsignal-indust.com

42

Page 43

Modelo 151XST serie luz estroboscópica

para uso en condiciones peligrosas

Instrucciones de instalación

y mantenimiento

256822J

Rev. J0 913

Impreso en los EE. UU.

43

Page 44

años

G

A

Garantía – El vendedor garantiza todas las mercaderías, durante cinco

años sobre las piezas y 2 1/2 años sobre la mano de obra, bajo las siguientes

condiciones y excepciones: El Vendedor garantiza que todas las mercaderías

fabricadas por el Vendedor se ajustan a las descripciones de las mismas para las

especicaciones que se consideran expresamente parte integrante de este contrato

de venta y en el momento de la venta por el vendedor dichas mercaderías se

encontrarán comercialmente libres de defectos en materiales o mano de obra. El

Vendedor se reserva el derecho de criterio del Vendedor de "Reparar y devolver"

o "Remplazar" cualquier elemento considerado defectuoso durante el período

de garantía. Esta garantía no cubre los gastos de viaje, el costo de equipos

especializados para acceder al producto o los cargos de mano de obra para el

desmontaje y la reinstalación del producto. Esta garantía quedará sin efecto y

no se aplicará a las mercaderías que han sido sometidas a maltrato, negligencia,

accidente, daño, mantenimiento inadecuado, o para las mercaderías alteradas o

reparadas por alguien que no sea el Vendedor o su representante autorizado, o

si han transcurrido cinco años desde la fecha de envío de las mercaderías por el

Vendedor con las siguientes excepciones: No están cubiertos por esta garantía

las lámparas y los tubos de luz estroboscópica. Las sirenas de alerta de exteriores

y los controladores fabricados por Federal Warning Systems están garantizados

por dos años sobre las piezas y un año sobre la mano de obra. Ningún agente,

empleado, representante o distribuidor del Vendedor tiene autoridad alguna para

obligar al Vendedor a cualquier representación, armación o garantía alguna

respecto de las mercaderías y ninguna representación, armación o garantía de

ese tenor será considerada parte de los fundamentos del contrato de venta y no

será ejecutable. LAS GARANTÍAS ANTERIORES SON EXCLUSIVAS Y EN

LUGAR DE TODAS LAS OTRAS GARANTÍAS DE COMERCIALIZACIÓN,

APTITUD PARA UN FIN Y DE CUALQUIER OTRO TIPO, YA SEAN

EXPRESAS O IMPLÍCITAS. Estas garantías no se aplicarán menos que el

Vendedor tenga la oportunidad razonable para investigar todas las reclamaciones

de las mercaderías supuestamente defectuosas. Siguiendo instrucciones del

Vendedor sólo una muestra de las mercaderías supuestamente defectuosas será

devuelta al Vendedor para su inspección y aprobación. El fundamento de todas

las reclamaciones por presuntos defectos en las mercaderías que no puedan

descubrirse tras una inspección razonable de la misma de conformidad con el

párrafo 8 de la presente garantía debe ser explicado completamente por escrito y

recibido por el Vendedor dentro de los treinta días después de que el Comprador

se entera de que el defecto o la reclamación serán considerados nulos.

A

I

R

T

A

N

Industrial Systems

2645 Federal Signal Drive • University Park, IL 60484-3167

Tel.: 1-708-534-4756 • 1-877-289-3246 • Fax: 1-708-534-4852

www.federalsignal-indust.com • www.fs-isys.com

© 2013 Federal Signal Corporation. Todos los derechos reservados.

44

Page 45

Modelos 151XST y 151XST-S

Contenido

Mensajes de seguridad para los instaladores .............................. 47

Descripción general de la serie 151XST........................................ 48

Desembalaje de la luz ..................................................................... 49

Montaje en tubo de la baliza (151XST) .......................................... 51

Montaje en supercie de la baliza (151XST-S) .............................. 52

Cableado de la baliza ...................................................................... 53

Cableado de los modelos de CA ............................................. 54

Cableado de los modelos de CC

Mensaje de seguridad al personal mantenimiento ...................... 56

Tareas de servicio en la baliza ....................................................... 57

Cambio del tubo de parpadeo ................................................. 58

Cambio de la placa de circuito impreso (PCB)

Limpieza del artefacto

............................................................ 61

Lubricación de la unión roscada

............................................. 56

...................... 60

............................................. 61

Servicio de reparación y asistencia técnica ................................. 61

Accesorios y repuestos .................................................................. 62

Cómo devolver el producto para obtener crédito ........................ 63

Cuadros

Cuadro 1 Especicaciones .............................................................. 49

Cuadro 2 Voltaje y corriente de funcionamiento ..............................50

Cuadro 3 Velocidad de parpadeo y candelas ..................................50

Cuadro 4 Clasicación de ubicaciones peligrosas ..........................50

Cuadro 5 Accesorio ......................................................................... 62

Cuadro 6 Piezas de repuesto .......................................................... 62

45

Page 46

Modelos 151XST y 151XST-S

Contenido

Figura 1 Baliza montada en tubo .....................................................52

Figura 2 Baliza montada en supercie ............................................53

Figura 3 Corte transversal de la baliza ............................................55

Figura 4 Tubo de parpadeo normal (A) y oscuro (B) .......................59

Figuras

46

Page 47

Instrucciones de instalación y mantenimiento

ADVERTENCIA

Mensajes de seguridad para los instaladores

Es importante que siga todas las instrucciones enviadas con este

producto. Este dispositivo debe ser instalado por un electricista

calicado que esté familiarizado con el Código Eléctrico Nacional

(NEC) y/o el Código Eléctrico Canadiense (CEC) y siga las

normas de los mismos, así como todos los códigos locales. Esta

baliza debe ser considerada como parte del sistema de alerta y no

el sistema de alerta completo.

La selección del lugar de montaje de la baliza, sus controles y la

ruta del cableado se hará bajo la dirección del ingeniero de las

instalaciones y del ingeniero de seguridad. Además, a continuación

se enumeran algunas otras instrucciones y precauciones de

seguridad que debe seguir:

• Lea y comprenda todas las instrucciones antes de instalar u

operar esta baliza.

• Nunca modique la unidad de ninguna manera. Se puede

poner en peligro la seguridad en áreas peligrosas si se realizan

aberturas adicionales u otras modicaciones a las unidades

diseñadas especícamente para su uso en estos lugares.

• No conecte esta luz al sistema cuando está encendido..

• Después de la instalación, asegúrese que el tornillo de

jación esté bien ajustado y que las uniones roscadas estén

completamente acopladas.

• Después de la instalación, pruebe el sistema de luz para

asegurarse que funciona correctamente.

• Después de completar la prueba, proporcione una copia de esta

hoja de instrucciones para todo el personal de operaciones.

• Establezca un procedimiento para vericar la integridad y el

funcionamiento adecuado de la instalación de la luz en forma

periódica.

Modelos 151XST y 151XST-S

47

Page 48

Instrucciones de instalación y mantenimiento

Si no se siguen todas las precauciones e instrucciones de seguridad

se pueden ocasionar daños a la propiedad, lesiones graves o la

muerte.

Descripción general de la serie 151XST

La luz estroboscópica para ubicaciones peligrosas modelo 151XST

de Federal Signal produce 80 parpadeos de alta intensidad por

minuto. Esta luz de advertencia está disponible en 12-24 VCC, 120

VCA y 240 VCA, 50/60 Hz.

La luz estroboscópica modelo 151XST gura en el listado de UL y

cuenta con la certicación CSA para clase I, división 2, grupos A,

B, C y D; clase II, división 1, grupos E, F y G; y clase III.

El modelo 151XST cumple con los requisitos de tipo 4X

(resistente al agua, resistente al polvo y resistente a la corrosión)

y se basa en IP66. Esta luz de advertencia para ubicaciones

peligrosas tiene una base de aluminio, recubierta para ofrecer

resistencia a la corrosión, y está lista para montarse en un tubo

NPT de 3/4 pulgadas.

La protección de la cúpula incluida puede colocarse sobre la

cúpula de vidrio para protegerla contra la colisión accidental con

equipos móviles, tales como carretillas elevadoras. También se

ofrece un soporte opcional para pared.

El 151XST tiene una candela efectiva (ECP, por su sigla en inglés)

de 165 y una candela pico de 520 000. Está disponible en seis

colores de cúpula, que incluyen ámbar, azul, transparente, verde y

rojo (magenta a pedido).

La resistente luz de advertencia estroboscópica 151XST de Federal

Signal está especícamente diseñada para ubicaciones peligrosas

o ambientes corrosivos donde se requiere una señal visual muy

brillante. Esta luz de advertencia puede usarse para la evaluación

de plantas u otras necesidades de comunicación.

Hay modelos disponibles para montaje en tubo (151XST) o

montaje en supercie (151XST-S).

48

Modelos 151XST y 151XST-S

Page 49

Instrucciones de instalación y mantenimiento

ADVERTENCIA

NOTA: El modelo 151XST puede montarse en un soporte

modelo LHWB de Federal Signal. Si se instala de esta forma,

el uso adecuado de todo el dispositivo ensamblado se limita a

ubicaciones de clase I, div. 2, grupos A, B, C y D; clase II, div. 2,

grupos F y G; clase III.

Desembalaje de la luz

RIESGO DE EXPLOSIONES: Las cúpulas dañadas pueden

ocasionar explosiones que podrían dar como resultado

lesiones graves o incluso la muerte. Cúpulas dañado DEBE

ser reemplazado.

Después de desembalar la baliza, examínela para vericar daños

que puedan haber ocurrido durante el transporte. Si la baliza se

ha dañado, no intente instalarla o hacerla funcionar. Presente

una reclamación inmediatamente con el transportista e indique

la magnitud de los daños. Revise cuidadosamente todos los

sobres, etiquetas de envío y otro tipo de etiquetas antes de quitar o

deshacerse de las mismas. La eliminación de todos los materiales de

envío debe llevarse a cabo de acuerdo con los códigos y las normas

nacionales y locales. Si falta alguna pieza, llame al Servicio al

cliente de Federal Signal al 708-534-4756 o 877-289-3246.

Cuadro 1 Especicaciones

Vida útil de la lámpara: 10 000 horas

Fuente de luz: Tubo estroboscópico

Temperatura operativa:

Peso neto: 3,8 lb (1.7 kg)

Peso de envío: 4,5 lb (2,0 kg)

Altura: 9,25 in (234,95 mm)

Diámetro: 5,5 in (139,7 mm)

Modelos 151XST y 151XST-S

-67 °F to 150 °F

(-55 °C to 65.6 °C)

49

Page 50

Instrucciones de instalación y mantenimiento

Cuadro 2 Voltaje y corriente de funcionamiento

Model Voltaje Corriente de

funcionamiento:

151XST(-S) 012-024__ 12-24 VCC 1,3 A a 0,60 A

151XST(-S)-120__ 120 VCA, 50/60 Hz 0,35 A

151XST(-S)-240__ 240 VCA, 50/60 Hz 0,16 A

__ Indica el color: (A) ámbar, (B) azul, (C) transparente, (G) verde, (M)

magenta o (R) rojo.

Cuadro 3 Velocidad de parpadeo y candelas

Modelo Índice de

destellos por

minuto

Pico

Candela

1

(Candela

ECP

Efectiva)

151XST(-S) 012-024__ 80 520 000 165

151XST(-S)-120__ 80 520 000 165

151XST(-S)-240__ 80 520 000 165

__ Indica el color: (A) ámbar, (B) azul, (C) transparente, (G) verde, (M)

magenta o (R) rojo.

1

La candela pico es la intensidad máxima de la luz generada por una luz

parpadeante durante su fase luminosa.

2

ECP (candela efectiva) es la intensidad que aparecería ante un

observador si la luz se mantuviera encendida permanentemente

Cuadro 4 Clasicación de ubicaciones peligrosas

Código de temperatura a temperatura máxima, °C

Ubicación peligrosa 66 ºC

Clase I, div 2, grupos A, B, C & D T1/301º

Clase II, div 1, grupos E, F & G T5/100º

Clase III T5/100º

2

Para disminuir el riesgo de incendio o de explosiones, no lo

instale la baliza en una ubicación peligrosa si la temperatura de

funcionamiento excede la temperatura de ignición de atmósferas

peligrosas.

50

Modelos 151XST y 151XST-S

Page 51

Instrucciones de instalación y mantenimiento

Antes de continuar, usa el Cuadro 4 anterior como guía y

determine que la temperatura de funcionamiento de la unidad NO

exceda la temperatura de ignición de atmósferas peligrosas.

Para aplicaciones marinas, todo el cableado, incluido el cableado

de alimentación, debe ser de cable trenzado y debe cumplir con los

requisitos de la USCG (CFR46), Secciones (110-113.)

NOTA: En ambientes de mucha humedad, cuando las unidades se

montan con la cúpula hacia abajo, puede producirse condensación

en el sistema de conductos. Use sellos/drenajes de conductos de la

clasicación correcta para impedir que la humedad ingrese en el

artefacto.

Montaje en tubo de la baliza (151XST)

ADVERTENCIA

RIESGO DE EXPLOSIONES: Para disminuir el riesgo de

incendio o de explosiones, no instale la baliza en una

ubicación peligrosa si la temperatura de funcionamiento

excede la temperatura de ignición de atmósferas peligrosas.

Antes de continuar, consulte la placa de identicación del

producto y determine la temperatura de funcionamiento de la

baliza.

NOTA: Para cumplir con la Sección 300-14 del NEC que requiere un

mínimo de 6 pulgadas de conductor libre en las conexiones, cuando

se monte el modelo 151XST, el tubo de montaje usado para unir la

unidad a una caja de empalme no debe tener más de 10 pulgadas.

El modelo 151XST puede montarse en un tubo de 3/4” y en

cualquier posición.

Antes de montar la baliza, asegúrese de que las roscas de

1.

acoplamiento estén limpias.

2.

Para prevenir el ingreso de agua y de polvo, aplique sellador

conductivo en las roscas de los conductos antes del montaje.

Si se usa sellador no conductivo, el gabinete debe conectarse

a tierra con el cable de conexión a tierra interno/tornillo de

conexión a tierra provistos para garantizar una continuidad

Modelos 151XST y 151XST-S

51

Page 52

Instrucciones de instalación y mantenimiento

correcta de la conexión a tierra (Figura 3 en la página 55).

3.

Consulte la Figura 1. Enrosque el artefacto en el tubo de 3/4

pulgada y sujételo con el tornillo de jación.

Figura 1 Baliza montada en tubo

UNIDAD DE LUZ 151

TORNILLO DE FIJACIÓN

TUBO NPT DE

3/4 PULGADA

Montaje en supercie de la baliza (151XST-S)

Para montar la baliza en supercie:

Consulte la Figura 2. Use la base de montaje como plantilla

1.

para marcar la ubicación de los dos oricios de montaje.

2.

Perfore un oricio de 9/32 pulgada (7,143 mm) en cada marca.

3. Sujete la baliza a la supercie de montaje con el equipo

provisto por el instalador.

52

Modelos 151XST y 151XST-S

290A7400

Page 53

Figura 2 Baliza montada en supercie

290A7401

UNIDAD DE LUZ 151

HARDWARE DE MONTAJE

PROVISTO POR EL

INSTALADOR

PERFORE DOS ORIFICIOS

DE 19/32 PULG. (7,143 mm)

Instrucciones de instalación y mantenimiento

SUPERFICIE DE MONTAJE

Cableado de la baliza

La baliza LED modelo 151XST debe instalarse según el NEC o el

CEC, y los CÓDIGOS ESTATALES y LOCALES. La elección de

sitios u orientaciones de instalación alternativa solo debe realizarse

con la aprobación de la autoridad competente. Asimismo, la unidad

puede montarse usando un montaje para techo opcional o un

montaje para pared opcional.

NOTA: Las unidades estroboscópicas de 120 VCA o 230-240 VCA

están diseñadas para funcionar con corriente eléctrica de 50 Hz

y 60 Hz. NO se requieren modicaciones especiales para las dos

frecuencias diferentes de la línea de CA.

Modelos 151XST y 151XST-S

53

Page 54

Instrucciones de instalación y mantenimiento

ADVERTENCIA

RIESGO DE DESCARGA ELÉCTRICA: Para evitar riesgos de

descarga eléctrica, no conecte los cables mientras se recibe

corriente.

ADVERTENCIA

RIESGO DE EXPLOSIONES: No desconecte la baliza mientras

haya tensión en el circuito o a menos que se sepa que el área

está exenta de concentraciones inamables. Mantenga la

baliza bien cerrada mientras se encuentra en funcionamiento.

POLARIDAD INVERSA/CABLEADO INCORRECTO: El 151XST

no es sensible a la polaridad, pero PUEDE VERSE DAÑADO

por una conexión eléctrica incorrecta. Se producirán daños si

se excede la clasicación de voltaje del modelo en particular.

NOTA: El cableado debe cumplir con el Código Eléctrico

Nacional o el Código Eléctrico Canadiense y con la autoridad local

competente.

Cableado de los modelos de CA

Los modelos de CA tienen dos cables de 24 pulgadas: uno

negro y otro blanco. Para conectar la baliza de CA:

Verique que la corriente esté desconectada.

1.

2. Retire la unidad de la cúpula roscada girándola en sentido

contrario a las agujas del reloj.

Conecte el cable negro al lado de la fase (caliente) de la

3.

fuente de alimentación y el cable blanco al lado común

(neutro) de la fuente de alimentación de CA.

De ser necesario, se incluye el tornillo verde de la carcasa

4.

para la conexión a tierra (Figura 3). Para obtener acceso al

tornillo, retire la unidad de la fuente de alimentación.

Sujete la cúpula a la base de la baliza.

5.

54

Modelos 151XST y 151XST-S

Page 55

Instrucciones de instalación y mantenimiento

(8,18 PULG.)