FEDCO HPB-2800 Installation & Operation Manual

English Version

INSTALLATION & OPERATION MANUAL

HPB™

HYDRAULIC PRESSURE BOOSTER

Models: HPB-2800

www.fedco-usa.com

ONE COPY OF THIS MANUAL MUST REMAIN WITH THE EQUIPMENT AT ALL TIMES

HPB-2800 Installation Operation Manual, 01-28C-XXXXXX-0

HPBTM Series

REGISTERED

ISO

ISO

REGISTERED

FEDCO Certications

ISO 9001 and ISO 14001:

FEDCO has adopted the ISO 9001 standard to dene and develop our Quality Management System (QMS.) The QMS allows FEDCO to better serve our customers’ needs

through continuous improvement of the quality, delivery, and eciency of our products.

3 FEDCO achieved ISO 9001 registration in September 2017.

FEDCO has adopted the ISO 14001 standard to dene and develop our Environmental

Management System (EMS) to better protect our environment.

3 FEDCO achieved ISO 14001 registration in September 2017.

14001:2015

9001:2015

CE Stamp:

CE marking conrms that specic products are in compliance with European Union

requirements. This allows FEDCO’s product lines to be sold throughout the European

Economic Area. Most FEDCO products can be provided with the CE mark.

Compliant Test Systems:

Performance acceptance testing of FEDCO pumps and energy recovery devices are

measured using procedures and instrumentation tested by a third party NSF® auditing

company to be in accordance to the Hydraulic Institute’s H.I. 14.6 standards for cen-

trifugal pump testing and data recording.

www.fedco-usa.com

© Copyright 2018 Fluid Equipment Development Company | www.fedco-usa.com

- 2 -

HPBTM Series

Commitment to Quality & Success

Fluid Equipment Development Company (FEDCO)

was founded in 1997 to develop new uid machinery

to reduce the cost of reverse osmosis desalination.

The results included patented concepts, highly integrated design, superior production software, and

sophisticated manufacturing processes. Our eorts

culminated in multiple lines of energy recovery tur-

bines and pumps uniquely suited for seawater and

brackish RO desalination.

We are the developers of the HP-HEMI™ ERD and

control system for mega-scale SWRO systems, as

well as the world’s rst low-cost integrated pump-ERD

for brackish water RO. Additionally, our Monroe facility

operates the largest pump and ERD test system dedicated to SWRO systems in the world.

Our teams of talented and energetic engineers,

manufacturing specialists and systems experts have

created a fully integrated enterprise with one aim – to

provide our customers with customized uid machines

with exceptional eciency and low capital cost cou-

pled with customer service that exceeds their expectations. The results include new designs, technology,

manufacturing processes, and standards. Our pumps

and ERDs use bearings that are lubricated by feed or

brine to eliminate the numerous maintenance and logistics issues associated with oil or grease lubricated

bearing systems. We oer three materials of construction: Duplex SS, Super Duplex SS and 316 SS.

FEDCO pumps only cover ows and pressures found

in BWRO and seawater SWRO applications. They are

designed for clean uids and are optimized for typical

suction pressures in RO systems. Our ERDs include

variable area nozzles that meet typical brine pressure

variations. Our products eliminate external tubing carrying high pressure feed or brine that can fail creating

hazards to personnel and equipment. Our units are

designed for operation and maintenance by unskilled

personnel in the harshest of desert or marine environments.

With the longest warranty and the highest eciencies,

our product lines are unmatched in quality and per-

formance by any manufacturer in the RO equipment

market. FEDCO is a widely recognized supplier with

thousands of units installed around the world.

We design uid machines to take full advantage of the

technical characteristics of the membrane process.

FEDCO USA

FEDCO

800 Ternes Drive

Monroe, MI 48162, USA

Telephone: +1 (734) 241-3935

Fax: 734-241-5173

Email: sales@fedco-usa.com

Oce 1910 | Concord Tower

P.O. Box 282102 | Media City

Dubai, United Arab Emirates

Telephone: +971 (0)4 242 3856

Email: sales@fedco-usa.com

FEDCO UAE

Fax: +971 (0)4 242 3856

www.fedco-usa.com

For patent coverage visit patent.fedco-usa.com

© Copyright 2018 Fluid Equipment Development Company | www.fedco-usa.com

Eli Oklejas - FEDCO CEO

FEDCO SINGAPORE

(No Oce Address)

Telephone: +(65) 9784 3813

Email: sales@fedco-usa.com

- 3 -

Table of Contents

HPBTM Series

Unpacking/ Inspection/ and Storage ...........5

HPB External Components ......................... 5

Inspection of Unit Upon Receipt ................. 5

Pump Storage Requirements...................... 6

Long-Term Storage (>6 Months) Checklist . 6

Theory and Operation ...................................7

HPB External Components ......................... 7

Installation Procedures .................................8

Warnings and Safety Precautions ............... 8

User Health and Safety .............................. 9

Booster Installation Requirements .............. 9

Lifting and Handling ................................. 10

Baseplate Installation ............................... 11

Installation Congurations......................... 12

Booster Piping Connections...................... 14

Recommended Instrumentation and

Operation With VFD .................................. 18

Upstream Filtration.................................... 18

Start Up Check List .................................. 19

Preparation For Booster Start Up ............. 19

Start Up Precautions ................................. 19

Booster Start Up ....................................... 19

Basic Troubleshooting ................................20

Visual Inspection ....................................... 20

Troubleshooting Chart ............................... 21

Specications ..............................................22

Fastener Torque Specications ................ 22

Lubricants and Compounds ...................... 22

Maintenance Schedule ............................. 23

Service Parts Kits...................................... 23

Ordering Parts........................................... 23

Service Policy ..............................................24

Return Material Authorization (RMA) ....... 24

Procedure ................................................. 24

Warranty Registration Form .......................27

HPB Unit Operating Conditions .................28

Notes.............................................................28

© Copyright 2018 Fluid Equipment Development Company | www.fedco-usa.com

- 4 -

HPBTM Series

Unpacking/ Inspection/ and Storage

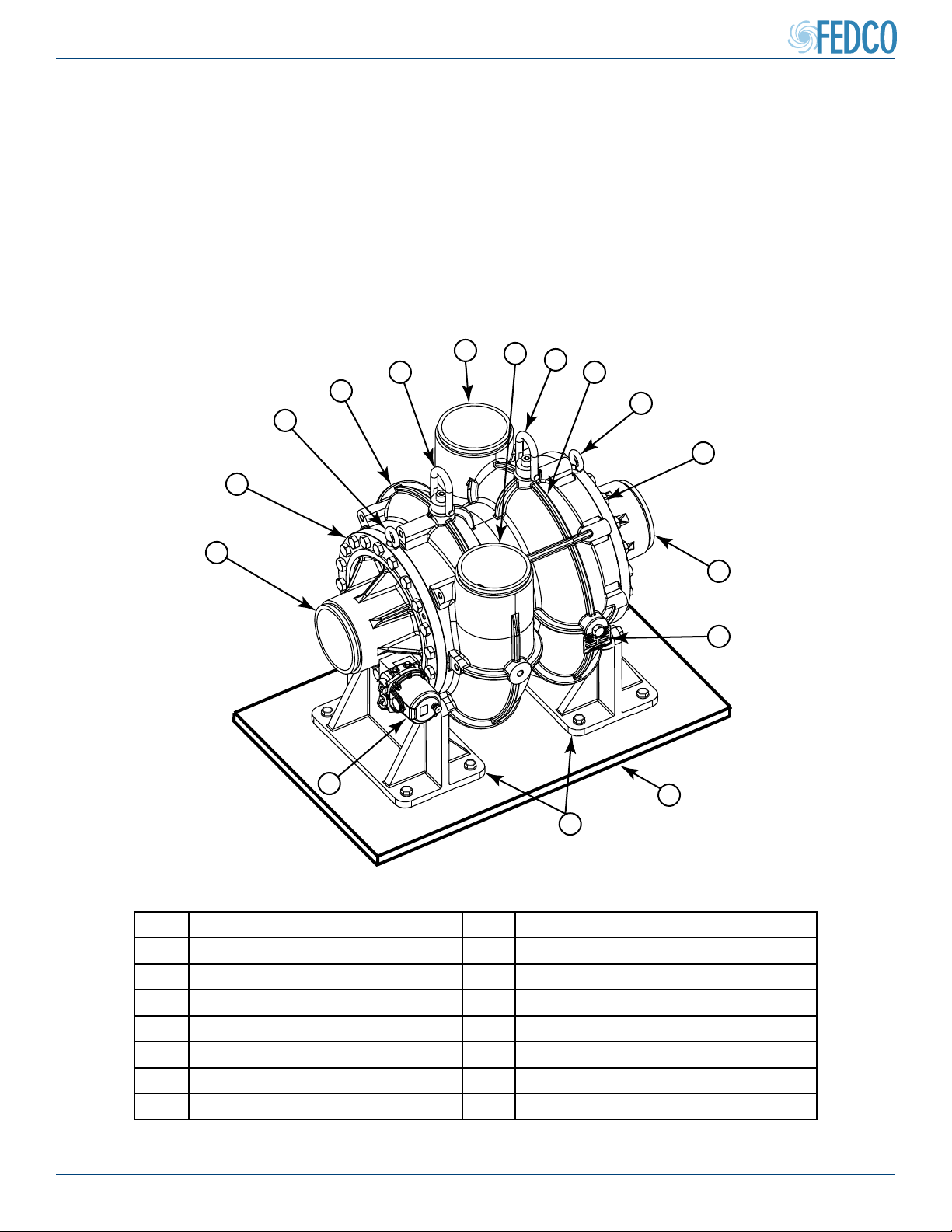

HPB External Components

Inspection of Unit Upon Receipt

• Review the contents of the packing list to make sure all components have been included.

• Inspect all components for signs of damage which may have occurred during shipping.

• If damage is present or if the contents are incomplete, please contact your shipping company

or a FEDCO representative before proceeding.

6

5

4

3

2

1

13

7

5

8

3

9

10

11

14

12

Item Description Item Description

1 Brine outlet 8 Pump casing

2 Turbine end cap 9 Pump end cap

3 End cap lifting eye 10 Feed inlet

4 Turbine casing 11 Unit nameplate

5 Hoist ring 12 Base Feet

6 Feed outlet 13 Actuator assembly (optional)

7 Brine intlet 14 Foundation plate

Figure 1 - HPB-2800 Booster External Components

© Copyright 2018 Fluid Equipment Development Company | www.fedco-usa.com

- 5 -

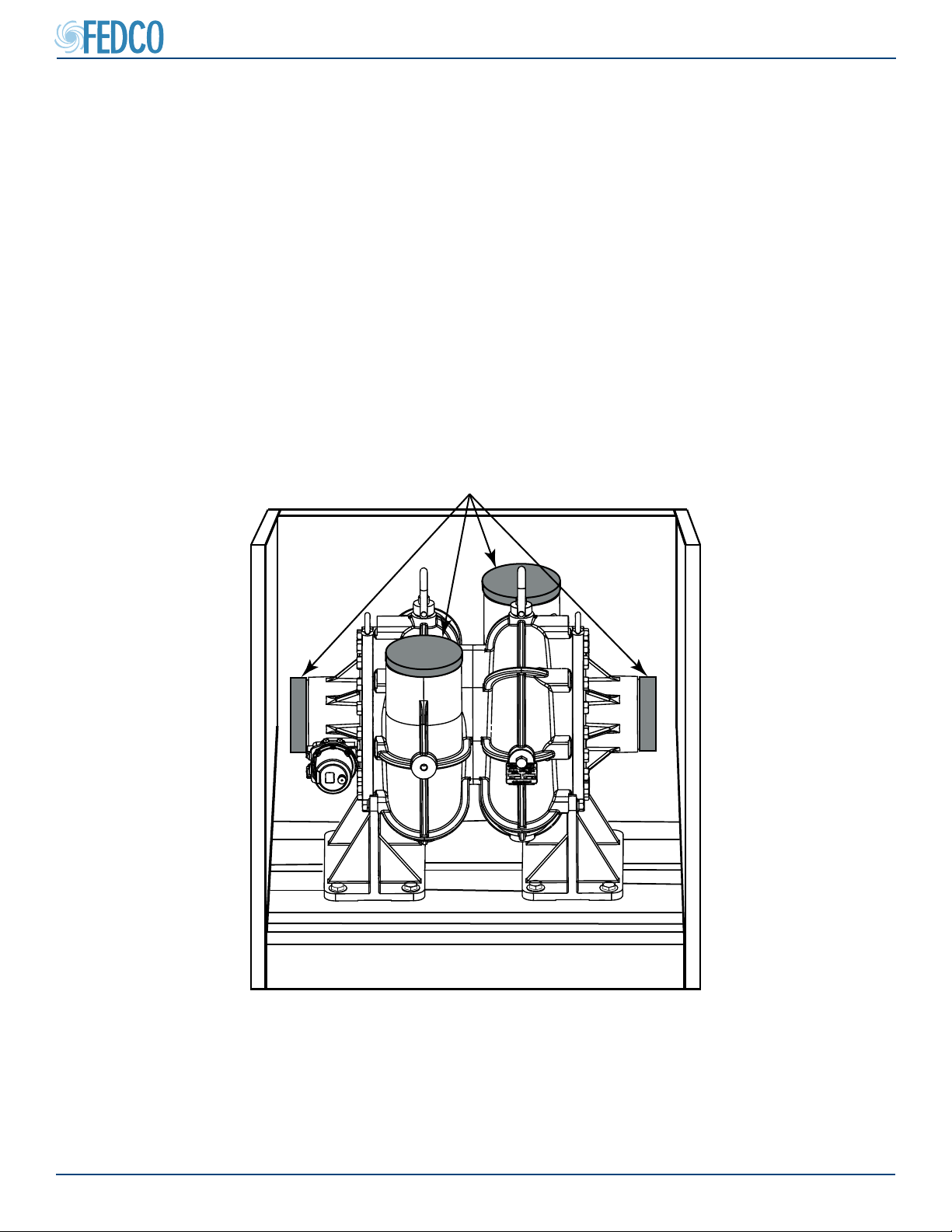

Unpacking/ Inspection/ and Storage Continued

HPBTM Series

Pump Storage Requirements

• The HPB™ unit must be protected from

sand, grit, and other foreign matter. For

long-term storage, the booster and all

other components should remain in their

original un-opened state. Both the unit

and its actuator (if equipped) are wrapped

and sealed in water/humidity proof foil with

desiccant bags added. The unit may be

stored at a temperature of 5-50° C or less

and/or a humidity level or 75% or less for an

indenite period of time. Do not remove the

protective covers until ready to install.

PROTECTIVE COVERS

Long-Term Storage (>6 Months) Checklist

1. Check caps to ensure they have not been

damaged or allowed debris inside the unit.

• Check for debris (wood, slag, sand or any

dirt) and clean up with a clean, wet rag if

minor.

2. Check rotor:

• Turn manually (through feed inlet) and

check for ease of turning.

• Check for axial movement.

3. Seal check:

• Prime HPB with clean water and allow the

O-rings to soak for 1 hr before start-up.

Check for leaks at end cap and aux valve.

Figure 2 - Proper HPB Storage

(Actuator Shipped Separately)

NOTES: Actuator manual provided by its manufacturer. Actuator installation, operation and

maintenance is not included in FEDCO HPB manual.

© Copyright 2018 Fluid Equipment Development Company | www.fedco-usa.com

- 6 -

HPBTM Series

Theory and Operation

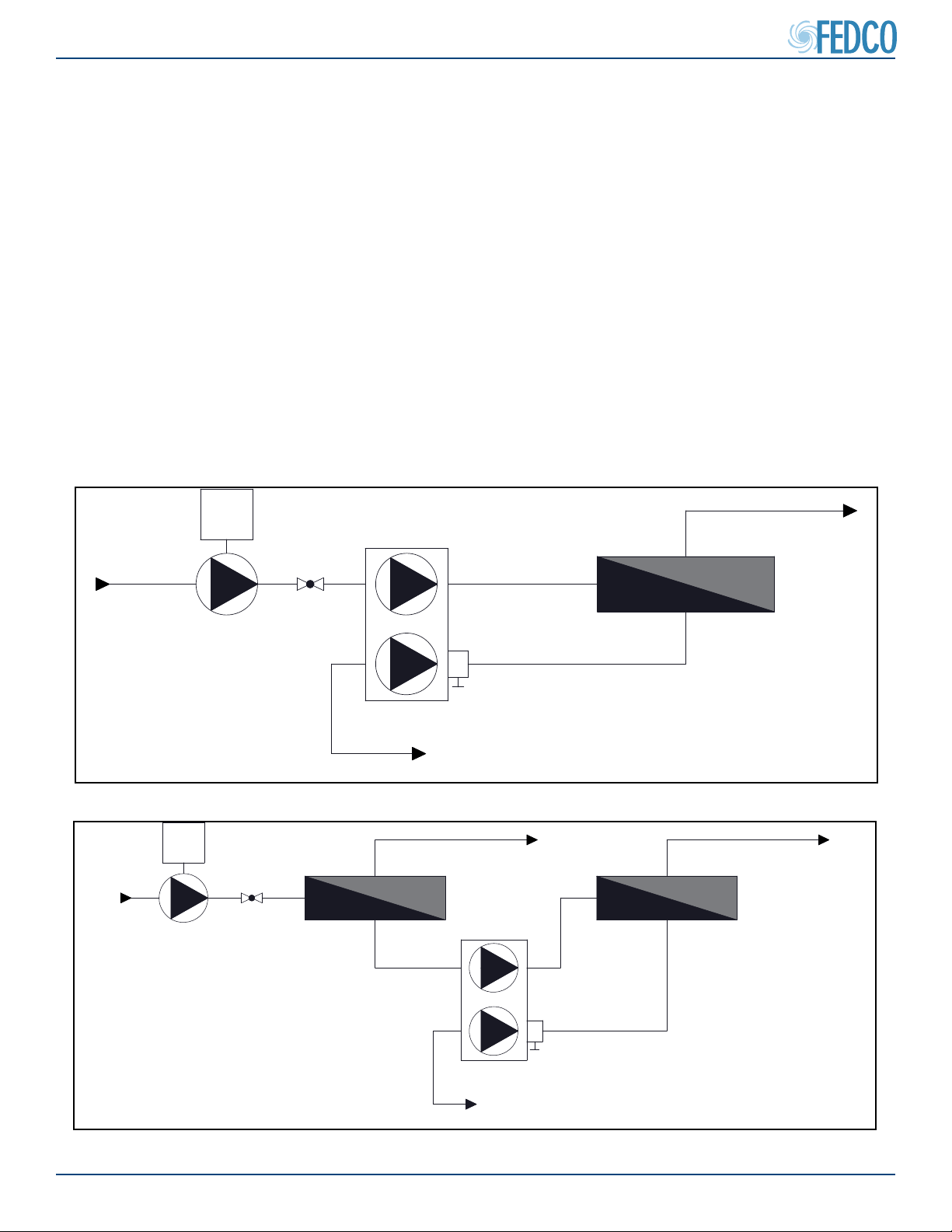

HPB External Components

The Hydraulic Pressure Booster™ or HPB™ is designed to provide brine energy recovery in

reverse osmosis (RO) systems. The HPB™ is energized by the high-pressure brine stream which

causes the HPB™ to generate a large pressure boost in the feed stream independent of the high

pressure feed pump.

The HPB™ is typically installed between the

high pressure feed pump and the membrane.

The feed passes through the pretreatment

system and then passes through the feed

pump which raises the feed pressure. The

pressurized feed passes through the HPB™,

which provides an additional pressure increase

before passing to the membrane. The high

pressure brine steam from the membrane is

directed back to the HPB™.

Motor

Throttle Valve

High Pressure

Pump

HPB™

The HPB™ recovers the pressure energy and

discharges the brine at low pressure for disposal. The HPB™ does not require a brine

disposal pump or gravity ow piping as the

brine can be discharged against a back pres-

sure. The HPB™ reduces feed pump energy

consumption and allows use of a smaller feed

pump, smaller motor, smaller motor starter,

electrical wiring, etc.

High Pressure Location

Feed

Brine

High Pressure

Brine Stream

Permeate

Product

Brine Outlet

Figure 3 - Hydraulic Pressure Booster Flow

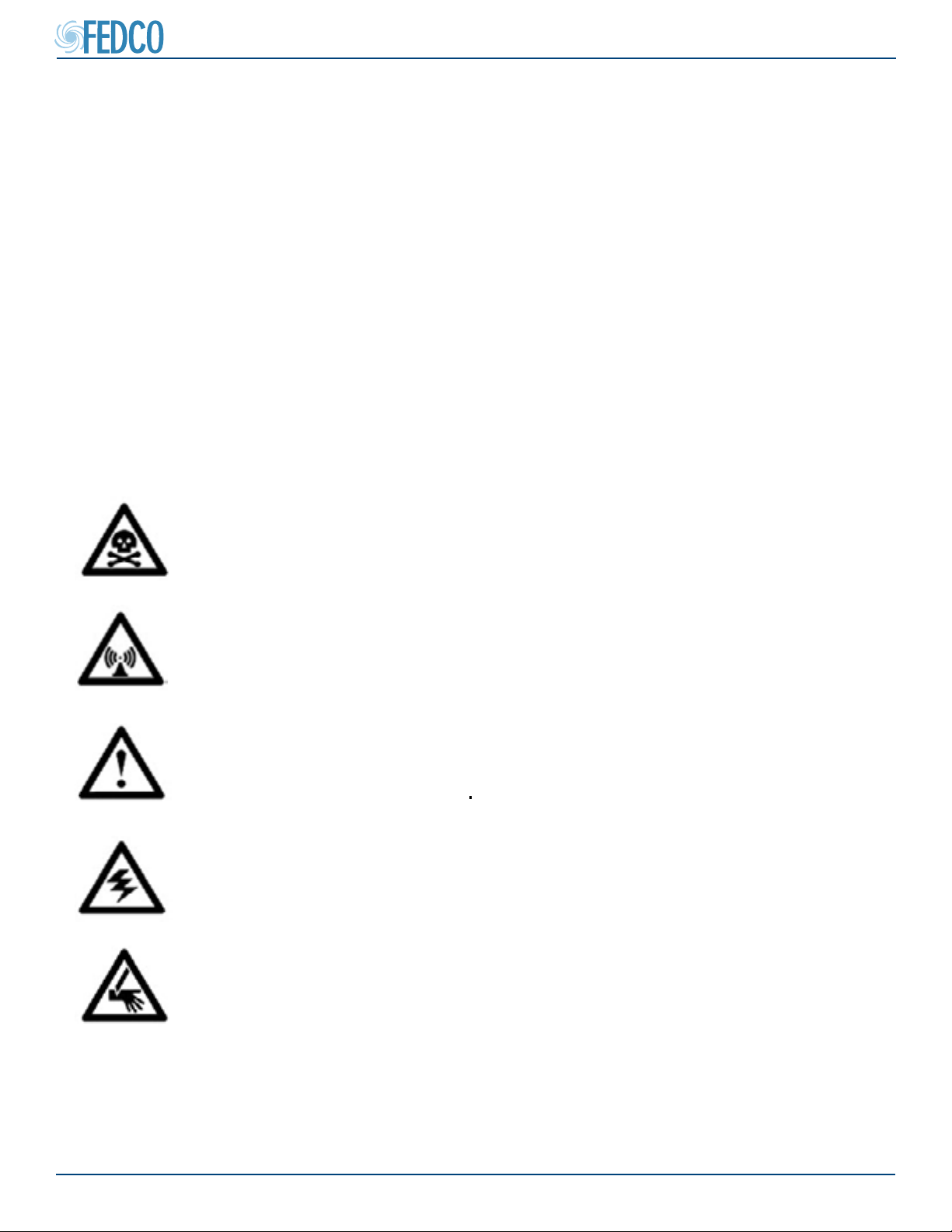

Motor

Throttle Valve

High Pressure

Pump

Location

High Pressure

Feed

Brine

Permeate

Product

First Stage

Brine

Brine Outlet

HPB™

Brine

High Pressure

Brine Stream

Permeate

Product

Figure 4 - Interstage Boosting Pump Conguration

© Copyright 2018 Fluid Equipment Development Company | www.fedco-usa.com

- 7 -

Installation Procedures

Warnings and Safety Precautions

Safety practices and precautions for the operation

and maintenance of all FEDCO pump products

and energy recovery devices MUST BE FOLLOWED. This information supplements oral or

written instructions that may be received. Safety

MUST be practiced as part of the standard oper-

ating procedures for this equipment during any

installation and operation. To ensure that safe

operating and maintenance procedures are followed, operators should develop and keep up

a program of safety checks and current instructions. This manual contains certain operating and

maintenance procedures that involve exposure

to potentially hazardous situations. The levels of

hazardous situations are as follows:

HPBTM Series

DANGER

WARNING

CAUTION

ELECTRICAL

HAZARD

PUNCTURE

HAZARD

Hazards which are IMMEDIATELY ACCESSIBLE, and capable of

causing SEVERE PERSONAL INJURY OR DEATH.

Hazards which are NOT IMMEDIATELY ACCESSIBLE, but are

capable of causing SEVERE PERSONAL INJURY OR DEATH.

Hazards which are NOT IMMEDIATELY ACCESSIBLE, and can

cause PERSONAL INJURY.

Hazards which are related to Electrical Components and can

RESULT IN ELECTRICAL RISKS, SHOCK, ELECTROCUTION

OR DEATH if instructions are not followed properly.

Hazards which are NOT IMMEDIATELY ACCESSIBLE and can

RESULT IN SEVERE PERSONAL INJURY OR DEATH if instructions are not followed properly.

© Copyright 2018 Fluid Equipment Development Company | www.fedco-usa.com

- 8 -

HPBTM Series

Installation Procedures Continued

WARNING

All HPB and safety precautions must be followed to prevent physical injury to the operator.

It is illegal to operate the equipment in an EU

member state if the manual(s) is not written in

that states language. Contact FEDCO if a translated copy is needed.

CAUTION

A hydraulic pressure booster (HPB) is a pressure-generating device with rotating parts that

can be hazardous. Any device containing generated pressure can rupture, explode or discharge

its contents if it is suciently over-pressurized

and may possibly result in personal injury, prop-

erty damage, environmental damage and death.

All necessary precautions must be exercised

to insure over-pressurization does not occur.

FEDCO will not accept responsibility for physical

injury, damage or delays caused by a failure to

observe the instructions in this manual.

WARNING

Installation, operation or maintenance of the

booster unit in any manner which is not covered

in this manual could cause damage to the equipment, serious injury or death. This includes any

modication to the equipment or the use of parts

not provided by FEDCO. If there is a question

regarding the intended use of the equipment,

please contact a FEDCO representative before

proceeding.

User Health and Safety

Safety equipment and PPE (Personal Protection Equipment) should be used in accordance with company regulations.

In the Work Area

• Always keep the work area clean and dry.

• Avoid all electrical dangers. Be aware

of risks from electric shock or arc ash

hazards.

• Utilize adequate lifting equipment and

methods.

Booster Installation Requirements

A rigid mounting surface is required for the

hydraulic booster assembly in order to prolong

the life of critical components. Mounting surfaces constructed of wood or other non-rigid

materials are NOT acceptable as they may

deect during operation. All anchoring fasten-

ers used should meet or exceed manufactur-

ers specications. All units must be mounted

on one of three types of substrates:

• concrete foundation.

• container with a suitable steel

substructure.

WARNING

Do not use the equipment for a dierent application than originally specied without the approval

of a FEDCO representative.

WARNING

FEDCO boosters are not intended for ammable or hazardous liquids. Solutions intended

for human consumption need proper purication

per product. FEDCO approval will be needed to

control slurry and particle size for this specic

product

© Copyright 2018 Fluid Equipment Development Company | www.fedco-usa.com

- 9 -

Loading...

Loading...