Federal Industries MCG1054DC Installation Manual

E2855

Revised 9/23/08

NEW MAXI-DELI STRAIGHT GLASS

FEDERAL INDUSTRIES

INSTALLATION & OPERATING INSTRUCTIONS

NEW MAXI-DELI CURVED GLASS

Self-Contained & Remote Models

MSG454DC MSG654DC MSG854DC MSG1054DC

MSG454DM MSG654DM MSG854DM MSG1054DM

MSG454DF MSG654DF MSG854DF MSG1054DF

MCG454DC MCG654DC MCG854DC MCG1054DC

MCG454DM MCG654DM MCG854DM MCG1054DM

MCG454DF MCG654DF MCG854DF MCG1054DF

KEEP THIS MANUAL FOR FUTURE REFERENCE

Engineering and technical data are subject to change without notice.

FEDERAL INDUSTRIES P.O. Box 290 Belleville, WI 53508

Toll Free 1(800) 356-4206 WI Phone (608) 424-3331 Fax: (608) 424-3234

New Maxi Deli Cases

- 1 -

CONTENTS

INTRODUCTION..........................................................................................................................3

WARNING LABELS & SAFETY INSTRUCTIONS................................................................4

PRE-INSTALLATION PROCEDURES.....................................................................................5

INSPECTION FOR SHIPPING DAMAGE ...................................................................5

INSTALLATION INSTRUCTIONS ...........................................................................................5

LOCATING THE DISPLAY CASE...............................................................................5

REMOVING CASE FROM SHIPPING SKID...............................................................6

REMOVING PACKAGING MATERIAL .....................................................................6

LEVELING THE CASE .................................................................................................6

GRILL REMOVAL ........................................................................................................6

CONDENSATE EVAPORATOR ..................................................................................7

LIGHTS...........................................................................................................................7

ELECTRICAL INFORMATION & GROUNDING..................................................................7

DEFROST TIMER CONTROL...................................................................................................8

SETTING TIME OF DAY ..............................................................................................9

SETTING SWITCHING TIMES (DEFROST)...............................................................9

OPERATING INSTRUCTIONS................................................................................................10

INITIAL START-UP ....................................................................................................10

DOORS .........................................................................................................................10

LIGHT REPLACEMENT.............................................................................................10

PLACING PRODUCT IN CASE LINE .................................................................10-11

OPERATING MANUAL..............................................................................................12

HINGED FRONT GLASS............................................................................................12

PERIODIC MAINTENANCE ......................................................................................12

CLEANING INSTRUCTIONS...................................................................................................13

DAILY CLEANING.....................................................................................................13

WEEKLY CLEANING.................................................................................................13

INTERIOR CLEANING...............................................................................................14

EXTERIOR CLEANING..............................................................................................14

SERVICE INFORMATION.......................................................................................................15

PRE-SERVICE CHECKLIST.......................................................................................16

PRE-SERVICE CHECKLIST.......................................................................................17

SPECIAL SERVICE SITUATIONS.............................................................................17

SALE & DISPOSAL....................................................................................................................17

OWNER RESPONSIBILITY .......................................................................................17

REFRIGERATION & ELECTRICAL DATA .........................................................................18

REPLACEMENT PARTS - COILS...........................................................................................19

REPLACEMENT PARTS – MCG DC SELF-CONTAINED & REMOTE.........................20

REPLACEMENT PARTS - MCG DM SELF-CONTAINED & REMOTE.........................21

REPLACEMENT PARTS – MCG DF SELF-CONTAINED & REMOTE ..........................22

REPLACEMENT PARTS – MSG DC SELF-CONTAINED & REMOTE..........................23

REPLACEMENT PARTS - MSG DM SELF-CONTAINED & REMOTE .........................24

REPLACEMENT PARTS – MSG DF SELF-CONTAINED & REMOTE ..........................25

WIRING DIAGRAM – SELF-CONTAINED...........................................................................26

WIRING DIAGRAM – REMOTE.............................................................................................27

New Maxi Deli Cases

- 2 -

INTRODUCTION

Thank you for purchasing a Federal Industries display case. This manual contains important

instructions for installing and servicing the Maxi Deli Refrigerated Cases. A repair parts list and

wiring diagrams are also included in the manual. Read all of these documents carefully before

installing or servicing your case.

NOTICE

Read this manual before installing your case. Keep this manual and refer to it before

doing any service on the equipment. Failure to do so could result in personal injury or

damage to the case.

NOTICE

Installation and service of the electrical components in the case must be performed by a

licensed electrician.

The portions of this manual covering components contain technical instructions

intended only for persons qualified to perform electrical work.

Improper or faulty hookup of electrical components in the case can result in severe

injury or death.

All electrical wiring hookups must be done in accordance with all applicable local,

regional, or national standards.

DANGER

SERIAL NUMBER

Record the model and serial numbers of the case for easy reference. Always refer to both model and serial numbers

in your correspondence regarding the case.

Case Model__________________________ Serial Number______________________

Condensing Unit Model________________ Serial Number______________________

This manual cannot cover every installation, use, or service situation. If you need additional information, call or

write us:

WARRANTY/TECHNICAL SERVICE DEPARTMENT

Federal Industries

P.O. Box 290

Belleville, WI 53508

Toll Free (800) 356-4206 / WI Phone (608) 424-3331

New Maxi Deli Cases

- 3 -

WARNING LABELS & SAFETY

INSTRUCTIONS

This is the safety-alert symbol. When you see this symbol on your case or in the

manual, be alert to the potential for personal injury or damage to your equipment.

Be sure you understand all safety messages and always follow recommended precautions and safe operating

procedures.

You must make sure that everyone who installs, uses, or services your case is thoroughly familiar

with all safety information and procedures.

NOTICE TO EMPLOYERS

Important safety information is presented in this section and throughout the manual. The

following signal words are used in the warning and safety messages:

DANGER: Severe injury or death will occur if you ignore the message.

WARNING: Severe injury or death can occur if you ignore the message.

CAUTION: Minor injury or damage to your case can occur if you ignore the message.

NOTICE: This is important installation, operation, or service information. If you ignore the

message, you may damage your case.

The warning and safety labels shown throughout this manual are placed on your Federal

Industries case at the factory. Follow all warning label instructions. If any warning or safety

labels become lost or damaged, call our customer service department at 1(800) 356-4206 for

replacements.

CAUTION

RISK OF ELECTRIC

SHOCK DISCONNECT

POWER BEFORE

SERVICING UNIT.

91-12340

This label is located on the back of the display case and This label is located below the display pans.

behind the left end access panel

New Maxi Deli Cases

C A U T IO N

H A ZA RD O US M O VI N G P A RT S

D O N O T O P E R A TE U N IT W IT H

D IS PLA Y P AN S R E M OV E D.

- 4 -

PRE-INSTALLATION PROCEDURES

Inspection For Shipping Damage

You are responsible for filing all freight claims with the delivering truck line. Inspect all

cartons and crates for damage as soon as they arrive. If damage is noted to shipping

crates, cartons, or if a shortage is found, note this on the bill of lading (all copies) prior to

signing.

If damage is discovered when the case is uncrated, immediately call the delivering truck

line and follow-up the call with a written report indicating concealed damage to your

shipment. Ask for an immediate inspection of your concealed damaged item. Crating

material must be retained to show the inspector from the truck line.

INSTALLATION INSTRUCTIONS

Locating The Display Case

The case should be located where it is not subjected to the direct rays of the sun, heating

ducts, grills, radiator, or ceiling fans, nor should it be located near open doors or main

door entrances. Also, avoid locations where there is excessive air movement or air

disturbances and avoid high humidity locations such as near cases with water misting or

fogging devices.

The case requires a minimum of 24” of clearance at the rear of the unit for air discharge.

Do not locate case with back tight against a wall. No clearance is needed on the sides of

the unit.

Removing Case From Shipping Skid

CAUTION: Do not push against the curved glass, end glass, doors, or doorframes when removing

the case from the skid or moving the case. Case damage or glass breakage could

result.

Move the case as near as possible to the final location before removing it from the

shipping skid.

Remove the screws and brackets that secure the case to the skid.

New Maxi Deli Cases

- 5 -

Removing Packaging Material

Remove the brackets that held the case to the shipping skid.

Remove the shipping tape that secures the doors and lift-up glass. If it is necessary to remove tape residue

from plastic materials, use cleaning compounds recommended in the cleaning section of this manual.

Leveling The Case

The case must be level for proper drainage of defrost water to the condensate evaporator

or floor drain.

Check the level of the case along the front rail and along the top of the display pan.

Adjust levelers (4 on 454, 6 on 654, 854, and 1054) as needed to level the case.

NOTE:

The leveled case must be sealed to the floor using an NSF Listed Sealant.

Grill Removal

DANGER: Electric shock hazard. Do not operate unit with panels removed.

The rear grill requires removal for case installation. Rear grill is secured with selftapping machine screws.

Grill must be in place for proper operation of the case. Grill must be reinstalled after case

installation.

New Maxi Deli Cases

- 6 -

Condensate Evaporator

NOTICE: During normal defrost cycles, steam from the condensate evaporator may be

visible around the case.

(Remotes Only With Optional Electric Condensate Evaporator Pans)

Self-contained cases (DC & DM) use a hot gas condensate evaporator.

The condensate evaporator is located behind the rear grill panel and is accessible from the

rear of the case.

Make sure that the drain line has not been dislodged during shipment and that the drain

terminates property over the water reservoir.

Fish cases (DF), self-contained and remote, must have the drain line plumbed into a

floor drain.

Lights

The ballasts used on this case allow removal of one or more top lights, or shelf lights if so

equipped, without affecting the remaining lights.

ELECTRICAL INFORMATION &

GROUNDING

This Case Must Be Grounded

DANGER:

display case can result in severe injury or death.

Only a licensed electrician must perform all case electrical connections.

All electrical wiring hookups must be done in accordance with all applicable local, regional, or

national electrical standards.

A separate circuit for each display case is recommended to prevent other appliances on the same

circuit from overloading the circuit and causing malfunction.

The electrical service must be grounded upon installation.

This unit is designed for permanent connection to a power source. See the electrical data plate,

next to electrical junction box, for proper circuit size and wire ampacity.

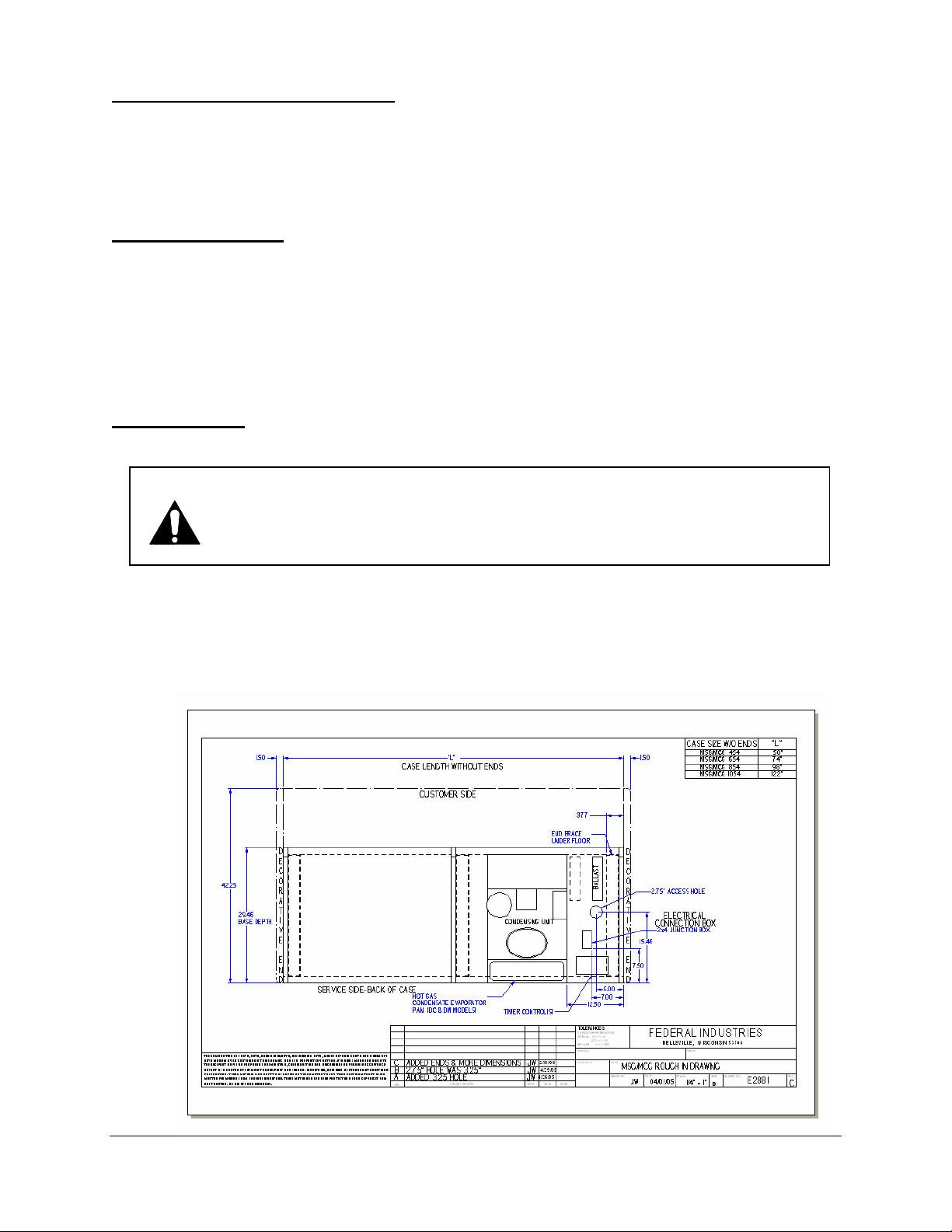

The electrical field connection 2 x 4 box is accessible from the rear of the case and is located in

the right (as viewed from case rear). See details below.

New Maxi Deli Cases

Improper or faulty hookup of electrical components in the

- 7 -

Defrost Timer Control

Note your new Maxi Deli unit is equipped with a 24 hr / 7 day a week digital electronic defrost timer. This

timer can be programmed to turn the compressor off for a preset time to cause the coils to warm up and

defrost.

The timer was factory pre-set for central time. You will need to change this for your Time Zone. Note

that the time of day must be set for the unit to operate.

Some default defrost were also set at the factory. You need to determine if these will be sufficient for

your application of the equipment. If the unit has been off for more than 5-10 days you may have lost the

programming of these defaults. If you hit the reset switch at the bottom of the timer you can clear all

preset defrosts.

You do need to have a time set on the clock and the I/O (on/off) set to the on position for the

compressor to run. Note that this defrost timer is located behind the switch / control panel at the back of

the unit. (See Photo below.) Note you may have to plug the unit in and turn the power switch on to

charge the battery for 6 to 8 hours if the battery has completely run down. Once you have the battery in

the timer charged and the clock set, the timer should maintain its programming for up to 5 days if the unit

is turn off or there is a power outage.

Note that on DM’s and DC’s the condenser fan runs all the time. This does not mean the compressor is

running. The Compressor is cycled on a timer based on the Refrigeration Control, located on the

switch panel at the back of the case. (See Photo below.) Note that a 1 setting on this control cycles the

compressor for approximately a 10 minute run time. A 5 setting on this control will be approximately a 50

minute run time. Note that the higher the setting the colder the case will get if you don’t have a problem

with the coils icing up. The off time is factory set to get the coils up to about 42 degrees before the time

cycle re-starts.

Switch Panel (Rear of Case) 24/7 Defrost Timer (behind Switch Panel)

New Maxi Deli Cases

- 8 -

This 24 hr / 7 day a week digital electronic defrost timer is used to initiate defrosts to keep the evaporator

coils from icing up. You need to determine what defrosts will be required throughout the week to keep the

coils clear and maintain the case temperature that your application requires. Note that some ice

formation and ice drips are normal on the top gravity coil.

Following are the programming instructions for the defrost timer.

This timer allows you to set up to 6 “on” and 6 “off” settings (defrosts) per day Mo thru Su.

AUTO RUN

P

T

INPUT

1

I / O 1...7 h m

P

Setting the time of day:

1. Slide the upper right switch to the right--toward the clock symbol.

2. Press the “1…7” button to confirm, and also set the correct day—

located at the top of the display. Mo, Tu, We, Th, Fr, Sa, Su.

3. Press the “h” button to confirm, and also to set the hour.

4. Press the “m” button to confirm, and also set the minutes.

5. After setting up, slide the switch to the center “RUN” position-it will show the current day and set time.

Setting the switching times (defrosts):

1. Slide the upper right switch to the left-toward the “P” for program.

2. Press the “1..7” button to set the day you wish to program:

With the first push of this button: MO TU WE TH FR SA SU will appear as the full week, MO TU WE

TH FR will appear at the next push of the button, SA SU will appear next, followed by the individual

days.

3. Press the “I/O” button to switch from program modes (on to off) for programs 1 through 6 for each day.

4. Press the “h” button to set the hour of the day (in military time) for the defrost to begin “off” or

end “on”. The “on” and “off” refer only to the compressor running ”on” or in defrost “off”.

5. Press the “m” button to set the minutes for the times.

6. After setting up, slide the upper right button back to the “RUN” position.

Factory default settings are:

1 on --:--1 off 1:00 Mon-Sun

2 on 2:00 Mon-Sun

2 off 4:00 Mon-Sun

3 on 5:00 Mon-Sun

3 off 14:00 Mon-Sun

4 on 14:30 Mon-Sun

4 off --:--5 on --:--5 off --:--6 on --:--6 off --:---

Note: You can manually turn the timer on or off by pressing the “I/O” button.

R

SWITCH

3

4

5

New Maxi Deli Cases

- 9 -

Loading...

Loading...