Federal Industries LMD9678 Owner’s Manual

E3670

REV E 8/18/16

INSTALLATION & OPERATIONS MANUAL

FEDERAL INDUSTRIES

MD4878, LMD7278, LMD9678

L

KEEP THIS MANUAL FOR FUTURE REFERENCE

EDERAL INDUSTRIES P.O. Box 290 Belleville, WI 53508

F

Toll Free 1(800) 356-4206 WI Phone (608) 424-3331 Fax: (608) 424-3234

LMD E3670

Engineering and technical data are subject to change without notice.

- 1 -

CONTENTS

INTRODUCTION ....................................................................................................................................................... 3

WARNING LABELS & SAFETY INSTRUCTIONS .............................................................................................. 4

PRE-INSTALLATION PROCEDURES ................................................................................................................... 5

INSPECTION FOR SHIPPING DAMAGE .............................................................................................. 5

INSTALLATION INSTRUCTIONS ......................................................................................................................... 5

LOCATING THE DISPLAY CASE ......................................................................................................... 5

REMOVING CASE FROM SHIPPING SKID ......................................................................................... 6

REMOVING PACKAGING MATERIAL ................................................................................................ 6

LIFTING AND MOVING CASE .............................................................................................................. 7

SINGLE CASE INSTALLATION ............................................................................................................ 8

LEVELING THE CASE ......................................................................................................................... 8

SEALING CASE TO FLOOR ................................................................................................................ 8

MULTIPLE CASE LINEUP INSTALLATION...................................................................................9-13

TWO CASES SINGLE REMOTE CONDENSER ............................................................................... 10

FLOOR PREPERATION ..................................................................................................................... 11

JOINING AND LEVELING LINE UP ........................................................................................... 11-12

SEALING ALL UNITS TO FLOOR ................................................................................................... 13

ELECTRICAL CONNECTION .............................................................................................................. 13

PERMANENTT CONNECTED ...............................................................................................................

BOTTOM BASE ELECTRICAL CONNECTION (STANDARD) .................................................. 13

TOP ELECTRICAL CONNECTION (OPTIONAL) ....................................................................... 13

CORD CONNECTED (OPTIONAL) ................................................................................................... 14

PANELS REMOVAL FOR ELECTRICAL ACCESS ............................................................................ 15

KICK PANEL ........................................................................................................................................ 16

NIGHT CURTAIN OPERATION ......................................................................................................... 16

SECURITY COVER INSTALLATION (OPTIONAL) ........................................................................ 17

BASE COMPONENT LAYOUT ........................................................................................................... 18

CONDENSATE DRAIN HOSE (STANDARD) ..................................................................................... 19

CONDENSATE PUMP (OPTIONAL) ................................................................................................... 19

SHELVING INSTALLATION ................................................................................................................ 20

SHELF LIGHTS ...................................................................................................................................... 21

OPERATING INSTRUCTIONS .............................................................................................................................. 22

CONTROLS DESCRIPTION .................................................................................................................. 22

USING ELECTRONIC CONTROL ........................................................................................................ 23

POWERING ON CONTROL ................................................................................................................ 23

ADJUSTING SET POINT ..................................................................................................................... 24

ENTERING MANUAL DEFROST MODE .......................................................................................... 24

ERROR CODE ...................................................................................................................................... 25

INITIAL START UP ............................................................................................................................... 26

PLACING PRODUCT IN CASE ............................................................................................................ 26

MAINTENANCE....................................................................................................................................................... 27

TOP LIGHT BULB REPLACEMENT ................................................................................................... 27

CLEANING CONDENSER COIL .......................................................................................................... 27

CLEANING INSTRUCTIONS ........................................................................................................................... 28-30

DAILY CLEANING ................................................................................................................................... 28

WEEKLY CLEANING .......................................................................................................................... 29-30

MISTER OPTION ..................................................................................................................................................... 31

SERVICE INFORMATION ..................................................................................................................................... 32

PRE-SERVICE CHECKLIST ................................................................................................................. 33

SPECIAL SERVICE SITUATIONS ....................................................................................................... 34

SALE & DISPOSAL ................................................................................................................................................. 35

REFRIGERATION & ELECTRICAL DATA ....................................................................................................... 35

REFRIGERATION OPERATION ..................................................................................................................... 36-37

REPLACEMENT PARTS - ...................................................................................................................................... 38

WIRING DRAWING ................................................................................................................................................ 39

OPTIONAL TOP CONDENSING UNIT INSTRUCTION .............................................................................. 40-47

LMD E3670

- 2 -

INTRODUCTION

Thank you for purchasing a Federal Industries display case. This manual contains important

instructions for installing and servicing the LMD Models. A repair parts list and wiring diagrams

are also included in the manual. Read all of these documents carefully before installing or

servicing your case.

NOTICE

Read this manual before installing your case. Keep this manual and refer to it before doing any

service on the equipment. Failure to do so could result in personal injury or damage to the case.

NOTICE

Installation and service of the electrical components in the case must be performed by a licensed

electrician.

The portions of this manual covering components contain technical instructions are intended only

for persons qualified to perform electrical work.

DANGER

Improper or faulty hookup of electrical components in the case can result in severe injury or death.

All electrical wiring hookups must be done in accordance with all applicable local, regional, or

national standards.

SERIAL NUMBER

Record the model and serial numbers of the case for easy reference. Always refer to both model and serial numbers

in your correspondence regarding the case.

Case Model__________________________ Serial Number______________________

Condensing Unit Model________________ Serial Number______________________

This manual cannot cover every installation, use, or service situation. If you need additional information, call or

write us:

TECHNICAL SERVICE DEPARTMENT

Federal Industries

215 Federal Ave/

Belleville, WI 53508

Toll Free (800) 356-4206 / WI Phone (608) 424-3331

LMD E3670

- 3 -

WARNING LABELS & SAFETY

INSTRUCTIONS

This is the safety-alert symbol. When you see this symbol on your case or

in the manual, be alert to the potential for personal injury or damage to

your equipment.

e sure you understand all safety messages and always follow recommended precautions and safe operating

B

procedures.

NOTICE TO EMPLOYERS

You must make sure that everyone who installs, uses, or services your case is thoroughly familiar with all

safety information and procedures.

Important safety information is presented in this section and throughout the manual. The

following signal words are used in the warning and safety messages:

DANGER: Severe injury or death will occur if you ignore the message.

WARNING: Severe injury or death can occur if you ignore the message.

CAUTION: Minor injury or damage to your case can occur if you ignore the message.

NOTICE: This is important installation, operation, or service information. If you ignore the message, you

may damage your case.

The warning and safety labels shown throughout this manual are placed on your Federal

ndustries case at the factory. Follow all warning label instructions. If any warning or safety

I

labels become lost or damaged, call our customer service department at 1(800) 356-4206 for

replacements.

CAUTION

RISK OF ELECTRIC

SHOCK DISCONNECT

POWER BEFORE

SERVICING UNIT.

91-12340

This label is located behind the removable kick This label is located below panel and under the display deck

pans. display deck pans.

LMD E3670

C AU T IO N

H A ZA R DO US M O V IN G P AR T S

D O N O T O P E RA T E U NIT W IT H

D IS PLA Y P AN S R EM O V ED .

- 4 -

PRE-INSTALLATION PROCEDURES

Inspection For Shipping Damage

You are responsible for filing all freight claims with the delivering truck line. Inspect all

cartons and crates for damage as soon as they arrive. If damage is noted to shipping

crates, cartons, or if a shortage is found, note this on the bill of lading (all copies) prior to

signing.

If damage is discovered when the case is uncrated, immediately call the delivering truck

line and follow-up the call with a written report indicating concealed damage to your

shipment. Ask for an immediate inspection of your concealed damaged item. Crating

material must be retained to show the inspector from the truck line.

INSTALLATION INSTRUCTIONS

Locating The Display Case

The case(s) should be located where it is not subjected to the direct rays of the sun, heating ducts,

grills, radiator, or ceiling fans, nor should it be located near open doors or main door entrances.

Also, avoid locations where there is excessive air movement or air disturbances and avoid high

humidity locations such as near cases with water misting or fogging devices. Failure to locate

this case as stated will reduce the performance of your display and will affect temperature of

interior of case and product.

If this case or cases are to be located against a wall there should be at least 6” between the case

and the wall to allow air circulation. Failure to give adequate space may cause exterior surfaces

to sweat.

LMD E3670

- 5 -

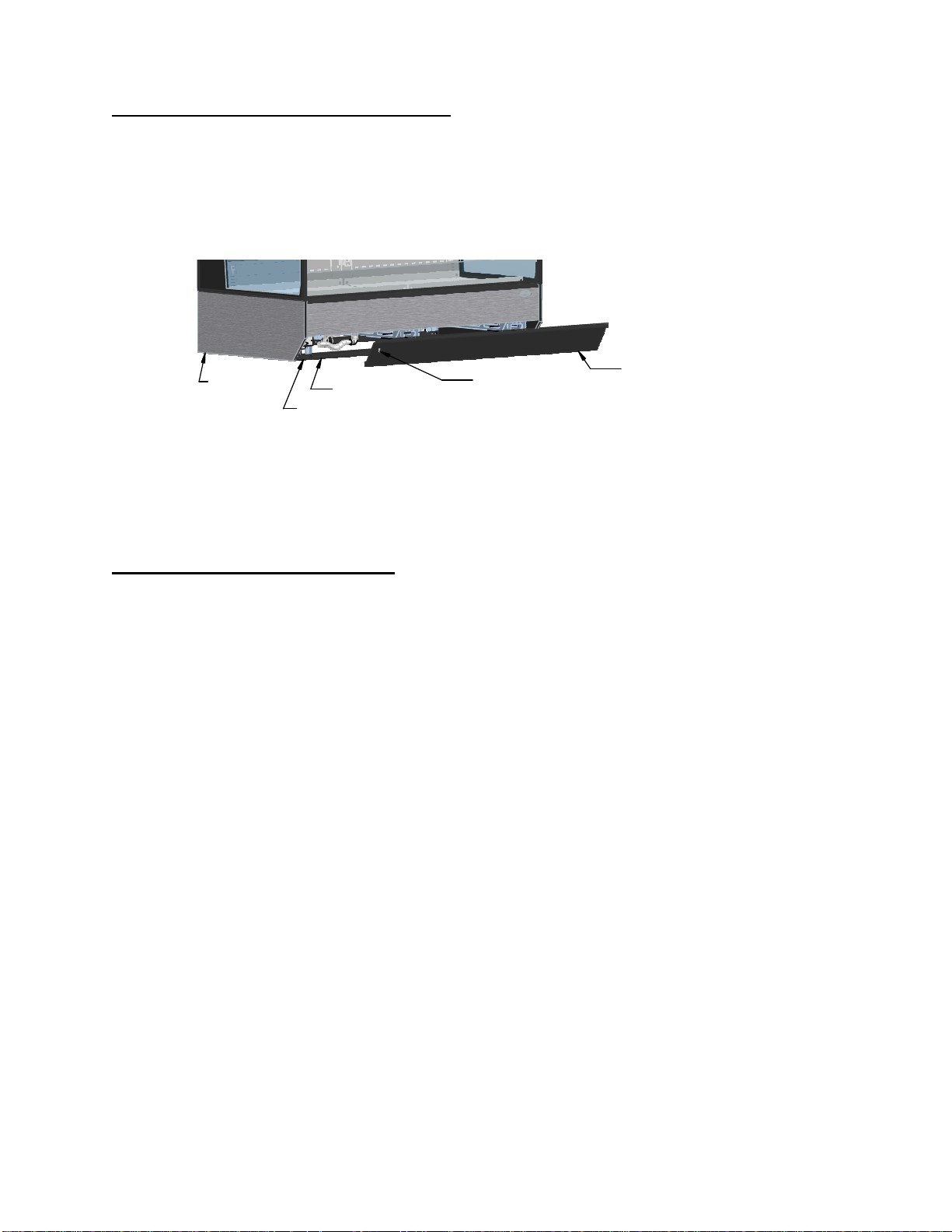

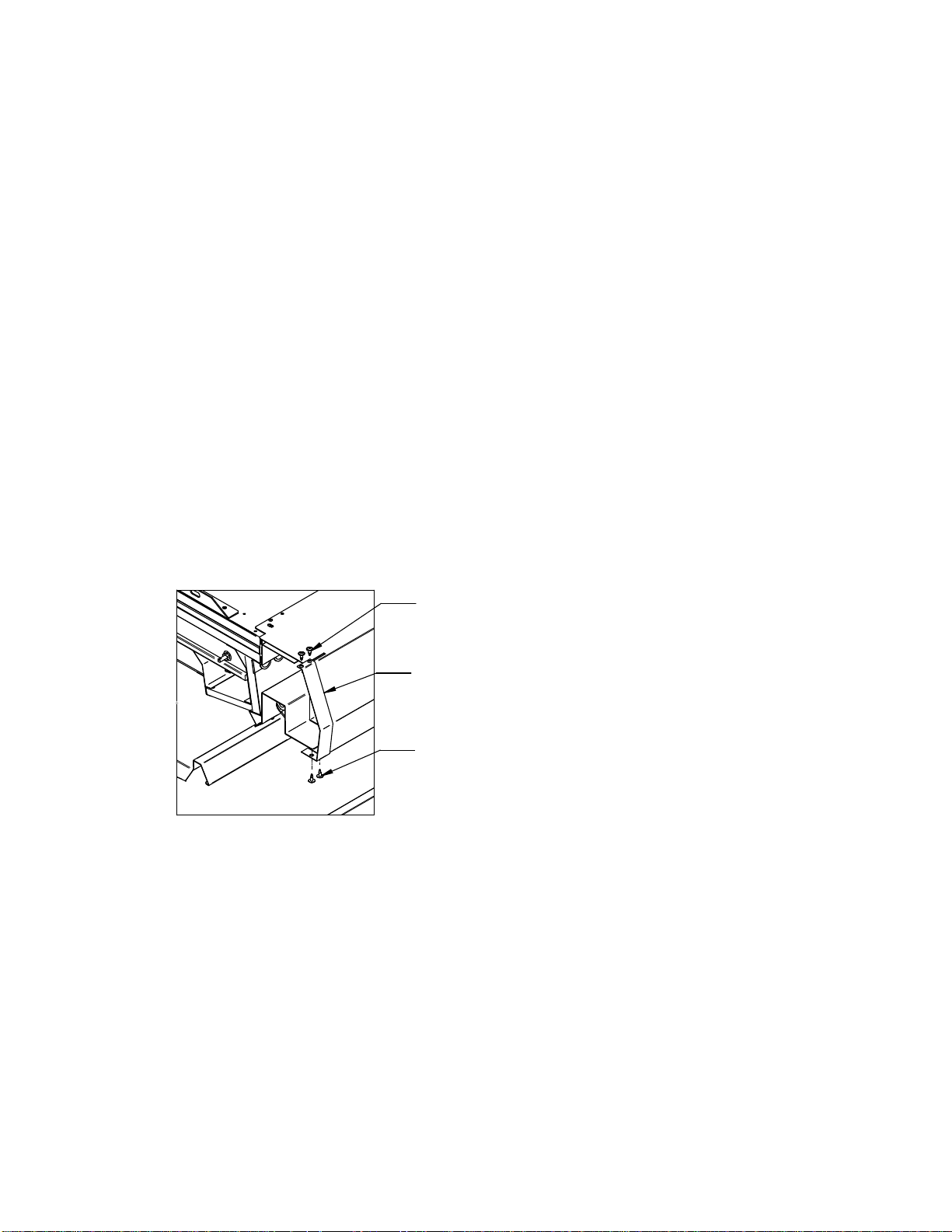

Removing Case From Shipping Skid

Remove the (8) 1/4” screws that secure the case to the skid. These screws are located in

the front and rear Base Rails. The (4) screws in the rear base rail are easily accessible

from the back of the case. In order to access the (4) screws in the front base rail the Front

Kick panel will need to be removed.

REAR

B

ASE RAIL

case has casters installed at factory to allow case to be moved to final location. There are

leg levelers on bottom of case, once case is off skid turn the leg levelers up to allow case

to roll on casters.

FRONT BASE RAIL

SKID MOUNTING SCREWS

(

4) 1/4" SCREWS THROUGH FRONT BASE RAIL

(4) 1/4" SCREWS THROUGH REAR BASE RAIL

Removing Packaging Material

Remove bubble wrap and packing material for all shelves and panel, brackets, etc. If it is

necessary to remove tape residue from plastic materials, use cleaning compounds

recommended in the cleaning section of this manual.

10-18 KICK

P

ANEL SCREWS

KICK PANEL

Note that the

LMD E3670

- 6 -

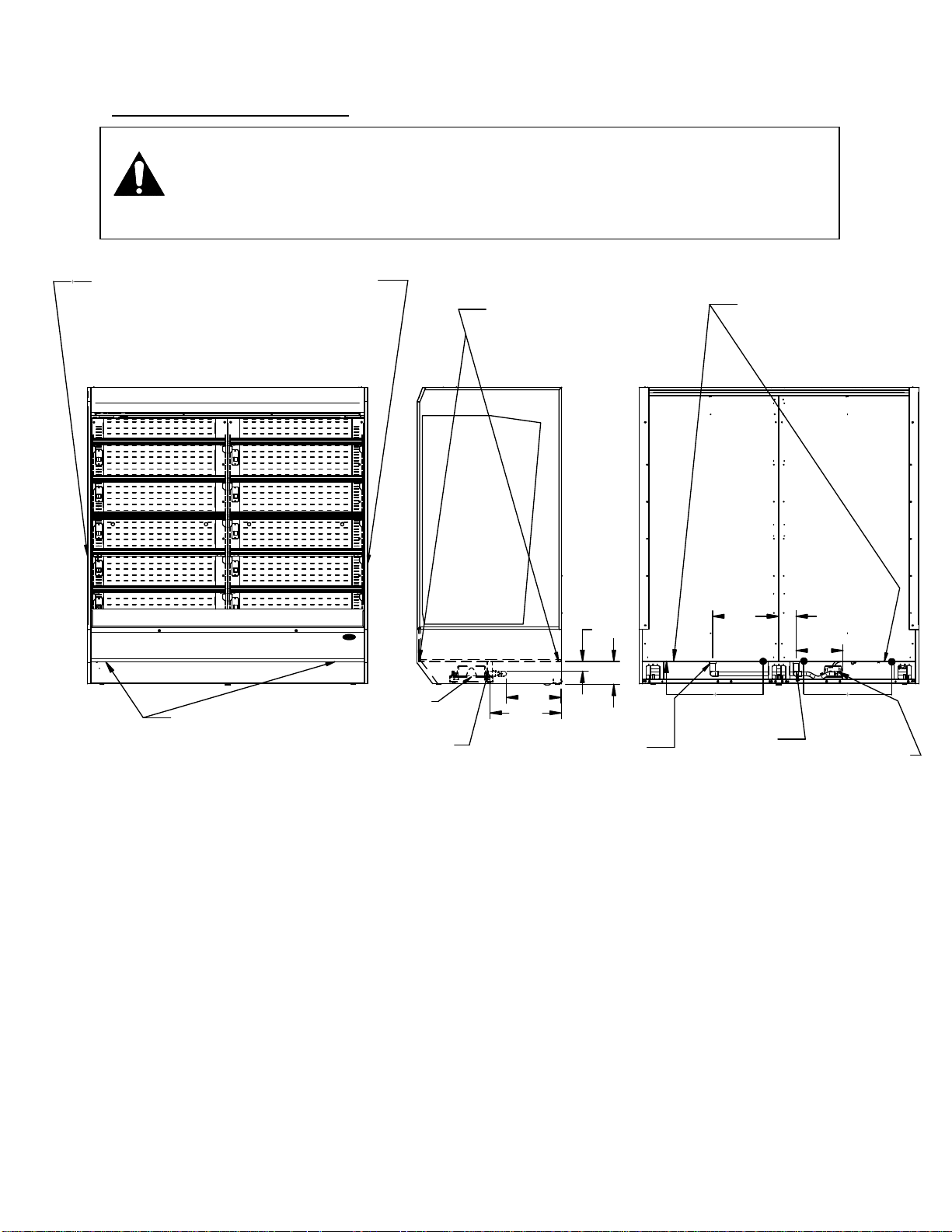

Lifting and Moving Case.

CAUTION: Do not push or pull against the clear acrylic deflector on front of

case. Doing so can cause the acrylic to break. Do not push or pull on side

glass or pull on base panel. Doing so will break glass or pull out panel

mounting screws. Care must be taken not to damage or tip the case when

removing it from the skid or moving the case.

IMPORTANT: NEVER PUSH OR PULL ON END GLASS.

DOING SO WILL BREAK GLASS OR STRIP END PANEL

SCREWS AND TEAR END PANEL FROM CASE.

IMPORTANT: NEVER PULL ON END PANEL.

DOING SO WILL STRIP END PANEL SCREWS AND

TEAR END PANEL FROM CASE.

IF MANUAL LIFTING,PUSHING

OR PULLIN REQUIRED.

GRAB UNDER FRONT AND REAR

LIP ON FRONT AND BACK OF CASE.

IF MANUAL LIFTING,PUSHING

OR PULLIN REQUIRED.

GRAB UNDER FRONT AND REAR

LIP ON FRONT AND BACK OF CASE.

2.6

23.5

6

OPTIONAL

IF MANUAL LIFTING,PUSHING

OR PULLIN REQUIRED.

GRAB UNDER FRONT AND REAR

LIP ON FRONT AND BACK OF CASE.

ON FRONT OF CASE IT MAY BE EASIER

TO REMOVE FRONT KICK PLATE.

-Care must be taken when lifting and moving cases from skid as well as moving case into positon.

CONDO

PUMP.

CONDENSATE

DRAIN

14.4

18.8

ADDITIONAL CONDENSATE

DRAIN ON 96" UNIT ONLY

REAR FORK

LIFT AREA

CONDENSATE

DRAIN, ALL

-The case should be lifted off of skid using a fork lift. The case must be lifted from rear in location noted

in picture above. Be sure case is balanced equally on forks. When sliding forks under case someone

must be watching that forks do not hit and damage refrigeration lines, drain or optional. condensate

pump.

-To prevent injury, it is not recommended to attempt lifting case manually. When lifting, pulling or

pushing is required grab under front and back lip of case.

-Case is supplied with casters and once case is off of skid and on floor it should move easily into

position. Light pushing on lower part of end near the base is fine. NEVER PUSH OR PULL ON

GLASS. DOING SO CAN BREAK GLASS. NEVER PULL ON END PANEL OR GLASS. Doing so

will strip end panel screws and tear end from case.

4.5 4' & 6'

1

6.5 9'

12.4

REAR FORK

LIFT AREA

OPTIONAL CONDO

P

UMP.

LMD E3670

- 7 -

Single Case Installation

Leveling The Case

It is important that the cases are level. This will allow for proper drainage of condensate water

from evaporator coil. Once the case is rolled to final location the case must be level for proper

drainage of defrost water to the condensate pump. A wrench is included to aid in adjusting leg

levelers

Check the level of the case along front of acrylic air deflector.

Adjust the (4) outside leg levelers as needed to level the case in each direction.

The LMD72 &LMD96 have (2) center leg levelers adjust these so that the center of base floor is

flat.

NOTE: If necessary use a wood or plastic shim under each leg leveler to avoid scratching the

tile floor.

Sealing Unit to The Floor

After the unit is positioned and the leg levelers are turned out, the unit needs to be sealed to the

loor for NSF approved installation.

f

LMD E3670

- 8 -

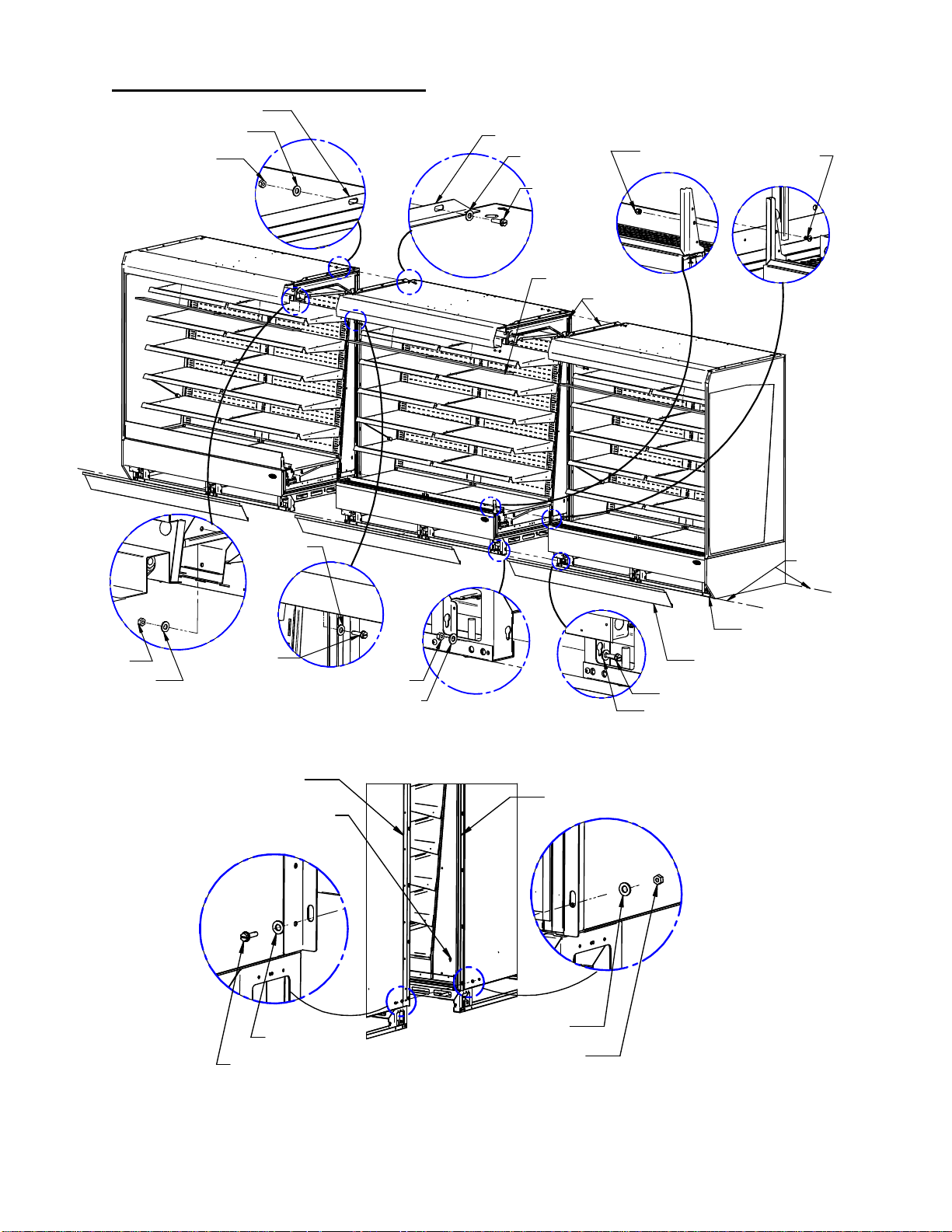

Multiple Case Lineup Installation

JOINING RAIL TOP

WASHER,1/4-20

NUT,1/4-20

LEFT CASE

WASHER,1/4

TOP JOINING RAIL

D

CENTER CASE

JOINING RAIL TOP

WASHER,1/4

BOLT,1/4-20

AIR DIFFUSER

ACORN

NUT,10-32

END GASKETS

RIGHT CASE

AIR DEFLECTOR

SCREW,10-32

C

CHALK

LINES

NUT,1/4-20

LMD E3670

BOLT,1/4-20

B

TOP SUPPORT

JOIN RAIL REAR

ALTERNATE REAR

ATTACHMENT POINT

WASHER,1/4

SCREW,14/20

NUT,1/4-20WASHER,1/4

WASHER,1/4

E

BASE RAIL

WASHER,1/4

NUT,1/4-20

A

JOIN RAIL REAR

LEG

LEVELERS

KICK PLATE

BOLT,1/4-20

WASHER,1/4

- 9 -

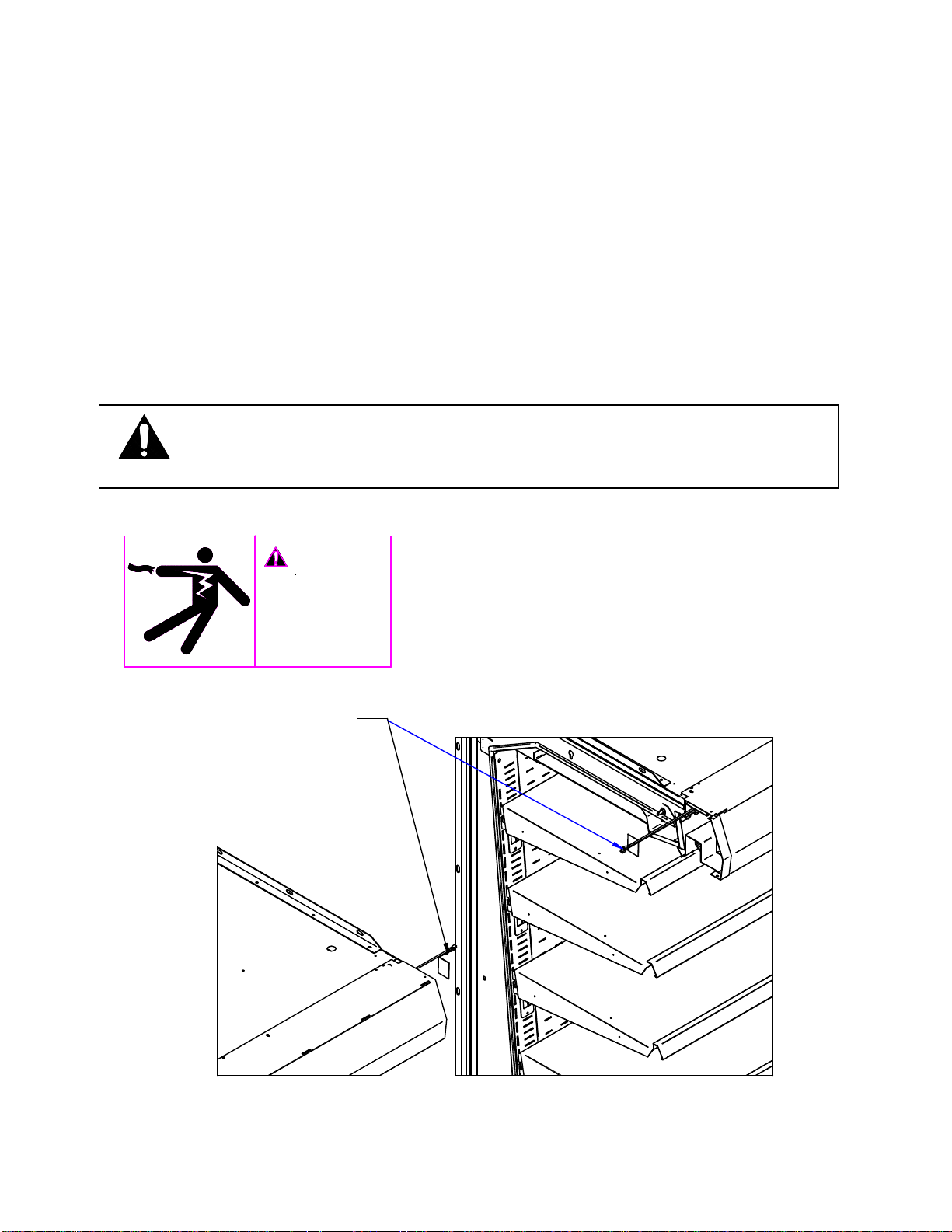

owered from the case that does have the control. When servicing

T

wo Cases Connected to Single Remote Condenser

If (2) cases are ordered from factory to run on a single condensing unit, there is only one

control that will operate both units.

The cases are prewired to connect both refrigeration solenoids together. These Wires are

hanging out from joining side of each case near the top front behind canopy.

Once all prep work is complete and both cases are ready to be joined, connect the wires from

each case together. Connect the yellow wire from case 1 to yellow wire to from case 2 and

connect the white wire from case 1 to white wire from case 2.

Once connected join cases as described below. Be careful not to pinch the wires between

cases.

CAUTION: The refrigeration solenoid on the case that does not have a control is

p

cases disconnect power from both cases to prevent electrical shock.

DANGER

HIGH VOLTAGE.

Turn power off

before servicing.

May have more than

one disconnect

switch.

"IMPORTANT"

BEFORE INSTALLING CASES TOGETHER

CONNECT YELLOW WIRE FROM CASE 1

TO YELLOW WIRE FROM CASE 2.

CONNECT WHITE WIRE FROM CASE 1

TO WHITE WIRE FROM CASE 2.

WHEN PLACING CASES TOGETHER DO

NOT PINCH WIRES BETWEEN CASES.

LMD E3670

- 10 -

Floor Preparation

Be sure the floor where the case line up will be located is strong enough to support cases

w

ithout sagging.

It is important that the cases are level. This will allow for proper drainage of condensate

water from evaporator coil and allow for proper alignment of cases.

Most floors are not level and the high and low spots in location of cases must be determined.

Place a chalk line in the desired position of where the back of the cases will be located. If the

back of the cases are to be along a wall there should be at least 6” clearance between wall

and the back of the cases.

Measure 33.25” from this chalk line to where the front of cases will be. This line is where the

front base rail meets the floor not the actual front of the case.

Mark the location along these lines that the outside edges of case will be. The cases without

end panels will be 48”,72”, or 96” depending on cases ordered. Add additional 1” to case end

that has an end panel.

Use a transit or line level to determine the highest point along chalk line.

Joining and Leveling Line Up

If case line up is along a wall it will make it difficult to gain access to back of case once line

p is complete. If it all possible make all connections accessible from front under side of

u

cases, but if necessary make any required connections at back of case as you install the cases.

-There are factory installed gaskets located on each end of all adjoining cases. Inspect all

gaskets to be sure they are properly located and not damaged.

-Remove the front kick plates from all cases as described Panel Removal section of this

manual.

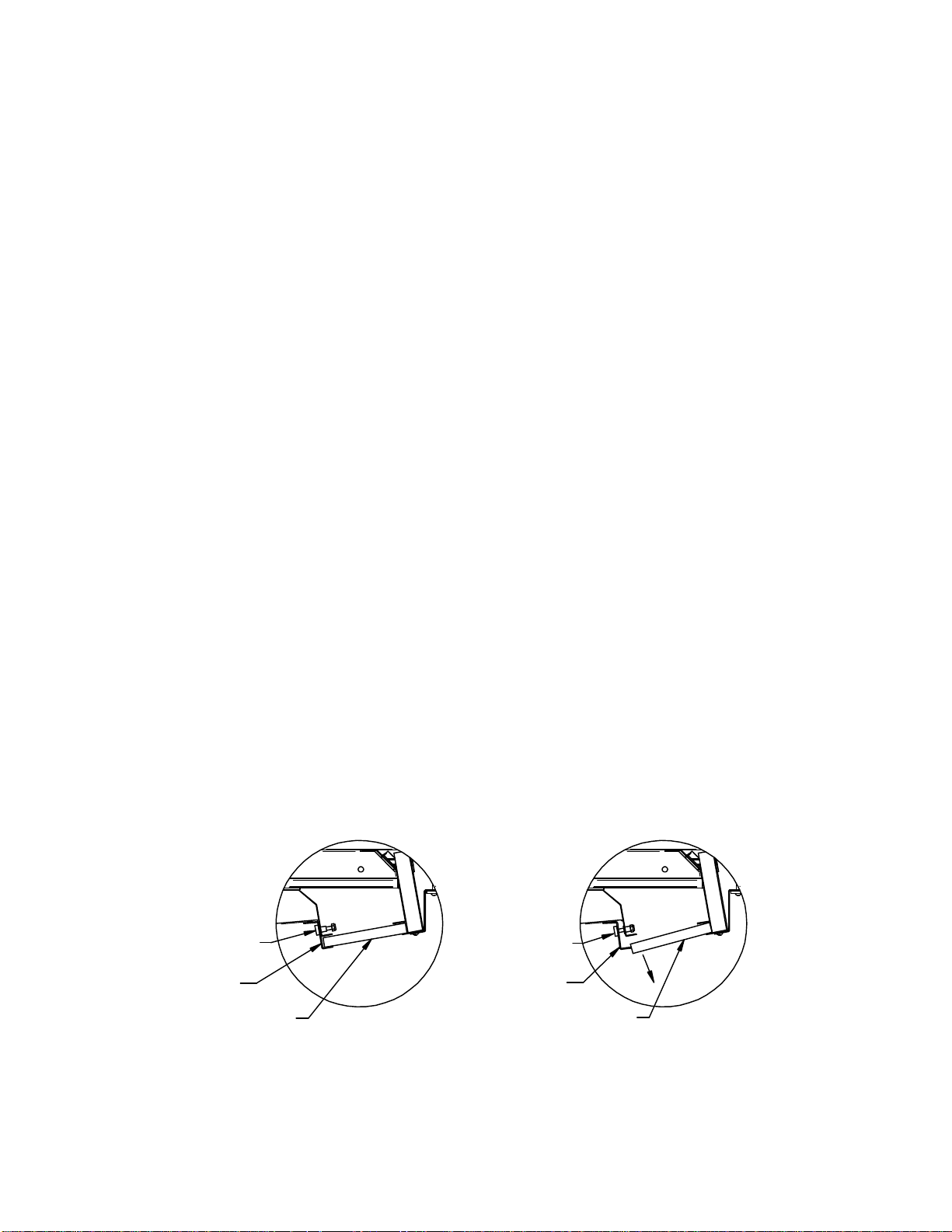

-Remove all Top Air Diffuser from all cases from upper air duct track. Loosen thumb screws

on Retainers located behind air diffuser. Retainer will drop down allowing diffuser to be

pulled out of case.

THUMB SCREW

RETAINER

AIR DIFFUSER

THUMB SCREW

RETAINER

AIR DIFFUSER

LMD E3670

- 11 -

-The required fasteners to join cases are installed at the factory in the location they will be

u

sed. These fasteners are on the left side of each case. As each case is installed remove these

fasteners from the case and reuse them.

-Determining highest point as described in Floor Preparation above. Install the case that will

be located over the highest point first. Once the first case is rolled to final location the case

must be level for proper drainage of defrost water to the condensate pump. A wrench is

included to aid in adjusting leg levelers Check the level of the case along the ledge in front of

acrylic air deflector. Adjust the (4) outside leg levelers as needed to level the case in each

direction. The LMD72 &LMD96 have (2) center leg levelers adjust these so that the center of

base floor is flat. If necessary use a wood or plastic shim under each leg leveler to avoid

scratching the tile floor

-Place the next adjoining case into line up. Level case until case end profiles are aligned and

ouching. Install fasteners in the order below as designated with corresponding letter in

t

detailed diagram. As cases are joined additional leg leveler adjustments may be necessary.

A) Align the front of the base rail and fasten through hole in base rail using ¼-20 bolt and ¼-20

nut, use a ¼ washer against each base support as shown in diagram.

B) Align the top front of case and fasten through hole in top support using ¼-20 bolt and ¼-20

nut, use a ¼ washer against each top support as shown in diagram. If necessary the top

valance can be adjusted to provide better alignment. Loosen the fasteners along the top of the

valance located on top of case and adjust as needed. If a perfect alignment cannot be

achieved Valance Joining strap can be used only if needed. Place strap over seam and attach

with self-drilling screws provided.

SELF-DRILLING

SCREWS

VALANCE JOINING

STRAP

SELF-DRILLING

SCREWS

C) Align the holes in the air deflector supports and join with 10-32 screw and 10/32 acorn nut.

D) Align slots in top joining rail and join using ¼-20 bolt and ¼-20 nut, use a ¼ washer against

each top joining rail as shown in diagram.

E) Align slots in rear joining rail and join using ¼-20 bolt and ¼-20 nut, use a ¼ washer against

each rear joining rail as shown in diagram. Alternate rear attachment point shown in diagram

is used if it is not possible to get to back of case. Using this attachment point requires

removing all shelving and slotted back panel from both cases to gain access. See appropriate

section of this manual for shelf and slotted back panel removal.

Repeat for all additional cases in line up. Once all cases are attached continue with electrical,

refrigeration and drain connections as described in appropriate section of this manual.

Reinstall Kick Panels and air diffusers as described in appropriate section of this manual.

LMD E3670

- 12 -

Sealing all Unit to The Floor

After the unit is positioned and the leg levelers are turned out, the unit needs to be sealed to the

f

loor for NSF approved installation.

Electrical Connection

DANGER: Improper or faulty hookup of electrical components in the

display case can result in severe injury or death.

Permanent Connected (Standard)

-Only a licensed electrician must perform all case electrical connections.

-All electrical wiring hookups must be done in accordance with all applicable local, regional, or

national electrical standards.

-A separate circuit for each display case is required to prevent other appliances on the same

circuit from overloading the circuit and causing malfunction.

-The electrical service must be grounded upon installation.

-See the electrical data plate located on the inside back wall of display case, for proper circuit

size and wire ampacity.

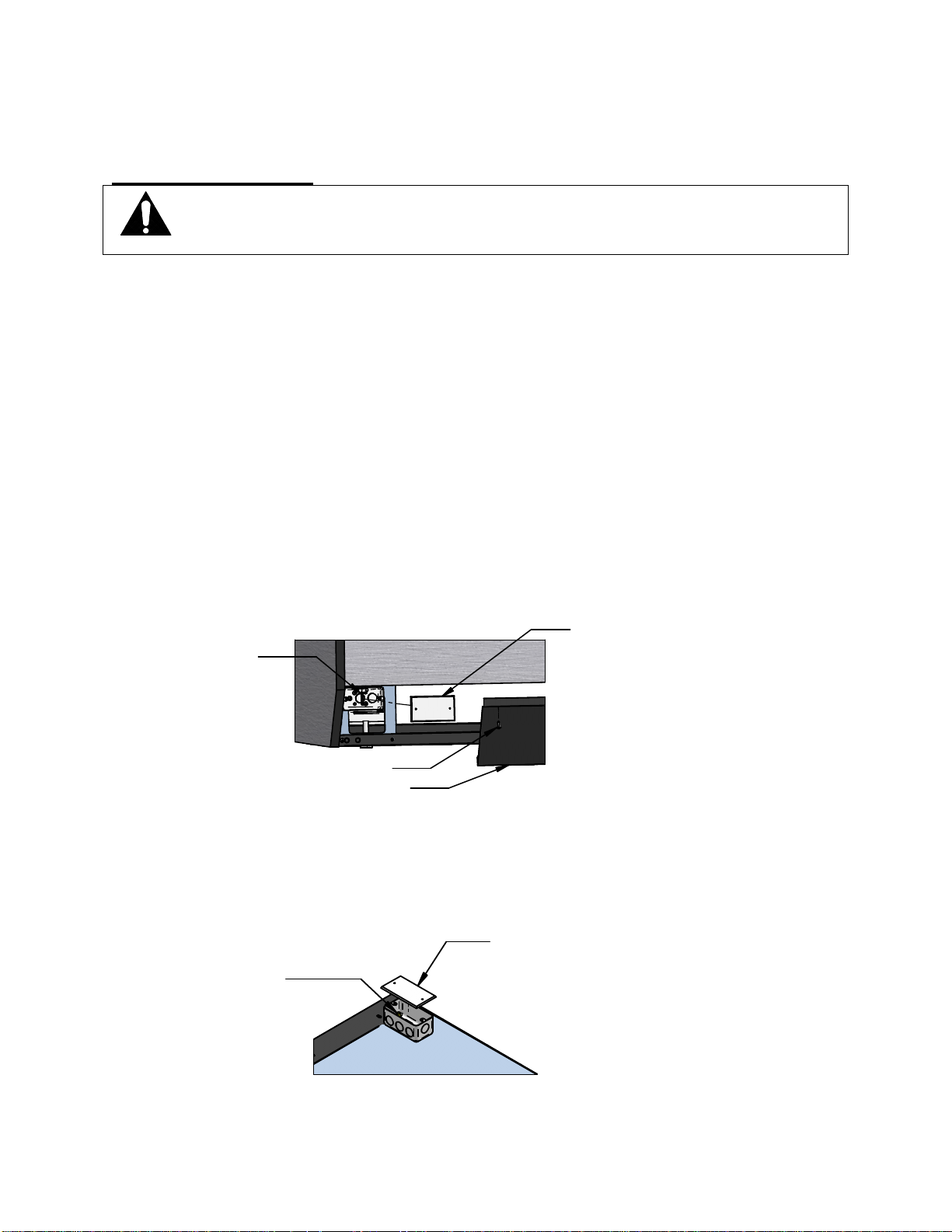

Standard Bottom Base Electrical Connection: Use this electrical connection when

power source is from floor or wall outlet. The electrical connection box is on the bottom left side

of case behind the bottom Front Kick Panel. The box is accessible by removing the Front Kick

Panel. (See “Panel Removal Section” of this manual for panel removal instructions). Remove

electrical box cover to access electrical connection.

PERMANENT

PERMANENT

CONNECTION

ELECTRICAL BOX

CONNECTION

ELECTRICAL

BOX COVER

WIRE CONNECTION

FRONT KICK PANEL SCREW

FRONT KICK PANEL

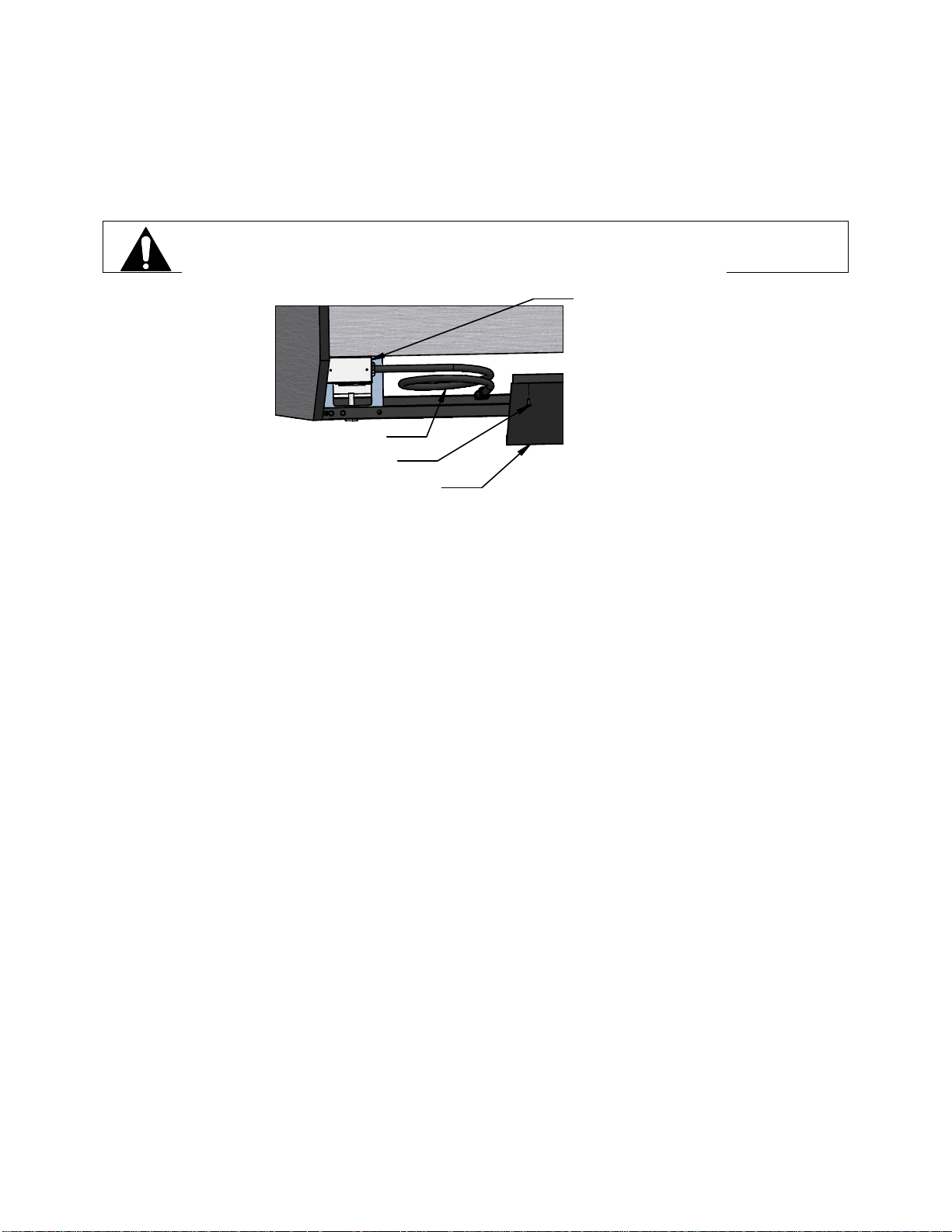

Top Electrical Connection (OPTION): Use this optional factory installed electrical

connection when power source is from the ceiling. If equipped with this option the connection

box is located on the top back left corner of case. Remove electrical box cover to access

electrical connection.

PERMANENT

CONNECTION

PERMANENT

CONNECTION

OPTIONAL TOP

OPTIONAL

TOP ELECTRICAL

BOX COVER

ELECTRICAL BOX

WIRE CONNECTION

LMD E3670

- 13 -

Cord Connected (OPTION)

-A factory installed optional power cord is properly sized to the amperage requirements of the

c

ase. See the electrical data plate located on the rear exterior of the case for the proper circuit

size for each case.

- The cord is can be factory installed from either the bottom base electrical box or the optional

top electrical box. A separate circuit for each display case is required to prevent other appliances

on the same circuit from overloading the circuit and causing malfunction.

CAUTION Risk of Electric Shock. If the cord or plug becomes damaged,

replace only with a cord and plug of the same type".

ELECTRICAL

CONNECTION

COX

OPTIONAL POWER CORD

KICK PANEL SCREW

KICK PANEL

LMD E3670

- 14 -

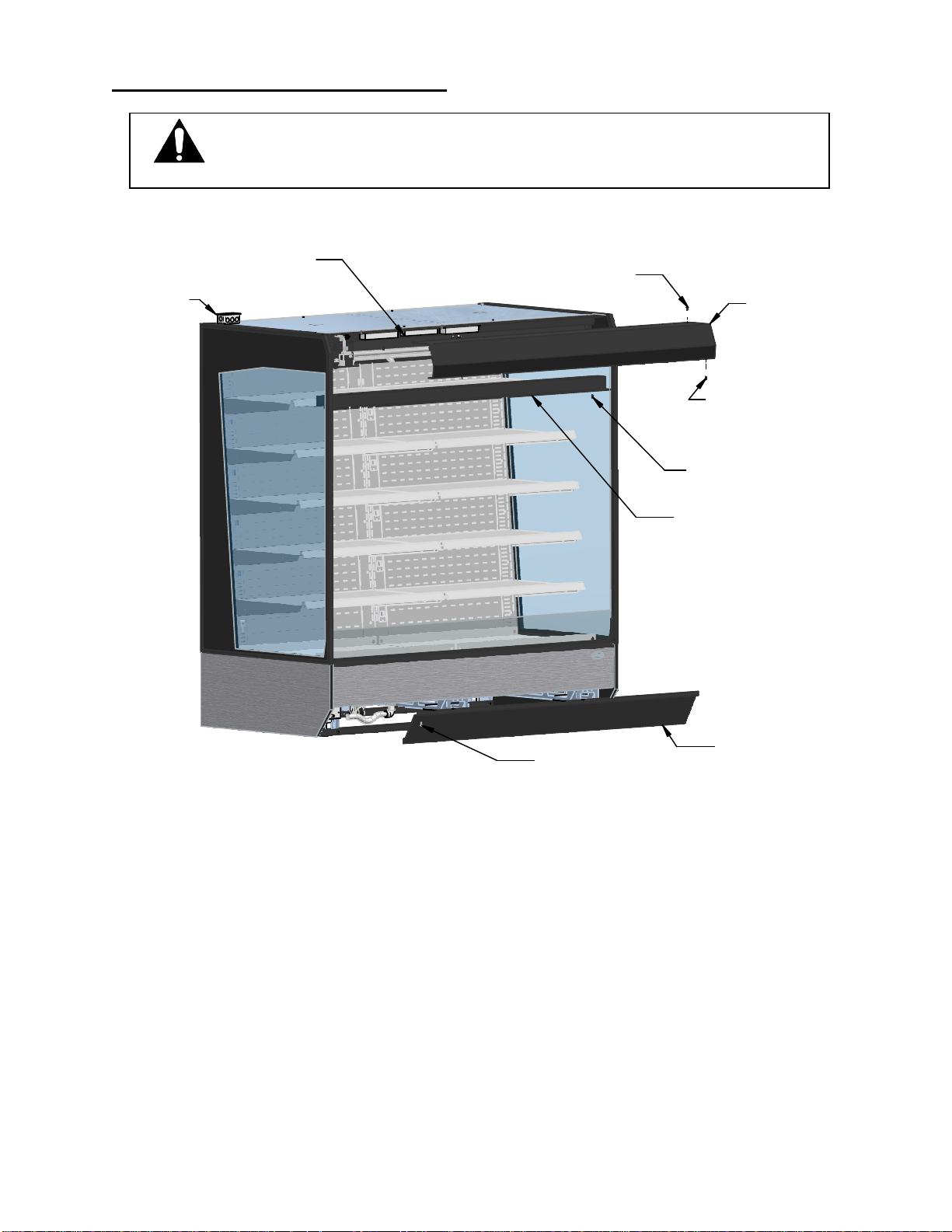

Panel Removal for Electrical Access

DANGER: Electric shock hazard. Do not operate unit with panels removed.

Panels must be in place when operating the case.

POWER SUPPLY

&

BALLAST LOCATION

OPTIONAL TOP

E

LECTRICAL

CONNECTION

10-32 TOP VALNCE SCREWS

TOP VALANCE

8-32 TOP VALNCE &

N

IGHT CURTAIN

HOUSING SCREWS

8-32 NIGHT CURTAIN

H

OUSING SCREWS

NIGHT CURTAIN

H

OUSING

10-18 KICK

KICK PANEL

P

ANEL SCREWS

Kick Panels

The kick panel located at the front base of unit can be removed to access electrical connection,

condensate drain trap

and hose, leg levelers and casters.

1. Loosen the 3 to 5 10-18 Kick Panel screws located under the front lip of Kick Panel.

2. Tilt the top of the Kick Panel away from the base. The bottom of Kick panel is

setting on top of a frame rail and once screws are removed the Kick Panel will drop

down and out of case

3. Set the Kick Panel and screws in safe place to prevent damage.

4. Reinstall Kick Panel in the reverse order.

LMD E3670

- 15 -

Loading...

Loading...