Page 1

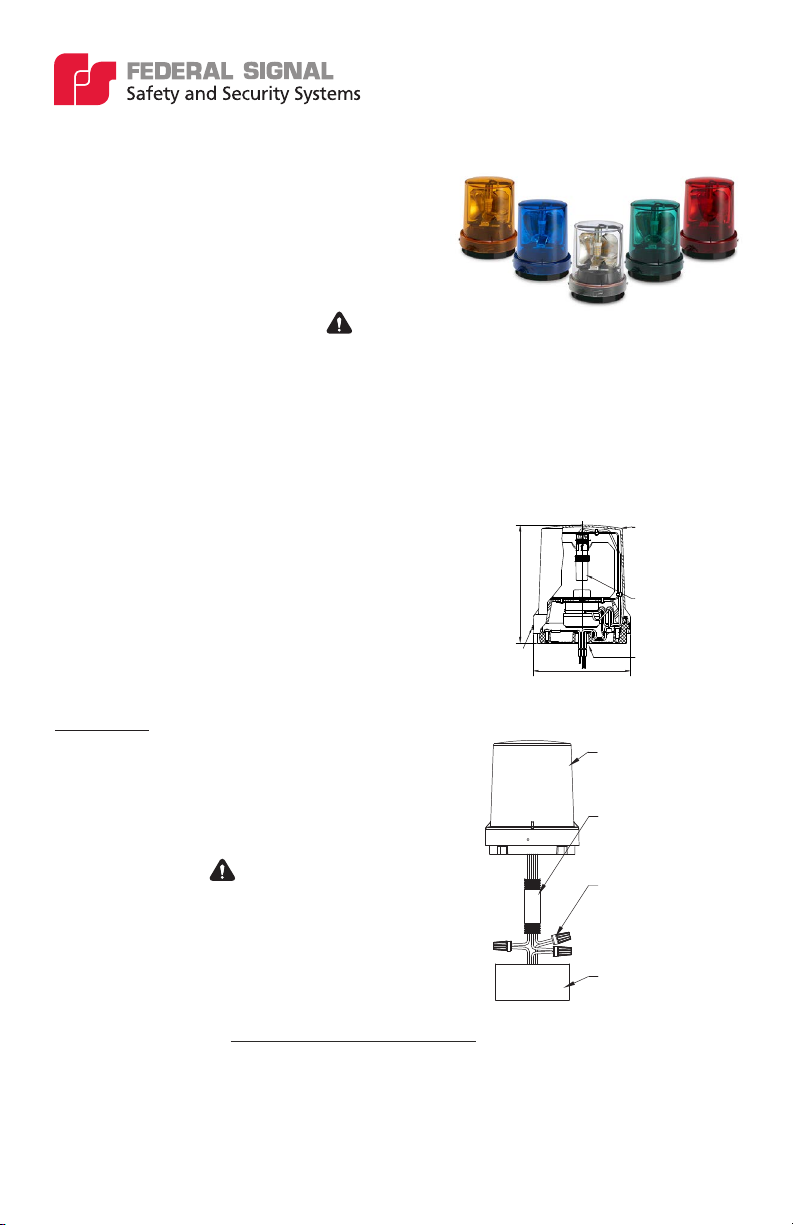

Model 121SLED and 121SLED-N

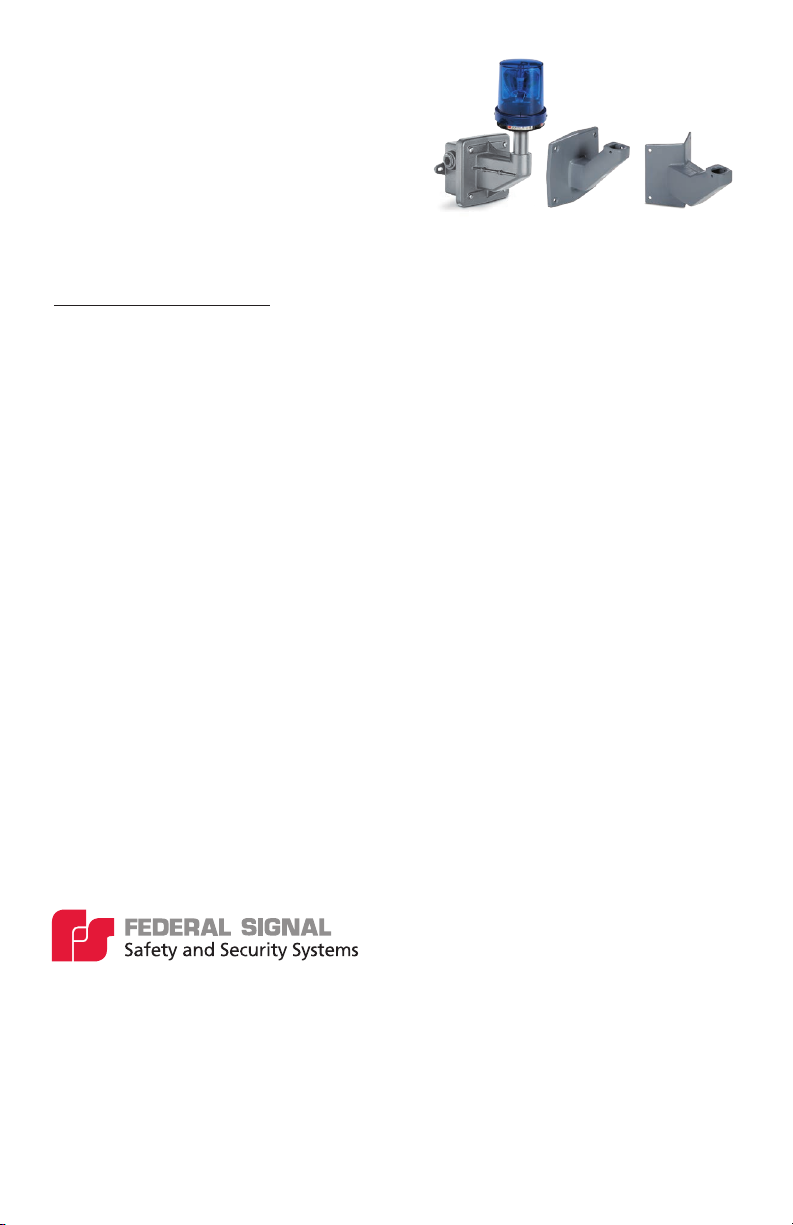

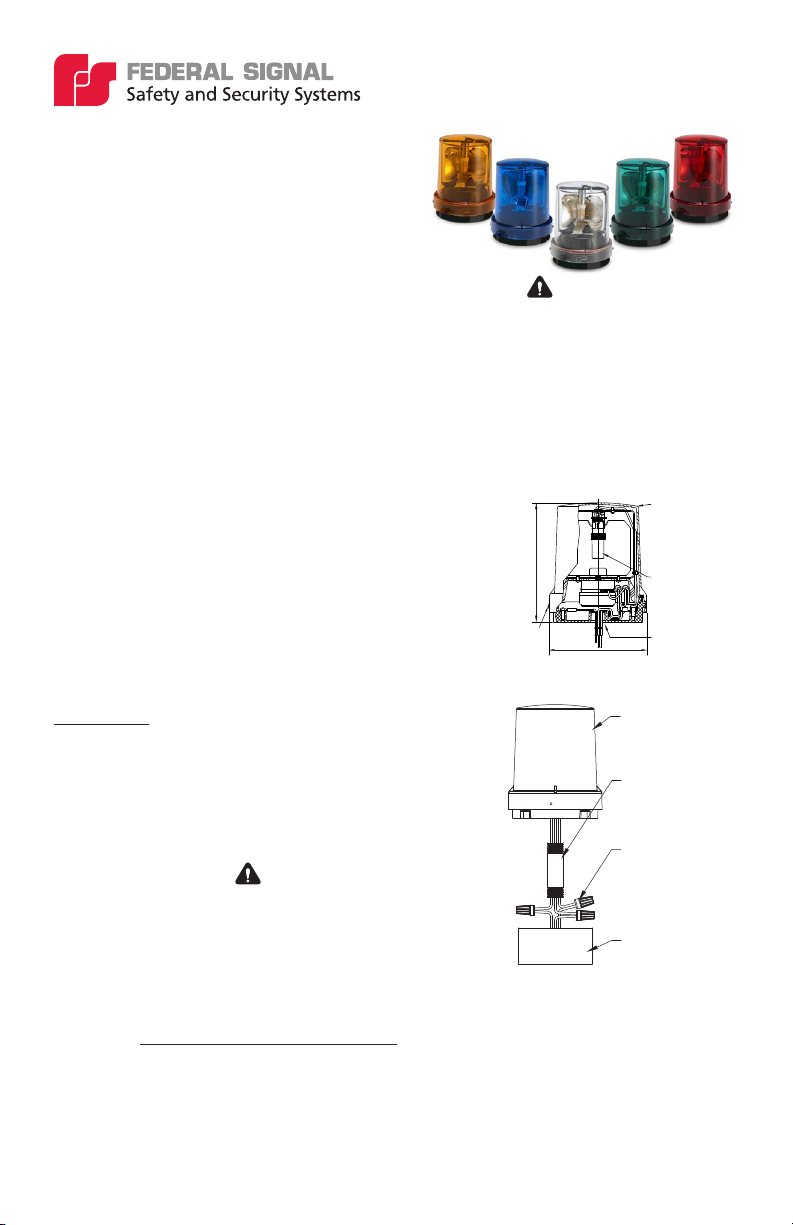

5.12"/ 130 mm

6.26"/ 159 mm

1/2" NPT

Pipe Mount

LED Lamp

Elliptical Dome

(12" Curvature

Radius)

Screw

in base

Junction box

(not supplied)

1/2" conduit

(not supplied)

121SLED

Wiring

Black to Line

(L or L1)

White to Neutral

(N or L2)

Green/yellow to Earth

(Ground)

Wire nuts not supplied.

Wiring

Vitalite® LED Rotating Light

Installation and Maintenance Instructions

Limited Warranty: This product’s limited warranty

can be found at www.fedsig.com/SSG-Warranty.

Safety Messages to Installers and Users : Products should be installed to code by a licensed electrician

and follow all safety instructions. Failure to do so may result in property damage, serious injury, or death.

• Read and understand instructions before installing or operating equipment.

• To avoid electrical shock hazards, do not connect wires when power is applied.

• To be an effective warning device, this product produces bright light that could be hazardous to eyesight.

The possibility exists that rapid ashing lights could induce photosensitive epilepsy. Do not stare directly at

the light.

Overview: Models 121SLED and 121SLED-N rotating LED warning lights are designed for mounting on a at

(horizontal or vertical) surface or on a 1/2” NPT threaded pipe. Units are available in 120VAC 50/60 Hz.

Certifications and Ratings:

• UL and cUL Listed

• Type 4X, IP66 enclosure. Indoor/Outdoor Use

• IP69K Compliant

• Model 121SLED-N is NSF Certied (dome-up) for

Splash Zones and Non-food Zones to

NSF/ANSI 2: Food Equipment

• Electrical ratings: 120VAC 50/60Hz, 0.075A

• Certied operating temperature:

-40°F to 150°F (-40°C to 66°C)

Installation:

Unpacking the Device: After unpacking the device, examine it

for damage and verify parts. Unit comes with: (1) 121SLED or

121SLED-N assembled unit with ying leads, (1) panel mount

gasket, and (3) # 8-32 panel mounting tapping screws. If a part

is missing or damaged do not install. Contact Federal Signal

Customer Support at

+1 708-534-4756 or iordersup@fedsig.com.

Electrical Connections : To avoid electrical shock, do not

connect wires when circuits are energized. Use 18AWG eld

wiring or larger.

• 120VAC 50/60Hz Models – Connect the line (L or L1)

power source lead to the black wire and connect the neutral

(N or L2) power source lead to the white wire. Connect

ground to the green/yellow wire if required.

Mounting the device: Units come standard to mount on a

at (horizontal or vertical) surface or a 1/2" NPT pipe. Model

121SLED-N (NSF Certied) must be mounted in a dome up position to resist water and debris accumulation

and maintain the NSF Certication. Wall or corner mounting accessories are sold separately.

• Pipe Mounting – On a 1/2" NPT Pipe, feed wires through pipe and turn clockwise to tighten.

• Surface/Panel Mounting – Using provided gasket as template, mark three mounting holes and center

Recommended tightening torque is 5-ft-lbs (6.8 N-m).

hole for wiring. Drill or punch 3/16" (4.8mm) diameter holes for mounting and a 1" (25.4mm) for wiring. Set

base on gasket, feed wires through center, and attach to the mounting surface using provided #8 tapping

screws from the underside.

Page 2

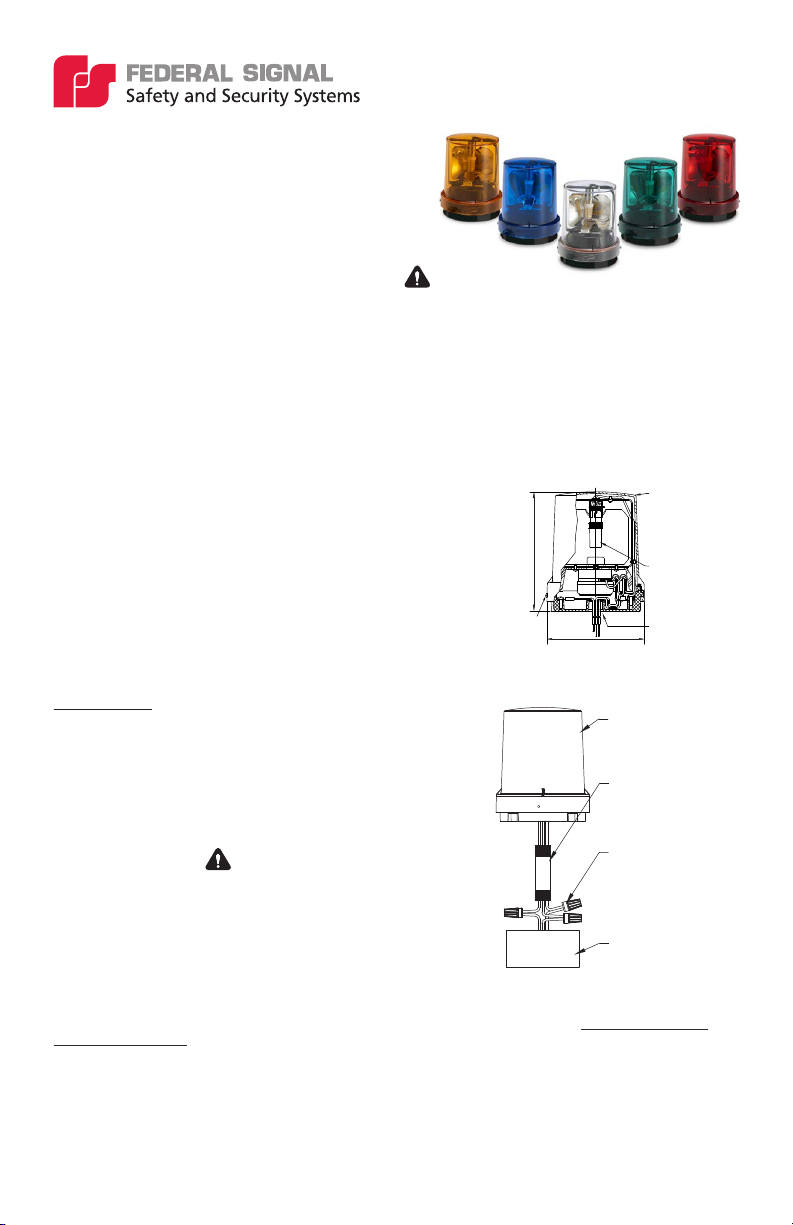

• Wall/Corner Mounting – Wall (Models LSWB,

LWMB2) and corner (Model LCMB2) brackets are

sold separately and intended for use with model

121SLED only. Mounting bracket accessories are not

NSF Certied and incompatible for use with Model

121SLED-N.

Note: LWMB2 and LCMB2 are Type 3R rated. If

installing in combination with a 4X device, the unit is

Type 3R rated. When Type 4X is required, pair with

Model LSWB.

Testing/Operating: After installation, test the system to

verify each signal operates and establish a program for periodic testing of the device. Provide copy of these

instructions to all operating personnel.

LWMB2LSWB

LCMB2

Maintenance and Service

Ordering Replacement Parts and Accessories: Consult product datasheet online for an updated list

of replacement parts. If your product requires a part that is not available for purchase, your unit must be

repaired or replaced.

Replacing the LED Lamp:

1. SHOCK HAZARD! – Disconnect power. Allow the lamp to cool.

2. Remove the set screw located at the bottom of the dome.

3. Grasp the top of the dome and push it down while turning dome counterclockwise.

4. Remove dome and ensure the gasket between the dome and base is secured.

5. Grasp lamp near the base and gently push toward socket while turning counterclockwise.

6. Insert the new lamp while gently pushing it toward the socket and turning clockwise.

7. Before replacing dome, ensure the gasket is properly seated on the housing base.

8. Place dome over base and aligning recesses inside dome lip with four pins on the base.

Push down on the dome and turn clockwise until it locks in place (approximately ¾").

9. Replace set screw on the bottom of the dome.

10. Test the light for proper operation.

Technical Assistance: Contact our technical support team at +1-708-587-3587 or signalsupport@fedsig.

com.

Repair Service: A return authorization is required. Contact your Authorized Distributor or Federal Signal

Customer Support at +1-708-534-4756 or iordersup@fedsig.com. Defective products under warranty will be

repaired or replaced at Federal Signal’s discretion. Lamp failures excluded.

Product Returns: A return authorization is required from Federal Signal prior to returning the product.

Contact your Authorized Distributor for more information or to request a product return.

2645 Federal Signal Drive

University Park, Illinois 60484

Additional translations available at www.fedsig.com

Traducciones adicionales disponibles en www.fedsig.com

Customer Support 1-800-344-4634

+1-708-534-4756, iordersup@fedsig.com

Technical Support 1-800-755-7621

+1-708-587-3587, signalsupport@fedsig.com

25500629A Rev. A1 0420

Page 3

Modelo 121SLED y 121SLED-N

Montaje de tubo

Cúpula elíptica

Blanco a neutro (N o L2)

Cableado

Luz giratoria LED Vitalite

Instrucciones de instalación y mantenimiento

Garantía limitada: la garantía limitada de este producto

se puede encontrar en www.fedsig.com/SSG-Warranty.

Mensajes de seguridad para instaladores y usuarios : los productos deben instalarse según el código

por un electricista autorizado y se deben seguir todas las instrucciones de seguridad. De lo contrario, puede

ocasionar daños a la propiedad, lesiones graves o la muerte.

• Lea y comprenda las instrucciones antes de instalar u operar el equipo.

• Para evitar peligros de descarga eléctrica, no conecte los cables mientras se aplica corriente.

• Para ser un dispositivo de advertencia efectivo, este producto produce una luz brillante que podría ser

peligrosa para la vista. Existe la posibilidad de que las luces intermitentes rápidas induzcan epilepsia

fotosensible. No mire directamente a la luz.

Descripción: las luces de advertencia LED giratorias (modelos 121SLED y 121SLED) están diseñadas para

montarse en una supercie plana (horizontal o vertical) o en un tubo roscado NPT de 1/2”. Las unidades están

disponibles en 120 VCA 50/60 Hz.

Certificaciones y clasificaciones:

• Certicaciones UL y cUL

• Gabinete tipo 4X, IP66. Uso en interiores o exteriores

• Cumple con IP69K

• El modelo 121SLED-N está certicado por la NSF (cúpula

hacia arriba) para zonas de salpicadura y zonas no

alimentarias según NSF/ANSI 2: equipos para alimentos.

• Clasicaciones eléctricas: 120 VCA 50/60 Hz, 0,075 A

• Temperatura de funcionamiento certicada: –40 °F a 150 °F

(–40 °C a 66 °C)

Instalación:

Desembalaje del dispositivo: después de desembalar el

dispositivo, examínelo para detectar daños y verique las piezas.

La unidad viene con: (1) unidad ensamblada 121SLED o 121SLED

con cables de conexión, (1) junta de montaje en panel y (3)

tornillos autorroscantes n.º 8-32 para montaje en panel. Si detecta

que falta una pieza o está dañada, no instale el producto. Póngase

en contacto con el Servicio de Atención al Cliente de Federal

Signal al +1 708-534-4756 o escriba a iordersup@fedsig.com.

Conexiones eléctricas : para evitar descargas eléctricas, no

conecte los cables cuando los circuitos estén energizados. Utilice

un cable de campo de 18 AWG o mayor.

• Modelos de 120 VCA 50/60 Hz: conecte el cable de la fuente

de alimentación de línea (L o L1) al cable negro y conecte el

cable de la fuente de alimentación neutral (N o L2) al cable

blanco. Realice la conexión a tierra al cable verde/amarillo si

es necesario.

Montaje del dispositivo: la unidad viene estándar para montarse sobre una supercie plana (horizontal o

vertical) o sobre un tubo NPT de 1/2”. El modelo 121SLED-N (con certicación NSF) se debe montar con

la cúpula hacia arriba para resistir la acumulación de agua y residuos y mantener la certicación NSF. Los

accesorios de montaje en pared o esquina se venden por separado.

• Montaje en tubo: en un tubo NPT de 1/2”, pase los cables por el tubo y gírelos en sentido de las agujas

del reloj para ajustarlos. La torsión recomendada es de 5 pies-lb (6,8 Nm).

• Montaje en superficie/panel: use la junta provista como plantilla y marque tres oricios de montaje y un

oricio central para el cableado. Taladre o perfore oricios de 3/16" (4,8 mm) de diámetro para el montaje

y un oricio de 1" (25,4 mm) para el cableado. Coloque la base en la junta, pase los cables por el centro y

fíjela a la supercie de montaje con los tornillos autorroscantes n.º 8 provistos desde la parte inferior.

®

Lámpara LED

6.26”/159 mm

Atornillar

a la base

5,12”/130 mm

121SLED

Conducto de 1/2”

(no provisto)

Cableado

Negro a línea (L o L1)

Verde/amarillo a tierra

(masa)

Tuercas para cables

no provistas.

Caja de empalmes

(no provista)

Español

(radio de

curvatura

de 12”)

NPT de 1/2”

Page 4

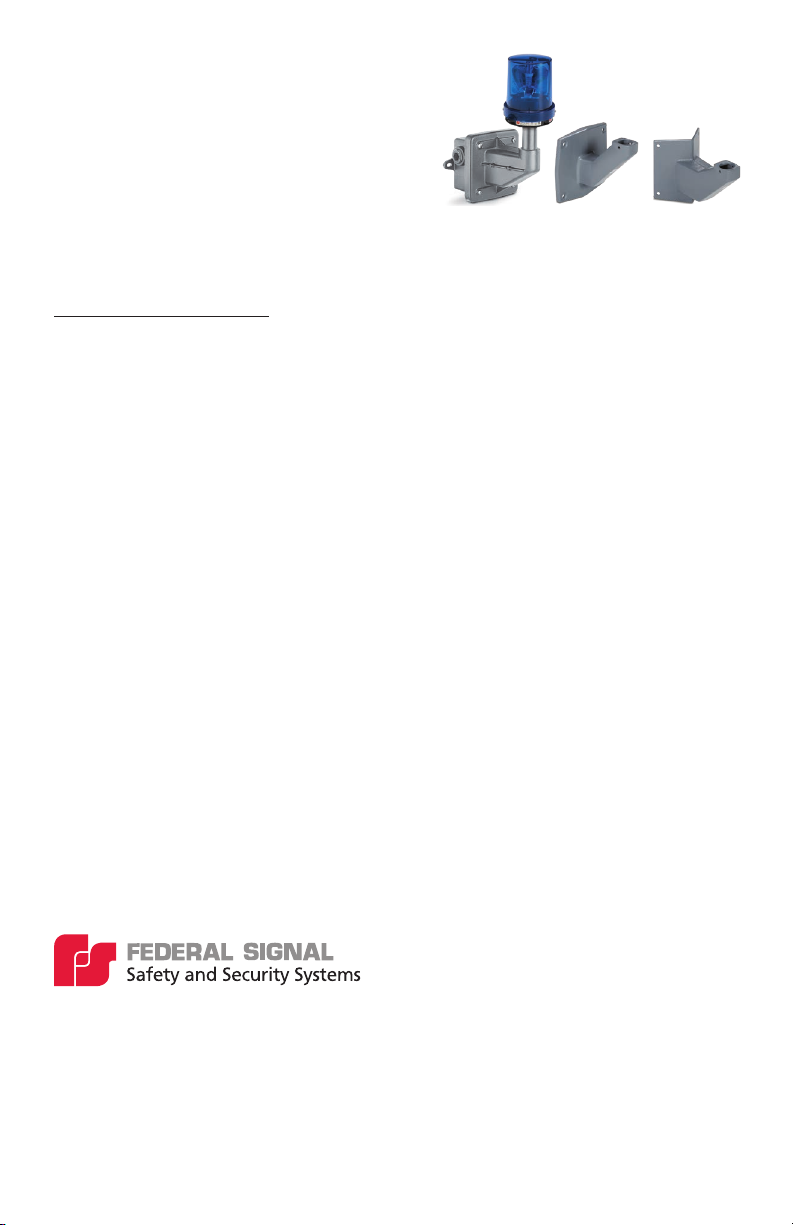

• Montaje en pared/esquinas: los soportes para

montaje en pared (modelos LSWB, LWMB2) y

en esquinas (modelo LCMB2) se venden por

separado y están diseñados para ser usados con el

modelo 121SLED únicamente. Los accesorios para el

soporte de montaje no tienen certicación NSF y son

incompatibles con el modelo 121SLED-N.

Nota: LWMB2 y LCMB2 tienen clasicación Tipo 3R.

Si se instala junto con un dispositivo 4X, la unidad

tiene clasicación Tipo 3R. Cuando se requiera el

Tipo 4X, combinar con el modelo LSWB.

Pruebas y funcionamiento: después de la instalación,

pruebe el sistema para vericar que cada señal funcione y establezca un programa para pruebas periódicas

del dispositivo. Entregue una copia de estas instrucciones a todo el personal de operación.

LWMB2LSWB

LCMB2

Mantenimiento y servicio

Pedido de piezas de repuesto y accesorios: consulte en línea la hoja de datos del producto para obtener

una lista actualizada de las piezas de repuesto. Si su producto requiere una pieza que no está disponible para

la compra, su unidad deberá ser reparada o reemplazada.

Cambio de la lámpara LED:

1. ¡PELIGRO DE DESCARGA ELÉCTRICA! Desconecte la corriente eléctrica. Deje que la lámpara se enfríe.

2. Retire el tornillo de jación ubicado en la parte inferior de la cúpula.

3. Sujete la parte superior de la cúpula y empújela hacia abajo mientras la gira en sentido antihorario.

4. Retire la cúpula y asegúrese de que la junta entre la cúpula y la base esté asegurada.

5. Sujete la lámpara cerca de la base y empuje suavemente hacia el portalámparas mientras la gira en

sentido antihorario.

6. Inserte la nueva lámpara mientras la empuja suavemente hacia el portalámparas y la gira en sentido de

las agujas del reloj.

7. Antes de volver a colocar la cúpula, asegúrese de que la junta esté correctamente asentada en la base de

la carcasa.

8. Coloque cúpula sobre base alineando las ranuras ubicadas dentro la pestaña de la cúpula con cuatro

clavijas en la base. Empuje la cúpula y gire en el sentido de las agujas del reloj hasta que se bloquee en

su lugar (aproximadamente ¾").

9. Vuelva a colocar el tornillo de jación en la parte inferior de la cúpula.

10. Pruebe el funcionamiento correcto de la luz.

Asistencia técnica: póngase en contacto con nuestro equipo de soporte técnico al +1-708-587-3587 o

escriba a signalsupport@fedsig.com.

Servicio de reparación: se requiere una autorización de devolución. Póngase en contacto con su distribuidor

autorizado o con el Servicio de Atención al Cliente de Federal Signal al +1-708-534-4756 o escriba a

iordersup@fedsig.com. Los productos defectuosos bajo garantía se repararán o reemplazarán a criterio de

Federal Signal. Las fallas de la lámpara están excluidas.

Devoluciones de productos: se requiere una autorización de devolución de Federal Signal antes de

devolver el producto. Póngase en contacto con su distribuidor autorizado para obtener más información o

para solicitar la devolución de un producto.

2645 Federal Signal Drive

University Park, Illinois 60484

Additional translations available at www.fedsig.com

Traducciones adicionales disponibles en www.fedsig.com

Atención al Cliente 1-800-344-4634

+1-708-534-4756, iordersup@fedsig.com

Soporte técnico 1-800-755-7621

+1-708-587-3587, signalsupport@fedsig.com

25500629A Rev. A1 0420

Page 5

Français

Dôme elliptique

Modèle 121SLED et 121SLED-N

Témoin LED giratoire Vitalite

Consignes d’installation et d’entretien

Garantie limitée : la garantie limitée de ce produit peut

être consultée sur le site www.fedsig.com/SSG-Warranty.

Messages de sécurité à l’intention des installateurs et des utilisateurs : les produits doivent être

installés par un électricien agréé et dans le respect de toutes les instructions de sécurité. Le non-respect de

ces instructions peut entraîner des dommages matériels ou des blessures graves, voire mortelles.

• Lisez les instructions et assurez-vous de bien les avoir assimilées avant d’installer ou d’utiliser le matériel.

• An d’éviter les risques de chocs électriques, ne branchez pas de ls si le dispositif est sous tension.

• Pour remplir sa fonction de dispositif d’alerte efcacement, cet article produit une lumière intense pouvant

affecter la vue. Il est possible que les lumières clignotantes rapides induisent une épilepsie photosensible.

Ne xez pas directement la lumière.

Présentation : les modèles 121SLED et 121SLED-N de feux d’urgence DEL giratoires sont conçus pour un

montage sur une surface plate (horizontale ou verticale) ou sur un tuyau à letage NPT de 12,7 mm (1/2 po).

Les unités sont disponibles en 120 V CA, 50/60 Hz.

Certifications et valeurs :

• Homologué UL et cUL

• Coffret type 4X, IP66. Utilisation intérieure/extérieure

• Conforme à la norme IP69K

• Le modèle 121SLED-N est certié NSF (dôme vers le haut)

pour les zones d’éclaboussures et les zones non alimentaires

en vertu des exigences NSF/ANSI 2 : équipement alimentaire

• Valeurs électriques : 120 V CA, 50/60 Hz, 0,075 A

• Température de fonctionnement certiée : -40 °C à 66 °C

(-40 °F à 150 °F)

Installation :

Déballage de l’appareil : après avoir déballé l’appareil,

examinez-le pour voir s’il est endommagé et vériez les pièces.

L’emballage contient les éléments suivants : (1) unité 121SLED ou

121SLED-N assemblée avec ls volants, (1) joint pour montage

sur panneau, et (3) vis autotaraudeuses n° 8-32 pour montage sur

panneau. N’installez pas l’appareil si une pièce est manquante ou

endommagée. Contactez l’assistance clientèle de Federal Signal au

+1 708 534 4756 ou à l’adresse iordersup@fedsig.com.

Branchements électriques : an d’éviter les risques de chocs

électriques, ne branchez pas de ls tant que les circuits sont sous

tension. Utilisez un câblage de terrain 18AWG ou plus.

• Modèles 120 VCA 50/60 Hz : connectez le l de ligne

(L ou L1) de la source d’alimentation au l noir et connectez

le l neutre (N ou L2) de la source d’alimentation au l blanc.

Connectez la terre au l vert/jaune si nécessaire.

Montage de l’appareil :

(horizontale ou verticale) ou sur un tuyau à letage NPT de 12,7 mm (1/2 po). Le modèle 121SLED-N

(certié NSF) doit être monté avec le dôme vers le haut pour résister à l’accumulation d’eau et de débris et

conserver la certication NSF. Les accessoires de montage mural ou en coin sont vendus séparément.

• Montaje en tubo:

le sens des aiguilles d’une montre pour resserrer. Le couple de serrage recommandé est de 6,8 N-m (5 pi-lb).

• Montage en surface/sur panneau : en utilisant le joint fourni comme modèle, marquez trois trous de

montage et le trou central pour le câblage. Percez ou poinçonnez des trous de 4,8 mm (3/16 po) de diamètre

pour le montage et un trou de 25,4 mm (1 po) pour le câblage. Posez la base sur le joint, faites passer les ls

par le centre et xez à la surface de montage à l’aide des vis autotaraudeuses n° 8 fournies, par le dessous.

les appareils sont conçus de série pour être montés sur une surface plane

sur un tuyau de 12,7 mm (1/2 po) NPT, faites passer les ls dans le tuyau et tournez dans

®

(rayon de

courbure de

304,8 mm

[12 po])

Lampe DEL

159 mm (6,26 po)

Vissez

la base

130 mm (5,12 po)

Câblage

Montage sur

tuyau à filetage

NPT de

12,7 mm

(1/2 po)

121SLED

Conduit 12,7 mm

(1/2 po) (non fourni)

Câblage

Noir à la ligne

(L ou L1)

Blanc à neutre

(N ou L2)

Vert/Jaune à la terre

(terre)

Les capuchons de

connexion ne sont

pas fournis.

Boîte de jonction

(non fournie)

Page 6

• Montage mural/en coin : les supports muraux

(modèles LSWB, LWMB2) et d’angle (modèle

LCMB2) sont vendus séparément et sont destinés à

être utilisés avec le modèle 121SLED uniquement.

Les accessoires des supports de montage ne sont

pas certiés NSF et sont incompatibles avec le

modèle 121SLED-N.

Remarque : LWMB2 et LCMB2 sont de type 3R.

En cas d’installation en association avec un appareil

4X, l’appareil est de type 3R. Lorsque le type 4X est

requis, il doit être couplé avec le modèle LSWB.

Tests/fonctionnement : après l’installation, testez le système pour vérier le fonctionnement de chaque

signal et établissez un programme de test périodique de l’appareil. Fournissez une copie de ces instructions

à tout le personnel de service.

LWMB2LSWB

LCMB2

Maintenance et entretien

Commande de pièces de rechange et d’accessoires : consultez la che technique du produit en ligne

pour obtenir une liste actualisée des pièces de rechange. Si votre produit nécessite une pièce qui n’est pas

disponible à l’achat, votre appareil doit être réparé ou remplacé.

Remplacement de la lampe LED :

1. RISQUES DE CHOCS ÉLECTRIQUES ! : coupez le courant. Laissez la lampe refroidir.

2. Retirez la vis de serrage située au bas du dôme.

3. Saisissez le haut du dôme et poussez-le vers le bas tout en le tournant dans le sens inverse des aiguilles

d’une montre.

4. Retirez le dôme et assurez-vous que le joint entre le dôme et la base est bien xé.

5. Saisissez la lampe près de la base et poussez-la doucement vers la douille tout en la tournant dans le

sens inverse des aiguilles d’une montre.

6. Insérez la nouvelle lampe en la poussant doucement vers la douille et en la tournant dans le sens des

aiguilles d’une montre.

7. Avant de remettre le dôme en place, assurez-vous que le joint est bien en place sur la base du logement.

8. Placez le dôme sur la base et alignez les renfoncements situés à l’intérieur de la lèvre du dôme avec les

quatre broches sur la base. Enfoncez le dôme, puis tournez-le dans le sens des aiguilles d’une montre

jusqu’à ce qu’il s’enclenche (environ 19 mm [3/4 po]).

9. Remettez la vis de serrage en place au bas du dôme.

10. Vériez que la lumière fonctionne correctement.

Assistance technique : contactez notre équipe d’assistance technique au +1 708 587 3587 ou à l’adresse

signalsupport@fedsig.com.

Service de réparation : une autorisation de retour est nécessaire. Contactez votre distributeur agréé ou

l’assistance clientèle de Federal Signal au +1 708 534 4756 ou à l’adresse iordersup@fedsig.com. Les

produits défectueux sous garantie seront réparés ou remplacés à la discrétion de Federal Signal. Les pannes

de lampes sont exclues.

Retours de produits : une autorisation de retour est nécessaire de la part de Federal Signal avant de renvoyer

le produit. Contactez votre distributeur agréé pour plus d’informations ou pour demander le retour d’un produit.

2645 Federal Signal Drive

University Park, Illinois 60484

Des traductions supplémentaires sont disponibles à l’adresse suivante : www.fedsig.com

Traducciones adicionales disponibles en www.fedsig.com

Assistance clientèle +1 800 344 4634

+1 708 534 4756, iordersup@fedsig.com

Assistance technique +1 800 755 7621

+1 708 587 3587, signalsupport@fedsig.com

25500629A Rév. A1 0420

Loading...

Loading...