FCI Home Appliances 8-66B, 12-64B User Manual

24 Hour Factory Service Hot Line: 1 (800) 854-1993

Document 06EN003322 Rev. -

12-64B, 8-66B Installation, Operation and

Troubleshooting Guide

Step 1. Pre-Installation

A. To get the best results, the sensor should be mounted 20 pipe diameters downstream from any flow disturbance

(valve, pipe elbow) and 10 pipe diameters upstream from any disturbance.

The instrument tag shows the model number, tag number (if

noted on the order) and serial number along with other

important safety information. Compare this information with the

appropriate pipe installation drawings to be sure the instrument

is the correct configuration. Match the tag serial number on the

enclosure, flow element and control circuit.

Tag Location

On the top side of the local enclosure

B. Verify the serial numbers on the enclosures, flow element and electronics (control circuit) match. The instrument

may not work if the serial numbers do not match.

Flow Element Serial Number.

Also Showing Sensor Orientation Flat.

(Located near the enclosure.

It is also on the enclosure tag.)

Electronics Serial Number

C. Recommended installation/troubleshooting tools are a 1-3/8 inch open ended wrench to fit the NPT connection, a

small flat blade screw driver for manipulating potentiometers, a medium flat blade screwdriver for tightening

connections, 3 mm allen wrench for CENELEC approved instruments, and a DVM for Ohm/Voltage

measurements.

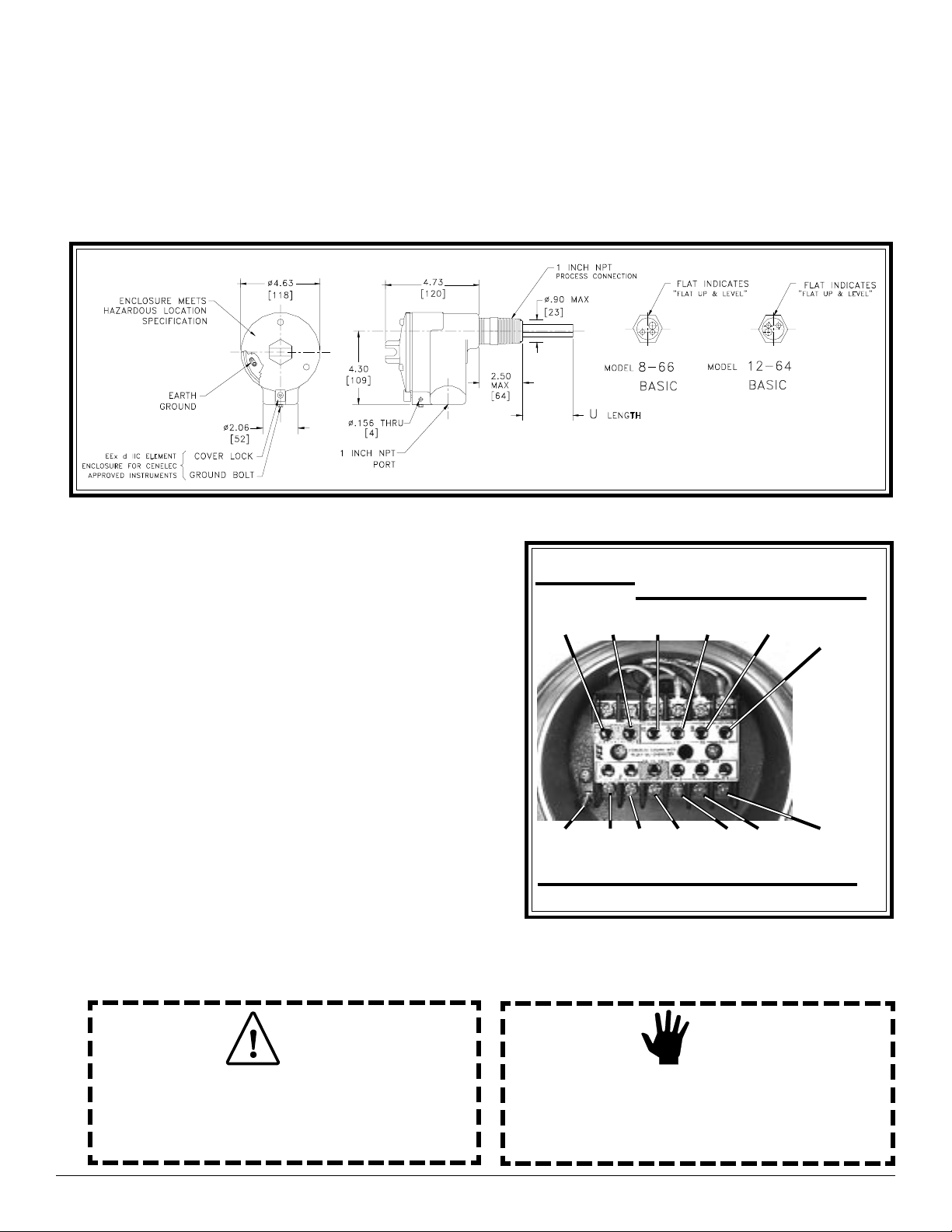

Step 2. Flow Element Installation

Alert: DO NOT change the orientation of the flow element in the enclosure as the interconnecting RTD and

heater wiring could be stressed and damaged. DO NOT apply any torque to the flow element

enclosure - only apply to the pipe surface itself.

Install the flow element, with the Flat Up and Level (shown above) or parallel to the flow media (±2°) for top mounted

instruments. The enclosure, flow element and electronic control circuit card serial numbers should all match.

When mounting the instrument the correct orientation of the flow element must be maintained to ensure repeatability to

within specifications.

Apply sealant to the male threads.

Carefully place in the process media line with the machined flat facing up.

Tighten the process connection. To avoid leaks do not overtighten or cross-thread connections.

Shown below is the 1 inch NPT mounting.

12-64 Flow Switch and 8-66 Level Switch Installation and Outline Drawing

Step 3. Wiring Preparation

Before the instrument is opened to install the wiring, FCI

recommends that the following ESD precautions be

observed: Use a wrist band or heel strap with a

1 megohm resistor connected to ground. If the instrument

is in a shop setting there should be static conductive mats

on the work table and floor with a 1 megohm resistor

connected to ground. Connect the instrument to ground.

Apply antistatic agents such as Static Free made by

Chemtronics (or equivalent) to hand tools to be used on

the instrument. Keep high static producing items away

from the instrument such as non-ESD approved plastic,

tape and packing foam.

The above precautions are minimum requirements to be

used. The complete use of ESD precautions can be found

in the U.S. Department of Defense Handbook 263.

Open the instrument enclosure to wire the instrument.

Remove the control circuit by lifting and rocking the

circuit board back and forth to expose the terminal block

as shown. The wiring connections are then accessible.

Step 4. Wiring the Instrument

CUSTOMER

WIRING

N/O

ALARM

# 2

SAFETY

GND

N/C

ALARM

# 2

PWR PWR

FACTORY WIRING

N/O

ALARM

# 1

(COM 8)

(COM 8)

COM

ALARM

# 1

(HTR 10)

AC or DC

(+) (-)

CUSTOMER WIRING

(REF 9)

COM

ALARM

# 2

12-64/8-66 Wiring Pictorial

(HTR 7)

(ACT 7)

N/C

ALARM

# 1

Caution:

Only qualified personnel are to wire or test this instrument.

The operator assumes all responsibilities for safe practices

while wiring or troubleshooting.

Model 12-64/8-66 2 Doc. No. 06EN003322 Rev.-

The instrument contains electrostatic discharge (ESD)

sensitive devices. Use standard ESD precautions when

handling the control circuit.

Alert:

Loading...

Loading...