Federal Industries SSRC3652 Installation Manual

- 1 -

E3091-3

Revised 01/21/20

REV. D

INSTALLATION & OPERATIONS INSTRUCTIONS

REFRIGERATED SSRC & ESSRC MODELS

KEEP THIS MANUAL FOR FUTURE REFERENCE

Engineering and technical data are subject to change without notice.

FEDERAL INDUSTRIES 215 FEDERAL AVE Belleville, WI 53508

Toll Free 1(800) 356-4206 WI Phone (608) 424-3331 Fax: (608) 424-3234

SSRC

ESSRC

- 2 -

CONTENTS

INTRODUCTION ....................................................................................................................................................... 4

WARNING LABELS & SAFETY INSTRUCTIONS ............................................................................................. 5

PRE-INSTALLATION PROCEDURES .................................................................................................................. 6

Inspection For Shipping Damage.................................................................................................................... 6

GENERAL ELECTRICAL & GROUNDING ......................................................................................................... 6

Permanent Connected .................................................................................................................................... 6

Cord Connected (Option)................................................................................................................................ 6

Electrical Information ..................................................................................................................................... 7

INSTALLATION INSTRUCTIONS ......................................................................................................................... 8

Locating The Display Case ............................................................................................................................. 8

Removing Case From Shipping Skid .............................................................................................................. 8

Cleaning .......................................................................................................................................................... 8

REFRIGERATION ............................................................................................................................................... 9-10

Self-Contained Models ................................................................................................................................... 9

Refrigeration Settings, SSRC .................................................................................................................... 9

Refrigeration Settings, ESSRC .................................................................................................................. 9

Remote Models ............................................................................................................................................... 9

Refrigeration Settings, SSRC Remote ....................................................................................................... 9

Remote Refrigeration Operation ............................................................................................................... 9

Remote Refrigeration Instruction ............................................................................................................ 10

SHELVING INSTALLATION & REMOVAL ................................................................................................. 11-13

Shelf Brackets & Supports Installation .................................................................................................... 11-12

Wire Shelves Installation .............................................................................................................................. 12

Glass Shelves Installation (Option) .............................................................................................................. 13

REAR DOORS .................................................................................................................................................... 14-16

Top Section Rear Sliding Doors Removal .................................................................................................... 14

Top Section Rear Swinging Doors Removal ................................................................................................ 15

Bottom Section Rear Doors Removal (Option) ............................................................................................ 16

NIGHT CURTAIN (SSRC OPTION) ..................................................................................................................... 17

Opening ........................................................................................................................................................ 17

Closing .......................................................................................................................................................... 17

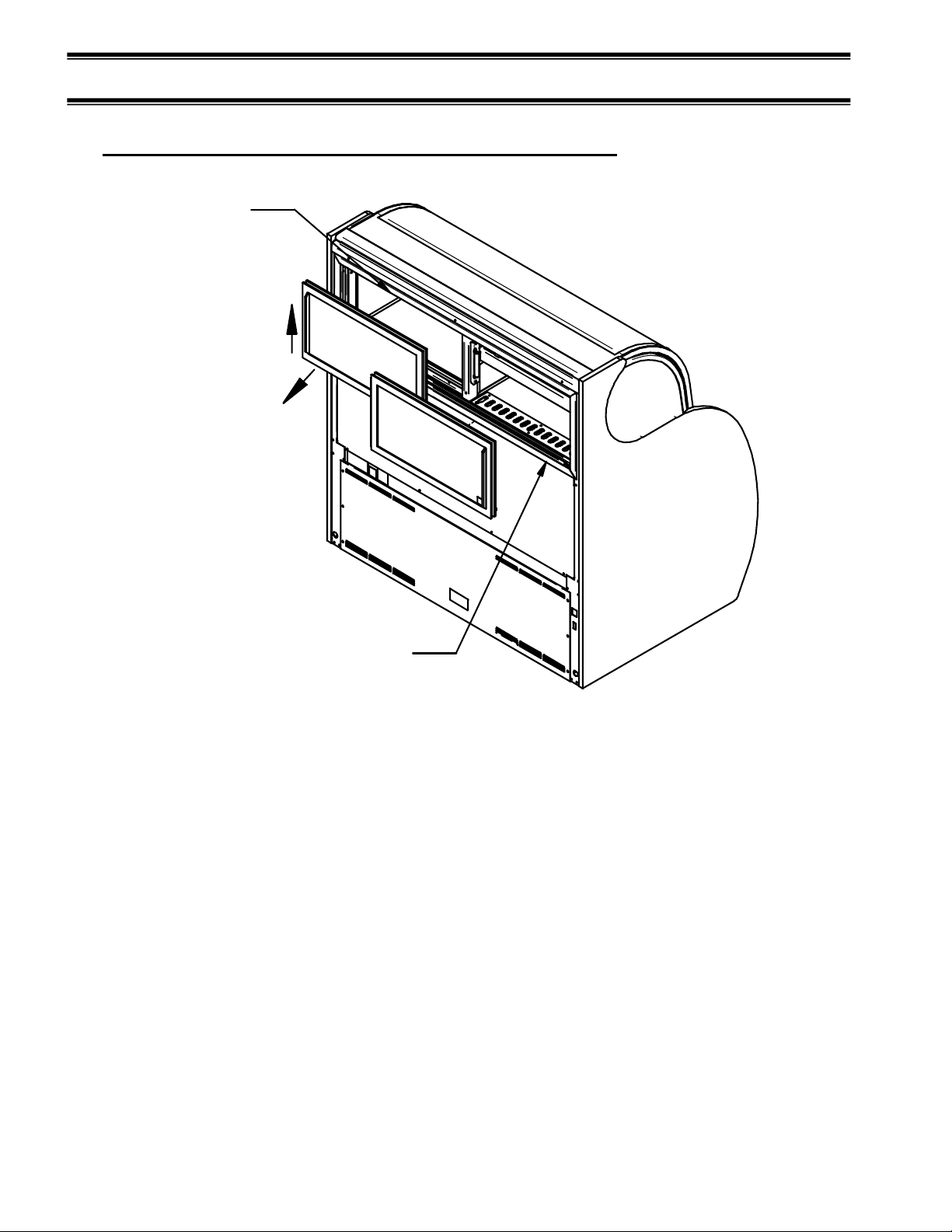

SECURITY NIGHT COVER (SSRC OPTION) .................................................................................................... 18

Installation .................................................................................................................................................... 18

Removal ........................................................................................................................................................ 18

OPERATING INSTRUCTIONS ........................................................................................................................ 19-23

Power Switch ................................ ................................................................ ................................................ 19

Light Switch ................................................................................................................................................. 19

Temperature Control ..................................................................................................................................... 19

Button and Display Overview ................................................................................................................. 20

Powering On Control............................................................................................................................... 20

Adjusting the Set Point ............................................................................................................................ 21

Entering Manual Defrost Mode ............................................................................................................... 21

Error Codes ............................................................................................................................................. 21

Electronic Control Operation .................................................................................................................. 22

Control Parameters ................................................................................................................................. 23

Initial Startup ................................................................................................................................................ 23

Top Section Refrigeration Louver Control ................................................................................................... 24

Placing Product In Case ................................................................................................................................ 24

MAINTENANCE ...................................................................................................................................................... 25

Top Light Bulb Replacement, Fluorescent ................................................................................................... 25

Shelf Light Bulb Replacement, Fluorescent ................................................................................................. 25

Top Light Bulb Replacement, LED (Cases mfg’d After 08/01/18) .............................................................. 25

Shelf Light Bulb Replacement, LED (Cases mfg’d After 08/01/18) ............................................................ 25

PERIODIC MAINTENANCE ................................................................................................................................. 26

Cleaning Condenser Coil .............................................................................................................................. 26

- 3 -

CLEANING INSTRUCTIONS ................................................................................................ ........................... 27-31

Daily Cleaning .............................................................................................................................................. 27

Weekly Cleaning .......................................................................................................................................... 28

Weekly Top Section Interior Cleaning .................................................................................................... 28-29

Weekly Bottom Section Interior Cleaning ................................................................................................ .... 30

Weekly Exterior Cleaning ............................................................................................................................ 31

SERVICE INFORMATION ............................................................................................................................... 32-33

Special Service Situations ............................................................................................................................. 32

Pre-Service Checklist .................................................................................................................................... 33

SALE & DISPOSAL ................................ ................................................................ ................................................. 34

Owner Responsibility ................................................................................................................................... 34

WIRING DIAGRAMS ........................................................................................................................................ 35-40

Self-Contained SSRC2452 w/ Fluorescent Lights ........................................................................................ 35

Self-Contained SSRC3652 & ESSRC3652 w/ Fluorescent Lights ............................................................... 36

Self-Contained SSRC5052/5952/7752, ESSRC5052/5952/7752 w/ Fluorescent Lights .............................. 36

Self-Contained SSRC2452 w/ LED Lights (Mfg’d After 12/1/19) .............................................................. 37

Self-Contained SSRC3652 & ESSRC3652 w/ LED Lights (Mfg’d After 12/1/19) ..................................... 38

Self-Contained SSRC5052/5952/7752, ESSRC5052/5952/7752 w/ LED Lights (Mfg’d After 12/1/19) .... 38

Remote SSRC2452, SSRC3652 w/ Fluorescent Lights ................................................................................ 39

Remote SSRC5052/5952/7752 w/ Fluorescent Lights ................................................................................. 39

Remote SSRC5052/5952/7752 w/ LED Lights (Mfg’d After 12/1/19) ........................................................ 40

REPLACEMENT PARTS - SSRC ..................................................................................................................... 41-44

REPLACEMENT PARTS - ESSRC .................................................................................................................. 44-46

- 4 -

INTRODUCTION

Thank you for purchasing a Federal Industries display case. This manual contains important instructions for

installing and servicing the Refrigerated Self-Service Merchandisers. A repair parts list and wiring diagram

are also included in the manual. Read all documents carefully before installing or servicing your case.

NOTICE

Read this manual before installing your case. Keep this manual and refer to it before doing any

service on the equipment. Failure to do so could result in personal injury or damage to the case.

NOTICE

Installation and service of the electrical components in the case must be performed by a licensed

electrician.

The portions of this manual covering components contain technical instructions intended only for persons

qualified to perform electrical work.

DANGER

Improper or faulty hookup of electrical components in the case can result in severe injury or death.

All electrical wiring hookups must be done in accordance with all applicable local, regional, or

national standards.

REGISTRATION & SERIAL NUMBER

It’s important to keep a record of the model and serial number of your merchandiser for warranty and part

identification. Please write them here for your quick reference.

Register your product online! Visit our website at www.federalindustries.com and register your product

today.

Case Model__________________________ Serial Number______________________

We’re here to provide you with the best possible experience with your new product, however, we cannot

cover everything about your merchandiser in this manual, so if you have any additional questions or issues,

please see the SERVICE INFORMATION PAGE to find who you should contact.

- 5 -

WARNING LABELS & SAFETY INSTRUCTIONS

This is the safety-alert symbol. When you see this symbol on your case or in the

manual, be alert to the potential for personal injury or damage to your equipment.

Be sure you understand all safety messages and always follow recommended precautions and safe

operating procedures.

NOTICE TO EMPLOYERS

You must make sure that everyone who installs, uses, or services your case is thoroughly

familiar with all safety information and procedures.

Important safety information is presented in this section and throughout the manual. The

Following signal words are used in the warning and safety messages:

DANGER: Severe injury or death will occur if you ignore the message.

WARNING: Severe injury or death can occur if you ignore the message.

CAUTION: Minor injury or damage to your case can occur if you ignore the message.

NOTICE: This is important installation, operation, or service information. If you ignore the

message, you may damage your case.

The warning and safety labels shown throughout this manual are placed on your Federal Industries case at

the factory. Follow all warning label instructions. If any warning or safety labels become lost or damaged,

call our customer service department at 1(800) 356-4206 for replacements.

This label is located on the back of the display case. This label is located below the display pan.

CAUTION

POWER BEFORE

RISK OF ELECTRIC

SHOCK DISCONNECT

91-12340

SERVICING UNIT.

CAUTION

HAZARDOUS MOVING PARTS

DO NOT OPERATE UNIT WITH

DISPLAY PANS REMOVED.

- 6 -

PRE-INSTALLATION PROCEDURES

Inspection for Shipping Damage

You are responsible for filing all freight claims with the delivering truck line. Inspect all cartons

and crates for damage as soon as they arrive. If damage is noted to shipping crates, cartons, or if a

shortage is found, note this on the bill of lading (all copies) prior to signing.

If damage is discovered when the case is uncrated, immediately call the delivering truck line and

follow up the call with a written report indicating concealed damage to your shipment. Ask for an

immediate inspection of your concealed damage item. Crating material must be retained to show

the inspector from the truck line.

GENERAL ELECTRICAL & GROUNDING

DANGER: Improper or faulty hookup of electrical components in the

display case can result in severe injury or death.

Permanent Connected (OPTION)

-Only a licensed electrician must perform all case electrical connections.

-All electrical wiring hookups must be done in accordance with all applicable local, regional, or national

electrical standards.

-A separate circuit for each display case is required to prevent other appliances on the same circuit from

overloading the circuit and causing malfunction.

-The electrical service must be grounded upon installation.

-See the electrical data plate located at the rear of the case for proper circuit size and wire ampacity.

-The electrical connection box is accessible from the rear of the case with rear grill removed.

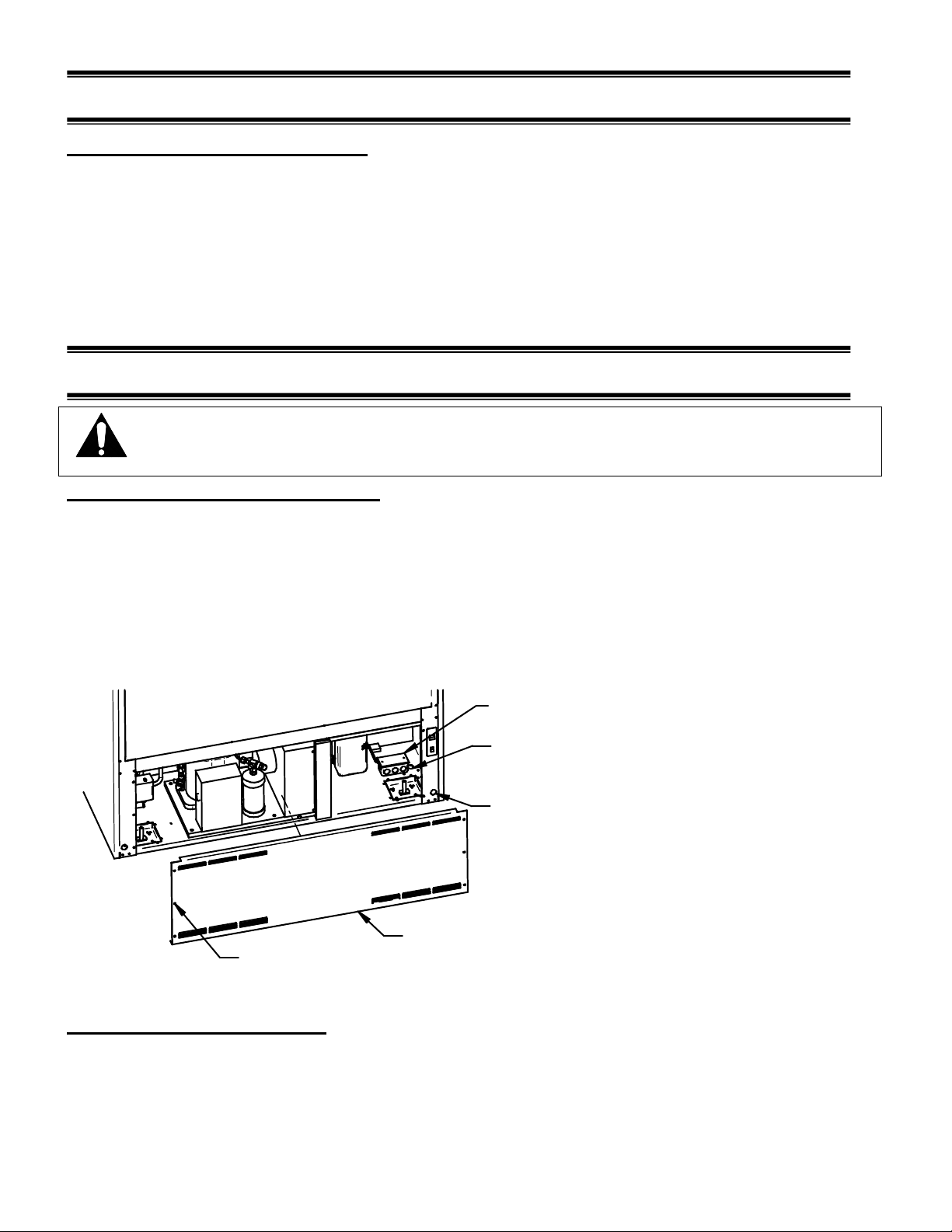

REAR BASE PANEL

(6) REAR PANEL SCREWS

CONDUIT OR

POWER CORD

CONNECTION .875O

FIELD CONNECTION BOX

FLOOR CONDUIT

CONNECTION .875O

Cord Connected (OPTION)

-A factory installed optional power cord is properly sized to the amperage requirements of the case. See the

electrical data plate located on the rear exterior of the case for the proper circuit size for each case.

- The cord is factory installed protruding from the rear corner of the case.

-A separate circuit for each display case is required to prevent other appliances on the same circuit from

overloading the circuit and causing malfunction.

- 7 -

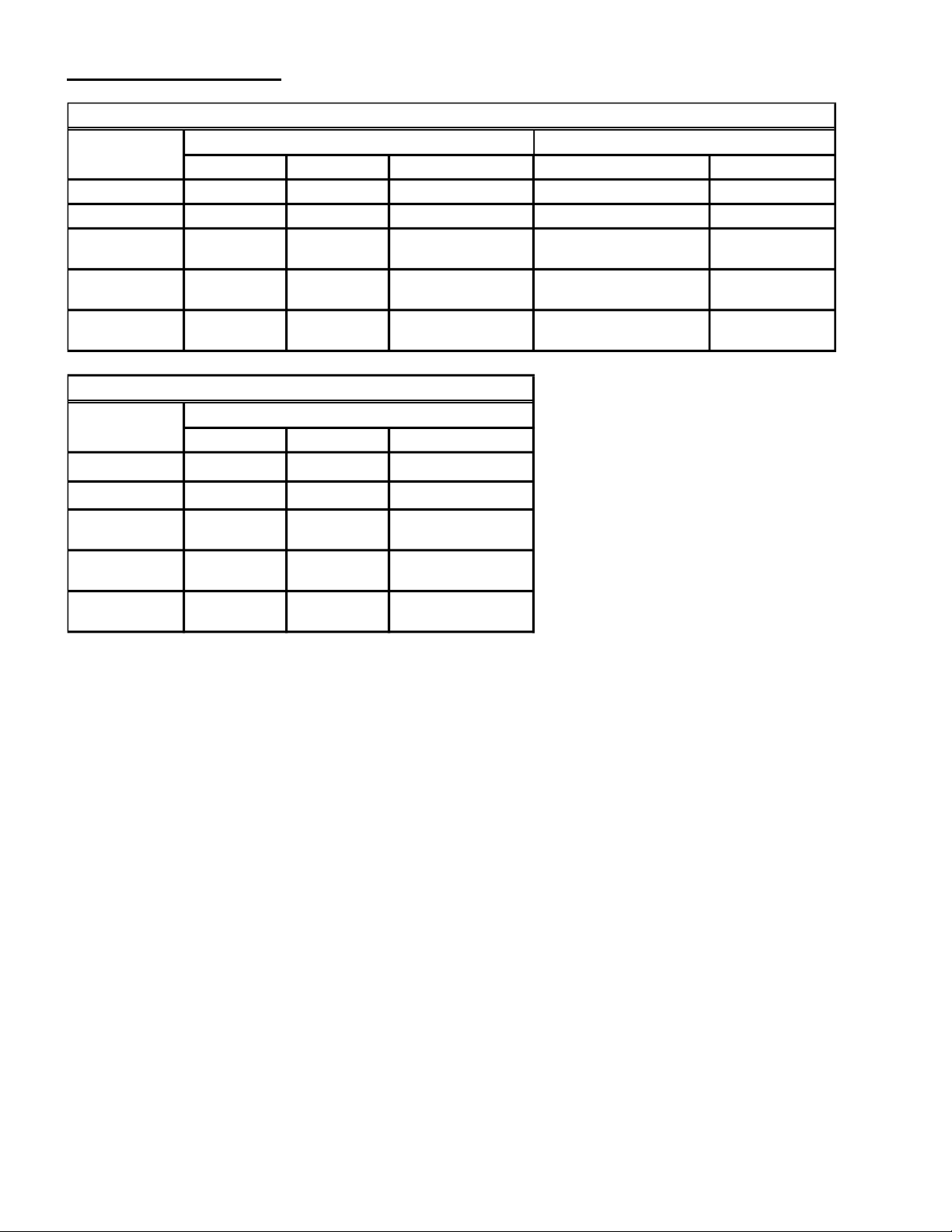

Electrical Information.

PERMANENTLY CONNECTED

MODEL VOLTAGE TOTAL AMPS MAX FUSE SIZE VOLTAGE MAX FUSE SIZE

SSRC2452 120/60/1 11.3 20 120/60/1 15

SSRC3652 120/60/1 14.3 20 120/60/1 15

SSRC5052/

ERSSC5052

230/60/1 9.5 15 120/60/1 15

SSRC5952/

ERSSC5952

230/60/1 14.5 20 120/60/1 15

SSRC7752/

ERSSC7752

230/60/1 14.5 20 120/60/1 15

MODEL VOLTAGE TOTAL AMPS CORD STYLE

SSRC2452 120/60/1 11.3

20AMP NEMA 5-20

SSRC3652 120/60/1 14.3

20AMP NEMA 5-20

SSRC5052/

ERSSC5052

230/60/1 9.5

15AMP NEMA 6-15

SSRC5952/

ERSSC5952

230/60/1 14.5

15AMP NEMA 6-20

SSRC7752/

ERSSC7752

230/60/1 14.5

15AMP NEMA 6-20

CORD CONNECTED OPTIONAL

SELF CONTAINED

SELF CONTAINED

REMOTE

(E3091-3 EXCEL)

- 8 -

INSTALLATION INSTRUCTIONS

Locating Display Case

The case should be located where it is not subjected to the direct rays of the sun, heating ducts, grills,

radiator, or ceiling fans, nor should it be located near open doors or main door entrances. Also, avoid

locations where there are excessive air movement or air disturbances.

The case requires a minimum of 12” clearance at the rear of the unit for air discharge. Do not locate case

with back tight against the wall.

No clearance is needed on sides of the unit.

Removing Case From Shipping Skid and General Installation

CAUTION: Do not push or pull against the top end glass, or

door frames and do not pull on end panels when removing the case

from the skid or moving the case. Case damage or glass breakage will result.

1. Remove crate top and sides and note missing or damaged items as explained in the pre-installation

procedures outlined above.

2. Move the case as near as possible to the final location and before removing it from the shipping skid.

3. Remove the (4) brackets that secure the case to the shipping skid.

4. Prepare cabinet according to instructions in this section that pertain to your model.

5. Lift the case off of skid and into required position. Only lift the case from under the rear lip and front

bottom trim channel above the base. Note: Do not push or pull on front bottom trim channel.

6. The case must be level for proper drainage of defrost condensate to the condensate evaporator. Using

the wrench provided level and square the case as needed by adjusting the leg leveler in each corner of

base. The 6’cases also have a set of leg levelers in the center. These must be adjusted so the base is flat.

7. The leveled case must be sealed to the floor using a NSF Listed Sealant.

Cleaning

For initial setup, clean the case as outlined in the “Weekly Cleaning” section of this manual.

- 9 -

REFRIGERATION

Self-Contained Models

SELF CONTAINED

Refrigeration R404 Charge 25 OZ 30 OZ 32 OZ 34 OZ 36 OZ

SSRC7752/

ERSSC7752

SSRC2452

WITH ELECTRONIC CONTROL

SSRC3652

SSRC5052/

ERSSC5052

SSRC5952/

ERSSC5952

(E3091-3 EXCEL)

The self-contained models are shipped from the factory with a completely operational 404A refrigeration

system and require no modifications or adjustments upon installation. Case must be installed as per the

installation section of this manual to provide proper condensing air cooling.

The dual pressure control is used as a safety device and is factory set. The pressure control works on a

differential. The low-pressure side is a safety to protect the compressor in the case of refrigerant loss. The

high-pressure side is a safety to protect from system failure causing too high of system pressure.

The high side of the pressure control is factory set to 400psi and is not adjustable. Low side setting

for the R404a cases are set at 40psi differential for the cutout and 60psi for the cut-in.

Note: The condenser fan runs continuously.

This unit also has a defrost timer that will shut the compressor off a set number of times per day to insure a

full defrost occurs. The compressor will remain off until the either the off time is reached or until the

temperature sensor on the coil reaches a set temperature, which ever happens first.

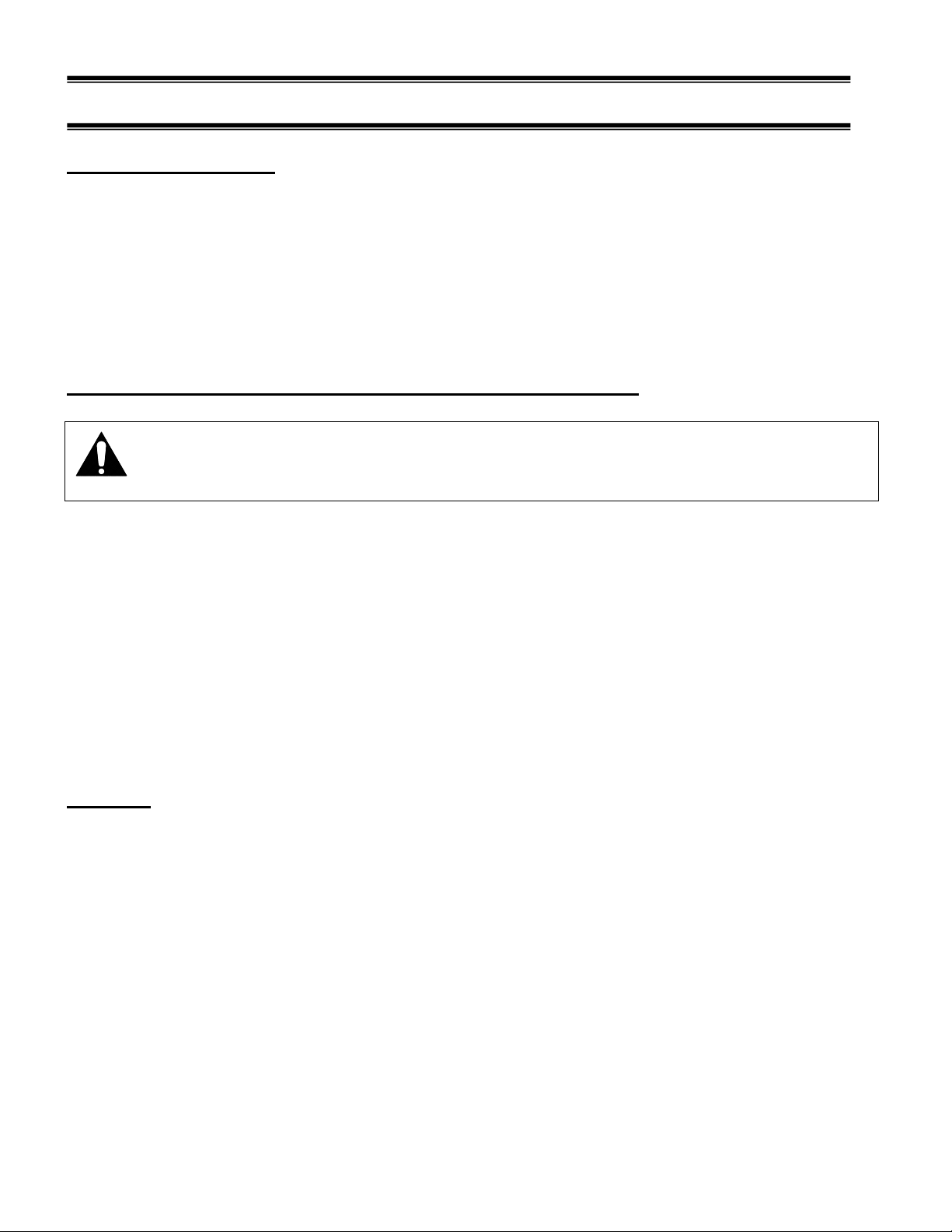

Remote Models

REMOTE

Refrigeration R449 Charge

Remote Low Press. Switch Cut In

Remote Low Press. Switch Cut Out

Remote High Press. Switch Cut Out

BTU Requirement @90F/20F 3600 4400 5400 6400 7400

450 psi

CHARGED IN FIELD

50

15

SSRC5952R/

ERSSC5952R

SSRC7752R/

ERSSC7752R

SSRC2452R

SSRC3652R

SSRC5052R/

ERSSC5052R

(E3091-3 EXCEL)

- 10 -

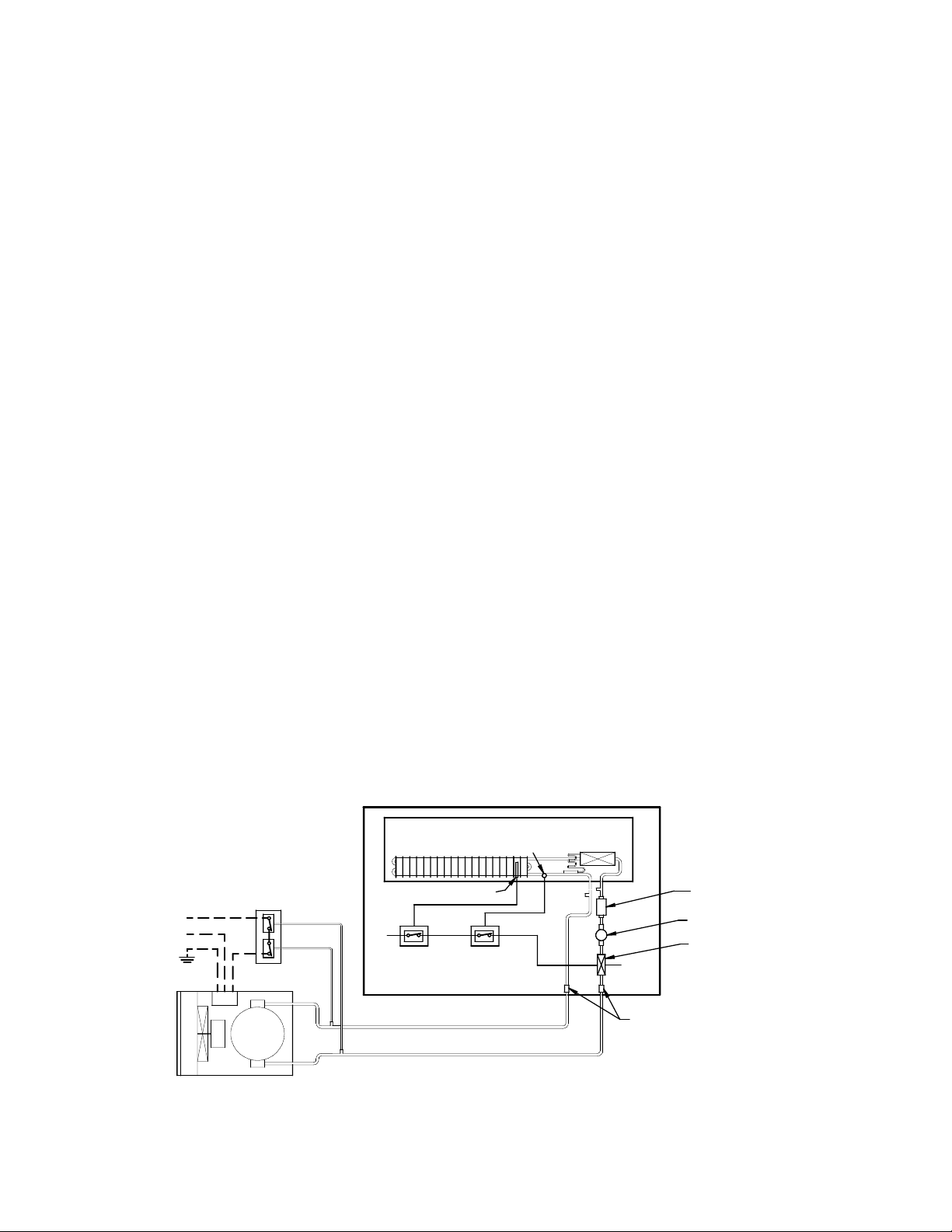

Remote Refrigeration Operation

The remote models are designed to use R449 refrigerant and shipped from the factory with the evaporator

coil, expansion valve, drier filter, sight glass and refrigerant solenoid valve. A thermostat senses evaporator

temperature and opens and closes the refrigerant solenoid valve. The solenoid valve closes and shuts off the

refrigeration flow to the unit and initiates a pump down cycle. This will allow the remote low-pressure

switch to open and shut off remote compressor. The temperature control may require some adjustment by

installer for proper operation of unit. This unit also has a defrost timer that will shut the refrigeration

solenoid off a set number of times per day (set at factory for 3 times per day) to insure a full defrost occurs.

The solenoid will remain off until the either the off time is reached or until the temperature sensor on the

coil reaches a set temperature, whichever happens first.

The condensing unit is optionally supplied from the factory for remote location installation. The

condensing unit supplied from the factory will include a high/low pressure switch that must be mounted

and wired by the installer. The high/low pressure switch must be wired in series with the compressor power

supply as shown in diagram below. If the factory is not providing the condensing unit a high/low pressure

switch will need to be supplied by installer and installed by installer.

Remote Refrigeration Instructions

1. Mount condensing unit indoors as close to the remote display case as practical. The refrigeration line

should be as short as possible.

2. All refrigeration and/or electrical materials between the condensing unit and display case are to be

supplied by installing contractor.

3. Route properly sized and designed refrigeration lines from the condensing unit to the cabinet.

Horizontal suction lines should be pitched downward towards the condensing unit at least ½” per 10’

run to aid the oil drainage. A “P” trap must be installed in the suction line at the foot of every riser to

insure oil return. Dry nitrogen must be used to flow through tubing while brazing refrigeration lines.

4. Suction line must be insulated the entire length with Armaflex (or equivalent). Do not run liquid line

inside insulation with suction line.

5. The remote high/low-pressure control must be mounted, wired and set pressures by the installer.

6. Leak check condensing unit, cabinet, and all connecting tubing. Cabinet and condensing unit tubing

should be checked to insure no leaks occurred during shipping or from rough handling.

Make certain all refrigeration valves are opened and evacuate system to 500 microns. Charge the

system with refrigerant type specified on the data plates.

REMOTE

HIGH LOW

PRESSURE

CONTROL

LIQUID LINE

SUCTION LINE (INSULATED)

REMOTE

CONDENSING

UNIT

EVAPORATOR COIL

DISPLAY CASE

EXPANSION

VALVE

HIGH

LOW

LIQUID LINE

SOLENOID VALVE

SIGHT GLASS

DRIER/FILTER

FIELD CONNECTION

HOT

FUSED

POWER

SUPPLY

DEFROST

TIMER

HOT

DEFROST

TERMINATE

TEMPERATURE

CONTROL

NEUT.

TEMP. CONTROL PROBE

- 11 -

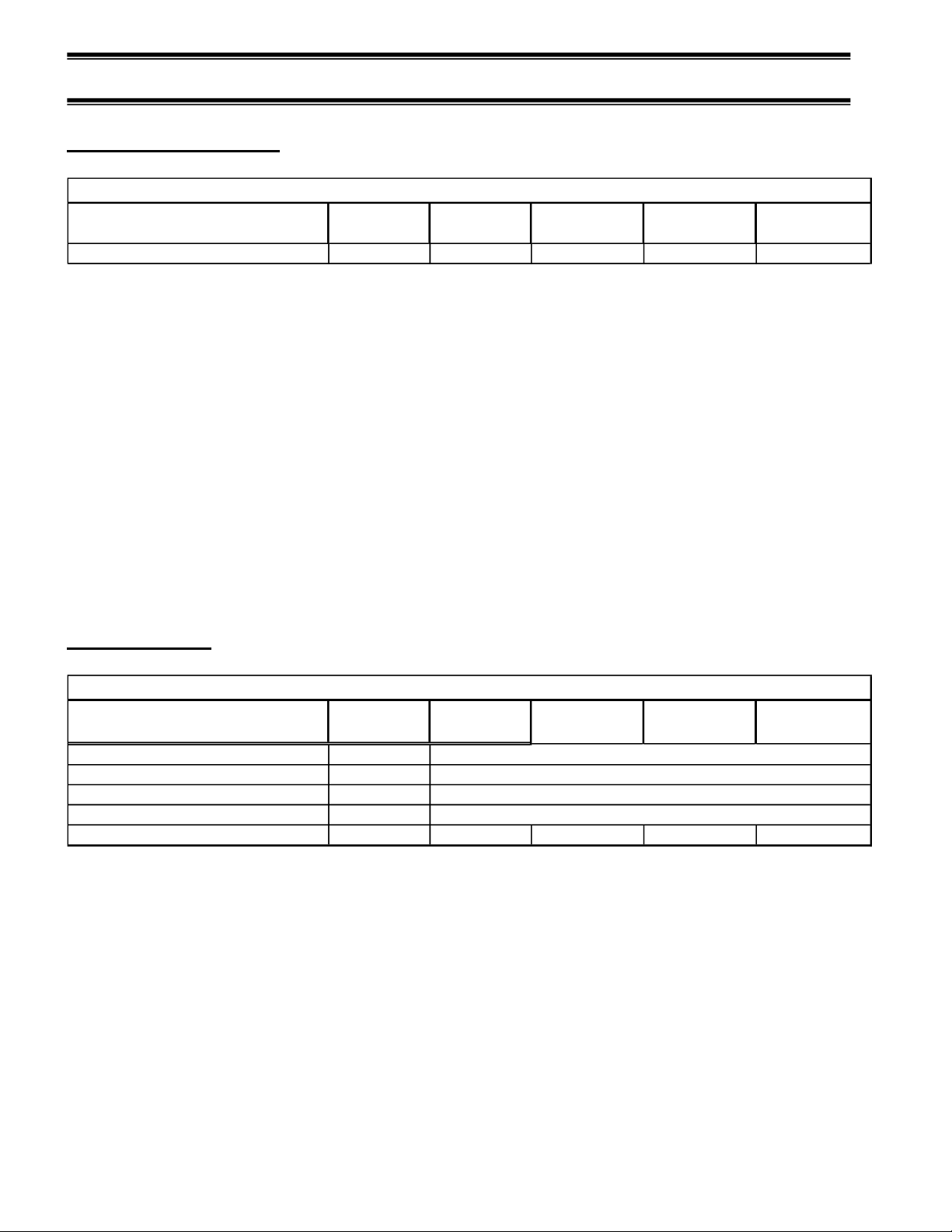

SHELVING INSTALLATION & REMOVAL

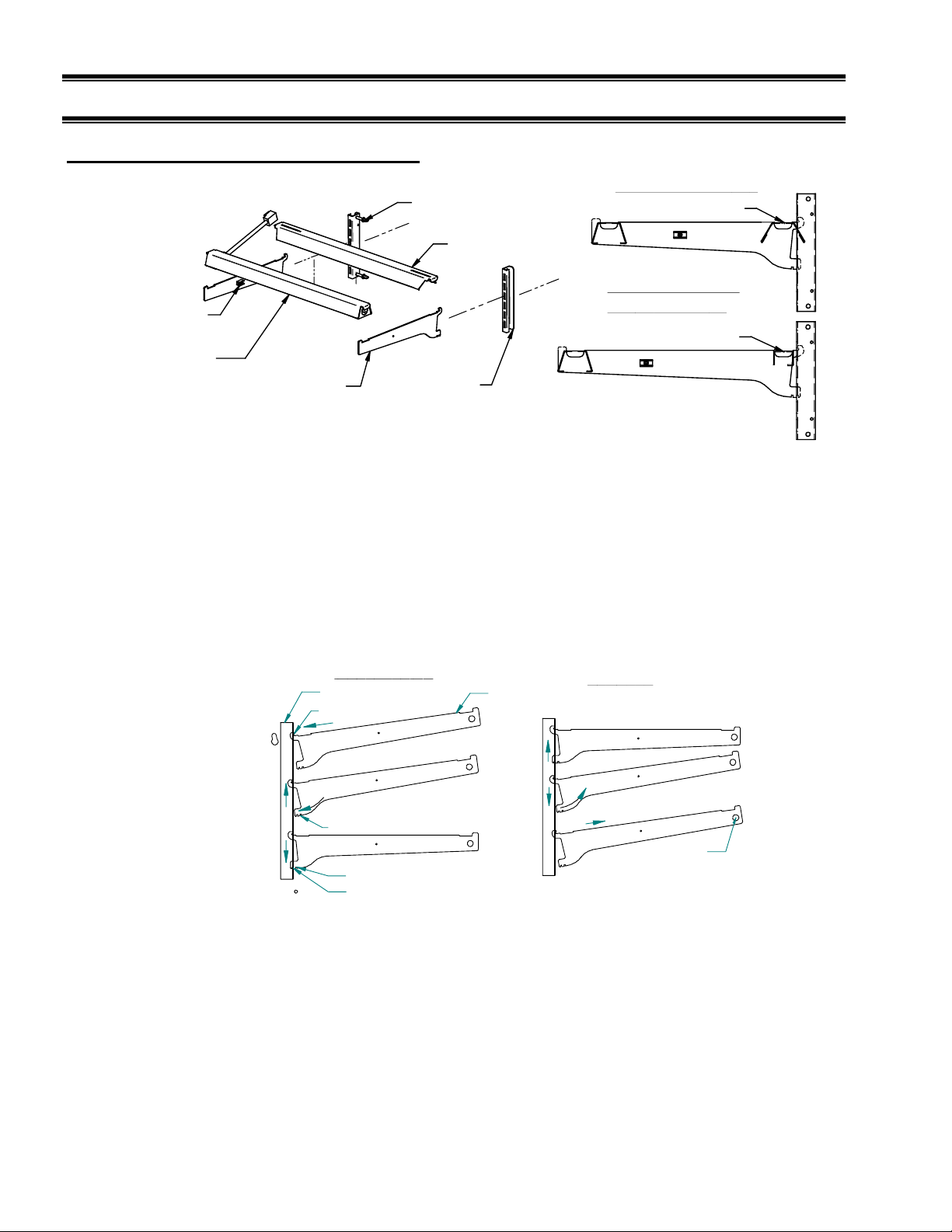

Shelf Bracket & Supports Installation

SHELF STANDARD

REAR SHELF SUPPORT

SHELF LIGHT ASSEMBLY

SHELF BRACKET

SHELF LIGHT CORD

RETAINER CLIP

SHELF STANDARD

RETAINING SCREW

OPTIONAL BOTTOM

SECTION SHELF

TOP SECTION SHELF

REAR SHELF SUPPORT

REAR SHELF SUPPORT

1. Turn the light switch to the off position. Remove rear doors as described in the “Rear Sliding Door

Removal” section of this manual to allow access to interior of case. On 24” cases, open the rear

swinging door past 90º until it locks in the open position.

2. Follow the instruction in the illustration below and insert (1) of the (2) shelf brackets in the desired

shelf standard slot on one side of the case. Place the additional shelf bracket in the same shelf standard

slot on the opposite end of case. The bracket with a shelf light cord retainer clip must be on the side

with the shelf light receptacle. Shelf brackets on the 24” case may have bends, making them left-hand

or right-hand specific. Install the brackets so they are farthest spread apart at the front of the case.

0v NOTCH

6v NOTCH

4

1

2

3

4

INSTALLATION

REMOVAL

2

3

1

TOP HOOK

BOTTOM TAB

SHELF BRACKET

SHELF STANDARD

1. Place shelf bracket top hook into desired shelf

standard slot.

2. Lift shelf bracket top hook to allow shelf bracket

bottom tab to clear shelf standard slot.

3. Swing shelf bracketbottom tab into shelf standard

slot.

4. Place the desired shelf bracket notch of 0, 6, or 12

degrees onto bottom of shelf standard slot.

1. Lift shelf bracket up to allow shelf bracket notch

to clear the bottom of shelf standard slot.

2. Swing shelf bracket bottom tab out of shelf

standard slot.

3. Drop shelf bracket down to allow shelf bracket top

hook to clear top of shelf standard slot.

4. remove shelf bracket top from shelf standard slot.

CLEAR BUMPER

TOWARDS END PANEL

3. Hang one end of shelf light housing or shelf support on the front notch of a shelf bracket. Hang the

other end of shelf light housing or shelf support on the notch of the shelf bracket on the opposite end.

4. Push shelf light cords into plastic shelf cord retainer clip located on inside of shelf bracket.

- 12 -

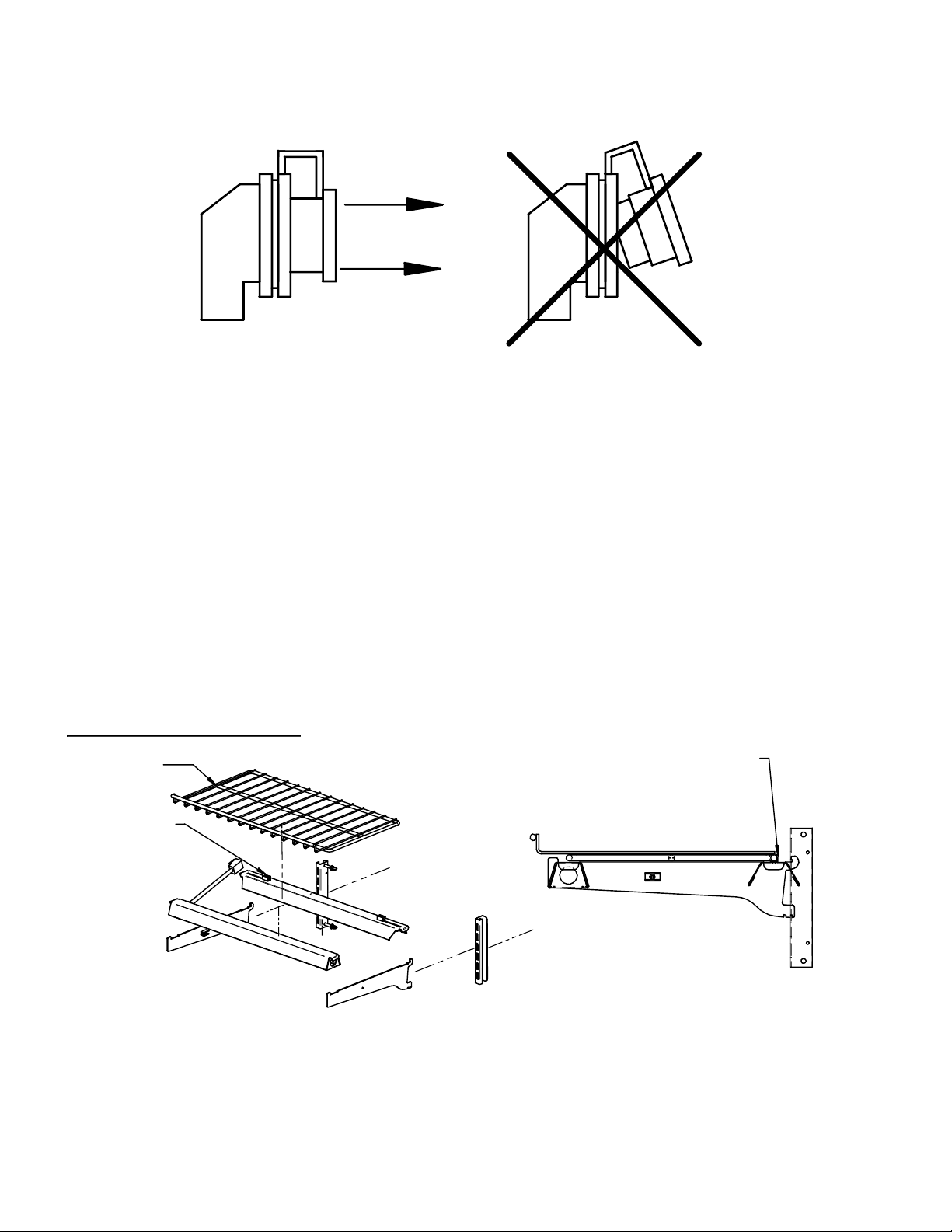

5. Remove the cap from the appropriate female light sockets.

IMPORTANT: Grip each side of cap firmly and wiggle and pull cap straight out of socket. Do not roll

cap during removal. Incorrect removal of cap may cause damage to electrical connection.

RIGHT

WRONG

6. If the socket is not being used for a shelf light, the cap must be plugged into the socket. On models with

the 5 pin shelf plug, this is necessary for the entire light system to operate. On models with the 3 pin

shelf plug, this is necessary to prevent buildup and damage to receptacle.

7. Plug in each shelf light by aligning the male pins on the appropriate shelf light cord plugs with the

female light sockets and push together. IMPORTANT: Do not roll plug during insertion.

8. Hang one end of the shelf support on to the rear notch of one shelf bracket and then on the rear notch of

the shelf bracket on the opposite side. NOTE: If the bottom open section shelf is supplied instead of

step risers, the bottom rear support is not the same as the top rear support. See illustration above.

9. Place supplied shelving onto shelf supports as outlined in the appropriate “Shelf Installation” section of

this manual.

10. Removal of shelving is performed by following steps in reverse order.

11. The shelf standards are removable from case by removing the (2) shelf standard retaining screws

holding them to the inside wall of case.

Wire Shelves Installation

WIRE SHELF

WIRE SHELF

RETAINER CLIPS

SNAP THE REAR RAIL OF

THE WIRE SHELF INTO

RETAINER CLIPS ON

REAR SHELF SUPPORT

1. Install shelf brackets & shelf supports as described in Shelf Bracket & Supports Installation Section of

this manual.

2. Place the front of wire shelf onto front shelf light or front shelf support.

3. Snap the rear of shelf into the clear plastic clips on rear shelf support.

- 13 -

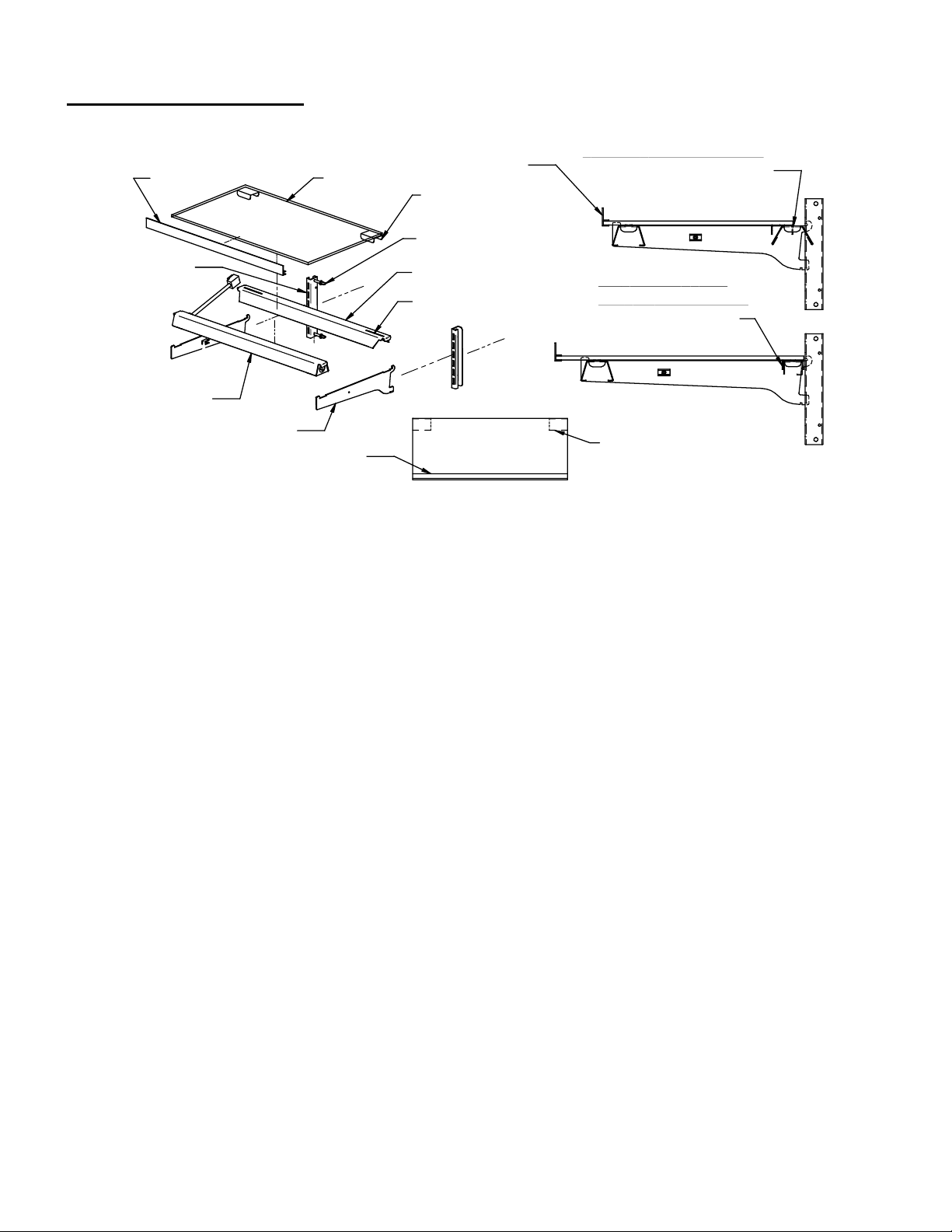

Glass Shelves Installation

GLASS SHELF

SHELF STANDARD

REAR SHELF

SUPPORT

SHELF LIGHT ASSEMBLY

SHELF BRACKET

GLASS SHELF

RETAINER CLIP

CORD RETAINER CLIP

PRODUCT STOP

RETAINER CLIP

SLOT

PLACE BACK SIDE OF GLASS

SHELF RETAINER CLIP INTO SLOT

IN OF REAR SHELF SUPPORT

TOP SECTION GLASS SHELF

PLACE GLASS SHELF RETAINER

CLIP OVER REAR SHELF SUPPORT

SHELF STANDARD

RETAINING SCREW

OPTIONAL BOTTOM

SECTION GLASS SHELF

CLIP LOCATED IN FAR

CORNER OF GLASS SHELF.

CLIPS FIELD INSTALLED TO GLASS.

TOP VIEW

PRODUCT STOP

PRODUCT STOP

1. For first time installation attach (2) glass shelf retainer clips to each glass shelf in location shown in

illustration. Clean area of glass where glass shelf holder is to be located with rubbing alcohol and let

air dry before installing shelf glass holder. Remove backing from tape located on flat side of glass shelf

holder. Position the glass shelf holders in the (2) far corners of glass. Repeat for each glass shelf.

2. For first time installation attach (1) product stop to each glass shelf as shown in detail above. Align the

product stop edge with the edge of the glass and push the “U” portion of the product stop on to glass lip

across the entire front of glass.

3. Attach a clear bumper on both sides of the light housing top surface for the front of the glass to set on.

This step may have already been performed at the factory for you.

4. Place front of glass shelf onto clear bumpers on front shelf light. (On front shelf support for models

without shelf lights.)

5. If clear plastic clips were factory-installed on top of rear shelf support, remove and discard clear plastic

clips.

6. For SSRC top section glass shelf set the rear of the glass shelf onto the rear shelf support so that the

back side of the glass shelf retainer sets into the slot on the rear shelf support. For ESSRC top section

glass shelf and all optional bottom section glass shelves, set the rear of the glass shelf onto the rear shelf

support so that the back side of the glass shelf retainer straddles the rear shelf support.

- 14 -

REAR DOORS

TOP SECTION REAR SLIDING DOORS REMOVAL

UPPER TRACK

LOWER TRACK

1. LIFT UP DOOR

2 SWING BOTTOM OUT

1. Starting with the outer door, lift the door upward until the bottom edge of door clears the

lower track and then swing the bottom of the door outward and down out of upper track.

2. After the outer door is removed repeat the procedure for the inner door.

3. Reverse this procedure for door reinstallation. The doors are not interchangeable.

Loading...

Loading...