Federal TM9-821 Operator Manual

TM

9-821

WAR

DEPARTMENT

TECHNICAL

.*

2^-TON

4x2

(FEDERAL)

OCTOBER

9

MANUAL

TRUCK

1943

H

it

TM

9-821

TECHNICAL

TM

PART

SECTION

VII

MANUAL

9-821

2

1

2

-TON

)

/

ONE-VEHICLE

I

Introduction

II

Description

III

IV

V

VI

Driving

Operation

First

Lubrication

Tools

echelon

tenance

and

the

vehicle

controls

4x2

(FEDERAL)

CONTENTS

OPERATING

.................

and

tabulated

and

operation....

under

unusual

preventive

service

equipment

.............

.............

..................

Washington,

TRUCK

data...

conditions

main

..I..

stowage

WAR

DEPARTMENT

9

October 1943

INSTRUCTIONS

Paragraphs

1

2-4

5-10

11-13

14-18

19-20

on

21-22

25-34

35-44

45-46

Pages

3-6

7-10

11-17

18-24

PART

XVIII

TWO-VEHICLE

VIII

XIII

XIV

XVI

XVII

XIX

IX

X

XI

XII

XV

Maintenance

Second

tenance

Organization

Trouble

Engine

tenance,

vehicle

Engine

Clutch

Fuel

system

Intake

Cooling

Ignition

Starting

MAINTENANCE

allocation

echelon

shooting

description,

removal

........................

and

system

system

and

preventive

...................

tools

and

....................

and

....................

exhaust

.................

.................

generating

.........

and

equipment.

..............

data,

adjustment

installation.

systems.......

systems...

1

INSTRUCTIONS

23-24

main

27-46

main

in

47-59

.

60-61

62-65

66-73

74-76 121-124

77-82

83-91

92-96

25

26

47-54

55-72

73

74-88

89-100

101-103

104-110

111-120

125-137

138-152

153-158

9-821

TM

SECTION

XX

XXI

XXII

XXIII

XXIV

XXV

XXVI

XXVII

XXVIII

XXIX

XXX

XXXI

XXXII

XXXIII

REFERENCES

INDEX

.......

2'/i-TON

Transmission

Propeller

axle

Front

axle

Rear

Brake

Wheels,

Springs

system

hubs,

and

Steering

and

Body

Hoist

Battery

........................

and

Instruments,

Power

take-off

Shipment

.

4x2

TRUCK

.................

................

shaft

....................

.....................

.................

wheel

and

absorbers

shock

.................

gear

frame

...............

lighting

gages,

................

temporary

and

system

and

(FEDERAL)

bearings

.....

....

switches.

storage

.

Paragraphs

97-99

100-102

103-112

113-117

118-135

136-143

144-152

153-160

161-172

173-178

179-187

188-199

200-204

205-207

Pages

159-162

163-165

166-172

173-176

177-198

199-209

210-215

216-219

220-225

226-235

236-246

247-252

253-254

255-259

260-261

262

TM

9-821

1

PART

Scope

1.

guidance

..............................................

SCOPE.

This

a.

of

maintenance,

addition

In

h.

manual

this

cation,

parts.

use,

Part

instructions.

vehicle

the

maintenance

responsibility

all

In

c.

adjustment

ordnance

suitable

service

tools

issued.

provide

*To

published

corrected

be

operating

in

ONE-VEHICLE

INTRODUCTION

using

minor

to

care of

section

Two,

manual*

arms

repair

description

a

technical

the

I

section

technical

the

and

contains

and

One,

Part

instructions

doing

of

where

cases

scope

beyond

is

and

advance

changes

by

the

should

be

equipment

instructions

complete

of

if

or,

OPERATING

Section

published

is

personnel

of

information

materiel.

through

section

VIII

to

maintenance

nature

the

facilities

or

informed

be

may

the

with

technical

extensive,

I

charged

materiel.

this

Vz-ton

2

of

manual

The

VII,

through

arms personnel

using

work within

the

of

that

so

provided,

materiel,

review. Any

early

an

by

INSTRUCTIONS

information

the

for

with

truck

4x2

required

gives

for

divided into

is

vehicle

section

their

modifications,

unit,

of

repair,

the

trained

proper

or

technical

this

errors

revision.

Paragraph

operation,

the

(Federal)

identifi

the

operating

XXXIII,

charged

jurisdiction.

responsible

the

personnel

instructions

manual

or omissions

has

1

and

two

gives

with

or

with

been

will

to

00

>

m

70

m

D

K

o

3

"^i

300051

PD

RA

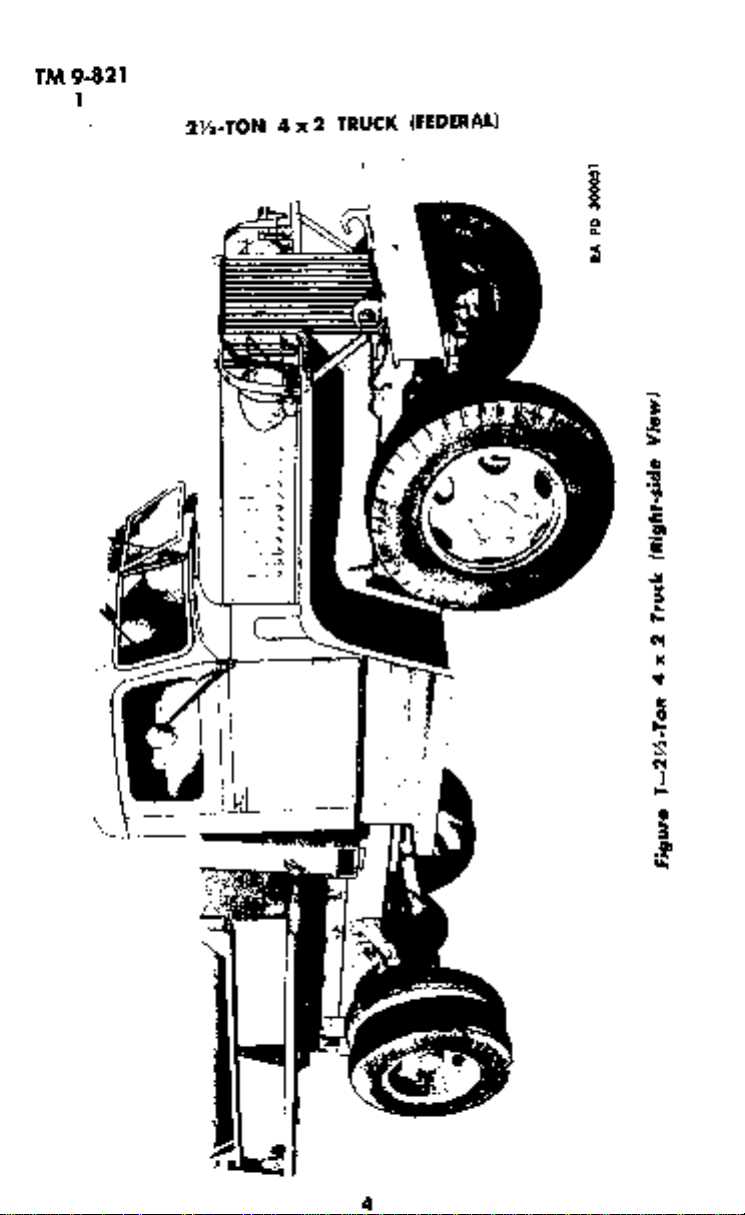

View)

(Right-side

Truck

4x2

-Ton

2

I-2'/

Figure

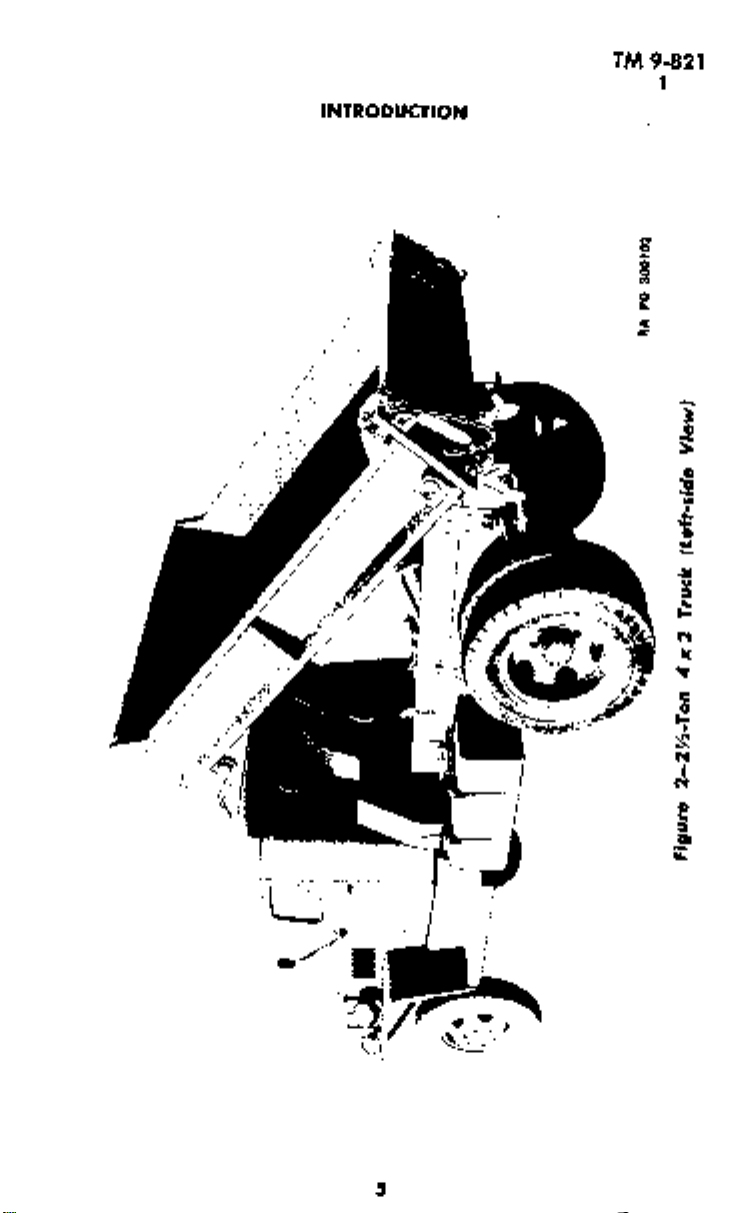

INTRODUCTION

TM

9-821

I

§

S

I

TM

9-821

1

Figure

2'.-TON

3—2

V*

4X2

-Ton

TRUCK

4x2

(FEDERAL)

Truck

RA

(Front

300103

PD

View;

Figure

2'A-Jon

4—

4x2

6

Truck

(Rear

RA

PD

300104

TM

9-821

2-3

DESCRIPTION

Description

Differences

...............................................

Data

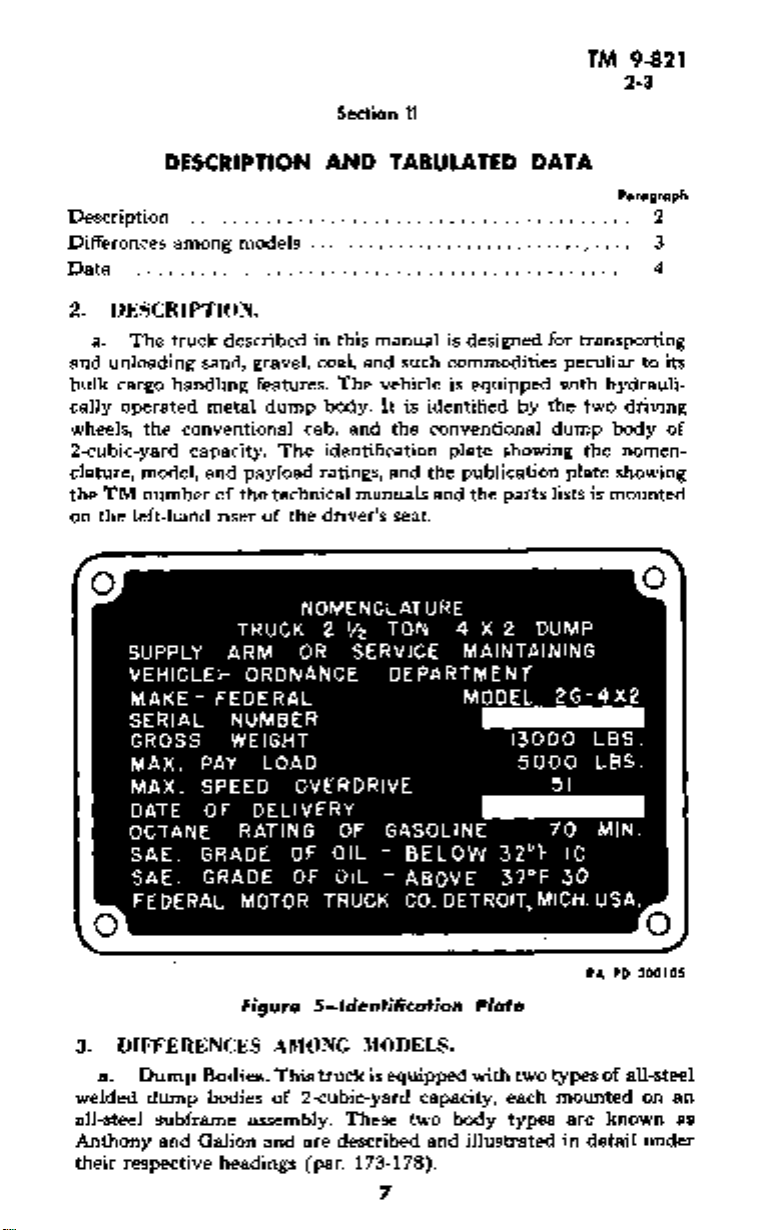

DESCRIPTION.

2.

The

a.

unloading

and

cargo

bulk

operated

cally

wheels,

2-cubic-yard

clature,

TM

the

the

on

SUPPLY

.........................................

among

described

truck

sand,

handling

metal

conventional

the

capacity.

model,

number

left-hand

and

of

riser of

ARM

VEHICLE^-

MAKE-

SERIAL

GROSS

MAX.

MAX.

DATE

OCTANE

SAE.

SAE.

FEDERAL

FEDERAL

NUMBER

WEIGHT

PAY

SPEED

OF

GRADE

GRADE

Section

AND

models

payload

the

TRUCK

.................................

this

in

gravel,

features.

coal,

The

body.

dump

and.

cab,

identification

The

ratings,

technical

the driver's

NOMENCLATURE

Vz

2

SERVICE

OR

manual

and

vehicle

It

manuals

ORDNANCE

LOAD

OVERDRIVE

DELIVERY

OIL

OF

OIL

OF

TRUCK

OF

RATING

MOTOR

II

TABULATED

designed

is

commodities

such

equipped

is

identified

is

conventional

the

plate

publication

the

and

the

and

seat.

TON

4X2

DATA

for

the

by

showing

parts

DUMP

MAINTAINING

DEPARTMENT

MODEL

13000

5000

_

GASOLINE

BELOW

ABOVE

-

CO.

32°F

32°F

DETROIT,

MICH.

Paragraph

transporting

peculiar

hydrauli-

with

driving

two

body

dump

nomen

the

showing

plate

mounted

is

lists

2G~4X2

LBS.

LBS.

51

MIN.

70

10

30

USA.

r

to

2

3

4

its

of

o

DIFFERENCES

3.

Dump

a.

welded

all-steel

Anthony

their

dump

subframe

and

respective

Figure

Bodies.

bodies

assembly.

Galion

headings

S—Identification

AMONG

truck

This

2-cubic-yard

of

These

described

are

and

(par.

MODELS.

equipped

is

capacity,

two

and

173-178).

Plots

with

each

types

body

illustrated

two

RA

of

types

mounted

are

detail

in

300105

PD

all-steel

on

known

under

an

as

TM

9-821

3-4

(1)

means

is

obtained

subframe.

(2)

by

means

on

a cross

4.

DATA.

a.

Vehicle

Nominal

Length,

Width,

Height,

Wheel

Tire

Tire

Tread

Crew

Weight

Weight

Ground

Ground

Ground

Pintle

Kind

b.

First

Second

Third

Fourth

Fifth

Reverse

Maximum

Approach

Departure

Minimum

Fording

Towing

Maximum

ANTHONY

of

two

forged

by

two large

GALION

of

two

bar

fitted

2>/i-TON

BODY.

BODY.

heavy

in

4x2

This

sections

hinge

This

hinge

the

subframe.

type

Specifications.

wheel

base

.................................

over-all

over-all

over-all

size

size

....................................

type

(center

...................................217

.......................................

.......................dump

.......................................

.........................................

to

center)

...............................................

of

vehicle empty

of

vehicle-loaded

pressure

contact

clearance

height

of

fuel

Performance.

speed

speed

speed

speed

speed

speed

governed

angle

angle

turning

depth

facilities

draw-bar

.....................................

......................................

.....................................

.........................................31

......................................

..........................................

......................................

........................................

direct

overdrive................................

.................................

.......................................

speed

................................61Va

................................

radius

........................................

(front)

(rear)

pull

TRUCK

type

of

welded

pins

of

brackets

body

to

fitted

body

that

the

(FEDERAL)

is

attached

body

at

the

is

attached

bolt

to

dump

........................front,

...........................

..........................

...........................

(left)

..........................

(right)

..........................

..........................Pintle

(direct

........................25ft

drive)..................

8

to

frame.

rear

to

body

body

body

8.25

subframe

Pivot

corners

the

subframe

side

and

up,

down,

20 x 7 in.

in.

Highway

rear,

12,975

70

.45

Tow

action

of

pivot

151

s

/s

90

120

89

x 20

63%

eS'^ie

2

men

7,251

57

228

10

octane

6

mph

12

mph

23

mph

41

mph

51

mph

6

mph

51

mph

degrees

degrees

25

.24

hooks

hook

875

by

the

in.

in.

in.

in.

in.

in.

in.

in.

Ib

Ib

psi

si

in.

in.

ft

in.

Ib

DESCRIPTION

ABCDEFDGHJKLMNOP

AND

TABULATED

DATA

TM

9-821

4

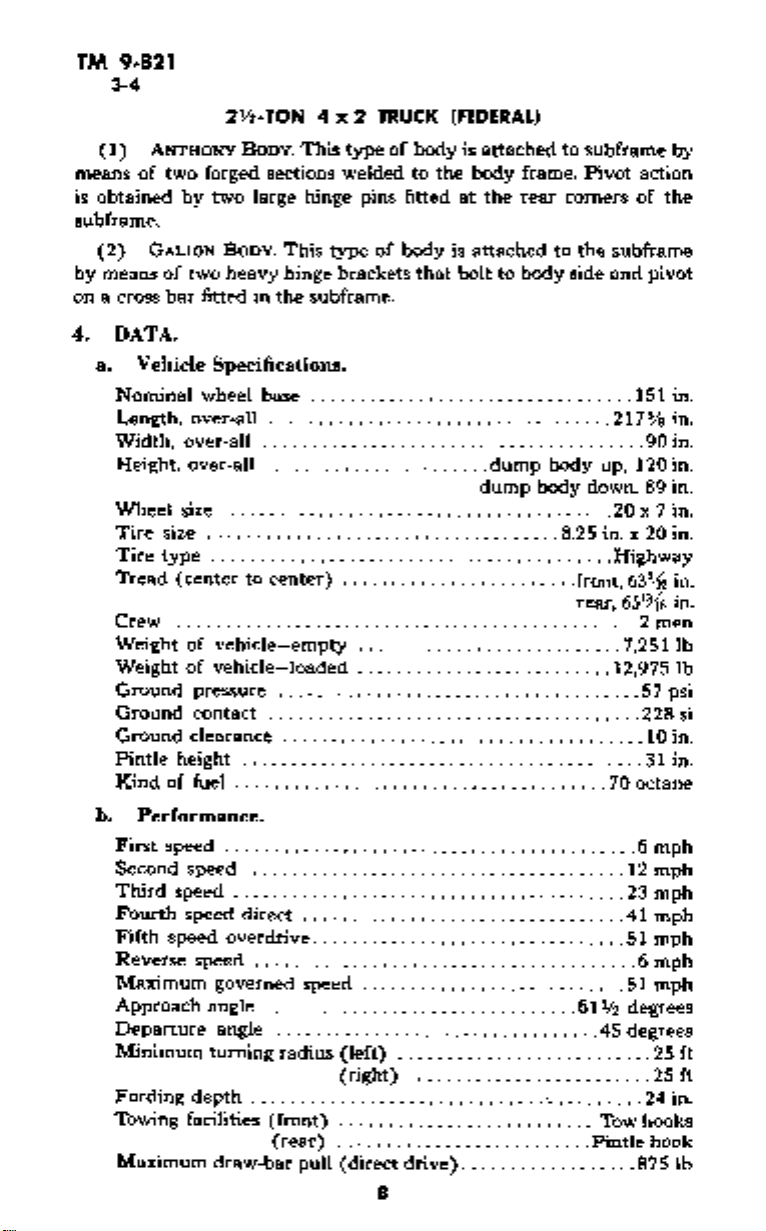

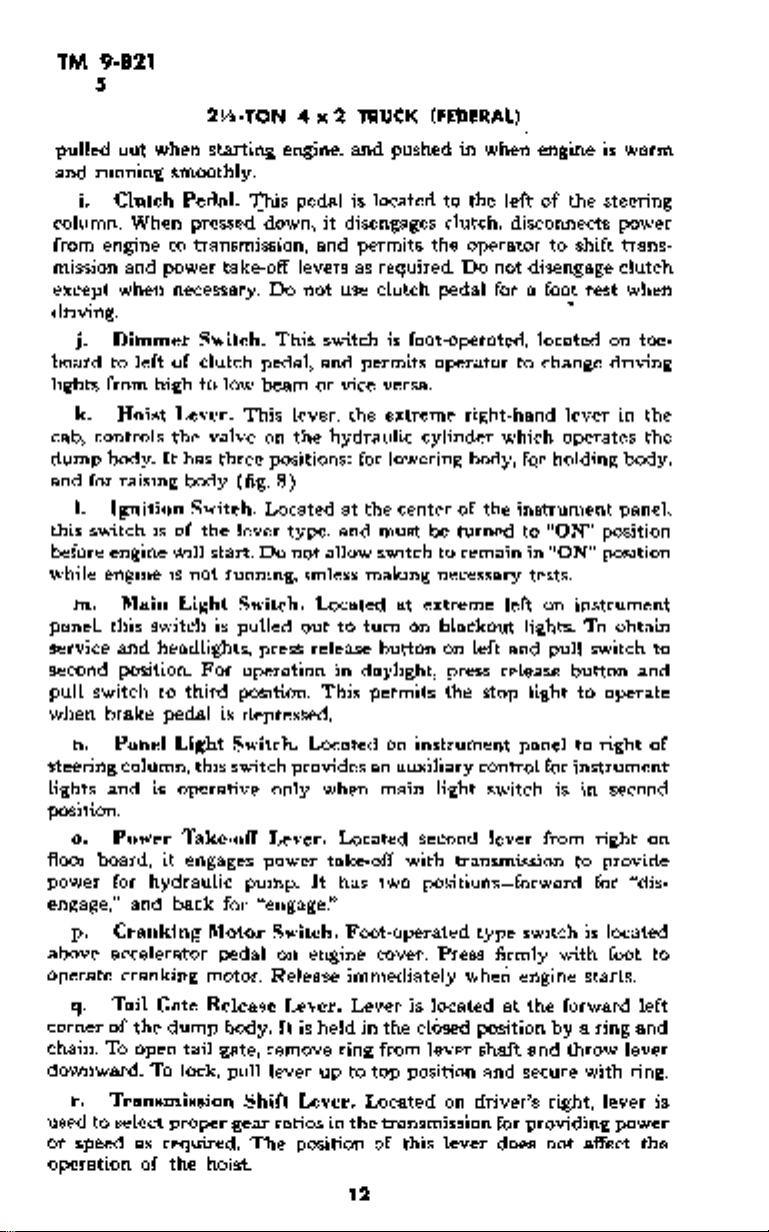

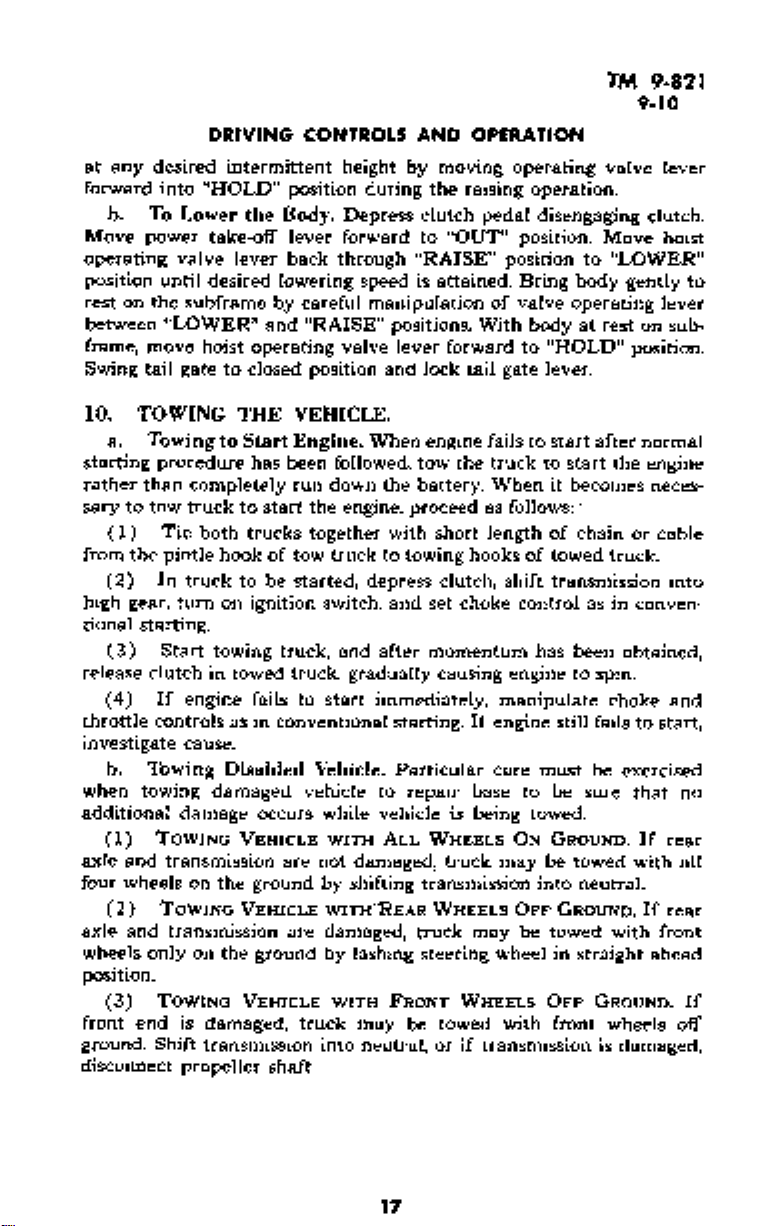

A—TEMPERATURE

B—MAIN

C—FUEL

D-PANEL

E—BLACKOUT

5-SPEEDOMETER

6—PANEL

H—AMMETER

J-OIL

K-CHOKE

I-

M-IGNITION

LIGHT

GAGE

LIGHT

LIGHT

PRESSURE

SHIFTING

DRIVING

DIAGRAM

SWITCH

Figure

GAGE

SWITCH

SWITCH

GAGE

6—Controls

LIGHT

SWITCH

9

U

T

5

R

N-CAUTION

O—THROTTLE

P—GLOVE

R—HOIST

S-POWER

T-HAND

U-CRANKING

V—TRANSMISSION

W-ACCELERATOR

X—BRAKE

Y—CLUTCH

Z—DIMMER

and

Instruments

PLATE

COMPARTMENT

CONTROL

TAKE-OFF

BRAKE

PEDAL

PEDAL

SWITCH

LEVER

MOTOR

SHIFT

LEVER

LEVER

SWITCH

RA

LEVER

PD

300052

TM

9-821

4

2'/2-TON

4x2

TRUCK

(FEDERAL)

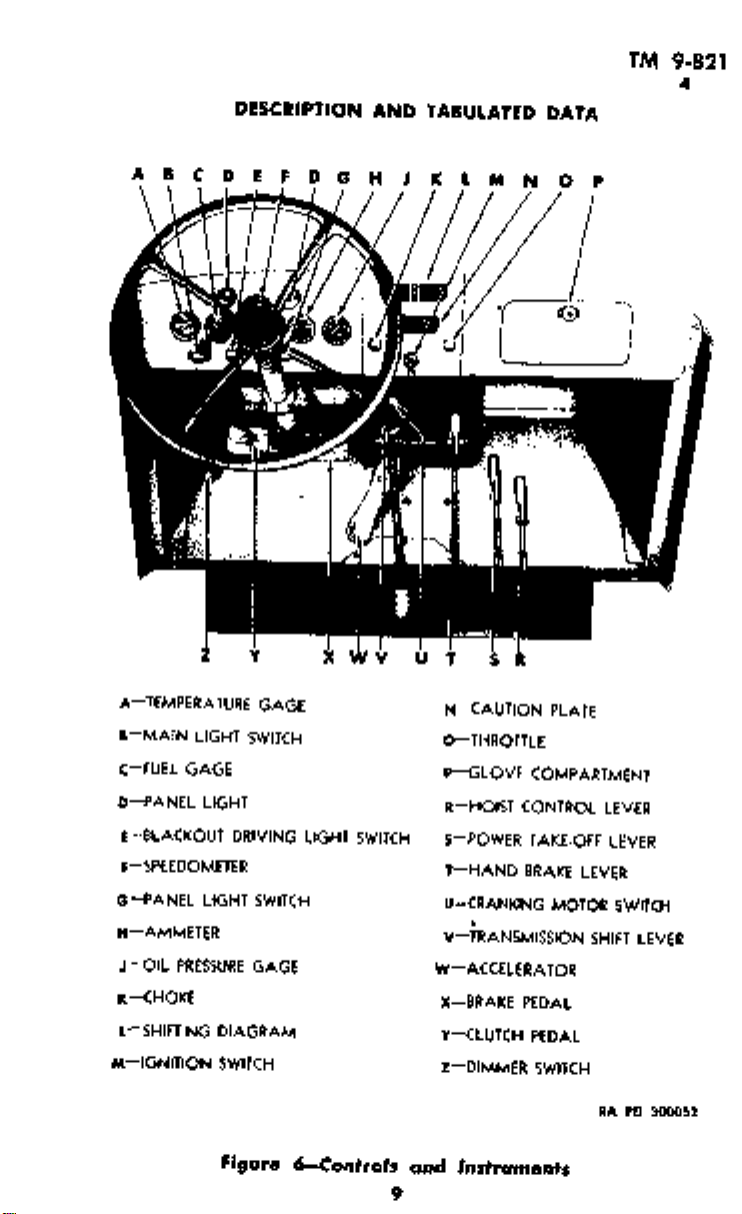

o

MAXIMUM^

FOLLOWING

OVERDRIVE

TH.

5

4 TH.

3

O\!

Maximum

Maximum

Cruising

(average

per

Miles

Capacities.

c.

Transmission

axle

Rear

tank

Fuel

Cooling

Crankcase

bath

Oil

bath

Oil

.

cylinder^

Hoist

ROAD

GEAR

RD.

2800

7.4

grade

grade

range

road

gallon

.........................................

capacity

capacity

system

capacity

cleaner carburetor..........................

air

cleaner crankcase

air

I

...

MAX.

RATIO

AX.

Figure

ascending

descending

without

at

(at

...........:...........................22

Galion

Anthony

7—Caution

ability

ability.................

refueling

mph)......

30

mph)............................

30

....................................

...................................

............................

body

body

SPEEDS

IN

POSITIONS

2ND.

REV.

ENG.

R.P.M.

8-25-20

Plates

gear)........

(low

12,975

breather..................

...........................

.........................

gross

THE

TIRES

RA

weight,

qt dry,

6

PD

45

45

250

o

300054

degrees

degrees

miles

6.25

14

15

gal

40

8

1

20

>/

13

12

pt

pt

qt

qt

qt

pt

qt

t

p

10

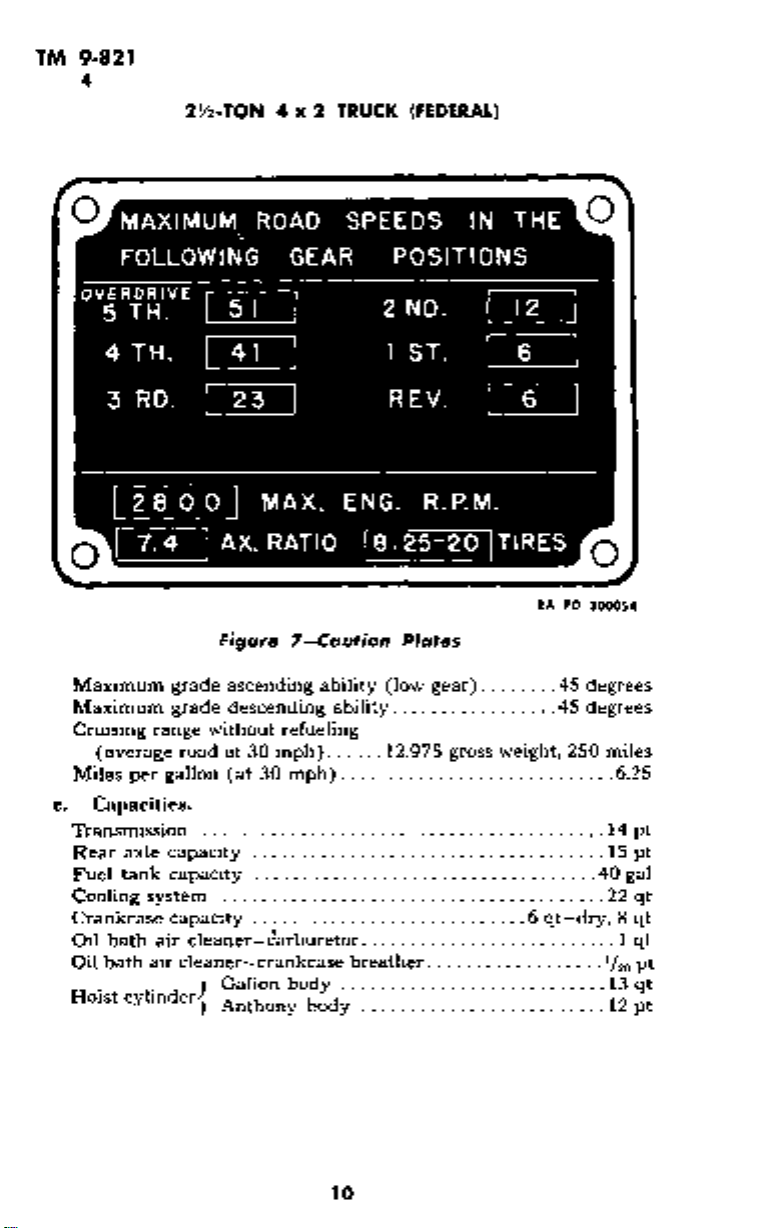

Section

III

TM

9-821

5

DRIVING

Controls

Instruments

Operation

Anthony

Galion

Towing

5.

a.

the

of

the

crankcase.

reinserted

should

operation

running.

b.

vehicle.

inserting

noting

c.

antifreeze

filler

be

d.

the

to

engine

e.

instrument

operate

to

on

f.

driver's right

controls

push

g.

driver's

to

and

wheel.

h.

admitted

................................................

of

dump

dump

the

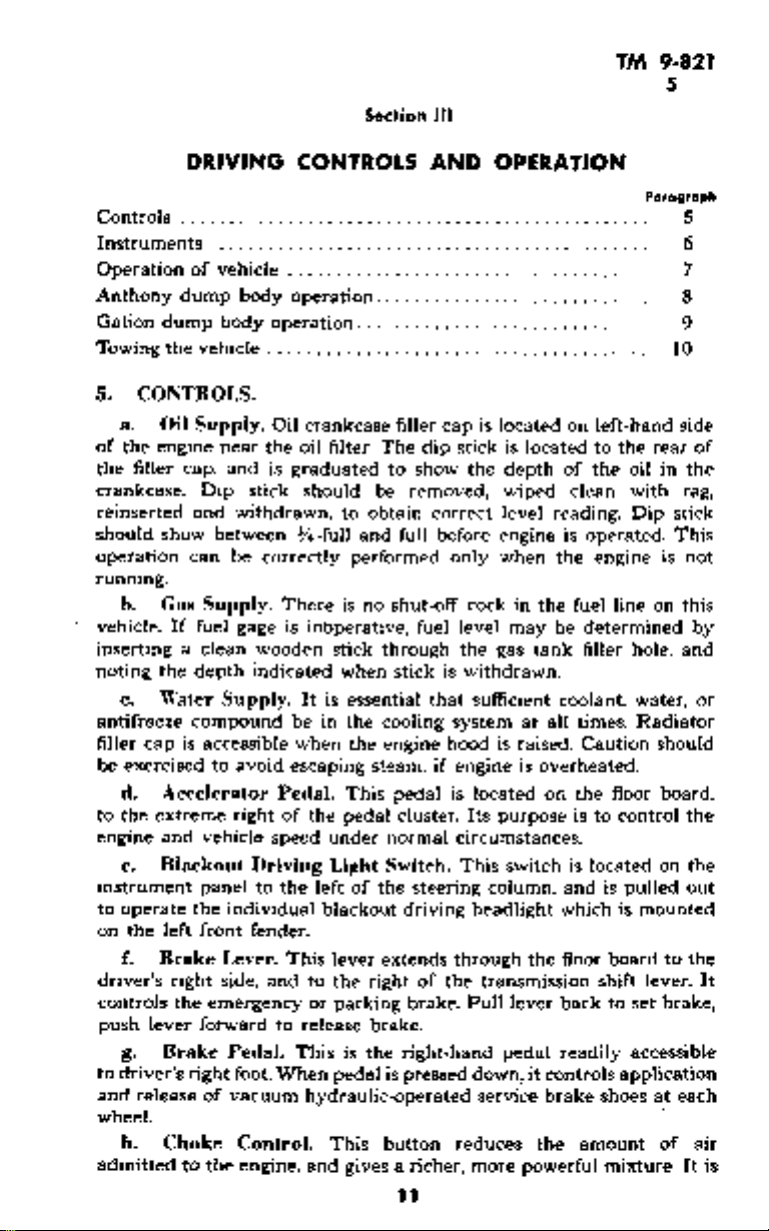

CONTROLS.

Oil

engine

cap,

filler

and

show

can

Gas

If

a

the

Water

compound be

is

cap

exercised

Accelerator

extreme right

and

Blackout

the

left

the

Brake

the

lever

Brake

right

release

Choke Control.

to

CONTROLS

............................................

vehicle

body

vehicle

Supply.

near

and

Dip

between

Supply.

fuel

clean wooden

depth

Supply.

accessible when

to

vehicle

panel

individual

front

Lever.

side,

emergency

forward

Pedal.

vacuum

of

the

.....................................

operation............................

body

operation..............................

.......................................

crankcase

Oil

filter.

oil

the

graduated

is

should

stick

withdrawn,

%-full

correctly

be

There

inoperative,

is

gage

indicated

It

escaping

avoid

Pedal.

of

speed

Driving

the

to

fender.

This

and

release

to

This

When

foot.

hydraulic-operated

engine,

and

the

to

or

be

obtain

to

and

performed

no

is

stick

when stick

essential

is

the

in

the

steam,

This

pedal

under

Light

the

of

left

blackout

lever extends

right

the

parking

brake.

the

is

pedal

This

gives

AND

is

cap

filler

stick

dip

The

the

show

to

removed, wiped

correct

before

full

only

level

fuel

the

withdrawn.

is

that

system

hood

engine

if

is

Its

circumstances.

This

steering

through

the

of

Pull

reduces

richer,

cock

sufficient

located.on the

headlight

transmission

down,

service

more

shut-off

through

cooling

engine

pedal

cluster.

normal

Switch.

driving

brake.

right-hand

pressed

is

button

a

11

OPERATION

located

is

depth

level

engine

when

may

gas

is

purpose

switch

column,

pedal

on

located

of

clean

reading.

operated.

is

the

fuel

the

in

determined

be

filler

tank

coolant,

times.

all

at

raised.

is

lever back

Caution

overheated.

is

is

and

which

floor

the

readily

controls

it

brake

amount

the

powerful

located

Paragraph

left-hand

rear

the

to

oil

the

with

Dip

engine

line

hole,

water,

Radiator

floor

control

to

pulled

is

mounted

is

board

lever.

shift

set

to

accessible

application

shoes

mixture.

5

6

7

8

9

10

side

the

in

rag,

stick

This

not

is

this

on

by

and

should

board,

the

the

on

out

the

to

brake,

each

at

of

It

of

or

It

air

is

TM

9-821

5

pulled

and

column.

from

mission

except

running

i.

engine

out

Clutch

When

and

when

driving.

j.

Dimmer

board

to

left

lights

from

k.

Hoist

cab,

controls

dump

body.

and

for

raising

1.

Ignition

this

switch

before engine

while

engine

m.

Main

panel,

service

second

pull

when

steering

lights

switch

n.

this

and

position.

brake

Panel

column,

and

position.

o.

Power

floor

board,

power

engage,"

above

operate

corner

chain.

p.

accelerator

q.

of

To

for

hydraulic

and

Cranking

cranking

Tail

the

open

downward.

r.

Transmission

used

to

select

or

speed

operation

as

of

2'/i-TON

when

starting

smoothly.

Pedal.

pressed

to

transmission,

power

necessary.

Switch.

of

clutch

high

to

Lever.

the

valve

It

has

three

body

Switch.

is

of

the

will

start.

is

not

Light

switch

is

headlights,

For

to

third

pedal

is

Light

this

is

operative

Take-off

it

engages

back

Motor

pedal

motor.

Gate

Release

dump

tail

gate,

To

lock,

proper

required.

the

hoist.

engine,

This

down,

take-off

Do

This

pedal,

low

beam

This

on

positions:

(fig.

8).

Located

lever

type,

Do

not

running,

Switch.

pulled

press

operation

position.

depressed.

Switch.

switch

provides

only

Lever.

power

pump.

for

"engage."

Switch.

on

Release

Lever.

body.

It

remove ring

pull lever

Shift

gear

ratios

The

4x2

TRUCK

and

pedal

is

located

it

disengages

and

permits

levers

as

required.

not

use

clutch

switch

and

permits

or vice versa.

lever,

the

the

hydraulic

for

at

the

and

must

allow switch to

unless

making

Located

out

to

turn

release

in

This

button

daylight,

permits

Located

an

when

Located

take-off

It

has

two

Foot-operated

engine

cover.

immediately

Lever

is

held

in

from

up

to

top

Lever.

position

in

Located

the

of

12

(FEDERAL)

pushed

to

in

the

clutch,

the

operator

Do

pedal

is

foot-operated,

operator

extreme

right-hand

cylinder

lowering

center

be

body,

of

turned

remain

necessary

at

extreme

on

blackout

on

left

press

the

on

instrument

auxiliary

main

light

second

with

transmission

positions forward

Press

when

is

located

the

closed

lever

position

on

transmission

this

lever

when

left

disconnects

not

disengage

for

a foot

to

which

fqr

the

instrument

to

in

tests.

left

lights.

and

release

stop

light

panel

control

switch

lever

type

switch

firmly

engine

at

the

position

shaft

and

and

secure

driver's

for

providing

does

engine

of

the

to

shift

rest

located

change

lever

operates

holding

"ON"

"ON"

on

instrument

To

pull

button

to

to

for

instrument

is

in

from

to

is

with

starts.

forward

by

a

throw

with

right,

not

affect

is

warm

steering

power

trans

clutch

when

on

driving

in

body,

panel,

position

position

obtain

switch

and

operate

right

second

right

provide

for

"dis

located

foot

ring

and

lever

ring.

lever

power

toe-

the

the

to

of

on

to

left

is

the

TM

9-821

5-7

s.

Throttle

of

the

ignition

engine

can

above

control

6.

current

from

the

slower

( )

when

tinuously

mately

at

miles

water

widely

to

will

are

speed;

be

used

t.

Windshield

the

windshield

and

INSTRUMENTS.

a.

Ammeter.

being

the

battery.

battery

speeds, or

side.

b.

Fuel

ignition

c.

Oil

when

26

pounds

once

until

d.

Speedometer.

per

hour.

e.

Temperature

in

engine

under

exceed

result

shown,

212 F.

in

DRIVING

Button.

switch,

it

is

usually

if

necessary

regulate

supplied

When

if

necessary,

when

Gage.

switch

Gage.

This

engine

at

cause

cooling

different

Continuous

serious

determine

CONTROLS

Located

this

button

pulled

as a manual

Wiper

This instrument

can

on

the

speed

This

instrument

from

engine

and

all

is

turned

instrument

is

running.

average

be

This

Gage.

system

operating

damage

cause

Control.

the

windshield

of

generator

exceeds

needle

lights

on.

engine speed.

determined.

instrument

This

conditions,

operation

to

the

and

AND

on

instrument

is

used

out

about l/z

speed-control

This

the

windshield

indicates

to

idling

shows

are

on,

needle

shows

indicates

This

gage

indicates

instrument

in

degrees

at

engine.

correct.

OPERATION

to

increase

inch

valve-type

wiper

body,

wiper arm.

rate

battery,

speed,

on

positive

will

amount

engine

should

If

pressure

vehicle

indicates

Fahrenheit.

but

must

any

temperature

If

excessive

panel

or

when

when

control

and

of

flow

or

rate

generator

show

of

fuel

oil

indicate

falls,

temperature

never

to

the

right

decrease

starting,

driving.

of

(-f-)

on

in

pressure

stop

road

It

be

over

temperatures

is

located

is

used

of

electric

discharge

charges

side.

negative

tank,

only

con

approxi

engine

speed

may

vary

allowed

200 F

and

the

to

At

in

of

7.

OPERATION

a.

Starting

(1)

scribed

secure

lever

should

in

(2)

in

(3)

to

move

(4)

about

Va

(5)

half

way.

be

too

much

OF

VEHICLE,

the

Engine.

BEFORE-OPERATION INSPECTION.

paragraph

APPLY

applied

MOVE

neutral

freely

SET

THROTTLE

15

BRAKE

position.

SHIFT

position

from

before

proceeding

LEVER.

LEVER

(fig.

right

Pull

TO

8,

CONTROL.

hand

NEUTRAL.

Shifting

to

left

without

Pull

Diagram).

inch.

SET

CHOKE

This

in

may

hot

CONTROL.

not

be

sufficient

weather/

Pull

choke

in

cold

Perform

with

the

brake

Move

effort.

throttle

control

weather,

the

inspections

following:

lever

back

transmission

At

this

control

button

and

point

button

will

and

leave

shift

lever

out

about

probably

de

out

TM

9-821

7

(6)

TURN

position.

(7)

DEPRESS

down

until

(8)

PRESS

switch

intervals

smoothly

speed

is

ing

gage,

until

than

(9)

ADJUST

at

up

if

(10)

(11)

RELEASE

PUSH

running

temperature.

(12)

RUNNING

and

oil

functioning

h.

Driving

(1)

WARM-UP.

up

period,

indicates

normal

gage shows

positive

Push

against

(fig.

pedal

vehicle

clutch

second

Release

ation.

fourth

(2)

(+)

SELECT

down

the

8).

Gradually

at

the

is

pedal,

speed

clutch

Follow

speed.

moving

conditions.

high

speed.

(3)

SELECT

Drivers

often

should

the

emergency

attention

vehicle.

engine

if

Transmission

starts

2-/2-TON

IGNITION

CLUTCH

engine

starts.

STARTING

engine

10

or

THROTTLE.

a

moderate

engine

IN

CHOKE

smoothly

pressure

properly.

the

which

will

engine

between

charge.

FORWARD

clutch

spring

same

pedal

and

time,

forward

and

position,

pedal

positions

This

Fifth

speed

FORWARD

devote

only way

and

brought

it

is

to

be

to

"lug"

4x2

SWITCH.

PEDAL.

This

SWITCH.

starts.

This

15

seconds.

speed.

shows

signs

CLUTCH

PEDAL.

CONTROL.

and

temperature

CHECK.

gage

to

Vehicle.

Always

not

allow

be

temperature

20

and

and

back,

speed

up

and

smoothly,

shift

transmission

which

gradually

shown

is

the

normal

or

overdrive

extra

the

vehicle

to

successfully

should

or

"labor."

TRUCK

Turn

is

very

switch

Push

in

Use

of

Note

readings

be

certain

the

completed

Push

foot

dying.

ignition

down

important

Press

should

throttle

throttle

Push

in

gage

that

engine

(FEDERAL)

firmly

choke

indicates

on

engine

to

until

(160

30

pounds,

and

TRANSMISSION

move

transmission

in

order

to

select

engine

release

with

hand

slow

shift

is

extreme left

and

speed

on

shifting

accelerator, releasing

brake

down

lever

up

diagram

operating

is

reserved

TRANSMISSION

time

to

practice

can

be

kept

a

stop.

This

operation

accomplished

always

Push

14

be

shifted

down

switch

clutch

in

not

be

button

(called

pedal and

cold

on

cranking

engaged

until

accelerator)

button

lever to

weather.

engine

when

favorable

ammeter,

run

for

the

to

180 F),

ammeter

temperature

and

accessories

an

initial

temperature

oil

shows

SPEEDS Low

shift

lever

first

lever.

the

speed,

engine,

or

As

through

and

forward

the

engine.

Repeat

(fig.

speed

under

for

open

SPEEDS HIGH

on

this

operation,

under

control

requires

without

to

clutch

lower

pedal;

Idamage

speeds

"ON"

motor

for

longer

engine

operat

warm-

gage

pressure

a

slight

TO

HIGH.

to

the

right

low

clutch

soon

as

depress

neutral

(fig.

oper

8)

until

usual

road

roads

TO

Low.

as

in

careful

to

when

decelerate

hold

runs

to

are

gear

the

the

to

8).

in

at

it

is

an

the

engine

mission

nize

down

then

same

position.

complete

by

to

engine

clutch

accelerate

procedure

CAUTION:

stop

SELECT REVERSE

(4)

complete

transmission

forward.

and

right

Stopping

c.

STOPPING

(1)

pedal.

Gently

DRIVING

decreasing

neutral.

speed

pedal

engine

as

(step

(step

stop

shift

the

apply

CONTROLS

pressure

Release

second

in

shift

and

and

outlined

//

below).

c

following).

c

to

lever

Gradually

Vehicle.

HIGH

FROM

pressure

AND

accelerator

on

pedal;

clutch

position

gear

transmission

gradually

above

difficulty

lever

release

shift

to

experienced,

is

TRANSMISSION

Depress

speed

SPEED.

to

position,

engine

up

brake

Remove

pedal

reverse

OPERATION

pedal

accelerate

with

into

clutch

second

from

SPEED.

clutch

which

and

foot

until

ANTHONY

POWER

I

TAKE-OFF

and

engine

vehicle

second

pedal.

bring

Bring

pedal

all

is

release

from

engine

TM

shift

to

speed.

gear

first

to

vehicle

vehicle

and

way

the

clutch

accelerator

decelerates

HOIST

VALVE

9-821

7

trans

synchro

Push

position,

the

Use

speed

to

move

the

to

pedal.

to

a

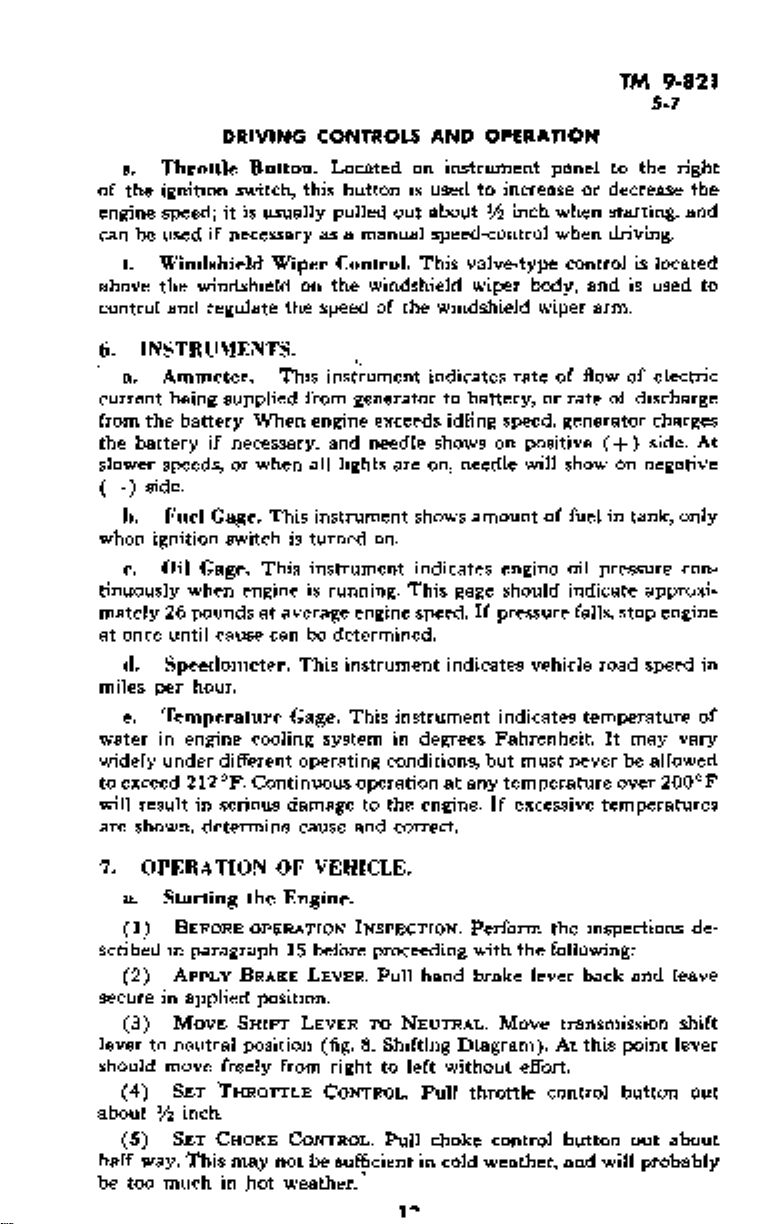

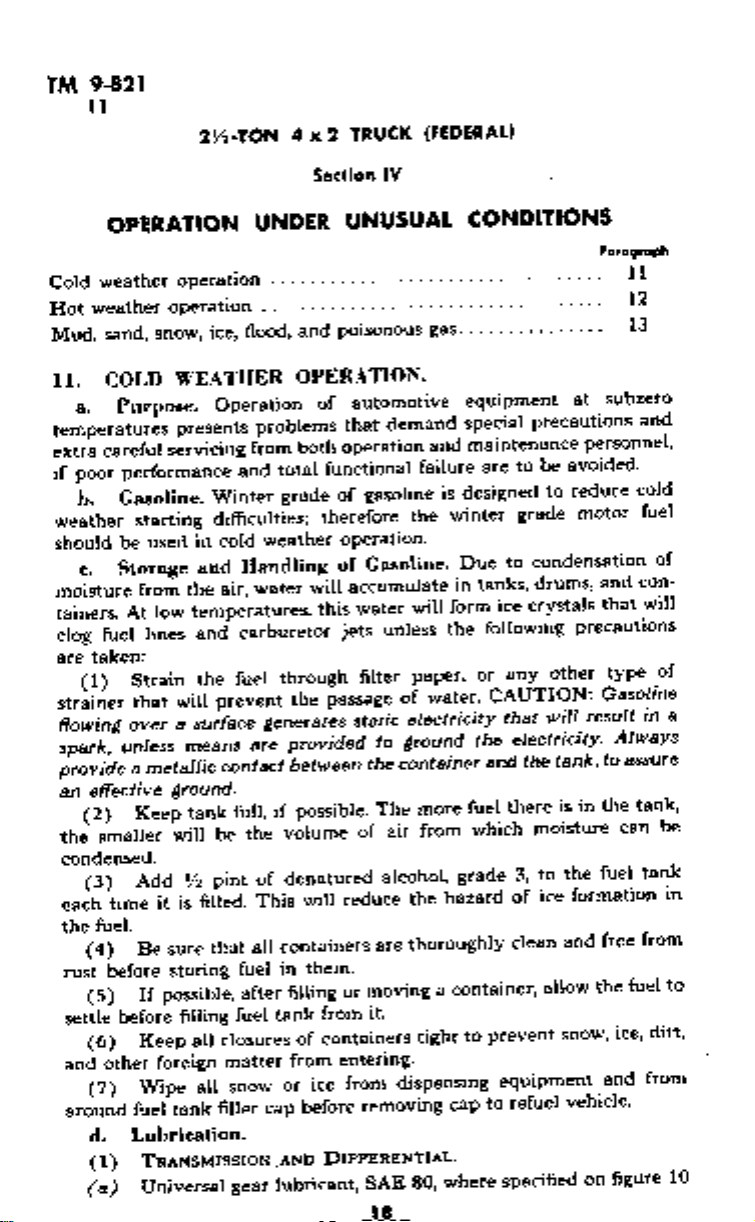

Figure

(Anthony)

(Gallon;

8—Shifting

1*

GEAR

IN

GALION

POWER

TAKE-

OUT

GEAR

IN

Diagram

OFF

RAISE

HOLD

HOIST

VALVE

HOLD

RAISE

LOWER

RA

PD

o

O

300053

9-821

TM

7-9

speed;

idling

to

neutral

to

lever

(2)

from

until

comes

STOPPING

accelerator

shift

vehicle

vehicle

foot

transmission

pedal

lights.

Stopping

d.

temperature

If

(1)

been

has

truck

momentarily

idle

.engine

If

(2)

has been

truck

about

.at

idle

to

To

hoist

to

switch.

Raise

valve

clutch

"IN

ignition

off

ANTHONY

8.

a.

Place

Depress

lever

valve operating

accelerate

time

engine.

lever back

at

backward

power

valve

until

subframe

and

operating

to

When

to

any desired

to

Lower

To

b.

take-off

forward

lever

desired

by

"RAISE"

valve

closed

position

"HOLD"

"HOLD"

lowering

carefully

4x2

-TON

2

2'/

depress

then

position.

a

to

Continue

complete

Low

FROM

stop.

pedal until

neutral

to

lever

a

to

comes

Engine.

the

gage

medium

operating

at

at

normal

speed

temperature

long

a

normal

DUMP

Body.

operating

disengaging

for

BODY

cargo

If

lever

operated

twice

pedal,

GEAR" position

forward

lever

raise

has

to

reached

engine

load

position

intermittent

height

position

Depress

Body.

forward

lever

speed

"RAISE"

is

through

manipulating

positions.

lever

and

With

forward

tail

lock

TRUCK

pedal

clutch

apply

to

Set

SPEED.

engine

position.

complete

shows

between

before

gage

period

speed

idle

OPERATION

to

is

in

clutch.

release

and

"RAISE"

to

load

desired

dumping

while

by

during

clutch

"OUT"

to

attained.

at

body

"HOLD"

to

lever.

gate

(FEDERAL)

and

pressure to

brake;

hand

Depress

reaches

stop.

light

and

shutting

shows

under

for

dumped,

be

extreme

Pull

desired

to

height,

moving

raising

the

pedal

position.

position

Bring

valve

rest

transmission

move

brake

off

turn

clutch

idling

Apply

Set

160 F

loads,

higher

heavy

minutes

5

rear

clutch

position

pedal.

speed;

pressure

brake;

hand

and

allow

ignition

off

than

load,

before

8).

(fig.

raise

"HOLD"

power

back

pedal.

and

tail

height.

valve-operating

pull

Load may

load.

operating

operation.

disengaging

hoist

Move

"LOWER"

to

gently

body

lever between

subframe,

on

position.

Swing

pedal

lights.

Remove

then

brake

to

turn

180 F,

engine

switch.

180 F,

engine

allow

shutting

gate

position.

take-off

Move

the

at

not

Do

be

valve

clutch.

Move

operating

position

rest

to

"LOWER"

move

tail

shift

until

move

off

and

to

if

or

lever.

hoist

same

race

held

lever

on

hoist

gate

GALION

9.

To

a.

hoist

Place

Depress

backward

operating

valve

accelerate

the

race

forward

lever

Raise

valve

clutch

"IN

to

engine

engine.

to

DUMP

pedal

BODY

If

Body.

operating

disengaging

cargo

lever

GEAR" position

back

lever

sufficiently

load

When

"HOLD"

position

OPERATION

be

to

is

extreme

in

clutch.

and

"RAISE"

to

raise

to

reached desired

has

while

16

8).

(fig.

dumped, release

forward

Pull

release

position

to

load

"HOLD"

power

clutch

and

desired

height,

dumping

load.

tail

take-off

pedal.

the

at

height.

push

Position

lever.

gate

position.

lever

hoist

Pull

time

same

Do

operating

load

not

at

any

desired

forward

Move

b.

into

To

power

operating

position

rest

on

the

between

frame,

Swing

10.

starting

rather

sary

move

tail

TOWING

a.

Towing

than

to

tow

procedure

(1)

from

the

(2)

In

high

gear,

tional

starting.

(3)

release

throttle

(4)

clutch

If

controls

investigate

b.

Towing

when

towing

additional

(1)

TOWING

axle

and

four

wheels

(2)

axle

and

wheels

only

position.

(3)

TOWING

front

end

ground.

Shift

disconnect

DRIVING

intermittent

"HOLD"

Lower

the

take-off

valve

lever back

until

desired

subframe

"LOWER"

hoist

operating

gate

to

closed

THE

to

Start

has

completely

truck

to

Tie

both

trucks

pintle

hook

truck

to

turn

on

ignition

Start

towing

in

towed

engine

fails

as

cause.

Disabled

damaged

damage

VEHICLE

transmission

on

the

TOWING

VEHICLE

transmission

on

the

VEHICLE

is

damaged,

transmission

propeller

CONTROLS

height

position

Body.

lever

during

Depress

forward

through

lowering

by

and

speed

careful

"RAISE"

valve

position

manipulation

positions.

lever

and

VEHICLE.

Engine.

been

run

start

of

tow

be

started,

truck,

truck,

to

in

conventional starting.

vehicle

occurs

are

ground

When

followed,

down

the

the

engine,

together

truck

with

to

depress

switch,

and

and

after

gradually

start

immediately,

Vehicle.

Particular

to

while vehicle

WITH

ALL

not

damaged,

by

shifting

towing

WITH^REAR

are

damaged,

ground

by

truck

into

lashing

WITH

may

neutral,

FRONT

shaft.

AND

OPERATION

by

moving

the

raising

clutch

to

pedal

"OUT"

"RAISE"

is

attained.

of

With body

forward

lock

tail

engine

tow

battery.

proceed

the

short

fails

truck

When

as

length of

hooks

clutch,

set

choke

momentum

causing engine

If

engine

care

repair

is

base

being

WHEELS

truck

transmission

WHEELS

truck

may

steering

WHEELS

be

towed

or

if

transmission

operating

operation.

disengaging

position.

position

Bring

valve

operating

to

"HOLD"

gate

lever.

to

start

to

start

it

becomes

follows:

of

towed

shift

transmission

control

has

to

manipulate

still

must

to

be

towed.

ON

GROUND.

may

be

into

OFF

GROUND.

be

towed

wheel

in

OFF

with

front

TM

valve

Move

to

"LOWER"

body

gently

at

rest

position.

after

the

chain

or

truck.

as

in

conven

been

obtained,

spin.

choke

fails

to

be

exercised

sure

that

towed

with

neutral.

with

straight

GROUND.

wheels

is

damaged,

9-821

9-10

lever

clutch.

hoist

lever

on

sub-

normal

engine

neces

cable

into

and

start,

no

If

rear

all

If

rear

front

ahead

If

off

to

17

TM

9-821

11

2>/2-TON

4x2

TRUCK

(FEDERAL)

OPERATION

weather

Cold

weather operation

Hot

sand,

Mud,

COLD

11.

Purpose.

a.

temperatures

careful servicing

extra

performance

poor

if

Gasoline.

b.

be

Storage

c.

fuel

taken:

(1)

unless

effective

(2)

smaller

starting

used

from

At

lines

Strain

that

over

metallic

a

Keep

weather

should

moisture

tainers.

clog

are

strainer

flowing

spark,

provide

an

the

condensed.

Add

(3)

time

each

fuel.

the

Be

(4)

before

rust

If

(5)

before

settle

Keep

(6)

other

and

Wipe

(7)

around

fuel

Lubrication.

d.

TRANSMISSION

(1)

Universal

(a)

operation

ice,

snow,

WEATHER

Operation

presents

Winter

difficulties;

cold

in

and

air,

the

temperatures,

low

and

the

prevent

will

surface

a

means

contact

ground.

tank

be

will

pint

/2

l

filled.

is

it

that

sure

storing

possible,

filling

closures

all

all

tank

matter

snow

filler

foreign

Section

UNDER

UNUSUAL

..................................

...................................

poisonous

and

flood,

OPERATION.

automotive

of

problems

from

total

and

grade

that

operation

both

functional

of

gasoline

therefore

weather

Handling

water

operation.

of

accumulate

will

Gasoline.

this water

carburetor

through

fuel

generates

are

if

full,

the

of

This

jets

passage

the

static

provided

between

possible.

volume

denatured

reduce

will

filter

the

of

all containers are

fuel in

after

fuel

them.

filling

tank

of

moving

or

it.

from

containers

from entering.

from

ice

or

removing

before

cap

DIFFERENTIAL.

.AND

gear

lubricant,

SAE

18

IV

gas.

demand

and

failure

the

will

unless

paper,

water.

of

electricity

ground

to

container

more

The

from

air

alcohol,

the

thoroughly

tight

dispensing

80,

CONDITIONS

..............

equipment

special

maintenance

to

are

designed

is

to

Due

tanks,

ice

following

any other

or

CAUTION:

that

electricity.

the

and

there

fuel

grade

the

winter

in

form

the

which

3,

grade

hazard

of

clean

container,

a

prevent

to

equipment

refuel

to

cap

specified

where

Paragraph

subzero

at

precautions

personnel,

avoided.

be

to reduce

motor

condensation

drums,

crystals

and

that

precautions

type

Gasoline

result

will

Always

to

tank,

the

in

is

moisture

to

ice

allow

can

fuel

the

formation

free

and

the

ice,

snow,

and

vehicle.

figure

on

11

12

13

and

cold

fuel

of

con

will

of

in

assure

tank,

be

tank

in

from

fuel

dirt,

from

a

to

10

OPERATION

or

War

Department

tures

as

low

as

anticipated, drain

universal

tures

SAE

engine,

lubricant,

before

(b)

engine

Put

being

point

(2)

grease,

(3)

hydraulic

absorber

(4)

suction

versal

gear

of

one

make-up

(5)

scribed

gear

lubricant,

below

0 F.

80

universal

in

the

proportion

may

it

is

added

After

engine

speed

at

transmission

careful

where

not

normal

CHASSIS

No.

0.

HYDROVAC

oil

above

fluid

below 20 F.

STEERING

gun

to

remove

gear

lubricant,

lubricant

part

oil

diluted

fuel

in

OILCAN

for

above

the

UNDER

Lubrication

20 F.

the

gear

If

cases

which

If

Grade

gear

75

lubricant

of

be

used.

Dilute

to

gear

cases.

has

been

fast

idle

for 5 minutes,

in

low

(first)

to

stall

engine.

operation

POINTS.

Lubricate

CYLINDERS.

20 F,

GEAR HOUSING.

as

much

Grade

to

six

same

POINTS.

0 F,

with

fuel

parts

proportion

For

use

light

75,

UNUSUAL

Guide,

consistent

while

is

suitable

universal

diluted

one

part

make-up

warmed

gear,

This

can

be

chassis

Lubricate

and

special

Drain

lubricant

or,

if

used

SAE

80

before

oilcan

lubricating,

is

suitable

temperature

warm

for

gear

with

fuel

to

oil

up,

engage

or

until

and

drive

will

heat

expected.

points

recoil

housing,

as

not

available,

in

the

universal

it

points

preservative

CONDITIONS

for

and

refill

operation

lubricant

the

fuel

six

parts

in

the

same

clutch

gears

can

vehicle

gear

lubricants

with

hydrovac

oil,

if

possible.

SAE

engine,

where

is

gear

added

engine

in

lubricant.

TM

9-821

11

use

at

tempera

below

with

at

is

universal

Grade

all

not

available,

used

0 F

tempera

by

the

gear

75

proportion

and

maintain

be

engaged.

for

100

yards,

to

the

general purpose

cylinders

or

light

possible,

Refill

80

the

with

shock

or

use

with

uni

universal

proportion

Dilute

to

the

housing.

oil

is

pre

oil.

is

e.

(1)

freeze

The

following

(2)

clean

the

system

refill

with

cleaned

(3)

Inspect

Repair

all

leakage

(4)

clean

add

antifreeze

to

the

at

least

during

Protection

USE

ANTIFREEZE

compound

CLEAN

cooling

has

been

clean water,

with

cleaning

REPAIR

all

hose

all

radiator

of

ADD

and

tight,

cooling

10 F

below

the

winter

of

Cooling

COMPOUND.

(ethylene-glycol

instructions

apply

COOLING SYSTEM.

system,

cleaned

and

recently,

and

completely

again

compound.

LEAKS.

clamps,

exhaust

ANTIFREEZE

fill

compound,

system

leaks

gas

the

system

capacity

the

lowest

Inspect

plugs,

before

or

air

COMPOUND.

using

temperature

season.

Systems.

Protect

type)

for

to

use

of

Before

adding

free

it

may

be

drain. Otherwise

all

hoses

and

and

pet

cocks

adding

into

antifreeze'compound.

the

cooling

When

with

water

to

the

proportion

indicated

19

below.

the

operation

new

antifreeze

antifreeze

it

from

necessary

replace

and

tighten

system.

the

about .l

of

antifreeze

Protect

expected

system

below

rust.

the

system

if

cooling

/3

capacity.

to

be

with

anti

+32 F.

compound.

compound,

If

the

cooling

only

to

drain,

will

deteriorated.

if

necessary.

Correct

system

Then

compound

the

system

experienced

be

is

to

9-821

TM

11

Temperature

WARM

(5)

water

with

engine

(6)

solution

(7)

strength

and

(8)

(a)

for

(b)

containers

(c)

antifreeze

hydrometer

(d)

f.

(1)

and

current

between

the

normal operating

to

TEST

with

INSPECT

and

new

add

CAUTIONS.

Antifreeze

ordnance material.

is

It

and

Use

compound

Do

Electrical

GENERATOR

bearings.

which

brushes

WIRING.

(2)

battery

present.

COIL.

(3)

spark.

DISTRIBUTOR.

(4)

the

Check

prevent

difficult

that

ignition

engine from

SPARK

(5)

to

recommended

more

2'/i-TON

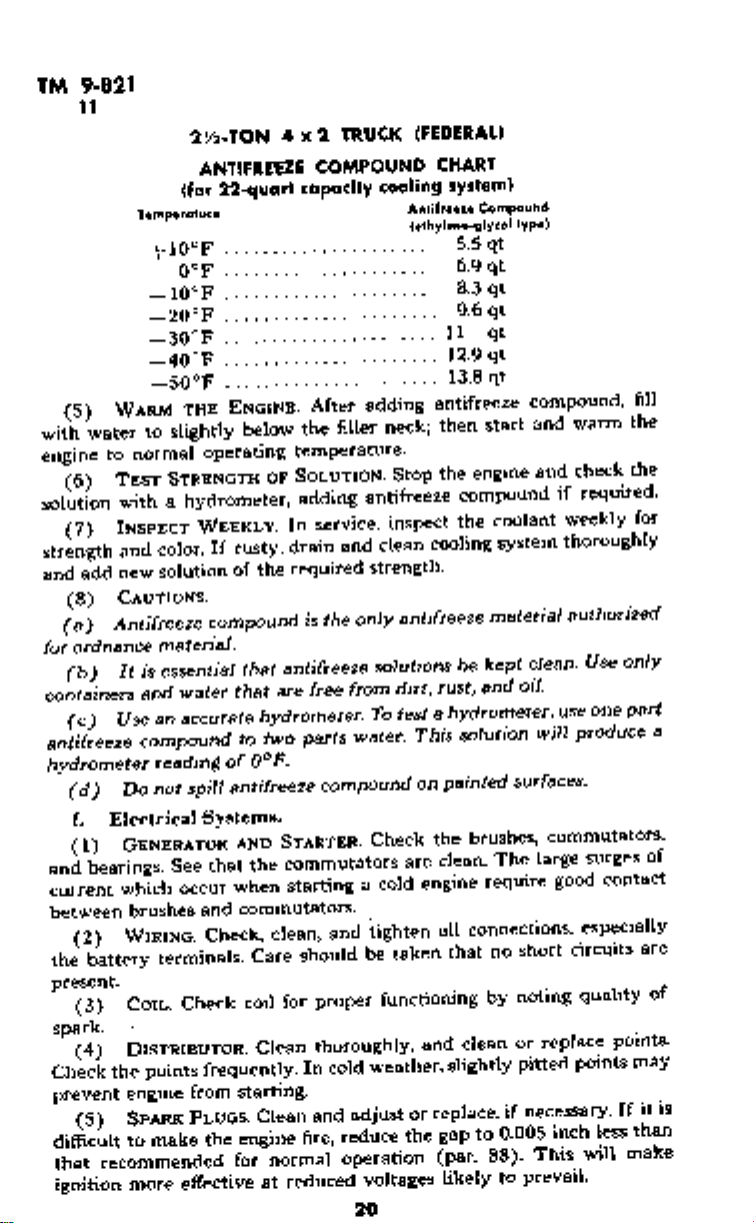

ANTIFREEZE

22-quart

(for

......................

10°F

+

0 F

10 F

20 F

30 F

40 F

50 F

THE

slightly

to

STRENGTH

hydrometer,

a

WEEKLY.

If

color.

solution

compound

essential

water

accurate

an

reading

spill

not

Systems.

that

See

occur

and

Check,

terminals.

Check

frequently.

points

PLUGS.

the

make

effective

TRUCK

4x2

COMPOUND

capacity

cooling

......................

......................

......................

......................

......................

......................

adding

ENGINE.

below

After

the

filler

temperature.

SOLUTION.

OF

adding

In

drain

rusty,

required

the

of

is

antifreeze

that

are

that

hydrometer.

parts

two

to

0 F.

of

antifreeze compound

STARTER.

AND

commutators

the

starting

when

antifreeze

service,

and

strength.

only

the

solutions

free from

To

water.

Check

a

clean

cold

commutators.

tighten

and

clean,

Care

coil

Clean

should

for

In

be

proper

functioning

thoroughly,

weather,

cold

starting.

adjust

and

Clean

reduce

engine

for

fire,

normal operation

reduced

at

voltages

20

(FEDERAL)

CHART

system)

5.5

6.9

8.3

9.6

11

12.9

13.8

Compound

qt

qt

qt

qt

qt

qt

qt

Antifreeze

(ethylene-glycol

antifreeze

start

then

neck;

engine

the

Stop

compound

coolant

inspect

dirt,

the

cooling

antifreeze material

rust,

a

test

This

on

system

kept

be

and

hydrometer,

solution

painted

surfaces.

the-brushes,

The

clean.

are

engine

taken

require

connections,

all

no

that

by

clean

and

slightly

to

if

0.005

88).

to

or

the

replace,

gap

(par.

likely

type)

compound,

warm

and

check

and

required.

if

weekly

thoroughly

authorized

Use

clean.

oil.

one part

use

produce

will

commutators,

surges

large

good

especially

circuits

short

noting

or

pitted

quality

replace

points

necessary.

inch

will

This

prevail.

fill

the

the

for

only

contact

points.

may

If

than

less

make

a

of

are

of

it

is

OPERATION

(6)

TIMING.

is

not

unduly

(7)

BATTERY.

(a)

The

temperatures,

the

engine

below

battery

the

30

is

available.

hydrometer

advanced

efficiency

and

with

the

F

until

reading

Check

becomes

battery

battery

See

UNDER

carefully.

nor

retarded.

of

batteries

practically

when

has

that

the

between

UNUSUAL

Care

should

decreases

nil

at

it

has

been

been

heated,

battery

1.275

is

and

CONDITIONS

be

taken

sharply

40

F.

Do

chilled

unless

always

1.300.

fully

A

fully

TM

that

the

with

decreasing

not

try

to

temperatures

a

warm

charged,

charged

9-821

11

spark

to

start

slave

with

bat-

tery

will

Arctic

at+5 F.

(b)

subzero

If

water

will

stay

the

acid.

(8)

and

presence

Figure

not

freeze

climates,

Do

not

temperatures

is

added

at

the

LIGHTS.

of

at

but

a

fully

add

water

unless

and

the

top

and

Inspect

moisture

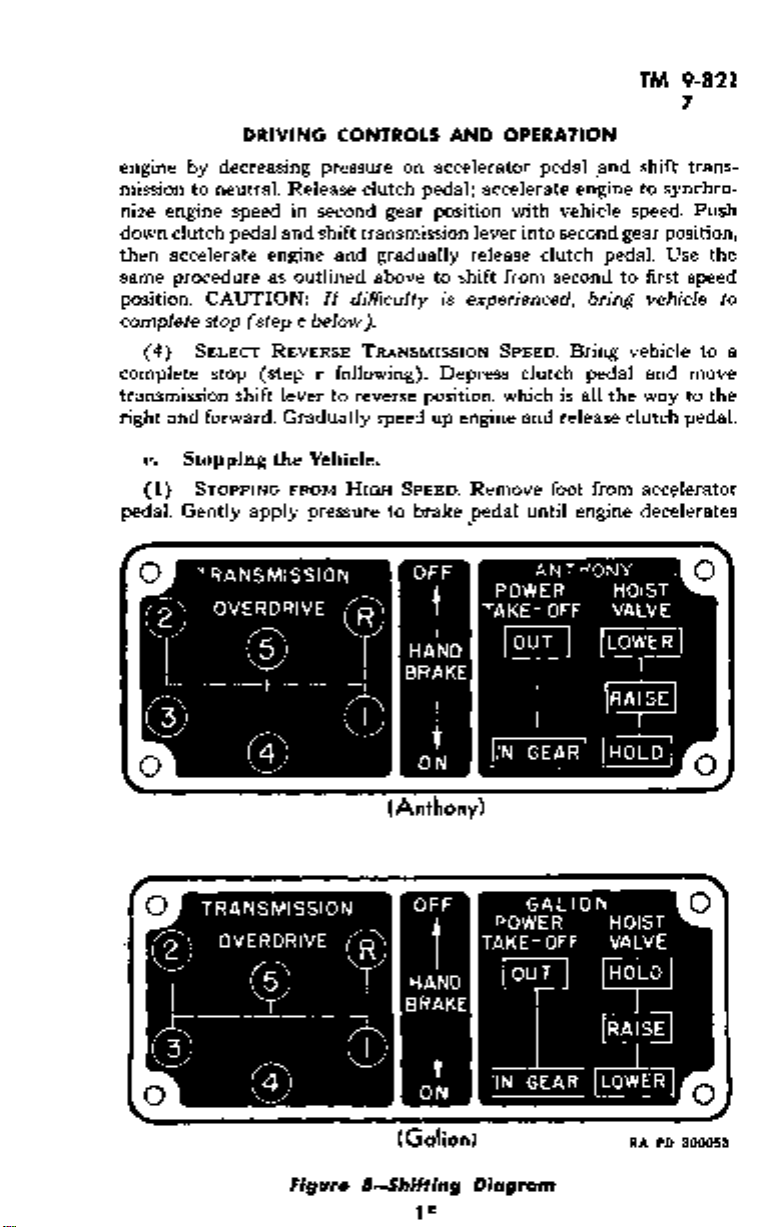

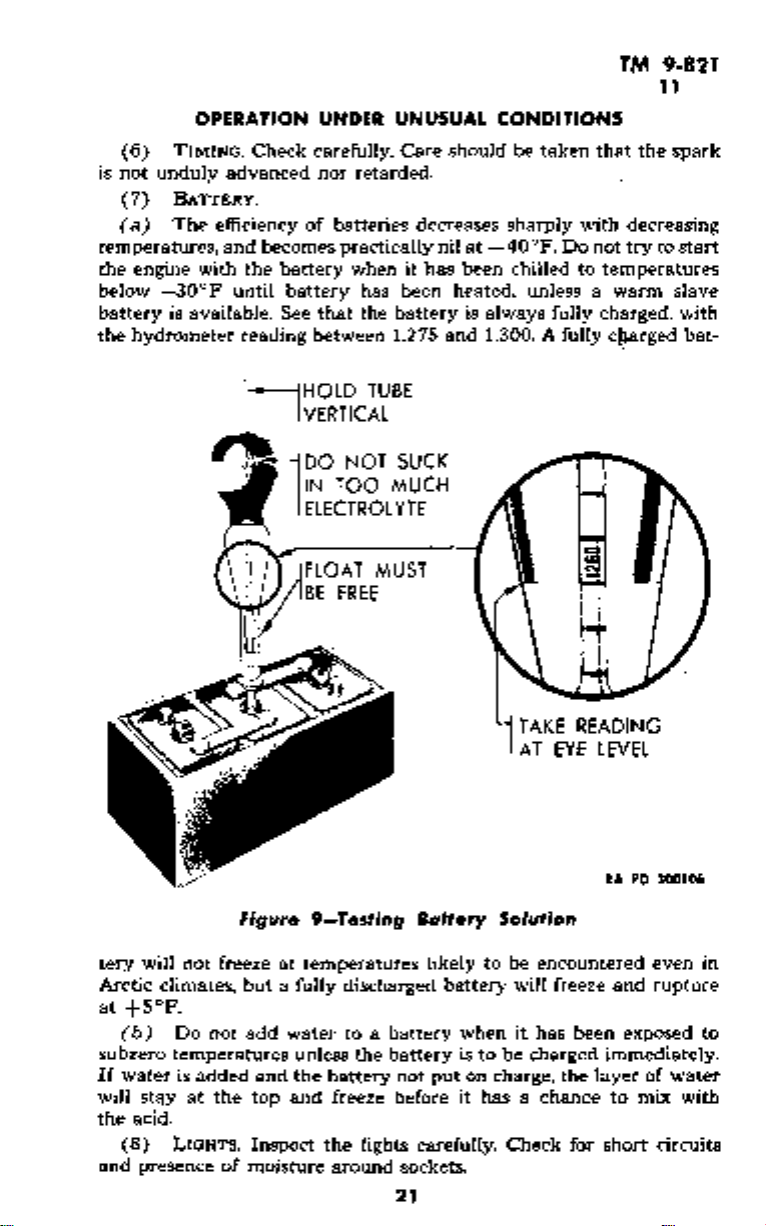

HOLD

VERTICAL

DO NOT

IN

ELECTROLYTE

FLOAT

BE FREE

TUBE

TOO

MUCH

MUST

9—Testing

SUCK

Battery

temperatures

discharged

to

a

battery

the

battery

battery

freeze

the

around

before

lights

not

carefully.

sockets.

21

likely

battery

when

is

put

it

to

to

on

has

HTAKE

I

AT

Solution

be

encountered

will

it

has

be

charged

charge,

a

chance

Check

READING

EYE

LEVEL

RA

freeze

been

immediately.

the

layer

for

short

PD

even

and

rupture

exposed

of

to

mix

300106

in

to

water

with

circuits

TM

(9)

other

9-821

11

ICE.

electrical

2Vi-TON

Before

equipment

every

4x2

start,

are

free

TRUCK

that

see

from

(FEDERAL)

spark

the

ice.

plugs, wiring,

or

Starting

g.

INSPECT

(1)

has

dirt

or

liable

is

dirt

or

remain

to

starter

the

USE

(2)

air-fuel

valve

give

operate

no

mixture

see

to

CARBURETOR

(3)

appreciable

no

satisfactorily

valves

leaky

delivering

temperatures

minute.

per

AIR

(4)

cleaners.

air

screens

Wash

formations

intake

etc.,

have

blow

or

released

under

vacuum

FUEL

(5)

daily.

Chassis.

h.

BRAKE

(1)

tendency to

a

torch

attempting

will

these

movement

EFFECT

(2)

vehicle

breaking,

of

result

ometer

tures

at

drag

frequently.

is

vehicles

screws

in

SPEEDOMETER

(3)

cable

30 F

of

temperatures,

these

caused

and

STARTER

left

been

to keep

after

mesh

in

necessitate

and

CHOKE.

OF

required

closes

it

that

diaphragm

or

amount

the

turning

when

CLEANERS.

oil

The

dry-cleaning

in

air

the

on

the

in

SYSTEM.

drain

Also

BANDS.

to

to

move,

handy

eliminate

circumstances,

vehicle.

the

of

OF

Shock

greatly

on

reduced

hard,

breaking,

the

at

and

high

the

by

Operating

MECHANISM.

the

on

the

the

A

for

all

AND

trouble

low

at

of

At

congeal

will

cleaner

carburetor

Remove

tank

fuel

Brake

when

bind

up

warm

vehicle.

the

most

TEMPERATURES

Low

resistance

frozen

ground

or

CABLE.

end

drive

below.

and

viscosity

Engine.

gears

engine

throwout

from

starts

starter

repairs.

choke

full

weather

cold

and

way

the

at

PUMP.

normal

FUEL

temperatures.

this

as

required

fuel

speeds

are

temperatures

and

solvent,

screens

horn

air

and

sump

bands,

they

parts,

these

Parking

binding.

the

of

the

block

to

extremely

at

causes

jarring

nuts

Disconnect

operating

when

cable

The

sometimes

the

of

22

sure

Be

mechanism.

being

running.

necessary to

is

starting.

otherwise

The

temperatures,

Be

prevent the

will

start

to

reduced

below

prevent the

and

dry,

cause

can

hose,

sediment

clean

daily to

particularly

very

are

they

if

the

Precaution

wheels

ON

metals,

of

temperatures.

low

strain

loose.

the

often

will

break,

will

with

oil

no

that

meshed,

The

secure

Check

functions

carburetor,

is

the

sure

fuel

the

to

30

to

do

0 F

easy

replace.

abnormally

an

resulting

bulb,

remove

water

on

Always

cold.

prior

bind

vehicle

otherwise

or

METALS.

resistance

or

jolting

and

oil-lubricated

vehicle

the

to

fail

due to

which

heavy

Heavy

cause

or

latter

the

which

liable

fuel

pump

engine

revolutions

60

not<use

flow

Ice

collapse.

in

new

to

with

must

Inspect

Operation

which

at

work

the

lubricated.

is

it

grease

grease

them

ruin

will

rich

the

butterfly

properly.

will

not

has

pump

from

low

at

oil

of

frost

and

high

strainers,

dirt.

and

vehicles,

have

moving,

brake

the

taken,

be

prevent

against

will

speed

tempera

properly

excessive

to

in

air.

a

the

12.

HOT

a.

General.

requires

devices,

regular

and

devices such

b.

Cooling

(1)

COOLING

system

tures;

liquids

contains

occurs

therefore

(par.

alkali

formations.

(2)

CLEANING COOLING SYSTEM.

thoroughly

in

extremely

(3)

FAN

regular

must

intervals

be

kept

(4)

THERMOSTAT.

Thermostat

heating

(5)

of

HOSE

leaks.

c.

Oil

at

more

frequent

Crankcase

d.

Air

dusty

cleaner

areas,

regions,

should

these

occur.

e.

Battery.

(1)

WATER

checked

If

this

is

daily

not available,

continuous

cause

damage

(2)

SPECIFIC

should

of

1.230

tive

1.300

for

plates

have

gravity,

a

recharged

there

is

no

OPERATION

WEATHER

Operation

maintenance

air

cleaners.

as

surge

System

LIQUID.

more

often

rust

preventives

77).

Use

or

other

cleaned

BELT

high

and

temperatures.

AND

and

in

good

operating

must

open

cooling

liquid.

CONNECTIONS.

Filter.

Oil

intervals

air

vent

cleaner

Cleaners.

carburetor

be cleaned

cleaners

should

LEVEL.

and

replenished

use

of

water

to

battery

GRAVITY.

a

weaker

the

electrolyte

fully

charged

and

separators.

at

about

danger

1.160.

with

UNDER

OPERATION.

of

In

extremely

or

overflow

Maintenance.

Formation

during

only

clean

substances

flushed

WATER

adjusted

Check

at

calibrated

Check

filter

elements must

if

vehicle

must

If

vehicle

air

daily.

be

In

torrid

any

water

with

and

should

Batteries operating

electrolyte

battery.

Under

Where

gravities

UNUSUAL

these

of

cooling

tanks

operation

should

water.

which

at

frequent

PUMP.

if

necessary

condition.

operation

hose

is

be

serviced

is

extensively

cleaner

If

vehicle

cleaned

zones,

if

necessary

fit

to

high

mineral

be

than

should

This

this

freezing

from

1.230

23

CONDITIONS

vehicles

units,

high

temperatures,

should

of

scale

in

extremely

always

be

Avoid

may

Cooling

intervals

Fan

belt

(par.

of

temperature

connections

be

operating

at

and

crankcase

is

operated

immediately

cell

with

drink

may

content

avoided.

for

temperate

be

adjusted

will

prolong

condition

conditions

to

1.075.

TM

in

high

temperatures

lubrication-filtering

water-saving

be

employed.

and

rust

in

high

added

to

the

the

use

of

water

cause

scale

t

,

system should

when

should

thermostat

80).

to

be

inspected

Water

(par.

prevent

frequently

checked

in

frequent

operated

hot,

and

sandy

intervals.

in

ventilator

in

dust

after